3D printing food future

3D Printing – USC Viterbi School of Engineering

3D printing is the process of building up a 3D object by depositing materials layer by layer onto the print bed of a 3D printer. The materials most commonly used to produce the 3D objects have been plastics and metals, but recently researchers, engineers, scientists and food connoisseurs have begun to experiment with edible materials. These professionals have started to create 3D printers for the sole purpose of printing food. This paper will discuss how the use of edible ingredients can unlock the creativity of the food industry, feed future astronauts in space, and soldiers on the battlefield, and solve some of the problems the world is currently facing. First, this paper will explain the engineering behind 3D printers. Then it will describe the current state of 3D food printing technology. Next it will discuss the goals for 3D food printing in the future, and lastly, it will conclude with the challenges and limitation of this new technology.

Introduction

3D printing has become a recent phenomenon due to a 2012 market divergence [1]. With the touch of a button, one has the ability to create almost anything imaginable with a device approximately the size of a microwave. The history of 3D printing began when the first 3D printer was patented in the 1980’s. Throughout its short history, its main function has been for industrial applications using mainly plastic and metal materials [1]. However, in 2012, a team at Cornell University started to experiment with hydrocolloids – a gel-like substance infused with flavors and textures to replicate solid foods [2]. Other 3D food printer companies have ventured into creating desserts with edible ingredients such as chocolate, sugar and candy. And recently, 3D food printers have been able to use batters and dough to print foods such as pizza, pasta and cookies. Even though 3D printed food is still in its infancy — constrained to ingredients that can be deposited out of a small nozzle — there is a lot of hope and speculation about where this new phenomenon will take the food industry, including creating beautiful, intricate edible creations, feeding our astronauts in space and soldiers on the battlefield, customizing foods, and helping with world hunger and food sustainability.

The Engineering Behind 3D Printing

3D Printers have both software and hardware components that work together to create the 3D designs.

Software

Before 3D printing can begin, a virtual design of the object must be created. This can be done in a Computer Aided Design (CAD) file using a specialized 3D modeling program or the using a 3D scanner [3]. The software slices the virtual object into thousands of horizontal layers, and then uploads the object onto the 3D printer. The printer sets down the edible ingredients layer by layer to create the 3D design [3].

Hardware

There are three major mechanisms that make up the hardware of a 3D printer: The print bed, the gantries and the printing head [4].

The Print Bed:

This is the component upon which the object is printed. The different materials, whether they are plastic or edible, are deposited layer by layer onto the print bed to make the printed model.

The Gantries:

The three gantries as shown in Fig. 1, navigate three axes of the 3D printer and can be compared to an arcade claw game [4]. The gantries located on the x- and y- axis navigate the horizontal plane and are equivalent to the left-to-right and forward-and-backward movement of the claw, respectively. The gantry that moves along the z-axis is similar to the up and down motion of the claw, and is responsible for building the depth of the object [2].

1, navigate three axes of the 3D printer and can be compared to an arcade claw game [4]. The gantries located on the x- and y- axis navigate the horizontal plane and are equivalent to the left-to-right and forward-and-backward movement of the claw, respectively. The gantry that moves along the z-axis is similar to the up and down motion of the claw, and is responsible for building the depth of the object [2].

Illumin

Figure 1: The Gantries[5].

In order for the gantries to create 3D designs, they are equipped with stepper motors that allow them to make precise movements. The stepper motors are controlled by digital pulses, in which “each pulse only moves the motor a small fraction of a full rotation”[4]. These small movements enable the gantries to create intricate and detailed 3D designs [4].

The Printing Head:

