3D printed tourbillon mechanical clock

You can now 3D print a triple-axis tourbillon clock for less than $100 on MyMiniFactory

0Shares

Watchmaking enthusiast Mechanistic has launched a crowdfunding campaign for a luxury 3D printed timepiece on leading 3D file marketplace MyMiniFactory.

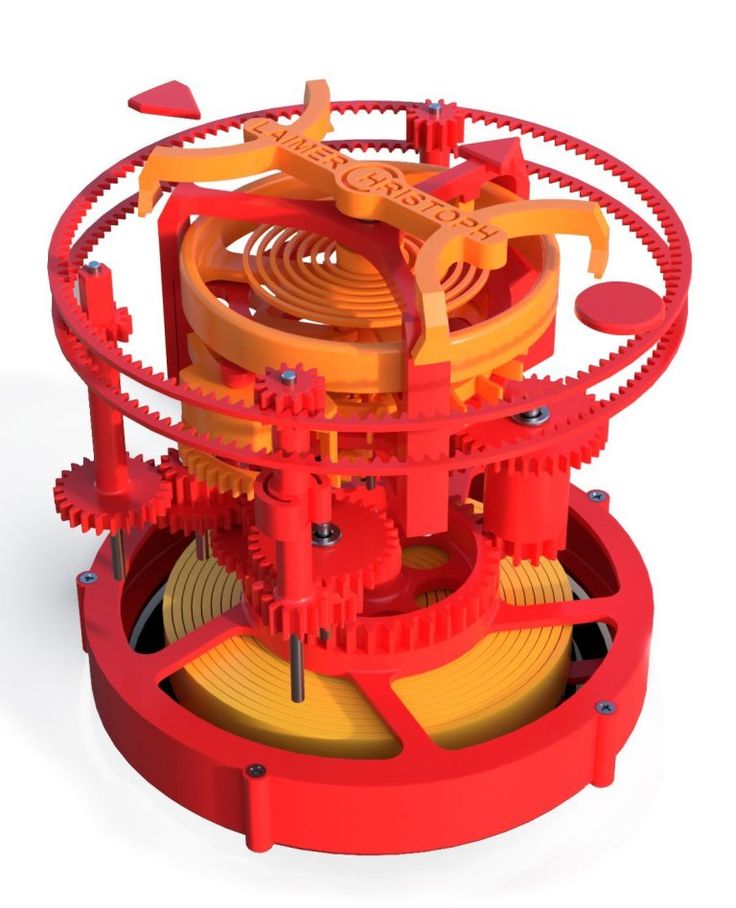

The Tourbillon Mechanica Tri-Axial is a high-end, triple-axis timekeeping mechanism designed to be 3D printed on consumer-grade FDM systems. With the one-month campaign set to end on May 12, MyMiniFactory users have already pledged over $16,000 in a single day.

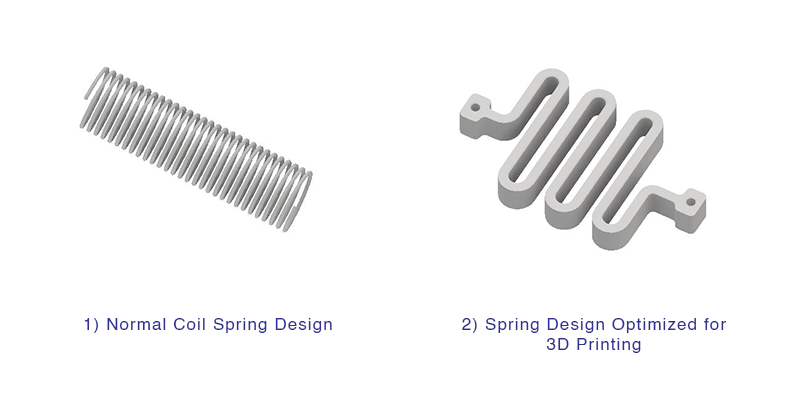

Comprising 230 individual components, the Tri-Axial is a functional mechanical clock that doesn’t need a battery, although it isn’t designed to be a long-term timekeeper. Due to limitations in 3D printed polymer materials, Mechanistic estimates that the assembly will run for around 90 minutes with a steel spring and 15 minutes with a PETG spring.

