3D printing pdf download

Cults・Download free 3D printer models・STL, OBJ, 3MF, CAD

Featured

By mcgybeer

Meet McSnowbeer, this amazing snowman has a print in place body with no supports. All three parts of his body can spin freely! This creation includes 2 snowman models, one with cute eyes and another one with classic button eyes.

Download 3D model

01

Filameno Cabezón

Free

02App for Cookie Cutters

€3.49

03Snowman in underwear

€1.93

04DECORATIVE SANTA CLAUS

€2.83 -35% €1.84

SKS (STAR KNOB SCREW)

€1. 25

Cute_Flexi_Turtle_Print_In_Place

€2.84

07NeoMonkey - cosplay mask

€20 -7% €18.60

JOYSTICK PHONE GAME

€2.85

09SMARS M1 set

€13.16 -40% €7.89

Barney the pug flexi toy

€2.41

11Jellyfish Swimming - Mechanical Interactive Art

Free

12BART SIMPSON

€1. -35% €1.29 99

99

Watering Can (Pressure Based System)

€1.99

14Fokker dr1 aircraft

Free

15Dinosaur T-REX Fossil Cookie Cutter

€1.23

16Christmas Park

€4.57

17Spacecraft Giraffe

Free

18Flash Wand by Wookie

€3.52

19SEA SNAKE

€3.17

20DR VEGAPUNK - ONE PIECE 1066

€8. 90

90

01

Christmas Holly Leaf - Polymer Cutter (Clay Cutter)

€2.64

02ItsLitho "Creamy" personalized lithophane Christmas ball

€1.90

03flork worldwide

€2.96

04Cosplay Paws

€4.82

05Cap curved band

€1.25

06Biting dragon

€3

07INDICATOR FOR BEST BED LEVELING FOR ENDER 3 V2

€2.88

08Wall shelf “Oyster fungus”

€2. 40

40

01

SOCCER FIELD WITH SPONGE SUPPORT

€1.39

02Keyblade

€1.99

03Owl mask

€4

04Cute Kitten Planter - Easy Print

€1.92 -15% €1.63

BOTTLE RACK WITH BOTTLES - COMPLEMENT FOR PLAYMOBIL

€2.75

06ZOU TURKEY - TURKEY WITH SHOES

€2.82

07Finger Tentacle Octopus Toy

€0.60

08JDM wheel key ring

€1. -34% €0.99 50

50

Christmas tree

€1.74

10C TREE

€2 -20% €1.60

Bobble Head Santa

Free

12JOYSTICK MARBLE GAME

€2.85

13🎄Articulated Xmas Gingerbread Man - Christmas Tree Decoration🎄

€2.50

14Momo Mask

€4

15Holiday Skull, Christmas Tree Ornament, Santa Skull, Santa Hat, Creepy Christmas

€1. -15% €1.64 93

93

Keychain Carabiner // llalavero Mosqueton

€0.63

17Ball Display Stand

Free

18Pachinko-style Dice Tower, with tray

Free

19Clone Trooper: Commander (HawkBat)

Free

203D Ping Pong Paddle Ball Holder

€3.62

01

flexi turtle

Free

02PRINT-IN-PLACE SPRING LOADED BOX

Free

03Jellyfish Swimming - Mechanical Interactive Art

Free

04carnivorous battle tank for solar void troopers

Free

05taurus transport for space auxiliaries

Free

06Samurai Dragon Mask | Liberty Square Fan Art

Free

07Cute Mini Octopus

Free

08New imperial armoured sentinel model

Free

🔁 Updated

Ender 5 Plus cooling shroud

Free

Cape haters shoulder protections

Free

Look Ma! I'm in Ravendorrrrr!

€6. 75

75

FIFA CUP GRINDER

€5.04

Goofy "the Crazy"

HitGirl KickAss Shoulder Pad

Space Dwarf Helmets

Cat jewelry box

Pterodactyl Dinosaur Fondant and Cookie Cutter

€1.13

batman pendant 3D print model

€25

STAR WARS VINTAGE EWOK, EWOK-REX ACTION FIGURE. CUSTOM KENNER, HASBRO, 3.75", 1/18, 5POA

€4.81

CUTTER FLORK TAKE A COOKIE / SIGN

€1.50

Goofy "the Crazy"

€2.90 -25% €2. 18

18

Husky DOG FONDANT AND COOKIE CUTTER FOR BAKING

€1.13

PLAYMOBIL LADDER

€2

Golden Retriever DOG FONDANT AND COOKIE CUTTER FOR BAKING

€1.13

See all 3D models

Cults, the 3D printing platform

Welcome to Cults, the world’s leading independent website for 3D printer files. Discover and download the best 3D models for all your 3D printing & DIY projects.

Cults is a digital marketplace for 3D printing and design. Use our 3D model library to discover everything you can do with a 3D printer (FDM, SLA, DLP, SLS) event with CNC machining and laser cutting. You don’t know how to make a 3D file but you want to 3D print objects? Cults is for you! Browse our different categories and download the best 3D printer models for free, open-source or paid mode. The formats you can download are in STL, OBJ, 3MF, CAD, STEP, SCAD or DXF, DWG, SVG format, they are all 3D printable guaranteed or CNC compatible.

The formats you can download are in STL, OBJ, 3MF, CAD, STEP, SCAD or DXF, DWG, SVG format, they are all 3D printable guaranteed or CNC compatible.

We are connecting 3D print files makers with people who want to use their 3D printer. Our 3D model repository acts as a real source of inspiration since the best designers share their best STL files daily to offer you their latest inventions!

On Cults you can also find a 3D printer nearby, get voucher codes to buy cheap 3D printers or filaments at best prices and also a whole series of 3D printing contests. Cults is a joyful community that brings together all 3D printing fans to dialogue and create together.

Commission system

You are a designer and you want to sell your 3D models optimized for 3D printing? Thanks to Cults you can earn money with your files STL, OBJ, CAD, 3MF, etc. ! For each download, you will receive 80% of the net selling price (excluding VAT) via PayPal. Cults keeps 20% of commission which is used to finance bank fees (about 5%) and then all the costs related to the technical maintenance of the platform: hosting, bandwidth, accounting, email communications, translations, etc. There is no subscription system or fixed fee to pay. You sell, you win!

! For each download, you will receive 80% of the net selling price (excluding VAT) via PayPal. Cults keeps 20% of commission which is used to finance bank fees (about 5%) and then all the costs related to the technical maintenance of the platform: hosting, bandwidth, accounting, email communications, translations, etc. There is no subscription system or fixed fee to pay. You sell, you win!

If you are still hesitating to share your models on Cults, feel free to read this article Why publish my designs on Cults? List of advantages and benefits to get an idea.

