3D print dias

3D Printed AR-15 Part Linked to Extreme Right Boogaloo Group - 3DPrint.com

When the topic of 3D printing guns comes up, it’s always difficult to know what to do. On the one hand, we can cover it and add to the scaremongering around the topic. Or we can ignore it and let a potentially newsworthy story slip by. However, as the trend has evolved, it may become increasingly difficult to look past it, as demonstrated by a recent criminal complaint filed against a West Virginia resident accused of selling over 600 3D-printed plastic parts that convert semi-automatics into fully automatic rifles.

The FBI has claimed that Timothy Watson used a website, Portablewallhanger.com, to sell what is known as a “drop-in auto sear” that makes it possible to turn an AR-15 semi-automatic assault rifle, legal in the U.S., into an automatic machine gun, banned in the country for over 20 years. The federal investigators suggest that Watson was disguising the device as a wall hook. Once an extra bit of 3D printed plastic was removed, buyers were left with a 3D-printed auto sear.

An Instagram commenter refers to “red coats”, code for the enemy of the Boogaloo Boys. Image courtesy of Wired.

For the over 600 units Watson sold, customers included multiple members of the Boogaloo group, the FBI claims. The far-right movement is the latest manifestation of newer right-wing extremists that have emerged leading up to the 2016 presidential election in the U.S. The group was said to have been responsible for the murder of multiple police officers. The Boogaloos have been involved in inciting violence at racial justice protests that erupted in the U.S. in the summer of 2020 in response to the police murder of George Floyd.

Most alarmingly, among those Boogaloo customers was Steven Carrillo, according to the FBI. Carrillo is accused of shooting Santa Cruz police officers and two Oakland courthouse security guards in May and June, which resulted in the deaths of one police officer and one guard.

The 3D printed auto sear works by preventing the bolt within an AR-15 from stopping when fired. As a bullet is fired from the weapon, the gases within the chamber push the bolt back to retrieve a new round from the magazine. The bolt pushes a spring in the gun’s stock down before propelling forward. The auto sear stops the bolt and causes the hammer to push the firing pin once more. This allows the gun to continue firing without any further pulling of the trigger.

As a bullet is fired from the weapon, the gases within the chamber push the bolt back to retrieve a new round from the magazine. The bolt pushes a spring in the gun’s stock down before propelling forward. The auto sear stops the bolt and causes the hammer to push the firing pin once more. This allows the gun to continue firing without any further pulling of the trigger.

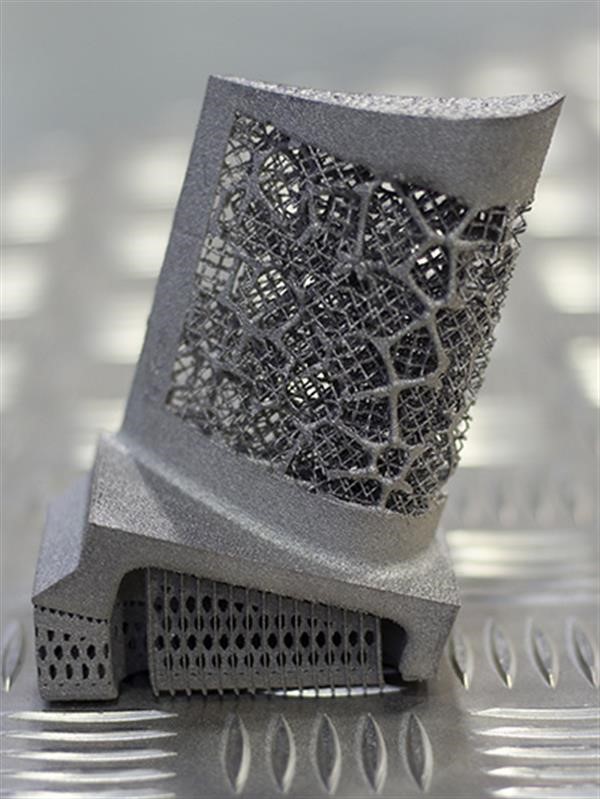

Once the extra black portion is removed, the red hook fits into an AR-15 to convert it into an automatic rifle. Image courtesy of Wired.

As we’ve covered in the past, 3D printed guns have so far posed little threat to the public at large due to the fact that the plastic parts are easily destroyed by the extreme forces of the weapon upon firing. They have been capable of firing but are dangerous to the users for this reason. However, this latest story represents a growing trend in the 3D printing of arms.

