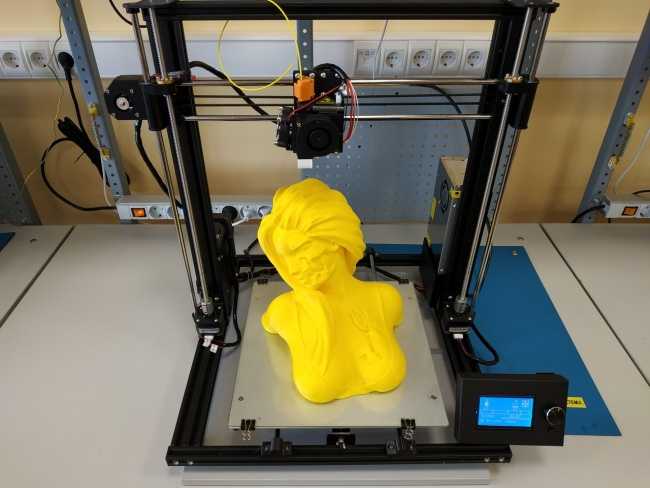

3D printing operation

3D printing for dummies: How do they work? | The Independent

It seems like everyone from the White House to Amazon.com is talking about 3D printing these days, but what exactly is it? Here’s a quick guide to what all the hype is about…

What is a 3D printer?

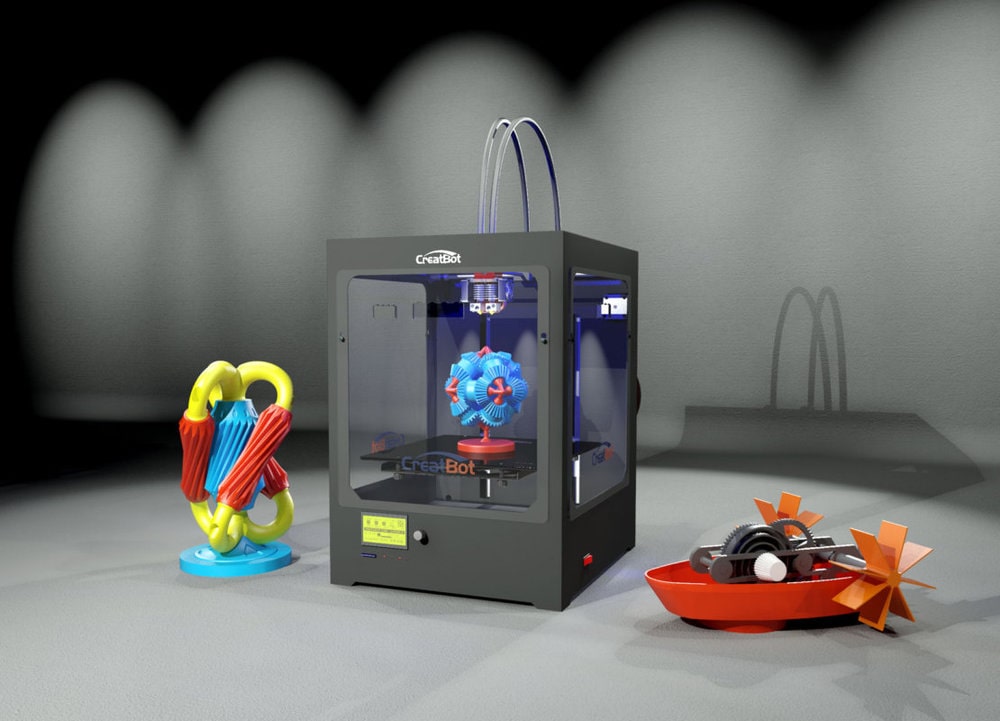

3D printers are a new generation of machines that can make everyday things. They’re remarkable because they can produce different kinds of objects, in different materials, all from the same machine.

