3D printing house plans

3D House Plans - 3D Printed House Models

House Plans with 3D Printing Options from The Plan Collection

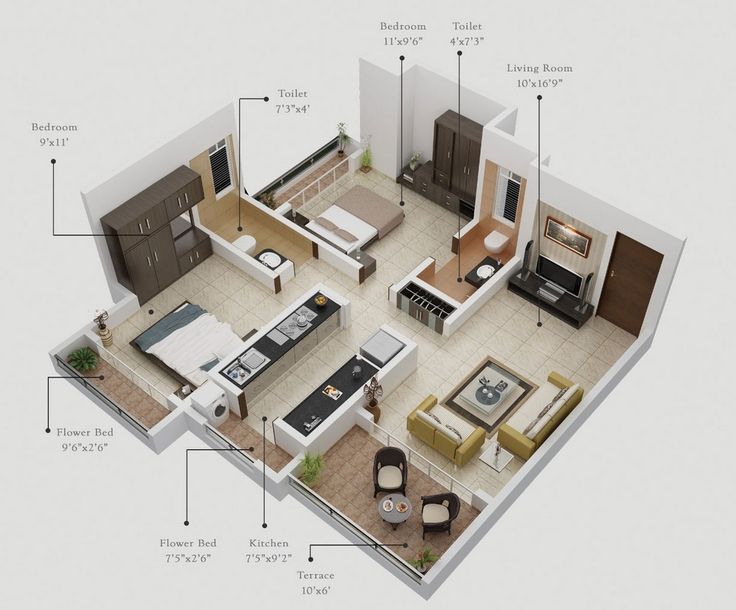

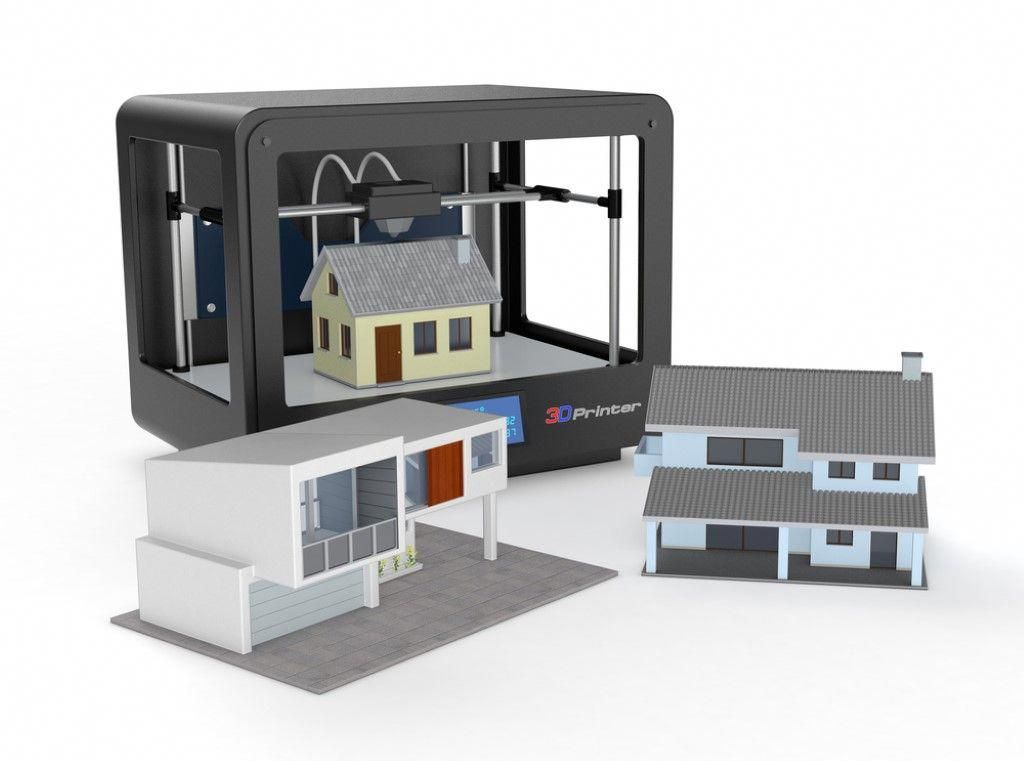

One of our most common questions is, “How can I get a better visual of what my home will look like once it is built?” We now offer our first house plan with a 3D printing option.

Today, for practical use, home builders and future home owners can actually use 3D printing technology to print out a 3D house plan model from specially prepared files.

As you can see, a three dimensional image of House Plan #187-1001 (left) is a helpful start for home builders to get “virtual” 360-degree views of your house plan, with much more detail than static images and renderings. 3D printing technology uses software files to e

ffectively convert your blueprints into an actual physical model of your home. This process allows home builders and owners to get a far better sense of the actual home to be built.

Today, for practical use, home builders and future home owners can actually use 3D printing technology to print out a 3D house plan model from specially prepared files.

As you can see, a three dimensional image of House Plan #187-1001 (left) is a helpful start for home builders to get “virtual” 360-degree views of your house plan, with much more detail than static images and renderings. 3D printing technology uses software files to effectively convert your blueprints into an actual physical model of your home. This process allows home builders and owners to get a far better sense of the actual home to be built.

Our First in the Series of House Plans with 3D Printing:

Traditional Home with Covered Porch (#187-1001)

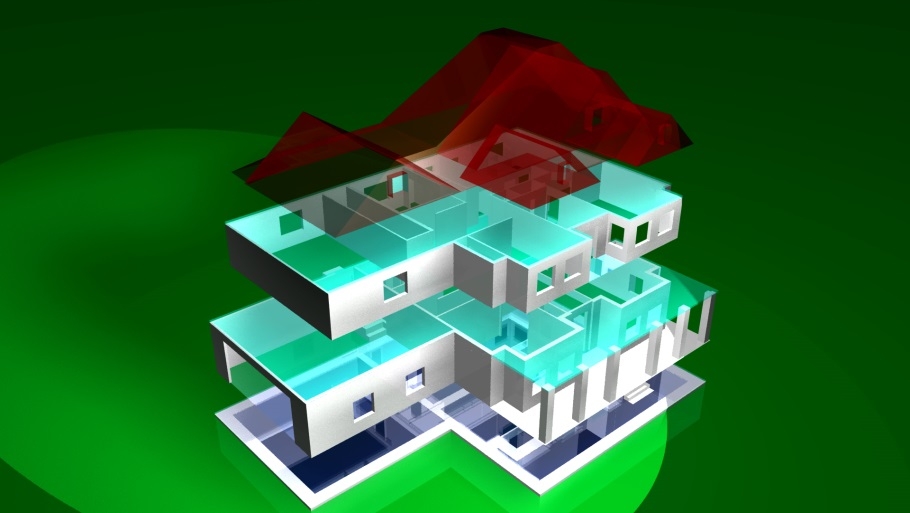

As the first in our series of house plans with 3D printing options, we selected this beautiful six bedroom home to highlight the openness of the floor plans as you walk through it. Many home owners have a tough time visualizing how floors stack on top of each other. In addition to the second floor, this home also includes a finished basement with two additional bedrooms and family area. The to-scale model allows users to quickly understand how these floors work together as a whole.

Many home owners have a tough time visualizing how floors stack on top of each other. In addition to the second floor, this home also includes a finished basement with two additional bedrooms and family area. The to-scale model allows users to quickly understand how these floors work together as a whole.

What is 3D printing? What is a 3D printer?

