Gemstone 3d scanner

guide and top 6 scanners

What is jewelry 3D scanning?

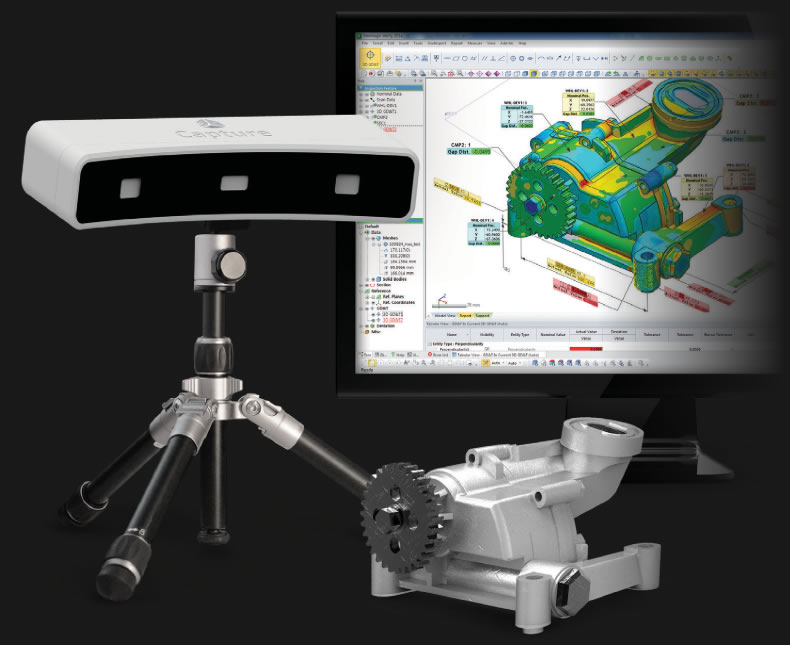

3D scanning is the process of digitally analyzing an object to obtain 3D information about its shape. A popular use of 3D scanning technology is jewelry 3D scanning.

This is the process of 3D scanning jewelry, precious metals, and gemstones with the goal of creating a digital copy of the original object. The digital copy can be used for many purposes, such as repairing or duplicating a valuable item.

3D scanners have been adopted as a supplementary tool by traditional jewelers, but the technology has also allowed newcomers to enter the field, many of which have combined 3D scanning with jewelry 3D printing.

This guide looks at some of the best jewelry 3D scanners on the market, in addition to discussing the various applications and benefits of 3D scanning jewelry.

A 3D scanned ring by B9 Creations. Source: B9 CreationsThe best jewelry 3D scanners in 2023

| Brand | Product | Accuracy | Country | Price Approximate starting prices based on supplier-provided information and public data. | |

|---|---|---|---|---|---|

| Shining 3D This brand is a certified partner from our network. | AutoScan Sparkle | 0.01 mm0.000394 in | China | $ 14,00014 000 €11,585 £1,886,584 ¥ | Quote |

| B9Creations | B9 Scan 350 | 0.015 mm0.000591 in | United States | $ 15,00015 000 €12,413 £2,021,340 ¥ | Quote |

| Polyga | HDI Compact C506 | 0.012 mm0.000472 in | – | $ 16,99015 982 €14,059 £2,289,504 ¥ | Quote |

| Medit | Solutionix D700 | 0.01 mm0.000394 in | South Korea | $ 25,00023 517 €20,688 £3,368,900 ¥ | Quote |

| Artec 3D | Micro | 0.01 mm0.000394 in | Luxembourg | $ 29,30027 562 €24,246 £3,948,351 ¥ | Quote |

| Evatronix | eviXscan FinePrecision | 0. 006 mm0.000236 in 006 mm0.000236 in | Poland | $ 35,00029 000 €28,963 £4,716,460 ¥ | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Accuracy | Max resolution | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|

| Shining 3D This brand is a certified partner from our network. | AutoScan Sparkle | 0.01 mm0.000394 in | 0.05 mm0.001969 in | China | $ 14,00014 000 €11,585 £1,886,584 ¥ | Get a quote |

| B9Creations | B9 Scan 350 | 0.015 mm0.000591 in | 0.052 mm0.002047 in | United States | $ 15,00015 000 €12,413 £2,021,340 ¥ | Get a quote |

| Polyga | HDI Compact C506 | 0. 012 mm0.000472 in 012 mm0.000472 in | 0.02 mm0.000787 in | – | $ 16,99015 982 €14,059 £2,289,504 ¥ | Get a quote |

| Medit | Solutionix D700 | 0.01 mm0.000394 in | 0.01 mm0.000394 in | South Korea | $ 25,00023 517 €20,688 £3,368,900 ¥ | Get a quote |

| Artec 3D | Micro | 0.01 mm0.000394 in | 0.029 mm0.001142 in | Luxembourg | $ 29,30027 562 €24,246 £3,948,351 ¥ | Get a quote |

| Evatronix | eviXscan FinePrecision | 0.006 mm0.000236 in | 0.028 mm0.001102 in | Poland | $ 35,00029 000 €28,963 £4,716,460 ¥ | Get a quote |

How jewelry 3D scanning works

Most jewelry 3D scanners are enclosed or partly enclosed desktop machines that offer ideal lighting conditions. Desktop jewelry 3D scanners almost always feature an automatic turntable, or auto-rotating table, on which the piece of jewelry is placed to be scanned.

Basic turntables only rotate at 360°, while more advanced, multi-axis turntable systems are able to tilt from side to side with multiple degrees of freedom. Hence, minimal manual input is required, and jewelers can 3D scan their objects at the click of a button.

In terms of technology, the majority of jewelry 3D scanners use structured light 3D scanning methods.

Structured light 3D scanners feature a light-emitting device (often a blue LED light) that projects a series of patterns onto the surface of the piece of jewelry. These patterns visibly deform according to the object’s surface and contours.