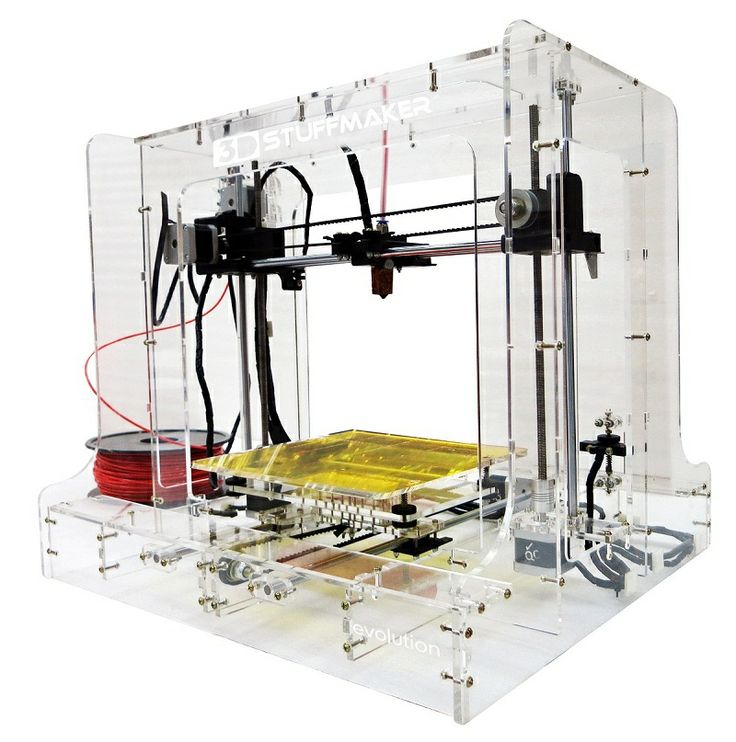

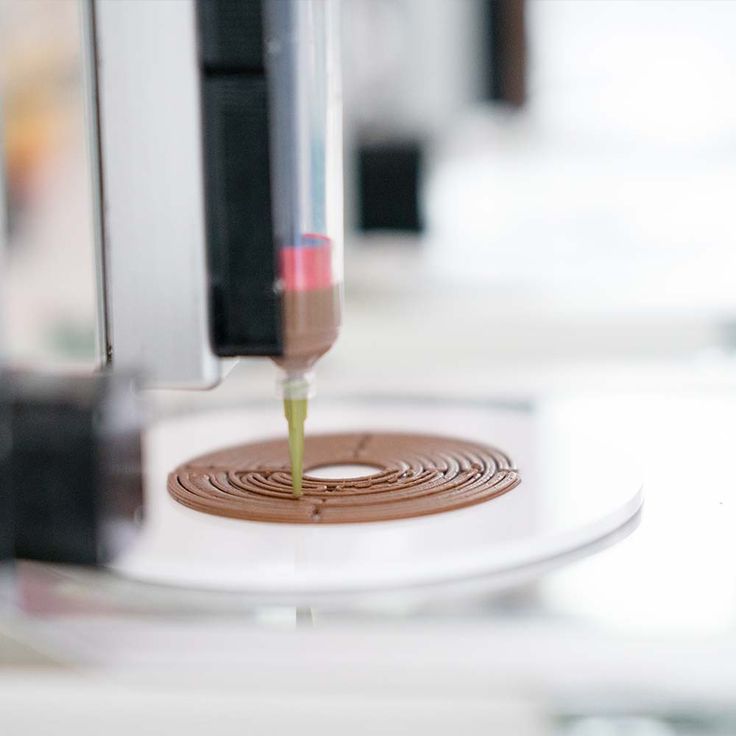

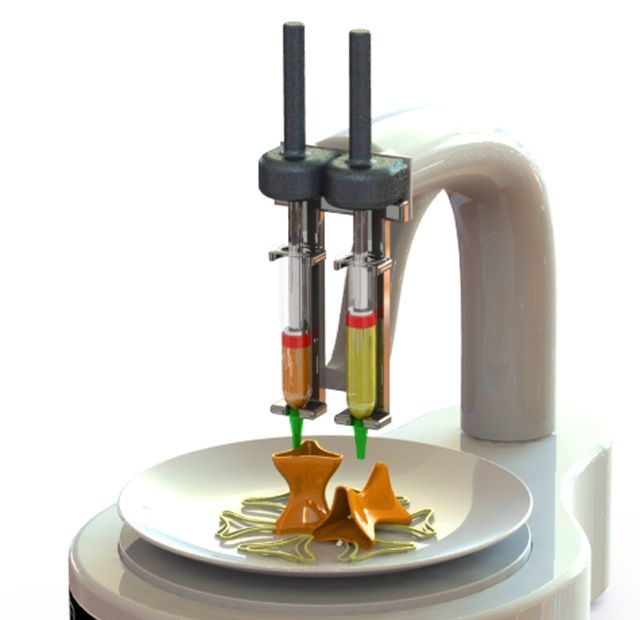

The printing head, shown in Fig. 2, is attached to the gantries and is responsible for setting down the edible ingredients layer by layer onto the print bed [3]. The edible materials are placed inside capsules that are mounted onto the print head. The ingredients are slowly extruded through the nozzles, similar to decorating a cake with icing.

The edible materials are placed inside capsules that are mounted onto the print head. The ingredients are slowly extruded through the nozzles, similar to decorating a cake with icing.

Illumin

Figure 2: Printing Head Making 3D Printed Food.

The World of 3D Printed Food

Printing food is still in its infancy, constrained to ingredients that can be deposited out of the small nozzles. Even though there are limitations to this process, this has not stopped professionals from venturing into this new territory and creating 3D printers for the sole purpose of printing food. Through the use of ingredients such as hydrocolloids, chocolate, sugar, batter and dough, these 3D printers have been able to mimic solid foods and help professionals unlock their creative potential. Despite the fact that 3D food printers have yet to hit the commercial market, this technology will impact the way the world views and eats food.

Hydrocolloids

In 2012, Hod Lipson and Evan Malone, who lead the team at Cornell Creative Machines Lab, began experimenting with Solid Freeform Fabrication (SFF) of food with the use of hydrocolloids. Hydrocolloids, shown in Fig. 2, are gel-like substances made of xanthium gum, a thickening agent, and gelatin [2]. They are combined with different flavors and textures to mimic solid foods such as bananas, mushrooms and mozzarella cheese [2,6]. The goal for hydrocolloid printing is to both enhance the culinary profession and positively impact food production at home. Culinary professionals are constantly looking for innovative ways to experiment with their craft. With the help of a 3D food printer, a professional can create a cake that displays a personal message upon cutting into said cake. [2]. Another application for food-Solid Freeform Fabrication is to one day assist the cooking process at home. According to the USDA, the average American spends more than 30 minutes per day preparing food and that number grows depending on family size. With food-SFF cooking time could be reduced with a “set-and-forget” feature. [2].

