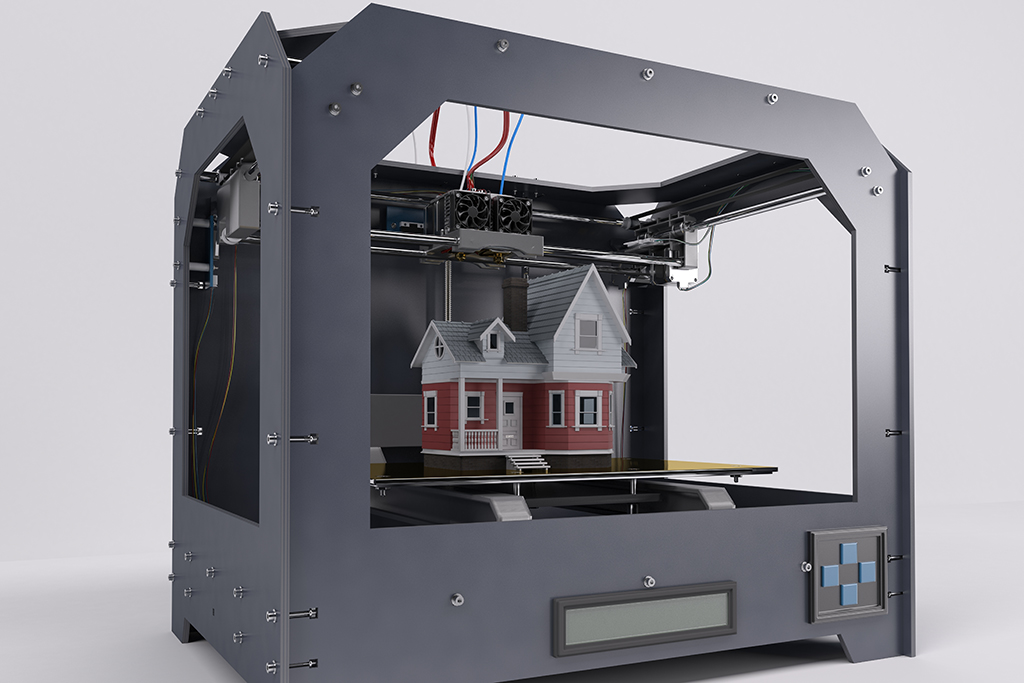

3D printer for construction industry

Ultimate guide to construction 3D printers in 2022 (concrete 3D printing)

What are the best house 3D printers?

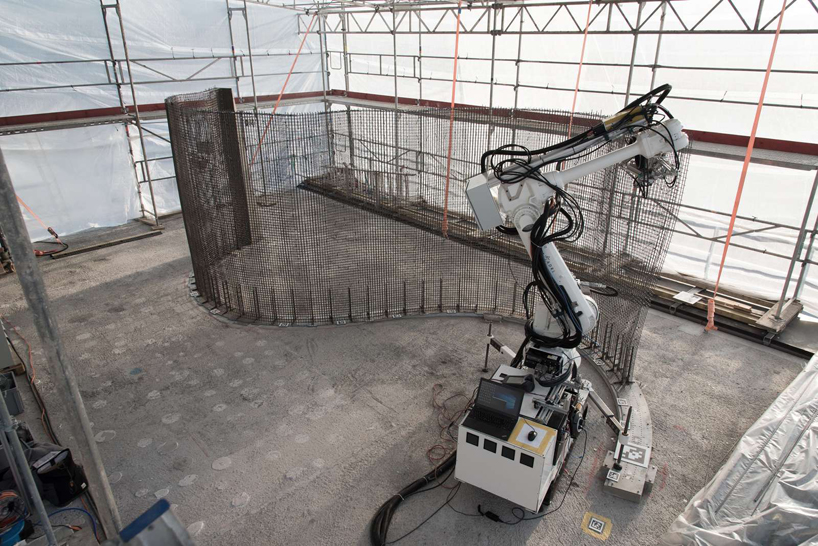

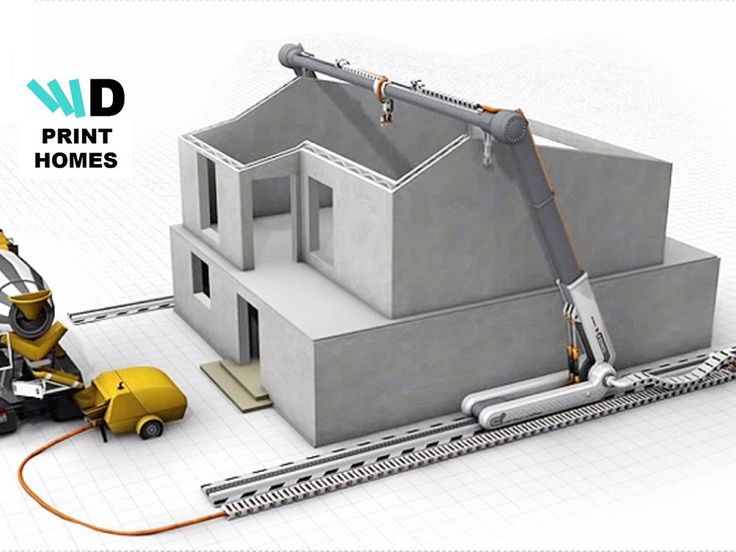

A construction 3D printer is a machine that can build houses by depositing a material (concrete for example) layer by layer. Concrete 3D printing – a.k.a. “Construction 4.0” – is a similar 3D printing technology to the one that FFF 3D printers use. Paste-type material, in this case, concrete or earth materials, is pushed through a nozzle in layers to print buildings in 3D.

Concrete 3D printing in the construction industry helps save time, effort, and material compared to traditional construction methods. It’s important to note, though, that 3D printers are not yet capable of creating a fully functional house.

Only the frame and walls of the house are built; other elements, such as windows, electricity, or plumbing, need to be installed separately. But concrete 3D printers can also be used to print bridges, benches, or simply outdoor decorations.

To provide a complete overview of the construction 3D printer market, we have listed 12 house 3D printing solutions. Some of them are 3D printers available for sale, while some are still at the start-up prototype stage or are external construction 3D printing services.

