3D printing delrin

Delrin 3D Printing Filament - Pros And Cons & Buying Guide

ADVERTISEMENT

Table of Contents

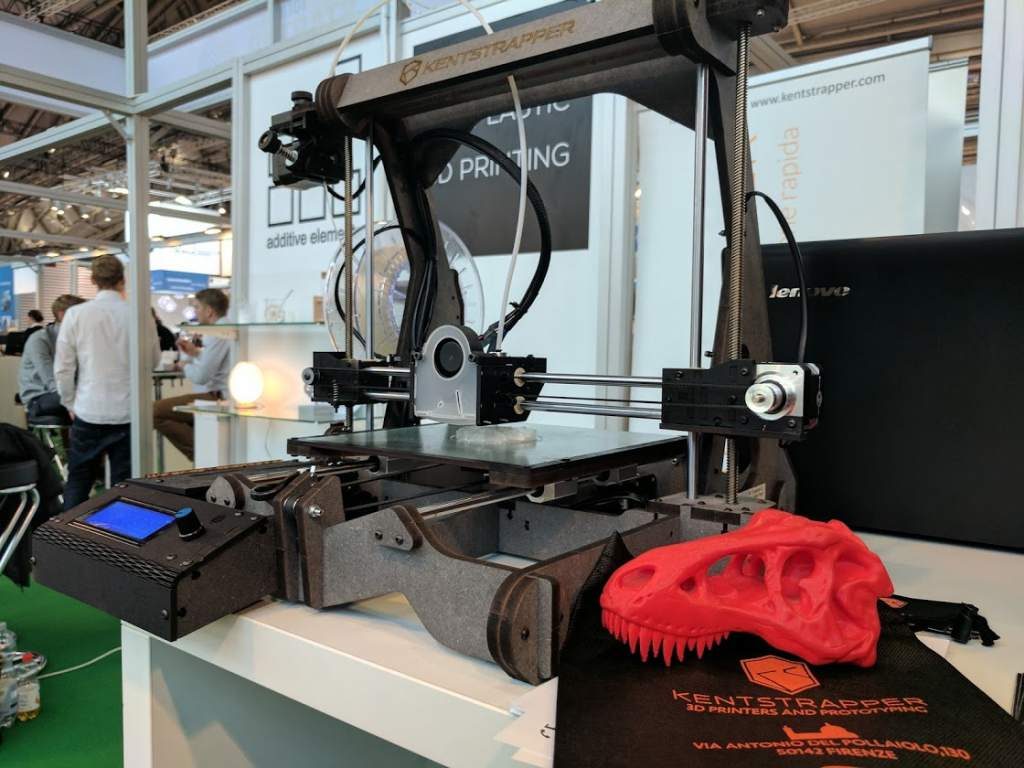

The quality of a part or functional prototype that you are 3D printing depends on a few factors such as the 3D design file, quality of the 3D printer you are using, and the quality of 3D printing filament.

The 3D Design file is a work of accurate playing with the software modeling tools. Buying the correct 3D printer for your application is based on the research that you do before buying and observing 3D printer features and matching them up.

But buying the correct 3D printing filament is a much tougher job because would not only have to research it out but also match it with your printer.

In this article, we are going to state and share facts and features of the Delrin 3D printing filament.

Reading this article would give you insight into this specific brand of filament, its use with the printers, the printer setting it recommends every user to keep, applications in which it is generally used, and where to easily get it from.

Let’s start with a little bit of an overview of this 3D printing filament.

ADVERTISEMENT

Overview of Delrin 3D Printing Filament

Delrin is factually a trading name used by a renowned company named Dupont, for its range of Acetal Resin. And as far as Acetal resin is concerned, it is a pet name or a colloquial name for what is technically named Polyoxymethylene filament.

Apart from manufacturing 3D printing filaments, DuPont is manufacturing many kinds of products that fit into many industry verticals.

Making a significant claim on their About Us, Dupont has its own community of scientists, engineers, visionaries, and all their partners working day in, day out to transform industries and improve everyday life.

Polyoxymethylene filament is available in two kinds:

- Polyoxymethylene copolymer acetal.

- Polyoxymethylene homopolymer acetal.

For those who wish to know more exactly about Delrin, the closest scientific name of it is Polyoxymethylene homopolymer acetal.

What to Keep in Mind while Delrin 3D Printing?

Whether while 3D printing a part or functional prototype, or manufacturing a part or functional prototype using any traditional manufacturing method, one thing remains the same i.e. the attributes of the part are credited to the material used for making the part or functional prototype.

So it is important, whether you are dealing with this or any other manufacturing method to know the characteristics or basic properties in mind while manufacturing a part or functional prototype using that raw material.

Here, the raw material is Delrin which has the following properties.

- The company, DuPont claims Delrin as an ideal material in parts that are designed to replace metal.

This the company reasons out, is because Delrin combines a low-friction and high-wear resistance with high strength and stiffness which applications of metal generally require. Delrin is also known to operate with a wide temperature range ranging from as low as -40 degrees Celsius to as high as 120 degrees Celsius. Offering excellent dimensional stability in precision molding, Delrin is known to mate easily with metals as well as polymers.