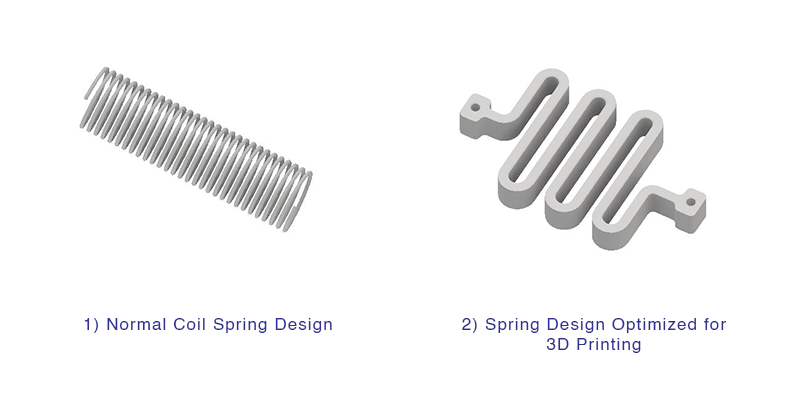

3D printing is the process of creating an object through sequential (additive) layering of materials. By using computer models developed in CAD or similar software, a 3D printer takes a digital model and converts it into a solid or physical one.

Benefits of 3D Printing

The benefits of using a 3D printer to create a physical model or replica of your future home include:

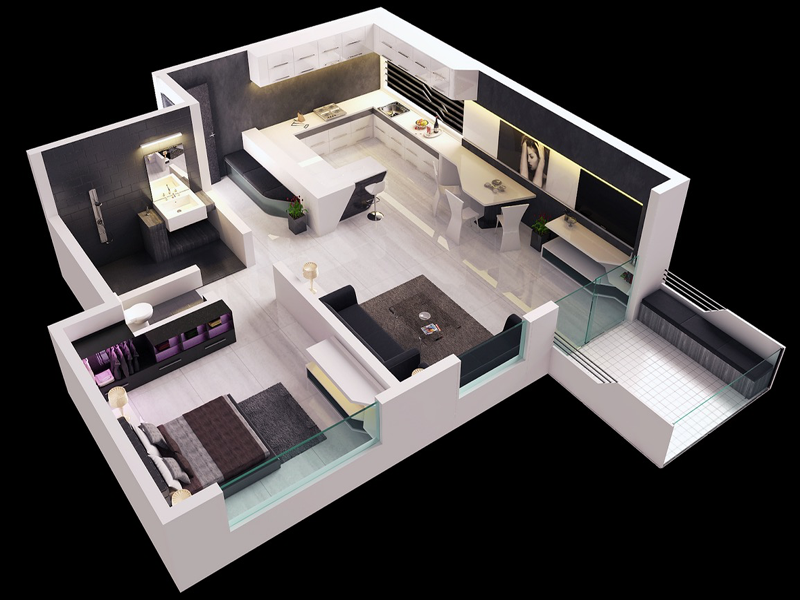

- Visualize all angles and spacing – both exterior AND interior.

- Improve communication with and engage your contractors to get the results you want.

- Provide a detailed emulation of the design found on the blueprints in only a 2D format.

- Showcase the interior and exterior while giving an overview of the entire home before it is built.

- Test the orientation of your home on your property to optimize sunlight in the home.

The benefits of using a 3D printer to create a physical model or replica of your future home include:

- Visualize all angles and spacing – both exterior AND interior.

- Improve communication with and engage your contractors to get the results you want.

- Provide a detailed emulation of the design found on the blueprints in only a 2D format.

- Showcase the interior and exterior while giving an overview of the entire home before it is built.

- Test the orientation of your home on your property to optimize sunlight in the home.

How can I get my 3D printed model?

If you have a 3D printer at home, then that is a great way to start. MakerBot is perhaps the most popular manufacturer of consumer 3D printers. However, not many people have 3D printers at home yet. Fortunately, there are 3D printer services in many cities and states today. Given that this technology is in such early stages and this is the first in our series of house plans with a 3D printing option, we are offering the 3D printer version of the files at no charge when you purchase a CAD File construction package of plan #187-1001.

However, not many people have 3D printers at home yet. Fortunately, there are 3D printer services in many cities and states today. Given that this technology is in such early stages and this is the first in our series of house plans with a 3D printing option, we are offering the 3D printer version of the files at no charge when you purchase a CAD File construction package of plan #187-1001.

Can I build my actual house with a 3D printer?

In theory, this could be done – but we wouldn’t advise it! In fact, homes have recently been built or are under development using 3D printers in Amsterdam and Los Angeles already. These homes demonstrate the possibilities of the technology. However, they are also not very practical – while also being extremely expensive. Some would say they are also not very “homey”.

3D printing technology is still at its very early stages – think of the personal computer in the early 70s or mobile phones in the early 80s. It is not inconceivable that advances in 3D printing technology could revolutionize the way we build houses. Some potential benefits of 3D printed homes in the future could be:

It is not inconceivable that advances in 3D printing technology could revolutionize the way we build houses. Some potential benefits of 3D printed homes in the future could be:

- Fewer wasted materials in home construction.

- Less transport of materials and products.

- Homes are built to order.

3D printing could even lead to changes in our own preferences in a home design itself.

- Individual expression.

- Democratization of architectural design.

The Plan Collection is constantly looking for new and innovative ways to offer a better user experience with everything related to the house and home building. We welcome your feedback and suggestions.

The 12 Most Exciting 3D Printed House Builds 2022

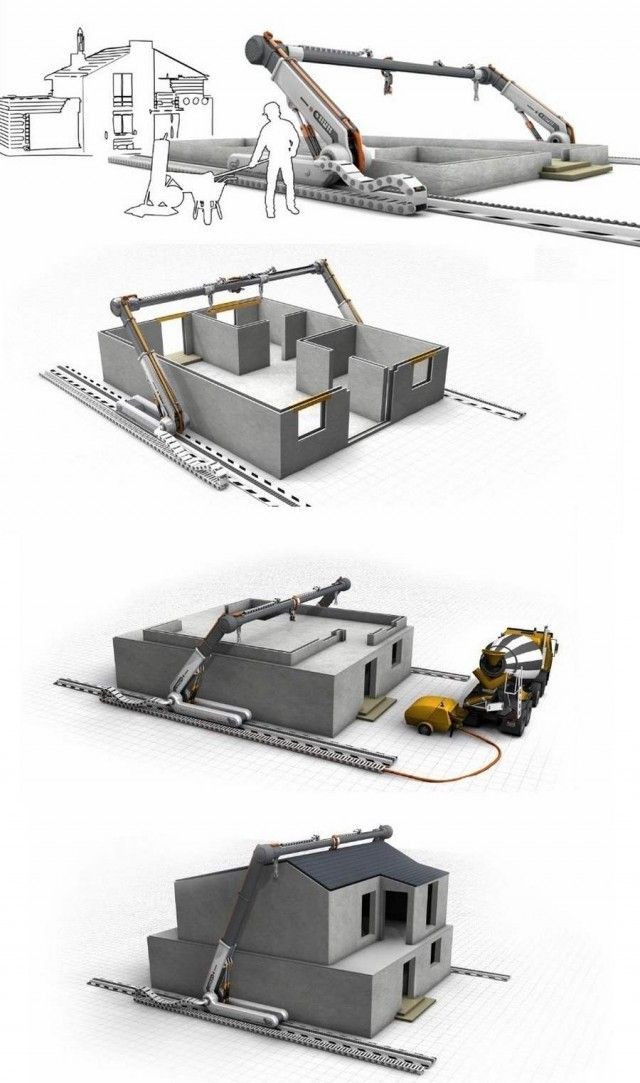

Traditional housebuilding methods may have changed in the last 200 years, but it has retained one key element — humans. Even with the latest diggers and cranes, people were still needed to pilot them. But now, industrial 3D printers can extrude concrete based on a 3D model and build houses completely autonomously. These gigantic 3D printers can build an entire 3D printed house in just hours!

But now, industrial 3D printers can extrude concrete based on a 3D model and build houses completely autonomously. These gigantic 3D printers can build an entire 3D printed house in just hours!