Hydrocolloids, shown in Fig. 2, are gel-like substances made of xanthium gum, a thickening agent, and gelatin [2]. They are combined with different flavors and textures to mimic solid foods such as bananas, mushrooms and mozzarella cheese [2,6]. The goal for hydrocolloid printing is to both enhance the culinary profession and positively impact food production at home. Culinary professionals are constantly looking for innovative ways to experiment with their craft. With the help of a 3D food printer, a professional can create a cake that displays a personal message upon cutting into said cake. [2]. Another application for food-Solid Freeform Fabrication is to one day assist the cooking process at home. According to the USDA, the average American spends more than 30 minutes per day preparing food and that number grows depending on family size. With food-SFF cooking time could be reduced with a “set-and-forget” feature. [2].

Sugar, Chocolate, and Candy

Illumin

Figure 3: Sugar Object Created with 3D Printer.

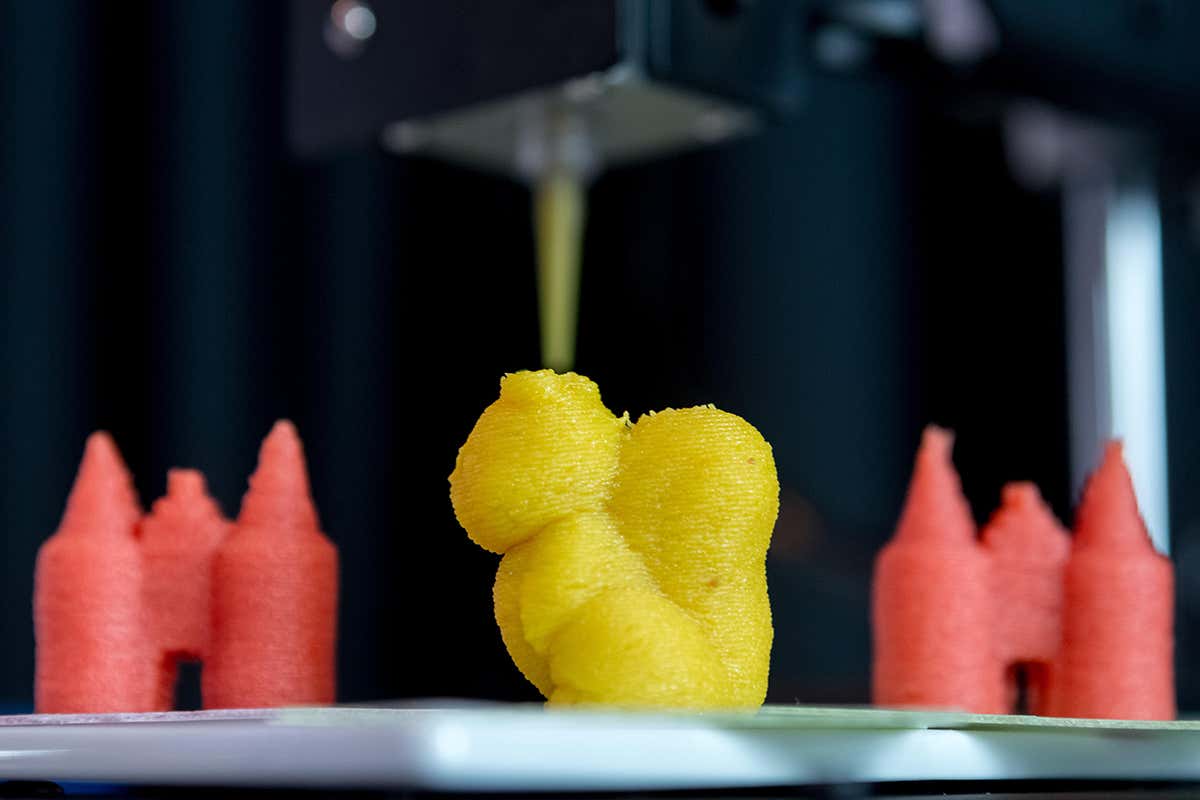

There are a number of 3D food printers that have been developed to create intricate sweets with ingredients such as sugar, chocolate and candy. Fig. 3 is an example of a detailed design made with a 3D printer and sugar [7]. The materials start out liquid and as they are extruded layer-by-layer onto the print bed, they begin to harden, building a stable 3D design [8]. Similar to the team at Cornell, these 3D printer inventers hope to unlock the imaginations of culinary professionals [7]. This technology allows bakers to create detailed cake toppers or restaurateurs to craft colorful cocktail decorations. One company has partnered with the Culinary Institute of America to provide students and teachers the opportunity to experiment with this new technology to incorporate it in future culinary creations. [9] These 3D printers also aim to appeal to a mass consumer base by being user-friendly. One 3D printer, which is expected to be commercially available in the second half of 2015, comes with specialized software that makes it easier for users to design a 3D creation [10].