A consultancy group called Armament Research Services published a report in March 2020 noting that the current trend for DIY gun enthusiasts has grown to include individual components and not entire weapons. This has resulted in hybrid guns, made up of a combination of 3D printed and traditionally made or off-the-shelf parts, and market-bought weapons with 3D printed receivers. The report notes:

This has resulted in hybrid guns, made up of a combination of 3D printed and traditionally made or off-the-shelf parts, and market-bought weapons with 3D printed receivers. The report notes:

“At present, the material limitations of consumer-grade 3D printers, and the high cost of those small number of industry-grade printers capable of producing objects in metals, means that certain essential pressure-bearing components must either be fabricated from metals using alternative methods or substituted for commercially made parts. In the case of a Glock-series handgun, for example, the frame and magazine body may be printed from PLA while the slide, barrel and trigger would usually be original, factory-made parts. The emergence of other technologies such as ECM and desktop/micro-CNC milling machines have bridged the technological gap, and now mean that viable, capable self-loading hybrid firearms such as the FGC-9 can be produced by the home gunsmith without using any regulated components.

Other areas for development, such as the production of 3D-printed ammunition, remain in their infancy.”

The auto sear part itself doesn’t take the stress of the bullets being fired, meaning that it can be used successfully even if made out of plastic. The piece would eventually wear away but could easily be replaced. With the price of industrial-grade polymer printers now dropping, it may be increasingly possible to print an auto sear from materials that can withstand the heat and impact of bullets firing.

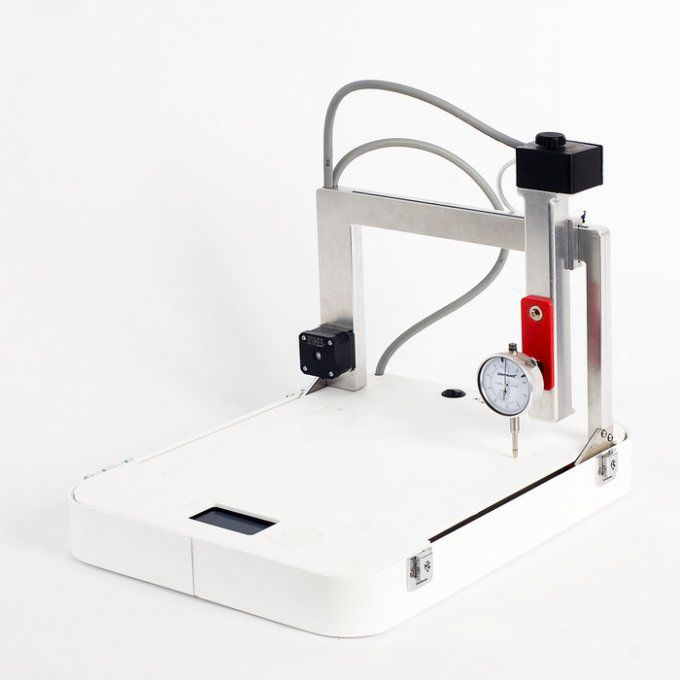

In some cases, the 3D printing of guns or gun parts may just be a hobby or a means to procure weapons outside of government control. The Ghost Gunner from Defense Distributed, for instance, was focused specifically on CNC machining the lower receiver for an AR-15 so that it might not be traced by government authorities.

Watson was specifically selling a component that would convert an AR-15 into a fully automatic rifle. U.S. legislation frames the auto sear itself as an automatic weapon, making anyone who 3D prints one a potentially culpable in a federal crime. However, groups like Deterrence Dispensed have released their own files for 3D printable auto sears.

However, groups like Deterrence Dispensed have released their own files for 3D printable auto sears.

While there may be a plethora of reasons for crafting guns or procuring guns outside of government scrutiny, 3D printable weapons and guns rights activists have seemingly been aligned with the right wing of the country. Ghost guns have been involved in more than one mass shooting in the US since 2013. Just this October, a far-right terrorist in Halle, Germany used a homemade submachine gun to murder two people following an attempt performing a mass shooting at a synagogue.

One of the key creators of the 3D printed gun movement, Cody Wilson, is a self-identified libertarian that has been described as right wing and founded Hatreon, referred to as an “alt-right crowdfunding platform.” Wilson himself was charged with sexually assaulting a minor when he allegedly met a 16-year-old on a site, SugarDaddyMeet.com, and paid her $500 in exchange for sex. This led him to step down as CEO of Defense Distributed, the leading site for 3D printable gun files. However, news of Timothy Watson’s 3D printed auto sears suggests that the far right and the 3D printed gun movement continue to commingle

However, news of Timothy Watson’s 3D printed auto sears suggests that the far right and the 3D printed gun movement continue to commingle

A screenshot from the Portable Wall Hanger website.

As detailed in a recent Wired article on the subject, the FBI claims that one witness in the case was a Boogaloo member who told the federal agency that he learned of Watson’s product from ads on a Boogaloo Facebook group. Portablewallhanger.com also advertised that it would donate 10 percent of its proceeds to Duncan Lemp, a militia member killed by police in March 2020.

Jon Lewis, a research fellow at the George Washington University Program on Extremism, told Wired:

“To the best of my recollection, there has been very little in the way of tangible evidence that domestic extremist groups have successfully used 3D printing to modify guns, until now. When you have individuals who so strongly support the second amendment—pro-gun, anti-government individuals trying to evade any kind of gun control measure—it makes sense for them to shift to this kind of technology.

