3D printing durban

3D Printing Service Durban | Instant Quotes Online

Our 3D printing capabilities

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

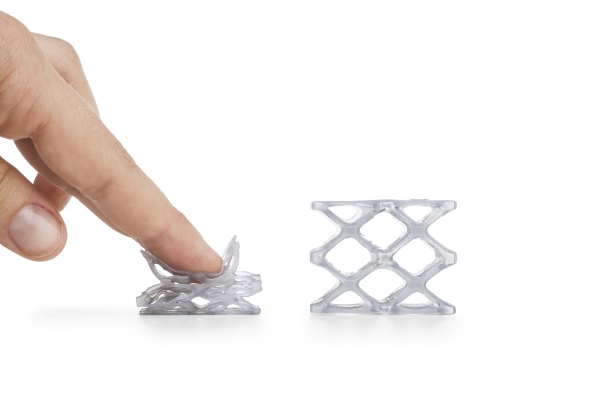

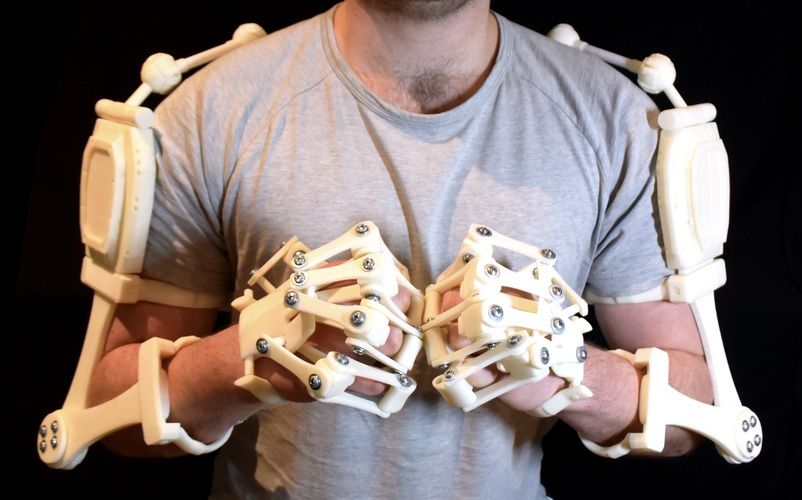

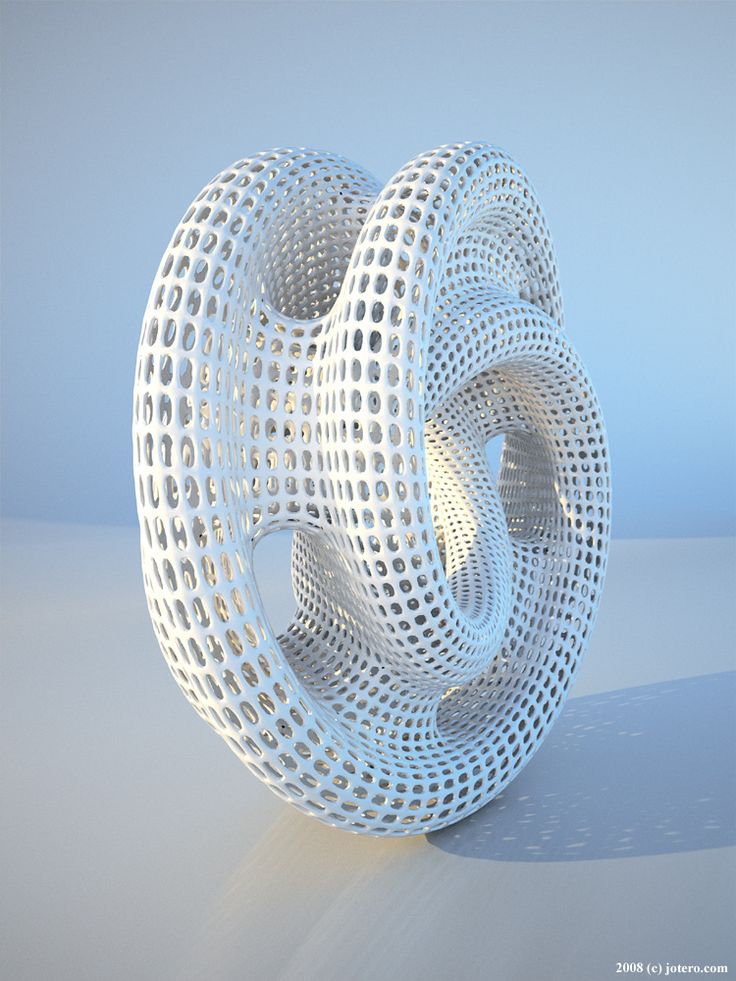

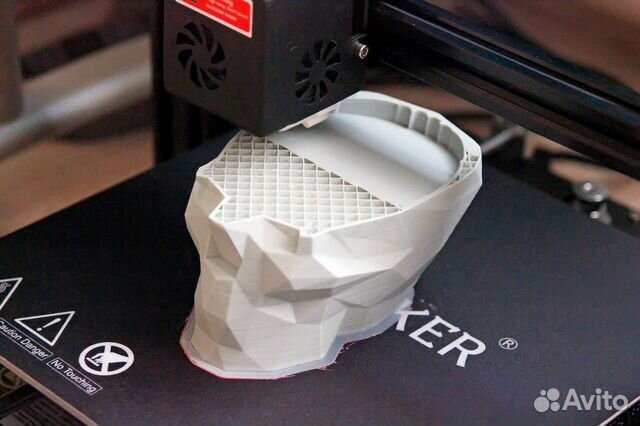