13 house construction 3D printers

| House 3D printer | Category* | Type** | Build size (m) | Country |

|---|---|---|---|---|

| BetAbram P1 | Available | Gantry system | 16 x 8.2 x 2.5 | Slovenia |

| COBOD BOD2 | Available | Gantry system | 14.62 x 50.52 x 8.14 | Denmark |

| MAXI PRINTER | Available | Robotic arm | 12.25 x 12.25 x 7 | France |

| CyBe Construction CyBe RC 3Dp | Available | Robotic arm | 2.75 x 2.75 x 2.75 | Netherlands |

| ICON Vulcan II | Available | Gantry system | 2. 6 x 8.5 x ∞ 6 x 8.5 x ∞ | United States |

| MudBots 3D Concrete Printer | Available | Gantry system | 1.83 x 1.83 x 1.22 | United States |

| Total Kustom StroyBot 6.2 | Available | Gantry system | 10 x 15 x 6 | United States |

| WASP Crane WASP | Available | Delta system | Ø 6.3 x 3 | Italy |

| Apis Cor | Project | Robotic arm | 8.5 x 1.6 x 1.5 | Russia |

| Batiprint3D 3D printer | Project | Robotic arm | Up to 7m high | France |

| SQ4D – ARCS | Service | Gantry system | 9.1 x 4.4 x ∞ | United States |

| Contour Crafting | Service | Gantry system | – | United States |

| XtreeE | Service | Robotic arm | – | France |

Build volumes are indicative and may vary based on the specific configuration of the machine.

*Category: some 3D printers are available for sale, others are working projects, and some are only available via a rental service.

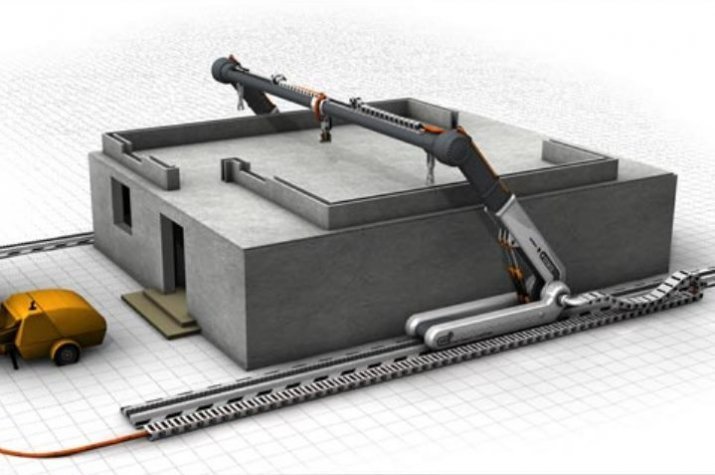

**Type: construction 3D printers either use a gantry system (like oversized desktop 3D printers with X, Y, and Z axes) or a mechanical, robotic arm.

How to build 3D printed houses?

Here we explain how 3D printers are able to print houses with paste extrusion.

House 3D printing technology

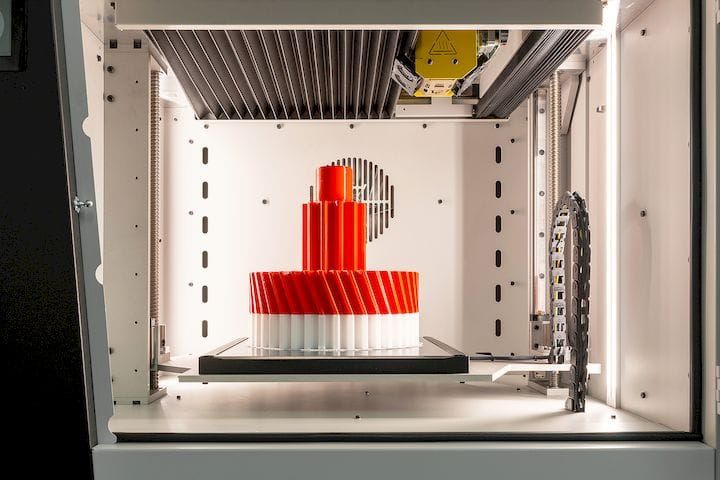

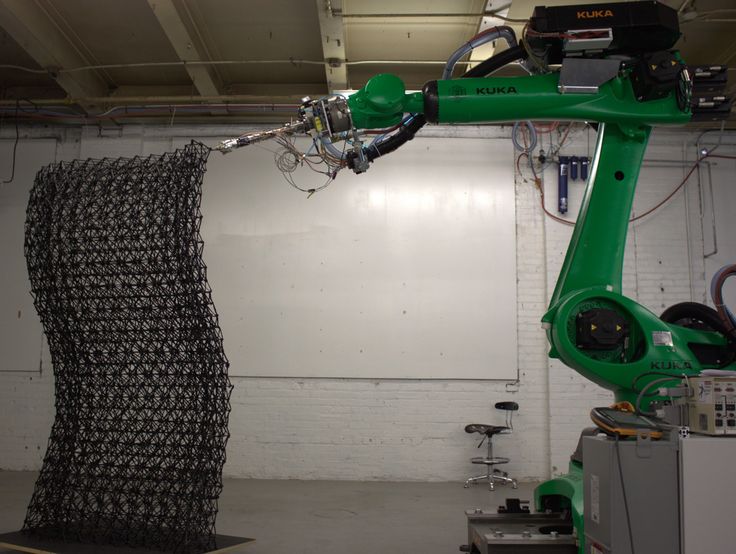

House 3D printers use extrusion technology. Some construction 3D printers look like super-sized desktop FFF/FDM 3D printers (gantry style), whereas others consist of a rotating mechanical arm.

In both cases, paste-type components such as concrete are used as filament. The material is pushed out of a special nozzle to form layers. To put it (very) simply, paste extrusion is similar to using a piping bag to spread frosting on a cake.

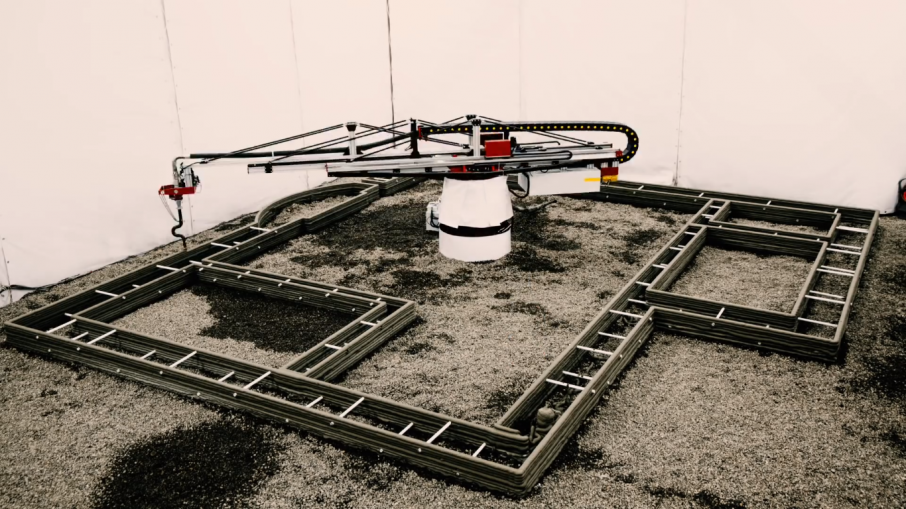

The printer creates the foundations and walls of the house or building, layer by layer. The ground is literally the printer’s build plate. Some concrete 3D printers, however, are used to 3D print brick molds. When molded, the bricks are then piled atop each other manually (or with a robotic arm).