This the company reasons out, is because Delrin combines a low-friction and high-wear resistance with high strength and stiffness which applications of metal generally require. Delrin is also known to operate with a wide temperature range ranging from as low as -40 degrees Celsius to as high as 120 degrees Celsius. Offering excellent dimensional stability in precision molding, Delrin is known to mate easily with metals as well as polymers. - When compared to Polyoxymethylene copolymer acetal, Delrin is known to offer higher tensile strength, with stiffness, creep, and fatigue resistance, additionally significantly higher impact resistance. And what does a combination of these mechanical properties give you as an outcome in the part or functional prototypes you are manufacturing? You get a single material that makes thinner weighing parts and functional prototypes, the material has shorter molding cycles and potential cost reductions.

Dupont also makes a claim “It’s more than acetal, it’s Dupont Delrin. ” And what does it exactly mean by claiming so, is explained in the section below, derived from the company’s article about this claim.

” And what does it exactly mean by claiming so, is explained in the section below, derived from the company’s article about this claim.

ADVERTISEMENT

It’s more than Acetal, it’s Dupont Delrin

Acetal copolymers are not as tough, light-in-weight, and durable as Dupont Delrin is. It inherently has low friction, wears, and moisture pick-up with excellent spring-back properties.

Delrin’s acetal homopolymer features a uniform backbone that has a larger crystalline block structure compared with acetal copolymers that provide a better chemical bonding.

Hence the parts or functional prototypes produced after Delrin 3D printing will be the stiffest and strongest.

Delrin has increased design flexibility, with thinner wall sections at the same physical part performance.

It is able to manufacture lighter parts and functional prototypes and enables less material usage. Mold filling is improved with shorter molding cycle times.

Compared to acetal copolymer, Delrin’s homopolymer has an 80 percent higher yield strain and a 65 percent higher flow rate.

Also over a 40 percent higher impact resistance particularly at low temperatures. More than a 1000 percent higher flex fatigue resistance is one of the most unique features of this material.

This particular combination of properties makes Delrin 3D printing then be used for a number of different purposes.

After having gone through these properties of Delrin, it would give you a nice idea about the kind of parts and functional prototypes one can manufacture using Delrin.

We hope that after reading this section of the article you can get an idea of where to use Delrin for. Let’s have a look at the applications of Delrin 3D printing.

ADVERTISEMENT

Applications of Delrin 3D Printing

Because of the high properties of Delrin, it is a favorite amongst engineers and designers. Below is the list of parts that one can manufacture using Delrin.

Gears and Bearings

Gears and Bearings as we all know are one of the key parts wherein most of the engineers and designers are interested.

Not only one has to deal with load and pressure, but also design gears in a way that will happen when they are subjected to wear!

Delrin is a 3D printing material with excellent resistance to wear, is an ideal material for such parts and functional prototypes.

Another property that a 3D printing material should have for making parts and functional prototypes like gears and bearings is the material’s coefficient of friction.

Delrin has a low coefficient of friction which makes it very smooth. So, for making rotating parts, Delrin is a very suitable choice.

High-Temperature parts and functional prototypes and Chemicals

Using Delrin 3D printing, one can manufacture piping because it has a low moisture absorption rate and is also chemically resistant to not only solvents but also hydrocarbons and neutral chemicals.

Delrin is a 3D printing material that delivers chemical as well as dimensional stability.

Rollers, as well as safety restraining materials, see the use of a Delrin 3D printing material which is more connected to Delrin’s application in traditional manufacturing techniques.

Delrin can withstand high temperatures as well as the part’s original dimensions which do not change even under temperature fluctuations.

After having seen some basic applications of Delrin material, let’s look at the few printing tips and tricks for manufacturing parts made from Delrin

ADVERTISEMENT

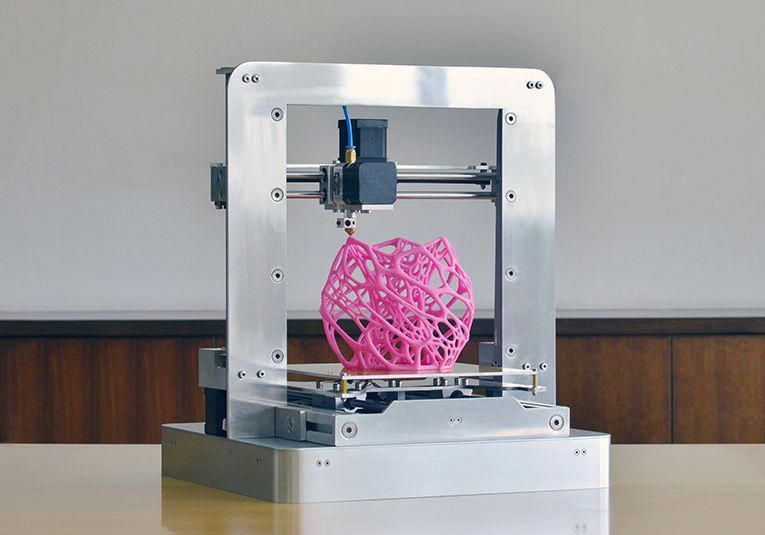

How to 3D Print Using Delrin?