- Designers 80%

- Cults 15%

- Banking fees 5%

Upload a 3D model

What is 3D printing? How does a 3D printer work? Learn 3D printing

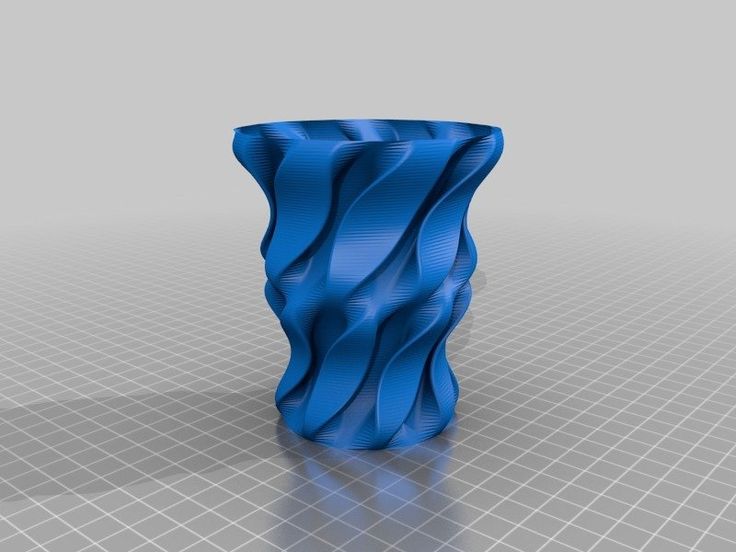

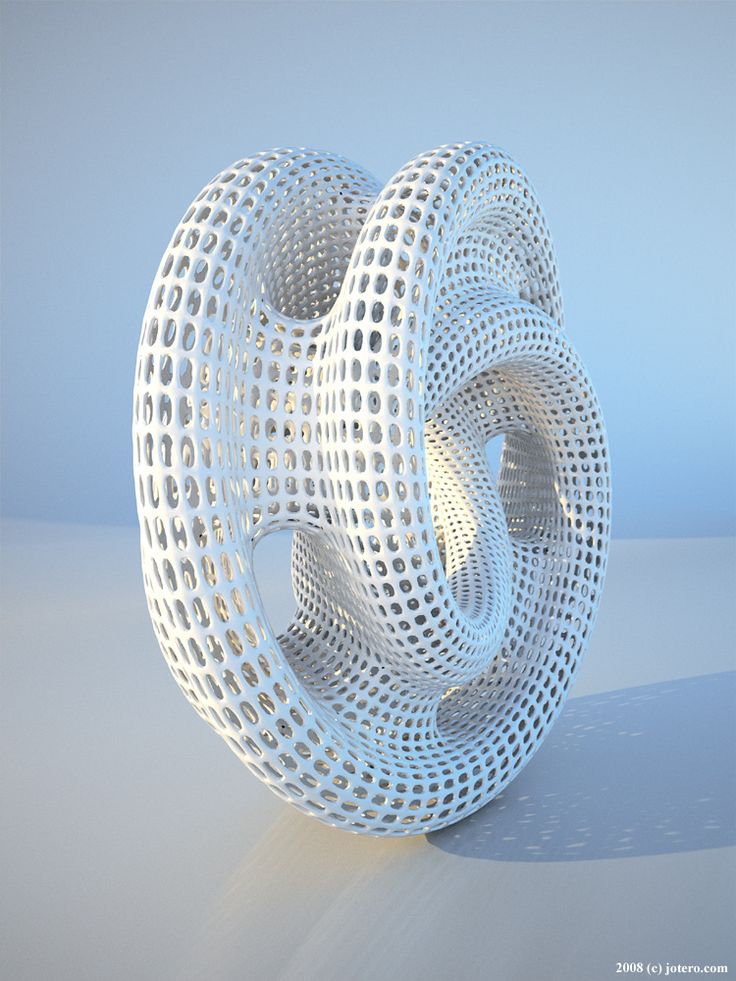

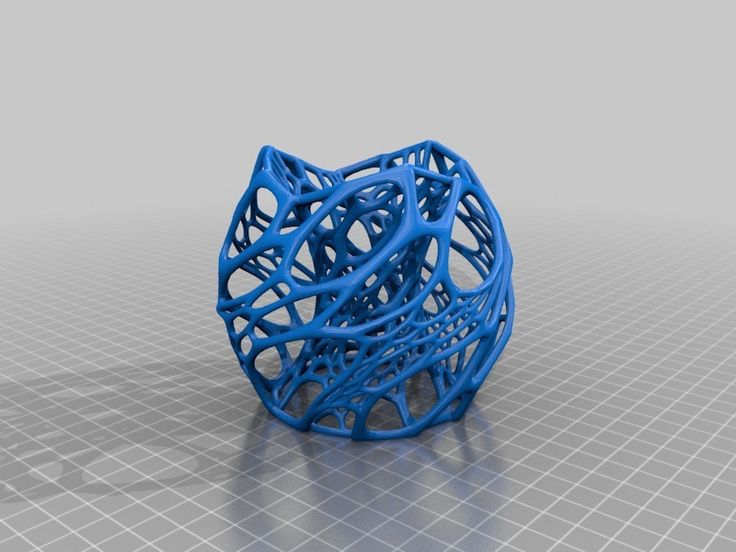

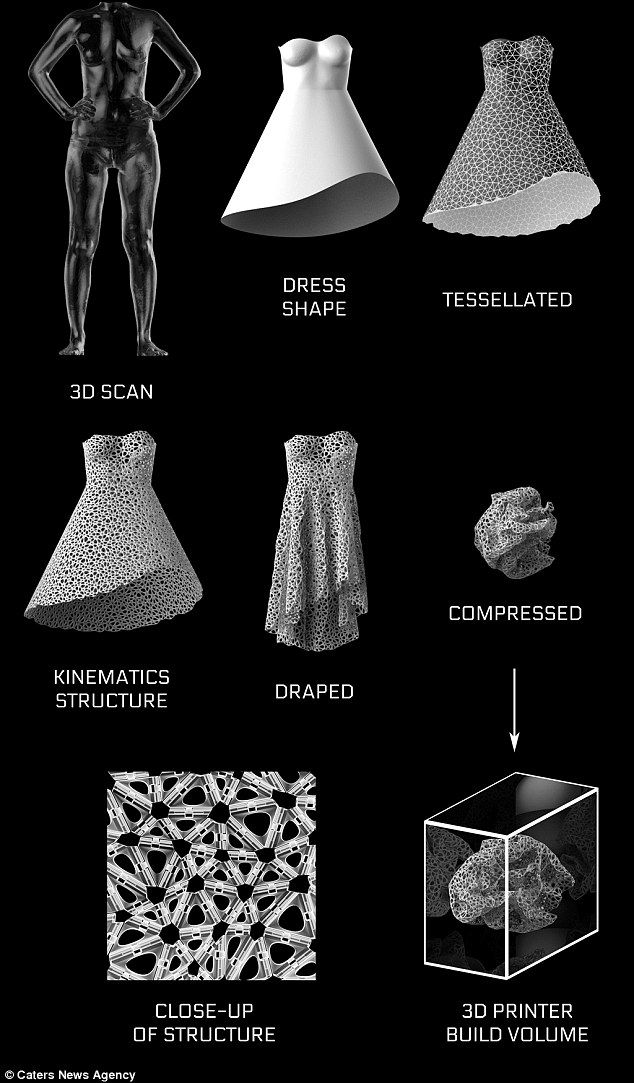

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced cross-section of the object.

3D printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with for instance a milling machine.

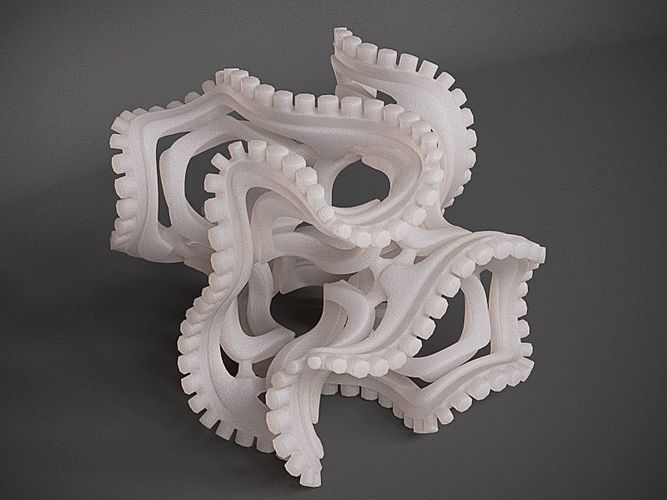

3D printing enables you to produce complex shapes using less material than traditional manufacturing methods.

Table of Contents

- How Does 3D Printing Work?

- 3D Printing Industry

- Examples of 3D Printing

- 3D Printing Technologies & Processes

- Materials

- Services

Jump to your field of interest:

- Rapid Prototyping & Manufacturing

- Automotive

- Aviation

- Construction

- Consumer Products

- Healthcare

- Food

- Education

Jump to process:

- All Technologies & Processes

- Vat Photopolymerisation

- Material Jetting

- Binder Jetting

- Material Extrusion

- Powder Bed Fusion

- Sheet Lamination

- Directed Energy Deposition

How Does 3D Printing Work?

