3D printing impossible

Impossible best 3D printer files・Cults

The Impossible Puzzle Made Possible by FDM Printing

Free

IMPOSSIBLE DOVETAIL

€1.90

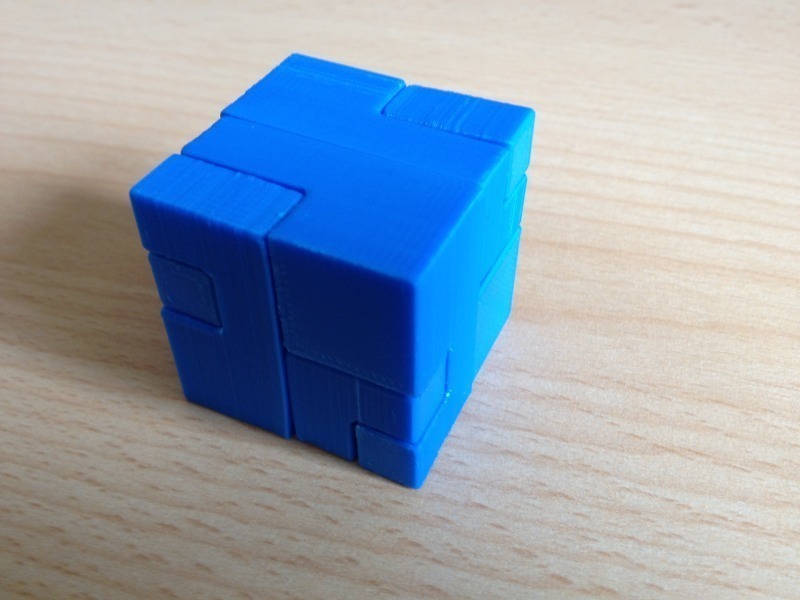

Impossible Dovetail Joint Cube (IDJC) inspired by "Clickspring"