Mechanistic writes, “The Tri-Axial was designed with the intention of being a functional mechanical sculpture that gives users a first-hand understanding and experience in the assembly and construction of the luxury mechanism. ”

The triple-axis tourbillon

The triple-axis tourbillon is widely regarded as one of watchmaking’s greatest technical challenges. These exclusive watches are equal parts engineering and art, and are very hard to come by in the real world. If you’re in the market for one, expect to shell out something in the range of $200,000 – $500,000. With Mechanistic’s Tourbillon Mechanica Tri-Axial, you can 3D print your own for less than $100.

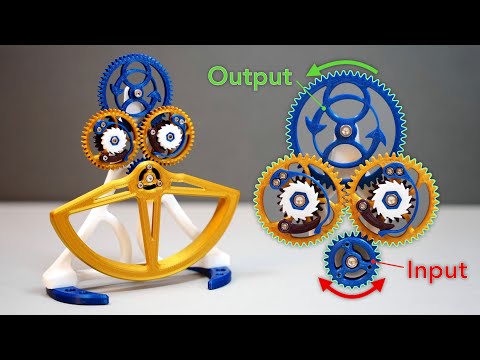

So how does it work? The design is centered around a triple-axis tourbillon that rotates the escapement mechanism – the time-keeping mechanism – about three different axes to cancel out the effects of positional variation on the time regulation. It does this using a very cleverly-assembled set of bevel gears and a wind-up spring, meaning there are no electronics or batteries involved. With symmetry in mind, the hours are kept on the indicator on the left while the minutes are kept on the indicator on the right.

Explaining the motivation behind the work, Mechanistic adds, “I’m not a watchmaker, but as a mechanical engineer who is both a watch nerd and a 3D printing geek, I was greatly inspired by Christoph Laimer and Adam Wrigly‘s efforts in creating a fully functional 3D printed clock and triple-axis tourbillon respectively.”

Designed to be printed in PLA and PETG, the Tourbillon Mechanica Tri-Axial should have a total print time of around 140 hours. As well as the polymer parts, users will need some screws, pins, and three ball bearings. The in-depth assembly guide can be downloaded for free.

The triple-axis tourbillon in action. GIF via MyMiniFactory.How do I back the crowdfunding campaign?

The MyMiniFactory crowdfunding campaign has three different pledge tiers, depending on what you’re looking to 3D print. The first pledge tier, Engineer ($24), grants access to two of Mechanistic’s previously released mechanical designs: the Mini Mechanica and the Tourbillon Mechanica. Please note that this pledge tier does not grant access to the new flagship assembly, the Tourbillon Mechanica Tri-Axial.

Please note that this pledge tier does not grant access to the new flagship assembly, the Tourbillon Mechanica Tri-Axial.

The next pledge tier, Lead Engineer ($61), gives users the Tourbillon Mechanica Tri-Axial and the Mini Mechanica. Finally, the Chief Engineer pledge tier ($79) grants access to the STL files of all three designs. Early bird discounts on all three pledge tiers are set to run until April 15.

Click here to back the crowdfunding campaign on MyMiniFactory.

The assembly is powered solely by winding its spring. GIF via MyMiniFactory.With the maker community so deeply ingrained in FDM 3D printing, the greatest innovations often come from individuals in their workshops. Late last year, open-source 3D printing enthusiast Johan Von Konow released his latest DIY project, a modular 3D printable MIDI synth. Dubbed the LEET Synthesizer, the fun project can be built for a grand total of $6, and requires only a few basic soldering and embedded electronics programming skills.

Elsewhere, Michigan Technological University’s Joshua Pearce has previously released the open-source design plans for a low-cost, high-temperature FDM printer that can be built at home. Dubbed the ‘Cerberus’, the three-headed machine can be assembled for less than $1000 and is capable of printing a number of high-performance materials such as PEKK and Ultem/PEI.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Mechanistic’s Tourbillon Mechanica Tri-Axial. Photo via MyMiniFactory.

