Metrology 3d scanner

3D scanning for Metrology: Guide and product selection

What is 3D metrology?

3D metrology is the process of acquiring highly accurate physical 3D measurements of an object. The result is a digital 3D model that can be analyzed or retro-engineered.

In the case of quality inspection, for example, the 3D scan can be compared to a reference CAD model to make sure the object respects established norms and standards. 3D metrology helps ensure product quality while saving time and, thus, lowering costs.

CMMs– coordinate measuring machines– have traditionally been the most common type of hardware used for precision measurement. However, advances in 3D scanning technology are making 3D scanners increasingly popular for metrology as well, as they are faster and more cost-effective.

In this guide, we offer a comprehensive overview of some of the best metrology 3D scanners available on the market, covering different types of hardware (stationary, handheld) and price points. We also provide basic insight into 3D metrology software, which is as equally important as the hardware side of things.

Note: Not sure if you need an industrial metrology-grade performance? Take a step back and learn about other types of 3D capture solutions (jewelry 3D scanners, dental solutions, SLAM, …) in our all-round 3D scanner buyer’s guide.

The best metrology 3D scanners in 2022

The table below recaps our selection of some of the best metrology-grade 3D scanning options. The goal is to provide a quick, visual overview of the market; there are of course numerous other factors to consider beyond tech specs (certifications, software, customer service, …) to get the full picture for each solution and eventually make the right choice.

| Brand | Product | Accuracy | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Shining 3D This brand is a certified partner from our network. | FreeScan UE | 0.02 mm0.000787 in | China | $ 18,69916 999 €16,587 £2,787,198 ¥ | Quote |

| Medit | Solutionix C500 | 0.01 mm0.000394 in | South Korea | $ 40,00036 500 €35,482 £5,962,240 ¥ | Quote |

| Creaform This brand is a certified partner from our network. | HandySCAN BLACK Elite This product has been reviewed by our team. | 0.025 mm0.000984 in | Canada | $ 65,00057 000 €57,658 £9,688,640 ¥ | Quote |

| GOM | GOM Scan 1 This product has been reviewed by our team. | – | Germany | upon request | Quote |

| GOM | ATOS Q This product has been reviewed by our team. | – | Germany | upon request | Quote |

SCANTECH (HANGZHOU) CO. , LTD , LTD This brand is a certified partner from our network. | SIMSCAN This product has been reviewed by our team. | 0.02 mm0.000787 in | China | upon request | Quote |

| SCANTECH (HANGZHOU) CO., LTD This brand is a certified partner from our network. | TrackScan-P42 | 0.025 mm0.000984 in | China | upon request | Contact |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Category | Accuracy | Max resolution | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|

| Shining 3D This brand is a certified partner from our network. | FreeScan UE | Mobile > Handheld | 0.02 mm0.000787 in | 0.05 mm0.001969 in | $ 18,69916 999 €16,587 £2,787,198 ¥ | Get a quote |

| Medit | Solutionix C500 | Stationary > Desktop | 0.01 mm0.000394 in | 0.028 mm0.001102 in | $ 40,00036 500 €35,482 £5,962,240 ¥ | Get a quote |

| Creaform This brand is a certified partner from our network. | HandySCAN BLACK Elite This product has been reviewed by our team. | Mobile > Handheld | 0.025 mm0.000984 in | 0.1 mm0.003937 in | $ 65,00057 000 €57,658 £9,688,640 ¥ | Get a quote |

| GOM | GOM Scan 1 This product has been reviewed by our team. | Stationary > Desktop | – | 0.037 mm0.001457 in | upon request | Get a quote |

| GOM | ATOS Q This product has been reviewed by our team. | Stationary > Industrial | – | 0.03 mm0.001181 in | upon request | Get a quote |

| SCANTECH (HANGZHOU) CO., LTD This brand is a certified partner from our network. | SIMSCAN This product has been reviewed by our team. | Mobile > Handheld | 0.02 mm0.000787 in | 0.02 mm0.000787 in | upon request | Get a quote |

| SCANTECH (HANGZHOU) CO., LTD This brand is a certified partner from our network. | TrackScan-P42 | Mobile > Handheld | 0.025 mm0.000984 in | 0.02 mm0.000787 in | upon request | Contact manufacturer |

Overview of the best 3D scanners for metrology in 2022

In this section, we give some more context and information about each 3D scanner from our selection.

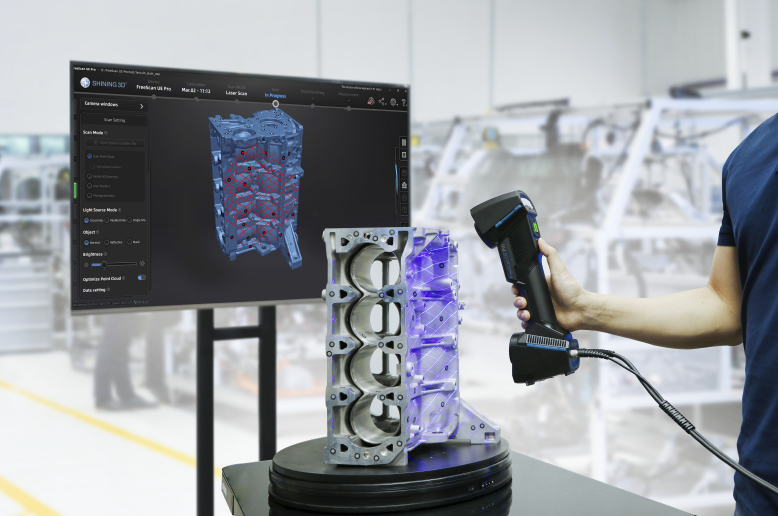

The FreeScan UE is a recent upgrade to the FreeScan X, boasting a faster acquisition rate, larger scanning range, lighter weight, and more competitive pricing.