Meanwhile, a camera captures these deformed patterns, which are then processed by the scanner’s software to determine the jewelry’s precise geometry. The result is a 3D CAD model that can be modified, re-used, sliced for 3D printing, etc.

To recap, most jewelry 3D scanners feature the following characteristics:

- Desktop format with an enclosed or partly enclosed scanning area

- Automated thanks to a rotating table with one or multiple axes of movement

- Structured light technology with blue LED patterns

- High precision for complex details

Typical 3D jewelry scanning workflow

Put simply, a piece of jewelry is 3D scanned thanks to blue structured light technology. Then, the 3D scanner’s software creates a 3D model, which can then be exported to specialist CAD software suites for jewelers.

A typical workflow goes like this:

A typical 3D jewelry scanning workflow combined with 3D printing and casting methods. Source: eLUXE3DHere’s a deeper look into the major steps linked to 3D scanning jewelry.

1. Prepare jewelry

Left untreated, jewelry is difficult to scan, because a 3D scanner’s optical hardware has trouble processing shiny or reflective surfaces. Structured light patterns become distorted if reflected by the metal object.

This problem can be mitigated by spraying the jewelry with a temporary or washable matte coating (3D scanning spray).

2. Position jewelry

Most jewelry 3D scanners use an automatic rotating table (a.k.a. automatic turntable, multi-axis turntable), allowing the scanner to view the piece of jewelry from as many angles as possible.

The most detailed side of the piece should face upwards, where there is no physical contact with the turntable. In most cases, the user will have to flip the piece over in order for the scanner to capture the previously hidden surfaces.

3. Begin 3D scanning

Jewelry 3D scanners are packaged with 3D scanning software on which the user can launch 3D scans, operate the automatic turntable, and adjust scanning parameters (e.g. resolution).

Many of them enable one-click 3D scans and, thanks to auto-rotating tables, there is very little need for manual intervention.

4. Manipulate 3D model with CAD software

When a jewelry 3D scanner has completed scanning, its software creates a 3D mesh file (in STL file format, for example) of the piece of jewelry.

3D jewelry models are then commonly exported to a CAD software platform where the jeweler can edit or rework the piece, share it online, or simply store it digitally for future reference.

5. 3D print model

3D models obtained via jewelry 3D scanning can be 3D printed with the help of Stereolithography (SLA) 3D printing. SLA 3D printers are compatible with castable resins, which act as an alternative to wax in the direct investment casting process.

A jeweler can 3D print jewelry in castable resin, before surrounding the printed model with an investment material to make a mold. The 3D printed model is burnt out, leaving a cavity in the mold shaped like the original piece of jewelry.

Finally, the jeweler can pour molten metal — gold, silver, or bronze, for example — into the mold to create a new piece of jewelry.

In some cases, it can be possible to skip the casting process and print the piece of jewelry directly with a metal 3D printer.

Overview of the best jewelry 3D scanners in 2023

Here we provide a deeper look into each jewelry 3D scanner from our list.

Artec 3D, a Luxembourg-headquartered company with offices in Moscow and California, has been developing handheld and portable 3D scanners since 2007.

Their Artec Micro is an easy-to-use, high-precision desktop 3D scanner built for jewelry scanning, though it also has uses in dentistry and machine part scanning. A fully automated machine with one-click functionality, the Artec Micro scans with a point accuracy of up to 0.01 millimeters.

Artec’s versatile desktop 3D scanner scans items of jewelry using structured light technology: twin color cameras (6.4 megapixels) and a blue LED projector are complemented by a circular platform with a dual-axis swing-and-rotate system.

Real-time digital capture and previsualization is achieved using Artec’s dedicated software package, Artec Studio.

Contact manufacturer Get a quote Add to comparison

South Korean 3D scanner manufacturer Medit has been in the business for two decades, providing solutions mainly destined for industrial and dental customers.

The Solutionix D700 is a fully automated desktop 3D scanner targeted at non-industrial users such as jewelry specialists who need to scan very small objects. The D700 is the most advanced 3D scanner in the Solutionix D-Series range of products, with a higher resolution than the D500.

The D700 scans items of jewelry with structured light technology that Solutionix calls “phase shifting optical triangulation.” This involves scanning from multiple angles to capture the entire profile of the object, then using those images to create a triangle mesh.

The D700’s two 6.4 megapixel cameras can capture details in full color.

Contact manufacturer Get a quote Add to comparison

B9Creations is a 3D printing and 3D scanning company based in South Dakota. It has been creating 3D printers since 2011, and 3D scanners since 2018.

It has been creating 3D printers since 2011, and 3D scanners since 2018.

Designed specifically for the 3D scanning of jewelry and other small objects, the B9Creations B9 Scan 350 is an entry-level structured light scanner with 2-axis turntable rotation and an accuracy of 0.015 millimeters.

B9Creations states that the B9 Scan 350 can 3D scan any ring in less than five minutes. It achieves this using an LED projector with a brightness of 100 ANSI-lumens and a camera with a resolution of 1.3 megapixels.

Contact manufacturer Get a quote Add to comparison

The Polyga HDI Compact C506 is a professional plug-and-play 3D scanner made by Polyga, a manufacturer from Canada.

It is part of Polyga’s HDI Compact C series of three professional 3D scanners. Polyga HDI Compact 3D scanners use blue LED structured light 3D scanning technology to capture objects in less than a second. They are the next generation of HDI 100 3D scanners.

The HDI Compact C506 is ideal for 3D scanning very small parts in high resolution and accuracy. Indeed, it features two 5.2 monochrome MP cameras.

Contact manufacturer Get a quote Add to comparison

Shining 3D is part of the 3D scanning industry’s market leaders, producing 3D scanners (and 3D printers) since 2004. Their AutoScan series caters to a range of applications, with the AutoScan Inspec for metrology and the Sparkle version for jewelry.

This automated 3D scanner for jewelry features one of the largest scanning volumes of its category, and offers three degrees of freedom with its integrated turntable.