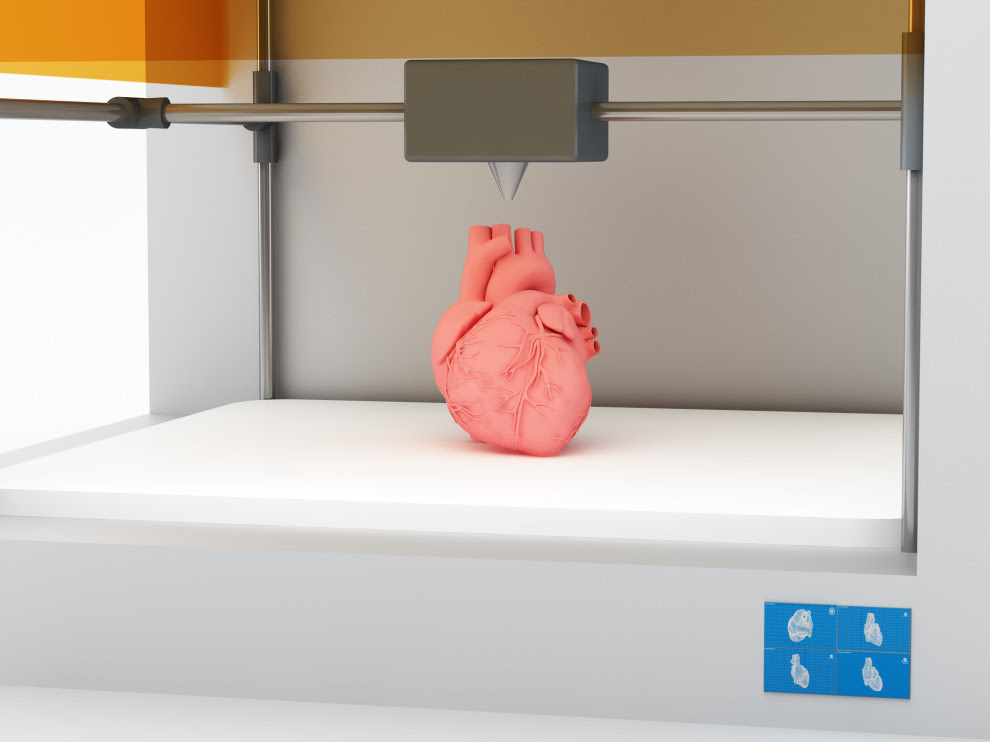

A 3D printer can make pretty much anything from ceramic cups to plastic toys, metal machine parts, stoneware vases, fancy chocolate cakes or even (one day soon) human body parts.

They replace traditional factory production lines with a single machine, just like home inkjet printers replaced bottles of ink, a printing press, hot metal type and a drying rack.

Why is it called printing?

If you look closely (with a microscope) at a page of text from your home printer, you’ll see the letters don’t just stain the paper, they’re actually sitting slightly on top of the surface of the page.

In theory, if you printed over that same page a few thousand times, eventually the ink would build up enough layers on top of each other to create a solid 3D model of each letter. That idea of building a physical form out of tiny layers is how the first 3D printers worked.

How do 3D printers work?

You start by designing a 3D object on an ordinary home PC, connect it to a 3D printer, press ‘print’ and then sit back and watch. The process is a bit like making a loaf of sliced bread, but in reverse. Imagine baking each individual slice of bread and then gluing them together into a whole loaf (as opposed to making a whole loaf and then slicing it, like a baker does). That’s basically what a 3D printer does.

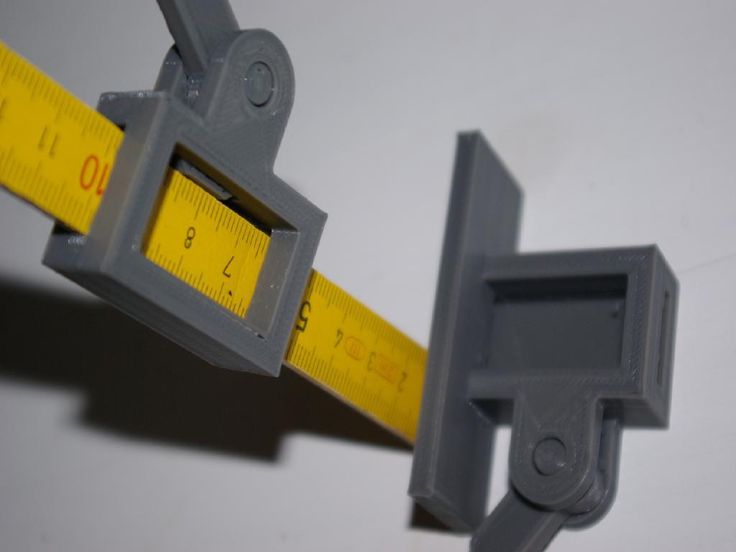

The 3D printing process turns a whole object into thousands of tiny little slices, then makes it from the bottom-up, slice by slice. Those tiny layers stick together to form a solid object. Each layer can be very complex, meaning 3D printers can create moving parts like hinges and wheels as part of the same object. You could print a whole bike - handlebars, saddle, frame, wheels, brakes, pedals and chain - ready assembled, without using any tools. It’s just a question of leaving gaps in the right places.