This blue laser 3D scanner offers metrology-grade precision and repeatability, all while being able to scan difficult surfaces in a wide range of environments and industries. Common industries and applications for this type of 3D scanner include the automotive industry, transportation, mould inspection, energy manufacturing, aerospace, and machine manufacturing, among others.

The FreeScan UE is available in two versions: (1) the UE7 features 14 laser lines + 1 extra laser line, and an acquisition speed of 650,000 points per second, while (2) the UE11 features 22 laser lines + 1 extra laser line, and an acquisition speed of 1,020,000 points per second.

Contact manufacturer Get a quote Add to comparison

Weighing only 570 grams, the SIMSCAN is extremely lightweight for a handheld 3D scanner. It’s also very compact with dimensions of 203 x 80 x 44 millimeters. Scantech earned a Red Dot Design Award in 2021 for the SIMSCAN’s disruptive design.

After using the SIMSCAN to 3D scan various types of parts, we can confirm it’s an excellent product that feels, looks, and works great. With a price of around €25,000, the SIMSCAN’s price-to-performance is outstanding. The only blemish lies in the software, but it receives updates regularly and you can export your scans to your preferred suite.

With a price of around €25,000, the SIMSCAN’s price-to-performance is outstanding. The only blemish lies in the software, but it receives updates regularly and you can export your scans to your preferred suite.

Read the full review: Scantech SIMSCAN review

Contact manufacturer Get a quote Add to comparison

The BLACK Elite tops out Creaform’s flagship HandySCAN range, which we have reviewed several times over the years. It delivers a powerful performance that reminds us of the Metrascan 750, but without all the hurdles (complex setup, number of parts and accessories, and large footprint).

It boasts a clean, robust finish, and everything exudes quality and rigor. The attention to detail is similar to the feeling that Apple products give off; it’s no wonder Creaform received a Red Dot Design Award (2019) for it.

The HandySCAN BLACK Elite comes with Creaform’s VXelements software, which includes dimensional inspection modules (VX Inspect). It can also be used with third-party suites from Autodesk, 3D Systems, Dassault, etc. Users may opt for the Creaform MaxSHOT CMM add-on to complement the HandySCAN’s performance.

Users may opt for the Creaform MaxSHOT CMM add-on to complement the HandySCAN’s performance.

Read the full review: Creaform HandySCAN BLACK Elite review

Contact manufacturer Get a quote Add to comparison

The TrackScan-P42 is a high-end, optical tracking system for highly demanding industrial metrology applications.

Scantech’s TrackScan works with 17 blue laser crosses for ultra-fast 3D scanning (up to 1.9M points per second), and features a single-laser-line mode to capture deep holes and dead angles. It can be paired with Scantech’s T-Probe, a portable and wireless CMM designed to easily capture holes and hidden details with a single point repeatability of 0.030mm.

Contact manufacturer Get a quote Add to comparison

With a starting price of around €20,000, the GOM Scan 1 is GOM’s most entry-level, metrology-grade solution. We visited GOM’s Benelux HQ to review the scanner in early 2022, and were not disappointed.

The offer? GOM quality and performance at an affordable price. It is on par with high-end metrology 3D scanners and is quite fast at 6,000,000 points per scan. The GOM Scan 1 also benefits from the same, powerful GOM Inspect software as its more premium counterparts.

It is on par with high-end metrology 3D scanners and is quite fast at 6,000,000 points per scan. The GOM Scan 1 also benefits from the same, powerful GOM Inspect software as its more premium counterparts.

It is a small, lightweight, and precise machine packed with very serious capabilities.

Read the full review: GOM Scan 1 review

Contact manufacturer Get a quote Add to comparison

Solutionix is part of the larger, South-Korean Medit group, and is known for its high-precision dental 3D scanners. Their C500 is able to scan larger objects while benefitting from the same, excellent precision and resolution. Its automatic turntable not only turns but also tilts, providing very thorough scans.

While the Solutionix C500 is sensitive to dark and shiny surfaces, it offers very clean data and high resolution when such surfaces are matted with special spray (like AESUB). The C500 comes with four different sets of lenses for varying fields of view, resolution, and accuracy. Its smallest lens set gives an accuracy of 10 microns and a resolution of just 28 microns (point-to-point distance).

Its smallest lens set gives an accuracy of 10 microns and a resolution of just 28 microns (point-to-point distance).

The C500 is particularly adapted to small parts, but can be mounted onto a tripod for the occasional large scan.

Contact manufacturer Get a quote Add to comparison

The GOM ATOS Q is GOM’s mid-level metrology 3D scanner. It uses blue structured light and benefits from GOM’s latest optical sensors and technology, providing industrial-grade results in a compact device. According to GOM, the scanner is able to capture difficult textures such as shiny, reflective surfaces.

Five different lenses are provided in order to adapt the scanner to objects of different sizes.

This 3D scanner comes with the GOM Inspect Suite for metrological applications and can be operated on a tripod or mounted onto a robotic arm for full 3D scan automation.