Every 3D printing material is compatible with one or the other specific type of setting which is more suitable while printing parts and functional prototypes using it.

Like most other 3D printing materials, Delrin too has problems with bed adhesion as well as warping. And this is because of Delrin’s property of low coefficient of friction.

Also as Delrin is a smooth material, users face some challenges with sticking the parts or functional prototypes to the print bed of the printer which is used for manufacturing it.

Most of the 3D printers are based on regular heating beds like glass or some other kind of textured surfaces.

But the bad news while Delrin 3D printing is those kinds of heating beds would not work as efficiently as they do with other 3D printing materials.

Instead, as suggested, you would need a wooden or cardboard surface on the top of the heated bed on which you can lay your printed part or a functional prototype.

A blue tape, hairspray, or methods like adhesives are advised because they are known to provide better results.

Another important point to note about Delrin is that it is a stiff material.

So, all you need is a metal hotend, but it should not get overheated, because then that leads to the production of formaldehyde fumes which are dangerous to inhale for any user dealing with the 3D printing of that part of a functional prototype.

A tip also suggests the user use a heated build chamber or a 3D printer with a closed body for decreasing the 3D printing time.

ADVERTISEMENT

What are the Best Printer Settings while Printing Delrin?

The suggested hotend temperature while Delrin 3D printing is in the range of 210 to 230 degrees Celsius.

Going above 230 degrees Celsius, you would overheat this material and ruin the 3D printing of part or functional prototype and put yourself in danger of inhaling unwanted fumes in the atmosphere.

Normally the printer with which you are 3D printing should have a temperature ranging from 120 to 150 degrees Celsius, but apart from this advice, experts also recommend trial and error yourself before deciding what’s best for you.

As far as the print speed of the printer is concerned, you are recommended industry-standard i.e. 30 millimeters per second.

This print speed is known to help in ensuring the layer bonding of top quality.

In case the print head moves faster than the mentioned speed, the stiff material as such as Delrin 3D printing would not get enough time for achieving good adhesion onto the previous layer of the part or functional prototype that has been printed.

After having gone through the printer settings which you need to take care of while Delrin 3D printing, let’s look at the pros and cons before concluding this article.

ADVERTISEMENT

Pros and Cons of Delrin 3D Printing

PROS:

- Compared to other 3D printing materials, Delrin has a high fatigue resistance.

- A higher creep resistance, as well as toughness combined with higher tensile strength and stiffness, makes these materials good enough to replace metal in the application of parts or functional prototypes.

- Using Delrin you can make thinner, lighter parts as well as reduce part production costs.

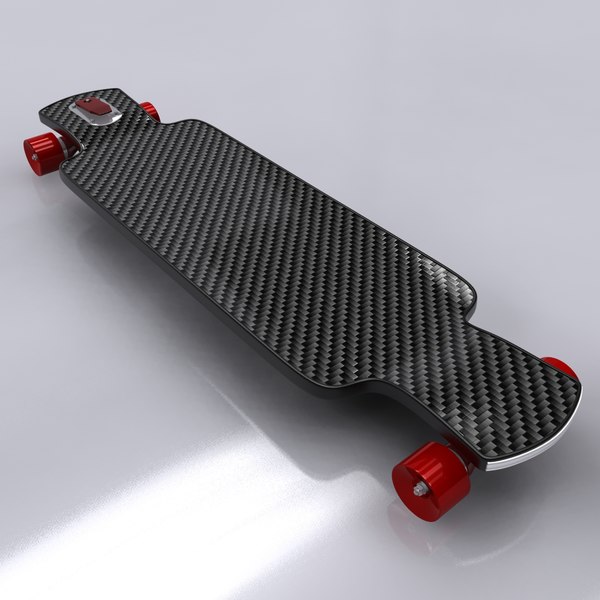

- You can see the application of Delrin in Gears, Safety resistant components, door system components, conveyor system components, medical delivery devices, ski bindings, as well as zip fasteners.

CONS:

- Because of lower bed adhesion, parts printed using Delrin are advised to print under an experienced hand on 3D printing. Otherwise, there are high chances of a bad adhesion in the printed parts and functional prototypes, due to the use of which, application failure can be a very likely outcome.

- Delrin requires a higher printing temperature range. So, 3D printers that offer a lower printing temperature range, which is often cheaper in price are not recommended for Delrin 3D printing.

- The cost of this filament as per GIZMODORKS, which is one of the many websites that offer this filament is $26.95 for a 1.75 mm diameter filament spool which is either black or white in color. ABS on the other hand costs $19.95. So, while you are doing a batch production of parts or functional prototypes, it would cost you much higher.

The Conclusion

Because of the increase in awareness of 3D printing technology, many websites have started offering 3D printing filaments, so you can easily find Delrin for Delrin 3D printing on GIZMODORKS as mentioned above.

Apart from that website, you can also find Delrin’s spool on 3D printers online store, 3D printing shop, and hobby king.

At each of these websites, you can get Delrin for Delrin 3D printing at varied prices such as $45, and $20 as well.

Hope that the aim with which we started presenting this article has been closely achieved and while you are busy doing your research for which filament to buy for your next metal 3D printing project, you consider Delrin as one of those.