”

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d print guns • 3D printed AR-15 auto sear • 3d printed gun parts • 3d printed guns • 3D printed weapons component • Boogaloo Boys • cody wilson

Please enable JavaScript to view the comments powered by Disqus.

▷ 3d printed dias 【 STLFinder 】

RICK DIAS 3D model

cgtrader

3D LOWPOLY GUNDAM

RMS-099 Rick-Dias 3D print model

cgtrader

RMS-099 Rick-Dias 3D model done in Blender. .blend (blender tool) -Almost all parts are decimated and you can use it in most popular 3d programs. Check out my profile to see the other cool stuff! ...

.blend (blender tool) -Almost all parts are decimated and you can use it in most popular 3d programs. Check out my profile to see the other cool stuff! ...

RMS-099 Rick-Dias 3D print model

cgtrader

RMS-099 Rick-Dias 3D model done in Blender. .blend (blender tool) -Almost all parts are decimated and you can use it in most popular 3d programs. Check out my profile to see the other cool stuff! ...

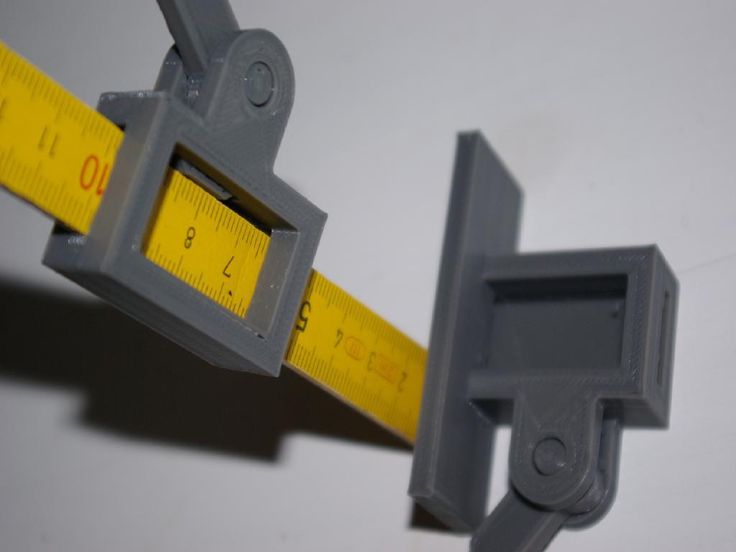

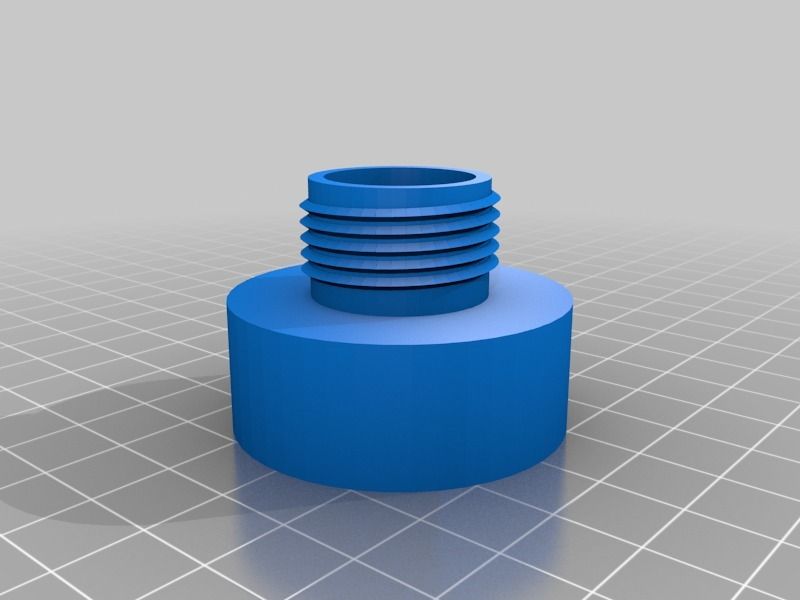

Swiftlink DIAS AR-15 3D model

cgtrader

This model is desgined to be printed on a 3d printer. The .stl File included is properly scalled to fit, has support materal included. ...Just drop in cura and print.

...Just drop in cura and print.

DIAS chandelier 3D model

cgtrader

Name: DIAS Version: 2013 Preview: No Units: Millimeters Dimension: 225.92 x 225.92 x 408.79 Polys: 99 088 XForm: No Box Trick: No Model Parts: 126 Render: V-Ray Formats: 3Ds Max 2013, OBJ, FBX, 3DS

dias podium 3D model

cgtrader

podium

DIAS

thingiverse

Used a design off the internet and 3D'd it :) enjoy

RMS-099 Rick-Dias Head Low-poly 3D model

cgtrader

RMS-099 Rick-Dias Head 3D model done in Blender. .blend (blender tool) -Almost all parts are decimated and you can use it in most popular 3d programs. Check out my profile to see the other cool stuff! ...