Free

impossible print, infinity cube

€1.89

False Blivet/Closet Blivet

Free

Impossible Puzzle Assembly Tool

Free

Apparently Impossilbe Egg- Large

Free

Steampunk Spider

€3.80

Impossible Cube

€0.50

imposible vase

€3.40

Impossible Dragon

Free

Impossible Pedestal

Free

PUZZLE - Brain teaser - Ultimate collection

€4. 50

PUZZLE - Brain teaser - LEVEL 5 - Impossible

€0.99

Print in Place Expanding Circular Linkage

€1.90

Print in Place Jigsaw Puzzle Ring

€1.90

Print in Place Impossible Screw Mechanism

€1.90

Print In Place Square Knot Puzzle

€1.90

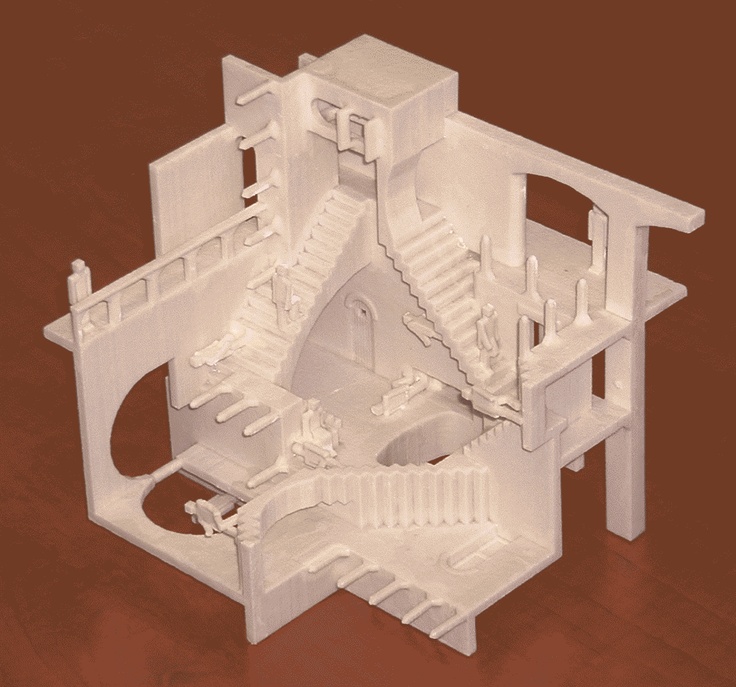

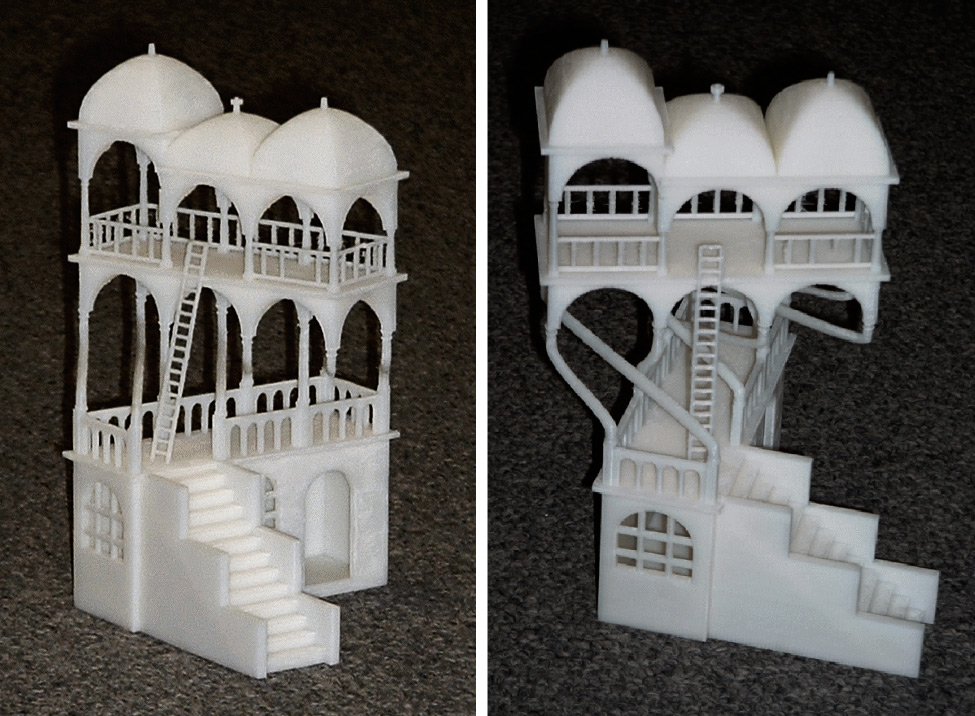

Never-Ending Staircase Impossible Perspective Illusion Sculpture

€0.62

Optical Illusion Impossible Staircase

Free

Key Hanger 'Impossible'

€0.50

Optical Illusion Impossible Object

€0.94

Dovetail Cube [Magnetic Lock]