You could print a whole bike - handlebars, saddle, frame, wheels, brakes, pedals and chain - ready assembled, without using any tools. It’s just a question of leaving gaps in the right places.

What are the opportunities?

Have you ever broken something, only to find it’s no longer sold and you can’t replace it? 3D printing means you can simply print a new one. That world, where you can make almost anything at home, is very different from the one we live in today. It’s a world that doesn’t need lorries to deliver goods or warehouses to store them in, where nothing is ever out of stock and where there is less waste, packaging and pollution.

It’s also a world where everyday items are made to measure, to your requirements. That means furniture made to fit your home, shoes made to fit your feet, door handles made to fit your hand, meals printed to your tastes at the touch of a button. Even medicines, bones, organs and skin made to treat your injuries.

You can get some of those things now if you’re wealthy, but 3D printing brings affordable, bespoke manufacturing to the masses. If that sounds like pure fantasy, try googling “personalised 3D printed products” and see for yourself. After all, the notion of doing your supermarket shopping on an iPad was like something out of Star Trek 20 years ago.

If that sounds like pure fantasy, try googling “personalised 3D printed products” and see for yourself. After all, the notion of doing your supermarket shopping on an iPad was like something out of Star Trek 20 years ago.

What are the limitations?

Although buying a 3D printer is much cheaper than setting up a factory, the cost per item you produce is higher, so the economics of 3D printing don’t stack-up against traditional mass production yet. It also can’t match the smooth finish of industrial machines, nor offer the variety of materials or range of sizes available through industrial processes. But, like so many household technologies, the prices will come down and 3D printer capabilities will improve over time.

Is it the next big thing?

Yes, if you’re a product designer or engineer, but for most people, no.

Like all new technologies, the industry hype is a few years ahead of the consumer reality. It’s an emerging technology which means, like home computers or mobile phones, most people will remain sceptical about needing one until everyone has got one… and then we’ll all wonder how we ever managed without them.

@Killdozer

3D Printing: What It Is, How It Works and Examples

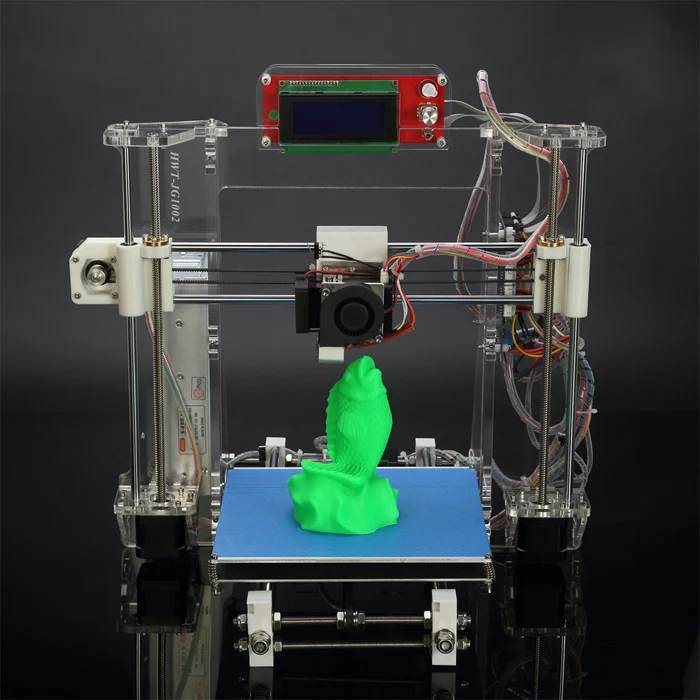

3D printers might seem like they're right out of a science fiction movie, but they're proving to be useful in a variety of industries. | Image: ShutterstockHow Do 3D Printers Work?