Read the full review: GOM ATOS Q review

Contact manufacturer Get a quote Add to comparison

Types of metrology 3D scanners

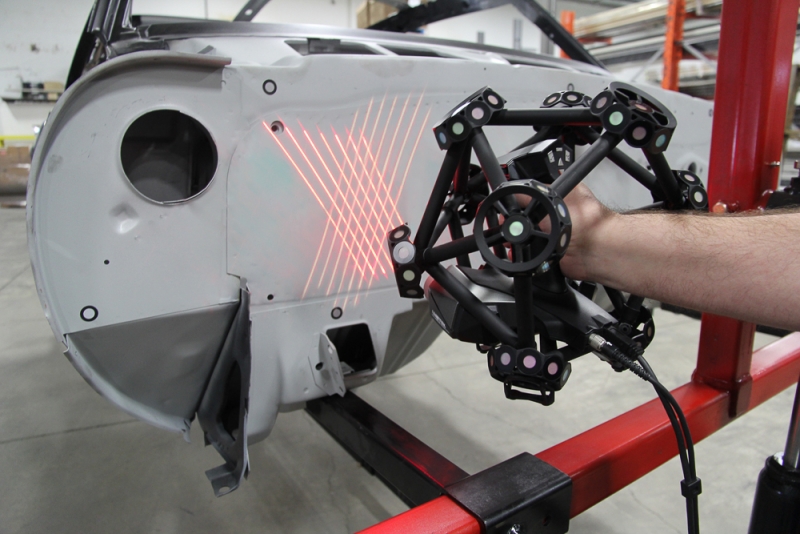

Handheld metrology 3D scanners

Handheld 3D scanners are convenient, versatile systems that grant access to hard-to-reach places (e. g. car interiors). They often feature several modes for users to adapt to small, medium, or large-sized parts.

g. car interiors). They often feature several modes for users to adapt to small, medium, or large-sized parts.

Using a handheld 3D scanner is comparable to recording a video or painting with a brush; the subject must be captured from all angles.

Pierre-Antoine using a handheld 3D scanner. Source: Aniwaa (Scantech SIMSCAN review)Stationary metrology 3D scanners

A stationary 3D scanner is similar to a camera on a tripod. For small or medium-sized objects, these scanners are usually paired with an automatic turntable for smoother workflows.

They can also be mounted onto an automated station. Such systems generally move the scanner up and down along the Z-axis while the object to be scanned sits onto an attached turntable.

An automated desktop 3D scanning station. Source: Aniwaa (GOM Scan 1 review)Stationary scanners are often more accurate solutions due to their fixed setup but are impractical for large objects or infrastructures. That said, some are robot-mountable.

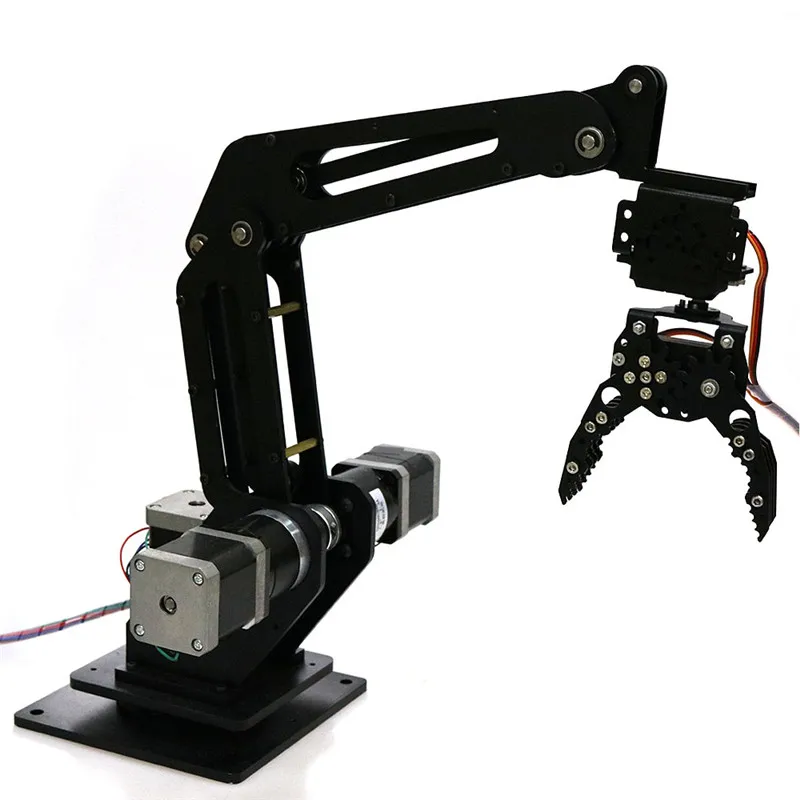

Automation in metrology with robotic arms

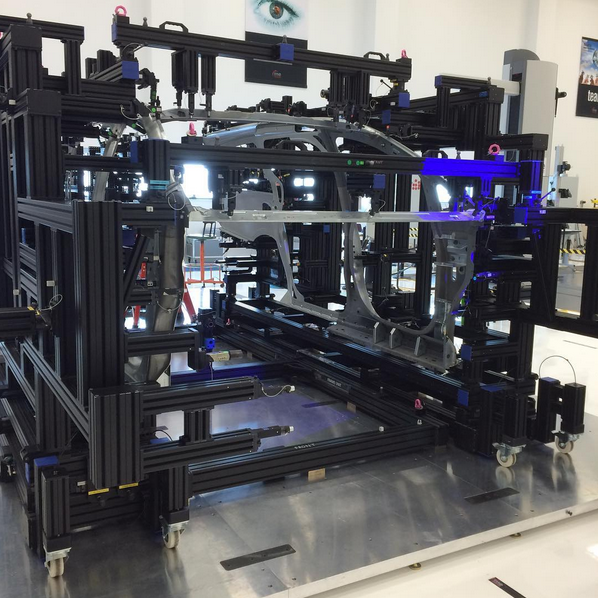

Many metrology 3D scanners, mostly in the stationary category, are designed to be mounted onto an industrial, robotic arm depending on specific needs.