And that it does suit your 3D printer and you have a safe and journey using this 3D printing material. We wish you good luck with 3D printing metal type parts and functional prototypes.

My experience 3d printing acetal, Delrin ™(DuPont), Chemical Name PolyOxy-Methylene (POM) : 3Dprinting

I could not find any info on the net, so I thought I would post my experience. Hopefully some others can contribute more and help us all. First, I am a big time amateur, but I’m also an engineer so I at least do things methodically. I have a printer in my shop where I build and service my race cars. Printing is just another tool in the toolbox and my ultimate goal was to design and print some carbon-nylon ready to use parts. I achieved that easily and then realized I could do some real fun stuff with Acetal. That’s when my smile turned upside down. In my research I could not find anyone successfully printing anything in the size I wanted or with any sort of home-based printer. Nor could I find anyone to print the parts for me.

That’s when my smile turned upside down. In my research I could not find anyone successfully printing anything in the size I wanted or with any sort of home-based printer. Nor could I find anyone to print the parts for me.

Why Acetal?

It is relatively cheap, rigid, good strength, dimensionally stable, easy to sand or machine, low moisture absorption, wear and abrasion resistant, chemically resistant, self-lubricating, suitable for useable parts.

Why not Acetal?

It is HARD to print and requires printer upgrades. Self-lubricating means it does not stick to anything. Like frying bologna on a Teflon pan. And if that is not enough, when heated it gives off harmful vapors that can cause cancer.

In summary, a good print is all about adhesion to the base. Ever heard that before? Well after 6 months of trials I finally gave up on that. But this is what I did to get close and can print some usable parts with the compromises I made. This is by no means a recipe for success for others. I came up with a process that gets me what I need but I can’t tell you exactly which variables you can change and get better or worse success with your projects. At this point I have frozen my process and I am no longer experimenting.

I came up with a process that gets me what I need but I can’t tell you exactly which variables you can change and get better or worse success with your projects. At this point I have frozen my process and I am no longer experimenting.

Material

I have been using the Gizmo Dorks version of Acetal filament in 0.4mm size. I purchased from Amazon and a 1kg roll seems to go for a long way. I read somewhere Acetal is somewhat hydroscopic and could cause print problems if left in high humidity area. I keep the roll in a sealed box with a small Peltier plate dehumidifier that keeps it around 50% or less. This was not a problem because I was already storing and printing Nylon. So far part shrinkage has been around 2.5%.

From Gizmo Dorks: “Please note that Acetal degrades when overheated and may give off small amounts of formaldehyde gas. Do not keep Acetal heated above 230°C. Please always use in a well ventilated area or in a ventilation system. Decomposition of the material depends on the length of time it is exposed to elevated temperatures. At typical print temperatures of 210 - 220 C, decomposition is not significant until after 30 minutes. At melt temperatures, acetal is incompatible with halogenated polymers and can cause spontaneous formaldehyde gas formation. Print using an all metal hotend.”

At typical print temperatures of 210 - 220 C, decomposition is not significant until after 30 minutes. At melt temperatures, acetal is incompatible with halogenated polymers and can cause spontaneous formaldehyde gas formation. Print using an all metal hotend.”

Print Size

My initial project was a suspension bearing that fits into a piece of square tubing. The final part is 34mm x 34mm x 75mm tall with a 25mm hole through the center. I mention this because size matters. Smaller parts should be slightly easier to print and larger parts will be more difficult. All my development so far has been getting this project to work.