.blend (blender tool) -Almost all parts are decimated and you can use it in most popular 3d programs. Check out my profile to see the other cool stuff! ...

RMS-099 Rick-Dias Head 3D print model

cgtrader

RMS-099 Rick-Dias Head 3D model done in Blender. .blend (blender tool) -Almost all parts are decimated and you can use it in most popular 3d programs. Check out my profile to see the other cool stuff! ...

RMS-099 Rick-Dias Low-poly 3D model

cgtrader

RMS-099 Rick-Dias 3D model done in Blender. .blend (blender tool) -Almost all parts are decimated and you can use it in most popular 3d programs. Check out my profile to see the other cool stuff! ...

Check out my profile to see the other cool stuff! ...

Estrutura 3D - LEONARDO DIAS 2019

sketchfab

No description provided.

3D Printed

myminifactory

This design is an entry into the Vectary Design Competition sponsored by MakeX This model was created with VECTARY - the free, online 3D modeling tool It was 3D Printed and then Made in to a Mold, for a Metal pooring prozess.

3d printed

thingiverse

http://www.thingiverse. com/apps/customizer/run?thing_id=52734 Instructions Using the following options: font_thickness = 5.5 stick_thickness = 3 hole_radius = 0 Font = write/Letters.dxf message = 3d printed stick_width = 5 flat_bottom = 1 font_size =...

com/apps/customizer/run?thing_id=52734 Instructions Using the following options: font_thickness = 5.5 stick_thickness = 3 hole_radius = 0 Font = write/Letters.dxf message = 3d printed stick_width = 5 flat_bottom = 1 font_size =...

3D PRINTED

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=518217 Instructions Using the following options: Font = write/orbitron.dxf box_depth = 40 box_wall_thickness = 3 message = 3D PRINTED OBJECTS raised = 0 box_high = 40 box_width = 50 font_size =...

3D PRINTED

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=73909 Instructions Using the following options: enable_hole = 0 base_style = 2 thickness = 15 extruder_ypos = 54 text = 3D PRINTED extruder_xpos = 68 output_style = 2 text_space = 10 style = 1. ..

..

3D PRINTED

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=749887 Instructions Using the following options: wall = 1 basethickness_percent = 0.1 fontname = Holtwood One SC textstring = 3d printed textsize = 25 RoundedBase = 0 base_radius_add_percent =...

Marco Dias rigged for animation 3D model

cgtrader

Marco Dias rigged for animation in blender 2.79

Marco Dias rigged for animation 3D model

cgtrader

Marco Dias rigged for animation in blender 2. 79

79

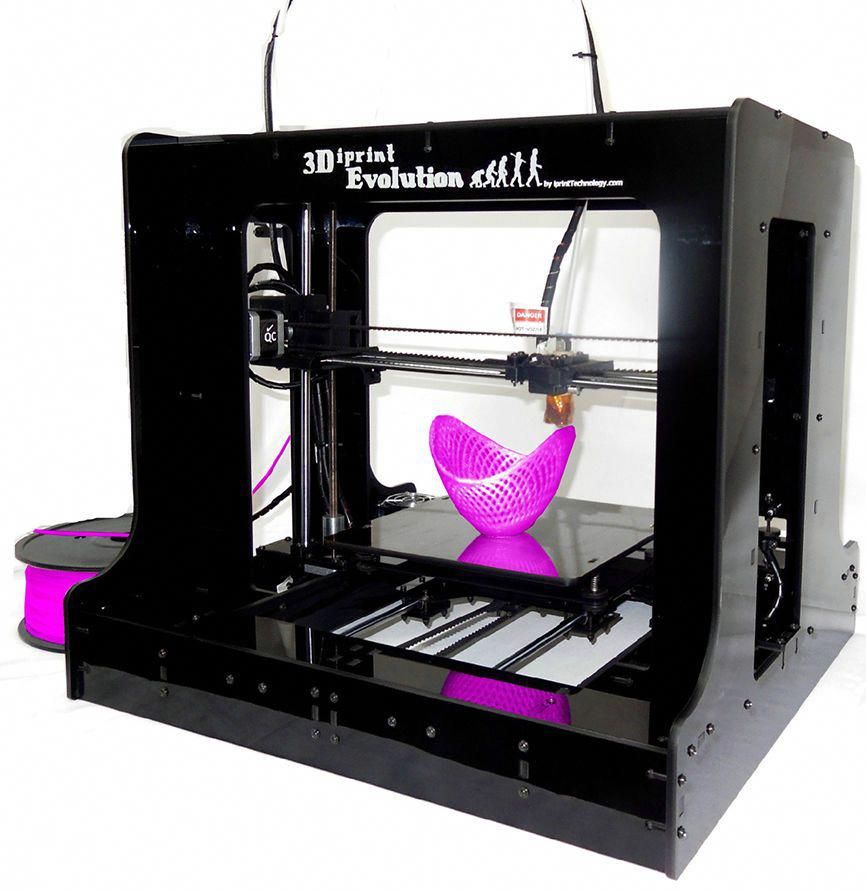

3D printed 3D printer

thingiverse

it is a 3D printer that can be printed by a 3D printer!