Here is an example from Scantech:

These 5-axis or 6-axis arms eliminate human errors and speed up the scanning process. Robotic 3D scanning arms are often used in assembly lines.

High-end industrial 3D metrology systems

For our main selection, we didn’t include high-end systems that are destined for heavy industrial applications. They can’t be compared on the same level as the scanners from our main list, whether it’s in terms of accuracy, pricing, software, or automation.

Several leading brands like Hexagon and GOM (which is now part of ZEISS) provide extremely accurate, automated 3D scanning solutions for industrial assembly lines.

Contact us for more information.

3D scanner vs CMM

CMM stands for coordinate measuring machine. This type of device uses a probe- either a physical, surface-touching probe or a light/laser source–to measure an object’s geometry. CMMs can be operated manually or computer-controlled.

These machines are highly accurate but are relatively slow at capturing data and only acquire a certain amount of points. A standard CMM captures several hundred points, in contrast to 3D scanners which acquire hundreds of thousands or millions of points.

Hence, CMMs are mostly used for targeted inspection rather than for providing full 3D models of objects, in which case 3D scanners are the best option.

The main advantages of 3D scanners over CMMs are:

- Speed: A 3D scan can be processed in a matter of minutes, while CMMs require more time.

- Automation: 3D scanning systems are much more compatible with industrial environments such as assembly lines.

- Scope: 3D scanners capture exponentially more information. This can allow engineers and designers to understand what the root cause of a potential part deformation is rather than simply identifying its existence. They can also scan much larger parts than CMMs, which have a fixed frame/volume.

- Flexibility: It is easier to relocate a 3D scanner and use it at several workstations to adapt to different production needs. CMM machines generally stay in one place and take up a large amount of space.

- Non-intrusive: While coordinate measuring machines don’t necessarily all need to physically touch the object, they do get close to the object, which can be a problem in some cases. 3D scanners can capture data at a safe distance.

- Price: 3D scanners are generally less costly acquisitions than CMM machines.

All of this being said, CMMs and 3D scanners can be complementary. CMMs are hard to beat when it comes to measuring holes and complex, intricate details.

By using both a CMM (such as a handheld probe) and a 3D scanner, it is possible to reach a high level of accuracy.

Which industries use metrology and why?

Integrating 3D metrology directly in the value chain of any industry ensures high part quality without interrupting the production line.

These are some of the many industries that take advantage of 3D metrology:

- Aerospace and automobile

- Electronics

- Power and energy

- General manufacturing

- Medical

- Tooling

The top application for 3D metrology is part inspection within general quality control processes. It is essential for any business to oversee that their manufactured goods are up to standard.

This is true whether these goods are simple household objects, like a microwave knob, or crucial airplane parts that must be 100% standard and safe.

Accurate 3D measurement data also provides the option to reverse-engineer replacement parts and make quick repairs.

Overall, using 3D metrology ensures fewer errors in production, saving both time and money.

Metrology software for inspection

A 3D scanner is only as good as the software it works with. For clarity, we can distinguish two kinds of software:

- Base software to operate the scanner: This is typically proprietary software (e.g. Artec Studio) that is included with the scanner to convert the data points and clouds into a 3D mesh of the scanned object. It offers basic functionalities such as mesh alignment and hole filling, but usually won’t be enough to perform advanced inspection and quality control operations.

This can be sufficient depending on the end-use of the scan, but when it comes to metrology, additional software is often needed.

- Software for inspection: For 3D metrology, engineers and designers use specific inspection software or modules with additional functionalities and power.

Indeed, the primary goal (among others) is to compare the 3D scan to a reference CAD file. The software must be able to do that in order to find potential discrepancies and deliver deviation maps or reports.

Indeed, the primary goal (among others) is to compare the 3D scan to a reference CAD file. The software must be able to do that in order to find potential discrepancies and deliver deviation maps or reports.

3D inspection software: what’s available?

In most cases, manufacturers either provide their own software or recommend third-party suites.

- Proprietary software: The manufacturer can develop their own separate inspection software, like GOM with GOM Inspect, which is a reference in the industry. Other proprietary inspection software suites for 3D scanners include:

- Creaform VXelements and VXinspect module

- FARO CAM2 2020

- ScanTech ScanViewer

- PolyWorks Inspector

- Third-party software: Manufacturers can recommend or bundle in a particular third-party software.

Some of the most renowned, “universal” metrology 3D scanning software suites include:

Some of the most renowned, “universal” metrology 3D scanning software suites include:- 3D Systems Geomagic Control X

- Verisurf Inspect

- Siemens NX

- GOM Inspect (comes with GOM scanners but is also recommended by other manufacturers)

Of course, there are exceptions to this distinction. Some manufacturers directly include inspection-type functionalities within their base software, like ScanTech with ScanViewer or GOM with GOM Inspect.