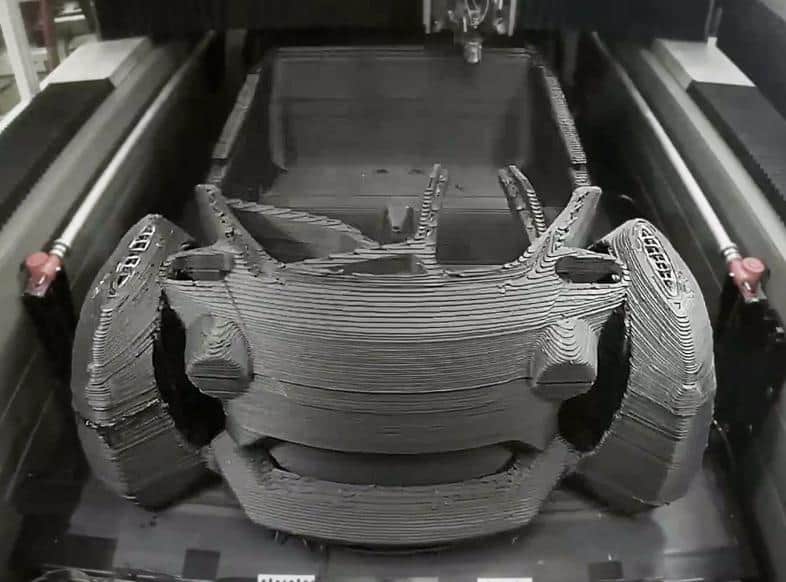

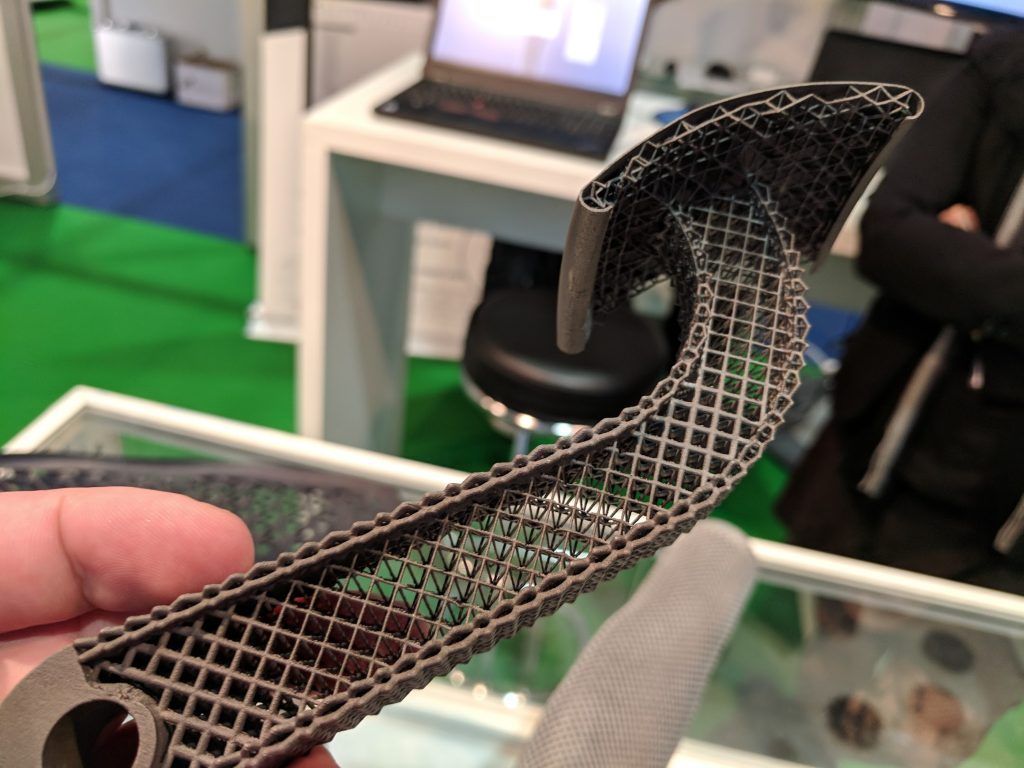

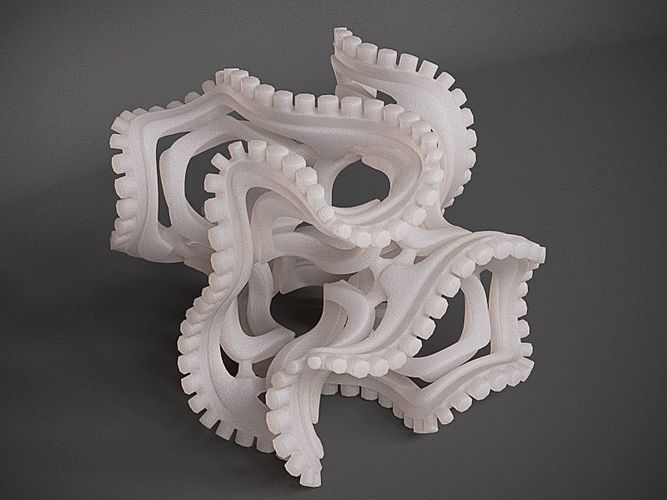

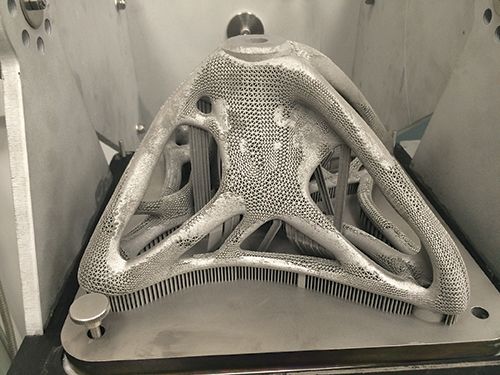

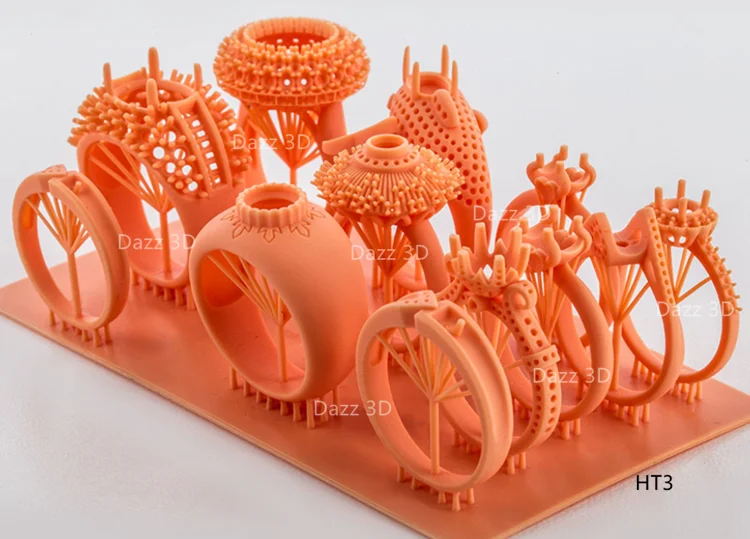

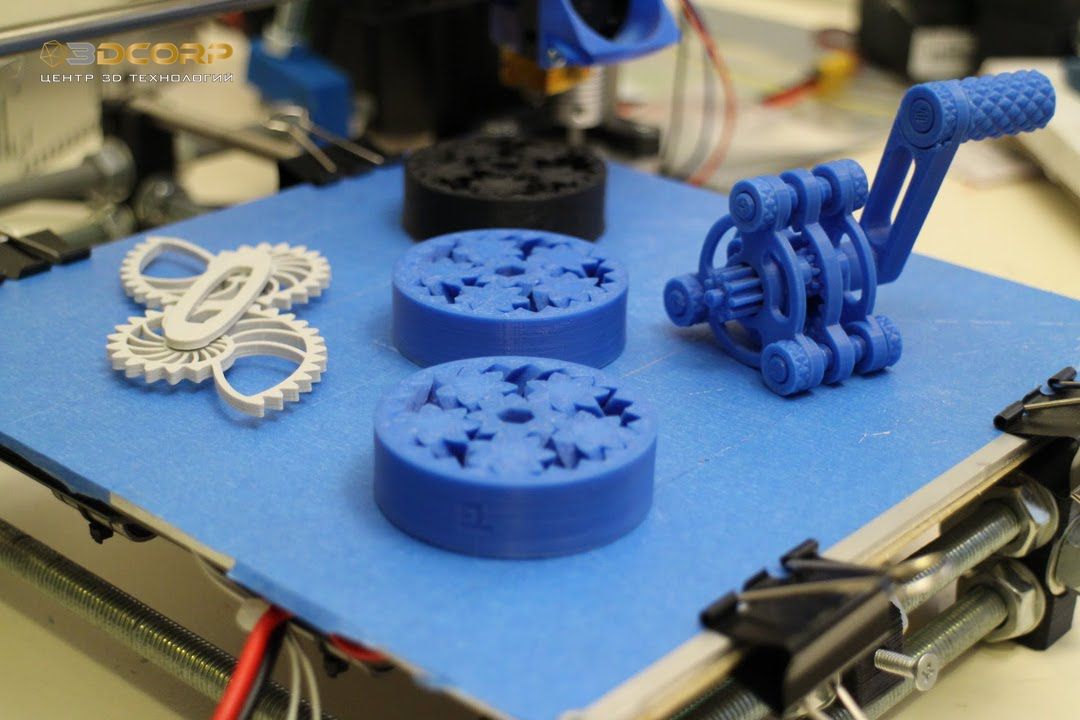

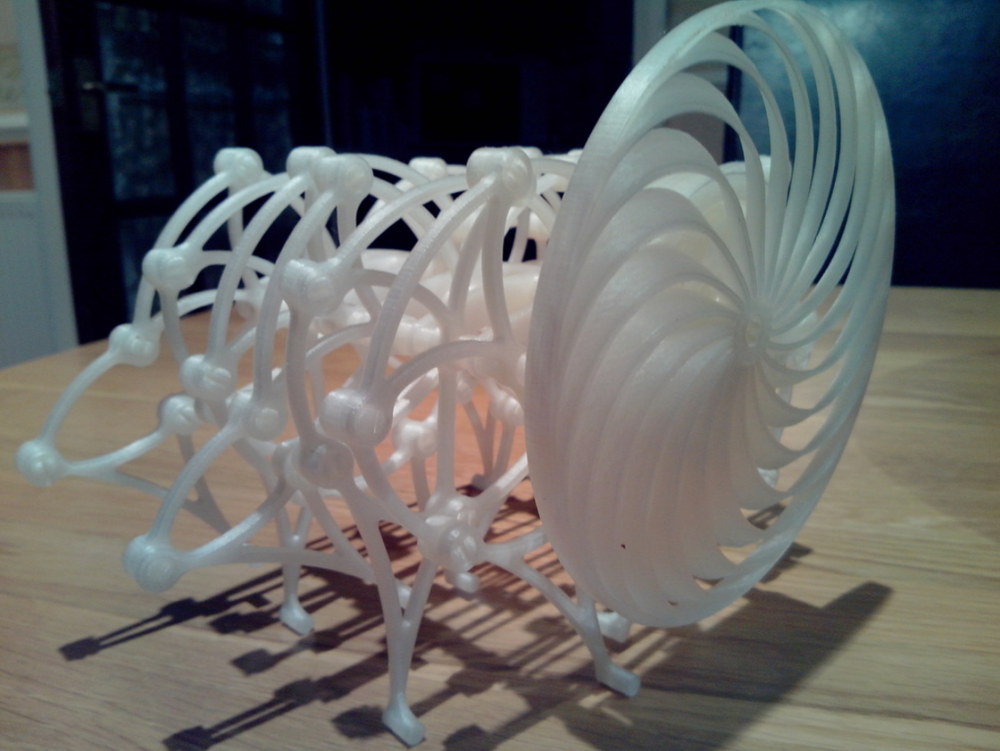

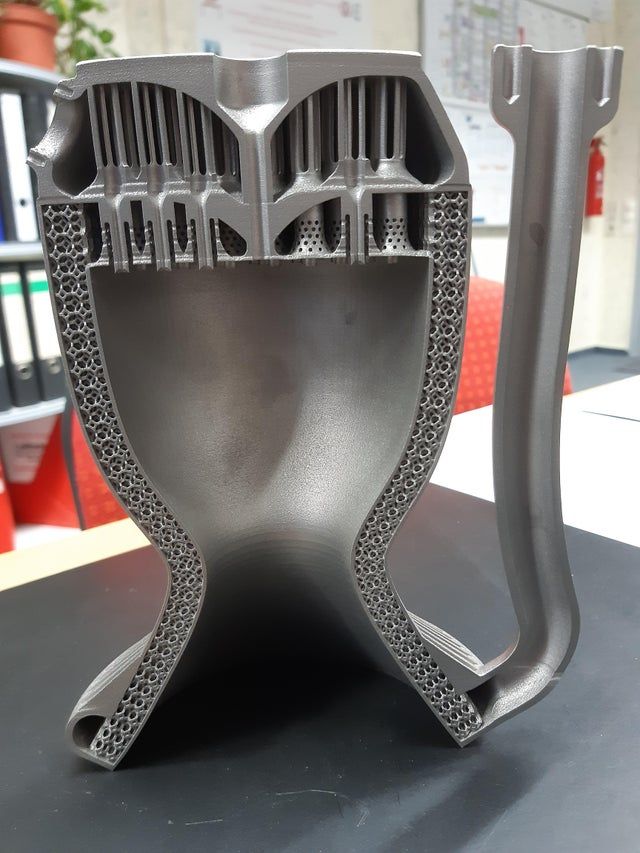

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc.

.

. -

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 193 customers are satisfied with our 3D printing service.

“Absolutely perfect, came out just right. ”

“Excellent service! And quick turn around time!”

“Great service, timely responses, good quality prints and amenable to additional request to make a project come together without hassle ”

“Very efficient in both responding to orders and printing.”

“Very fast turnaround. Great print quality.”

“Awesome service as usual. Thank you Jason”

“Great servece, great print quality, awesome reaction time. Just all round a great experience.”

“Thank you for your prompt response and all-round great service!”

“Even with some of the lifting issues of my design, the print came out perfectly. Great to deal with and super communication.”

“Quality is good, service and communication are good.”

“Amazing service and will continue using it.”

