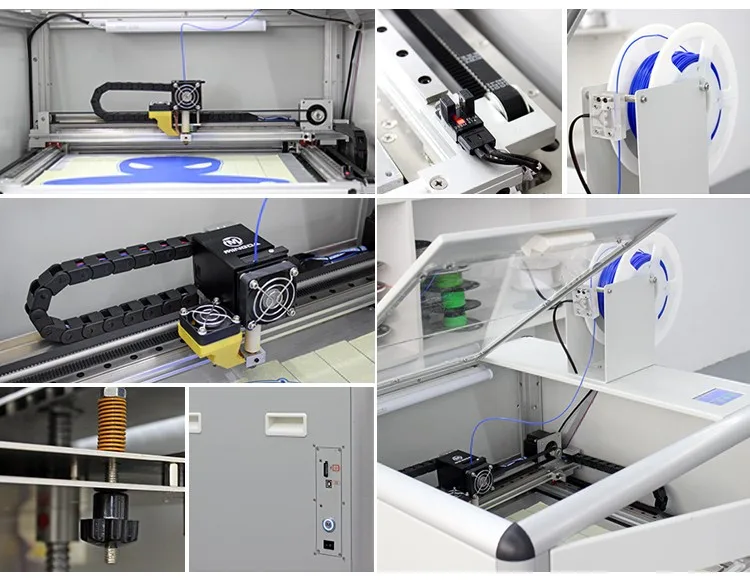

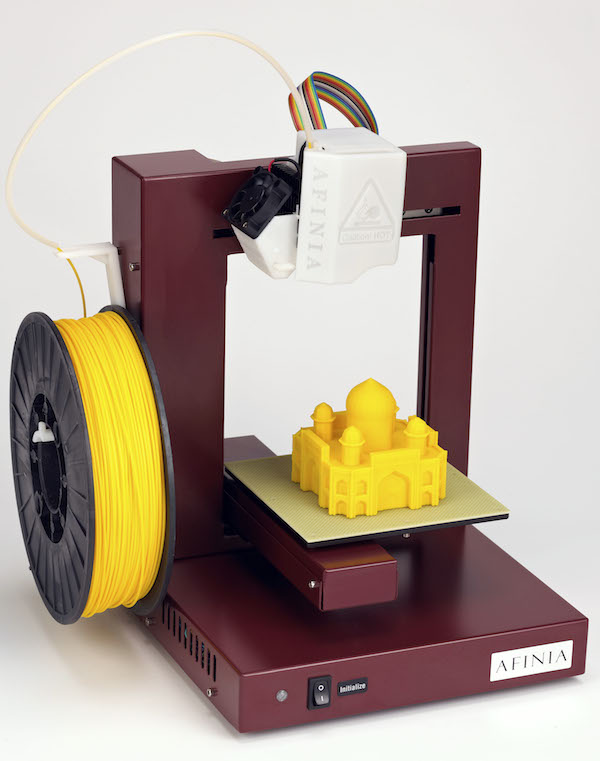

Mp 3 series commercial 3d printer

HP Industrial 3D Printers - Leading The Commercial 3D Printing Revolution

Contact an HP 3D Print expert

Choose the phone number for your country to speak to a local HP 3D Printing sales expert today.

België/Belgique

+32 78 48 44 69

Czech Republic

+420 239 050 531

Deutschland

+49 7031 986 90 13

+49 7031 986 90 17

España

+34 93 003 45 95

France

+33 6 28 78 35 59

Italia

+39 02 8295 2406

Nederland

+31 20 241 5685

Norway

+47 23 96 00 13

Österreich

+43 720 117035

+43 1424 0091

Romania

+40 376 300 174

Sweden

+46 8 446 891 49

Suisse/Switzerland

+41 44 511 2308

+41 44 511 2333

United Kingdom

+44 20 7365 8158

United States

+1 877 468 8369

Data courtesy1

Integrity.

Production ready

and reliable

Together, we can take revolutionary designs seamlessly from prototype to production grade.

Ability meets

agility

Let’s implement production processes that allow you to rapidly develop unique solutions while remaining flexible.

Reimagining

realities

Now we have the power to customize like never before and produce wherever, whenever your product is needed.

The possibilities are endless

Partnership makes anything

possible

Breakthrough digital technology alone isn’t enough. Today, you need a trusted partner who knows how to apply it effectively to help solve your specific supply-chain challenges.

Availability, pricing, product configuration and specifications may differ according to geographical location, local laws and practices.

Please contact us or talk to your local HP 3D Printing representative for further information or for product configurations specific to your local country.

- Data courtesy of Bastian Solutions & Fast Radius, Heygears, Avular, Breezm, Volkswagen and Cupra Racing

- Data courtesy of GoProto and Ropes Edge

- Data courtesy of Gimatic

- Data courtesy of SmileDirectClub

- Data courtesy of Volkswagen

- Data courtesy of Invent Medical

- Data courtesy of Cobra Golf

- Data courtesy Addit.ion

- Data courtesy of Hopkins, J., Lobete, A., Remacha, C.