Conversely, sometimes inspection software is capable of serving as base software by importing and processing raw 3D scanning data, too.

3D scanning software pricing

Metrology and inspection software prices are quite high, sometimes even higher than the hardware itself. They can cost anywhere from several thousand dollars to over $30,000 and are not always included in the 3D scanner’s price, so it is something to watch out for when choosing a scanner.

If you already have a license for a specific inspection software suite, you can also check which scanners are compatible with it.

What specifications to look for in a 3D scanner?

There are several specifications to look into before purchasing a 3D scanning solution for metrology.

Accuracy

Accuracy defines how close a measurement is to its true value. This is of utmost importance for metrology applications. Often, manufacturers provide two different kinds of accuracy specifications: single scan accuracy and volumetric accuracy.

Light source

3D scanners use different kinds of light sources to capture 3D images: laser lines and crosses, which are typically red or blue; or LED light patterns, which are usually white or blue.

Generally, the more lines or lasers a 3D scanner has, the faster it will be at 3D scanning.

Resolution

Resolution is typically measured in point-to-point distance, and sometimes in points per scan.

As is the case with images, the higher a scan’s resolution is, the more details will be visible and the crisper the results will be.![]()

There are two different kinds of resolutions: measurement resolution and mesh resolution. Mesh resolution is the most important kind to consider, as it will be the resolution of your final 3D model.

It may at times be unclear which resolution manufacturers are referring to in their product specifications.

Speed

Data acquisition speed can be expressed in point measurements per second, frames per second, or seconds per scan.

Software

Some 3D scanner manufacturers develop their own software, while others have partnerships with existing, leading 3D scanning software brands.

It is also important to keep in mind that 3D scanning software always requires powerful laptops in terms of RAM, graphics cards, etc. If you are not well equipped, you may need to allocate several thousand dollars of your budget to a new PC.

Range and field of view

Evidently, it is inefficient to 3D scan a large object with a 3D scanner that has a small range or field of view. Hence it is mandatory to see if a scanner’s range is compatible with what you are planning on 3D scanning.

Hence it is mandatory to see if a scanner’s range is compatible with what you are planning on 3D scanning.

Some 3D scanners offer multiple 3D scanning modes to adapt to different object sizes.

Marker placement

Markers are small, adhesive “targets” that aid 3D scanners in positioning the data that they have acquired. In other words, they help the scanner align the different captured frames together, relatively to each other and in space, to form the 3D model.

In order to enhance their global accuracy, a number of structured light or laser 3D scanners integrate marker acquisition with photogrammetry technology, through dedicated cameras.

They are in a way “hybrid” 3D scanners, explaining why some metrology 3D scanners require the user to place markers on the object to be scanned or its environment, especially for large-sized objects (over 1 meter).

Metrology 3D scanner price

The price for a metrology 3D scanner largely depends on its accuracy, software, and other factors. For heavy industrial applications, the price for an appropriately accurate scanner and software can go well over $100,000.

For heavy industrial applications, the price for an appropriately accurate scanner and software can go well over $100,000.

For less demanding use cases, the price for an entry-level metrology 3D scanner can start at around $15,000.

FAQ

How much is a metrology 3D scanner?

Metrology-grade 3D scanners generally cost between $20,000 and $50,000. Industrial, robotic automated systems can cost over $100,000.

How accurate is 3D scanning?

Currently, accuracy can get all the way down to 0.004 mm- 16 times thinner than an average human hair.

What is the maximum size of objects you can 3D scan?

The maximum scanning area depends on the scanner itself. Keep in mind that the bigger the scan, the less accurate the result will be (linearly).

Can I do metrology with a handheld scanner?

It is possible to do metrology with a handheld 3D scanner. For repeated industrial applications, however, stationary or automated scanners are preferable.

For repeated industrial applications, however, stationary or automated scanners are preferable.

How much time does it take to 3D scan an object?

Depending on the 3D scanner’s speed and the object’s complexity and size, it can take anywhere from less than a minute to several dozen minutes. Software processing adds a bit of time to the total.

Can I scan shiny objects? Can I scan dark objects?

Shiny and dark objects are hard to 3D scan, regardless of the 3D scanner’s quality. Special sprays and techniques exist to overcome this obstacle.

3D Scanning Services, Equipment & Software

-

Reverse Engineering + CAD Modeling

Reverse Engineering uses different forms of 3D scanning to create a CAD model where no model exists. 3D scanners, portable CMMs and laser trackers are used for other reverse engineering solutions beyond models including process optimization, full dimensional part inspections, part analysis, tool building, prototyping, and assembly integration.

LEARN MORE

-

3D Scanning + Long Range Scanning

Exact Metrology selects the right scanning technology that delivers the accuracy, speed and resolution needed for your application. Our non-contact 3D scanning tools are grouped in the short-range measurement technology class. Each of these technologies is portable, so we can bring the scanning services to you. When your parts demand a longer range than 20 feet, we will roll out our 3D long range scanning and PCMM solutions that grab measurements at 30, 100, 500 and 900 feet.

LEARN MORE

-

3D Inspection + 3D Measurement

The 3D measurement data from our scanners and PCMMs offers a comprehensive definition of a physical object that is used for measurement, inspection, comparison and reporting. When a part is defined by millions of points, you can see subtle deviations, slight variations and fine details to verify that a part (or mold) meets specifications.