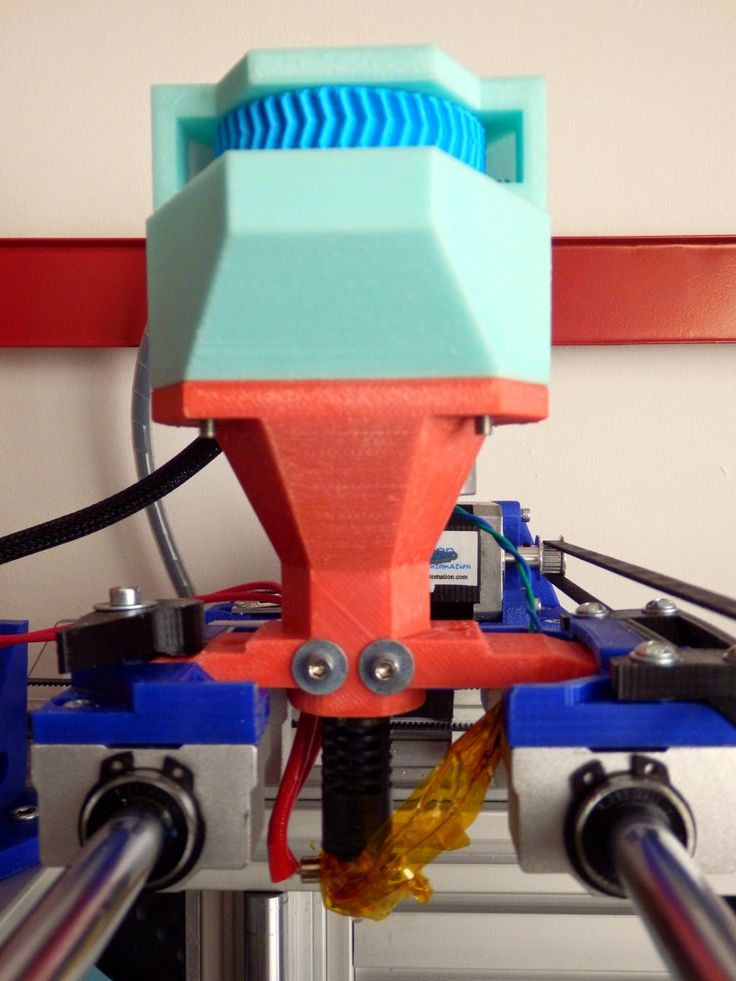

Machine

I am using a Creality CR-10S I have been running for over a year. It has several modifications to be able to print the Carbon-Nylon material and also the Acetal. It has a V3 hot end upgrade with carbon-nylon housing to hold it, tool steel 0.4 nozzle and a 110V heating bed upgrade. The Acetal seems to be very easy on the nozzle and brass is probably fine. I checked my tool steel nozzle after 100+ hours of printing Acetal and it had 0 wear. I also upgraded the feeder to an aluminum piece. This mod is required for the Acetal. It will slip in the stock plastic feeder.

I checked my tool steel nozzle after 100+ hours of printing Acetal and it had 0 wear. I also upgraded the feeder to an aluminum piece. This mod is required for the Acetal. It will slip in the stock plastic feeder.

Environment

This is where things started getting tricky. I had a polycarbonate enclosure surrounding the printer with a vent fan for fumes. I noticed I was getting better prints as the internal air temperature went up and suspected the vent fan was not helping. I then built an enclosure inside the enclosure with insulation board and masking tape. This seemed to stabilize the printing environment and improved the quality again. The vent fan pulls air from around the inner enclosure without drafting the print area and allows higher air temperatures inside. I initially melted all my PLA brackets inside the enclosure and upgraded them to ABS. When everything has stabilized the air temperature in the inner box remains between 32 and 37 Degree C depending on the room temperature. I suspect a fully heated chamber would be required to print larger projects and get better reaults.

I suspect a fully heated chamber would be required to print larger projects and get better reaults.

Machine/Slice Settings

To getting a structurally good print I tried several nozzle temps. Acetal seems to like hotter settings for good internal fusion. I ended up at 255C. At this temp, it prints clear and is hard to see. It takes a few minutes to cool down and whiten. At this elevated temperature, Acetal gives off formaldehyde gas, and quite a bit of it. One time I had the vent fan wired backwards and my print room smelled for a week. I ended up venting the gases up into the loft of my shop near an attic fan. The formaldehyde is easy to detect and produces burning eyes and throat.

I kept cranking and cranking up the surface plate temp and getting better results. I assume it slows down the shrinking. I was afraid to go too high with my set up because I don’t want to fry the printer. It is only rated at 135C. I ended up building the raft out at 150C and printing the part at 135C. I experimented backing on down to 90C after the raft, but it caused some problems. I noticed the cloth build surface does insulate somewhat so the bottom layer of the print is less than the plate temp, but I have not directly measured it.

I experimented backing on down to 90C after the raft, but it caused some problems. I noticed the cloth build surface does insulate somewhat so the bottom layer of the print is less than the plate temp, but I have not directly measured it.

This stuff likes to print slow. Limiting the amount of wet material out there reduces shrink rate and helps with structural integrity. I currently print and infill at 40mm/s with at with a 20mm/s outer wall and initial layer speeds. I tried to go even slower but then the flows got all out of whack. Layer height is 0.15 and infill is 100%.

I ended up with a 20mm margin 8-layer raft with 0 gap. I could never get a brim to work. The raft WILL lift on its outside edges hopefully no more than about 1/8 inch. If it gets to ¼ inch it will throw the print head off track and possibly break things. This stuff is rigid. I must observe the full raft construction to make sure everything is sticking as planned. If it lifts too much, I abort and start over.

Build plate surface

Tried all normal stuff like tape, glues, etc. even birch wood. Nothing seemed to work. Then I started trying cloth glued on glass with Elmer’s glue stick. I had a bag of rags from local hardware store and one was like a t-shirt on 1 side and had some extra knitting on the other. I got the best print yet out of that cloth. Then as I tried other similar cloth from the bag, I lost the recipe. T-shirt, denim, canvas do nothing. I tried texture like a towel which is knitted on both sides, it sticks well to the model but not the plate. I didn’t have any more of the special rag, so I began trying cheap athletic socks. The smooth on 1 side (plate) and knitting on the other (model side) gives just about the best holding ability I have gotten so far. That is when I essentially gave up on ever getting a final part off a plate. The first 10mm or so still pulls the raft up and distorts slightly plus you must cut or sand he raft off anyway. This is where I stopped developing the surface.