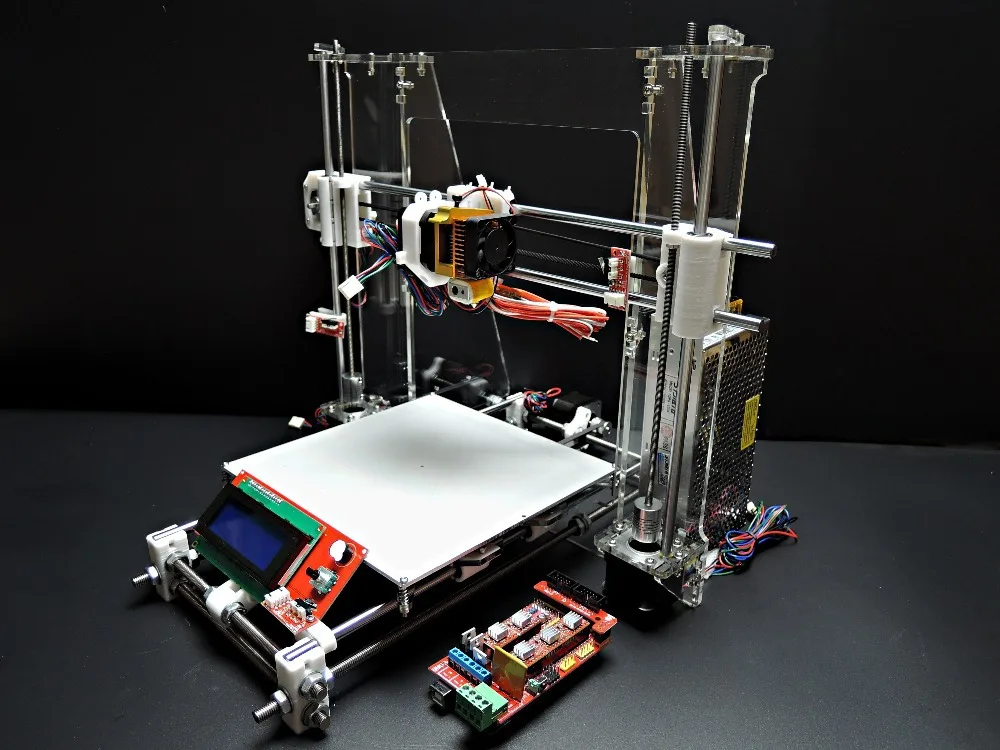

3D printing is part of the additive manufacturing family and uses similar methods to a traditional inkjet printer — albeit in 3D. Additive manufacturing describes the process of creating something in layers, adding material continuously until the final design is complete. This term most often refers to molding and 3D printing.

It takes a combination of top-of-the-line software, powder-like materials and precision tools to create a three-dimensional object from scratch. Below are a few of the main steps 3D printers take to bring ideas to life.

How Does a 3D Printer Work?

3D printers are related to additive manufacturing. 3D printers use computer-aided design to understand a design. When a design is ready, a material that can be dispensed through a hot nozzle or precision tool is printed layer by layer to create a three-dimensional object from scratch.

3D Modeling Software

The first step of any 3D printing process is 3D modeling. To maximize precision — and because 3D printers can’t magically guess what you want to print — all objects have to be designed in a 3D modeling software. Some designs are too intricate and detailed for traditional manufacturing methods. That’s where CAD software comes in.

Modeling allows printers to customize their product down to the tiniest detail. The 3D modeling software’s ability to allow for precision designs is why 3D printing is being hailed as a true game changer in many industries. This modeling software is especially important to an industry, like dentistry, where labs are using 3D software to design teeth aligners that precisely fit to the individual. It’s also vital to the space industry, where they use the software to design some of the most intricate parts of a rocketship.

3D PRINTERS USE MODELING AND SLICING SOFTWARE TO GUIDE THE PRINTER IN CREATING EACH OBJECT. Video: Digital Trends

Slicing the Model

Once a model is created, it’s time to “slice” it. Since 3D printers cannot conceptualize the concept of three dimensions, like humans, engineers need to slice the model into layers in order for the printer to create the final product.

Slicing software takes scans of each layer of a model and will tell the printer how to move in order to recreate that layer. Slicers also tell 3D printers where to “fill” a model. This fill gives a 3D printed object internal lattices and columns that help shape and strengthen the object. Once the model is sliced, it’s sent off to the 3D printer for the actual printing process.