Exact Metrology delivers the best of both worlds. We combine 3D scanning with our contact, touch-probe measurement tools to deliver precise dimensions on geometric shapes.

Exact Metrology delivers the best of both worlds. We combine 3D scanning with our contact, touch-probe measurement tools to deliver precise dimensions on geometric shapes.LEARN MORE

-

CT Scanning + Industrial X-Ray

This technology is used for Internal Defect Analysis/3D Quantitative Porosity Analysis, Materials Structural Analysis or Assembly Control. It’s the only method to get 3D views of the inside of a part [like the aluminum casting at left] and the only way to obtain true dimensional data non-destructively.

LEARN MORE

We're here to support!

We have started a series of training, tips & tricks, unboxing, and product videos to assist through these trying times and social distancing. Visit "What's New" Section below to view. [Popcorn and beverage optional].

Through these unprecedented times, while the world handles the Coronavirus Covid-19, we are safely here to support you. We have enacted procedures to maintain office safety for our families, team, and our customers, and continue to monitor the situation closely. As things develop, we will act accordingly. We are able to operate effectively, while maintaining safety, to complete your projects, deliver equipment & software, and work on-site until further notice. Through all of this, we wish you and your families great health, and extend our support however possible. Please feel free to reach out.

We have enacted procedures to maintain office safety for our families, team, and our customers, and continue to monitor the situation closely. As things develop, we will act accordingly. We are able to operate effectively, while maintaining safety, to complete your projects, deliver equipment & software, and work on-site until further notice. Through all of this, we wish you and your families great health, and extend our support however possible. Please feel free to reach out.

Stay well,

-Exact Metrology

3D Laser Measurement and CT Scanning: Services, Equipment, Sales & Rentals

Exact Metrology, Inc. is a full service exact laser measurement company. In addition to selling CT Scanners and performing CT contract services on-site or in-house, we provide contact (Probing & Digitizing) and non-contact (3D Scanning) measurement, on-site inspection, and reverse engineering technologies. Our complete range of portable Coordinate Measurement Machines (CMMs) and scanning equipment allows us to handle most measurement tasks at your facility. Once the measurements are complete, our team of technicians will convert and output the raw data into the model, report, image, animation or whatever deliverable best gives you the answers and results you need.

Once the measurements are complete, our team of technicians will convert and output the raw data into the model, report, image, animation or whatever deliverable best gives you the answers and results you need.

We also rent metrology equipment solutions, and offer software training.

Metrological 3D Scanner│KSCAN Magic& KSCAN 20 3D Scanner

High Precision Metrology 3D Scanner

The KSCAN Composite 3D Scanner line is a series of professional, highly integrated and portable 3D scanners. It features an innovative infrared laser + blue laser scanning model, built-in photogrammetry system, compatibility with portable CMMs and automated 3D systems. It provides high repeatability of scan results with excellent detail at high efficiency. When it comes to measurements, it is suitable for both large scale and miniature objects. These versatile handheld 3D scanners offer a competitive 3D solution for manufacturing, automotive and other industries that require highly accurate 3D data and want to optimize product lifecycle management.

KSCAN-Magic Series 3D Laser Scanner

Multi-functional 3D laser scanner designed for industrial use with standard operating modes, in particular the globally pioneered infrared laser technology for extensive sanitization.

Accuracy

0.020 mm resolution

0.010 mm

Learn more >

KSCAN20 3D Scanner

Dedicated handheld 3D scanner with the widest range of applications. From quality control to product development, the KSCAN20 3D scanner provides a 3D solution to quickly create an accurate 3D model.

Accuracy

0.020 mmResolution

0.010 mm

Learn more >

Which 3D solution is best for your needs?

We provide you with a customized solution for 3D measurement

CONTACT OUR SPECIALISTS

| KSCAN-Magic Series | |

|---|---|

| Precision | Up to 0. 020 mm 020 mm |

| Scan speed | Up to 1,650,000 measurements/s |

| Scan area | 1440 mm × 860 mm |

| approval | 0.010mm |

Collaborate with the leading supplier of 3D scanners

Allows you to measure and scan all

FREE DEMO NOW

Scantech's 3D composite scanner designed for the unique needs of various industries

Find out how our metrology 3D scanner can help.

Quality control

3D solutions for rail transport. In this project, 3D scanning plays a critical role in quality control of components and molds.

Product Development

This project demonstrates the detection of insulation products using 3D scanning technology. Inspection of parts with 3D scanners contributes greatly to our safety.

Inspection of parts with 3D scanners contributes greatly to our safety.

Reverse engineered

In this video, a 3D scan of the rear wing is made for custom modification to get the most powerful downward force and better driving at high speeds.

Review of 3D scanners for metrological control / Sudo Null IT News

In this article we will talk about optimizing quality control processes using 3D scanning, about the design and principles of operation of metrological 3D scanners. Using real examples, we will show the effectiveness of using equipment for solving various problems. After reading the review, it will be easier for you to navigate among a large number of models on the market and determine the criteria for choosing the right device.

Introduction

Every year the industry produces more advanced instruments and devices. Machine parts often have a complex geometric shape, are in close interaction with each other. In order to ensure the smooth operation of the mechanisms, it is necessary to match the shapes, sizes, assembly accuracy and other parameters. Quality control in mechanical engineering was carried out using various technologies, including using coordinate measuring machines (CMMs). However, scanning is by far the most efficient method in terms of the ability to capture data for measurements and the speed of information processing.