Free

Imposibeedrill

€0. 62

62

Impossible Trapped Box

Free

spinning toy

Free

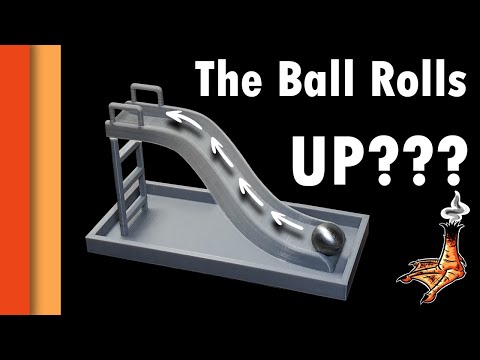

Impossible Slide Interactive Optical Illusion

€1.89

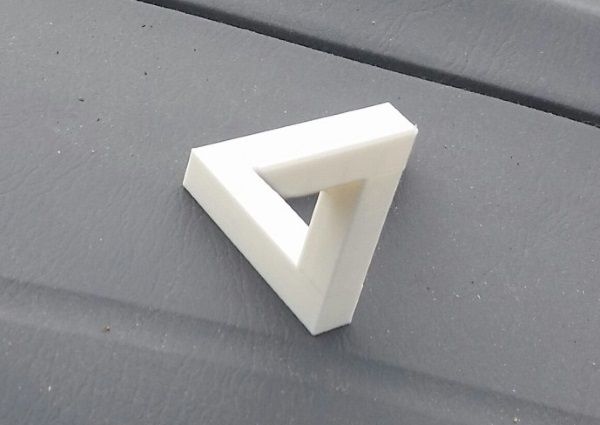

Penrose Triangle Impossible Object Optical Illusion

€1.89

The IMPOSSIBLE Dovetail Triangle Puzzle - one more

Free

Impossible Nut & Bolt Puzzle: Impossibilised!

Free

Penrose triangle like figure

Free

Impossible phone stand

Free

Merde the piggy bank, a Box impossible unlocked

€1.90

WHATSAPP POOP, MERDE THE GIFT BOX. BOX IMPOSSIBLE, SD CARD BOX

€1. 25

25

WHATSAPP POOP, MERDE THE SD BOX. BOX IMPOSSIBLE, SD CARD BOX

€1.25

TOM CRUISE ETHAN HUNT

€10

Impossible box piggy bank

€1.20

BOX IMPOSSIBLE, BLANK BOX

Free

BOX IMPOSSIBLE, SD CARD BOX

Free

heart box, gift box, BOX IMPOSSIBLE, christmas time, wedding anniversary

€0.50

Impossible box with ball inside - ball can't fall out

€0.71

Impossible Triangle Lithophane

Free

St. Jude Thaddeus

€5

Puzzle Box M1

Free

Möbius piece

€0. 74

74

TRAPPED SPHERE

€1

Impossible Table 5 Point Stable One Piece

Free

Impossible Planter

€1.43

3D printing the solution of "impossible designs"

Posted By Hannah Bensoussan on Jan 18, 2017 |

Last week, we started the 3D printing benefits series with our article on Mass Customization. To continue, we’ll address today another one of the many advantages of 3D printing: the possibility to create “impossible designs”.

In a previous series, we explained the principal uses that can be made of 3D printing (prototyping, production, etc.). In the continuity of this series, we are starting a series about the great Benefits of 3D Printing. Mass customization is the first of these benefits.

This blog post is part of ‘Benefits of 3D Printing’ Series, to elucidate with you all the different ways in which producing with 3D printing has many advantages and can change the industrial landscape.

Find the other episodes here!

Benefits of 3D Printing: Mass Customization

Benefits of 3D Printing: Integrated Assembly

What is called a 3D printed impossible designs?

What we call an impossible design is a design that couldn’t be created using traditional manufacturing techniques. Typically, built-in interlocked objects that require no assembly and can’t be disassembled, internal channels that couldn’t be created without 3D printing, etc.

In this article, I’ll explain those different types of impossible designs and how they solve manufacturing issues.