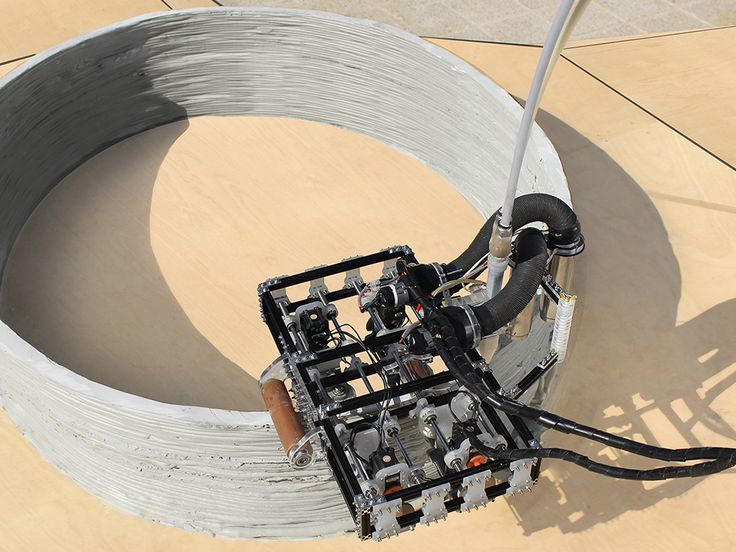

WASP’s construction printer 3D printing with Earth materials (clay, soil). Source: WASPBenefits of house 3D printing

Eco-friendly

3D printed houses can be built with organic, eco-friendly materials. Moreover, some house 3D printers use solar energy and generate low CO2 emissions.

Affordable

House 3D printers can build affordable housing, being of great aid for people in poverty-stricken regions or after natural disasters.

Scalable

Construction 3D printing reduces certain building costs. For example, the cost for 1 square meter of a wall using traditional construction methods is approximately $75, whereas with the Apis Cor house 3D printer it is only $27.

Efficient

Since the materials are 3D printed on-demand, the machines produce less waste. Also, construction 3D printers can finish a home’s foundations in less than a few days, while traditional construction methods take several weeks or even months.

Design flexibility

With a 3D construction printer, it’s possible to easily create curved walls and unique facades. (Good thing it’s possible to 3D print furniture to match the curves!)

Limits of 3D printing houses

Expensive initial investment

House 3D printers can sometimes cost up to one million dollars.

Partially-built houses

House 3D printers only build house frames. The 3D printing process is usually paused to manually settle plumbing, wiring, and rebars.

The 3D printing process is usually paused to manually settle plumbing, wiring, and rebars.

Rough exterior

Most 3D printed homes’ exteriors are not as smooth as traditionally-built houses.

Lack of certification

Construction sites are regulated by laws and there are important safety standards that need to be met, which can be challenging with 3D printing techniques (varying repeatability, dimensional stability, etc.).

Another downside that has been noted over the years is that house 3D printing can potentially harm local economies, especially in poverty-stricken regions or cities with high unemployment rates. Indeed, since construction 3D printers reduce the need for manual labor, they create much less employment for local workers.

Differences between 3D printed houses and traditional houses

Concrete 3D printing saves time, uses less material, and requires less manual labor. Even 3D printed houses have a rougher exterior, post-processing is an option just as it is for regular 3D printed objects. 3D printed houses tend to be smaller due to 3D printer build volume limits, but this is not always the case.

Even 3D printed houses have a rougher exterior, post-processing is an option just as it is for regular 3D printed objects. 3D printed houses tend to be smaller due to 3D printer build volume limits, but this is not always the case.

Construction 3D printers: overview

We break down construction 3D printers into three categories: house 3D printers that are available for sale, concrete printer prototypes, and 3D concrete printing services.

House 3D printers available for sale

BetAbram is a small Slovenian team that has been working on construction 3D printing hardware since 2012. Their flagship home 3D printer, the BetAbram P1, is currently in its second version and is available with optional print heads: basic, “Orto” for smoother layers, and rotating for more design possibilities.

Contact manufacturer Get a quote Add to comparison

This construction 3D printer is fast, reaching announced speeds of up to 60 meters per minute. The BOD2 is modular and can be adapted is many different sizes. COBOD is a 3D Printhuset company.

The BOD2 is modular and can be adapted is many different sizes. COBOD is a 3D Printhuset company.

Contact manufacturer Get a quote Add to comparison

Constructions-3D is a subsidiary of French 3D printer retailer Machines-3D.

Their MAXI PRINTER machine is mobile thanks to its caterpillar-style rubber tracks and fits into a 20-foot shipping container for easy transport from one construction site to another.

Contact manufacturer Get a quote Add to comparison

The CyBe RC 3Dp consists of a single robotic arm with a nozzle at its end.

This easy-to-move house 3D printer is capable of reaching up to 2.75 meters high and requires only two people to operate it.

Contact manufacturer Get a quote Add to comparison

ICON wishes to revolutionize the construction field with their Vulcan II printer. The whole process is designed to be user-friendly with a tablet-based interface, and ICON’s Lavacrete concrete mix is optimized to be easier to print.

Contact manufacturer Get a quote Add to comparison

MudBots is a concrete 3D printer manufacturer based in the United States. Their smallest model (1830 x 1830 x 1220 mm approx.) is available at the price of $35,000. Larger build sizes are available as well, reaching up to 30 meters long.

Their smallest model (1830 x 1830 x 1220 mm approx.) is available at the price of $35,000. Larger build sizes are available as well, reaching up to 30 meters long.

According to MudBots, their 3D printers can 3D print a small house in only 12 hours and can drive costs down 70% compared to traditional construction methods.

Contact manufacturer Get a quote Add to comparison

The StroyBot, also known as the Rudenko 3D construction printer (made by Andrey Rudenko), is an all-in-one mobile construction printing system delivered as a kit to be assembled by the user. On average, it is able to print a 100-square-meter house in 48 hours (walls only).

The Crane WASP is the evolution of WASP’s previous construction printer, the BigDeltaWASP 12MT. This open source construction printer is modular and multiple Crane printers can work together on one project, for theoretically infinite 3D printing possibilities.

Concrete printer working projects

Apis Cor, a 3D construction company, is based in San Francisco and claims to be able to 3D print a house in under 24 hours. Their Apis Cor printer is similar to a robotic arm and has won first place in NASA’s Phase 3 3D-Printed Habitat Competition.

Their Apis Cor printer is similar to a robotic arm and has won first place in NASA’s Phase 3 3D-Printed Habitat Competition.