Machine parts often have a complex geometric shape, are in close interaction with each other. In order to ensure the smooth operation of the mechanisms, it is necessary to match the shapes, sizes, assembly accuracy and other parameters. Quality control in mechanical engineering was carried out using various technologies, including using coordinate measuring machines (CMMs). However, scanning is by far the most efficient method in terms of the ability to capture data for measurements and the speed of information processing.

Capabilities of 3D scanners

Source: solutionix.com

3D scanners cope not only with smooth surfaces, but also with complex areas: corners between edges and faces, depressions, holes. An important advantage of the devices is the non-contact method of operation, which allows scanning at a distance, in hard-to-reach places.

After the changes are made, the information is transmitted online to a computer, where the software compares the received data and the specified parameters and demonstrates deviations: size mismatches, cracks, signs of deformation and corrosion, and other changes.

Applications

Source: sastrarobotics.com

Digital measurement is a high-tech process that has a number of important advantages over other verification methods. The only disadvantage of the technology is the high price of the equipment. In large industries, with a quick payback, the use of 3D scanners is economically justified. Consider examples:

- large-scale production of parts and devices with mandatory input and output quality inspections;

- small-scale production of objects of complex geometry, impossible without constant quality control.

Situations when other technologies cannot be applied:

- work with objects made of specific materials deformed during the contact method for determining parameters;

- measurement of electronic parts at risk of being damaged by static electricity;

- re-measurements of objects that are not physically present can also be made on a pre-made digital copy.

Purposes of use

Source: www.capture3d.com Input control of materials and details is necessary at any enterprise. For large-scale production, selective batches are inspected. However, this requires a large number of controllers, which increases the cost of the product.

The use of 3D scanners automates the workflow, eliminates errors associated with the “human factor”, allows you to switch from selective quality control to continuous, increases the speed of verification several times compared to manual labor.

Analysis of the location of parts relative to each other

In a product consisting of several parts, it is important to monitor the correct arrangement of elements in relation to each other. Scanning technology easily captures the position of objects in space and transmits information to a computer monitor.

Checking the geometry of large objects

A number of large objects, such as construction equipment, marine and air transport, require regular testing of the hull geometry. The process is lengthy and requires the search for specialists with the necessary qualifications and experience. Metrological 3D scanners easily cope with the digitization of large-sized objects, guarantee high measurement accuracy and save time and financial resources of companies.

The process is lengthy and requires the search for specialists with the necessary qualifications and experience. Metrological 3D scanners easily cope with the digitization of large-sized objects, guarantee high measurement accuracy and save time and financial resources of companies.

Checking the geometry of small objects

Sometimes measuring small objects is more difficult than measuring large ones. 3D scanners successfully measure to within a few microns, regardless of the size of the parts. Deviations of shape and size from the base model are highlighted in the program, which makes it easy to notice and eliminate them.

Selection of equipment

Source: tool-maker.net

There are dozens of models of metrological scanners on the modern digital equipment market. The choice of instrument begins with the identification of the range of tasks set by the production. Here are some parameters that you need to pay attention to and compare with key goals:

1. Working area

Working area

It is quite clear that large objects require devices with a large working area. Please note that the size of the working area is in inverse proportion to the resolution. By choosing a device with an excessive scan area, the user may find insufficient accuracy and resolution.

2. Data Accuracy

It is obvious that in aircraft construction and the production of other critical parts, the highest possible accuracy is required.

In reverse engineering of consumer goods, products without complex mechanics, as well as when used in the creation of works of art, souvenirs, in the development of computer games, such accuracy will not be used, for these purposes it makes no sense to overpay for a scanner tens and hundreds of times.

3. Run speed

This parameter includes the calibration and direct scan time. For high-volume production, where 3D scanning is used for quality control, involving dozens of measurements per minute, high speed is an important characteristic. Production of small batches of products and reverse engineering are less demanding on the speed of the device.

Production of small batches of products and reverse engineering are less demanding on the speed of the device.

4. Software

We recommend giving preference to scanners that work with proprietary highly specialized software. The software required for processing scans, if not included, may require significant additional financial investments.

5. Price

When choosing a 3D scanner, you must independently or with the help of a qualified specialist correlate the tasks of the user and the capabilities of the device. It makes no sense to overpay for unnecessary features. At the same time, it is important that the device has the necessary set of parameters that are guaranteed to give the desired result. It is important to predict the payback period of the equipment.

Examples of 3D scanners for metrological quality control

Let's start our acquaintance with the presentation of the Russian sample - RangeVision Pro. The device is officially approved as a measuring instrument by the Federal Agency for Technical Regulation and Metrology.

The device is officially approved as a measuring instrument by the Federal Agency for Technical Regulation and Metrology.

Basic information about RangeVision Pro

Source: top3dshop.ru

The device is designed as a universal measuring device for small and large objects with a size of 30 to 1000 mm. Three working zones and a set of interchangeable lenses allow the scanner to accurately digitize jewelry and car body parts.

Measuring accuracy is ensured by structured illumination technology, 6-megapixel cameras and original software solutions.

RangeVision software allows you to stitch image elements, fill in empty areas and straighten images. The program includes basic functions for checking the geometry and taking measurements. The output file format is supported by all popular computer-aided design and virtual simulation systems. Software updates are freely available.