The AutoScan Sparkle comes with Shining 3D’s Ultrascan software for mesh exports but will require additional software for design purposes. Shining 3D namely lists Geomagic Design X, ZBrush, and Polyworks as suitable solutions.

Contact manufacturer Get a quote Add to comparison

The eviXscan FinePrecision is a desktop 3D scanner produced by Evatronix. Evatronix is a 3D scanner manufacturer based in Poland.

Evatronix is a 3D scanner manufacturer based in Poland.

The Evatronix eviXscan FinePrecision uses structured light technology.

Contact manufacturer Get a quote Add to comparison

Alternatives (other 3D jewelry scanners)

Here are a few other jewelry 3D scanning solutions from lesser-known manufacturers:

- Vylo Falcon3DX (South Korea)

- EGSolutions JScan 3 (Italy)

- eLUXE3D Gold 6.4 (United States)

3D jewelry software

After obtaining a 3D model from a 3D scan, jewelers may need to reverse engineer the mesh file into a new CAD format.

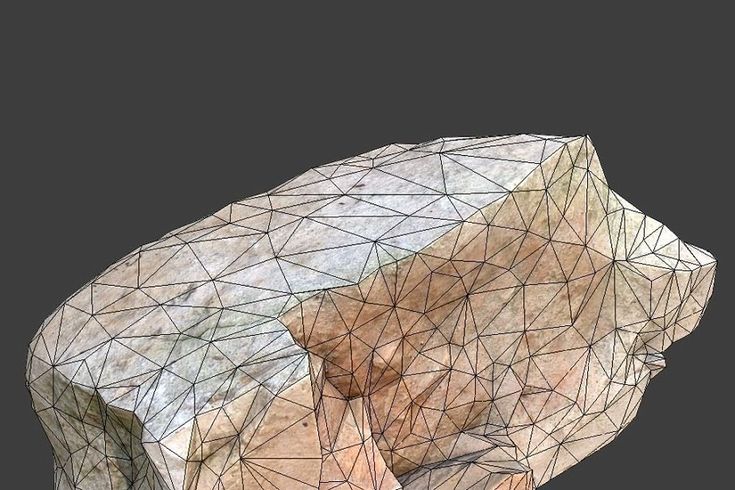

This is because mesh formats like STL interpret 3D models as an assortment of polygons, whereas actual pieces of jewelry tend to contain smooth, curved surfaces — not dozens of tiny triangles. CAD geometries like NURBS surfaces are better at representing these curves and are easier to edit.

The process of converting meshes into NURBS or subdivision surfaces is sometimes called retropology, and common tools for the practice include 3D Systems’ Geomagic X suite and the Mesh3Surface plugin for Rhino.

Once the scan has been converted, the jeweler can edit and rework the model.

Common CAD platforms used for jewelry design include 3Design, Rhino, and Matrix, while there are also a handful of jewelry-specific software suites such as Stuller’s MatrixGold and Gesswein’s JewelCAD, which provides features like automatic stone setting.

A brief look at file formats and 3D jewelry/design software suites. Source: D3D-SKey specifications for jewelry 3D scanners

There are several specifications to look into before purchasing a 3D scanning solution for metrology.

Knowing the important specifications of 3D scanning technology makes choosing the right jewelry 3D scanner much easier.

Terms you will frequently encounter include:

Scanning volume or field of view

The scanning volume of a 3D scanner is the size of the envelope in which it can detect the scanned object. The larger the volume, also called the field of view, the larger the objects it can scan.

The larger the volume, also called the field of view, the larger the objects it can scan.

Most jewelry 3D scanners have small scanning volumes.

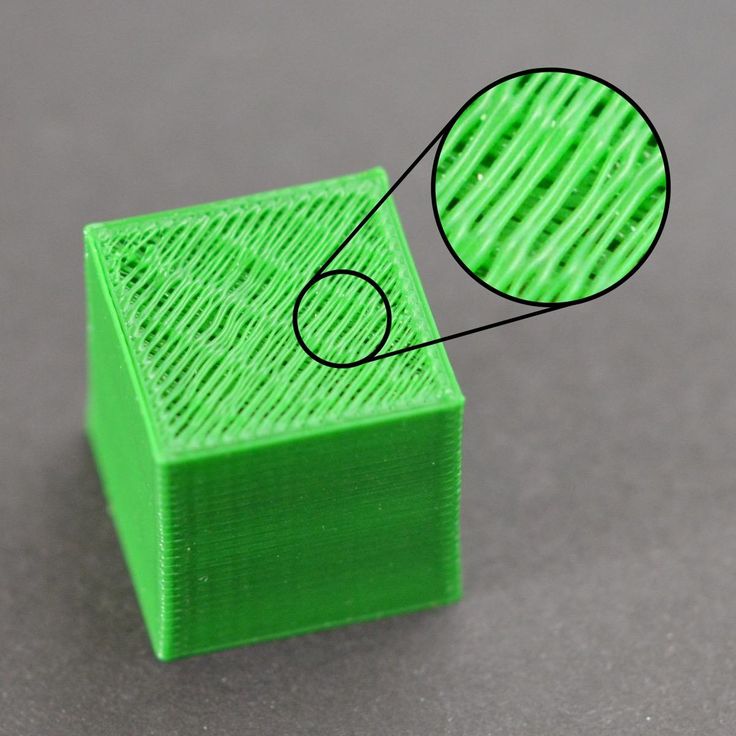

Scanning resolution

Measured in millimeters or microns, the resolution is the smallest possible distance between two points of a 3D scan. It is also called point-to-point distance or points per scan. A smaller number, therefore, represents a higher resolution and a greater level of detail in the finished 3D model.

There are two different kinds of resolutions: measurement resolution and mesh resolution. Mesh resolution is the most important kind to consider, as it will be the resolution of your final 3D model. Manufacturers are sometimes unclear about which resolution they are referring to.