- Data courtesy of Lumenium

- Data courtesy of Breezm

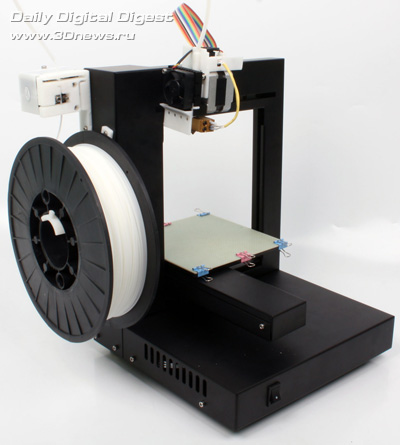

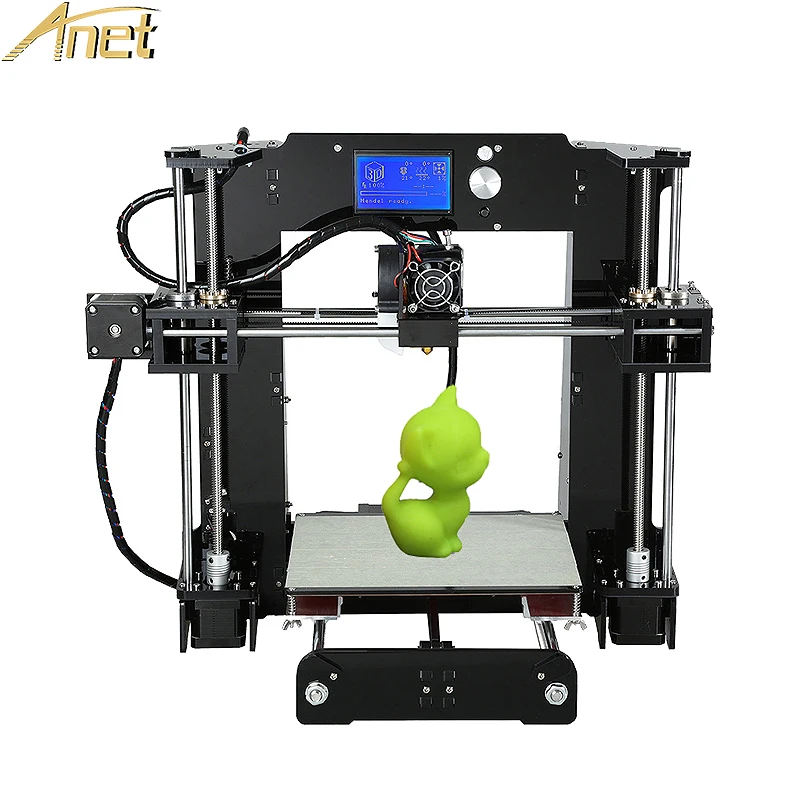

CES 2017: Monoprice Announces Upgrade, Expansion of Popular 3D Printer Line - 3DPrint.com

California-based online electronics retailer Monoprice entered the world of 3D printing back in 2014, when they introduced the Monoprice Dual Extrusion ABS/PLA/PVA 3D printer. At CES 2016, they unveiled a pair of remarkably inexpensive 3D printers, and in a recent report from IT market research company CONTEXT, Monoprice was revealed to be number five on the top desktop 3D printer manufacturers list, in terms of actual units sold last year. This makes sense, as they’re recording 600% sales growth in 3D printing. Today at CES 2017 in Las Vegas, the company announced the expansion of their popular 3D printer line, introducing some new models for both home and professional use.

At CES 2016, they unveiled a pair of remarkably inexpensive 3D printers, and in a recent report from IT market research company CONTEXT, Monoprice was revealed to be number five on the top desktop 3D printer manufacturers list, in terms of actual units sold last year. This makes sense, as they’re recording 600% sales growth in 3D printing. Today at CES 2017 in Las Vegas, the company announced the expansion of their popular 3D printer line, introducing some new models for both home and professional use.