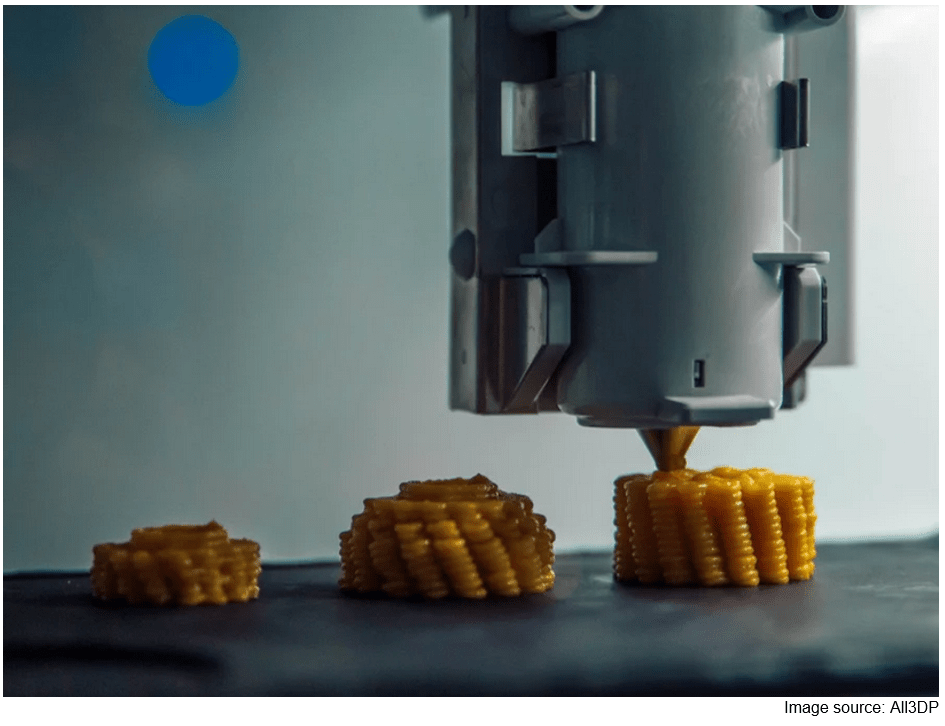

Other 3D food printing companies have begun to print with materials such as batter and dough to create pizza, pasta and cookies [11]. But, current 3D food systems do not have the ability to cook these food items so they must be cooked in a secondary source, such as an oven [11]. Clearly printing food is still in its early stages but there is a lot of hope for the future.

The Hope for the Future

NASA

NASA has awarded a six-month, $125,000 grant to a Texas Company, Systems & Materials Research Cooperation, to create 3D printing technology to feed future astronauts in space. NASA hopes to venture farther into space than what has previously been explored, but unfortunately these long duration flights are not possible with the current food system. The food only has a 5-year shelf life and would not provide the necessary nutrients needed to support astronauts on a mission to Mars, for example [12]. NASA hopes that with 3D printing technology, long exploration missions will be made possible. 3D printing in space would allow food to be mixed with vitamins and amino acids to provide the necessary nutrients for astronauts. [6] The 3D printer plans to utilize cartridges filled with carbohydrates, sugars and protein that can last up to 30 years, due to the sustainability of the ingredients [13]. Lastly, this technology will allow for maximum use of spacecraft resources by taking up less space than the current supply of packaged food. [6] It is important to note that SMRC has created its first printed food, pizza, as shown in Fig. 4, making NASA one step closer to feeding astronauts in space [13].

3D printing in space would allow food to be mixed with vitamins and amino acids to provide the necessary nutrients for astronauts. [6] The 3D printer plans to utilize cartridges filled with carbohydrates, sugars and protein that can last up to 30 years, due to the sustainability of the ingredients [13]. Lastly, this technology will allow for maximum use of spacecraft resources by taking up less space than the current supply of packaged food. [6] It is important to note that SMRC has created its first printed food, pizza, as shown in Fig. 4, making NASA one step closer to feeding astronauts in space [13].

Illumin

Figure 4: NASA’s 3D printer printing a pizza layer by layer.

The Army

Similarly to NASA, the U.S. Army is looking to 3D printed food technologies to feed their soldiers on the battlefield. Lauren Oleksyk, a food technologist at the Army’s Natick Research center, explained that their vision is to tailor the 3D printed food to the nutritional needs of individual soldiers [14]. Their goal is to equip soldiers with head-to-toe sensors that can relay information to 3D printers. The 3D printers would then produce personalized meals for the soldiers depending on their body’s dietary needs [14]. For example, the sensor would detect that a specific soldier is low in vitamin B. The 3D printer will receive this information, and then create a vitamin B rich meal for that individual soldier. Another advantage of 3D printing technology is that the food cartridges do not need to be refrigerated. This provides a crucial benefit to soldiers on the battlefield [14].

Their goal is to equip soldiers with head-to-toe sensors that can relay information to 3D printers. The 3D printers would then produce personalized meals for the soldiers depending on their body’s dietary needs [14]. For example, the sensor would detect that a specific soldier is low in vitamin B. The 3D printer will receive this information, and then create a vitamin B rich meal for that individual soldier. Another advantage of 3D printing technology is that the food cartridges do not need to be refrigerated. This provides a crucial benefit to soldiers on the battlefield [14].