- We also have a ranking of the most innovative house 3D printer companies

3D printing offers the chance to build houses faster, more accurately and cheaper than ever before. We will be showcasing some interesting 3D printed house projects that already exist, the advantages and disadvantages of 3D printed houses, and mentioning some 3D printer companies who are working hard to commercialize the tech.

We have divided this complete guide to 3D printed houses into three parts:

- Part 1: Five key advantages of 3D printed houses, and how 3D printed buildings would benefit us

- Part 2: A selection of the most exciting 3D printed mansion, house and apartment projects

We have also published the complete history of 3D printing, which you can view here.

Part 1: Advantages of 3D printed houses

Environmentally Friendliness: 3D printing is a form of additive manufacturing and only uses up the exact material required to build a house. Therefore, in the building of a 3D printed house, less concrete and other materials are used up than traditional methods, benefiting the environment. Concrete production is one of the main pollutants, so minimizing this is key.

3D printed houses cost less: A large part of the costs in building a house is the labor involved, as houses take so long to construct. A house 3D printer only requires one person to monitor it, thereby vastly reducing costs involved in building a house – though there is the counterargument of putting people out of work.

Moreover, the University of Tartu, Estonia, with the Estonian University of Life Sciences, have collaborated to create a low-cost 3D printed house concrete material made primarily of peat which could reduce the material cost of building a house by up to 10x! Additionally, because peat is so common it could be dug up locally — such as in deprived third-world countries — and used to build houses, so materials do not have to be shipped there.

3D printed houses can be made quicker: Houses take between four and six months to build on average, but a 3D printer can print the structure of a house in just a day. With effective contractors to put doors, roofs and windows in, this means completed houses could be built in just a few weeks.

More options architecturally: Because 3D printing allows for accuracy far beyond what humans are capable of, complex designs can be created by 3D printers of all shapes and sizes. This is beneficial not just aesthetically, but also in the ability to create houses customized to be as efficient as possible as retaining heat, saving money, as well as creating environments that disabled people can live in comfortably.

Ability to help those in need: Being able to create basic shelter structures quickly, cheaply, with minimal labor and with accessible materials makes 3D printing the only clear option for the task. It is no wonder therefore that much research is being conducted in order to refine the technology, and with non-profits such as New Story attempting to utilize 3D printing in the third world.

However, it is still important to be realistic.

3D printed houses are likely not as cheap as the companies who have built 3D printed houses claim they are. They only list the cost of the house in terms of the materials consumed to build it, omitting key factors such as labor, the cost of the printer (renting or buying), interior and external finishing, and wiring, pipes and other key foundations.

The house in Nantes, France built for £170K is an accurate cost for a habitable 3D printed building, not the outlandish claims to build a fully-functioning domicile for $4,000.

Part 1: The most Exciting 3D Printed Houses & 3D Printed Buildings

1. World’s Largest 3D Printed House by Apis Cor in Dubai

If you hear of an exciting or innovative building project, there is a high likelihood it will involve Dubai. Dubai have been championing ambitious architectural projects for years, and have recently made the bold move of aiming to have 25% of new buildings 3D printed by 2030.

This administrative building comprises two floors, featuring beautiful 3D printed architecture born out of an ongoing collaboration between Russian 3D printed house company Apis Cor and the Dubai Municipality.

We expect much more to come from Apis Cor in Dubai as this building is considered by them to be just a test for larger 3D printed house projects for the future. It is claimed to have been to test whether Apis Cor’s concrete 3D printer could print a building in Dubai’s heat — and passed with flying colors.

Expect more very soon: 3D printed apartment blocks, skyscrapers, landmarks and more.

For the full story covering the world’s largest 3D printed building, click here.

2. First family move into a 3D printed house in France

- 3D printed house price: £170,000

- Located: France

In July 2018, a French family moved into their new four-bedroom home, becoming the first family to live in a 3D printed house. This was a collaboration between the city council, housing association, and the University of Nantes. The goal was to build a prototype with the long-term goal of creating 3D printed houses that are cheaper and faster to build than traditional houses. The house cost around £176,000 – 20% less than traditional construction.

The goal was to build a prototype with the long-term goal of creating 3D printed houses that are cheaper and faster to build than traditional houses. The house cost around £176,000 – 20% less than traditional construction.

This 1022 square foot 3D printed house took 54 hours to build — though this was just the structure. An additional four months for fitting the windows, doors, and other parts was necessary before the home was finished. The team behind this extraordinary achievement now believe they could create a similar house in 33 hours, citing additional knowledge and tech advances.

Benoit Furet, the man behind the project, believes 3D printed houses offer a solution to the growing housing shortage and for social housing in the future. Moreover, he claims that with growing economies of scale and technological advances, 3D printed houses will become 40% cheaper to build in 10-15 years.

Perhaps the most exciting part of this build however is the architecture – the house was built to curve around environmentally-protected trees. This is simply not plausible for traditional builds as they are more restricted by the shape of bricks, whereas 3D housebuilding can create curved shapes without issue. This offers potential for more compelling designs, as well as creating custom houses to suit disabled people.

This is simply not plausible for traditional builds as they are more restricted by the shape of bricks, whereas 3D housebuilding can create curved shapes without issue. This offers potential for more compelling designs, as well as creating custom houses to suit disabled people.

3. Apis Cor 3D Printed House Built in 24 Hours

- 3D printed house price: $10,000

- Located: Russia

Probably the most famous and viral 3D printed house build, this interestingly shaped house was built back in 2017 in just one day – while it snowed! According to the team the house cost just over $10,000 to build, including the furnishings with windows and doors, though we will discuss why these figures may not tell the full story further on in this article.

A viral hit, this was definitely the moment the world woke up to the possibility of 3D printed concrete houses in the future. This viral video not only proved it could be done, but that 3D printed dwellings could be built faster than people could build them, and the cost of a 3D printed house was far lower.

Apis Cor’s build brought 3D printed structures into the public eye, encouraging others to get involved and democratize 3D printed house building.Apis Cor built this magnificent 3D printed house in just 24 hours!

4. ICON & New Story 3D Printed House in Austin, Texas USA

- 3D printed house cost: $10,000

- Located: USA

Another recent viral story, this collaboration between ICON and New Story made headlines when they 3D printed a house in Texas, USA earlier this year. The prototype 3D printed house built cost the companies approximately $10,000, though they assert that this number can be brought down to $4,000 going forwards.

The house, like Apis Cor’s 3D printed concrete house in Russia, was built in 24 hours, and is part of ICON’s longer-term plan to assist in infrastructure in poorer parts of the world through housing. Non-profit ICON has already built over 800 houses in Haiti, El Salvador, Bolivia and Mexico, and plans to utilize 3D printing to create low-cost houses in these areas – ICON currently source local workers but some areas may not have the skilled builders required.

Therefore, 3D printed houses offer a solution to this lack of skilled builder problem. Large construction 3D printers can be brought to these impoverished areas where there are few skilled builders to build homes for people in poverty. This is an example of 3D printing helping improve the lives of society’s most vulnerable, and we commend ICON and New Story for their fantastic work here.

This is also a project we are actually likely to see develop. New Story is Co-Founded and advised by some very powerful and successful people, including Glassdoor’s CEO, and Reddit Co-Founder Alexis Ohanian. Many of the people attached to the project have a track record of execution and success, so we look forward to seeing the project’s progress. Since the Texas project they have also printed a series of 3D printed houses in Mexico.

- 3D printed house price: $450,000

- Located: Texas

ICON has been keeping busy since our last update and has now formally listed their first 3D printed home for sale on the streets of Austin, Texas.

Joining forces this time with developer 3Strands, ICON has used its Vulcan technology to construct four multi-story buildings in East Austin ranging from 1,000 to 2,000 square feet, featuring modern open plans and timeless interiors.

This is in conjunction with their new East 17th Street initiative, a project that hopes to use this innovative technology to build a small community of 3D printed homes in the growing area of East Austin.