The 3D Printing Process

When the modeling and slicing of a 3D object is completed, it’s time for the 3D printer to finally take over. The printer acts generally the same as a traditional inkjet printer in the direct 3D printing process, where a nozzle moves back and forth while dispensing a wax or plastic-like polymer layer-by-layer, waiting for that layer to dry, then adding the next level. It essentially adds hundreds or thousands of 2D prints on top of one another to make a three-dimensional object.

It essentially adds hundreds or thousands of 2D prints on top of one another to make a three-dimensional object.

3D Printing Materials

There are a variety of different materials that a printer uses in order to recreate an object to the best of its abilities. Here are some examples:

Acrylonitrile Butadiene Styrene (ABS)

Plastic material that is easy to shape and tough to break. The same material that LEGOs are made out of.

Carbon Fiber Filaments

Carbon fiber is used to create objects that need to be strong, but also extremely lightweight.

Conductive Filaments

These printable materials are still in the experimental stage and can be used for printing electric circuits without the need for wires. This is a useful material for wearable technology.

Flexible Filaments

Flexible filaments produce prints that are bendable, yet tough. These materials can be used to print anything from wristwatches to phone covers.

Metal Filament

Metal filaments are made of finely ground metals and polymer glue. They can come in steel, brass, bronze and copper in order to get the true look and feel of a metal object.

They can come in steel, brass, bronze and copper in order to get the true look and feel of a metal object.

Wood Filament

These filaments contain finely ground wood powder mixed with polymer glue. These are obviously used to print wooden-looking objects and can look like a lighter or darker wood depending on the temperature of the printer.

The 3D printing process takes anywhere from a few hours for really simple prints, like a box or a ball, to days or weeks for much larger detailed projects, like a full-sized home.

How Much Do 3D Printers Cost?

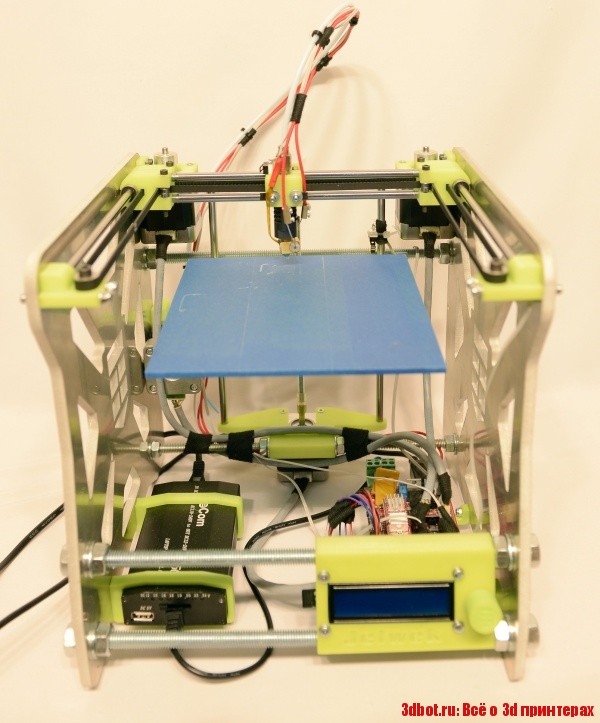

The cost of 3D printers vary based on the size, specialty and use. The cheapest 3D printers, for entry level hobbyists, typically range from $100 to $500. More advanced models can range between $300 and $5,000. Industrial 3D printers can cost up to $100,000.

3D Printing Processes and Techniques

here are also different types of 3D printers depending on the size, detail and scope of a project. Each different type of printer will vary slightly on how an object gets printed.

Each different type of printer will vary slightly on how an object gets printed.

Fused Deposition Modeling (FDM)

FDM is probably the most widely used form of 3D printing. It’s incredibly useful for manufacturing prototypes and models with plastic.

Stereolithography (SLA) Technology

SLA is a fast prototyping printing type that is best suited for printing in intricate detail. The printer uses an ultraviolet laser to craft the objects within hours.

Digital Light Processing (DLP)

DLP is one of the oldest forms of 3D printing. DLP uses lamps to produce prints at higher speeds than SLA printing because the layers dry in seconds.