Tags Adam Wrigly Christoph Laimer Mechanistic myminifactory

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

3D file Tourbillon Mechanica - Tourbillon Escapement Mechanical Clock・3D print design to download・Cults

Mini Mechanica 2.0

€9.61

Tourbillon Mechanica Tri-Axial

€71.05

Fully Functional Grand Piano

€66.29

Micro Jib - A Table Top Camera Crane

€34.84

Mecha Studio

€19.12

Grand Piano Action Mechanism (5 Keys)

€14.41

Grand Piano Action Model (13 Keys)

€19.21

Mini Mechanica 1.0

Free

Best 3D printer files of the Various category

Gamesir G3w,G3s phone holder

Free

Pinocchio

Free

replacement keys for Mini piano

Free

COVID-19 Low Cost Face Guard / Mask

Free

Bart keychain lithophane

Free

Repair Dashboard R4

€0. 50

50

Brain Beetle

€0.80

Bird House

€2.87

Best sellers of the category Various

Gengar - Flexi Articulated Pokémon (print in place, no supports)

€2

Gnome Yeah ( Supportless )

€2.49 -20% €1.99

ItsLitho "Swirl" personalized lithophane Christmas ball

€1.90

Christmas Stitch

€1.25

Middle Finger Keyholder

€1

ItsLitho Christmas Balls Bundle

€7.60

RS-X-Bow "Government - 1911" style

€6. 25

25

Christmas Park

€4.64

Articulated Rayquaza Flexible Pokemon Dragon

€1

MOATY

€4.76

Mickey Christmas night light lithophane

€3.50

MMPR Dragon Dagger

€4.80

CHRISTMAS TREE v2

€1.50

ItsLitho "Pure" personalized lithophane Christmas ball

€1.90

Adderini - 3D Printed Repeating Slingbow / Crossbow Pistol

€12.50

M2 Browning Cal.50 American Heavy Machine gun 3D-print 1/35 and 1/16