With the help of Logan Architecture, they’ve designed 4 styles of homes that take around 5-7 days to build and are planned to be move-in-ready by the summer of 2021.

Rendering of the 3D printed houses in East Austin, Texas.5. Coachella’s 3D Printed Neighborhood

- 3D printed house price: $595,000

- Located: California

We’ve all heard of the Hollywood-infused Coachella music festival, but have you ever heard of Coachella’s 3D printed neighborhood?

Mighty Buildings, a 3D printing construction and technology company, and Palari Group, a specialized sustainable real estate company, are set to begin building what’s been dubbed the world’s first 3D printed neighborhood by the Guardian, CNN, and other major news outlets.

The neighborhood is named Rancho Mirage and will sit nestled in the waves of Coachella Valley.

Mighty Buildings and Palari Group plan to develop 15 homes by 2022, each consisting of three bedrooms, two bathrooms, a terrace, and a swimming pool within 1,450 square feet of space.

Made from a stone composite material, the walls are said to join together like Legos, according to Palari CEO Basil Starr.

There’s also the customizable option to add a 700 square foot extra residence, or AUD, to the property that will consist of two bedrooms and a bathroom.

Rancho Mirage has the potential to become the future blueprint of neighborhoods moving forward, not only for its immense sustainability but also for the incredible solution it poses for the global housing crisis.

Future News: Keep your eyes peeled for the 3D printed school Mighty Buildings has planned with Thinking Huts to open in Madagascar later this year.

6. The COBOD BOD2 Printer Takes Over Europe

- 3D printed house price: N/A

- Located: Belgium

Sustainable building company Kamp C 3D printed an entire two-story house in Belgium’s Flanders region with Europe’s largest 3D printer.

The finished two-story terraced home came in just under 1,000 square feet. It’s a low-energy home with a green roof but still manages to blend seamlessly into the surrounding architecture.

The most impressive aspect of this project however is the construction process itself.

Traditionally, being a two-story building, construction would’ve taken place in two parts, off-site in a separate facility. But Kamp C ingeniously used the stationary COBOD BOD2 concrete printer to print it on-site in one piece.

COBOD, or Construction of Building on Demand, developed the BOD2 3D printer, which operates on three axes, making it possible to print in a circular design on-site, and more importantly, print multiple floors.

It’s not only about looks though. According to Kamp C project manager Marijke Aerts:

“The material’s compressive strength is three times greater than that of conventional quick brick.”

Construction began on March 19th, 2020, and took around three weeks to print, but Kamp C believes future homes can be completed in just two days.

COBOD Part 2

The COBOD BOD2 printer isn’t finished making headlines yet.

Over in Wallenhausen, Germany, German-based construction company PERI Group started construction on a 3D printed three-story multi-family apartment building, following the success of the two-story home they printed earlier that year.

The building will contain 4,090 square feet of live-in space and hold five apartments and a basement. The floorplans will vary between single occupants and families.

Construction began in November of 2020 with an anticipated finish of March-April 2021, so we expect to see them gracing headlines again very soon.Germany’s first 3D printed house.

7. 3D Printed “Office of the Future” in Dubai

- 3D printed building price: $140,000

- Located: Dubai

Dubai is always making headlines for being ambitious and outlandish in its declarations of future goals – none more so than their claim that 25% of buildings will be built using 3D printing by 2030. And they’re backing this up with action; this office — claimed to be the most advanced 3D printed building in the world — cost roughly $140,000 to build (not including finishing details) and took 17 days.

And they’re backing this up with action; this office — claimed to be the most advanced 3D printed building in the world — cost roughly $140,000 to build (not including finishing details) and took 17 days.

Affectionately named the “office of the future”, the building was created by a 20-foot-tall concrete 3D printer using a robotic arm to deposit cement. Only one employee was needed to monitor the house 3D printer whilst it printed, and seven employees worked on building components of the office whilst the printer worked.

Additionally, 10 electricians and other specialists worked on the inner workings of the office across the 17-day build. We cannot therefore call it a completely 3D printed house, as other workers filled in various other components. But 3D printing has never claimed to be able to insert complex electrical systems as it prints, just create the structure in record time. With this project showing huge ambition, perhaps Dubai will become a world leader in 3D printed houses. This 3D printed office looks stunning and futuristic.

This 3D printed office looks stunning and futuristic.

8. SQ4D Releases First 3D Printed Home for Sale

- 3D printed house: $299,999

- Located: New York

SQ4D, previously charmed the world in January 2020 when they built the then world’s largest 3D printed home, but now it’s charming us again, as they officially announce the first 3D printed home to receive a certification of occupancy in the US.

It’s currently listed for sale on Zillow at $299,999 – 50% cheaper than traditional new builds in the area.

The 1,400 square foot two-story home is made from special concrete material and boasts three bedrooms, two bathrooms, and a 2.5 door covered garage.

However, the real cleverness is found in their patent-pending ARCS technology.

ARCS, or Autonomous Robotic Construction System, is a low-power consumption technology that robotically builds the house on-site. Along with printing the exterior and interior walls, it also prints utility conduits, siding, and sheathing, effectively taking an entire crew’s worth of labor down to three people.

With ARCS, each home took only 48 hours of print time over a few weeks.

When discussing the power and implications this technology could pose for the future, SQ4D’s director of operations Kirk Andersen had this to say:

“I want people to not be afraid of automation…it is just a different tool and different method. But it’s still the same product… we can make things more affordable and safer. We can use the technology to tackle homelessness and aid in disaster relief in an eco-friendly way.”

9. Gaia Italy 3D Printed Concrete House

- 3D printed apartment price: $1,000

- Located: Italy

Italian house 3D printing company WASP built ‘Gaia’, a 3D printed hut made from a mix of concrete and mud-based material. The 215 square foot structure took 10 days to complete, though the total time when accounting for all the furnishings and additions would be longer. The most extraordinary part is that the hut cost just $1,000 in materials to build, though this doesn’t factor in labor and other costs.

- WASP make a number of desktop delta FDM printers. You can also view our ranking of the best delta 3D printers.

Like New Story’s plans for the developing world, this interesting prototype may form the basis for building houses in poorer countries. In more deprived areas where the imminent problem is shelter rather than wiring and pipes inside houses, these cheap 3D printed houses offer an effective solution to a real crisis.Though not as visually appealing as the office in Dubai, this hut cost just $1,000 to build.

10. Project Milestone, Eindhoven — Building 5 3D printed condos in Holland

- 3D printed building price: N/A

- Located: Holland

Project Milestone – the code name for the project to develop five habitable and beautifully shaped homes in Eindhoven, Holland, is a fascinating collaboration between Houben and Van Mierlo Architecten, Van Wijnen, and the Eindhoven University of Technology.

Pioneered as a solution to the shortage of skilled bricklayers in the Netherlands, the first of these houses – and the first 3D printed house for sale – attracted over 20 interested buyers in its first week on the market.

Though currently only the cement structure of the houses are 3D printed, with advances in technology it is hoped that by the time the fifth house is built that other features, such as drainage pipes, will also be made using the house 3D printer. This will further reduce costs and influence 3D printing’s adoption in housebuilding.Visuals of what the five 3D printed houses will look like in Eindhoven.

11. Czech Out the Floating 3D Printed Home PRVOK

- 3D printed house price: N/A

- Located: Czech Republic

No home design is safe from the evolution of technology as the Czech Republic sets sail on the new, more or less, 3D printed houseboat. This 462 square foot 3D printed house may be tiny, but it packs a serious punch in terms of gumption and sheer originality.

Called the PRVOK, the house has space for two, including a living room, kitchen, bedroom, and bathroom.

It’s devoid of all sharp angles, consisting of only curves, and is printed with an external and internal layer that’s filled with insulation in between. The house is also fitted with eco-tech, from a recirculating shower to a green roof.

The house is also fitted with eco-tech, from a recirculating shower to a green roof.