Contact manufacturer Get a quote Add to comparison

Batiprint 3D made international headlines when completing their Yhnova 3D printed house in Nantes, France. Their 3D printer not only prints cement but also insulation foam, which makes it one of the most complete 3D construction solutions.

Construction printing services

This automated construction system is able to 3D print large buildings and tall infrastructures. Contour Crafting (a.k.a. CC Corp) aims to make disaster relief more efficient with their concrete additive manufacturing technology.

SQ4D – ARCS aims to provide quick, robust, eco-friendly, and affordable housing solutions for impoverished areas.

XtreeE develops specific 3D printing solutions for construction, engineering, and architectural design. This startup is based in France and has already completed a number of 3D construction projects.

Special mentions: interesting 3D construction projects

DFAB HOUSE

This unique building was completed by a consortium of companies in early 2019 and is based in Switzerland. The 3-story DFAB building offers 200 square meters of space.

Branch Technology C-FAB and WATG’s Curve Appeal design

The WATG architectural design firm won the Branch Technology Freeform Home Design Challenge in 2016. In 2019, their project is set to be printed in Tennessee by Branch Technology’s C-FAB freeform construction 3D printing method.

DUS Architects XL 3D printer (KamerMaker)

The XL 3D printer was created by DUS Architects to build a prototype canal-house (simply dubbed “3D Print Canal House”) in Amsterdam using recycled materials.

Haus.me

This US-based company, previously known as PassivDom (dom.ai), 3D prints walls, floors, and roofs for their fully autonomous prefab houses.

Autodesk metal construction printer

Autodesk may or may not be working on a construction 3D printer that uses metal material. This 3D printer, which is more a pair of robotic arms than a printer, is able to make metal components for construction sites. We can’t wait to hear more about this!

CONCR3DE Armadillo stone 3D printer

CONCR3DE is a Dutch company that manufactures stone 3D printers. They are able to 3D print stone thanks to a special binder jetting process. Their two 3D printers, Armadillo Black and Armadillo White, aren’t able to print a house but can 3D print stone decorations or molds.

Discontinued projects and printers

Many startups have come and gone in the construction 3D printing industry.

D-Shape construction 3D printer

The D-Shape 3D printer is a multifunctional construction 3D printer that can 3D print very large objects, including houses and prototypes. D-Shape seems to be inactive since 2015.

D-Shape seems to be inactive since 2015.

Winsun house 3D printer

The Winsun 3D printer is a house 3D printer that was in the spotlight a few years ago. In 2015, however, Contour Crafting’s CEO accused Winsun of stealing their patented technology. Winsun’s website has since been taken down.

Cazza X1 3D printer

Cazza was founded in 2016 with its X1 construction 3D printer. However, it seems that one of the co-founders stole the company’s funding in 2018, and Cazza is now on standby.

HuaShang Tengda

HuaShang Tengda 3D printed a house capable of withstanding a base 8 earthquake on the Richter magnitude scale. Today, the company seems to be off the radar.

3D printed house time and cost

Construction 3D printing is faster and more affordable than traditional construction methods.

However, since construction 3D printing is still in its early years, it is difficult to provide definitive statements about how long it takes to 3D print a house and how much it costs to 3D print a house.

How long does it take to 3D print a house?

Various construction 3D printer manufacturers such as Apis Cor or ICON boast that they are able to 3D print a small house in 24 hours. As mentioned before though, print jobs generally only include laying down the house’s foundations and walls.

This does save whatever amount of time it usually takes for a standard team to build walls for a certain project. The rest of the timeframe for building a house remains equal.

3D printed house price

In general, it is estimated that a 3D printed house costs 30% to 55% less than a traditionally-built house.

For reference, Apis Cor’s small house cost less than $10,000 to produce, and ICON’s compact 3D printed home even cost less than $4,000.

Construction 3D printer price

A construction 3D printer can cost anywhere between around $180K to over $1M. Robotic arm systems tend to have higher price tags than gantry-type systems.

Other 3D printed infrastructures

Aside from housing or buildings, construction 3D printers are able to 3D print bridges and space-station infrastructures.

3D printed bridges

Construction 3D printers can also 3D print bridges. In 2015, the world’s first 3D printed steel bridge was 3D printed for testing in Amsterdam by MX3D. MX3D printed the final version of their stainless steel bridge in 2018 and installed it in Summer 2021.

In 2017, a 12-meter-long pedestrian bridge was 3D printed in Madrid, Spain. In the same year, the first 3D printed concrete bridge was built in the village of Gemert in the Netherlands.

More recently, in 2019, Shanghai became home to the world’s longest concrete 3D printed bridge. It is 26.3-meters long and 2.6-meters wide, and was 3D printed in only 18 days.

3D printed infrastructures in space

NASA’s 3D-Printed Habitat Challenge has given life to a number of teams dedicated to bringing 3D printing to space. Apis Cor, namely, won the top prize for one of this project’s phases. The goal is to create sustainable and efficient 3D printed housing for deep space exploration.

Many other companies have been involved in space-building projects, including the European Space Agency and Elon Musk’s SpaceX. It is possible that we will see the first space house 3D printers in space sometime in the next couple of decades (!).

Apis Cor and SEArch+ team’s 3D printed space infrastructure (render) for the NASA 3D-Printed Habitat Challenge. Source: Apis Cor and SEArch+FAQ: construction 3D printing

What is a 3D-printed house?

A 3D printed house is a house composed of 3D printed elements, such as 3D printed walls, floors, or roofs. It is also possible to use the term “3D-printed home”.

It is also possible to use the term “3D-printed home”.

How much does it cost to 3D print a home?

It can cost as low as $4,000 to 3D print a home. Prices vary greatly according to the material being used and the size of the home to be 3D printed.

What are the best 3D printed house companies?

See our selection of the best 3D printed house companies here.

Where are there 3D-printed houses for sale?

There are 3D printed houses for sale in the US (Los Angeles, San Francisco), China, France, Russia, UAE, and many other countries.

Is concrete 3D printing just for houses?

No, concrete 3D printing is also for infrastructures such as bridges.

3D Printing in Construction: Growth, Benefits, and Challenges

3D printing offers big promises for construction.

Will the innovation live up to the hype?

Will the innovation live up to the hype?3D printing has been a big buzz term over the past decade–and for good reason. Though initially developed for product prototyping purposes, 3D printing technology has advanced to the point where it has emerged as a key player in a variety of industries.

While clearly, 3D printing technology has proven beneficial in the medical, aerospace, and tool-making arenas since its inception, there’s one other field that’s potentially poised to break out: the construction sector.

With 3D printers now capable of printing building walls and processing cement, the technology could help reshape construction as we know it. But is 3D printing in construction just a fleeting trend or does it have real staying power as a technology that can serve as a key long-term solution? Below, we’ll explore how 3D has been already making waves in construction and what the future looks like.