Camera resolution

The scan resolution is directly affected by the resolution of the scanner’s camera since the camera is what captures the light deformation.

Camera resolution is measured in megapixels, and a higher number of megapixels means higher resolution. 3D scanners often have dual cameras.

3D scanners often have dual cameras.

Accuracy

Accuracy is the degree to which the dimensions of the digital scan match those of the physical object. It is measured in millimeters or microns, with a lower number translating into better accuracy.

Speed

In 3D scanning, speed is the amount of time it takes to 3D scan an object. It can be measured in seconds per scan or in measurements per second (number of 3D points captured in one second).

However, the chosen resolution, object size, and other parameters affect scanning speed.

Degrees of freedom/movement

A 3D scanner’s number of degrees of freedom is the number of directions in which its scanning bed can move by rotating and tilting from one side to another.

More degrees of freedom allow the scanner to automatically capture the object from a greater number of angles, resulting in a more accurate and more complete scan. This also allows professionals to save time, requiring less manual manipulation.

Jewelry 3D scanner price

Jewelry 3D scanner prices start at around $8,000 and can go up to over $30,000 for the most advanced systems. Resolution, accuracy, amount of movement axes,, and other factors all contribute to the scanner’s pricing.

It is also important to keep in mind that 3D scanning software always requires powerful laptops in terms of RAM, graphics card, etc. If you are not well equipped, you may need to allocate several thousand dollars of your budget to a new PC.

A metal ring made with a castable 3D printed model. Source: FormlabsApplications of jewelry 3D scanning

Jewelers use 3D scanners for many reasons. Some of the more common uses of jewelry 3D scanning include:

Heirloom reproduction

Using a 3D scanner, it is possible to create a 3D model of a valuable piece of jewelry, which can then be used to create a replica using 3D printing and casting techniques.

Customers may wish to create copies of a family heirloom to give to other family members, or so they can wear the duplicate while keeping the original safe.

Matching wedding bands

Many customers demand wedding bands that match the scale of their engagement ring. By 3D scanning the engagement ring, it is easy to create a matching wedding band using the digital model.

Stone setting

Jewelers often need to create new rings and settings for existing precious stones. By 3D scanning the gemstone, the jeweler can use the 3D model to create a setting that perfectly fits the stone.

Quality control

Even jewelers committed to traditional techniques may find 3D scanning useful as a tool for quality control. By scanning finished pieces, the jeweler can accurately measure overall dimensions and detailed features (a.k.a. metrology).

Reverse engineering and repairs

3D scanning jewelry allows jewelers to take an existing piece and build on the digital model in various ways. They may use the 3D model to create a new piece with modifications or to repair a damaged piece.

Archiving, concept showcasing, distribution

Once a jeweler has obtained a 3D scan of an item of jewelry, the digital file can be stored on a hard drive for safekeeping or uploaded to the internet.

Some modern jewelers sell their creations as digital files, allowing the customer to print the design themselves or through a 3D printing service.

Unique advantages of 3D jewelry scanning

3D scanning jewelry has benefits for both jewelers and customers when compared with traditional methods of jewelry creation, jewelry repair, and jewelry commerce.

- Speed: The speed that 3D scanning provides is vital for jewelers, who might otherwise spend many hours manually designing a piece to a similar level of detail.

- Accuracy: If a scanner is properly calibrated, it can reach a high level of accuracy. This is especially important with, for example, custom rings designed to fit the customer, or for perfect-fit gemstone settings.

- Permanent record: 3D scanning produces a permanent digital record of a piece of jewelry which can be revisited at any future point.

- Efficiency: Scanning is efficient because it only needs to take place once, even if thousands of duplicates will be made with the resulting digital file.

- 3D printing: 3D scanners can export files into a 3D printable format such as STL. Jewelers can use a 3D printed wax model to create a functional metal cast.

Current limitations of jewelry 3D scanning

Jewelry 3D scanning is still a new and developing process, and there are several areas where it could — and will — improve.

- Post processing: Even high-end 3D scanners produce partially incomplete models, and it is almost always necessary to fine-tune the resulting model (hole filling, smoothing, etc.)..

- Reflective surfaces: The shiny surfaces of metal objects reflect LED projections and lasers, confusing the data received by the scanner. Applying matte spray, which is the most common solution to this problem, is not always feasible with delicate or fragile pieces.

- Material recognition: A scanner cannot yet differentiate between metal and a precious stone. This means, for example, that a diamond ring is processed as one solid shape, not as one object (diamond) within another (ring).

- Formats: Exported file formats like OBJ and STL may present compatibility issues, since they are not easily editable like a CAD file.

- Conversion: Converting a mesh or point cloud into a 3D model is much more difficult than converting in the opposite direction.

FAQ

How do you scan jewelry?

For professional-quality jewelry 3D scanning, you need a dedicated jewelry 3D scanner or a scanner designed to scan small objects.

Which 3D scanners are best for jewelry scanning?

Most dedicated jewelry 3D scanners are structured light scanners, which use high-resolution cameras and LED projectors.

Will all jewelry be 3D printed in the future?

Combining 3D scanning with 3D printing allows jewelers to create new pieces using the traditional investment casting process. 3D printing is not yet used to print the actual piece of jewelry, although there are a few exceptions (plastic pendants, for example).

Can you 3D scan a wedding ring?

Jewelers frequently use 3D scanning to create wedding bands that match an engagement ring in size and style. Wedding rings can also be saved as digital files or duplicated.

Wedding rings can also be saved as digital files or duplicated.

The Best Jewelry 3D Scanners [2022]

Jewelry 3D scanners have revolutionized how jewelers approach the task of repairing, reproducing, and designing rings, bracelets, fittings, mounts, and so much more, saving both time and money in the process.

Fast, efficient, and incredibly easy to use, they are arguably one of the most critical advancements in the industry in recent years.

You’ve come to the right place if you’re looking to level up your jewelry service with some bleeding-edge technological help. This guide will highlight a curated selection of the best jewelry 3D scanners currently available.