“Perfect print, great communication, fast delivery”

“Very good quality, happy to deal with them, i recommend them for any one who need 3d printing”

“Outstanding job! Will order again next time. ”

”

“Great service! Everything came out nicely. Thanks!”

“Amazing company. Fast work, friendly personnel, best prices, impressive quality. ”

“I had a tight deadline and they supported me and delivered ahead of schedule. Happy with the result ”

“Great job, quick service, will use again. Very happy”

“Great service and transparency with regards to operations and product delivery with great quality print to boot. ”

“I would recommend this hub. Excellent service. ”

“The serivce was outstanding and I would recommend it!”

“Got the product in good quality. Recommended place for students and people who want 3D Printing at a nominal rate.”

“Super professional. And good-looking too.”

“Great supplier, and the level of service makes me return and seek him out whenever I need something printed.”

“Excellent service, very professional and helpful. Thanks a lot!”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Durban

Durban Johannesburg Pretoria

Port Elizabeth Cape Town Abu Dhabi

Dubai Tel Aviv Irákleio

Chaniá

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

Part Manufacturing & 3D Printing Service South Africa

Akhani 3D provides an optimal, Professional, Production and Industrial part manufacturing service for manufacturers and innovators.

Low volume part requirements? Complex part geometries? Critical end-use parts? Supply chain delays?

Get your parts manufactured locally and optimally using world class, advanced manufacturing technologies.

Professional ISO 9001:2015 Certified 3D Printing and Finishing Services

Looking for more than a desktop 3D printer or your tooling and engineering shop is able or willing to provide? Our industrial Polymer and Metal 3D printing services give you accuracy and repeatability. You get precise parts—every time. Get your functional prototypes, complex part designs, and low volume serial production components manufactured. Start by uploading your 3D CAD model(s) and get a 3d printing price online.

Part Manufacturing. Optimised.

A comprehensive approach is the only way to optimise your parts for cost-effective and efficient Additive Manufacturing production. Akhani 3D is your local South African parts manufacturer and ISO 9001:2015 certified production 3D Printing Service bureau that combines advanced manufacturing technologies to optimise your parts and part production.

The Akhani 3D team has helped thousands of customers bring their products to market with quality 3D-printed parts and by using a hybrid approach to optimally manufacture their parts.

Design for AM

Additive Manufacturing creates design possibilities that are infeasible for traditional manufacturing processes. We can help your team with part optimisation to take advantage of these possibilities.

Optimise for AM Production

There are a number of 3D printing technologies. We’ll help you optimise your parts to take advantage of these technologies that will allow you to use AM for part production, not just prototyping.

Finishing

We offer a number of finishing options for your 3D printed parts. These include CNC post-processing, support removal, polishing and dyeing facilities.

We use the optimal manufacturing technologies to produce your parts.

Whether we employ a hybrid approach or manufacture your parts using additive manufacturing, you get the benefits of the range of technologies we employ to manufacture your parts.

Akhani 3D offers turnkey part production facilities to manufacture your specialised, low volume parts. The technologies we employ include CNC, 3D scanning and 3D-printing services that includes part optimisation, 3D printing, and finishing.

Here’s a list of the 3D Printing Services + Finishing capabilities we have in-house:

- Direct Metal 3D Printing (DMP/DMLS)

- DMLS 316L Stainless Steel printing

- DMLS High-Speed 316L Stainless Steel printing

- DMLS Aluminium 6061 printing

- DMLS MS1 Maraging Steel printing (MS1 1.2709 Tool Steel)

- DLMS Copper (subject to demand)

- Selective Laser Sintering (SLS)

- Nylon 11 (PA650)

- Nylon 12 (PA650)

- Stereolithography Resin (SLA/DLP)

- RCP 130 Photosilver (High-resolution ceramic filled resin)

- E Shell (Clear Acrylic Resin)

- E-Dentstone (General Purpose Model Material)

- Fused Deposition Modelling (FDM)

- General Purpose PLA

- Onyx Nylon w/Chopped Carbon Fiber

- Fused Filament Fabrication (FFF)

- Composite (FFF)

- Polyshot 3D Surfacing

- Deepdye 3D Colouring

- CNC Machining

Get your 3D printing price right now on our 3D Print Service Online Quotation Engine

Obligation-free quotes to 3D print your designs.