RangeVision Pro Features

3D Scanner Applications in Various Applications

Quality Inspection at Dolsatech

Source: rangevision. com

com

RangeVision PRO 3D scanner was used to optimize the process. Current measurement technologies involve the transportation and storage of control samples in specially designated areas. The mobility of the Russian scanner made it possible to reduce logistics costs.

Source: rangevision.com

With the scanner, there was no need to move batches for measurements. RangeVision PRO works in workshops and warehouses - in any convenient place.

In this case, a three-dimensional model of a part with a size of 1700 mm * 720 mm was created. Stickers were pasted onto the part, which made it possible to automatically assemble individual images into a single 3D model. The information was processed by the proprietary ScanCenter software supplied with the scanner.

Quality Inspection at INKAY TECHNOLOGY

Source: rangevision.com

INKAY TECHNOLOGY SRL in Italy had the task of verifying that the dimensions of the body casting matched the base model saved in the CAD file. Given the non-standard geometry of the object, it was decided to abandon the usual technologies and use the RangeVision 3D scanner.

The work was done in 3 stages:

- We created scans of the outer part of the body using markers for automatic image stitching.

- To scan the inside, the case was divided into 2 parts, each of which was digitized separately.

- Stitched all the images into a single model.

Source: rangevision.com

Quality inspection at Krasnoye Sormovo plant

Source: rangevision.com

As we mentioned above, 3D scanning is justified not only in high-volume production. Often the equipment is effectively used in the piece production of parts. The shipbuilding industry uses cast components with complex geometry, the quality control of which is difficult and time consuming. Therefore, the use of 3D equipment in the industry is becoming more common.

Often the equipment is effectively used in the piece production of parts. The shipbuilding industry uses cast components with complex geometry, the quality control of which is difficult and time consuming. Therefore, the use of 3D equipment in the industry is becoming more common.

Krasnoye Sormovo specialists chose RangeVision to inspect the quality of the controllable pitch propeller hub.

Part height - 70 cm, diameter - 80 cm. The RangeVision PRO 3D scanner was moved around the hub, taking pictures from different angles. A 3D model was assembled from the 100 images obtained. The stl-file was combined with the basic calculation model in the GOM Inspect software to determine deviations. The work, as a result of which the specialists received an accurate report of the conformity of the finished product to the base model, took several hours.

ScanTech PRINCE775

Source: www.3d-scantech.com

ScanTech PRINCE 775 portable handheld 3D laser scanner is based on 2 cameras with LED illumination. 2 operating modes are available to users:

2 operating modes are available to users:

- In BLUE mode, the blue laser is active; this mode is used to obtain models of high detail;

- RED mode with red laser is enabled when high sampling rate is a priority.

As a result of scanning, a point cloud is created, which is processed using the ScanTech software solution. The finished image is displayed on the screen of the working device.

Scanner Features

Using PRINCE 775

The main scope of the scanner is the digitization of large-sized objects, such as parts of ships, cars, industrial installations. The device can also work with small objects, such as jewelry.

ScanTech PRINCE 775 Applications:

- reverse engineering;

- industrial design;

- quality inspection;

- creation of computer games and 3D films;

- and in many other areas.

Source: www. 3d-scantech.com

3d-scantech.com

An example of using the PRINCE handheld scanner with MSCAN - the use of two instruments increases the efficiency of the process, due to the features of the equipment.

The first device provides high accuracy and detail, the second helps to study large objects using photogrammetry.

Source: www.3d-scantech.com

Digitization of Airbus A350 parts using the kit: MSCAN+ PRINCE. The pair has proven itself in the rapid resolution of quality inspection tasks.

Source: www.3d-scantech.com

Digitization made it possible to create a three-dimensional model of the impeller, since it was impossible to accurately measure it in other ways.

Creaform HandySCAN Black Elite

Source: creaform3d.com. The device is suitable for most users, including those who do not have practical skills in working with such equipment. Despite the ease of use, the scanner guarantees high-precision models, even when digitizing large objects of complex geometry.

Despite the ease of use, the scanner guarantees high-precision models, even when digitizing large objects of complex geometry.

Scanner features

Application area Creaform HandySCAN Black

The device is designed for professional use in various fields. HandySCAN Black excels in tasks such as:

- incoming and outgoing quality control in production;

- reverse engineering;

- pipeline inspection;

- digitization of objects for any purpose.

The scanner is easy to use: to get started, you need to connect to a laptop and select a program. During the digitization process, you can pause, examine the intermediate results and continue working.

Creaform MetraScan 750|Elite

Source: industryarena.com

Another handheld metrology scanner that generates high precision models even for large objects.

Specification MetraScan 750|Elite

MetraScan 750|Elite

The device is widely used in architecture, energy industry, for reverse engineering and metrological control.

Solutionix C500

Source: psarta.com

Solutionix C500 is a compact color 3D scanner. The mobile device is placed on any flat surface.

The design is based on a turntable and two cameras with a resolution of 5 megapixels each. The rotation of the platform allows cameras to capture an object from different angles. High speed operation and ease of use provide excellent equipment performance.

Specifications Solutionix C500

Application Solutionix C500

Due to its compact size and the ability to quickly and accurately color scan the device is in demand in many areas, for example:

- in dentistry;

- jewelry industry;

- in education;

- for solving reverse engineering problems in various fields.

Terminals

The use of metrological 3D scanners improves the quality of products and reduces their cost by saving time and resources, minimizing scrap.