We’ve covered a range of price points to suit both solo jewelers and larger setups with cash to throw around, but all these are strong picks regardless of their price tag.

Why 3D Scan Jewelry

Jewelers can obtain highly-accurate, quick, and relatively cheap digital models of existing jewelry pieces and gemstones thanks to a 3D scanner.

This digitization of jewelry has many benefits and uses for jewelers, chiefly replication, adjustments, design, and repairs, or to fast track the creation of high-resolution resin, silicone, or wax molds for traditional molding and casting.

Uses of 3D Scanning Jewelry

Replication/Duplication: Using a jewelry 3D scanner to create a digital model of an antique, custom, or heirloom piece allows a jeweler to quickly and easily create a duplicate.

This can be done both as insurance for precious items or to create a copy for customers to wear while the original remains under lock and key for safekeeping.

Repairs: An editable and modifiable 3D model of a broken piece of jewelry allows jewelers to create modified, custom molds to cast a replacement.

With a 3D model, jewelers can also quickly take stock of what needs repairing without dismantling the piece.

Design: 3D scanning opens new opportunities in the jewelry design phase. With the ability to scan objects from the world around them, jewelers can quickly and cheaply experiment and prototype new designs and ideas.

With the ability to scan objects from the world around them, jewelers can quickly and cheaply experiment and prototype new designs and ideas.

From personalized pieces for specific customers to radically new designs, jewelry 3D scanners blow the creative possibilities wide open.

Setting: By scanning stones, jewelers can create settings, rings, and designs perfectly sized and shaped to fit.

Similarly, 3D scanning existing engagement rings to capture fit and design details greatly simplifies the creation of matching wedding bands.

Quality Inspection: 3D scanning pieces or even molds to obtain exact measurements allows jewelers to pick up on discrepancies or faults and implement adjustments before committing to an entire production run, saving time and money.

Archiving: 3D scanning jewelry is a cost-effective way to create a digital archive for valuation, insurance, or the conservation of degraded old pieces prone to decay.

How Jewelry 3D Scanners Work

Jewelry 3D scanners employ structured light technology, much like traditional 3D scanners.

The scanner beams a light pattern, usually an LED, onto the object’s surface. A rotating turntable ensures the light hits the object from all angles.

A set of cameras record how the object distorts, deforms, and reflects the light, translating it into a 3D model matching the object’s dimensions and shape via software.

Aside from placing the object on the turntable and triggering the scan, the process is often completely automated.

Jewelers can then edit and modify that 3D model in design software such as a CAD suite for replication, repairs, 3D printing, wax/resin castable models, etc.

Best Jewelry 3D Scanners

Artec Micro

- Price: $29,000-$30,000

- Accuracy: 0.01 mm

- Resolution: 0.029 mm

- Max Scan Volume: 90 × 60 × 60 mm

- Technology: Structured light

The Artec Micro is a professional, fully-automated desktop-sized 3D scanner with usability and precision at its core.

The Artec delivers pristine models up to 0.01 mm accuracy and a sharp, detailed 0.029 mm resolution with one simple click.

The Artec Micro comes housed in a single all-in-one semi-enclosed shell, fitted with a height-adjustable dual-axis turntable that both pitches and rotates to capture an object’s intricacies.

There are two dual-color cameras, and a blue LED light source capable of scanning in full color.

The Artec Micro has an automatic mode that chooses the optimum scanning path and frame count to keep both scan times and 3D model file sizes to a minimum.

Artec Studio, the software suite that comes with the Micro, offers useful functions such as real-time in-progress scan preview and easy model exporting to all the most popular CAD software.

Though the Artec Micro is suited to various applications, it hits its stride with jewelry thanks to the ability to take an intricate piece such as a brooch, ring, or single gemstone and create a high-precision digital equivalent in minutes.

From there, jewelers can tinker and modify the 3D model for repairs, replication, refitting, and more.

Medit Solutionix D700

- Price: $24,000-$25,000

- Accuracy: 0.01 mm

- Resolution: 0.029 mm

- Max Scan Volume: 90 x 60 x 60 mm

- Technology: Structured light

Designed and manufactured by Medit, the Solutionix D700 is a professional-grade semi-enclosed 3D scanner particularly well suited to jewelry.

It specializes in the scanning of small objects with complex geometries.

The Medit Solutionix D700 excels at capturing the surface intricacies of a gemstone, fine details and all, at the high level of precision required by jewelry applications.

It does this thanks to a crisp 0.029 mm resolution allied to a 0.01 mm accuracy, powered by a duo of 6.4 MP cameras and a blue LED light source.

Like the Artec Micro, the Medit Solutionix D700 aims to deliver effortless scanning. Firing up a scan is as hands-off as it gets, requiring you to position the object on the turntable and click once to start scanning.

Firing up a scan is as hands-off as it gets, requiring you to position the object on the turntable and click once to start scanning.

The scanner automates the rest of the process, scanning objects from multiple angles to create a complete triangle mesh with vivid color texture, exportable to CAD software.

Other notable features include automatic calibration, a scanning path generation tool, and active synchronization.

B9 Scan 350

- Price: $13,000-$15,000

- Accuracy: 0.015 mm

- Max Scan Volume: 90 x 80 x 55 mm

- Technology: Structured light

With the B9 Scan 350, B9 Creations are solely focused on providing a 3D scanner suited from the ground up for jewelry.

It’s a desktop-sized option that ships in a compact, fully-enclosed body designed to provide the perfect environment to capture every facet and angle of a piece in great detail.

On the technology side, the B9 Scan 350 combines a blue LED 100 ANSI-lumen structured light, dual 1. 3 MP cameras, and a two-axis turntable for 360° scans.

3 MP cameras, and a two-axis turntable for 360° scans.

The machine pushes a 0.015 mm accuracy – a bargain considering it costs nearly half the price of market-leading options like the Artec Micro.