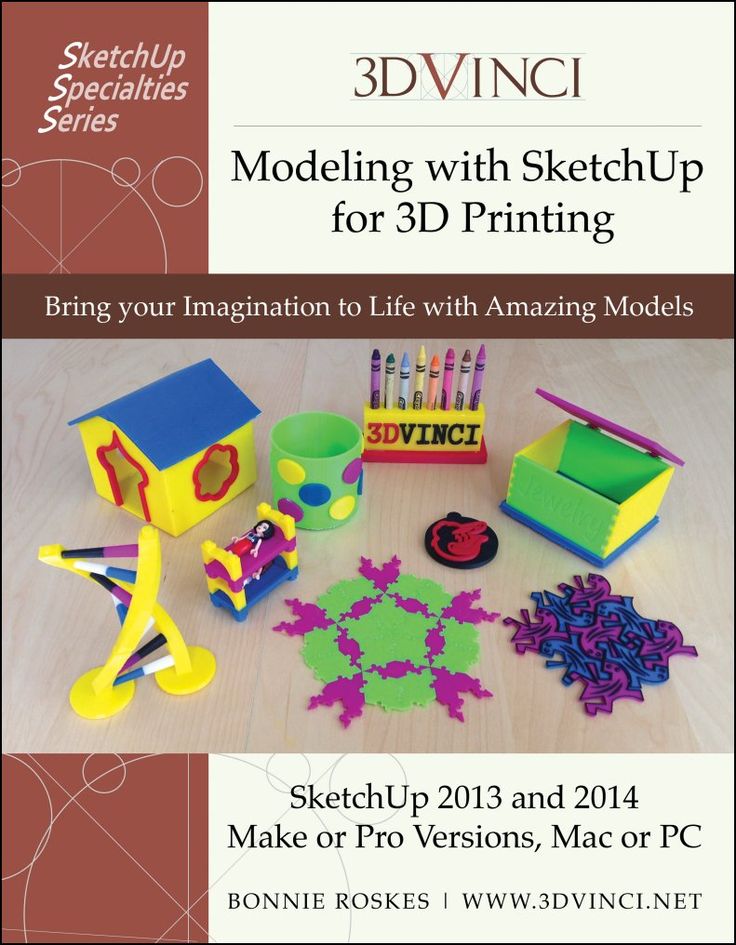

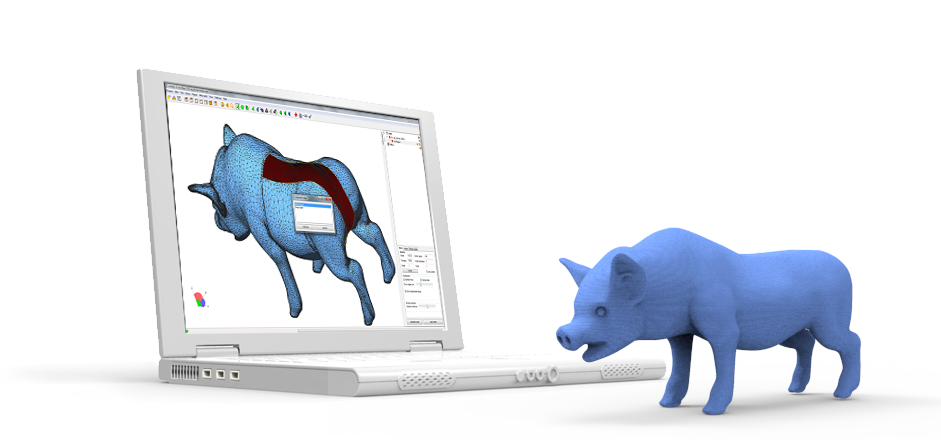

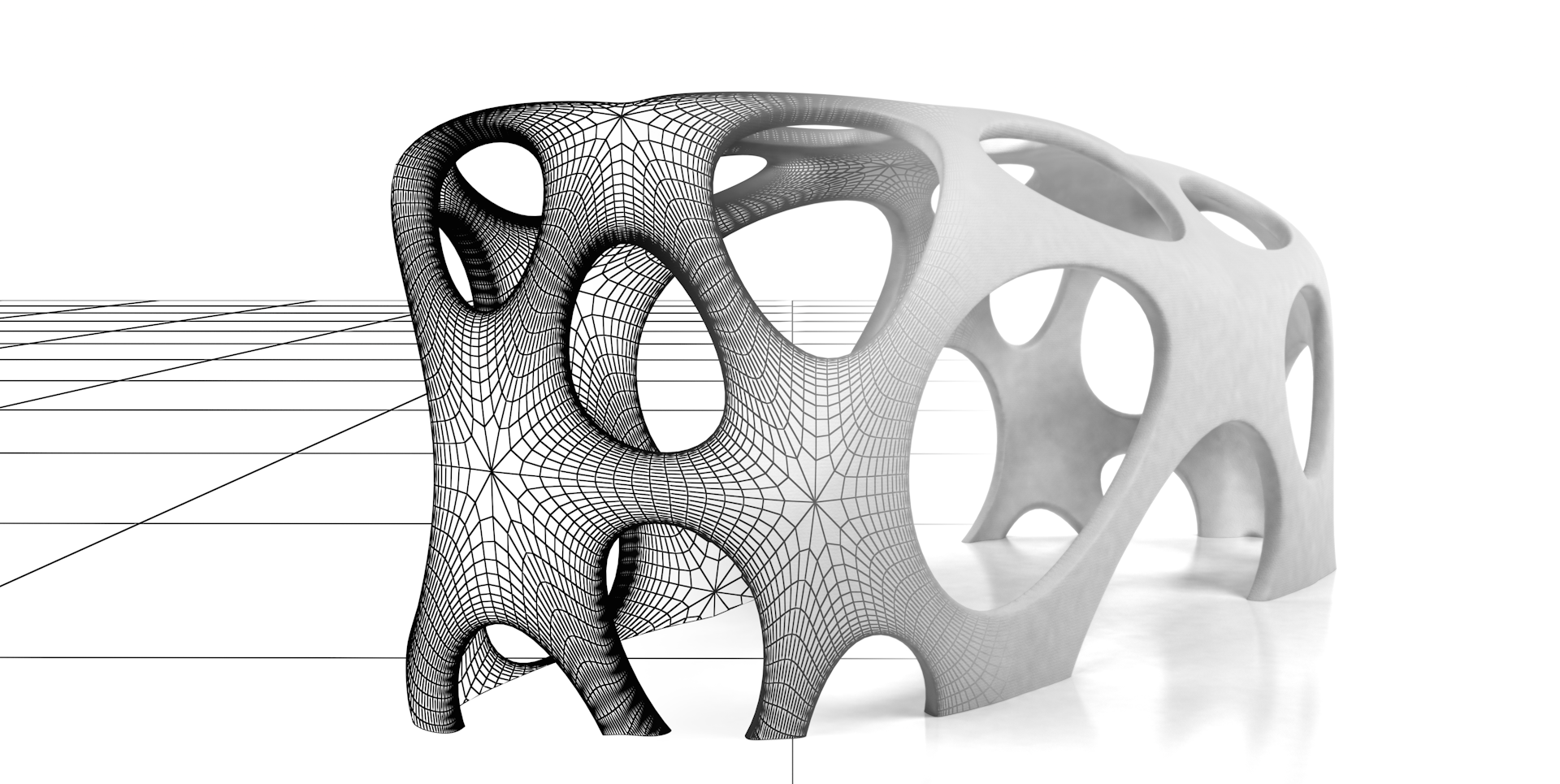

It all starts with a 3D model. You can opt to create one from the ground up or download it from a 3D library.

You can opt to create one from the ground up or download it from a 3D library.

3D Software

There are many different software tools available. From industrial grade to open source. We’ve created an overview on our 3D software page.

We often recommend beginners to start with Tinkercad. Tinkercad is free and works in your browser, you don’t have to install it on your computer. Tinkercad offers beginner lessons and has a built-in feature to export your model as a printable file e.g .STL or .OBJ.

Now that you have a printable file, the next step is to prepare it for your 3D printer. This is called slicing.

Slicing: From printable file to 3D Printer

Slicing basically means slicing up a 3D model into hundreds or thousands of layers and is done with slicing software.

When your file is sliced, it’s ready for your 3D printer. Feeding the file to your printer can be done via USB, SD or Wi-Fi. Your sliced file is now ready to be 3D printed layer by layer.

3D Printing Industry

Adoption of 3D printing has reached critical mass as those who have yet to integrate additive manufacturing somewhere in their supply chain are now part of an ever-shrinking minority. Where 3D printing was only suitable for prototyping and one-off manufacturing in the early stages, it is now rapidly transforming into a production technology.

Most of the current demand for 3D printing is industrial in nature. Acumen Research and Consulting forecasts the global 3D printing market to reach $41 billion by 2026.

As it evolves, 3D printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future.

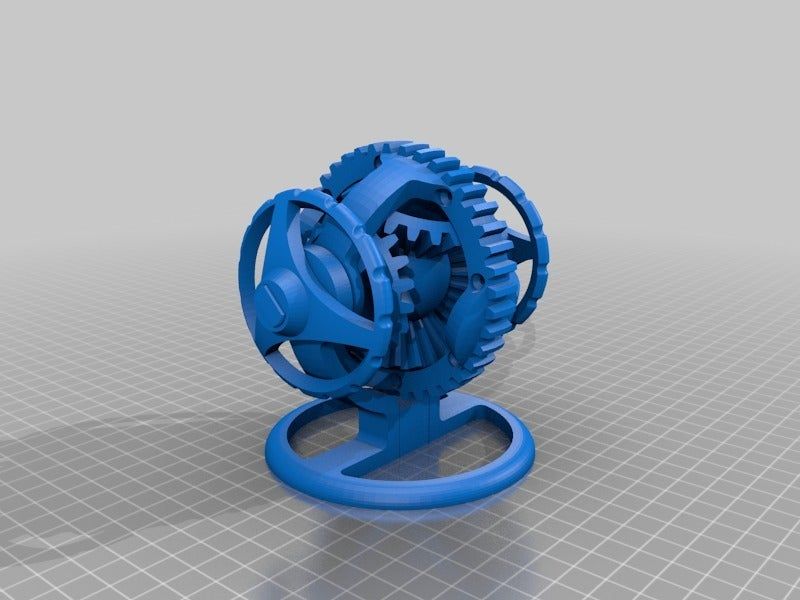

Examples of 3D Printing

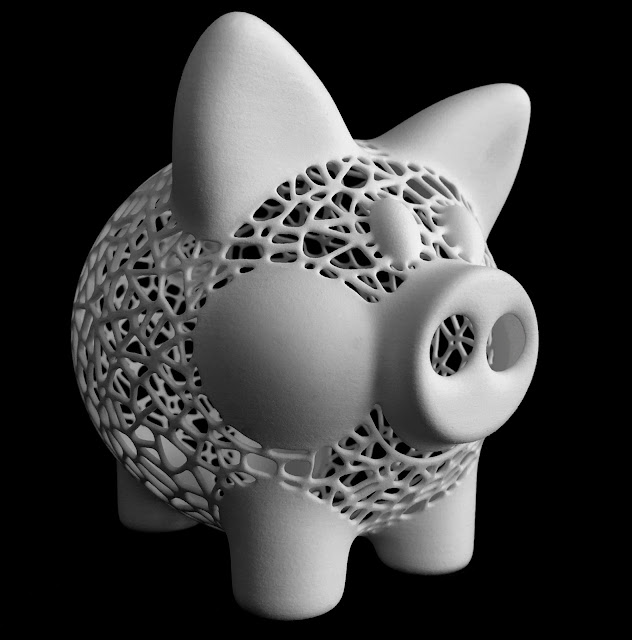

3D printing encompasses many forms of technologies and materials as 3D printing is being used in almost all industries you could think of. It’s important to see it as a cluster of diverse industries with a myriad of different applications.

A few examples:

- – consumer products (eyewear, footwear, design, furniture)

- – industrial products (manufacturing tools, prototypes, functional end-use parts)

- – dental products

- – prosthetics

- – architectural scale models & maquettes

- – reconstructing fossils

- – replicating ancient artefacts

- – reconstructing evidence in forensic pathology

- – movie props

Rapid Prototyping & Rapid Manufacturing

Companies have used 3D printers in their design process to create prototypes since the late seventies. Using 3D printers for these purposes is called rapid prototyping.

Using 3D printers for these purposes is called rapid prototyping.

Why use 3D Printers for Rapid Prototyping?

In short: it’s fast and relatively cheap. From idea, to 3D model to holding a prototype in your hands is a matter of days instead of weeks. Iterations are easier and cheaper to make and you don’t need expensive molds or tools.

Besides rapid prototyping, 3D printing is also used for rapid manufacturing. Rapid manufacturing is a new method of manufacturing where businesses use 3D printers for short run / small batch custom manufacturing.