A History of 3D Printing in Construction

Before we get into a history of 3D printing in the construction industry, it’s first important to take a step back in time to the origins of 3D printing itself.

3D printing’s roots date back to the mid-1980s when stereolithography, or SLA, was conceived. SLA works as a high-powered laser and turns a liquid resin into a solid material. SLA is an additive technology, which means it involves creating a product from the ground up in a layer-by-layer fashion. Today, SLA is still one of the most popular 3D printing technologies, though 3D printing is generally considered any technology that creates parts in an additive way. Some other popular additive technologies include selective laser sintering (SLS), fused deposition modeling (FDM) and direct metal deposition (DMD).

3D printing initially was utilized for quickly and accurately creating prototype parts. As additive processes improved, however, its viable uses began to expand. Prior to the adoption of building information modeling (BIM), 3D printing was even used by architectural firms to build scale models. It wasn’t long before it was administered for more ambitious construction purposes.

For more than a decade, 3D printing has been used in several ambitious initiatives and projects in construction, including:

- In 2004, a USC professor attempted to 3D print a wall in what’s widely accepted as the technology’s first entry into construction.

- In 2014, a full canal house built using 3D printing was completed in Amsterdam.

- In 2016, a 3D-printed mansion was completed in China.

- Also in 2016, the Dubai Future Foundation built its Office of the Future via 3D printing, a major milestone for the technology in the commercial construction sector. The fully functioning 2,700-square foot building was built by a large 3D printer that measured 120 x 40 x 20 feet. Construction took just 17 days.

Today, the 3D printing construction market is quickly growing, expected to reach $1.5 billion by 2024.

The Growth of 3D Printing in Construction

While 3D printing’s emergence in the construction industry is ongoing, certain building aspects are poised for more growth than others.

3D Printing Concrete

Concrete, specifically, is one of them. In fact, the concrete 3D printing market is projected to be valued at $56.4 million by 2021, growth that’s largely spurred by the amount of new, innovative projects that are being planned in construction. 3D printing in concrete doesn’t appear just to be a grassroots movement, either. In February 2017, Vinci, one of France’s leading construction firms, purchased a stake in XtreeE, a French startup company that specializes in 3D printing concrete structural elements.

In 2019, BAM opened Europe’s first concrete printing centre in the Netherland. The factory has already been tasked to deliver several 3D printed bridges throughout the region. Watch the video below to see how BAM and Saint-Gobain are changing the future of infrastructure with sustainable, scalable, and affordable 3D concrete printing solutions.

Though 3D printing concrete shows great potential, it’s worth noting that the overall technology when it comes to the concrete material is still relative in its infancy. In fact, most 3D printers that process concrete are still being tested and tweaked today, and aren’t yet designed for manufacturing purposes. However, as we can see from the video above, the potential is there to additively build everything from foundations to walls to individual cinder blocks to bridges in a faster, more affordable, and more environmentally-friendly manner as the technology continues to progress.

In fact, most 3D printers that process concrete are still being tested and tweaked today, and aren’t yet designed for manufacturing purposes. However, as we can see from the video above, the potential is there to additively build everything from foundations to walls to individual cinder blocks to bridges in a faster, more affordable, and more environmentally-friendly manner as the technology continues to progress.

The Benefits of 3D Printing in Construction

Just why is 3D printing gaining so much buzz in the construction sector? As the industry faces increasing pressure to meet tight schedules and budgets, companies are looking to new innovations to help fill the gaps. 3D printing in construction offers a significant potential to increase efficiency in the building sector, including the following ways.

Recommended reading: Check out key takeaways from our podcast episode on harnessing the power of 3D printing in construction. In this deep-dive with Stephan Mansour, a 3D Printing & Emerging Technology Advisor at MaRiTama Ltd, he shares big benefits, common misconceptions, and meaningful opportunities for those who embrace 3D printing.

Speed

3D printing has already shown that it can build a home or building from the ground up in a matter of days. That’s a significantly faster timeframe than conventional construction, which can take months and years to fully construct a commercial building. According to Marco Vonk, Marketing Manager at Saint-Gobain Weber Beamix, “You save about 60% of the time on the jobsite and 80% in labor.”

Waste reduction

Worldwide construction waste currently totals more than 1 billion tons each year, and according to Construction Dive, this number is expected to double by 2025. While 3D printing won’t be able to solve all of the construction waste problems, it can help. This is largely because 3D printing is an additive manufacturing process that only uses as much material as is necessary for creating a structure. When paired with other waste-reducing processes and building methods like prefabrication and lean construction, the potential of a waste-zero building seems all the more likely.

Design freedom

One of the great things about 3D printing is the design freedom that it offers. Architects are able to build complex designs that are otherwise unattainable, or too expensive or labor-intensive to create by conventional construction means. This can allow for a lot more innovation and creativity in the commercial construction space. Vonk adds, “3D concrete printing enables you to make any shape. You can bend it, you can make angles, you can make virtually any organic shape you want to, and it’s a one-to-one copy to what you designed on paper.”

Reduce human error

According to OSHA, more than 5,000 workers are killed on the job each day. Because construction would be more programmable and automated, worker injuries and fatalities would likely decrease if 3D printing was incorporated onto the jobsite.

The Challenges of 3D Printing in Construction

Despite the benefits and potential that 3D printing has in the construction sector, there are a number of factors that may prohibit the technology from becoming mainstream. Below, let’s explore a few of these challenges.

Below, let’s explore a few of these challenges.

Perhaps the biggest challenge to the widespread adoption of 3D printing technology on construction sites is the high cost of purchasing or renting such equipment and the logistics involved in getting these large 3D printers to the work site. 3D printers are costly, and that upfront purchase cost doesn’t include materials or maintenance. Right now, it’s difficult for many construction professionals to justify 3D printing’s cost over the technology’s benefits.

Labor shortageThe construction sector is booming and skilled workers are in high demand. The only problem is that there are not enough of them.

Even considering the labor shortage, 3D printing requires an even more specific skill set that would have to pull from a slimmer and more niche group of candidates. Construction labor shortages are already a problem, and finding qualified workers to employ in 3D printing construction environments could prove to be even more challenging in the future.

Weather already has the potential to slow construction progress, but issues with Mother Nature may be amplified with 3D printing. The weather, environmental factors and more are all conditions that could make 3D printing in commercial construction more of a bust than a boom. Furthermore, quality control in construction can already be a tricky matter. If not constantly monitored and overseen by real humans, quality in 3D printing could end up being a very expensive mess.

RegulationsOne drawback that might not immediately come to mind is the regulation of 3D printing. While regulation in 3D printing has made the news cycle recently, it still hasn’t fully impacted the construction industry. However, there’s also the liability that may come with using printers rather than humans to perform certain construction tasks. Currently, there’s much uncertainty in this aspect of 3D printing in construction. Until laws and regulations are clearly defined, it’s unlikely that 3D printing will make too much of a mark in the construction sector.