Customization of Your Food

A number of 3D food printer advocates believe that this technology will become a standard kitchen appliance in the future [15, 16]. With a 3D food printer people will have complete autonomy over the food they put into their bodies. In the same fashion as the U.S. Army, people could wear sensors that would connect to a home 3D printer to create customized meals based on the user’s individual nutritional needs [15]. Not only could people embed specific nutrients in their food, but also have control over the shape, flavor, consistency and color [16]. The possibilities are endless; imagine creating pasta in the shape of a rose for Valentines Day, or printing a cheeseburger with the onions, cheese and ketchup in the middle of the patty – a picky eater’s dream come true.

Not only could people embed specific nutrients in their food, but also have control over the shape, flavor, consistency and color [16]. The possibilities are endless; imagine creating pasta in the shape of a rose for Valentines Day, or printing a cheeseburger with the onions, cheese and ketchup in the middle of the patty – a picky eater’s dream come true.

World Hunger and Sustainable food

As the world’s population grows, scientists and researchers are looking to 3D printing to not only help with world hunger but for a sustainable food source as well. Anjan Contractor, a mechanical engineer at Systems & Materials Research Corporation, believes the food printing technology he is creating to feed astronauts in space could also help feed the world. He explained, “The nutrient cartridges can last up to 30 years, so they eliminate waste, particularly in quick-rotting environments like Africa, South America, and Asia.”[13] Other researchers like Kjeld van Bommel have suggested similar uses for 3D printers. He explained that if Western consumption spreads to the rest of the world, 3D printers may be the answer to sustaining this growth by transforming other proteins like algae and insects into food people would want to eat [15].

He explained that if Western consumption spreads to the rest of the world, 3D printers may be the answer to sustaining this growth by transforming other proteins like algae and insects into food people would want to eat [15].

Challenges and Limitations

Because printing food with 3D technology is still a relatively new innovation there are inevitable challenges and limitations that come with this 3D printing technology. One of the biggest challenges is the limitation of materials that can be used to create 3D printed food. Right now the ingredients are constrained to specific consistencies that can be extruded out of a small nozzle [7]. Another limitation is that current 3D printers cannot cook the food, restricting the food you can print. However, some speculate that in the future 3D printers will be equipped with lasers enabling the printer to cook the food [16]. An additional challenge is the price; some companies believe that 3D food printers can and should replace microwaves [11] that are priced as low $50. Unfortunately, because this is a new innovation 3D food printers are not at this price point yet, and can range from $500 to as much as $10,000 [8].

Unfortunately, because this is a new innovation 3D food printers are not at this price point yet, and can range from $500 to as much as $10,000 [8].

Conclusion

Even though 3D printing food is still in its infancy many companies have already gained a lot of attention for embracing this innovative approach to the food industry. Not only is 3D printing an exciting new way to experience food it can also solve some problems we are currently facing. These include feeding astronauts in space and soldiers on the battlefield, customizing food to our nutritional needs, and potentially helping with world hunger and food sustainability. It is clear that 3D printed food has started to make a mark on our society and will most likely continue to innovate to reach the future goals.

Why 3D printed food is the future

We've covered nutritional insects to vertical farming and everything in between. Our big take out is the positive effect on 3rd world economics when local populations cease to have to worry about where the next meal is coming from and can focus their attention more on their quality of life - improving the way they live and consuming more. That's got very positive implications all over the world.From DigitalTrends:

That's got very positive implications all over the world.From DigitalTrends:

It’s 2015, and 3D printing, a technology long priced beyond many people’s reach, is quickly undergoing democratization. So much democratization that companies are trying to 3D print all kinds of new things, including food.

Think about the replicators on Star Trek and the many other machines that litter science fiction movies, which prep, cook, and serve meals on command. This could actually be our future. 3D food printing has the potential to revolutionize food production by boosting culinary creativity, food sustainability, and nutritional customizability, but technical and market barriers still face it in the years to come.

3D printing food ain't easy

Most 3D printers work by slowly depositing layers of material, one on top of the other, until an object is constructed. The process is called “additive manufacturing,” and it uses deposition printers. Others bind layers together with adhesive — they’re called binding printers.

Others bind layers together with adhesive — they’re called binding printers.

3D food printers are more difficult to explain. Hod Lipson, director of Cornell University’s Creative Machines Lab, laid out the three dominant methods of printing food at the 2015 Inside 3D Printing conference in New York City, which are nozzles, powdery material, and lasers. “You can think of it as the ‘RGB of food,’” he told Digital Trends.

Many systems mix and match those approaches. The 3D Systems ChefJet crystalizes thin layers of fine-grain sugar into virtually any geometric configuration, while Natural Foods’ Choc Edge dispenses chocolate from syringes in beautiful, melty patterns. The Foodini uses fresh ingredients loaded into stainless steel capsules to prepare a surprisingly wide array of dishes. Its latest model isn’t a soup-to-nuts solution — it only prints raw doughs, which then must be cooked as normal — but the printer can partially make pizza, filled pasta, quiche, and even brownies.

None of these machines will be next in line for the Bocuse d’Or chef championship, though. Emilio Sepulveda, co-founder of Foodini maker Natural Machines, has said publicly that food synthesizers like those seen in Star Trek and The Fifth Element will take “many more years” of development.