1. 3D Printed built-in interlocked objects with no assembly required

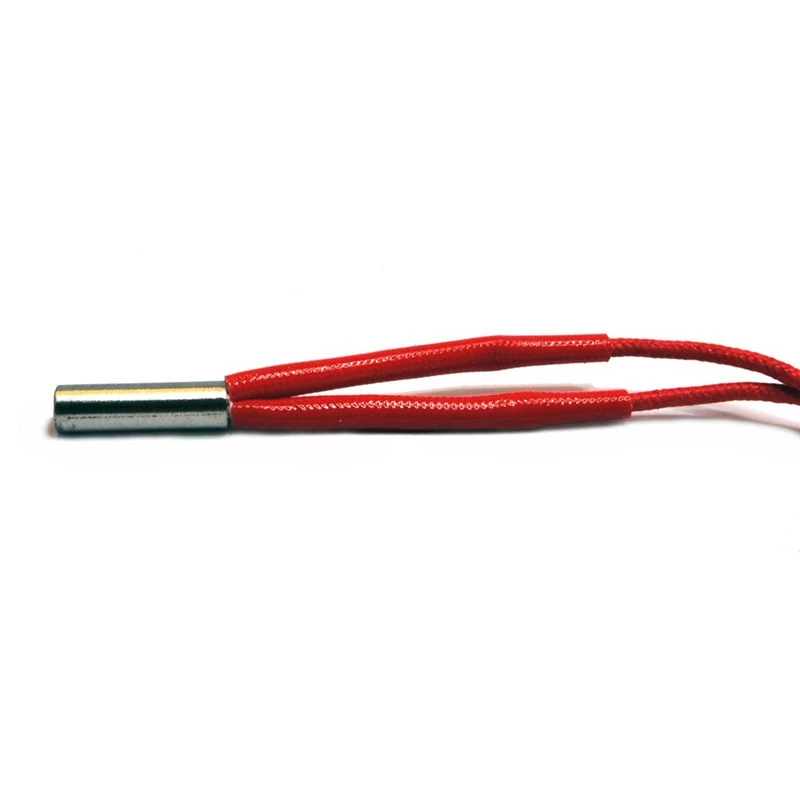

One of the things that are made possible with 3D printing are the combination of multiple parts within a unique object without any assembly step.

As you know, 3D printing is an additive manufacturing process that works layer by layer. Thanks to this, as long as the two interlocking parts are separated by a minimum distance in the design (to prevent them from sticking together), they can be created in just one 3D print.

Hinges, gear bearings and ball joints can be manufactured within the same machine and material to reduce cost and manufacturing time. One can imagine that metal 3D printing can be a valuable step in the manufacturing process for larger objects, mixing traditional methods (machining, molding) to additive manufacturing methods to achieve complex parts.

2. Internal channels and no-access features

It is also possible to create cavities and internal features that wouldn’t be possible or would be very complicated to create with traditional manufacturing techniques, as they are limited by the access zone of the various tools that are used.

Internal and cooling channels are often the reason why industrials are choosing additive manufacturing techniques, especially metal 3D printing techniques like SLM or DMLS to create their parts. That allows them to solve structural and thermal issues by designing a model that takes into account stress and can reduce it in an innovative way.

A good example of this is the team of scientists of the von Karman Institute in Belgium, who created a 3D printed metal vane for a turbine. The design of this turbine part included its cooling cavities in order to 3D print them directly. This allowed them to innovate and create a pulsed cooling technique, which reduces the intensity of the shock waves endured by the turbine!

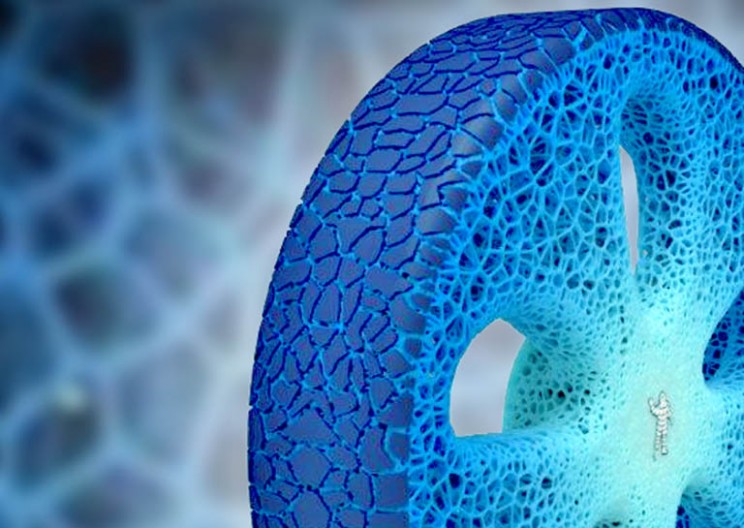

On top of cooling options, internal channels can help reduce a component’s weight. This is an important feature, that is starting to be explored and will be explored more and more, especially in fields where weight is key, like in the construction industry. A good example is Neri Oxman’s alveolar cement design.