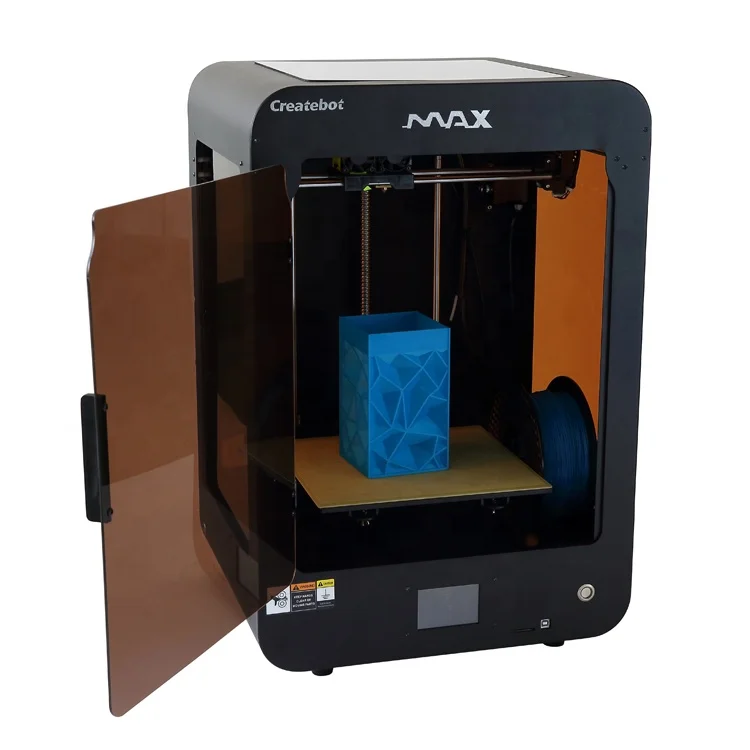

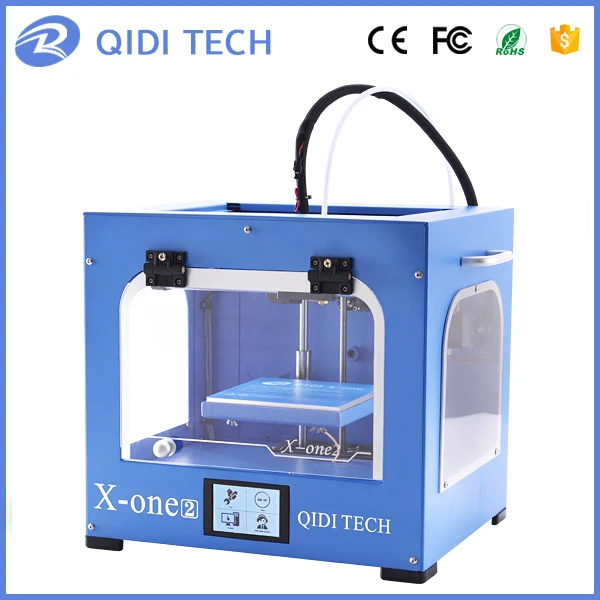

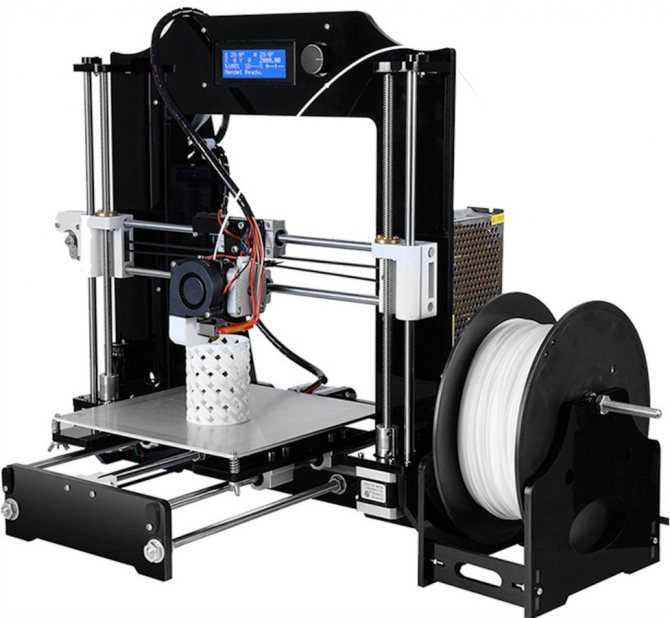

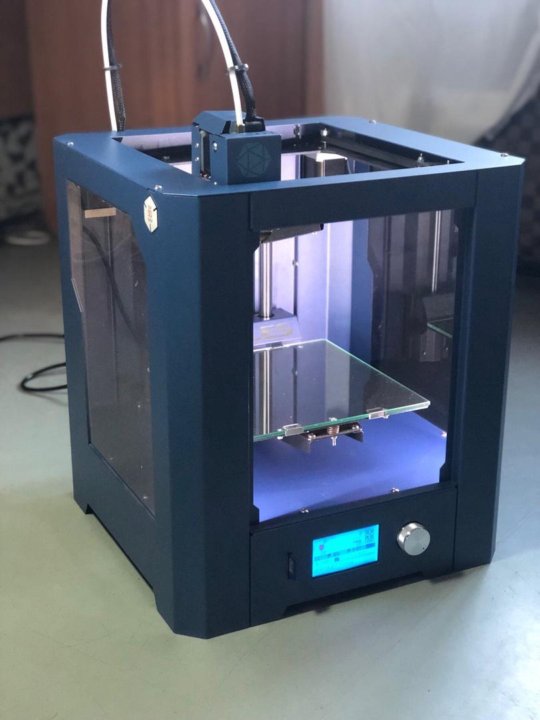

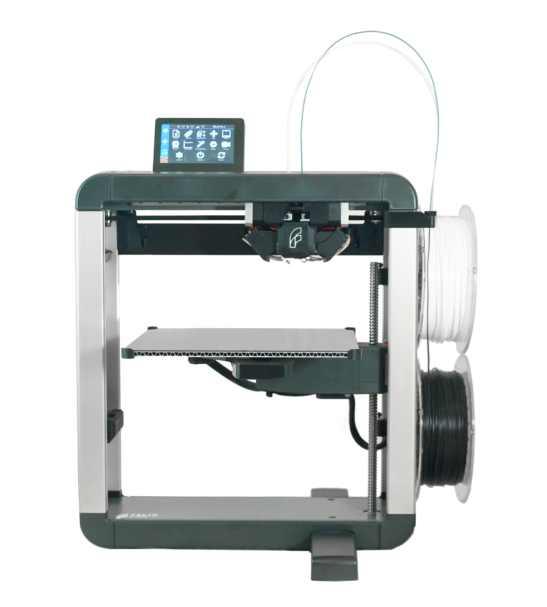

Monoprice is well-known for their affordable, quality computer accessories, and with the 3D printing market expected to triple in revenue by the year 2020, is hoping to continue moving onward and upward. The company made upgrades to one of their existing 3D printers, rolled out two models designed for beginners, and introduced their first professional SLA printer. The new printers join the existing models in featuring the latest developments in 3D printing technologies, versatility, rapid printing speed, and solid metal construction.