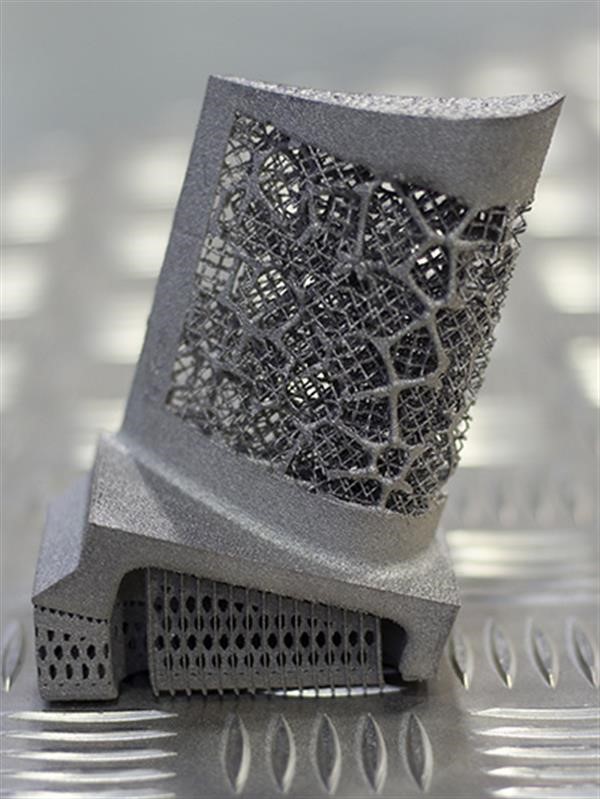

Engineering Solutions

Even with cloth surface and 20mm raft, I still get too much lift in the corners of the actual part. The lift was still enough to destroy the print cause structural problems. I decided to design some features on bottom of the models to compensate for the initial corner lifting. I needed roughly 10mm build height for the shrinking to settle out ON TOP OF THE RAFT. I tried a few things like supports on the sides, a sort of side raft, corner anchors, etc. but anything that increases the footprint goes bad in a hurry. The 2 geometry designs that seem to work the best are the pyramid and reverse pyramid. I really liked the reverse pyramid because so much less material is required and have a few good trials from it. But the expanded base pyramid gave the best overall results if the cloth to glass bond is marginal, which is 50% of the time. Even with these solutions, I get some dimensional inconsistencies over the length of the part. I have seen up to 0. 25mm differences in the part width but that is acceptable for me. I judge the success of the print by the raft distortion directly underneath the part.

25mm differences in the part width but that is acceptable for me. I judge the success of the print by the raft distortion directly underneath the part.

That is about everything I can think of. If you contribute to this discussion, please detail any success or failure you have had and what you tried.

PHOTOS

Typical lifting if raft failure

https://flic.kr/p/2iJDeFJ

https://flic.kr/p/2iJDeDK

Clogged nozzel

https://flic.kr/p/2iJyQKx

Base lifting too much failure

https://flic.kr/p/2iJDewA

Structural failure due to lifting

https://flic.kr/p/2iJyQBG

https://flic.kr/p/2iJBzQ4

Failed raft next to a good print

https://flic.kr/p/2iJDenh

https://flic.kr/p/2iJBzK9

Very failed raft

https://flic.kr/p/2iJyQu7

My 2 engineering solutions, pyramid and reverse pyramid

https://flic.kr/p/2iJBzFg

https://flic.kr/p/2iJDecs

https://flic.kr/p/2iJyQmG

Detail of Pyramid design

https://flic. kr/p/2iJDG79

kr/p/2iJDG79

Base and corner failures. Should have canceled print early.

https://flic.kr/p/2iJBzzV

Sock detail

https://flic.kr/p/2iJBzpz

My enclosure inside an enclosure

https://flic.kr/p/2iJBzkg

https://flic.kr/p/2iJBzi2

Sock dissection

https://flic.kr/p/2iJyPYC

https://flic.kr/p/2iJDdK5

characteristics, photos and customer reviews

3 543 ₽The product is not available now, look similar

Go to the storeThe product is no longer for sale, look similar

Link copied, share it

Or send via social networks

This product is currently not available, but there are similar and similar ones

The price has increased by 417 ₽

More expensive than average, significantlyReliable seller – 89%

Above average, can buy, ENERGTIC 3D Store

- On the site for more than 4 years

- High overall rating (3621)

- Customers satisfied with communication

- Items as described

- 3 Dissatisfied with the goods quickly 290903 last 3 months

Prices from other sellers from 1978.

89 ₽

89 ₽ 10 968 ₽

FLEXBED PEEK 3D printing filament, 1.75mm, 250g, high temperature 3d printer PEEK filament

1 Accessi

1 order

Reliability-89%

Seller ENERGTIC 3D Store

In the store in the store

10 968 ₽

Thread for the 3D printer FLEXBED, 250 g, high-temperature thread for 3D 3D -Print, natural color

0 times

0 orders

Reliability-89%

Seller ENERGTIC 3D Store

In the store in the store

1 979-2 029 ₽

9000 3D 3D 3D 1,000 mm 1 kg Petg Petg Petg PETG PETG PETG PETG PETG PETG PETG PETG PETG PETG Petg 3D Plastic Fiber Printer White Black Pink Color PETG Filment1 Access

1 price

Reliability -89 %

Seller T -BEST WHOLELSALES OUTLET

In the store

found 45 similar products

9000 -4 9000 % 9000 %9000

2 085 ₽

flsun 3d printer pla filament 1. 75mm filament error +/-0.02mm 1kg 343m 2.2lbs printing material for 3d printer