Continuous Liquid Interface Production (CLIP)

CLIP is amongst the faster processes that use Vat Photopolymerisation. The CLIP process utilizes Digital Light Synthesis technology to project a sequence of UV images across a cross-section of a 3D printed part, resulting in a precisely controlled curing process. The part is then baked in a thermal bath or oven, causing several chemical reactions that allow the part to harden.

Material Jetting

Material Jetting applies droplets of material through a small diameter nozzle layer-by-layer to build a platform, which becomes hardened by UV light.

Binder Jetting

Binder Jetting utilizes a powder base material layered evenly along with a liquid binder, which is applied through jet nozzles to act as an adhesive for the powder particles.

Fused Deposition Modeling (FDM)

FDM, also known as Fused Filament Fabrication (FFF), works by unwinding a plastic filament from a spool and flowing through a heated nozzle in horizontal and vertical directions, forming the object immediately as the melted material hardens.

Selective Laser Sintering (SLS)

A form of Powder Bed Fusion, SLS fuses small particles of powder together by use of a high-power laser to create a three-dimensional shape. The laser scans each layer on a powder bed and selectively fuses them, then lowering the powder bed by one thickness and repeating the process through completion.

Multi-Jet Fusion (MJF)

Another form of Powder Bed Fusion, MJF uses a sweeping arm to deposit powder and an inkjet-equipped arm to apply binder selectively on top. Next, a detailing agent is applied around the detailing agent for precision. Finally, thermal energy is applied to cause a chemical reaction. Direct Metal Laser Sintering (DMLS) also utilizes this same process but with metal powder specifically.

Sheet Lamination

Sheet Lamination binds material in sheets through external force and welds them together through layered ultrasonic welding. The sheets are then milled in a CNC machine to form the object’s shape.

Directed Energy Deposition

Directed Energy Deposition is common in the metal industry and operates by a 3D printing apparatus attached to a multi-axis robotic arm with a nozzle for applying metal powder. The powder is applied to a surface and energy source, which then melts the material to form a solid object.

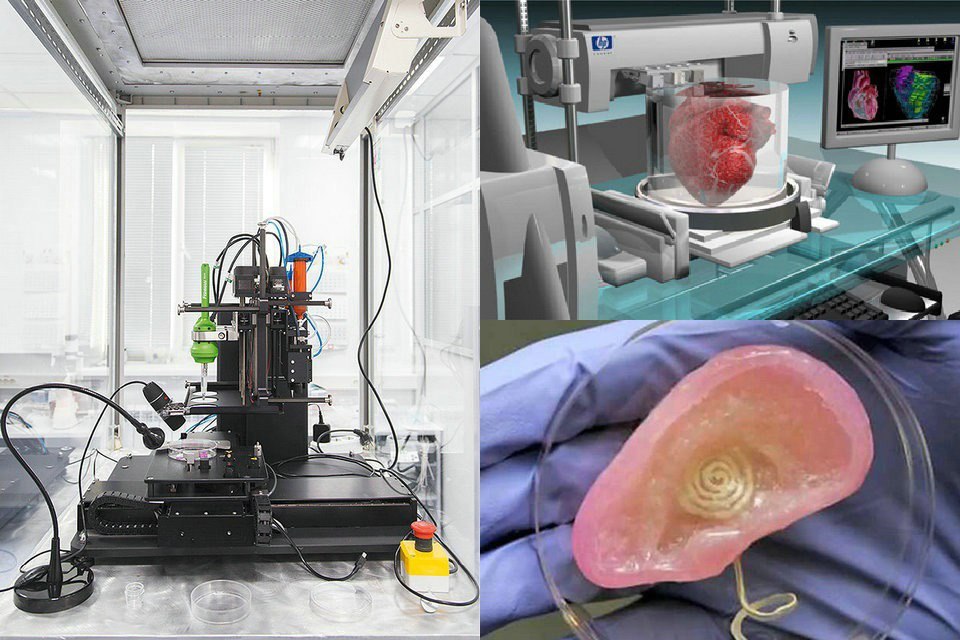

3D printing for surgical planning

Why surgeons need 3D printing | Examples in Russia | Veterinary operations | Choosing a 3D printer

How 3D printing helps surgeons

Comprehensive preparation for surgery is one of the most important criteria for its success. Modern 3D printing makes it possible to produce high-precision surgical models from various materials based on computed tomography data from real patients. With their help, surgeons can simulate the upcoming operation, try out different approaches and scenarios, test tools, and calculate timing.