Select Mini v2

Bernard Luthi, CEO of Monoprice, said, “With an aggressive growth plan and increased manufacturing power, we’re focused on maintaining our strong position in burgeoning technology categories like 3D printing, so we can continue delivering better and wider choices at more affordable prices to our customers. We’re also keeping our finger on the pulse of other product categories that present opportunities for us and our disruptive business model. After vetting the home appliance industry, we realized we owed it to our customers to introduce quality products at fair prices.”

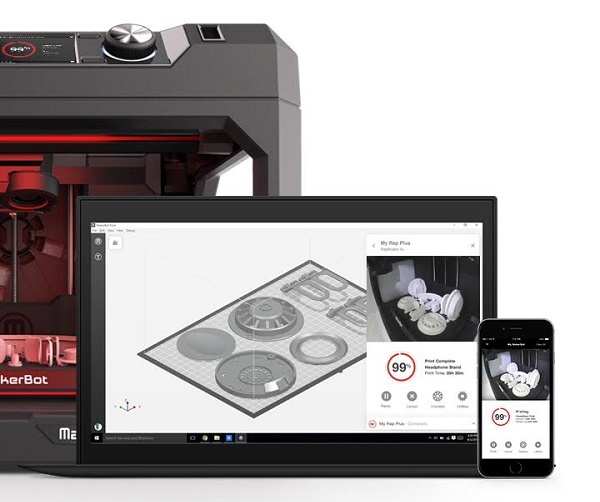

The company remains focused on expanding their cost-effective 3D printer line and keeping the technology accessible to everyone. Their new 3D printers will be debuted and demonstrated at CES 2017 this week. First up, Monoprice upgraded their best-selling $199 Select Mini 3D printer to version 2.0, adding some community-inspired upgrades, but keeping it at the same low price. Their new plug and play MP Delta Mini 3D printer comes with Wi-Fi, and can create high-quality 3D prints right out of the box. It’s the perfect option for beginners, and even more perfect for your wallet – at just $149.99, the Delta Mini is the company’s lowest-cost 3D printer!

Their new plug and play MP Delta Mini 3D printer comes with Wi-Fi, and can create high-quality 3D prints right out of the box. It’s the perfect option for beginners, and even more perfect for your wallet – at just $149.99, the Delta Mini is the company’s lowest-cost 3D printer!

MP Select Mini 3D printer

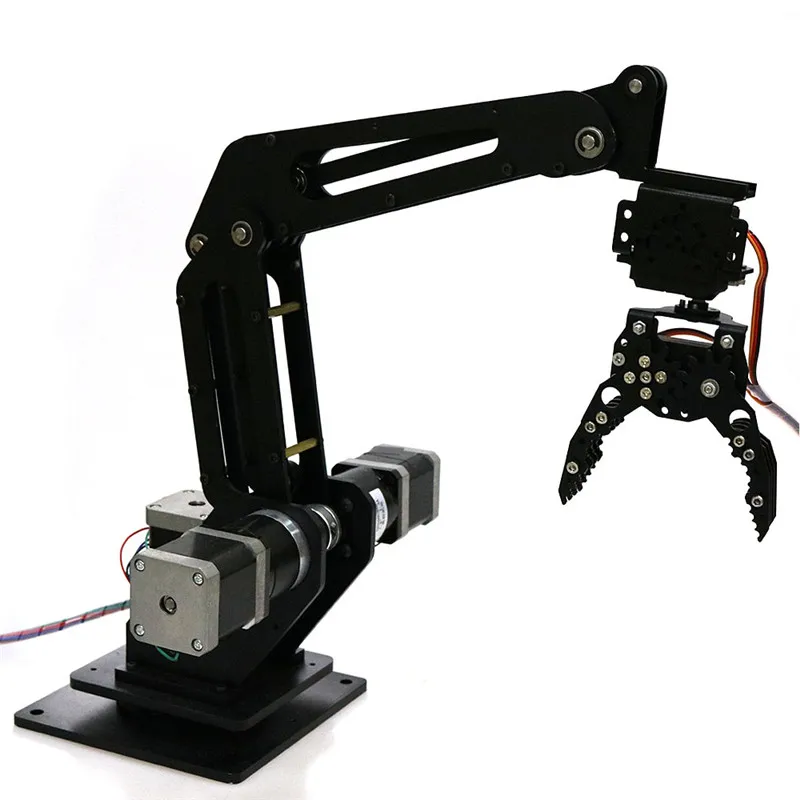

The professional MP 3 Series Commercial 3D printer is well-suited for industrial and commercial rapid prototyping, thanks to its large 400 x 400 mm build volume. This model will set you back $799.99, but has a full enclosure and features the latest FDM technology. Finally, Monoprice is introducing the big kahuna, their first professional quality SLA resin printer. The price for the MP Maker Prism Professional SLA Resin Printer may seem steep at $3,499, but the 3D printing solutions it offers are on par with other 3D printers that cost over $9,000. It’s ideal for creating objects that require high levels of accuracy, such as prototypes, jewelry, and dental products, due to its impressive 0. 03 micron layer resolution.