75mm filament error +/-0.02mm 1kg 343m 2.2lbs printing material for 3d printer

3

1

Seller Reliability 0%

-0.3

0006 %2 209 ₽

Northcube 3d printed silk pla filament 3d printers filament 1.75mm 1kg-like silk series silk red wine color filament

1

0

15

%

1 079-1 319 ₽

PETG 3D printer Black 1.75 mm Dooling Gift Material Black Black Color PETG 3D FIRTS 1 kg/2.2LBS

0

9000 0Relia seller 72%

-7

%

Ends

1 880 ₽

KCAMEL Wooden PLA 3D printer of thread 1.75 mm 1 kg smooth discharge of threads for 3D printers

9000 00

9000 % -0. 2

2

Reliability of the seller 72%

$15.00

Northcube pla 3d printer filament 1.75mm for 3d printers, 1kg (2.2lbs) +/-0.02mm filament holder clear blue

1

1

seller 55%

1 795 ₽

Two wood 3d printer wood thread 1.75 mm 1 kg wood color 3d printing material pla wood 3d pinter synthetic thread 1kg sample 1.75 mm

0

0

5 %2 406 – 3 049 ₽

Easythreed 3d printer pla filament 1.75mm surround filament +/-0.05mm 1kg gold 3d plastic printing material for reprap

0

0

1 553 ₽

Northcube pla 3d printer filament 1.75mm for 3d printers, 1kg (2.2lbs) +/-0.02mm coffee color

1

0

Seller Reliability 9003

-8

%

1 428 ₽

Abs filament for 3d printer 1. 75 mm 1 kg printing materials 3d plastic printing filaments black

75 mm 1 kg printing materials 3d plastic printing filaments black

1

2

The reliability of the seller 55 %

-27

9000 %1 480 ₽

Tronxy 3D Plane Printer 1.75 mm PLA PLAT PLAC Black 3D 3D Prints Axuara Printers

0

1

The reliability of the seller 68 %

-0.7

9000 %815.37 -1 017 ₽

Pla silk thread with a silk texture of 1.75 mm Diameter 0.02 mm Shining color High strength High strength high fdm 3d printer printing material

1

0

Reliability of the seller 100%

-13

%

822.33 – 1895 ₽

3d printers filament color white, black, orange, blue, red, purple solid plastic materials flament for 3d printing

2

5

Reliability of the seller 89% 75mm flexible TPU 3d printer filament 1. 75mm 1kg/spool 3d printing wear-resistant flexible tpu pad material 3d printer drawing pens supplies

75mm 1kg/spool 3d printing wear-resistant flexible tpu pad material 3d printer drawing pens supplies

1

1

The reliability of the seller is 89 %

9000 -4%

1 553 ₽

NorthCube 3D printer 1.75 mm 3D printers S, 1 kg (2.2LBS) +// -0.02mm fluorescent lamp - green color

0

0

Reliability of the seller 55%

1 835 – 4 082 ₽

abs filament for printing consumables filamento 3d material refills 3d printer parts filament

0

1

The reliability of the seller 89 %

9000 -2 9000 %1 333 -1,723 ₽

thread for 3D printer, 1.75 mm, silk, gold, 1 kg

0

1

The reliability of the seller is 100 %

-10

9000 %1 428 ₽

ABS 3D printer 1. 75 mm 1 kg 3D Plastic prints Orange

75 mm 1 kg 3D Plastic prints Orange

1

1

1

The reliability of the seller 55 %

2 151 ₽

3d printer filament PC (polycarbonate) 1.75mm 1kg/2.2lb plastic consumables material for 3d printer filament

3

11

Reliable seller 100%

-10

428 ₽ABS threads for 3D printer 1.75 mm 1 kg materials for printing 3D Plastic threads for printing Green

1

1

The reliability of the seller 55 % 9000 -06 -0.7

9000 %1 378 -2 088 $

Creality pla 3d printer filament 1.75mm 1kg/2.2lbs filament tolerance +/-0.02mm

4

2

The reliability of the seller is 89 %

9000 -4 9000 %Equal data

3 203 ₽

GOHIN 2 Rolons PLA Carbon fiber weighing more than 2 kg of 2. 75 mm threads 1.75 mm 3D printer Carbon incandescent coil effect black color printing

75 mm threads 1.75 mm 3D printer Carbon incandescent coil effect black color printing

0

0

Reliability of the seller 0%

incomplete data

974.82-2 144 ₽

GOHIGH Silk PLA 1 kg Smooth 3D silk gloss 3D 3D 3D 3D 3D 3D 3D 3D printing materials shiny metallic consumables

0

0

The reliability of the seller 0 %

9000 -9%

1 428 ₽

ABS 3D printer 1,75 mm 1 kg printed materials 3D plastic printed threads

9000 10

Reliability of the seller 55%

-9

%

900.32 – 1 884 ₽

2.2 lb (1 kg) spool

1

3

The reliability of the seller is 89%

11 850-13 692 ₽

Sunlu 10 silk rolons 3D 3D Silk PLA 3D threads with silk texture 3D printed materials