A Hopeful Future Remains for 3D in Construction

Does 3D printing in construction have real staying power? From what we’ve seen, the promise is strong, just as long as companies like BAM and Saint-Gobain continue to innovate and push boundaries.

Overall, the potential of 3D printing is too great to ignore. While the industry may never reach a point where it’s used exclusively, it’s only a matter of time that the technology will be improved and advance significantly. Overall, 3D printing is poised to be a viable solution that offers key benefits in cost savings and environmental friendliness for our building’s future.

3D printers in construction: prospects for application

At first glance, 3D printing structures seem to be some kind of shell of a half-finished building. But upon closer examination, you will not find even a brick. Layers of material seem to build up one on top of the other - this is how a complex structure is created. It's a futuristic world of 3D printing where robotic arms automatically layer and compress layers of concrete or plastic or any other material into a foundation and build a structure.

This method of construction is quite niche today - only a few prototypes of 3D houses and offices have been printed in the world. However, this technology represents an exciting and potentially powerful solution to building change.

What is 3D printing in construction, what is the potential, and will we be working on 3D printed projects in the near future?

- What is 3d printing in construction?

- 3D printers in construction: how is it done?

- 5 examples of innovation

- How can 3d printed projects help construction companies?

- 3D printing distribution

- 3D printing in civil engineering

- Wiki House technology - an open source project for 3D printing: what is behind the concept

- Reverse side of the coin

- How can 3D printing be integrated into construction

- About PlanRadar

3D printing in construction - what kind of technology?

3D printing for construction uses both a 3D printer that has a robotic “crane-arm” that builds structures right on the construction site, and the creation of certain elements by printers at the factory, which are already assembled into a structure on site.

The concept of 3D printing is not new: it first appeared in the 80s. But it's only in the last decade that this technology has been improved enough (and the cost significantly reduced) to become a real mainstream.

3D printers are not much different from conventional inkjet office printers. The software tells the printer about the dimensions of the final product. And then the printer starts to output the material to the platform according to the plan. 3D printers often use liquid metals, plastics, cement, and variations of various materials that, when cooled and dried, form a structure.

In a 3D construction printer, the CAD or BIM programs tell the device what to print, and the machine begins layering the material according to the design plan.

3D printers in construction: how do they work?

3D printing concept - The printer extrudes a defined liquid mixture in layers, level by level, creating a design based on a 3D model. The prepared mix of concrete, filler, plasticizer and other components is loaded into the hopper of the device and fed to the print head. The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

Robotic printer

Read also: New technologies in construction 2021

5 innovative examples of 3D printing

To date, only a few 3D printing projects have been implemented in the construction industry. Here are five of the most impressive and promising projects:

Dubai City Hall Office Building, UAE

1. Dubai City Hall Office Building, UAE

3D printed building. The office block built in the UAE is 9,5 meter high building with an area of 640 m2.

An Apis Cor 3D printer moved around an open-air construction site with a crane and erected different parts of the structure.

2. Office of the Future, UAE

Office of the Future, UAE

Another impressive 3D printed building in the UAE, the Office of the Future is a unique, fairly large structure that currently houses a temporary headquarters organization Dubai Future Foundation.

For this building, the elements were not created on site and were printed in 17 days, while the building itself was assembled in 48 hours.

3. WinSun 3D Printer Homes, China

WinSun 3D Printer Homes, China

WinSun 3D Printing Company of China has also applied factory-built 3D printers to build residential buildings. The company has created several house projects, including a small multi-storey building. All construction details can be printed quickly and cheaply and then quickly assembled on the construction site.

The company calculated that it would cost as little as $161,000 to build and print their five-story building.

4. 3D printed license plate at Lewis Grand Hotel, Philippines

3D printed license plate at Lewis Grand Hotel, Philippines

When planning a trip to the Philippines, consider staying at the Lewis Grand Hotel in Angeles City , Pampanga, where visitors will be greeted with the world's first 3D printed hotel suite. The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

5. Two-story mansion in Beckum, Germany

Two-story mansion in Beckum, Germany

The first 3D-printed residential building with an area of about 80 square meters - the brainchild of the German construction company PERI GmbH and the architectural design bureau MENSE-KORTE ingenieure + architecture. A BOD2 3D printer was used to print one square meter of double wall cladding in 5 minutes. The building is a structure with three-layer hollow walls filled with insulating mass. Installation of hollow pipes and connections during printing was carried out manually.

3D printing in construction seems really impressive, but what are the real benefits of such technology?

How can 3D printed designs be useful for construction companies?

Proponents of 3D printing houses and commercial offices point to several advantages of this construction method:

- Zero waste construction

In the UK, almost a third of the waste comes from the construction industry. According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

Conversely, 3D printing can reduce waste to almost zero. A 3D printer uses a well-defined amount of material that is required to print a design - no more, no less. This can be a big savings.

- Reduced energy consumption

3D printing in construction encourages the use of locally available materials and natural ingredients. This practice can reduce energy costs in transportation, construction and manufacturing, as most local materials require less energy to process or install. If traditional materials with toxic chemical impurities are replaced with natural ones, then the toxicity of the entire construction can be reduced. In addition, local materials are often better suited to local climates and can reduce a building's heating or cooling load, which also reduces construction costs.

- Save time and money

As with AI in construction, a 3D printer can run 24 hours a day, 7 days a week. This means construction projects have the potential to be completed much faster and a number of low-skilled labor costs can be avoided. What's more, 3D printing eliminates the need for temporary structures, such as formwork and scaffolding, that are commonly used in traditional construction. Studies of 3D printed concrete structures have shown a significant reduction in formwork requirements, reducing costs by 35-60%.

- Can realize unusual design shapes

One of the most attractive characteristics of 3D printers is their ability to create complex and unusual design designs, including a single, unique one. Since the job of a 3D printer is to layer the material, they can be programmed into absolutely any unusual shape that would be much more difficult to create with traditional techniques.

- Minimize human error and improve safety

The published injury statistics at the workplace by the American agency BLS in 2020 indicates that construction is one of the most traumatic areas and a high incidence of diseases. Every day, about 5333 workers die on the construction site. And with the advent of 3D printing, the number of work injuries and fatalities will obviously decrease, as it makes construction more programmable and automated. Robotic construction requires standardized, accurate and complete digital building information, making this technology more accurate and efficient, with minimal rework due to human error or any information inconsistencies. The usual problems with materials and components that need to be stored somewhere, protected from damage are leveled out, problems with installation and work in progress due to damage also disappear - 3D elements are created as they are built, they do not need to be moved and stored.

- Exploring new markets

The use of a 3D printer also allows construction companies to enter new market sectors that were previously inaccessible to them. And for start-up companies, having a 3D printer will be a competitive advantage. What's more, 3D printing is a brilliant way to elevate or improve the reputation of a construction company's brand among those who believe that concrete production has an impact on the planet's environment.