As well as XtreeE’s new way to 3D print buildings. You can read a complete interview of XtreeE CEO here.

3. Complex geometries: the example of NightHawk headphones

Some designs allowed by 3D printing aren’t per say impossible with traditional manufacturing, but would be very complex to create, or very expensive. Therefore, 3D printing does make them possible for businesses to afford. A good example of this is the The NightHawk headphones by our client AudioQuest, that we have talked about many times already.

Therefore, 3D printing does make them possible for businesses to afford. A good example of this is the The NightHawk headphones by our client AudioQuest, that we have talked about many times already.

These headphones, produced in series at Sculpteo, integrate a 3D printed part, which has an intricate diamond cubic latticework. These unique parts increase the acoustic properties of the headphones, and exist solely thanks to 3D printing!

When 3D printing solves manufacturing issues

With all these new design possibilities, 3D printing is solving manufacturing issues, and creating new opportunities. In particular, it allows to reduce tooling costs and lead time (thanks to the integrated assembly options), it gives the opportunity for engineers to innovate technically (for example with the cooling channels).

6 problems that 3D printing has not yet overcome

Any new technology provokes a lot of hype. People do not get tired of listing its advantages, but often lose sight of the disadvantages. With the advent of 3D printers, there are certainly many new opportunities for industrial growth and development.

With the advent of 3D printers, there are certainly many new opportunities for industrial growth and development.

On the other hand, there are some problems with 3D printing. I wonder how this technology will be perceived by people when such problems become known? Before getting excited about this new technology, we'd like to take a look at some of the challenges we'll face as we move into the 3D printing era. nine0003

Energy inefficiency

A recent study by Loughborough University found that 3D printers use 50 to 100 times more energy than conventional plastic injection molding. This makes it impossible to use a 3D printer on an industrial scale.

Health risk

A 3D printer poses a serious health hazard if used inside the home. Printers emit particles similar to those emitted by cigarettes. Such particles are emitted in large quantities and can lead to serious health problems. nine0003

nine0003

Use of plastic

Movements are taking shape around the world to reduce the use of plastic. They are designed to raise public awareness that plastic bags, bottles and other household items should be made from recycled materials and not plastic. 3D printers use plastic as a raw material. If 3D printing is used on an industrial scale, the disposal of this by-product will become a new environmental problem. nine0003

Gun proliferation control

The effects of 3D printed guns are still out of control. There are already several companies that sell such 3D printed weapons. The Undetectable Firearms Act prohibits the use of all weapons that cannot be detected by a scanner. The law, however, does not prohibit the use of 3D printed weapons, which have a small amount of metal. nine0003

Intellectual Property Rights and Liability Issues

This technology raises the issue of possible infringement of intellectual property rights. There is also the issue of liability. Who will be responsible if someone gets hurt by a 3D printed knife? Who will be held responsible if the motorcyclist was wearing a 3D non-printed helmet in the event of an accident? Who can be given ownership? To the owner of the printer, or to the company that made the printer, or to the person who printed it? nine0003

There is also the issue of liability. Who will be responsible if someone gets hurt by a 3D printed knife? Who will be held responsible if the motorcyclist was wearing a 3D non-printed helmet in the event of an accident? Who can be given ownership? To the owner of the printer, or to the company that made the printer, or to the person who printed it? nine0003

Food Safety Issues

Anyone can 3D print a spoon or fork, but the plastic used for printing is not free of toxins. New non-toxic plastic filaments are being produced for this purpose, but they are not yet widely available. Moreover, there are places in 3D printers where bacterial growth is possible. Truly safe cooking utensils can only be produced on machines that are approved by the Food and Drug Administration. nine0003

There is no denying the fact that 3D printing is an innovative phenomenon. However, there are real concerns about its widespread use that need to be addressed. People's opinions are still divided on issues related to 3D printers. It will be interesting to see how things will develop. Follow this.