But that’s not stopping early adopters. Some German nursing homes serve a 3D-printed food product called Smoothfoods to elderly residents who have difficulty chewing. Purees, the conventional alternative, typically aren’t very appetizing, which sometimes leads to under eating. Residents “get malnourished in certain cases,” said Kjeld van Bommel, a research scientist at the Netherlands Organization for Applied Scientific Research, in an interview with the Washington Post.

The tastier Smoothfoods — made of mashed carrots, peas, and broccoli, which 3D printers congealed with an edible glue — are already a hit; 1,000 of the country’s facilities now serve them daily.

3D food printers invade the gourmet world

On the opposite end of the gastronomic spectrum, 3D food printers are beginning to breach gourmet spaces. Earlier this year at the Consumer Electronics Show (CES) in Las Vegas, the Culinary Institute of America (CIA) unveiled a partnership with 3D Systems, maker of the ChefJet. The CIA plans to begin beta testing with the ChefJef, and 3D Systems will provide CIA students with fellowship and internship programs at the company’s headquarters in Los Angeles.

Earlier this year at the Consumer Electronics Show (CES) in Las Vegas, the Culinary Institute of America (CIA) unveiled a partnership with 3D Systems, maker of the ChefJet. The CIA plans to begin beta testing with the ChefJef, and 3D Systems will provide CIA students with fellowship and internship programs at the company’s headquarters in Los Angeles.

Tom Vacarro, dean of Baking and Pastry Arts at CIA, spoke to WAMC Northeast Public Radio about the arrangement. “We just took that ran with it and said, okay, we could do many different things with these printers and here’s our ideas” he said. “[You can] design your mold on the screen, and hit print, and out it comes. It just shaves off all of that back-and-forth time.”

3D Systems Creative Director Liz von Hasseln, speaking at CES, said she sees food printing “as something that … will become a part of the culinary fabric.”

“I think the way that happens really powerfully is when it impacts the cultural ritual of eating, which is actually a really powerful part of being a person in the world,” she clarified. Hasseln predicts most of her team’s culinary experiments, which include shaping chocolate and sugar into wedding cake toppers and cocktail garnishes, are just the beginning. Cornell’s Lipson agrees.

Hasseln predicts most of her team’s culinary experiments, which include shaping chocolate and sugar into wedding cake toppers and cocktail garnishes, are just the beginning. Cornell’s Lipson agrees.

“These are things that no pastry chef, no confectionary chef could ever make,” he said. “They represent a new design space in food. We’re getting to that point of artistry.”

Food printing moves beyond the kitchen

Other chefs are looking beyond the kitchen. Dutch food designer Chloé Rutzerveld documented the creation of cracker-like yeast structures containing seeds and spores that sprout over time, and thinks the snack he synthesized and those like it — natural, transportable products printed efficiently — could someday transform the food industry. And he’s not alone.

Some experts believe food printers could minimize waste by using cartridges of hydrocolloids, substances that form gels with water. Those same machines, they theorize, could also use unpalatable but plentiful ingredients — ingredients such as algae, duckweed, and grass — to form the basis of familiar dishes. In a study headed by Van Bommel, scientists added milled mealworm to a shortbread cookie recipe. “The look [of the worms] put me off, but in the shape of a cookie I’ll eat it,” he said in an interview with Popular Mechanics.

In a study headed by Van Bommel, scientists added milled mealworm to a shortbread cookie recipe. “The look [of the worms] put me off, but in the shape of a cookie I’ll eat it,” he said in an interview with Popular Mechanics.

To that point, people are very conservative when it comes to food, Lipson said. “Most people will only enjoy foods that are very similar to what they’ve had before. We have a very deep, visceral reaction to foods we don’t recognize,” he said. 3D food printers could be used to make the unappetizing, appetizing.

“Consider a food source that’s not something you’d want to eat in its raw form but a good source of protein, like insects,” Lipson said. “There’s an interesting advantage there — being able to make something that looks and tastes good from something that doesn’t.”

Anajan Contract, an engineer who’s currently developing a pizza-making printer with a $125,000 grant from NASA’s Small Business Innovation Research program, envisions a machine that can produce food from capsules of powders and oils with shelf lives up to 30 years. He believes such a printer would not only reduce the environmental impact of cooking, but also offer a renewable form of sustenance to a growing world population.

He believes such a printer would not only reduce the environmental impact of cooking, but also offer a renewable form of sustenance to a growing world population.

“I think, and many economists think, that current food systems can’t supply 12 billion people sufficiently,” he told Quartz. “So we eventually have to change our perception of what we see as food.”

Beyond sustainability, 3D food printing holds great promise for nutrition. Lynette Kucsma, CMO and co-founder of Natural Machines, says printers like the Foodini can help people cut down on the amount of chemical additives in their food and reduce overconsumption. The food printers of tomorrow could even allow customization at the macronutritional level, allowing users individualize the amounts of calcium, protein, omega-3, and carbohydrates in their meals.

“You’ll be able to say when I wake up in the morning I want the printer to print my breakfast and I want to have the right amount of trans fats, whatever we need,” said Lipson.

The many obstacles ahead

But 3D food printing has many challenges to overcome, chief among them speed. Devices like the recently announced Carbon3D can fabricate a mind-boggling number of objects in minutes, but that level of advancement hasn’t trickled down to food printers yet. The most common designs require successive layers of ingredient to cool, leading to exceedingly long wait times for some foods.