Distribution of structural 3D printing

3D printing for structural reinforcement, small scale components and structural steel could revolutionize design, construction and space exploration. In addition, the European Space Agency (ESA) believes that using 3D printed metals to create high-quality complex shapes can significantly reduce their cost, and they will become very common.

ESA has developed a project with the European Commission to improve the printing of metal components that can be used in space. In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

Almost everything can be designed on a computer, so AMAZE plans to install a 3D printer on board the spacecraft, and as soon as an astronaut needs any part, a tool, he can simply print it.

Structural 3D printing

Civil engineering 3D printing

Civil engineering 3D printing has been gaining popularity over the past decade, as has the aerospace and biomedical industries. This revolutionary manufacturing technique is based on its unique ability to create any geometric shape without any formal restrictions, minimizing waste but increasing productivity and results. The construction industry's push towards automation has recently reached important milestones, including the creation of the first structures using robotic "arms" and 3D printing technology.

The use of 3D printing in the creation of structural elements from polymer materials, concrete and metals is becoming more common.

These civil engineering technicians can create freeform and innovative architectural designs using CAD-integrated software.

However, despite considerable research in the aerospace and bioengineering industries to evaluate and analyze this mechanism, there is still a lack of understanding of its use, the impact of 3D printed materials in civil structures, both in terms of material properties and structural response.

Imperial College London

Read also: Best Building Apps in 2021

WIKI HOUSE - 3D printing in construction: what is the concept behind

Wiki House is an innovative project created by a small group of architects in London in 2011 . It offers an open source digital house design system that allows users to create, upload and share designs and print their own houses.

The kit does not require any special knowledge and training and can be created in 1 day. Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

A standard two bedroom house can be built for less than £50,000 and additional components such as cladding, insulation, windows and more can be added to the main frame of the structure. The first house that was built on the basis of the open source Wiki House technology was a two-story building. The 3D printed house was presented at the London Design Festival in 2014.

The Wiki House movement was spearheaded by Alastair Parvin, whose TED presentation "Architecture for People, Built by People" talked about the promise of 3D printing in construction. The creator of this project believes that Wiki House can help solve the housing problem, especially in emergency situations such as earthquakes (there is already evidence that 3D-printed houses can withstand shocks up to magnitude 8).

In the future, this could become a real alternative to low-cost houses, while allowing the customer to control the design of the project.

3D building built using Wiki House

Will 3D printing be the sustainable future of building?

3D printing has the potential to revolutionize the supply chain and structure through a new method of design and manufacturing. According to the study, 3D printing can help the construction industry become more economical, more efficient and greener.

Saxon University of Applied Sciences scientists Ivo Kotman and Neils Faber claim that 3D printing technology will be a "game changer". They explored the possibilities of 3D printing concrete, and their conclusions are:

- 3D printing shortens the supply chain and the entire design process. 3D printing right on the job site eliminates time-consuming steps in the design process. The architects, engineers, contractors, clients, and executives who normally have to be actively involved in a project are no longer needed in 3D printing.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs. - Pipe fitting and electrical wiring become easier and more efficient. Heating systems, insulation, plumbing and electricity all require the laborious on-site installation of conventional construction. However, in 3D printing, some of these features can be incorporated into the 3D printing process. Cavity wall printing is less resource intensive, improves insulation, and allows the use of 3D-printed hot or cold water channels. Moreover, the need for on-site installation is eliminated, which directly affects the reduction of waste.

- The best logistics. 3D printing eliminates 3 logistics and shipping issues. Firstly, a lot of materials and elements often deteriorate upon delivery, and if everything is printed on site, then damage is minimized

Secondly, in order to withstand transportation, the parts must be with increased technical characteristics, which by default increases the cost of them, and therefore the entire project. 3D printing right on the construction site will help to avoid such additional costs.

3D printing right on the construction site will help to avoid such additional costs.

- Creation of individual house designs available to the general market. Usually, building a house with the involvement of an architect is an expensive pleasure for most consumers. But with concrete 3D printing, you don't have to worry about the chosen shape, it won't cost more. In fact, this means that in the future, more people will be able to buy houses of their own design, according to their individual needs

Reverse side of the coin

While 3D printing is definitely attractive, it's still important to look at it impartially, removing some of the promotional stimulus. Skeptics note several disadvantages of this technology.

- Research and development costs

Most construction companies operate with relatively low profitability. To start using 3D printing everywhere, significant investments will be required.

- Will consumers see this as a marketing ploy?

3D printed houses, offices, shops and other infrastructure are often impressive. But do most people really want to live or work in one? For most people, brick houses are much more familiar and attractive. Other technologies such as prefabricated houses also seemed like an attractive technology of the future for some time, but have not been widely adopted, despite the fact that in many cases they were cheaper than traditional ones.

- Difficulty integrating with other components

3D printers can create unique and interesting designs. However, if you need a building that will use different materials or different elements that will not be suitable for 3D printing, then it will be a challenge to include a 3D printer for the building process.

- Skilled labor shortage

With the current problem of a shortage of skilled labor in the construction sector as a whole, 3D printing will require an even larger set of specialized knowledge and skills, which will have to be selected from an already small niche of candidates. So finding specialists to work in 3D printing for construction may be another difficult task in the future.

- Construction quality control

Weather conditions can slow down the traditional building process, but things are even worse for 3D printing. The environmental factor for commercial construction may reduce the demand for 3D printing. What's more, quality control can be a much more serious task, requiring constant monitoring of the process by real people at the construction site.

- No standards and regulations

Despite the regular mention of 3D printing in the media, it still has not had a significant impact on the construction sector. There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

Read also: New technologies in construction 2021

How can 3D printing be integrated with construction?

At the moment there is strong evidence that 3D printing is worthy of attention and can be applied in the construction segment, and most likely that this technology will be used more in the coming years. True, it is not known how widely these devices will be used on the construction site, or whether they will remain only a tool for the manufacture of block elements for prefabricated structures. But for certain projects, it is reasonable to assume that 3D printers and this technology in construction will be a must-have tool in the arsenal of builders.

ABOUT PLANRADAR

PlanRadar was founded in 2013 and provides an innovative mobile software solution for construction and real estate. Our app is available on all iOS, Android and Windows devices and has already helped over 13,000 customers digitize their workflow in over 55 countries. Find out more about the app here.

13 BEST CONSTRUCTION 3D PRINTERS OF 2019

A 3D construction printer is a machine that can build houses by applying material (concrete) layer by layer. The paste type material used, in this case concrete or earth, is forced through the nozzle in layers to print buildings.

Concrete 3D printing in the construction industry saves time, effort and material when compared to traditional methods. However, it is important to note that 3D printers are not yet capable of creating a fully functional home, only the frame and walls can be created, other elements such as windows, electricity or plumbing must be installed separately. Concrete 3D printers can also be used to print bridges, benches, or simply outdoor decorations.