€14.99

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

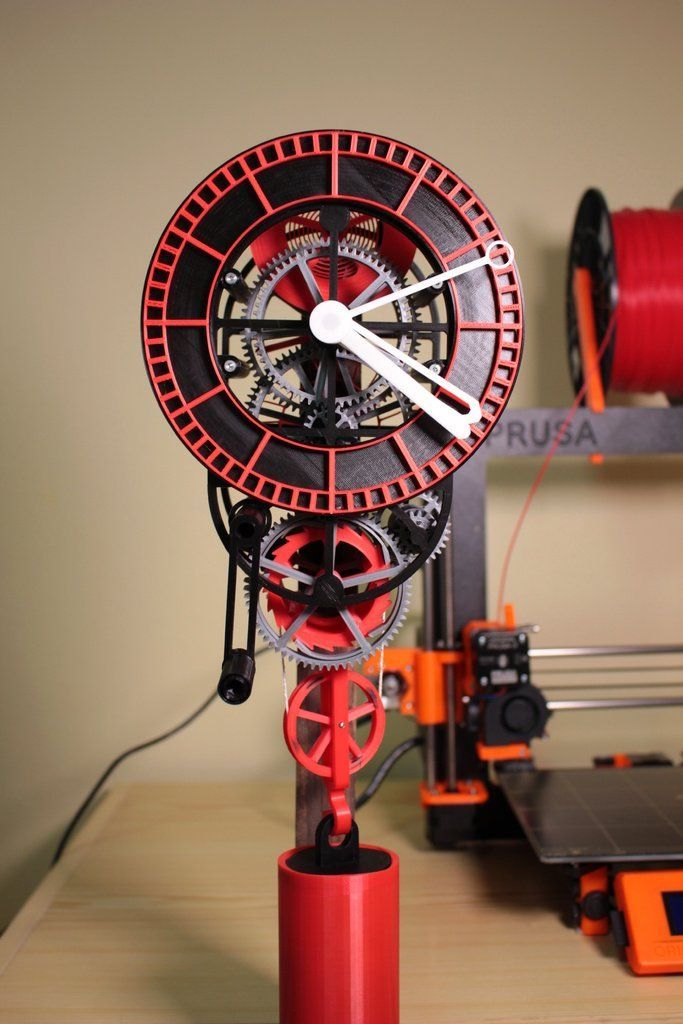

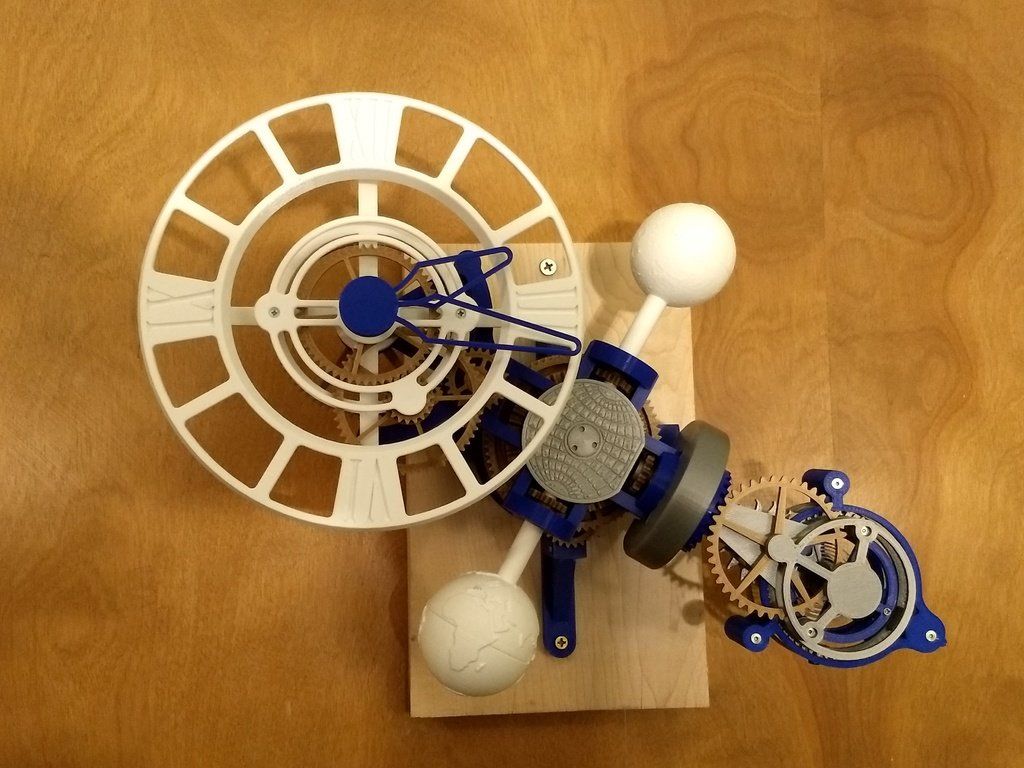

"Christoph Laimer Tourbillon" - the world's first 3D printed tourbillon watch

Swiss engineer and designer Christoph Laimer has introduced the world's first fully functional 3D printed mechanical watch.

Every day 3D technologies are gaining more and more fans,

becoming more common and accessible, and their application

is becoming more and more diverse. Therefore, it will be interesting to see how

the art of watchmaking will be reflected in the designs created from

with this modern technology.

A few years ago, the world's first 3D printed tourbillon

was already developed and introduced.

software engineer Nicholas Manousos introduced the so-called Tourbillon 1000%,

, with all the details printed on a 3D printer. In the future

Nicholas planned to create a full-fledged watch since he was

I'm sure that sooner or later it will be possible to produce a fully functioning watch with

3D printing technology.

This year, only two years later, Christophe Laime decided to

make a very complex, but really amazing project using 3D printing technology - a functioning mechanical tourbillon watch, not just

turning into reality the idea of Nicholas, but also surpassing it. The tourbillon is one of the

famous and popular watch complications, developed over 200 years ago by the famous watchmaker Louis Breguet

, and is still considered one of the most complex movements.