Many food printers have chocolate, dough, and sugar nailed, but more complicated products like meat are tougher to master. “Printing in food materials is a lot more difficult from an engineering point of view than plastic of metals,” said Lipson. “They interact with each other in very complex ways.”

That’s not to say producing them isn’t feasible. Modern Meadow, a company in New York, raised $10 million in funding to research the production of printable biomaterials — but achieving the right texture and flavor is a lot harder. And even if scientists are able to closely replicate natural beef, consumers might not bite; in a survey by GlobalMeatNews. com, only 34 percent of respondents said they’d even try 3D-printed meat.

com, only 34 percent of respondents said they’d even try 3D-printed meat.

There’s also the issue of expectations. The Star Trek replicator comes to mind when many people think about food synthesizers, but such a device would hardly be practical — a simple vegetable, like a tomato, would likely require tens of millions of different ingredient cartridges alone. “It sounds simple to say ‘we’ll have a fat cartridge,’ but there are hundreds of kinds of fats,” van Brommel explained.

And how does the culinary world at large feel about 3D food printers? I’ll let Tony Tantillo, food expert and contributor to CBS in New York, expresses a sentiment felt by many: “Those two things shouldn’t be together. ‘Printed food’ for a magazine, yes. But to eat? Nah, nah.” Vacarro thinks they might have a place… in cheap in-and-out joints. “If I think about what’s happening in fast food, there might be something there where some fast foods are printed instead of handmade,” he said.

But perhaps like any new technology, 3D food printers just take some getting used to. “When people first heard about microwaves they didn’t understand the technology,” Lynette Kucsama, Chief Marketing Officer at Natural Machines told Fortune. “Now 90 percent of households have microwaves.”

“When people first heard about microwaves they didn’t understand the technology,” Lynette Kucsama, Chief Marketing Officer at Natural Machines told Fortune. “Now 90 percent of households have microwaves.”

3D food printers may not produce great-tasting food right now, or be able to cook meals from scratch. Or have the wholehearted endorsement of the epicurean elite. But they’re getting better every year, and what they promise — sustainable, nutritional perfection — is worth the pursuit.

“I don’t see 3D food printing as a novelty. I see it as something that really will become a part of the culinary fabric for years to come,” von Hasseln said recently.

A lot changes in 70 years. Boulestin, like any great chef on the bleeding edge of gastronomy, would understand that.

3D food printing, pastry and food 3D printers

Food 3D printing, pastry and food 3D printers | project news 3DPulse.Ru3d pulse.ru

Our new report "Construction 3D printing in Russia" has been published

Our report "Construction 3D printing in Russia" has collected information about domestic companies and start-ups that produce. ..

..

Vladimir Viktorovich Molodin (SIBSTRIN): "The idea [of printing with polystyrene concrete] appeared three years ago, and it took 30 years to get there."

Interest in 3D construction printing is growing rapidly around the world, with most of the developed 3D printers working with...

Mass 3D printing of individual houses: reality or utopia? - public study by Techart group

In its public survey, Techart explores whether 3D printing can bring something really new to the construction industry...

Viktor Mann (RUSAL): "In Russia, additive manufacturing is one of the fastest growing industries"

RUSAL is a leading company in the global aluminum industry and the largest aluminum producer with a low carbon footprint. Her...

"3D Printing in the Oil and Gas Industry: Incentives and Constraints" - Techart Group Public Study

Techart Consulting Group published a study analyzing the current state and development prospects...

Current news

Food

3D food printer from Moscow scientists prints chocolate, cakes and nuggets

Scientists have created a 3D food printer with a system of "smart" recipes that prints food with specified properties. ..

..

Food

Wiiboox Launches $159 LuckyBot Food 3D Printing Extruder

Chinese 3D printer manufacturer Wiiboox has announced a new food 3D printing extruder.

Food

SavorEat and Sodexo to Pilot Robot Chef 3D Food Printer at US Universities

SavorEat, an Israeli startup developing plant-based alternatives to meat products through 3D printing,...

Food

Chocolate printer from STANKIN

Director of the Center for Work with Students Ramil Nezhmetdinov suggested that the guys from the team of the youth project office...

Food

Dry heat treatment of wheat starch produces hydrogels suitable for 3D printing

Brazilian scientists from the University of São Paulo and their French colleagues from the National College of Veterinary Medicine,...

Food

Cakewalk3d will teach a home 3D printer to print food

Cakewalk3d, founded by Marin Core-Baye, who previously served as Deputy Director of a well-known 3D service. ..

..

Food

"Meat of the future": KFC and 3D Bioprinting Solutions will print KFC nuggets on a bioprinter

KFC takes the next step in developing its innovative concept of "the restaurant of the future" and begins cooperation with...

Food

Startup Legendary Vish to commercialize vegan 3D printed salmon

An international group of students has developed a 3D printing technology that allows complex binders to be printed and...

Food

Redefine Meat introduces printed plant-based meat substitutes

Israeli startup Redefine Meat has unveiled the first plant-based Alt-Steak products. Supposed to be later in this...

?