Modern 3D printing makes it possible to produce high-precision surgical models from various materials based on computed tomography data from real patients. With their help, surgeons can simulate the upcoming operation, try out different approaches and scenarios, test tools, and calculate timing.

Operation planning stages using a 3D printed bone model.

There are a number of reasons why 3D printing is an effective and profitable tool for surgeons.

You know what to do. The surgeon uses a model obtained from a tomography of a real patient. With its help, you can accurately plan each stage of the operation, find solutions for complex and non-standard tasks, and distribute roles. No surprises during the actual operation.

You save time. Preparation can significantly reduce the time of the actual operation. Doctors spend less energy, patients are under anesthesia for a shorter period, which positively affects the results of operations. The patient needs a shorter period of rehabilitation.

You save money. A qualified doctor is a valuable resource that costs money to use. By reducing the operation time, you save the surgeon's time and the hospital's money. It also reduces the cost of the rest of the staff, anesthesia, electricity.

Surgical model of the pelvis and x-ray after the operation.

The increasing use of 3D printed models in the work of surgeons is driving the emergence of additive centers that specialize in the production of such products to order. Hospitals and private clinics that are unable to purchase their own 3D printer turn to such companies to print samples based on CT scans.

Russian experience of using 3D printing in surgery

Privolzhsky Federal Medical Research Center uses 3D printing for preoperative planning for severe deformities of the human skeletal bones. Doctors create accurate models of bones using a 3D powder printer. Computed tomography data serve as the basis for the development of a 3D bone model.

X-ray of the bone to be corrected and the process of simulating the upcoming operation.

The model of the damaged bone allows developing an individual operation for high-precision correction of the deformity, determining the required size and position of the fixators, and reducing the time of the surgical intervention.

More about the experience of Nizhny Novgorod doctors >>

At Tyumen State University , problematic parts of organs and bone structures of patients are printed to order. The resulting models are sent to doctors for preoperative study, surgery planning and implant manufacturing.

The process of preparing patient tomography data for 3D printing.

Upon admission, the patient undergoes a standard cone beam tomography, the data files are transferred to the university, where they are processed and a model is created for printing on a 3D printer. Material - plastic. With the help of such models, the doctor can more accurately examine the problem area, see convenient accesses and order an exact implant for surgery.

“By the fall of 2016, we successfully operated on three patients using this technology,” says Dmitry Shcherbakov, the leading operating otorhinolaryngologist in Tyumen. “The technology implemented at Tyumen State University allows us to take a completely new look at pathologies and more accurately plan operations in the facial skull, as well as obtain a material that is completely suitable for the size of a bone defect.”

3D printing and veterinary surgeries

Veterinarians use 3D printing to prepare complex surgeries. For example, Cornell University (USA) uses the results of tomography to make exact copies of bone structures.

Model of a dog paw joint created to simulate surgery.

This model was used to treat a puppy named Becca, whose CT scan showed a deformity of the paw bones. The veterinarians knew that surgery would be required and wanted to train on a 3D printed replica of the joint. “During the operation, we clearly knew what to do and how to do it,” says Dr. Ursula Krotczek. “This significantly reduced the time that Becca was under anesthesia, which greatly increased the chances of a successful operation.

Ursula Krotczek. “This significantly reduced the time that Becca was under anesthesia, which greatly increased the chances of a successful operation.

Australian veterinarians are taking the power of 3D printing even further. They not only train on 3D printed samples, but also make surgical templates and implants. In addition, 3D modeling helps visualize the problem and the need for surgery to concerned owners.

— Take, for example, a dog with a joint injury. A CT scan or X-ray will reveal the problem, but it will be difficult to explain it to the owners with the help of a picture alone, says clinic owner Charles Kunz. “With the help of a physical sample, we can clearly demonstrate what the essence of the damage is and how we plan to fix it.

Video: how Australian veterinarians are using 3D printing.Selecting a 3D Printer for Printing Surgical Models

Surgeons have multiple 3D printing technologies and a variety of materials at their disposal. The choice of a specific model of a 3D printer depends on the requirements for the resulting model and the budget. With the help of 3D printing, you can create both relatively rough plastic models and high-precision surgical models from special polymer materials (including elastic, colored, transparent).