Automotive

Car manufacturers have been utilizing 3D printing for a long time. Automotive companies are printing spare parts, tools, jigs and fixtures but also end-use parts. 3D printing has enabled on-demand manufacturing which has lead to lower stock levels and has shortened design and production cycles.

Automotive enthusiasts all over the world are using 3D printed parts to restore old cars. One such example is when Australian engineers printed parts to bring a Delage Type-C back to life. In doing so, they had to print parts that were out of production for decades.

One such example is when Australian engineers printed parts to bring a Delage Type-C back to life. In doing so, they had to print parts that were out of production for decades.

Aviation

The aviation industry uses 3D printing in many different ways. The following example marks a significant 3D printing manufacturing milestone: GE Aviation has 3D printed 30,000 Cobalt-chrome fuel nozzles for its LEAP aircraft engines. They achieved that milestone in October of 2018, and considering that they produce 600 per week on forty 3D printers, it’s likely much higher than that now.

Around twenty individual parts that previously had to be welded together were consolidated into one 3D printed component that weighs 25% less and is five times stronger. The LEAP engine is the best selling engine in the aerospace industry due to its high level of efficiency and GE saves $3 million per aircraft by 3D printing the fuel nozzles, so this single 3D printed part generates hundreds of millions of dollars of financial benefit.

GE’s fuel nozzles also made their way into the Boeing 787 Dreamliner, but it’s not the only 3D printed part in the 787. The 33-centimeter-long structural fittings that hold the aft kitchen galley to the airframe are 3D printed by a company called Norsk Titanium. Norsk chose to specialize in titanium because it has a very high strength-to-weight ratio and is rather expensive, meaning the reduction in waste enabled by 3D printing has a more significant financial impact than compared to cheaper metals where the costs of material waste are easier to absorb. Rather than sintering metal powder with a laser like most metal 3D printers, the Norsk Merke 4 uses a plasma arc to melt a metal wire in a process called Rapid Plasma Deposition (a form of Directed Energy Deposition) that can deposit up to 10kg of titanium per hour. A 2kg titanium part would generally require a 30kg block of titanium to machine it from, generating 28kg of waste, but 3D printing the same part requires only 6kg of titanium wire.

A 2kg titanium part would generally require a 30kg block of titanium to machine it from, generating 28kg of waste, but 3D printing the same part requires only 6kg of titanium wire.

Construction

Is it possible to print a building? – yes it is. 3D printed houses are already commercially available. Some companies print parts prefab and others do it on-site.

Most of the concrete printing stories we look at on this website are focused on large scale concrete printing systems with fairly large nozzles for a large flow rate. It’s great for laying down concrete layers in a fairly quick and repeatable manner. But for truly intricate concrete work that makes full use of the capabilities of 3D printing requires something a little more nimble, and with a finer touch.

Consumer Products

When we first started blogging about 3D printing back in 2011, 3D printing wasn’t ready to be used as a production method for large volumes. Nowadays there are numerous examples of end-use 3D printed consumer products.

Footwear

Adidas’ 4D range has a fully 3D printed midsole and is being printed in large volumes. We did an article back then, explaining how Adidas were initially releasing just 5,000 pairs of the shoes to the public, and had aimed to sell 100,000 pairs of the AM-infused designs by 2018.

With their latest iterations of the shoe, it seems that they have surpassed that goal, or are on their way to surpassing it. The shoes are available all around the world from local Adidas stores and also from various 3rd party online outlets.

Eyewear

The market of 3D printed eyewear is forecasted to reach $3.4 billion by 2028. A rapidly increasing section is that of end-use frames. 3D printing is a particularly suitable production method for eyewear frames because the measurements of an individual are easy to process in the end product.

But did you know it’s also possible to 3D print lenses? Traditional glass lenses don’t start out thin and light; they’re cut from a much larger block of material called a blank, about 80% of which goes to waste. When we consider how many people wear glasses and how often they need to get a new pair, 80% of those numbers is a lot of waste. On top of that, labs have to keep huge inventories of blanks to meet the custom vision needs of their clients. Finally, however, 3D printing technology has advanced enough to provide high-quality, custom ophthalmic lenses, doing away with the waste and inventory costs of the past. The Luxexcel VisionEngine 3D printer uses a UV-curable acrylate monomer to print two pairs of lenses per hour that require no polishing or post-processing of any kind. The focal areas can also be completely customized so that a certain area of the lens can provide better clarity at a distance while a different area of the lens provides better vision up close.

When we consider how many people wear glasses and how often they need to get a new pair, 80% of those numbers is a lot of waste. On top of that, labs have to keep huge inventories of blanks to meet the custom vision needs of their clients. Finally, however, 3D printing technology has advanced enough to provide high-quality, custom ophthalmic lenses, doing away with the waste and inventory costs of the past. The Luxexcel VisionEngine 3D printer uses a UV-curable acrylate monomer to print two pairs of lenses per hour that require no polishing or post-processing of any kind. The focal areas can also be completely customized so that a certain area of the lens can provide better clarity at a distance while a different area of the lens provides better vision up close.

Jewelry

There are two ways of producing jewelry with a 3D printer. You can either use a direct or indirect production process. Direct refers to the creation of an object straight from the 3D design while indirect manufacturing means that the object (pattern) that is 3D printed eventually is used to create a mold for investment casting.

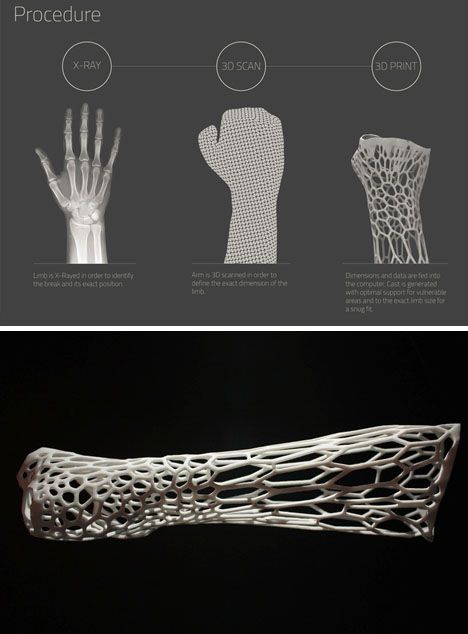

Healthcare

It’s not uncommon these days to see headlines about 3D printed implants. Often, those cases are experimental, which can make it seem like 3D printing is still a fringe technology in the medical and healthcare sectors, but that’s not the case anymore. Over the last decade, more than 100,000 hip replacements have been 3D printed by GE Additive.

The Delta-TT Cup designed by Dr. Guido Grappiolo and LimaCorporate is made of Trabecular Titanium, which is characterized by a regular, three-dimensional, hexagonal cell structure that imitates trabecular bone morphology. The trabecular structure increases the biocompatibility of the titanium by encouraging bone growth into the implant. Some of the first Delta-TT implants are still running strong over a decade later.

Another 3D printed healthcare component that does a good job of being undetectable is the hearing aid. Nearly every hearing aid in the last 17 years has been 3D printed thanks to a collaboration between Materialise and Phonak. Phonak developed Rapid Shell Modeling (RSM) in 2001. Prior to RSM, making one hearing aid required nine laborious steps involving hand sculpting and mold making, and the results were often ill-fitting. With RSM, a technician uses silicone to take an impression of the ear canal, that impression is 3D scanned, and after some minor tweaking the model is 3D printed with a resin 3D printer. The electronics are added and then it’s shipped to the user. Using this process, hundreds of thousands of hearing aids are 3D printed each year.

Phonak developed Rapid Shell Modeling (RSM) in 2001. Prior to RSM, making one hearing aid required nine laborious steps involving hand sculpting and mold making, and the results were often ill-fitting. With RSM, a technician uses silicone to take an impression of the ear canal, that impression is 3D scanned, and after some minor tweaking the model is 3D printed with a resin 3D printer. The electronics are added and then it’s shipped to the user. Using this process, hundreds of thousands of hearing aids are 3D printed each year.

Dental

In the dental industry, we see molds for clear aligners being possibly the most 3D printed objects in the world. Currently, the molds are 3D printed with both resin and powder based 3D printing processes, but also via material jetting. Crowns and dentures are already directly 3D printed, along with surgical guides.

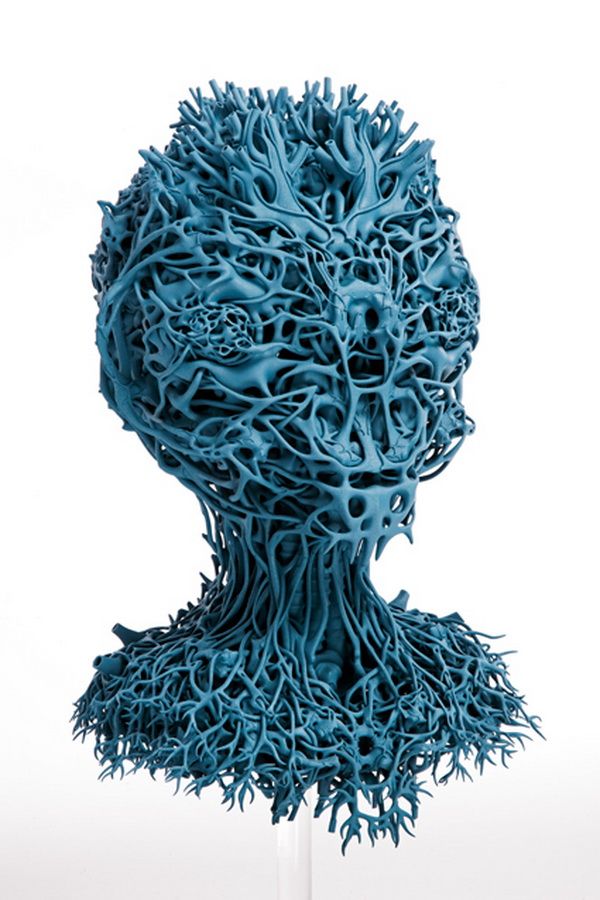

Bio-printing

As of the early two-thousands 3D printing technology has been studied by biotech firms and academia for possible use in tissue engineering applications where organs and body parts are built using inkjet techniques. Layers of living cells are deposited onto a gel medium and slowly built up to form three dimensional structures. We refer to this field of research with the term: bio-printing.