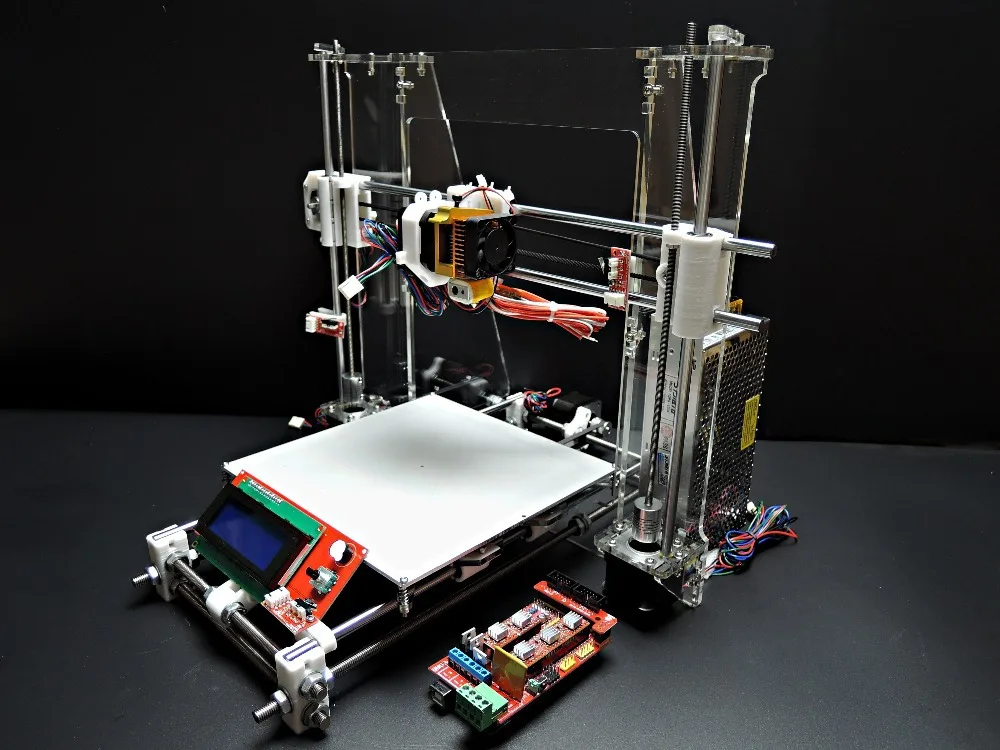

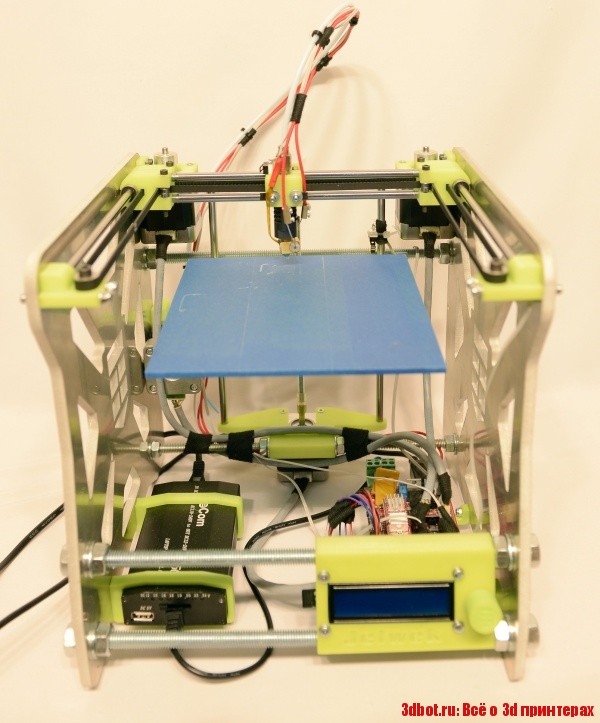

3d-Printed 3d-Printer

thingiverse

This is 3d printed 3d printer. ... The user supplies al nuts , bolts , slide rails ect.

3d Printed 3d Printer

thingiverse

... files for an upcoming 3d Printer instructable. ...Like this to stay tuned! *These are based off of the laser cut files that I designed last month, but they are completely redesigned to be optimized for 3d printing. ...You will need support material.

...You will need support material.

3D Printedable Lampshade

thingiverse

i just designed a lampshade in fusion 360. it will fit the ikea "sekond" lamp cort set just added a fixed version. ...you need to turn it around 180 degrees to make it printable.