03 micron layer resolution.

Monoprice is also displaying their new home appliances and audio technology at CES, including a new blender and a new Onyx Series 3.5 mm audio cable. All of their new 3D printers and appliances will be start shipping in the first quarter of 2017. Visit them at CES 2017 at the Venetian Palazzo Hospitality Suites, #VEN-3132. Don’t forget, 3DPrint.com will be also be roaming the show floors, and bringing you all the latest from CES 2017! Discuss in the Monoprice forum at 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3D printer retailers • CES 2017 • consumer electronics show • fdm 3d printer • inexpensive 3d printer • monoprice • monoprice 3d printer • monoprice dual extrusion 3d printer • MP 3 Series Commercial • MP Delta Mini • MP Maker Prism Professional SLA • Select Mini v2 • sla printer • wifi

Please enable JavaScript to view the comments powered by Disqus.

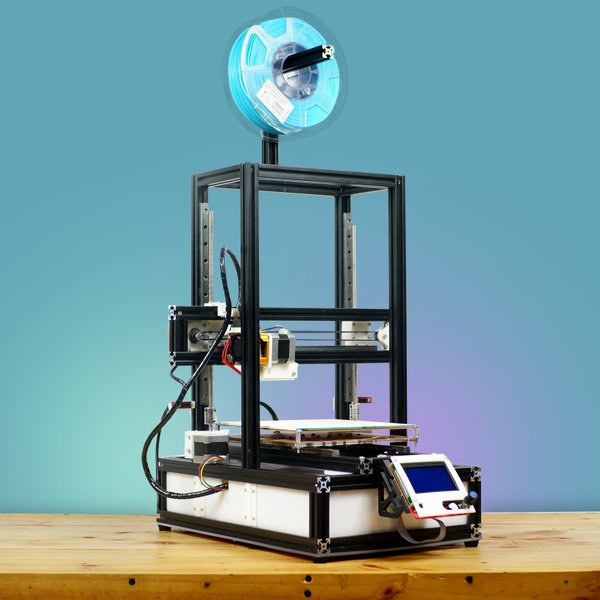

Large Area 3D Printer

Create functional plastic items up to 2.5 meters!

Learn more

Discovery 3D Printer is a range of industrial 3D printers made in Spain for creating large-sized products and prototypes using FFF/FDM technology.

Discovery 3D Printer additive machines produce objects from high-strength thermoplastics and are designed for industries ranging from shipbuilding and automotive to architecture and medicine.

Problems solved

Replacement of spare parts or lost parts in engineering, shipbuilding, oil and gas and energy enterprises

Production of small and medium series of products as an alternative to injection or molding of plastic parts automotive, shipbuilding and oil and gas industries

Creation of objects of exterior and interior design and design products for construction, production of facing materials

Production of functional prototypes for R&D and design bureaus in mechanical engineering, shipbuilding and aircraft construction

Production of large-sized wax or burnt master models for metal casting and metallurgy or trolleys)

Looking for a 3D printer for your needs?

Leave a request for a personal consultation!

Solutions catalog

3D printers

3D printer DISCOVERY 3D Printer 2021

Compact solution for 3D printing of large-sized products

Read more

3D printer Super Discovery Compact

Combination of compactness and high performance of the performance

Learn more

Super Discovery 3D Printer Hybrid

Advantages of granule and filament printing in one machine

More details

Super Discovery 3D Printer 3D Printer

Large build chamber and print speed up to 6 kg/h

More details

Super Discovery 3D Printer Workstation 3D Printer

3D large format printer combination: unique 2 in 1 combination and milling systems

More details

Your unique 3D printer

Do you need to print a product larger than 6 meters?

We will develop an individual solution with any build chamber for your needs. tasks - for printing products of any size!

tasks - for printing products of any size!

Choose the right solution for you - compare specifications by model

Compare 3D Printer

Solutions catalog

3D Printing Consumables

Do you have questions about 3D printing media?

Set them to our experts online!

Discovery 3D Printers work with all thermoplastics, including:

- PLA / PLA

- biodegradable polymer provides a smooth and gliding surface products. Designed to obtain detailed and ready-to-use objects

- ABS / acrylonitrile butadiene styrene

- impact-resistant material is able to withstand heavy loads and high temperature, resistant to heat, moisture and various alkalis

- PET / polyethylene terephthalate

- is a hard and strong material with high abrasion resistance.

Excellent suitable for making gears, carriages and guides

Excellent suitable for making gears, carriages and guides - PA / polyamide

- hard engineering plastic with excellent mechanical properties characteristics. Widely used in various industries

- ASA / acrylonitrile styrene acrylate plastic

- analogue of ABS, characterized by increased weather resistance, minimal shrinkage and high impact strength

- Nylon

- is elastic, wear-resistant and remarkably durable. Good suitable for printing functional parts and mechanisms

- HIPS / polystyrene

- Lightweight, alkali and acid resistant polymer. deserved popular in traditional manufacturing due to its impact resistance

Advantages of Discovery 3D Printer Solutions

ISO 9001 certified products

3D printers with the largest build chamber in the world

Ability to design a custom printer

The only 3D printer on the market with an integrated CNC system for finishing milling a part after printing

Accelerate the creation of new products thanks to the dual extrusion system

Repair and replacement of products faster and more economically than contractors

Ability to use a large number of third-party materials

Self-leveling platform function for automatic compensation of irregularities

Case Studies

FDM Airbus Spare Parts 3D Printing

| Industry: | Aircraft industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | CFRP SABIC LNP™ THERMOCOMP™ AM EZ006EXAR1 |

Created a strong mold for autoclave forming parts with a sealed surface and a low thermal expansion coefficient.