Simply upload your 3D CAD files, select your material and you will get a live quotation, ready for processing. You can then place your order, which will then be placed directly into our print queue.

See how easy it is — this online 3D printing quotation walkthrough takes you through the steps and details the options available to you.

If you have any questions, our engineering team will help guide you through the process.

Get Your 3D Metal & Plastic Parts Built + Finished

Upload & Get an Instant 3D Printing Quote

Akhani 3D | 3d Print Service Offices in South Africa – Gauteng (Johannesburg – Sandton – Midrand – East rand – Pretoria) | KZN (Howick – Pietermaritzburg – Durban) | Western Cape – (Cape Town – Stellenbosch)Offices in South Africa

The Gauteng 3D printing office is in City Deep, serving the greater Johannesburg area. We also service clients in Sandton, East rand (Ekurhuleni), Midrand and Pretoria.

The Western Cape office is in Montague Gardens and serves customers in Cape Town, Stellenbosch and Paarl.

The Akhani 3D head office is located in Howick, KwaZulu-Natal. This office serves 3D printing clients in Pietermaritzburg, Durban and internationally.

If you are looking to buy a 3D printer, visit our sister company, Rapid 3D.

Durban Deep, Painting by Tim Malone

© 2017 Tim Malone

More shots of

Let us know if you'd like to see more photos of this artwork!

- Back of work / Side of work

- Details / Signature / Surface or texture of artwork

- artwork in the room, Other...

Additional shots

Let us know if you would like to see more photos of this piece of art!

- Back of work / Side of work

- Details / Signature / Surface or texture of artwork

- artwork in the room, Other.

..

..

One of a kind

Signed by the artist

Certificate of authenticity included

- Genuine work of art Painting, Acrylic on Paper

- Genuine Artwork

Original Artwork is any work that is considered authentic and not a copy or imitation of the artist's original work. Original artwork can be any kind of painting, sculpture, performance or other media.

There are many types of original media. Mixed media includes oils, acrylics and watercolors. For workshop paintings that testify to craftsmanship, this attribution should be more subtle. While they may be less valuable for a variety of reasons, reproductions and copies have had a huge impact on our experience. They reach a wider audience than the originals and act as an anti-commodification tonic. Original work may also refer to the first work, which always precedes all others. It can also refer to a prototype or model from which other work can be done. Each work is very similar to the original.

There are many types of original media. Mixed media includes oils, acrylics and watercolors. For workshop paintings that testify to craftsmanship, this attribution should be more subtle. While they may be less valuable for a variety of reasons, reproductions and copies have had a huge impact on our experience. They reach a wider audience than the originals and act as an anti-commodification tonic. Original work may also refer to the first work, which always precedes all others. It can also refer to a prototype or model from which other work can be done. Each work is very similar to the original. - one-of-a-kind (OOAK)

One-of-a-kind pieces of art are also known as "OOAK" pieces of art. This means that each work of art is unique and there will never be one identical.

- Limited Edition

Edition is out of production.

The number of copies produced is determined and indicated in the job description.

The number of copies produced is determined and indicated in the job description. - Open Edition

The publication has not been completed. The production of new works continues. Works may be numbered, this also includes commissioned and print-on-demand works.

- Unknown edition

It is not known how many copies were made after the end of the run.

- Genuine Artwork

- Dimensions Height 69cm, Width 49cm

- Frame This work is not framed

- Categories Paintings up to 1,000 € abstract Industry

Durban deep is a gold mine situated close to johannesburg. the mine was closed in 2001 and now zama zamas (which means willing to try your luck or take a chance) work shallow portions of mines such as durban deep, where they abseil and slither down tunnels under johannesburg to extract gold. about[...]

the mine was closed in 2001 and now zama zamas (which means willing to try your luck or take a chance) work shallow portions of mines such as durban deep, where they abseil and slither down tunnels under johannesburg to extract gold. about[...]