Layers of living cells are deposited onto a gel medium and slowly built up to form three dimensional structures. We refer to this field of research with the term: bio-printing.

Food

Additive manufacturing invaded the food industry long time ago. Restaurants like Food Ink and Melisse use this as a unique selling point to attract customers from across the world.

Education

Educators and students have long been using 3D printers in the classroom. 3D printing enables students to materialize their ideas in a fast and affordable way.

While additive manufacturing-specific degrees are fairly new, universities have long been using 3D printers in other disciplines. There are many educational courses one can take to engage with 3D printing. Universities offer courses on things that are adjacent to 3D printing like CAD and 3D design, which can be applied to 3D printing at a certain stage.

In terms of prototyping, many university programs are turning to printers. There are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Printed prototypes are also very common in the arts, animation and fashion studies as well.

There are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Printed prototypes are also very common in the arts, animation and fashion studies as well.

Types of 3D Printing Technologies and Processes

The American Society for Testing and Materials (ASTM), developed a set of standards that classify additive manufacturing processes into 7 categories. These are:

- Vat Photopolymerisation

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Continuous Liquid Interface Production (CLIP)

- Material Jetting

- Binder Jetting

- Material Extrusion

- Fused Deposition Modeling (FDM)

- Fused Filament Fabrication (FFF)

- Powder Bed Fusion

- Multi Jet Fusion (MJF)

- Selective Laser Sintering (SLS)

- Direct Metal Laser Sintering (DMLS)

- Sheet Lamination

- Directed Energy Deposition

Vat Photopolymerisation

A 3D printer based on the Vat Photopolymerisation method has a container filled with photopolymer resin. The resin is hardened with a UV light source.

The resin is hardened with a UV light source.

Stereolithography (SLA)

SLA was invented in 1986 by Charles Hull, who also at the time founded the company, 3D Systems. Stereolithography employs a vat of liquid curable photopolymer resin and an ultraviolet laser to build the object’s layers one at a time. For each layer, the laser beam traces a cross-section of the part pattern on the surface of the liquid resin. Exposure to the ultraviolet laser light cures and solidifies the pattern traced on the resin and fuses it to the layer below.

After the pattern has been traced, the SLA’s elevator platform descends by a distance equal to the thickness of a single layer, typically 0.05 mm to 0.15 mm (0.002″ to 0.006″). Then, a resin-filled blade sweeps across the cross section of the part, re-coating it with fresh material. On this new liquid surface, the subsequent layer pattern is traced, joining the previous layer. Depending on the object & print orientation, SLA often requires the use of support structures.

Depending on the object & print orientation, SLA often requires the use of support structures.

Digital Light Processing (DLP)

DLP or Digital Light Processing refers to a method of printing that makes use of light and photosensitive polymers. While it is very similar to SLA, the key difference is the light source. DLP utilizes other light sources like arc lamps. DLP is relatively quick compared to other 3D printing technologies.

Continuous Liquid Interface Production (CLIP)

One of the fastest processes using Vat Photopolymerisation is called CLIP, short for Continuous Liquid Interface Production, developed by Carbon.

Digital Light Synthesis

The heart of the CLIP process is Digital Light Synthesis technology. In this technology, light from a custom high performance LED light engine projects a sequence of UV images exposing a cross section of the 3D printed part causing the UV curable resin to partially cure in a precisely controlled way. Oxygen passes through the oxygen permeable window creating a thin liquid interface of uncured resin between the window and the printed part known as the dead zone. The dead zone is as thin as ten of microns. Inside the dead zone, oxygen prohibits light from curing the resin situated closest to the window therefore allowing the continuous flow of liquid beneath the printed part. Just above the dead zone the UV projected light upwards causes a cascade like curing of the part.

Simply printing with Carbon’s hardware alone does not allow for end use properties with real world applications. Once the light has shaped the part, a second programmable curing process achieves the desired mechanical properties by baking the 3d printed part in a thermal bath or oven. Programmed thermal curing sets the mechanical properties by triggering a secondary chemical reaction causing the material to strengthen achieving the desired final properties.

Components printed with Carbon’s technology are on par with injection molded parts. Digital Light Synthesis produces consistent and predictable mechanical properties, creating parts that are truly isotropic.

Digital Light Synthesis produces consistent and predictable mechanical properties, creating parts that are truly isotropic.

Material Jetting

In this process, material is applied in droplets through a small diameter nozzle, similar to the way a common inkjet paper printer works, but it is applied layer-by-layer to a build platform and then hardened by UV light.

Material Jetting schematics. Image source: custompartnet.comBinder Jetting

With binder jetting two materials are used: powder base material and a liquid binder. In the build chamber, powder is spread in equal layers and binder is applied through jet nozzles that “glue” the powder particles in the required shape. After the print is finished, the remaining powder is cleaned off which often can be re-used printing the next object. This technology was first developed at the Massachusetts Institute of Technology in 1993.

Binder Jetting schematicsMaterial Extrusion

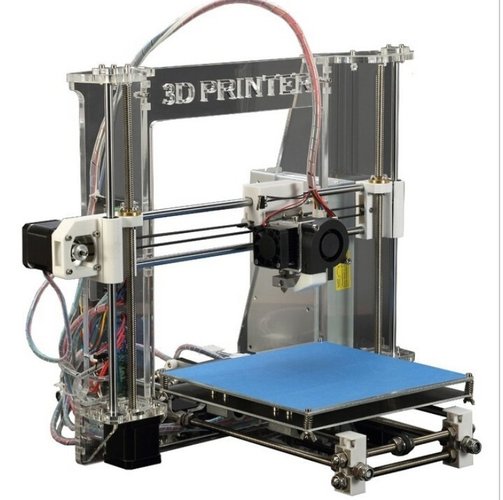

Fused Deposition Modeling (FDM)

FDM schematics (Image credit: Wikipedia, made by user Zureks)FDM works using a plastic filament which is unwound from a spool and is supplied to an extrusion nozzle which can turn the flow on and off. The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism. The object is produced by extruding melted material to form layers as the material hardens immediately after extrusion from the nozzle.

The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism. The object is produced by extruding melted material to form layers as the material hardens immediately after extrusion from the nozzle.

FDM was invented by Scott Crump in the late 80’s. After patenting this technology he started the company Stratasys in 1988. The term Fused Deposition Modeling and its abbreviation to FDM are trademarked by Stratasys Inc.

Fused Filament Fabrication (FFF)

The exactly equivalent term, Fused Filament Fabrication (FFF), was coined by the members of the RepRap project to give a phrase that would be legally unconstrained in its use.

Powder Bed Fusion

Selective Laser Sintering (SLS)

SLS uses a high power laser to fuse small particles of powder into a mass that has the desired three dimensional shape. The laser selectively fuses powder by first scanning the cross-sections (or layers) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness. Then a new layer of material is applied on top and the process is repeated until the object is completed.

After each cross-section is scanned, the powder bed is lowered by one layer thickness. Then a new layer of material is applied on top and the process is repeated until the object is completed.

Multi Jet Fusion (MJF)

Multi Jet Fusion technology was developed by Hewlett Packard and works with a sweeping arm which deposits a layer of powder and then another arm equipped with inkjets which selectively applies a binder agent over the material. The inkjets also deposit a detailing agent around the binder to ensure precise dimensionality and smooth surfaces. Finally, the layer is exposed to a burst of thermal energy that causes the agents to react.

Direct Metal Laser Sintering (DMLS)

DMLS is basically the same as SLS, but uses metal powder instead. All unused powder remains as it is and becomes a support structure for the object. Unused powder can be re-used for the next print.

Due to of increased laser power, DMLS has evolved into a laser melting process. Read more about that and other metal technologies on our metal technologies overview page.

Sheet Lamination

Sheet lamination involves material in sheets which is bound together with external force. Sheets can be metal, paper or a form of polymer. Metal sheets are welded together by ultrasonic welding in layers and then CNC milled into a proper shape. Paper sheets can be used also, but they are glued by adhesive glue and cut in shape by precise blades.