3D printed car bumper

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Prototype car bumper printed, measuring 1800 x 600 x 4500 mm and weighing 12 kg.

Large format 3D printed chair

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | 3D850 |

Printed design armchair measuring 45 x 50 x 95 cm and weighing 18 kg.

3D printed architectural statue

| Industry: | Architecture |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with cellulose fiber |

The solid statue is printed and is 1. 87 m high and 45 kg in weight.

87 m high and 45 kg in weight.

3D printing of railway components

| Industry: | Railway industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | plastic |

The front part of a tram for CAF was made in one printing session.

Helicopter seat 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Printed helicopter seat measuring 120 x 70 x 45 cm and weighing 20 kg.

3D printed internal combustion engine

| Industry: | Engineering |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | Premium PLA |

Prototype of an internal combustion engine was created, the dimensions of which were 100 x 60 x 50 cm and the weight was 5. 5 kg.

5 kg.

3D printed exclusive piece of furniture

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS |

A custom and exclusive chair created without the need for any further finishing.

Architectural 3D printed in durable ABS with cellulose

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS |

A street sculpture has been made that fully implements the initial decorative idea of the project.

Dior boutique window dressing

| Industry: | Advertising |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | plastic |

Huge bottles 3D printed for exclusive display at Dior's flagship stores.

FDM Cap Prototype

| Industry: | Design |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | 3D850 |

Prototype cap printed at 29 x 19 x 4.5 cm and weighing 146 g.

A prototype of a modular toilet has been printed, measuring 2200 x 1700 x 1200 mm and weighing 250 kg. At the same time, the weight of the product was reduced by almost 50%.

3D printed marine ventilation grille

| Industry: | Shipbuilding |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Ventilation grill printed 59 x 89 x 4. 5 cm and weight 3500 g.

5 cm and weight 3500 g.

Printed motorcycle part measuring 42.5 x 16.5 x 4.5 cm and weighing 165 g.

Prototype printed with support measuring 10 x 9 x 2.5 cm and weighing 18 g.

Created a square mold that measures 10 x 10 x 2 cm and weighs 67 g.

Printed fender for a wheel measuring 55 x 16 x 20 cm and weighing 645 g.

3D printed and post-processed a high-strength mold for wind turbine blades.

3D printed car wheel

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

A wheel for a car was made, the diameter of which was 440 mm, and the weight of the product was 5 kg.

3D printed designer vase

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Printed vase in ABS for excellent interlayer adhesion and minimal warping.

Geometric 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Pyramid printed with an 8mm extruder with a smooth surface thanks to the built-in milling system.

More projects and examples of 3D printing in production - in the blog 3D experts

Go to blog

Useful materials

Webinar on 3D printing large objects with complex geometry

- How can 3D printing help you optimize production?

- Features FDM-technology for printing products up to 2.

5 meters

5 meters - Benefits of using 3D plastic printing

- Real cases

Large Format Plastic 3D Industrial Printing Brochure

Benefits of FDM Technology, Overview of Equipment and Consumables, industries and implementation examples - this and much more in one material!

About the manufacturer

CNC Barcenas / Spain

is one of the leaders in the European market for large format 3D printing.

The company specializes in the production of industrial 3D printers Discovery 3D Printer for printing large-sized products and prototypes based on FFF/FDM technology.

discovery3dprinter.com

Take a closer look at Discovery 3D Printer solutions - take a virtual tour of companies!

3D TOUR OF COMPANY

About us

iQB Technologies is a Russian distributor of 3D printers, consumables, 3D scanners and software from the world's leading manufacturers.

We develop complete 3D solutions, provide printing services and scanning, as well as training specialists in the use of 3D technologies in their work.

iQB Technologies is the exclusive distributor of Discovery 3D Printer solutions in Russia.

3D printers are available for order

in this section .

iqb.ru

Why order a 3D printer from iQB Technology?

The best prices for this class of equipment

Training on how to use 3D printers

A wide range of integrated solutions: 3D printer + 3D scanner + software

Provision of services for the implementation, maintenance and repair of 3D equipment throughout Russia

Participation in public procurement and tenders

Still have questions?

Our experts will advise you free of charge on Discovery 3D Printer solutions

Frequently Asked Questions

Which technology to choose: the method of fusing granules (FGF) or polymer filaments (FFF / FDM)?

What are the kinematics and mechanics of the Discovery equipment?