It requires minimal setup and the bundled Leios 2 software works a treat, processing high-quality scans in minutes.

Whether you’re reproducing heirloom jewelry, scanning gemstones, or repairing, the B9 Scan 350 is a solid and relatively affordable choice.

Shining 3D AutoScan Sparkle

- Price: $13,000-$14,000

- Accuracy: 0.01 mm

- Max Scan Volume: 100 x 100 x 75 mm

- Technology: Structured light

Another scanner designed exclusively to capture the intricacies and detail of jewelry, the AutoScan Sparkle comes from Shining 3D, one of the leading brands of industry-grade handheld scanners.

With that know-how transferred to the AutoScan Sparkle, the company has created a compact desktop machine that, through a combination of AI scanning algorithms, one-click scanning, and powerful JewelScan software, makes easy work of creating digitized versions of even the most complex jewelry pieces.

The AutoScan Sparkle features a three-axis multi-angle scanning turntable, blue LED light source, dual 5.0 MP cameras, 0.01 mm metrology-grade accuracy, and, unusually for jewelry 3D scanners, an above-average 100 x 100 x 75 mm scannable area.

A sleek, compact design with a hinged front panel sees it meld seamlessly into any jewelry workshop or design studio.

Like the B9 Scan 350, the AutoScan Sparkle hits a price point that’s appealing to jewelers on a tight budget, especially considering you won’t find a three-axis turntable on those pricier alternatives.

Aurum LT

- Price: $17,000-$18,000

- Accuracy: 0.01 mm

- Resolution: 0.086 mm

- Max Scan Volume: 110 x 95 mm

- Technology: Structured light

With a focus on capturing highly-detailed scans of small, complex objects such as jewelry, Open Technologies’ Aurum LT is another jewelry 3D scanner well worth adding to your shortlist.

It easily captures all the fine detail of even the most complex gemstones.

The Aurum LT boasts one of the largest scannable areas on the market, hitting a roomy 110 x 95 mm.

While not the best out there, the 0.086 mm resolution is sufficient for producing detail-rich scans of everything from bands to odd-shaped gemstones.

It also features a 360° turntable, two 2.62 MP cameras, one-click scan triggering, and the Open Technologies’ Optical RevEng software, which is stacked with mesh repair options, alignment profiles, and exportable formats for CAD editing.

D3D-s 3D Jewelry Scanner

- Price: $6,000-$8,000

- Resolution: 0.010 mm

- Max Scan Volume: 100 x 130 mm

- Technology: Structured light

Born of a successful Kickstarter campaign, the D3D-s 3D Jewelry Scanner is one of the most affordable jewelry 3D scanners available.

D3D-s offers such a low price by producing in small batches to keep costs down without sacrificing the quality of the scanned models.

Instead of the industry-standard light pattern scanning method, the D3D-s Jewelry Scanner uses LED-line technology to create a more uniform capture.

The scanner has six degrees of freedom, meaning it can tilt and rotate to capture every aspect of an object for a complete scan with next to no user input.

It features a 5 MP camera capable of a 0.010 mm resolution, a roomy 100 x 130 mm scan area, and compatibility with in-house D3D-s-developed software that allows export to popular CAD suites like Blender, Maya, ZBrush, and many others.

FAQs

Can you 3D scan a wedding ring?

Yes, absolutely.

Scanning both wedding rings and engagement rings is a service a steadily growing number of jewelers are starting to offer, whether to create custom-fitted wedding bands or produce a striking ring at a much lower price.

Additionally, 3D scanning allows jewelers to create 3D models of heirloom wedding rings passed down through the generations for repairs, replication, insurance against loss or irreparable damage, or replacing an aging fitting.

How to choose a 3D scanner for jewelry?

When choosing a jewelry 3D scanner, consider specifications such as accuracy and resolution.

These largely determine what jewelry you can scan and the quality and precision of these scans. We recommend at least a 0.01 mm accuracy and a 0.2 mm resolution for solid results.

Price is also a significant consideration. You can expect to pay anywhere from $8,000 for the lowest cost professional jewelry 3D scanner to $30,000 for the most advanced, high-precision options.

How easy is it to 3D scan jewelry for 3D printing?

Extremely so.

Most jewelry 3D scanners feature one-touch scanning. The process is automated, leaving you with a 3D model that you can quickly process into a format compatible with a high-resolution resin SLA 3D printer.

Choose your object, place it on the scanner, trigger the scan, then process the results via software to obtain the model.

Although we recommend some experience, the process is unlikely to overwhelm first-timers thanks to clear instructions, user-friendly functionality, and intuitive controls.

Other articles you may be interested in:

- The Revopoint POP 2 hands-on review

- The best cheap 3D scanners

- DIY 3D scanners and 3D printable 3D scanners reviewed

- The best 3D scanner apps

Application of a 3D scanner in the jewelry industry

Jewelry industry

Author: Semyon Popadyuk

Author: Semyon Popadyuk

Who can benefit from 3D scanning? In short, everyone involved in manufacturing, design, engineering, development or testing. 3D scanning technology can be applied at any stage of the production cycle - from concept development to quality control - saving time, money and materials. 3D scanners produce better, more precise parts that are also cheaper to manufacture. The cost of the product design and production cycle can be reduced by 75%. Let's take a look at a few examples of the benefits 3D scanning gives to jewelry designers.