According to the Swiss engineer, all parts for the mechanical watch "Christoph Laimer Tourbillon", except for metal screws and pins, are printed on a 3D printer. The main task is to demonstrate that 3D printing technology is developing and its capabilities open up new horizons for creativity and serious projects.

The main task is to demonstrate that 3D printing technology is developing and its capabilities open up new horizons for creativity and serious projects.

Smaller than its predecessors, it looks more like a table clock, but it is not small enough to carry on your arm or even in your pocket.

With a diameter of 10 cm and a height of 10 cm,

is much smaller than even the first tourbillon created by

Nicholas.

Of course, this is not the first attempt to create working hours

using this technology, but one of the most difficult

and interesting watch designs. Christoph Laime

is also not the first project, among his works there were already

working hours, but they were not so complicated and their dimensions were much larger.

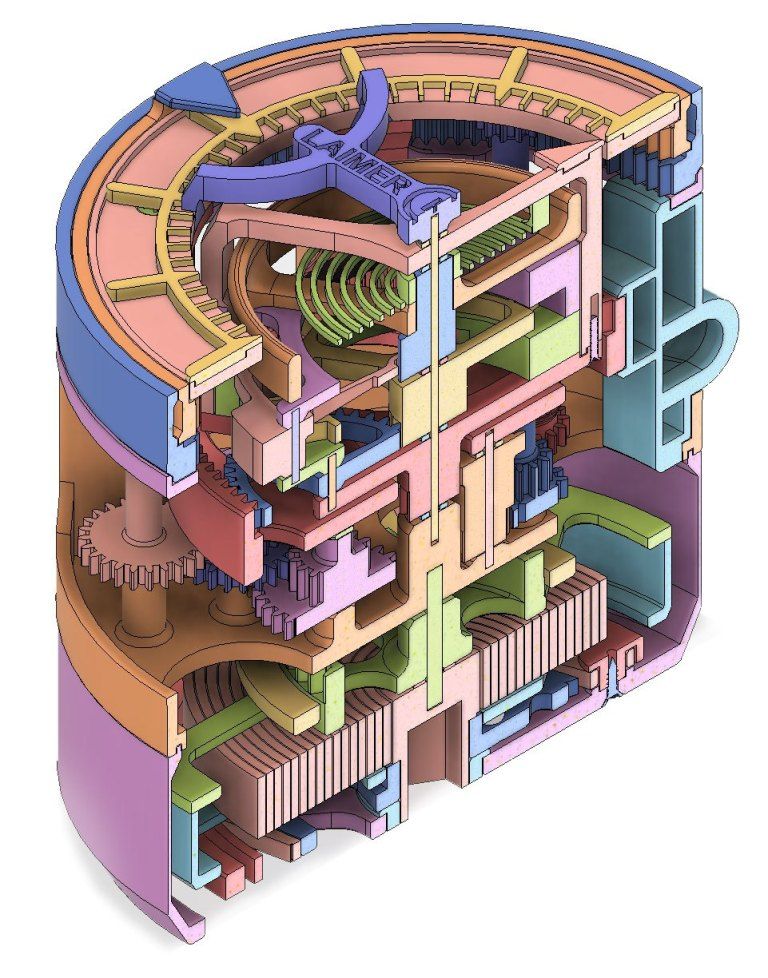

The project was developed in Autodesk Fusion 360 and printed on the Ultimaker 2 3D printer. As for the reliability of the movement and the performance of the watch, the tourbillon chronometer surprisingly works quite well, of course, it is inferior in accuracy to conventional watches, its accuracy is +/- 2 seconds per minute. The power reserve of the watch is also small, they can display the time of only about 35 minutes. The clock is wound with a plastic spring.

The power reserve of the watch is also small, they can display the time of only about 35 minutes. The clock is wound with a plastic spring.