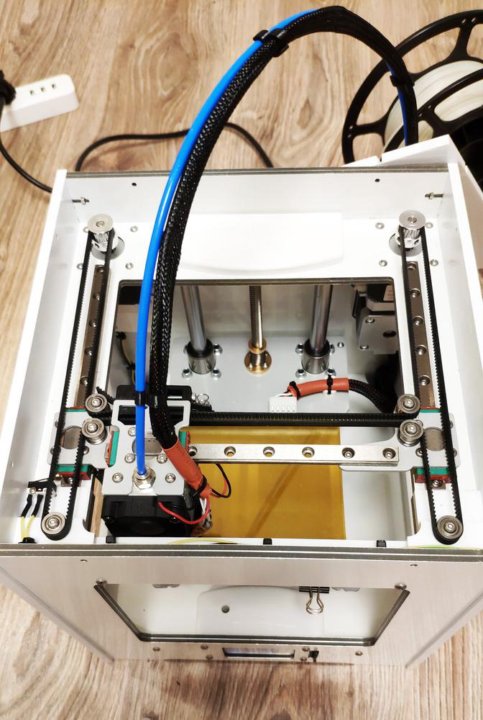

In this respect, all Discovery equipment differs from budget additive solutions. The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

What consumables can be used with Discovery products?

Any material (other than PEEK and PEKK) sold in bars or pellets. First of all, thanks to the heating of the table to 175 ° C and vacuum fixation, as well as due to the installed nozzles made of hardened steel.

How is such a large print platform heated?

A matrix of separate equidistant heaters is built into the platform from the bottom side; these modules provide uniform heating of the surface of the printing platform. The maximum recorded temperature difference over the entire area is 3°C.

How to speed up printing on such large dimensions?

There is a special method for properly emptying the internal volume, which you can learn more about from our technical experts. This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

It is important to consider that with a large range of large-sized products, it is better to consider Super Discovery 3D Printer or Super Discovery 3D Printer Workstation with a capacity of up to 11 kg / h (depending on the material used).

Is it possible to upgrade this equipment for a specific enterprise?

Yes. Most of the Discovery machines can be upgraded for a specific production project. This is possible, since the equipment was designed for the tasks of Production 4.0, and our specialists will help to integrate it correctly.

What is the warranty for this equipment?

24 months, which is 1.5 - 2 times more than analogues from Europe, Russia and China. Permanent customer support is provided directly by the vendor or iQB Technologies specialists.

How to get a high quality product so that it can be handed over as a final product?

3D printing is basically a high quality preform process. If you need to get the final product, it is suggested to use milling or turning equipment, manual machining, priming, painting or varnishing.

If you need to get the final product, it is suggested to use milling or turning equipment, manual machining, priming, painting or varnishing.

This is often not necessary as the product is not visible.

full name *

Company *

E-mail *

Telephone *

Message

Legal issues of the near future: 3D printers

Photo from amazonaws. com

com

3D Printing technology, which appeared in the last millennium, was used only by specialized companies and large industries until recently. But over the past three years, equipment has fallen in price by an order of magnitude. The ability to create an object at home, with only a standard "raw material" and a computer file-instruction, means a fundamental shift in the control of production towards the consumer. "Pravo.Ru" considers the likely legal problems associated with the spread of 3D printers.

Rapidly developing 3D printing equipment is not yet able to reproduce a working car on its own, but can easily create a simpler object, such as a copy of a sculpture or a machine part. In Europe, prices for such devices start at just 500 euros, while in Russia they still cost between $3,000 and $6,000 for personal 3D printers. Some models can already use almost any material with the desired plasticity.

Current intellectual property rights legislation was in place before the widespread use of 3D printers. Therefore, in the near future, lawyers will have to find answers to a number of new questions - what can be the subject of intellectual property rights, taking into account the peculiarities of the 3D printing process, how to determine them, what is a violation of rights and how they can be protected. Apparently, the new technology will be the same test for this area of legislation as it was before - software, mp3 players and the Internet.

Therefore, in the near future, lawyers will have to find answers to a number of new questions - what can be the subject of intellectual property rights, taking into account the peculiarities of the 3D printing process, how to determine them, what is a violation of rights and how they can be protected. Apparently, the new technology will be the same test for this area of legislation as it was before - software, mp3 players and the Internet.

3D printing poses an immediate threat to small manufacturers, especially when the value of the product lies primarily in the design. The simpler the inside of a product, the smaller it is, and the fewer different materials it needs to make it, the more likely it is to be illegally copied. When using a 3D printer, the cost per unit of production is reduced to the cost of raw materials and energy; Obviously, as technology spreads, the price of cartridges will decrease. Under these conditions, copying will inevitably take on a significant scale - for printing, in addition to raw materials, you only need a CAD file (CAD - Computer-Aided Design, computer-aided design). Material is sold in standard cartridges or loaded directly into the printer, and the CAD file can be emailed or posted online.

Material is sold in standard cartridges or loaded directly into the printer, and the CAD file can be emailed or posted online.

Now, in most jurisdictions, the owner of the rights can bring a claim against the individual or company directly involved in the illegal copying and those who contributed to the infringement. But from a practical point of view, the current system of rights protection may be ineffective.