Simplified schematics of ultrasonic sheet metal process (Image credit: Wikipedia from user Mmrjf3)Directed Energy Deposition

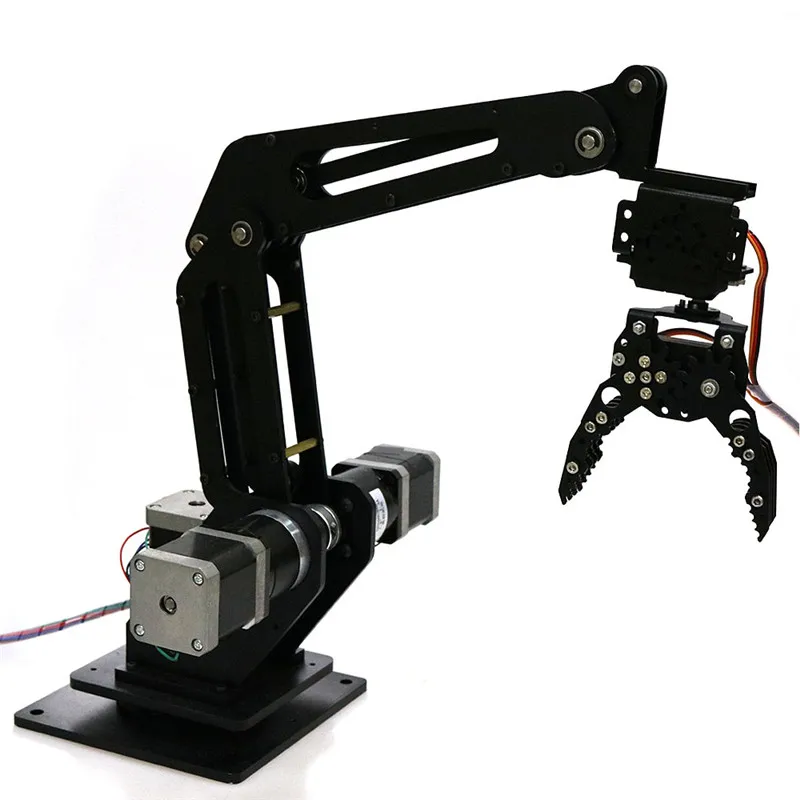

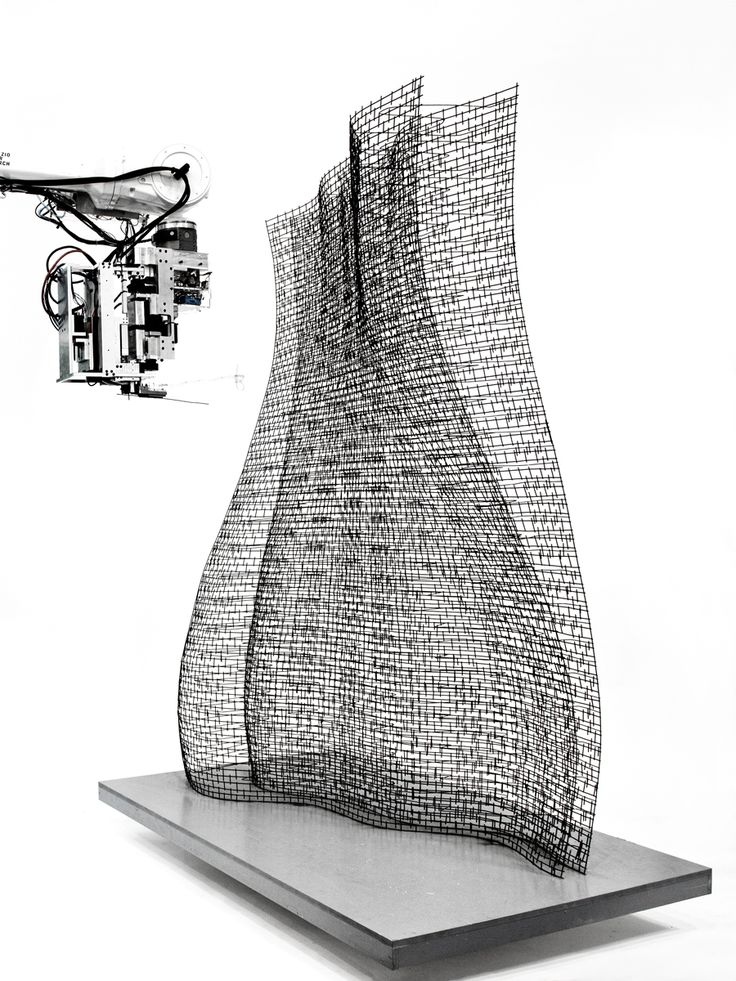

This process is mostly used in the metal industry and in rapid manufacturing applications. The 3D printing apparatus is usually attached to a multi-axis robotic arm and consists of a nozzle that deposits metal powder or wire on a surface and an energy source (laser, electron beam or plasma arc) that melts it, forming a solid object.

Materials

Multiple materials can be used in additive manufacturing: plastics, metals, concrete, ceramics, paper and certain edibles (e.g. chocolate). Materials are often produced in wire feedstock a.k.a. filament, powder form or liquid resin. Learn more about our featured materials on our materials page.

Services

Looking to implement 3D printing in your production process? Get a quote for a custom part or order samples on our 3D print service page.

Book 3D printing from scratch (D. Gorkov)

Book “ 3D printing from scratch ” – title page

from prominent Russian-speaking authors on the subject of volumetric printing - Dmitry Gorkov in 2015. The publication is rightfully considered one of the best sources of information on 3D printing technology and related equipment for beginners.

On this page of the electronic library of the portal you will find a description of this book, content and a direct link to a third-party source on the Internet, where you can download this book for free and without registration.

Description of the book “3D printing from scratch”

The purpose of this book was to fill an empty niche in teaching 3d printing technology. This technology is just beginning to massively penetrate into the life of society. One of the reasons that this process does not happen quickly (according to the author) is the lack of structured information on the topic “where to start”.

The Internet is filled with promotional articles about the use of industrial printers. But you have to look for information on how to work on a “regular” (household / desktop) FDM printer bit by bit on specialized forums. Much of the information is teeming with specific terms and can be difficult for beginners to understand.

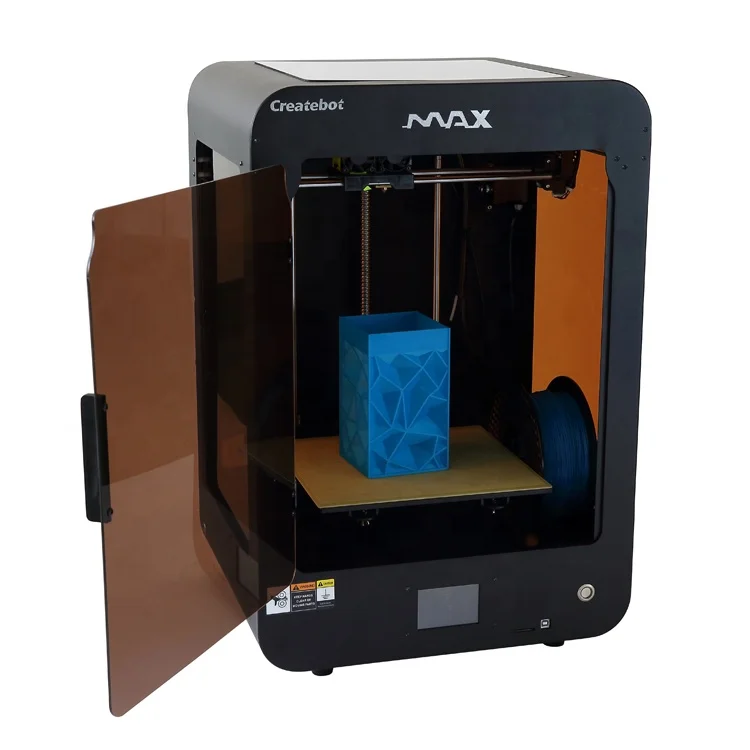

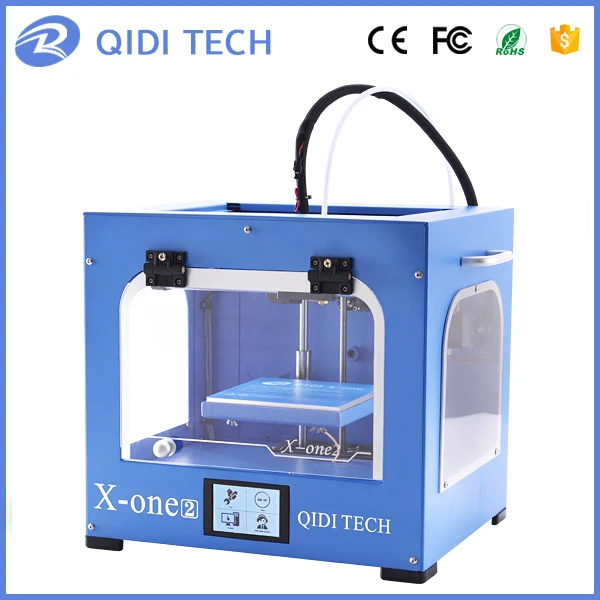

The goal of the book “3D printing from scratch” is to convey all the basic information to the end user in an accessible language without trying to “break the brain”. The author tried to create a step-by-step guide that will allow even a beginner in the field of 3dp to choose the right 3D printer for individual needs. The book also takes a detailed look at how to work with different types of 3D printing plastics. The book also pays special attention to such an important issue as 3d printing software: it discusses the currently used (at the time of writing the book - 2015) computer programs for 3D printing on a printer with practical examples of designing in a 3D editor of simple objects.

The book also takes a detailed look at how to work with different types of 3D printing plastics. The book also pays special attention to such an important issue as 3d printing software: it discusses the currently used (at the time of writing the book - 2015) computer programs for 3D printing on a printer with practical examples of designing in a 3D editor of simple objects.

After studying this book, you will receive the necessary basic knowledge to start your work in the field of 3D printing - one of the most promising and rapidly developing branches of science and business in the modern world. Study programs Cura, Tinkercad. Master the skills of post-processing printed products. Learn about all the top causes of poor print quality and how to avoid them.

| Author : | Dmitry Gorkov |

| Issued : | 3D-Print-nt.ru |

| Release date: | 2015 |

| Free download (direct link) | PDF (36. 3 Mb ) 3 Mb ) |

| Volume: | 400 pages |

Contents of the book “3D printing from scratch”

- Brief summary of the book

- Introduction

- Children's dreams. Or like everything, someday it will come true

- Suitable 3D printers and where to buy them

- Which 3D printer to choose?