Printed WiFi - 3D Printed Wireless Connected Objects

thingiverse

- Note 2: Part 3 - dipole_antenna.stl and Part 9 - switch_base.stl - These pieces were printed partially with "Electrifi Conductive 3D Printing Filament" on the contact surfaces. See the images and research paper for more info about this process. ...

...

3d Printed Laravel Logo

thingiverse

3d printed laravel logo

3D printed house

grabcad

3D printed house

3D Printed Pinhole Box

cults3d

3D Printed Pinhole Box

3D PRINTED COMPONENT 7

grabcad

3D PRINTED COMPONENT 7

3D PRINTED COMPONENT 23

grabcad

3D PRINTED COMPONENT 23

3D PRINTED COMPONENT 6

grabcad

3D PRINTED COMPONENT 6

3D PRINTED COMPONENT 24

grabcad

3D PRINTED COMPONENT 24

Who are the influential women entrepreneurs in 3D printing?

International Women's Day March 8 was declared by the United Nations as a day to celebrate the achievements of women around the world. 3Dnatives asked readers to help find influential women entrepreneurs in additive manufacturing. Take a look at the list, which is presented in alphabetical order, and learn more about some of the women selected from around the world.

3Dnatives asked readers to help find influential women entrepreneurs in additive manufacturing. Take a look at the list, which is presented in alphabetical order, and learn more about some of the women selected from around the world.

Beatrice Biel - founder of Detresdé

One of the most important barriers that companies face when introducing additive manufacturing into their operations is the lack of knowledge. There are more and more courses and schools offering classes in these new technologies. To democratize the teaching of 3D printing, Beatrice Biel founded Detresdé. Initially Detresdé was a service provider for additive manufacturing and now it organizes all kinds of technology courses and trainings. At Detresde Academy, any user can access all kinds of knowledge about additive manufacturing. In addition, Beatriz is also a volunteer for Women in 3D Printing as an ambassador in Zaragoza, holding various events to raise awareness of the possibilities of this technology.

Nadine Briallon - founder of 3Desserts Graphiques

After several professional experiences, Nadine Briallon decided to launch 3Desserts Graphics in 2016. Based in Lyon, in the heart of Foodtech and Frenchfab, the company designs and distributes CE (EU) certified 3D food printers. The company's flagship product is a solution called L'Impressionnante. The machine, capable of applying patterns and decorations to desserts or sculptures, is mainly intended for the food industry, such as confectioners, chocolate makers and catering companies. Nadine Briallon and 3Desserts Graphiques also offer food personalization and design events.

Photo: Bruno Amsellem

Marin Kore-Baye - Founder of Digital Pastry

After 7 years at Sculpteo, Marine Core-Baye decided in 2020 to start her own startup specializing in 3D food printing. A company called La Pâtisserie Numérique aims to revolutionize the confectionery market with 3D technology by developing a special slicer and food extruder. Marin combined her two passions, cooking and 3D printing, and went back to school to take the pastry chef test. Before starting her company, she worked as a clerk in large restaurants, especially in the famous Parisian palace of Meurice. It certainly was a lucky bet for the entrepreneur who won the 3D Print Paris 2021 startup competition.

Marin combined her two passions, cooking and 3D printing, and went back to school to take the pastry chef test. Before starting her company, she worked as a clerk in large restaurants, especially in the famous Parisian palace of Meurice. It certainly was a lucky bet for the entrepreneur who won the 3D Print Paris 2021 startup competition.

Cassandra Delage - Founder of Plast'If

In 2017, Cassandra Delage founded Plast'if, a company whose mission is to help companies achieve zero plastic waste. More specifically, Plast'if recycles plastic waste and uses it to 3D print new objects. Having received her Bachelor of Commerce from McGill University in Canada and her Master of Entrepreneurship from HEC Paris, Cassandra has developed a machine capable of processing various plastics such as PET, polystyrene or polypropylene. And all this accompanied by her team. As you can see, Plast'if offers companies the opportunity to minimize their environmental impact and change their consumption patterns.

Photo: Christophe Pouget

Mariel Diaz - CEO of Triditive

Mariel Diaz is a mechanical and industrial engineer specializing in industrial management and mechanical design with over 9 years of experience in additive manufacturing. She was a professor at the University of Oviedo with a Master in 3D Printing in Spain. In addition, Mariel Diaz has received numerous awards, including being the best female entrepreneur in Spain in 2018. Mariel was also a finalist for the Global Women in Tech 2020 award. She is currently one of the spokespersons for Woman in 3D Printing and also founded Triditive, an online platform where manufacturers can upload their designs, get quotes and details in a very short time, 5 years ago. terms. Her company has patented automated 3D printing technology for the production of metal and polymer parts based on advanced robotics.