3D printing events

Email:

By submitting this form, I consent to the processing of my personal data in accordance with Policy regarding the processing of personal data.

1 23...89Next

what lies ahead for 3D printing

The prospects for 3D printing

Even now, the prospects for 3D printing are extremely promising. Scientists are actively developing existing 3D printing techniques, developing new technologies and types of materials, and finding new areas of application. Many call 3D printing the technology of the future, and for good reason. The technique is able to completely turn the usual way of life, changing the way most things are produced. In fact, a 3D printer is a real multifunctional factory, small and compact. Due to this, the future of 3D printing can definitely be called successful.

3D printers can significantly reduce production costs, thereby reducing the cost of products. Judging by the growing trend towards the popularization of 3D technologies, raw materials for 3D printing will become the main commodity unit in the future. In general, the prospects for 3D printing are defined for many areas. And now we will try to reveal them as much as possible.

And now we will try to reveal them as much as possible.

The future of 3D printing

If you try to imagine the future of 3D printing, the imagination paints a rather interesting picture. Given the great interest of scientists in the 3D bioprinting technique, which is one of the most promising 3D printing technologies, the production of artificial organs on a 3D printer is not far off. It is also safe to say that the future of 3D printing will bring us dramatic changes in areas such as:

- Construction. 3D printing of houses, or contour construction, attracts many with its futurism and simplicity. The first steps in this direction have already been taken. The pioneers in 3D printing of houses were the Chinese, followed by the government of Dubai who discovered contour building. The first 3D printed office building has already been built in this city of the future, and an entire block is planned to be printed in the near future. And just recently, the first printed house in Europe was created on a 3D printer;

- Electronics.

When listing the prospects for 3D printing, this point should be given special attention. Scientists believe 3D printing of electronics is the future of digital device manufacturing, and with good reason. Graphene properties and its application in additive manufacturing are currently being actively researched. A huge breakthrough in this area is the creation of a graphene battery with an unlimited service life on a 3D printer;

When listing the prospects for 3D printing, this point should be given special attention. Scientists believe 3D printing of electronics is the future of digital device manufacturing, and with good reason. Graphene properties and its application in additive manufacturing are currently being actively researched. A huge breakthrough in this area is the creation of a graphene battery with an unlimited service life on a 3D printer; - Automotive and aerospace industry. The future of 3D printing is largely based on its ability to reproduce almost any element of varying complexity. In this regard, 3D printing is already widely used in the development of aircraft, machines and satellites. The ISS even has its own 3D printer, not to mention a number of successful 3D printing of cars.

- Pharmaceutical industry. Yes, yes, you can imagine. The future of 3D printing is in the manufacture of tablets and other medicines. This is confirmed by epilepsy pills legalized in the USA, made according to a special technique.

The essence of this perspective of 3D printing is the gradual release of active substances, so that instead of many tablets, you can drink just one.

The essence of this perspective of 3D printing is the gradual release of active substances, so that instead of many tablets, you can drink just one. - Food industry. 3D food printers are gradually gaining space in cafes and restaurants. While this is probably one of the most raw 3D printing technologies out there, it has potential. Food 3D printers are especially interesting for the possibility of making food for astronauts, as well as the freedom to display culinary talent. This is confirmed by the amazing 3D-printed desserts of our compatriot.

Other questions and answers about 3D printers and 3D printing:

- Finance Which 3D printer manufacturers are best?

- Finance Which 3D printer is better to buy?

The future of 3D printers

Now let's try to imagine the future of 3D printers. There are several important points to be noted here. Below we list the most likely scenarios for the future of 3D printers.

- Improving the reliability and quality of instruments. Surely, many users are looking forward to this, because most of the existing models of 3D printers cannot boast of uninterrupted operation and the absence of printing errors;

- Large distribution. It is certain that the future of 3D printers will please us with their popularization. Even now, one can observe a growing trend towards the use of 3D printing in almost all areas of industry. In parallel with the fact that more and more users learn about the possibilities of technology, the demand for desktop 3D printers is also growing;

- Availability. In continuation of the previous paragraph, it is worth noting that the growing demand for 3D printers will lead to lower prices for these devices. The use of 3D printing for domestic purposes is gaining momentum, which brings new equipment manufacturers to the market. Naturally, such a step will entail a reduction in the cost of devices;

- Enlargement of the construction area.

3D printing of large-sized objects has long occupied the minds of developers. Of course, this applies to industrial 3D printers, because the functionality of 3D printing at this scale will allow you to create full-fledged components, for example, cars and aircraft;

3D printing of large-sized objects has long occupied the minds of developers. Of course, this applies to industrial 3D printers, because the functionality of 3D printing at this scale will allow you to create full-fledged components, for example, cars and aircraft; - Expanding the range of available materials. The future of 3D printers depends a lot on 3D printing materials, because more means more possibilities. The development of special equipment and related materials is being carried out by many companies, and news about the release of new polymers is constantly appearing.

3D technologies of the future

Summing up, it remains to consider only 3D technologies of the future. These include various futuristic scenarios that, to one degree or another, are already beginning to develop today. These include the technique of virtual reality, 3D scanning to create the perfect clothes and shoes, 3D printed makeup, and more. In a way, 3D technologies of the future also include bioprinting.