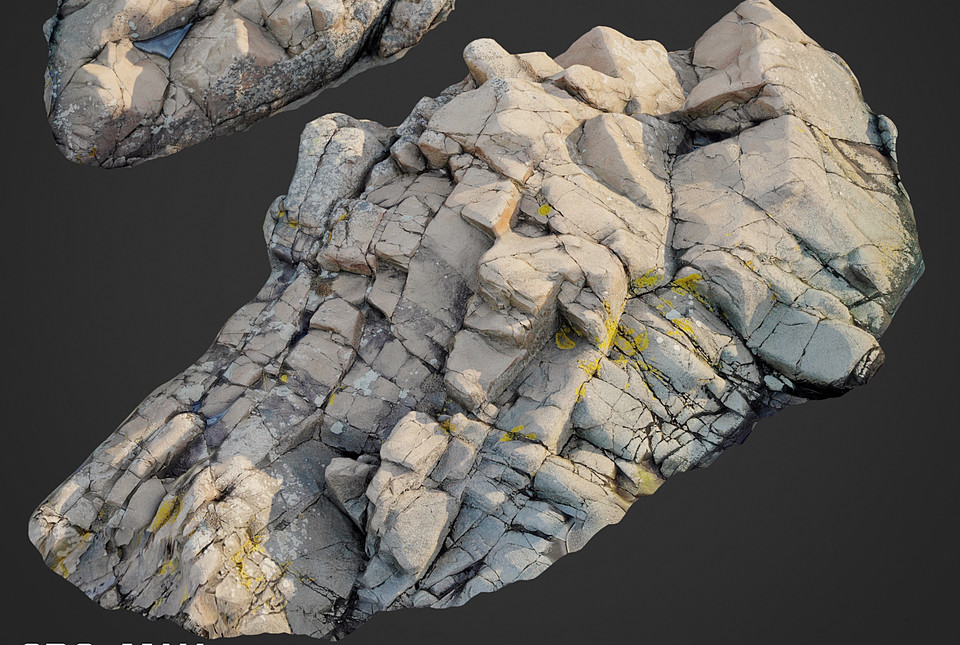

Photo 1. An example of a complex shape

Some shapes, such as the one shown in photo 1, are difficult to model in Rhino3D. It takes a lot of time to recreate in the right proportions objects of nature, such as animals and especially plants, a lot of time. In such cases, a 3D scanner can greatly simplify the modeling process.

It takes a lot of time to recreate in the right proportions objects of nature, such as animals and especially plants, a lot of time. In such cases, a 3D scanner can greatly simplify the modeling process.

The trick is to first handcraft the form layout, then scan it and load the file into Rhino3D to model the rest of the elements. This method makes it easier to create naturally shaped jewelry, as well as making subsequent changes.

Watch video : the new 3D scanner for jewelers Solutionix D500

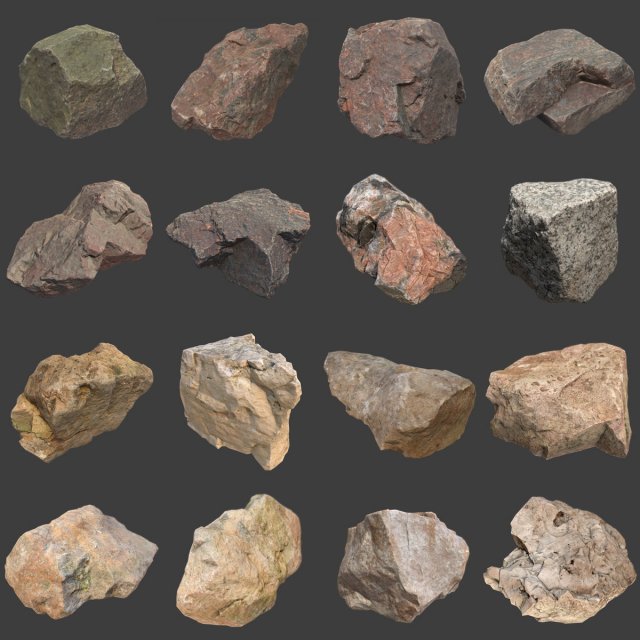

Photo 2. Working with natural materials

The same principle can be applied when designing prongs for loose stones or for gemstones of irregular shapes and sizes. 3D scanning of the stone allows to obtain its exact dimensions and shape, which is necessary for the precision design of the prong setting. Consider the technique of using a 3D scanner as a modeling tool.

Making a bird brooch using clay

Photo 3. 3D printing process

3D printing process

First you need to give the clay the desired shape. In this case, the main attention should be paid to the overall balance and expressiveness of the image of the bird. Work on finer details will take place in the simulation program. Using the scanned data as input, the product model must then be reproduced in the simulation program. At this stage, it is also necessary to provide places for installing stones.

Photo 4. Finished product

A 3D scanner makes the process much easier and faster than traditional image modeling. In addition, the finished product has natural-looking surfaces, which are difficult to achieve by creating the product exclusively in a computer program.

Designing a prong for baroque pearls

In this case, the task is to create a prong setting for securely fastening a pearl with an uneven surface. The work was done in the Z-Brush program.

First you need to get a 3D scan of the pearl, as shown in photo 5, then duplicate the scan data and hide one layer.

Photo 5. Scanned image of a baroque pearl

Photo 6 Cropping scan data

Photo 7. Thickening of the backtack

Photo 8. Finished prong setting

Photo 9. Finished prong setting (another angle)

The upper part of the pearl must be cut off, leaving only the lower part, which will become the setting. See photo 6.

Increase the thickness of the remaining part, as shown in Figure 7. If you make the duplicate image of the pearl visible again, it will be set in a bartack.

The traditional way to create a prong setting for irregularly shaped stones was to use:

- or molten wax to make an impression of the stone surface;

- or manually adjusting the setting to the stone.

Thus, the 3D scanner significantly reduces the manufacturing time and allows you to get a more accurate result.

Additional advantages of 3D scanning in jewelry production:

- high-precision scanning of models with a small size and many small details;

- easy and fast jewelry recovery;

- obtaining a 3D model in the automated mode of "gluing" images;

- ease of use with 3D scanner software;

- the ability to quickly make adjustments to the 3D model at the design stage;

- creating a digital archive.