So, imagine a hobbit home from the rolling hills of the shire meets the rivers of a bustling metropolis.

PRVOK’s main focus was on speed and efficiency, claiming to be seven times faster than building a traditional brick house.

It’s made from specially formulated concrete with nano polymers that harden faster than normal concrete. Within the first 24 hours, it registers at the standard hardness of a brick house, and after 28 days it’s hardened to that of a bridge.

It’s claimed this house can last up to 100 years.

Needless to say, we’re excited and hopeful to see these homes floating through our waterways in the near future.

12. 3D Housing 05 – Milan Design Week 3D printed building

- 3D printed house price: N/A

- Located: Italy

A collaboration between engineering firm Arup and architecture studio CLS Architetti, and 3D printed by CyBe Construction; this stylish 3D printed house, named ‘3D Housing 05’, exhibited at Milan Design Week following its construction in November 2018.

The 3D printed home, built in a week on a Milan square using recycled concrete, is around 100 square meters and contains a living area, bedroom, kitchen, bathroom and roof terrace. Prominent 3D printed house constructor CyBe Construction created the house with their concrete 3D printer; able to print a single wall in between 60 to 90 minutes.

The most exciting part is the recycled concrete, developed by Italcementi, which uses debris from demolition sites to create the 3D printable material. This can then be recycled again after the building has been demolished.

Massimiliano Locatelli, the principal architect at CLS Architetti, claims that each square meter costs €1,000 to build – half the price of traditional construction. With advances in the technology, he believes this can be reduced to between 200-300 euros in the future.

How much does a 3D printed house cost?

This question of 3D printed house cost is a common one, and just as with traditional housebuilding, it depends. Though projects such as Apis Cor’s 24-hour build cost just around $10,000, this is a far smaller and more basic house than most in the West are accustomed to.

Though projects such as Apis Cor’s 24-hour build cost just around $10,000, this is a far smaller and more basic house than most in the West are accustomed to.

The same is the case for ICON and New Story’s 3D printed house in Texas. The house is small, basic and the house 3D printer had already been moved there. Therefore, for a 3D printed domicile a whole family could comfortably live in, it would probably not suffice.

The most accurate project in terms of a 3D printed house’s cost is the French build in number 2 on our ranking. This project cost around $170,000 and was roughly 20% than traditional methods would have cost.

However, construction 3D printing is still in its infancy, and will likely come down in price quickly. The main costs are the materials and labor, and without any labor required except one operator to monitor the print, these costs are dramatically lower.

When will 3D printed houses be available?

Arguably, they are already available. 3D printable houses are a reality, they are just not widespread. The companies developing construction 3D printers for houses are still refining the technology, and do not have enough of these machines to build thousands of houses yet.

The companies developing construction 3D printers for houses are still refining the technology, and do not have enough of these machines to build thousands of houses yet.

We are likely to see a large increase in 3D printed buildings in the next decade or two, with countries like Dubai striving to 3D print 25% of new buildings by 2030.

Yes, you can. There are a variety of architecture design software tools for creating 3D models of buildings. Architecture firms use 3D printing to create miniature versions of future building projects, and house 3D printers themselves create buildings based on 3D models.

- For more information, view our ranking of the best architecture software

- We also have a ranking of the best 3D software modeling tools

Conclusion: The future of housebuilding

Though far from being perfected, the potential with 3D printed houses is exciting. It has proven to work and stand up to the elements in Europe and the USA, and really can work faster and more efficiently than people.

In poorer areas with few skills builders and little building material available, large house printers such as those by ICON and New Story offer a fantastic way to build basic huts and 3D printed shelters. If able to use locally source material, this reduces building costs dramatically, allowing for shelters to be built for those who need them most.

3D printing therefore doesn’t just promise to revolutionize construction for rich tycoons who want to boast about their latest build, but offers a scalable and effective solution to homelessness in the developing world.

The question now is how the technology will be received: will people resent concrete printers for making builders obsolete? Or will they take to them, glad that they can save them money on their dream build?

Even the most advanced house printers of the future will require skilled operators to prevent accidents, and we are a world away from a printer that can concurrently 3D print the glass windows, wooden doors, pipes, electronics and other furnishings along with the house.

House 3D printers therefore do not replace people, but complement them; doing the heavy lifting while the specialists do what they do best. It is important therefore to focus on how 3D printed houses can benefit both us and those in the third-world, and respect the advantages that 3D printed houses offer.

3D printing is the future in construction

Laser scanning and BIM project support.

St. Petersburg: 8 (812) 450-05-55, Moscow: 8 (495) 414-25-95, RF: 8 (800) 201-91-45

Interesting Reviews

3D printing is the future in construction

In 2004, Professor Beroch Khoshnevis of the University of South Carolina created the first robotic system capable of building a house without human intervention. The technology, called contour construction, according to the developer himself, is a scaled 3-D printer in which the robot is a system of guides along which the hypertrophied inkjet printer head moves in two planes.

Instead of the plastic material used in 3-D printers, the system uses quick-drying concrete mix. The laying of reinforcement, the construction of internal walls and partitions, the placement of beams, the laying of the truss system and even the roof with hemming is also carried out by a construction robot moving along pre-prepared rails.

The use of contour construction technology makes it possible to obtain a number of indisputable advantages, such as high speed of building construction, minimal requirements for finishing (walls are perfectly even), cost and risk reduction, as well as ease of creating complex architectural forms. Not surprisingly, the work of Professor Khoshnevis marked the beginning of the large-scale use of 3-D printing in construction.

Construction giants are quickly realizing the potential of 3D technology and its impact on the future of construction. The market for concrete 3D printing is expected to reach $56.4 million in 2021, and there are all prerequisites for this. More and more companies are entering this sector when creating innovative projects. Some of them are rather futuristic, others are very real today, for example, the Apis Cor 3D printer, which can build a small house in just 24 hours.

More and more companies are entering this sector when creating innovative projects. Some of them are rather futuristic, others are very real today, for example, the Apis Cor 3D printer, which can build a small house in just 24 hours.

1. Robotic arm extruders

Contour construction method, the same method developed by Prof. Khoshnevis, involves the use of building material to create a large-scale 3D model with a smooth surface. The rails, installed around the base of the building, act as a structure that guides the manipulator moving back and forth, extruding concrete layer by layer. To level the extruded layers and ensure the strength of the model, trowels are located on the sides and above the nozzle. When applying this technology, you cannot use ordinary concrete, only quick-drying, since for the application of each subsequent layer, the previous ones must harden.

Contour Crafting, the pioneer of contour building technology, is very cautious in its progress. Meanwhile, various competing companies are actively developing machines that use various technologies to 3D print concrete. For example, the French company Constructions-3D has created a polar 3D printer that prints inside the construction site and, upon completion of construction, leaves the place of work through the front door of the constructed building. The machine consists of a mechanical base and a robotic arm with a concrete extrusion nozzle. The possibilities of such a hand are impressive: it can print an area of more than 250 m² and more than 8 meters in height.

Meanwhile, various competing companies are actively developing machines that use various technologies to 3D print concrete. For example, the French company Constructions-3D has created a polar 3D printer that prints inside the construction site and, upon completion of construction, leaves the place of work through the front door of the constructed building. The machine consists of a mechanical base and a robotic arm with a concrete extrusion nozzle. The possibilities of such a hand are impressive: it can print an area of more than 250 m² and more than 8 meters in height.

The Cazza Construction robot has a similar design, but the use of a mobile crane system allows it to cope with larger volumes of work, creating larger and taller structures.

Other companies are content with existing printing technologies, paying more attention to the materials used. A striking example is the BatiPrint 3D technology, developed and patented jointly by the University of Nantes, Bouygues Construction and Lafarge Holcim. This industrial robot simultaneously prints three layers of material, two of which are polymer foam, the third is concrete. Thus, according to one of the developers, Professor of the University of Nantes Benoit Furet, not only the construction is carried out simultaneously, but also the external and internal insulation of the structure.