Individuals

If the infringer is an individual, the first problem is that before you can sue, you must first find him, which can be difficult in itself. Prosecuting a single minor infringement, especially if the object is made for personal use, is technically difficult and usually not worth the trouble. Search and prosecution can be costly both literally and figuratively in terms of the public image of the copyright holder company. "No one wants to file a lawsuit against individuals - look at Monsanto's PR problems [ international biotechnology corporation. - "Pravo. En" ] arising from their desire to punish farmers for patent infringement," says Peter Yim of the law firm Morrison & Foerster. And almost certainly the compensation received will not cover the costs - in most cases it will be about

- "Pravo. En" ] arising from their desire to punish farmers for patent infringement," says Peter Yim of the law firm Morrison & Foerster. And almost certainly the compensation received will not cover the costs - in most cases it will be about

Worse, in Britain and other European jurisdictions, copying a product by an individual for personal, i.e. non-commercial use is not considered an infringement of intellectual property rights at all. 100,000 people “printed” the networks and the product,” says David Knight of the law firm Field Fisher Waterhouse. “What will you do in this situation?” It follows that the most heated debate will be about the source of the file, its original distributor - pursuing intermediaries can also be a difficult matter, as the music industry has already seen.

So, the first target will be "accomplices" of the crime, for example, sites on the Internet that allow users to exchange files containing descriptions or images of objects protected by the copyright holder. But Professor John Bryson of the University of Birmingham draws attention to the growing popularity of 3D scanners. “Users of the future will use this technology widely, and it will be very difficult to regulate this area,” he explains.

But Professor John Bryson of the University of Birmingham draws attention to the growing popularity of 3D scanners. “Users of the future will use this technology widely, and it will be very difficult to regulate this area,” he explains.

You can also try to sue the equipment manufacturers. But the prospects for such a process will not be very promising for the rights holder. In the USA at 19In '84, the era of VCRs, a landmark judgment was reached in Sony Corp. of America v. Universal City Studios, Inc.. According to this decision, manufacturers of recording devices are exempt from liability for copyright infringement if the devices they produce are created for use with a legitimate purpose (then it was the use of video recorders for illegal copying and watching movies). The same logic will obviously apply to 3D printers - they also have a perfectly legitimate application.

But even when the direct producer is known, prosecution is not necessarily easy. Let's say a 3D print shop has printed a certain object for a customer who has sent the appropriate CAD file. At a minimum, it will be necessary to prove that the print bureau knew that the ordered object violates someone's rights - this may turn out to be a non-trivial task.

At a minimum, it will be necessary to prove that the print bureau knew that the ordered object violates someone's rights - this may turn out to be a non-trivial task.

Legal entities

What tool to use to protect your intellectual property if the infringer is a legal entity? You need to choose from several basic options - patents, trademark rights and copyrights. If a company "prints" a product patented by another company, the patent owner will have to prove that the new product contains all the structures and components described in the patent. This makes it possible to create a product that resembles the original, but is not similar enough to be considered infringing on the rights of the patent owner, explains Mark Hankin, founder of Hankin Patent Law. Likewise, for a product to infringe trademark rights, confusing similarity must be proven, which is not always obvious.

Finally, copyrights protect, among other things, works of art, such as sculptures. But functions are not subject to protection, so curious situations may arise when, for example, an armchair manufacturer will claim that his chair is primarily a sculpture, which also has an additional functional purpose.

What to do

In this situation it is short-sighted to rely on the protection of the law alone. Elizabeth Ferrill and Robert Yoches of the law firm Finnegan, Henderson, Farabow, Garrett & Dunner, LLP, advise holders of intellectual property rights that may be at risk to use the following three approaches:

1. Develop, don't defend. Organize your production cycle so that you are always ahead of those who copy your products. If your designers are constantly coming up with new ideas, potential intruders will be less tempted to wait for the CAD file to show up. This model of self-defense has been successfully used by the fashion industry for a long time. However, she has her own Achilles heel - 3D scanners.

Prof. Bryson agrees: “Some UK firms are already preparing to leave the old ways of protecting their intellectual property, because innovation itself protects them. Three or four technologies a year are enough for them to stay ahead, and by the time someone figure out how to copy their product, these firms will already be making money on the next product. "

"

2. Use technology to your advantage. Printing a quality 3D product at this stage of technology development is not as easy as it sounds. Many users may be willing to pay for an official CAD file for the printer, which is supposed to create fewer printing problems and guarantee a minimum level of quality. In addition, copyright holders can offer an easy way to make some changes to the original file (as Nokia did with cases for the Lumia 820). You can sell, for example, spare parts with additional functionality or made from materials not used by personal 3D printers. But the lawyers consider setting the price of the final product comparable to the cost of home "production" as the most promising technique; however, it is not profitable in all cases.

3. But do not neglect the traditional tools to protect your rights. Protect your product by fixing the rights as soon as possible, and rush to protect them as soon as possible. For example, in the US, companies send letters in the category "cease and desist letters" (lit. "stop and refrain from now on"). This is how HBO secured its rights to the iPhone docking station, designed as the Iron Throne from Game of Thrones.

"stop and refrain from now on"). This is how HBO secured its rights to the iPhone docking station, designed as the Iron Throne from Game of Thrones.

Ronen Kadushin, designer and consultant, understands those who are not ready to give up traditional methods of protection. "Manufacturers are afraid of the project to 'print' weapons that are not protected by a patent, not because they are weapons - in the US you can just buy them in a store; who needs to print a gun in these conditions? No, manufacturers believe that the technology threatens their sales. A real revolution will begin when anyone can assemble a self-replicating 3D printer for themselves from parts available on the open market. This will mean that the consumer is no longer dependent on the manufacturer. " .

Meanwhile, the international RepRap group, which includes developers from New Zealand, the UK, and the US, is already distributing for free a project of the eponymous printer that can make a copy of itself and is completely user-controlled.