Durban Deep is a gold mine situated close to Johannesburg. The mine was closed in 2001 and now Zama Zamas (which means willing to try your luck or take a chance) work shallow portions of mines such as Durban Deep, where they abseil and slither down tunnels under Johannesburg to extract gold.

About this work: Classification, Methods & Styles

Acrylic

Paint using traditional pigments mixed with synthetic resins.

Abstract Wassily Kandinsky believes that art, in order to give emotions, must be separated from figuration. To do this, he first simplified the forms, then from 1910 he completely removed any reference to the model, his work became abstract.

Painting Painting is an art form of drawing onto a surface by the aesthetic application of colored liquids. Artists are a very personal expression on supports such as paper, stone, canvas, wood, bark, glass, concrete and many other materials. A work of fine or inventive art may be naturalistic and figurative or abstract. It may have narrative, descriptive, symbolic, spiritual or philosophical content.

Related topics

MineGoldMiningZama ZamaUnderground

Automatically translated

abstract mine gold mining zama zama underground

Subscribe

Tim Malone

Great Britain

Tim Malone studied fine art in South Africa and then served as an award-winning advertising and creative director for nearly 40 years. now this experience defines his creative process. his approach[...]

now this experience defines his creative process. his approach[...]

Tim Malone studied fine art in South Africa and then worked as an award-winning advertising and creative director for almost 40 years. Now This Experience Defines His Creative Process. His Painting Approach Reflects The Layout Design Process For Print Ads; Any Addition, Deletion, or Change to Any Part of the Work Affects All Other Parts. This means that the solution to one design problem often gives rise to others, until finally a balanced result is achieved.

While Tim's work is sometimes biased, it is always influenced by the social complexities, colors, shapes and textures of the places he has lived and worked in South Africa, Saudi Arabia, England and Portugal.

Tim works with acrylics on canvas, paper and cardboard, creating details using a variety of other materials. Most of his work is Hot Pressed Watercolor Paper, which absorbs moisture slightly but allows the paint to move relatively easily across the surface.

Project of a cluster initiative to introduce smart manufacturing technologies in Brest and the region – CLUSTERLAND.BY – The first information portal dedicated to the development of clusters in Belarus

Project of the cluster initiative to introduce smart manufacturing technologies in Brest and the region

November 11, 2021

Project of the cluster initiative to introduce smart manufacturing technologies in Brest and the region

growth of the innovative economy of Belarus will be complex “projects of the future”, multi-level and large-scale drivers of economic growth. These include is a project of a cluster initiative to introduce smart manufacturing technologies in Brest and region , which is piloted by the Brest Technopark with the support of its residents and the Brest Technical University.

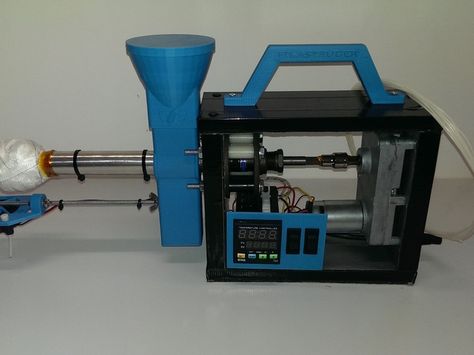

BIM design, artificial intelligence, Internet of Things (IoT), robotics, 3D printing, a cloud platform for working with specialized software and big data arrays - all this will help to implement and use in the processing industry, agriculture and large-scale production high-tech cluster . Its creation in Brest is scheduled for the period from 2021 to 2030.

Its creation in Brest is scheduled for the period from 2021 to 2030.

The project is not a sprint, but rather a marathon. Its starting point will be the formation of a pool of high-tech equipment on the basis of the shared use center. This will enable the production of those components and equipment that will be needed for the introduction of smart technologies. In parallel, it is planned to deploy a cloud computing center for the digitalization of production processes.

The second stage of the project is the creation of industrial and information solutions based on robotics, artificial intelligence, machine vision and the Internet of things. This will be done for specific customers already working in Brest and the region.

The final stage is the implementation and integration of the above solutions at processing enterprises, industrial plants and organizations of the agro-industrial complex of the Brest region.

Estimated payback period of the project is eight years.