It will be interesting to see how things will develop. Follow this.

Source

Things that cannot yet be created using 3D printing

Blog navigation

Article search

Categories

Latest articles

Popular articles

-

How to draw with a 3D pen?

12/16/2015

17252 views

Connect the 3D pen and let it warm up for a few seconds. Insert ABS or PLA filament into feed hole...

Read more

-

Top 20 interesting toys for children on a 3D printer.

Posted in: 3D printing

02/15/2022 nine0003

12570 views

What kind of toys can be created on a 3d printer? What are the advantages of 3d printing toys at home? In this article you will find...

Read more

-

10 improvements for your Ender-3

Posted in: Basics of 3D printing, 3D Printing Tips and Tricks

09/22/2021

12369 views

10 inexpensive upgrades to improve the stability, performance and security of Ender 3 - the most popular.

..

.. Read more

-

3D Print Delamination - 5 Tips and Tricks to Avoid Delamination

Posted in: 3D printing tips and tricks, 3D printing

05/14/2019

11612 views

If you have owned a 3D printer for a while, then you are probably used to solving many problems. Delamination is...

Read more

-

History of 3D pen

Posted in: Basics of 3D printing, Draw 3D

03/21/2019

9869 views

The advent of the 3D pen has led to some areas of art that were previously impossible. In this article we...

Read more

Read all articles

Recommended articles

Article archive

5372 views Posted on: 06/08/2019

Author: 3D4U. COM.UA

Nowadays, 3D printing has become very popular: it is used to create three-dimensional models of buildings, molds for the production of pharmaceuticals, business card holders, plastic wrenches and much more. Because of this, it seems that everything can be printed, but this is a delusion. nine0003

However, the list of applications for 3D printing is expanding daily, so you can buy a 3D printer from us and implement your ideas.

- Food. Many experiments have been carried out on the production of food on 3D printers. In particular, attempts were made to make chocolate, biscuits, and even extruded mass from meat, but all of them ended in failure. Theoretically, it is still possible to print food on a 3D printer, albeit of very poor quality. However, this is not advisable due to high costs: it is the same as producing children's toy cars at the facilities of a large car factory. nine0092

- Metal products. For 3D printing, mainly special plastic is used, which, by the way, can also be purchased on our website.

But metal is not. The production of parts from it on a 3D printer is theoretically possible from powdered gold or silver, but their cost will be simply astronomical.

- Microcircuits. Printing them on a 3D printer is currently impossible due to the need to use a large number of different components (not only plastic, but also metals, magnets, and so on). A 3D printer usually produces an electronic product case, and only then a finished microcircuit is inserted into it. nine0092

- Transparent items. 3D printers can use translucent materials for printing, but completely translucent materials cannot.

- Jewelry. 3D printers currently only create injection molds, which are then filled with metal. But the decorations themselves, complex in pattern and geometric shape, cannot be created on them due to the laboriousness of the process.

Well, you can buy 3D printers, as well as materials for 3D printing right here on our company website. nine0003

Dream and create! despite some limitations, the possibilities of this amazing technology are endless.

Related Products

-

CR-10S PRO 3D printer Creality

Price: 30 600 ₴

Creality CR-10S PRO is a 3D printer with a large printable area (300x300x400),...

Related articles

- Top 20 interesting toys for children on a 3D printer.

Category: 3D printing

02/15/2022

12570 views

What kind of toys can be created on a 3d printer? What are the advantages of 3d printing toys at home? In this article you will find...

Read more - 12 common 3D printing mistakes to avoid.

5378 views

As an industry, 3D printing is evolving every day, so it's important to know all aspects of this technology today. In this...

Read more - 9 romantic 3D printed gifts for Valentine's Day. nine0002 Category: 3D printing

02/09/2022

1980 views

3D printing can help you create unique and personalized gifts for your significant other.

Learn more