Material provided by Solutionix

Article published on 12/13/2017, updated on 04/08/2022

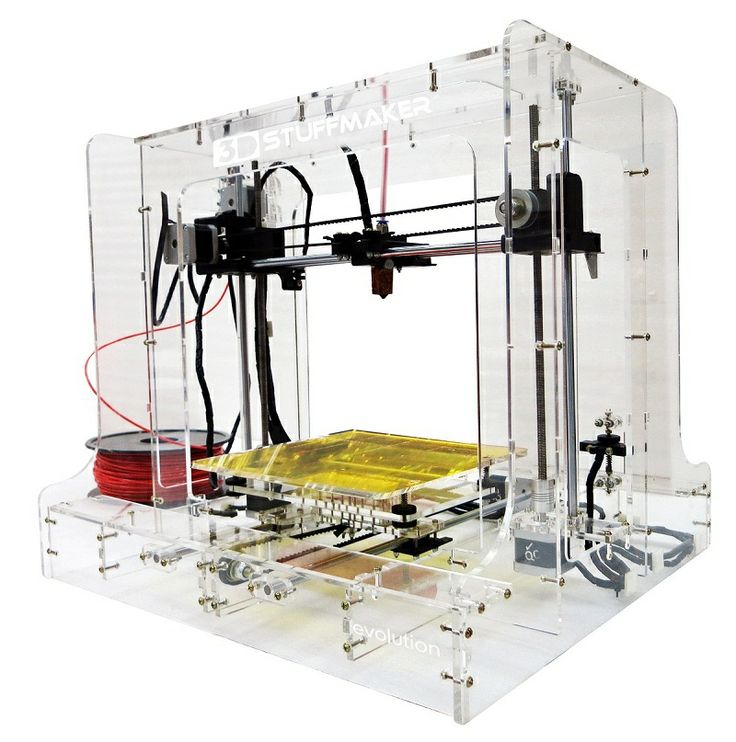

Created the most accurate 3D scanner | Jewelry INFO

07/05/2019 03:53 Production

Ukrainian inventor Leonid Nazarenko and his son Denis create a high-precision 3D scanner for jewelers. It has no analogues in the world in terms of price and quality.

The story of two inventors began about four years ago when they wanted to get high-precision 3D models of small objects, such as coins or figurines. But faced with the fact that the laser scanners available on the market, firstly, are very expensive, and secondly, their accuracy left much to be desired.

The very idea of the scanner was born when Denis Nazarenko was trying to make a model of the statue of Manjushri. “But scanners capable of capturing the smallest details of a model cost at least 17,000 euros and were out of reach for a small company. So we decided to create our own,” the Kickstarter presentation reads.

So we decided to create our own,” the Kickstarter presentation reads.

Who are Nazarenko

In a small office in the town of Vyshneve near Kiev, father and son set about experimenting. The background allowed them to use deep knowledge from completely different engineering fields.

Leonid Nazarenko began his career at the Antonov plant, which built the world's largest An-225 aircraft. He created models of aircraft from childhood, and then taught schoolchildren to do the same. Leonid had a good understanding of metalworking and a wide range of knowledge in engineering disciplines.

Denis Nazarenko won various competitions in mathematics, physics and computer science. He has been working on software development for many years. And his most famous project is Start Menu X, a convenient alternative to the Windows Start menu, which has been used by many people around the world.

LED vs Laser

Two engineers found that a laser projector creates a lot of noise when scanning, which is detrimental to the quality of the 3D copy. And he has a worthy alternative. The light-emitting diode (LED) beam in combination with good lenses made it possible to achieve noticeably better results.

And he has a worthy alternative. The light-emitting diode (LED) beam in combination with good lenses made it possible to achieve noticeably better results.

This photo shows how much noise the laser beam has compared to the LED beam:

Another bonus. This technology does not require expensive projectors and cameras.

Entrepreneurs decided to take their idea to Kickstarter through a partner who lived in Canada. Last spring, they managed to raise over $22,000 to produce their first model, the D3D-s desktop 3D scanner.

According to Denis Nazarenko, who was contacted by the journalist of Liga.Tech , together with his father, they collected and delivered about 10 scanners to investors who supported them with money on the crowdfunding site. A few pieces are still being finalized.

Fashion for second rings

According to Nazarenko, during this time they managed to find the exact niche for their devices - the American jewelry market. According to him, the tradition of wearing so-called shadow wedding bands is widespread in the States. These are additional rings that spouses order in addition to engagement rings, for example, for a wedding anniversary, and then both of them are worn on the same finger.

According to him, the tradition of wearing so-called shadow wedding bands is widespread in the States. These are additional rings that spouses order in addition to engagement rings, for example, for a wedding anniversary, and then both of them are worn on the same finger.

In such cases, jewelers need to scan the engagement ring and actually make a replica of it.

Antique ring scanned with D3D-s scanner by D3D-s on Sketchfab

Ukrainian inventors started receiving requests from jewelers and dentists. Such niche demand prompted Nazar and Denis to launch their second Kickstarter campaign - a 3D scanner specifically for jewelers. They launched it a week ago, at the end of June 2019, and have already collected the requested amount - $13,600 out of $15,000. The project was supported by eight people who wanted to get a jewelry scanner. The first supporters will get it for $4000-6000. And in retail, the device will already cost $8,000

“The D3D-s scanner is suitable for both self-employed jewelers and professional teams with experience using ultra-expensive scanners,” the developers note in the project description.

According to Denis Nazarenko, a 5 megapixel camera is installed in the scanner, which is much cheaper than a less accurate 1.2 megapixel camera designed for laser scanners.

Another innovation is mobility. The scanner also has six directions for movement. This allows you to scan figures of any complexity with a light beam. Scanning is fully automatic. You just need to specify the size and click the button.

“When we created the desktop scanner, we wanted to achieve a resolution that would allow us to scan a coin. As a result, adapting the scanner to the needs of jewelers was not a problem. We have added another axis of rotation and reduced the size of the scanner. We've also upgraded the optics and camera, as jewelers don't need color scanning. We also installed high-precision motors,” the developers of the device say.

The price of the device is much cheaper than analogues. The closest model is B9Scan 350 - will cost almost $15,000.