The choice of a specific model of a 3D printer depends on the requirements for the resulting model and the budget. With the help of 3D printing, you can create both relatively rough plastic models and high-precision surgical models from special polymer materials (including elastic, colored, transparent).

Want to learn more about 3D surgical printing? Globatek.3D specialists will help you in choosing the right equipment, calculate the cost of manufacturing models and answer all your questions.

Get advice on choosing a medical 3D printer

Globatek.3D is a leading provider of professional 3D printing and non-contact measurement solutions. If your business is planning to purchase a 3D printer or 3D scanner, call 8 800 333-12-82 and our experts will help you choose the right solution.

3D printing technologies helped Petersburg neurosurgeons conduct a complex operation

News

Subscribe to

Subscribe

- modeling and 3D printing in planning a surgical operation to remove a tumor in the eye socket of the skull of a teenage patient.

According to the press service of the Almazov Center, 3D printing technologies have been used by the staff of the institution since 2017 when planning surgical interventions in children with complex combined malformations of the skull, tumors of the skull bones and trepanation defects of a complex configuration. Additive technologies make it possible to model implants taking into account individual anatomy, and in cases with tumors of the skull base and orbit, to plan in advance the trajectory of the surgical approach and the minimum sufficient volume of craniotomy, which significantly reduces the invasiveness of operations, as well as improves functional and cosmetic results.

Vadim Ivanov (right) and colleagues prepare for surgery

3D models of operated areas are created using computed tomography data, after which plastic layouts are printed to help doctors plan the stages of the operation and create surgical templates. At the Almazov Center, 3D printing technologies are being introduced at the initiative of pediatric neurosurgeon Vadim Ivanov. The Russian manufacturer of 3D printers PICASO 3D helped with the technical side of the matter: before Vadim mastered 3D printing technologies himself, the company assisted with medical prototyping on Designer X PRO branded 3D printers.

The Russian manufacturer of 3D printers PICASO 3D helped with the technical side of the matter: before Vadim mastered 3D printing technologies himself, the company assisted with medical prototyping on Designer X PRO branded 3D printers.

At the end of 2020, a teenage patient came to the Almazov Center complaining of swelling of the eyeball (exophthalmos) and pain in the left superciliary area. Examination revealed a volumetric formation of the left orbit, penetrating into the walls of the orbit with spread into the cranial cavity. Doctors performed a minimally invasive operation to remove a tumor at the base of the skull. The operation lasted an hour and a half, during which time the specialists performed an osteoplastic resection of the zygomatic process of the frontal bone, removed the mass and affected structures. The bone flap was subsequently placed in its original position with fixation with biodegradable miniplates. The superimposed cosmetic seam will make the scar from the operation invisible.

Left: 3D reconstruction of the skull before surgery. Volumetric formation destroys the roof of the orbit, penetrates into the zygomatic process of the frontal bone. Right: Preoperative 3D modeling. Volumetric education is highlighted in pink. Illustrations: Almazov Center

“Using modern neuroimaging techniques, followed by the construction of a virtual model, a real-size 3D model of the tumor with its surrounding structures was created. Such thorough preoperative preparation with planning the trajectory of surgical actions, lines of bone dissection and the least sufficient degree of resection of invasive structures made it possible to perform the operation through a minimal access,” said Vadim Ivanov.

Since 2017, more than fifty operations have been performed at the Almazov Center using additive technologies for various neurosurgical pathologies. In 2020, the Ministry of Health of the Russian Federation adopted for implementation a clinical testing protocol developed by specialists from the pediatric neurosurgical department, “Clinical testing of a method for preoperative planning of cranial reconstruction using 3D printing in children with complex synostotic deformities of the skull for preoperative preparation in comparison with the use of stereolithographic models. ”

”

Vadim Ivanov takes part in 3D printing festivals 3Dtoday Fest ( read the interview at this link ), and also maintains his own blog on 3Dtoday, where he shares the details of the use of 3D printing technologies in pediatric neurosurgery.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

More interesting articles

7

Subscribe to the author

Subscribe

Don't want

In July, the international isolation experiment SIRIUS-21 ended in Moscow, which lasted 240 days...

Read more

four

Follow author

Follow

Don't want

SHINING 3D, a leading provider of 3D scanning and 3D printing solutions, has launched a handheld.