- Basic circuits used in 3D printers

- 3D printer device

- 3d printing supplies

- Used file types

- 3D printing software

- Cura 3d

- Useful features of Cura. Part 1

- Useful features of Cura. Part 2

- Tinkercad Simulation Editor

- Making a bumper for Iphone

- Metric thread in Tinkercad

- Useful resource Thingiverse

- Post-processing of parts in 3D printing

- How I design parts in the 3D editor

- Types of defects in 3D printing

- 3D Scanners

- Robot with 3D scanner Cyclop

- Processing models in MeshLabs

- 3D Printing Use Cases

- Spare parts for cars (3D printing)

- Auto tuning with 3D printing

- Souvenir printing

- Products for fishermen

- Hobby and model parts

- 3D printing and industrial design

- Souvenir products for organizations

- Parts for small batch production using 3D printing

- Coffee mask

- 3D printing parts for household appliances

- Tool and Equipment Repair Parts

- Extreme

- Print accessories for GoPro cameras

- Photo and video equipment

- Models

- Subculture

- Phone cases

- Fittings for clothes and various accessories

- Appendixes to this book

- Printer and Hardware Reviews

- My Replicator from China.

Or how a 3D copy can be better than the original

Or how a 3D copy can be better than the original - Gefesh, as he is. Teapot Notes

- Ultimaker 2 in the grip of a kettle

- How many eyes does a Cyclop have?

- Testing filament for 3D printing

- Flex by REC

- PLA from REC

- Prototyper T-Soft from Filamentarno!

- Ruber from REC

- Afterword to the book 3D printing from scratch

- Book supplements

The book 3D printing from scratch contains a large number of detailed illustrations on the topic of narration - 3D printing (technology, equipment, consumables, application practice).

| Author : | Dmitry Gorkov |

| Issued : | 3D-Print-nt.ru |

| Release date: | 2015 |

| Free download (direct link) | PDF (36. 3 Mb ) 3 Mb ) |

| Volume: | 400 pages |

Noticed a mistake? Select it and press Ctrl+Enter

Tweet

Displaying 3D Models in PDF Files, Adobe Acrobat

User Guide Cancel

Search

Last update Sep 28, 2022 03:13:25 PM GMT | Also applies to Adobe Acrobat 2017, Adobe Acrobat 2020

- Acrobat User Guide

- Introduction to Acrobat

- Access Acrobat from desktops, mobile devices, and the web

- What's New in Acrobat

- Key combinations

- System Requirements

- Workspace

- Workspace basics

- Opening and viewing PDF files

- Opening PDF documents

- Navigating PDF 9 Document Pages0096

- View settings PDF

- Setting PDF View Modes

- Enable thumbnail preview of PDF files

- Display PDF in browser

- Working with online cloud storage accounts

- Accessing files from Box

- Accessing files from Dropbox

- Accessing files from OneDrive

- Accessing files from SharePoint

- Accessing files from Google Drive

- Acrobat and macOS

- Acrobat notifications

- Grids, guides and measurements in PDF

- Use of Asian text, Cyrillic and left-to-right text in PDF documents

- Workspace basics

- Creating PDF documents

- Overview of how to create PDF documents

- Create PDF files in Acrobat

- Creating PDF documents with PDFMaker

- Using the Adobe PDF Printer

- Convert web pages to PDF

- Creating PDF files with Acrobat Distiller

- Adobe PDF conversion settings

- Fonts PDF

- Editing PDF documents

- Editing text in PDF documents

- Editing images and objects in a PDF document

- Rotate, move, delete and renumber pages PDF

- Edit scanned PDF documents

- Enhance document photos taken with a mobile device camera

- Optimizing PDF documents

- PDF document properties and metadata

- Links and attachments in PDF

- Layers of PDF documents

- Thumbnails and bookmarks in PDF documents

- Action Wizard (Acrobat Pro)

- PDF files converted to web pages

- Setting up PDF documents for use in a presentation

- Articles PDF

- Geospatial PDF

- Applying Actions and Scripts to PDF 9 Files0096

- Changing the default font for adding text

- Deleting pages from PDF documents

- Scanning and OCR

- Scanning Documents to PDF

- Document photo enhancement

- Troubleshooting scanner problems when using Acrobat to scan

- Forms

- Fundamentals of Working with Forms PDF

- Create forms from scratch in Acrobat

- Create and distribute PDF forms

- Filling out PDF forms

- PDF Form Field Properties

- Filling out and signing PDF forms

- Configuring Buttons to Perform Actions on PDF Forms

- Publish interactive web forms PDF

- Fundamentals of working with PDF form fields

- PDF form fields for barcode

- Collecting and Managing PDF Form Data

- Form Inspector

- Help with PDF Forms

- Send PDF forms to recipients using email.

mail or internal server

mail or internal server

- Combining files

- Combining or merging files into a single PDF file

- Rotate, move, delete and renumber pages PDF

- Adding headers, footers, and Bates numbering to PDF documents

- Crop PDF pages

- Adding watermarks to PDF documents

- Adding a background to PDF documents

- Working with PDF Portfolio Files

- Publish and share a PDF portfolio

- Portfolio Overview PDF

- Creating and customizing a PDF portfolio

- Sharing, editing, and annotating

- Sharing and tracking PDF documents online

- Mark text when editing

- Preparing to edit a PDF document

- Start PDF 9 editing process0096

- Hosting collaborative reviews on SharePoint or Office 365 sites

- Participation in the editing of a PDF document

- Adding comments to PDF documents

- Adding a stamp to a PDF file

- Approval processes

- Comment management | view, add answer, print

- Import and export of comments

- PDF editing tracking and management

- Saving and exporting PDF documents

- Save PDF

- Convert PDF files to Word format

- Convert PDF document to JPG file

- Converting and exporting PDF documents to other file formats

- File formatting options for PDF export

- Reusing PDF content

- Security

- Enhanced security for PDF documents

- Protecting PDF documents with passwords

- Digital ID Management

- Protecting PDF Documents with Certificates

- Opening protected PDF documents

- Removing sensitive data from PDF documents

- Setting security policies for PDF files

- Selecting a security method for PDF documents

- Security warnings when opening PDF documents

- Protect PDF files with Adobe Experience Manager

- PDF Protected View

- Overview of security features in Acrobat and PDF files

- JavaScript in PDF files is a security risk

- Attachments as a security risk

- Allow or block links in PDF files

- Electronic signatures

- Signing PDF documents

- Capture a signature on a mobile device and use it in any application

- Sending documents for electronic signatures

- About certificate signing

- Certificate Signatures

- Confirmation of digital signatures

- Adobe Approved Trusted List

- Proxy Management

- Printing

- Basic tasks for printing PDF files

- PDF Brochure & Portfolio Printing

- PDF advanced print settings

- Print to PDF

- Print color PDF documents (Acrobat Pro)

- Printing PDF files using custom sizes

- Accessibility, tagging, and reflow

- Create and test accessibility tools for PDF documents

- Accessibility features in PDF files

- PDF Reading Order tool

- Reading PDF documents with accessibility and reflow features

- Edit document structure in the Content and Tags panels

- Creating Accessible PDF Documents

- Search and indexing

- Indexing PDF files

- Search in PDF documents

- 3D Models and Media

- Add Audio, Video, and Interactive Objects to PDF Files

- Add 3D models to PDF files (Acrobat Pro)

- Displaying 3D models in PDF files

- Interaction with 3D models

- Measuring 3D objects in PDF files

- Setting up 3D views in PDF files

- Enable 3D content in a PDF document

- Adding multimedia content to PDF documents

- Add comments for 3D layouts in PDF files

- Play video, audio and multimedia formats in PDF files

- Adding comments to videos

- Prepress Tools (Acrobat Pro)

- Prepress Tools Overview

- Printing marks and fine lines

- Color separation preview

- Processing transparency

- Color conversion and ink management

- Color Trapping

- Preflight (Acrobat Pro)