2

0

Reliability of the seller 65%

-2

%

2 177 ₽

0. 03mm, 2.2lbs(1kg) white to blue

03mm, 2.2lbs(1kg) white to blue

3

1

Reliability of the seller 55%

1 715 – 1 960 ₽

Sunlu petg thread 1.75 mm 1 kg measurement accuracy +/-0.02 mm 3d printer supplies petg 3d03

0

The reliability of the seller 55 %

9000 -9 -9 9000 %1 428 ₽

ABS 3D printer 1.75 mm 1 kg 3D plastic threads for printing jade green 9000 0

0

Reliability of the seller 55%

-7

%

213.77 -2 053 ₽

3D printers of the thread PLA PLA 1.75 mm 1 kg Wooden coils of the roll plastic 9000 2

8

Reliability of the seller 100 % 9000 -9000 -3

6666 %

1 566 ₽

Topzeal red 3D PLA printer PLA 1,75 mm 1kg (2. 20LBS) 3D printing plastic for 3D printer

20LBS) 3D printing plastic for 3D printer

0

0

Reliability of the seller 100 % 9000 -13

%

827.90 – 1 673 ₽

Petg 3d printer filament 1.75mm dooling gift material hot sale black color petg 3d filament supplies 1kg/2.2lbs

5

5

Reliability of the seller 6006 -

%

1 428 ₽

ABS thread for a 3D printer 1.75 mm 1 kg materials for printing 3D Plastic threads for printing purple

0

0

Reliability of the seller 55 % 9000 -11

%

1 428 ₽

ABS filament for 3d printer 1.75mm 1kg printing materials 3d plastic filaments for coffee

1

0

. 75mm dimensional accuracy high strength 3d printing consumables 1kg spool nature

75mm dimensional accuracy high strength 3d printing consumables 1kg spool nature

0

0

Seller Reliability 83% plastic filamento 3d printer filament reprap makerbot material

1

0

Reliability of the seller 100 %

9000 -9%

1 428 ₽

ABS thread 1,75 mm 1 kg Materials for printing 3D Plastic threads for printing gray

9000 20

Reliability of the seller 55%

-11

% 3d printers

3

1

The reliability of the seller 55 %

9000 -11%

1 534 ₽

Topzeal ABS Transpare of Red Nita ABS 1.75 mm 1 kg/roller consumption materials material for 3D -princes of thread

1

1

Reliability of the seller 100%

Partial data print

1

1

The reliability of the seller 0 %

9000 -2%

1 392 -1 934 ₽

IdeAformer 3D printer PLA/silk PLA 1,75 mm 1 kg rolons for vacuum packaging Foreign Shoes Different colors for 3D printing

2

1

The seller’s reliability 100 %

-2

9000 %1 483 ₽

3D printer 3D TPU TPU Fitty thread 3d fiber prints Pipligraphic materials gray black green blue

2

0

The reliability of the seller 89 %

9000 -10 9000 %1 428 ₽

ABS Plane 1,75 mm 1 kg materials for printing 3D Plastic threads for printing Bronze

9000 1

1

The reliability of the seller 55 %

-8

9000 %1 503 ₽

ABS thread for 3D printer 1,75 mm 1 kg Materials for printing 3D Pink -red printing 9000 9000 0

0

The reliability of the seller is 55 %

-9

%

2 122 ₽

PLA thread for a 3D printer, 1. 75 mm, 1 kg, 1.75 mm, 1 kg

75 mm, 1 kg, 1.75 mm, 1 kg

0

0

Relia Seller 51%

0 OTO TELO

0 PrOSA

Photos from buyers not yet

Product characteristics

- Brand Name: FlexBed

- Form: Solid 9000 Plakm Printer 1.5MMM. white)

JavaScript seems to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.Proceed to Checkout

Total price

$0.00

Basket 0

Want free shipping? click here Find out more!

{{/findAutocomplete}}

SKU: {{sku}} {{#isFreeshippingEnabled}} Free shipping on eligible orders {{/isFreeshippingEnabled}}

{{#isDiscountFlag1Enabled}}

{{/isDiscountFlag1Enabled}} {{#isDiscountFlag2Enabled}}

{{/isDiscountFlag2Enabled}} {{#isDiscountFlag3Enabled}}

{{/isDiscountFlag3Enabled}} {{#isDiscountFlag4Enabled}}

{{/isDiscountFlag4Enabled}} {{#isDiscountFlag5Enabled}}

{{/isDiscountFlag5Enabled}} {{#isDiscountFlag6Enabled}}

{{/isDiscountFlag6Enabled}} {{#isDiscountFlag7Enabled}}

{{/isDiscountFlag7Enabled}} {{#isDiscountFlag8Enabled}}

{{/isDiscountFlag8Enabled}} {{#isDiscountFlag9Enabled}}

{{/isDiscountFlag9Enabled}} {{#list_image_url}}{{/list_image_url}} {{^list_image_url}}{{/list_image_url}} 9isProhibited}} More {{/isProhibited}} {{/is_combo_product}} {{#isProhibited}}

We are sorry, this product is not available in your country

{{/isProhibited}}

{{#hbk_price.

Learn more