This industrial robot simultaneously prints three layers of material, two of which are polymer foam, the third is concrete. Thus, according to one of the developers, Professor of the University of Nantes Benoit Furet, not only the construction is carried out simultaneously, but also the external and internal insulation of the structure.

2. Binding sand layers together

This method of 3D printing on a D-Shape printer was developed by the Italian architect Enrico Dini, who was the first to become widely known as a person who prints houses on a 3D printer. The construction process is as follows: the nozzle travels along a pre-programmed path, injecting a liquid adhesive sand-based composition mixed with a solid catalyst.

Coupling agent reacts with the catalyst to start the bonding process; the residual sand at this time serves to support the structure. Then another layer of sand is added and the process is repeated. Sand layers are applied according to the desired thickness. The machine is capable of creating structures up to 6 cubic meters in size.

The machine is capable of creating structures up to 6 cubic meters in size.

3. Metal Structural Printing

The Dutch company MX3D has developed a unique construction method called WAAM (Wire Arc Additive Manufacturing), which allows 3D printing of metal structures with a 6-axis robot. This robot, the result of a collaboration between Air Liquide and ArcelorMittal, is equipped with a welding machine and a nozzle for layer-by-layer welding of metal rods.

Works with various metals such as stainless steel, bronze, aluminum and inconel. The machine can be compared to a giant soldering iron. According to the developers, the design "is a combination of an industrial robot with a welding machine."

Prospects for using 3D printing in construction

The most important advantage of using 3D printing in construction is significant time savings. In particular, the use of these technologies potentially reduces the two-week work to 3-4 days. In addition, the automation of the process reduces the risk of occupational injuries to an absolute minimum. Benoît Furet of the University of Nantes states: “The reduction of difficulties and risks is a reality. We carried out the construction of a 3.8 m high facility without any scaffolding. In addition, the construction site is very quiet.”

In addition, the automation of the process reduces the risk of occupational injuries to an absolute minimum. Benoît Furet of the University of Nantes states: “The reduction of difficulties and risks is a reality. We carried out the construction of a 3.8 m high facility without any scaffolding. In addition, the construction site is very quiet.”

His team succeeded in printing the city's first 95 m² 3-D residential building. Benoist says their BatiPrint technology also makes it easier to create curved shapes at a lower cost. What's more, because 3D printers don't need to eat or sleep, they don't stop working until the project is complete. This greatly reduces the waiting time.

Benefits of 3D printing in construction

In terms of material usage, 3D printing is economical. It uses fewer materials than traditional manufacturing processes. This reduces the environmental impact as less waste is produced.

However, the dream of 3D printing houses, bridges and skyscrapers created using this technique is still quite a long way off. Axel Teri of Constructions-3D explains that “the main difficulty stems from the fact that the process of 3D printing buildings today is not recognized as a construction method by many regulatory and standardizing bodies. Because printed designs are not traditional, some calculations are difficult to implement, so habitable works will need to be checked on a case-by-case basis first.” Standards bodies are concerned about whether such structures are strong enough and can withstand the environment.

Axel Teri of Constructions-3D explains that “the main difficulty stems from the fact that the process of 3D printing buildings today is not recognized as a construction method by many regulatory and standardizing bodies. Because printed designs are not traditional, some calculations are difficult to implement, so habitable works will need to be checked on a case-by-case basis first.” Standards bodies are concerned about whether such structures are strong enough and can withstand the environment.

3D typography: a solution to the housing crisis?

With 3D printing now making it possible to build structures faster, it is ideal for dealing with the housing crisis. As a result, some companies are moving towards additive manufacturing, including Italy's WASP, which aims to build a more sustainable world through 3D printing. They have developed one of the world's largest 3D printers that can build houses from local materials using solar, wind or hydropower. This allows regions that do not yet have access to electricity to 3D print building materials from environmentally friendly structures.

Similarly, in Brazil, Aniel Guedes founded Urban3D to deal with the housing crisis. Her company prints parts of buildings in a special factory, and then they are assembled into a single whole at the construction site. This allows her to create buildings that are taller than would be possible if 3D printed on site. The company is currently testing several prototypes and hopes to provide a solution for Brazilian slum development.

The Russian company Apis Cor is also convinced of the positive impact of 3D printing on housing issues. Its founder and CEO Nikita Chen-yun-Tai explains: “We believe that additive manufacturing is an effective solution to the housing crisis and that is why we developed our project. We hope that in a few years this approach will be tested around the world, which will demonstrate its feasibility. We believe that more and more construction companies will apply this technology, the prerequisites for which we already see.”

3D printing in space

Additive manufacturing can also become one of the ways for humanity to explore space. NASA has launched the 3D Printing Environment Test project, which looks at the technologies used to build houses in space, such as on the Moon or Mars. While the project is ambitious, it's too early to tell if 3D printing in space will be a viable solution. However, it can already be said that 3D printing in construction should become a very real global force.

NASA has launched the 3D Printing Environment Test project, which looks at the technologies used to build houses in space, such as on the Moon or Mars. While the project is ambitious, it's too early to tell if 3D printing in space will be a viable solution. However, it can already be said that 3D printing in construction should become a very real global force.

Like

Share

Architectural 3D printing

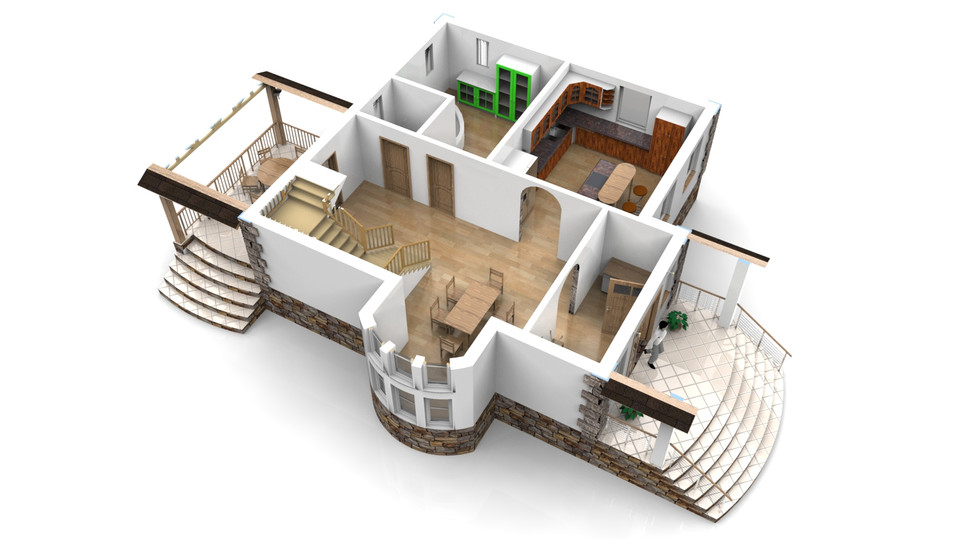

0 Digital 3D-modeling (BIM) is used today by half of the world's architectural companies, and few argue with the fact that the advent of BIM has made a real revolution. Architects have finally got a trouble-free way to quickly, clearly, visually and accurately convey their ideas to the customer.

It's time to master the innovative technology of the presentation of the physical model. The physical model is much more complete than the picture on the monitor, allowing the customer to understand and feel the architectural design. The architect also needs both models: a 3D digital model is required to analyze the components of the project, and a physical model is required to effectively assess the details and scale. More importantly, the physical model allows architects to speak in a language understandable to the customer, even the most distant from architecture. The client, on the other hand, gets the opportunity to evaluate the project on an emotional level, to perceive it taking into account all the subtleties.