Pauline Eveno - co-founder of SYOS

In 2016, Pauline Eveno decided to start SYOS - Shape Your Own Sound - a startup that designs 3D printed saxophone mouthpieces. She will then add clarinet mouthpieces to her range. Polina is an engineer and doctor of acoustics, passionate about music since childhood. Thanks to additive manufacturing, SYOS now offers custom-made sounds according to the needs and desires of musicians. This is where 3D printing brings all its added value: it allows you to create unique products that maximize productivity.

She will then add clarinet mouthpieces to her range. Polina is an engineer and doctor of acoustics, passionate about music since childhood. Thanks to additive manufacturing, SYOS now offers custom-made sounds according to the needs and desires of musicians. This is where 3D printing brings all its added value: it allows you to create unique products that maximize productivity.

Nancy Hardwick - founder of MELD Manufacturing

Nancy Hardwick is the founder of MELD Manufacturing and the creator of their proprietary technology, the solid state process, which she describes as , "unlike any other printing process and in its own category because it does not melt metal. It is based on a thermomechanical process that generates very high pressures and frictions: they provide plastic deformation of the extruded material and the substrate on which the layers are applied.” In addition to being the CEO of MELD Manufacturing, she was also the CEO of Aeroprobe Corporation, which supplies data measurement systems to the aerospace, automotive, turbomachinery, wind and aerodynamic industries. She has also received a number of awards for her work, including the 2019 Department of Defense People's Choice Maintenance Innovation Award, a 2019 USARMY xTechSearch Finalist, and the 2019 Edison Award.of the Year and the 2018 R&D100 Special Award for Most Revolutionary New Technology.

She has also received a number of awards for her work, including the 2019 Department of Defense People's Choice Maintenance Innovation Award, a 2019 USARMY xTechSearch Finalist, and the 2019 Edison Award.of the Year and the 2018 R&D100 Special Award for Most Revolutionary New Technology.

Elvira Leon - CEO and co-founder of ADDvance Manufacturing Technologies

The next inspiring female entrepreneur is Elvira Leon of Spain. With an aeronautical engineering degree and a master's degree in materials science from the Polytechnic University of Madrid, as well as a master's degree in business administration, Elvira is a professional with over 20 years of experience in additive manufacturing for various industries. She developed new ventures and led teams on multinational and cross-functional projects. In addition, she has in-depth knowledge of 3D printing, composite materials and Industry 4.0 technologies. She is currently one of the Women in 3D Printing Ambassadors and founded ADDVANCE Manufacturing Technologies, which offers services and products to support the efficient industrialization of advanced manufacturing.

Christina Perla - co-founder and CEO of Makelab

Christina Perla is not only the co-founder and CEO of Makelab, which is of course the reason why she made it to the list of influential women entrepreneurs, but she is also the board director of Women in 3D Printing and an ambassador in New York. . Not to mention, she was one of the first 250 recipients of the Forbes Next 1000 2021, an initiative that sheds light on entrepreneurs in the United States. In 2017, she co-founded Makelab, a 3D printing service that democratizes additive manufacturing by helping customers move from idea to production with professional 3D printing. The company continues to grow despite the pandemic and, according to Forbes, its customers include the likes of Verizon, Barkbox and RocNation.

Hanna Riedl - Founder of ANAMOS

Hanna Riedl completes our list of influential women entrepreneurs currently working in the field of additive manufacturing. Although Hanna Riedle focused on medical technology during her studies at the Technical University of Munich, she subsequently completed her PhD at the Friedrich Alexander University of Erlangen-Nuremberg, where she focused more on additive manufacturing, biomechanical and medical testing. Thus, the foundation was laid for her future career as CEO and CTO of her own company ANAMOS, as the company was based on the topic of her doctoral thesis at the time. During a lecture at the university, Riedl said that she was most inspired by the development of anatomical models for surgical modeling and the emergence of new innovative 3D printing technologies on the market. Driven by endless possibilities, Hanna Riedle has now focused her company ANAMOS on the production of individually configurable anatomical models for surgical simulation based on additive manufacturing using elastic materials.

Although Hanna Riedle focused on medical technology during her studies at the Technical University of Munich, she subsequently completed her PhD at the Friedrich Alexander University of Erlangen-Nuremberg, where she focused more on additive manufacturing, biomechanical and medical testing. Thus, the foundation was laid for her future career as CEO and CTO of her own company ANAMOS, as the company was based on the topic of her doctoral thesis at the time. During a lecture at the university, Riedl said that she was most inspired by the development of anatomical models for surgical modeling and the emergence of new innovative 3D printing technologies on the market. Driven by endless possibilities, Hanna Riedle has now focused her company ANAMOS on the production of individually configurable anatomical models for surgical simulation based on additive manufacturing using elastic materials.

Author: Madeleine P.