To provide a complete overview of the construction 3D printer market, we have listed the top 12 construction 3D printing solutions. Some of them are 3D printers already available for sale, while others are still in the prototype stage or provide 3D printing services for external structures.

HOW TO BUILD A 3D PRINTED HOUSE?

Construction 3D printers use extrusion technology. Some construction 3D printers are similar to FFF/FDM desktop 3D printers, only larger (gantry style), while others consist of a rotating mechanical arm.

In both cases, paste-type components such as concrete are used as the filament. The material is ejected from a special nozzle to form layers. In simpler (very) extrusion of pasta is like using a bag to dispense frosting on a cake.

The printer creates foundations and walls layer by layer. The base is literally the printer's build plate. However, some concrete 3D printers are used to 3D print brick molds. Once molded, the bricks are stacked on top of each other manually (or with a robotic arm).

Benefits of 3D Building Printing

• Eco-Friendly : 3D printed houses can be built with sustainable materials. What's more, some construction 3D printers use solar energy and emit little CO2.

• Affordable: 3D construction printers can build affordable housing, providing great relief to people in poor areas or after natural disasters.

• Scalable: 3D construction printing reduces certain construction costs. For example, the cost of 1 square meter of wall using traditional construction methods is approximately $75, while for an Apis Cor house 3D printer it is only $27.

• Efficient: Because materials are 3D printed on demand, machines produce less waste. In addition, 3D construction printers can complete the foundation of a house in less than a few days, while traditional construction methods take weeks or even months.

• Design flexibility: Curved walls and unique facades can be easily created with a 3D printer

Disadvantages of 3D construction

• Expensive initial investment: These 3D printers can sometimes cost up to a million dollars.

• Partially built houses : build only the shells of the houses. The 3D printing process is usually paused to manually install plumbing, wiring, and fittings.

• Rough Appearance : The exterior of most 3D printed houses is not as smooth as traditional houses.

• Lack of Certification: Construction sites are regulated by law and there are important safety standards that must be met, which can be difficult with 3D printing methods (different repeatability, dimensional stability, etc.).

CONSTRUCTION 3D PRINTERS: OVERVIEW

We divide construction 3D printers into three categories: house building 3D printers that you can buy, prototype concrete printers, and concrete 3D printing services.

Home 3D printers available

AMT printers

Pictured: AMT S-6044 Long and AMT S-300

), 11 x 31 x 80 (maximum)

• Material : Concrete / Clay / Gypsum

• Country : Russia

Equipment manufactured by AMT-SPETSAVIA - workshop and field portal construction 3D printers (COP-printers, Construction Objects Printing) : and from small format (for printing small architectural forms) to large (for printing buildings up to 30 floors high). Productivity from 0.5 to 2.5 cubic meters per hour, management by 2 people. AMT printers are capable of printing with any kind of concrete, clay and gypsum.

Productivity from 0.5 to 2.5 cubic meters per hour, management by 2 people. AMT printers are capable of printing with any kind of concrete, clay and gypsum.

BetAbram P1

• Assembly size : 1.6 x 8.2 x 2.5 m

• Material : Concrete

• Country : Slovenia

for the creation of equipment - BetAbram, a small Slovenian team that works on the creation of 3D-3D equipment - BetAbram printing since 2012. Their flagship home 3D printer, the BetAbram P1, is currently in its second iteration and is available with additional printheads: basic, "Orto" for smoother layers, and rotatable for more design options.

COBOD BOD2

• Build Size : 11.98 x 45.07 x 1.53 m

• Material : Concrete

• Country : Denmark

This design 3D printer is fast, up to 18 meters per minute . BOD2 is modular and can be adapted to various sizes. COBOD is a 3D Printhuset company.

Constructions-3D 3D Constructor

• Assembly size : 13 x 13 x 3. 8 m

8 m

• Material : Concrete

• Country : France

Constructions-3D is a subsidiary of French 3D printer retailer Machines-3D. Their 3D Constructor machine is mobile thanks to its rubber tracks and fits in a 20ft shipping container for easy transportation from one construction site to another.

Material : Concrete

Country : Netherlands This easy-to-use 3D printer is capable of reaching heights of up to 2.75 meters and only requires two people to operate.

ICON Vulcan II

• Build Size : 2.6 x 8.5 x ∞ m

• Material : Concrete

• Country : United States

ICON wants to revolutionize the construction industry with its Vulcan II printer. The whole process is designed to be user friendly with a tablet-based interface, and the ICON Lavacrete concrete mix is optimized for easy printing.

MudBots Concrete 3D Printer

• Build Size : 1.83 x 1.83 x 1.22 m (minimum)

• Material : Concrete

• Country : United States

MudBots is a manufacturer of concrete 3D printers in the USA. Their smallest model (approximately 1830 x 1830 x 1220 mm) is available for $35,000. Large build sizes are also available, reaching up to 30 meters in length.

Their smallest model (approximately 1830 x 1830 x 1220 mm) is available for $35,000. Large build sizes are also available, reaching up to 30 meters in length.

MudBots says their 3D printers can print a small house in just 12 hours and cut costs by 70% compared to traditional building methods.

Stroybot2

Build Size : 10m x 15m x 6m

Material : Concrete

Country : United States

StroyBot, also known as the Rudenko 3D Printer, is a versatile mobile design printing system supplied as a build kit user. On average, he can print a 100 square meter house in 48 hours (walls only).

WASP Crane WASP “Infinity 3D Printer”

• Assembly size : Ø 6.3 x 3 m

• Material : Concrete / Earth materials

• Country : Italy

The Crane WASP is an evolution of the previous WASP construction printer, the BigDeltaWASP 12MT . This open source builder is modular and multiple Crane printers can work together on the same project, giving theoretically endless 3D printing possibilities.

Concrete printers working projects

Apis Cor 3D printer

• Assembly size : 8.5 x 1.6 x 1.5 m

• Material : Concrete

• Country : United States

Apis Cor, a 3D construction company based in San Francisco, claims to be able to 3D print a house in less than 24 hours. Their Apis Cor printer is similar to a robotic arm and won first place in NASA's 3-stage 3D printing competition.

Batiprint3D 3D Printer

• Build Size : -

• Material : Concrete / Other

• Country : France

Batiprint 3D made headlines internationally when it completed its 3D print shop at Nantova, France. Their 3D printer not only prints cement but also insulating foam, making it one of the most complete 3D building solutions.

S-Squared ARCS VVS NEPTUNE

• Build Size : 9.1 x 4.4 x ∞

• Material : Concrete

• Country : United States

S-Squared, also known as SQ3D, is working on a large scale project "4D printing", which aims to provide fast, reliable, environmentally friendly and affordable housing for poor areas.