The art of hand-crafting architectural models certainly deserves all respect, but it is so time-consuming that the creation of such a model in itself becomes a separate project. First, the architectural drawings are handed over to the model maker, who embodies the overall concept in the material. This takes two to four weeks. If the project has successfully passed the approval, the layout is finalized without significant changes. If not, the architect has to make changes to the project and submit a new version of the model to the customer for approval. It happens that the process of manufacturing a physical layout stretches for months, disrupts deadlines and jeopardizes the fate of the entire project.

This takes two to four weeks. If the project has successfully passed the approval, the layout is finalized without significant changes. If not, the architect has to make changes to the project and submit a new version of the model to the customer for approval. It happens that the process of manufacturing a physical layout stretches for months, disrupts deadlines and jeopardizes the fate of the entire project.

In the fast-paced world of digital modeling, relying on manual production of approximate models is old-fashioned and far too expensive. But what if the production of the layout were faster, cheaper and more accurate? Just imagine the possibilities! The same 3D model could be directly used in the workflow... Z Corporation's 3D printers make these dreams come true.

Visualization

When Z Corporation's first 3D printer, capable of printing 3D physical models, hit the market, it brought with it a host of new possibilities. No longer constrained by the high cost and size of prototyping machines, designers were suddenly able to afford to routinely use visual 3D mockups early in a project.

Morphosis, a Tom Mine Architecture Award-winning company accustomed to working only with cutting-edge technology, was among the first to adopt 3D printing. Morphosis CIO Marty Doscher talks about the company's headquarters in Eugene, Oregon: "We have two 3D printers here, and any project goes straight to 3D from day one."

Tom may do a couple of sketches on paper, but the rest of the work is done in 3D space and there are a lot of 3D prints all over it.

Protecting ideas, winning in business

“The human brain works in three dimensions, not two,” explains R. “Partha” Parthasarathy, owner of the iKix architectural bureau. “Architects and contractors have relied on 2D drawings for centuries. But no matter how accurate these drawings are, there is always a danger that the customer will interpret them incorrectly.

As an example, he cites a recent story with a residential complex with hundreds of buildings. The client was quite pleased with the drawings, but as soon as he saw the 3D layout, he was immediately worried about the too dense placement of buildings. To dilute this heap, the architect had to place a swimming pool and a fitness room in the center of the complex. One can only guess what the belated solution to this problem would have cost the customer - say, when half of the complex would have been built ... The presence of a 3D layout saved the architect a lot of time, and the customer saved the huge costs of changes in the complex already under construction ...

To dilute this heap, the architect had to place a swimming pool and a fitness room in the center of the complex. One can only guess what the belated solution to this problem would have cost the customer - say, when half of the complex would have been built ... The presence of a 3D layout saved the architect a lot of time, and the customer saved the huge costs of changes in the complex already under construction ...

Jerde Partnership purchased ZPrinter 310 Plus printers and now uses them in the development of any project - from a skyscraper to a kiosk. The ability to 3D print in the office allows you to make models very quickly, and, in addition, create models that would simply be impractical to do manually.

Just a week after purchase, the ZPrinter 310 Plus helped win the Jerde Partnership's San Diego Coastal Landscape project. The detailed physics model showed how the Jerde project enhances the contours of the landscape while maintaining its overall style. Al Waas, deputy vice president and chief designer of the project, says that creating the same layout by hand would require a week of effort from an entire team of specialists. And with the help of the ZPrinter 310 Plus, the layout was printed in just half a day. “The more detailed the project, the more complex it is, the more benefits 3D printing provides,” Vaas notes. And he adds that the use of 3D printers gives an approximately twofold increase in productivity.

And with the help of the ZPrinter 310 Plus, the layout was printed in just half a day. “The more detailed the project, the more complex it is, the more benefits 3D printing provides,” Vaas notes. And he adds that the use of 3D printers gives an approximately twofold increase in productivity.

How does it work?

Z Corporation 3D printers work with BIM file formats to create 3D physical layouts from composite powdered plaster.

Z Corp cuts a model from software such as Autodesk Revit or Autodesk 3ds Max into thousands of horizontal layers. The printer's print head then makes thousands of passes through the powder, leaving a liquid binder at the intersection points. Where this substance comes into contact with the powder, it quickly hardens. Thus, printing at a vertical speed of about one inch per hour, the printer deposits the material layer by layer and creates a finished layout from powdered plaster.

Z Corp 3D printers are unique in that they are the only ones that can make models in color. No other technology for creating 3D layouts offers such a possibility. In addition, graphics and photographs can be applied to the model to further enhance the resemblance to the original.

No other technology for creating 3D layouts offers such a possibility. In addition, graphics and photographs can be applied to the model to further enhance the resemblance to the original.

Z Corp software allows you to go beyond the size of the plot area. The layout of the building can be divided into parts, and ZEdit Pro will automatically add studs and holes to them for subsequent assembly almost flush.

Savings

While a handmade mock-up can cost several thousand dollars, the cost of the same mock-up printed on a Z Corporation 3D printer is only $2-$3 per cubic inch.

"For medium to large projects, the cost of making a mock-up pays off almost immediately," says Scott Harmon, Vice President of Development at Z Corporation. – The device itself often pays off very quickly: if, for example, at the very early stage of the project, thanks to the model, it was possible to detect a serious error or the company became the winner of the tender, presenting its project in the most advantageous light. While 3D building layouts are relatively new, the majority of our clients are architects, who get value from the printer from day one.”

While 3D building layouts are relatively new, the majority of our clients are architects, who get value from the printer from day one.”

Speed and scalability

Where it took weeks to produce a medium-sized layout, a 3D printer can do it in less than 12 hours. Z Corporation inkjet 3D printers do not smoke, produce a minimum of waste, and the material remaining unused during the printing process is suitable for further use. Printers print at resolutions up to 600 dpi, scrupulously reproducing the smallest surface details.

The Z Corp line includes the ZPrinter 310 Plus black and white printer and three color devices: the ZPrinter 450, the Spectrum Z510 and the high-resolution ZPrinter 650.

"Other manufacturers' presses don't allow multiple layouts to be created at the same time: it's impossible to print models one on top of the other," says Scott Harmon. “Z Corp printers allow you to print as many layouts as they physically fit in the build area, thanks to a thin layer of powder between them. ”

”

Not so long ago, the Realization Group was once again convinced of the advantages of mass printing on Z Corp printers. When its office in Coral Gables, Florida, ordered 100 copies of a mockup for marketing purposes, Realization Group was able to complete the order in just two days, thanks solely to its ability to print multiple copies at the same time with no loss in accuracy, quality, or reliability.

Along with the benefits of speed and affordability, a 3D printer is of particular value to aspiring architects. The use of 3D printing at an early stage of design allows you to quickly gain valuable experience, protecting both the architect and customers from costly mistakes caused precisely by a lack of experience.

Thanks to Z Corporation's 3D printers, which produce architectural models much cheaper and faster than by hand, 3D printing can now be applied early in the design process, making the entire process more efficient. Just as BIM digital modeling makes designing cheaper and more efficient, 3D mockups created at the design stage of a project help to better understand its concept, avoid mistakes and provide business opportunities that were previously only dreamed of.

Building a house: 3D printing as the engine of the project

Throughout twenty years of work in the field of computer-aided design, R. "Parta" Parthasarati meets a new client with the same question: "What problem can we solve for you?"

Regular the answer is: “Fast time to market for our product.”

When it comes to architecture, Parthasarathy found that the two main reasons for delays came down to a lack of theoretical development of the project and poor communication.Two years ago, he discovered 3D printing, a completely new technology, significantly reduces design time.It allows you to produce an accurate 3D physical model of the building and make it an important part of the work of every designer.Partha saw this as a great opportunity to improve mutual understanding among all those involved in the project, increase efficiency and eliminate costly errors.And so iKix was born (www.ikix .in) is India's first archit service bureau textured 3D printing.

Previously, all construction models were made by hand. Since this process is time consuming and expensive, architects only make the layout at the final stage of the project, just before the public presentation.