The two materials

already tested were

PETG and PLA to create the case and movement of the watch. For the mechanism Christophe

used a common thermoplastic

PLA (polylactide), which has a higher resistance

to strong ultraviolet

radiation, temperature and high humidity

. The watch case is printed with

high impact plastic PETG, which is

very durable material.

Christophe Laime is not going to stop at this project and plans to improve the watch and perhaps make it even more compact. In addition, he posted the source materials for printing in free access to the well-known 3D printing site Thingiverse. And everyone can try to make a watch themselves or try to improve it. But Christoph draws attention to the fact that without knowledge of the principles of operation of a mechanical watch, it is impossible not only to create a working watch, but even to assemble a working model according to diagrams and instructions is quite difficult.

Also, for those who do not have their own 3D printer, Christoph Laime offers to purchase this watch model with a tourbillon "Christoph Laimer Tourbillon". In total, the series available to customers includes 12 copies, presented in four versions.

to the newsfeed

3D printed tourbillon watch - how it's made

Creativity

Follow author

Follow

0002 16Dear friends! While gathering the best content for you, we couldn't get past popular YouTube videos like '3D Printed Tourbillon Watch - How It's Made'.

Therefore, now we will translate the most interesting of them so that you can enjoy them to the fullest :)

3D printed tourbillon watch - how it's made

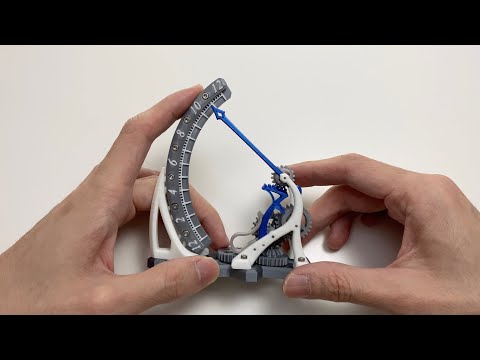

This project presents a 3D printed mechanical tourbillon watch. The main driving force of the clock is the spring installed inside. The approximate operating time of the watch on a single charge is 30 minutes. Accuracy is approximately one second deviation within one minute (depending on printing settings).

The main driving force of the clock is the spring installed inside. The approximate operating time of the watch on a single charge is 30 minutes. Accuracy is approximately one second deviation within one minute (depending on printing settings).

Clock designed in Autodesk Fusion 360 and printed on Ultimaker 2.

Download model available on Thingiverse

TimeLapse assembly time

Animated assembly process

Design in Autodesk Fusion 360:

Non-printed parts in assembly

1 Pin, 1.5 mm diameter, 55.5 mm long (tourbillon axis)

1 Pin, 1.5 mm diameter, 12 mm long (armature axis)

1 Pin, 1.5 mm diameter, length 8.5 mm (planetary gear axle)

3 Pins, 2 mm diameter, 57 mm long (shaft for minute and hour gears)

6 Pins, 2 mm diameter, 22 mm long (axle for base gear)

1 Pin, 2 mm diameter, length 15 mm (main spring mounting)

1 Pin, 3 mm diameter, 22.5 mm long (main spring shaft)

1 Pin, 3 mm diameter, 31 mm long (main gear shaft)

3 Washers, diameter 3 mm ( main spring , gear wheel )

6 Washers, 2 mm diameter (transmission)

5 Washers, 1. 5 mm diameter (tourbillon, escapement)

5 mm diameter (tourbillon, escapement)

5 Screws, 1.8 mm diameter, 6.5 mm long (ratchet pawls)

5 Screws, diameter 1.5 mm, length 5 mm (running drum)

4 Screws, diameter 1.5 mm, length 10 mm (base plate)

4 Screws, diameter 1.8 mm, length 12 mm (dial)

3 Screws, diameter 1.5 mm, length 10 mm ( tourbillon )

Source of information. Translated by iGo3D.

Our groups in social networks:

VKontakte

Your iGo3D team

Follow author

Follow

Don't want

16

More interesting articles

thirty

Subscribe to the author

Subscribe

Don't want

Greetings to all.

My sister's birthday is coming soon.