Source

women entrepreneurs in additive manufacturing, 3D printing, 3D technology, Detresdé, 3Desserts Graphiques, Digital Pastry, Plast'If, Triditive, SYOS, MELD Manufacturing, ADDvance Manufacturing Technologies, Makelab, ANAMOS

3D is in Prague -printed tram stop

News

Subscribe to the author

Subscribe

Don't want

2

Shelter designed using generative design, concrete elements printed by a 3D printer based on a multi-axis robotic arm. The pavilion was installed near the Stromovka park not far from the center of the Czech capital.

The pavilion was installed near the Stromovka park not far from the center of the Czech capital.

The pavilion is designed taking into account the distribution of internal forces. Generative design using topological optimization allows you to create the most lightweight, but at the same time sufficiently strong elements with material savings of up to 60% and minimal manual labor costs. The pavilion was 3D printed and built by the construction company So Concrete, and the additive manufacturing phase took about thirty-six hours. The consumable material was ultra-high-strength concrete (UHPC). As a rule, this term refers to materials with a compressive strength above 120 MPa.

“Topological optimization ensures that volume and shape contain only the essentials. Let's imagine a 3D printer, but in contrast, our robot works on six axes, so we can afford more complex shapes. The service life of the material is extreme: it is used, for example, in the construction of dams - it is a hundred years or more, ”said Federico Diaz, CEO of So Concrete.

“I like to use the analogy with nature: the rocks are weathered and only loaded arcs remain. The same is created with this new technology, friendly to nature and the environment. We use this method, for example, for the construction of the Štvanice Bridge, the reconstruction of the Barrandovsky Bridge. We are trying to test it in various ways on the territory of Prague,” commented Adam Scheinherr, Deputy Mayor of Prague for transport infrastructure.

According to Novinky.cz, for now this stop will remain the only one of its kind: the Prague administration has no plans to build additional 3D-printed pavilions at the moment, although the technology itself is used in other projects to improve the urban environment.

For example, last year a playground with 3D printed parkour obstacles was opened in the Prague 11 municipal district ( in the illustration above ).

Another interesting project completed in 2020: the Czech company Scoolpt, led by artist-sculptor and architect Michal Trpak, built a 43-square-meter 3D printed house on a pontoon. The design was demonstrated near Streltsy Island.

The design was demonstrated near Streltsy Island.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

construction Prague So Concrete

Follow author

Follow

Don't want

2

More interesting articles

7

Subscribe to the author

Subscribe

Don't want

New intervertebral cages from the Russian company Pozvonoq, which are used to solve problems of stabilization...

Read more

four

Subscribe to the author

Subscribe

Don't want

53

Subscribe author

Subscribe

Don't want

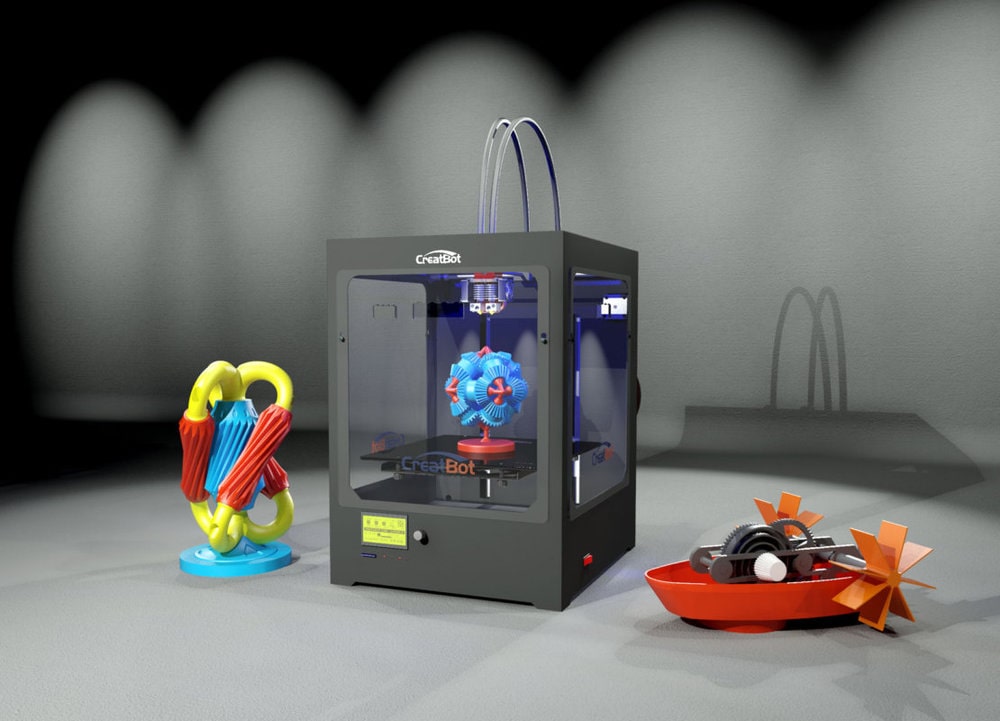

As we all know, a true 3D printer must have a solid acrylic body, high quality.