- PDF/X-, PDF/A-, and PDF/E compliant files

- Preflight profiles

- Extended Preflight

- Preflight reports

- Viewing preflight results, objects, and resources

- PDF output methods

- Fixing problem areas with the Preflight tool

- Automate document analysis with droplets or preflight operations

- Analyzing documents with the Preflight tool

- Additional check with the Preflight tool

- Preflight Libraries

- Preprint variables

- Color Management

- Color Consistency

- Color settings

- Document Color Management

- Working with color profiles

- Color Management Basics

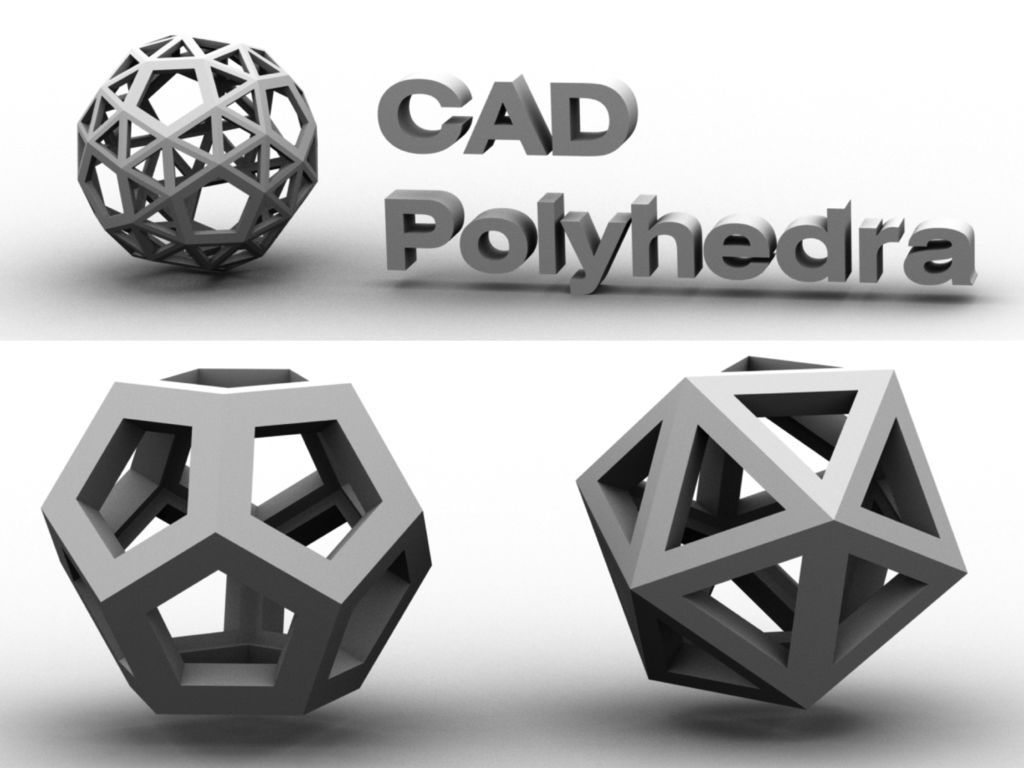

Acrobat lets you view and manage high-quality 3D content created with 3D CAD or 3D modeling programs and embedded in a PDF document. For example, you can hide and show parts of a 3D model, remove a cover to look inside, and rotate elements as if holding them in your hands.

For example, you can hide and show parts of a 3D model, remove a cover to look inside, and rotate elements as if holding them in your hands.

The 3D model is initially displayed as a 2D image. The model can be activated by clicking it with the Hand tool or the Selection tool; this opens the 3D toolbar and plays the animation.

Selected 3D objectA. Model tree B. 3D toolbar C. 3D object

If you open a PDF document with 3D content, a yellow bar appears at the top with the message " 3D content is disabled. Please enable this feature if you trust this document. »

Autoplay 3D content is disabled by default Enable 3D content in the current document:

Press the Options button and select one of the options:

- Trust this document for now only

- Always trust this document

Enable 3D content for all documents:

- Select Edit > Preferences > 3D & Multimedia and check the box Enable 3D content playback .

For more information, see Enable 3D content in a PDF document.

The 3D toolbar appears when you click on the 3D model with the Hand tool. This action activates the 3D model and plays animations if they are set to play when the file is activated. The 3D toolbar always appears in the area located in the upper left corner of the 3D model and cannot be moved to another location. An arrow appears to the right of the Rotate tool that you can click to hide or expand the toolbar.

The 3D toolbar can be used to zoom in and out, rotate and pan around an object. To hide individual parts of the model, isolate them or make them transparent, use the "Model Tree".

You can manipulate the 3D model by selecting and dragging various 3D navigation tools. During 3D navigation, it is convenient to imagine that you are observing a stationary 3D model with a camera. It can be rotated, panned (moved up, down, and sideways), as well as zoomed in and out.

Turn

Rotates 3D objects relative to the screen. How you move objects depends on the initial view, where you started dragging, and the dragging direction.

How you move objects depends on the initial view, where you started dragging, and the dragging direction.

You can also use the Hand tool to rotate an object. Make sure "Enable 3D Selection with Hand Tool" is selected in the "3D" panel of the "Preferences" dialog box.

Rotation

Rotates the 3D model in parallel along the two fixed model axes, x-axis and z-axis.

Panorama

Allows you to move the model only vertically or horizontally. You can also pan using the Hand tool by holding down the Ctrl key while dragging.

Scale

Moves the camera closer or further away from the displayed object. You can also move in or out of an object using the Hand tool by holding down the Shift key while dragging.

Bypass

Rotates horizontally around the view when moving horizontally. Moves forward or backward in the view when moved vertically, maintains a constant level regardless of how you drag. The Walk tool is especially useful for architectural 3D models. To change the crawl speed, you need to change the display units in the settings (3D).

The Walk tool is especially useful for architectural 3D models. To change the crawl speed, you need to change the display units in the settings (3D).

To use the Walk tool, you must select the Preferences option, which combines the tools, or right-click the 3D model and choose Tools > Walk.

Appearance

Navigate the model while maintaining the orientation of the surface. Right click and drag in the 3D window. The Appearance tool supports a decrease in speed as the distance to the object decreases. Drag the mouse pointer to the right or left to rotate.

To rotate the camera view, left-click inside the 3D window and drag the pointer to rotate the camera view. To return to the original camera position, move the mouse back to the initial click.

Use the scroll wheel to quickly move back and forth along the camera's direction of view. This feature is useful if you become disoriented inside the model or collide with the surface.

Camera Properties

Sets the camera angle, alignment, and other properties that determine the type of lens through which the 3D model is viewed. Camera properties are an integral part of views, but are set separately.

3D measurement tool

Measures the dimensions of parts and distances in a 3D model.

3D toolbar view controls

Default View

Returns the default zoom, pan, and rotate mode for a 3D model. Use the Options menu in the View area of the Model Tree to set a non-default view. Or use the Manage Views command on the Views menu on the 3D toolbar to set a different default view.

If the object disappears from view, then the user has turned the camera away from it. Click the Default View icon on the 3D toolbar to return to the object.

Views menu

Shows the list of views defined for the current 3D model.

Switch Model Tree

Shows and hides the Model Tree panel.

Play/Pause Animation

Allows you to play or pause any animation based on JavaScript. The Play/Pause Animation pop-up menu will open a slider that you can move back and forth to move through the animation sequence.

Use orthogonal/perspective projection

Allows you to switch between perspective and orthographic projection of a 3D object.

Model Render Mode Menu

Specifies how the 3D shape will appear. For an illustrated guide, see Examples of Model Rendering Modes.

Menu "Turn on additional lighting"

Brings up the various lighting effects available to enhance the illumination of a 3D object. Trial to install the desired visual effects.

Background color

Opens a color picker that can be used to select a new color for the space around the 3D object.

Switching cross section

Shows and hides the cross section of an object. Click the pop-up menu to open the Cross Section Properties dialog box. For more information, see Creating Cross Sections.

Add multimedia/3D commentary

Allows you to add a note to any part of the 3D model. The note remains visible. See Add comments to 3D layouts in PDF files.

In the "3D & Media" panel of the "Preferences" dialog box, you can specify whether you want the 3D toolbar and model tree to be displayed by default. You can also define the default renderer and determine if animation is allowed.

Enable 3D content playback

The dynamic nature of 3D creates a potential security vulnerability. Therefore, automatic playback of 3D content in PDF documents is disabled by default. Select this option to enable 3D content in PDF documents.

renderer

Allows you to set a rendering engine that affects both performance and quality, so choosing the right renderer is important. Depending on the system settings, you can change the renderer. When DirectX® or OpenGL is selected, rendering is performed by the GPU hardware of the graphics card. Selecting Software takes longer to render, but the result often matches the rendering of the model in the original application better.

Depending on the system settings, you can change the renderer. When DirectX® or OpenGL is selected, rendering is performed by the GPU hardware of the graphics card. Selecting Software takes longer to render, but the result often matches the rendering of the model in the original application better.

Allow hardware rendering for legacy graphics cards

Enables hardware acceleration even when using graphics cards that do not support pixel shaders.

Enable 2-sided rendering

Parts of some models have two sides. To save time and space, you can disable this option and view only the front of the model. If the user looks inside a part that has only been rendered one-sided, the back side will be invisible.

Preferred rendering mode 3D PMI

Specifies the use of PMI mode for rendering. You can select one of the following options.

Use content parameter. PMI rendering uses the setting of each PMI to determine if the Z-buffer is being used.

PMI rendering uses the setting of each PMI to determine if the Z-buffer is being used.

Always display 3D PMI in front of the model. PMI rendering ignores the Z-buffer regardless of the setting in the file.

Always output 3D PMI using Z-buffer. PMI rendering always includes a Z-buffer regardless of the setting in the file.

Show panel when 3D graphics are activated

Determines whether the Model Tree panel is displayed when a 3D model is activated. Select Use Comment Options to use any of the options set by the author when adding the 3D model to the PDF document.

Show toolbar by default

Specifies whether the 3D toolbar is displayed when the 3D model is activated. Select Use Comment Options to use any of the options set by the author when adding the 3D model to the PDF document.

Allow Selection with the Hand Tool

Allows the user to select and highlight parts of the 3D model using the Hand tool. If this option is disabled, the Object Data tool (Tools > Live Objects > Select Object) is used to select the object.

If this option is disabled, the Object Data tool (Tools > Live Objects > Select Object) is used to select the object.

Merge Tools in the 3D Toolbar

This option places the control and navigation tools in the Rotate tool, thus shrinking the 3D toolbar.

Enable View Transitions

Some 3D models have animated view transitions. Deselect this option if 3D animation is not required.

Show 3D rotation axes

Shows or hides the axis that represents the current orientation of the 3D scene.

Low Frame Rate Optimization Scheme

Determines the actions applied to the animation when the frame rate drops. Turning the setting off will keep the frame rate low. Selecting a bounding box displays the 3D planes that enclose the parts of the model, rather than the parts themselves, to help maintain high frame rates.