"iKix 3D prints an average of six to 10 days, which is much faster than the month it takes to make a similar model by hand," Parta says. for golf and more - we can produce in six weeks versus five months of manual work. Time and financial savings become even more noticeable when plans change and the layout has to be adjusted on the fly.”

iKix uses the color Spectrum Z510 from Z Corp. The capabilities of this printer allow the architect and project manager to quickly obtain multiple copies of the layout - one each for the architect, client, general contractor, subcontractor and civil authorities. “A 3D printer is more than just a prototyping machine,” Parta says. – It really became one of the developer's tools. 3D printing is a breakthrough that I believe will determine the future of technical information exchange for the next two hundred years. Each project must be presented in 3D, and soon it will be so. I sincerely believe that all architects will work in 3D. iKix clients come here to implement more and more new projects in three-dimensional layouts. The benefits are undeniable."

Each project must be presented in 3D, and soon it will be so. I sincerely believe that all architects will work in 3D. iKix clients come here to implement more and more new projects in three-dimensional layouts. The benefits are undeniable."

Parta believes that infrastructure objects also need physical layouts. For example, when the authorities decided to build a highway interchange, it is necessary to plan traffic in all modes of its operation. The presence of a physical 3D model simplifies the solution of this problem.

Visibility: Civilian 3D Printing

Scandinavian consulting company Ramboll Group's (www.ramboll.com) has a track record of restored landmarks, stunning bridges, excellent roads and sustainable utilities. However, each new tender requires not only bright ideas, but also their bright presentation - this is the only way to count on success. This is one of the reasons why Ramboll adopted 3D printing technology.

Ramboll operates in a highly competitive international marketplace offering a full range of consulting services in the fields of infrastructure, telecommunications, architecture, healthcare, oil and gas, energy, environmental protection, information technology and management.

Ramboll is justifiably proud of the design findings already realized, but prospective customers are more interested in suggestions for possible future orders. The company is looking for ways to best present its ideas, and in this area, the possibilities of 3D printing cannot be overestimated.

From the very beginning, Ramboll's absolute requirement was color printing. This predetermined the choice: Ramboll purchased a Z Corporation Spectrum Z510 3D printer, the only high-resolution color printer to date. The

Spectrum Z510 quickly generates 3D architectural and engineering layouts - in less time and typically at a fraction of the cost of a traditional hand-held method. Due to the clear color detailing, layouts better convey the ideas of the project. And the ability of the Spectrum Z510 to apply textures to the surface makes the layouts realistic and spectacular, which is especially important for infrastructure projects. For example, Ramboll engineers can apply a brickwork texture to the surface of the wall, and a bird's-eye photo of it on a landscape model.

New opportunities have significantly increased the chances of Ramboll. Shortly after acquiring the Spectrum Z510, the company won a tender to design a major bridge at its home in Denmark.

The layout faithfully displayed special V-shaped stops that took up less space and required less material than their classic counterparts. He perfectly conveyed the zest of the concept.

“This is just one example where color 3D printing has won a tender,” says Jita Monshizadeh, CAD designer for Ramboll's transportation and infrastructure division. “And we already have many such examples. 3D printing, like nothing else, helps the customer to feel the uniqueness of our projects, not to miss any of the ideas embedded in them. We create presentations that represent the capabilities of Ramboll in high definition and color. The color, clarity and textures – right down to the pattern of the stonework on the wall – all really make a lasting impression.”

In addition, 3D printing saves Ramboll money. For example, recently, when a company needed a mock-up of a 12-story apartment building, it was calculated that it would cost three times less to print a color model on a 3D printer than ordering it by hand.

For example, recently, when a company needed a mock-up of a 12-story apartment building, it was calculated that it would cost three times less to print a color model on a 3D printer than ordering it by hand.

“Printing a color physical model is almost effortless, as long as the scale is right,” continues Jita Monshizadeh. - If the project is made in a 3D design program, this is quite enough to form a 3D model. Sometimes the model needs to be slightly optimized to scale it to the resolution of the printer, but this is usually not difficult. Problems rather arise in the manual production of a layout - when, for example, one single small detail takes a lot of time! In other words, 3D printing encourages creativity and spatial thinking. At different stages of the project, you can easily make printouts of the layout and compare them. ”

Highlight: using 3D mockups in presentations

For Robin Lockhart, Associate Manager and Head of Operations at OBM International (www. obmi.com), design projects that typically involved many hours of discussion and required many trial and error decisions and mistakes, have now become a catalyst that sets the overall dynamics.

obmi.com), design projects that typically involved many hours of discussion and required many trial and error decisions and mistakes, have now become a catalyst that sets the overall dynamics.

The thing is that not so long ago the company integrated 3D printing into its production processes.

One of the most important projects is the construction of a new headquarters for OBM International in Coral Gables. Using a 3D printer purchased from Z Corporation, “I made a mock-up of a four-seat workbench with components broken down so that they can then be assembled in different configurations,” says Robin Lockhart. – The design team came up with solutions that can be combined by swapping components. This saved us from unnecessary debate, saved a lot of time and effort, and most importantly allowed us to quickly and dynamically come to the desired solution. In addition, the search process itself turned out to be extremely exciting.

OBM International acquired a Z Corp Spectrum Z510 3D printer in December 2007. “Now we use the Z Corp Spectrum Z510 with all the options, including the automatic cleaning module for powder residue. In essence, we have here the entire set of devices for working with layouts, which gradually developed around the main printer.

“Now we use the Z Corp Spectrum Z510 with all the options, including the automatic cleaning module for powder residue. In essence, we have here the entire set of devices for working with layouts, which gradually developed around the main printer.

Lockhart commented that 3D printing had the best impact on the nature of OBM International's business: “Our level of understanding with the customer is amazing. The general mood of the presentation instantly changes for the better as soon as we present the layout to the customer. Clients are now able to discuss in a way they understand well, the model consistently makes a good first impression, and clients are grateful.”

Previously, OBM International used traditional 2D drawings, color projections and videos for presentations. Designers used tracing paper, hand sketches, CAD, 3D visualization and modeling. “All this was in our arsenal and all this imposes certain restrictions. When we make a presentation for a customer who is not fully familiar with the nuances of this format, the information content is reduced, and this can negatively affect the decision made. ” According to Robin Lockhart, OBM International also makes 3D models for its own needs: for the purpose of critical analysis and evaluation of the project.

” According to Robin Lockhart, OBM International also makes 3D models for its own needs: for the purpose of critical analysis and evaluation of the project.

“Our document workflow is focused on the ubiquity of physical layouts,” says Lockhart. – With the increasing use of the 3D printer, we can hope that the quality of our projects will only improve. In addition, this device really became the highlight of all our architectural presentations.”

Export from Autodesk Revit

The increasing use of 3D printing in architectural design has resulted in a tool that allows users to upload STL files imported from Autodesk Revit directly to Z Corp.'s 3D printer. Not so long ago, Autodesk announced the release of a new STL Exporter utility for the Autodesk Revit 2009 platform.(BIM). In the past, converting Revit files to STL format required third-party software.

This development highlights Autodesk's confidence in 3D printing and its growing adoption as the process becomes more cost-effective and efficient.

“Physical 3D models are becoming an integral part of the design process, offering visual insight into the design and improving the relationship between designer and customer,” says Emile Kfoury, senior line manager for Autodesk AEC Solutions. – 3D mock-ups are essential for our customers throughout the entire life cycle of a product, but above all when looking for a conceptual solution. The STL Exporter for the Revit platform has full support for Z Corporation devices, which have made 3D printing not only incredibly fast and high quality, but also truly affordable. We are also developing other interesting solutions for printing physical layouts on Z Corporation printers.”

Kfoury also noted that he is confident in the bright future of 3D printing. “Most of the 3D models are printed so far only at the stage of conceptual development – during the study and design of the outlines of the future building. In addition, the physical layout appears at the final stage, when the project is made public.