3D printing bra

The right bra for every woman thanks to 3D technology

Published on September 18, 2020 by Carlota V.

3D printing technologies can also have an impact on lingerie: Dutch designer Lidewij Vera Arí van Twillert used Artec 3D scanning solutions and 3D printing to design made-to-measure bras, fully adapted to each woman’s morphology. She started from the observation that the current solutions on the market were very often uncomfortable in terms of underwire, cup and straps. Therefore, she came up with a personalised design based on a 3D scan of a woman’s breasts. The designer developed an alternative to the underwire called Curvearis – it is 3D printed and made-to-measure support forming the technical scheme of the bra.

Are today’s bras really comfortable? Most women will tell you that they are not, and that’s not surprising: today’s bras are made according to a specific model and then available in universal sizes. In fact, they should all be designed to fit the wearer’s breasts, making them unique and individual. For obvious cost reasons, mass production is more attractive for lingerie manufacturers. And yet, some companies have started to manufacture personalised underwear. This is the case of Dutch designer Lidewij Vera Arí van Twillert, who launched her first Mesh Lingerie collection in 2015. She explains: “I’ve always been fascinated by fashion and, during my engineering studies, I decided to combine my passion for technology with styling. The 3D scan technology inspired me to create the optimal made-to-measure bra. Nowadays, the design and function of the bra can be dissociated: they are either comfortable or pretty. I wanted to build a project where aesthetics and function are one and the same”.

By combining 3D scanning and 3D printing, the stylist can design a made-to-measure bra | Credits: Lidewij Vera Arí van Twillert

The manufacturing process of the 3D printed bra

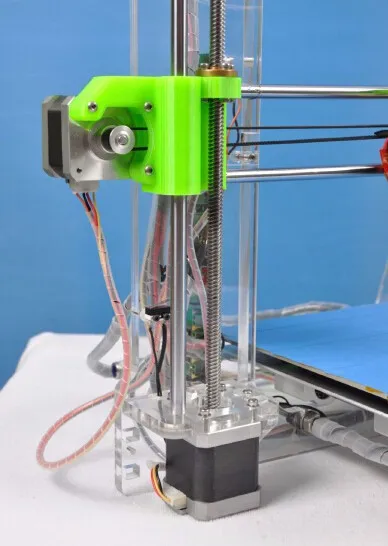

She approached the company Artec 3D to find an optimal 3D digitisation solution to scan a woman’s breasts. The stylist is now working with the Artec Eva Lite scanner, an accessible professional solution perfectly adapted to the digitisation of the human body. It all starts with a 3D scan of the client’s chest in a studio in Rotterdam – the stylist points out that no physical contact is made here. The scan consists of more than 20,000 data points. Then you can choose the model and read the bra fabric. Following this, the 3D printing process begins: using an Ultimaker machine, Lidewij Vera Arí van Twillert designs the first Curearis test: a curved structure that replaces the traditional underwire. The fabrics she has chosen are added so that the bra can be adjusted if necessary. The final manufacturing phase can then begin. The feedback so far has been very positive, as this testimonial shows: “It is soft and fits my body perfectly. There is no pressure or rubbing on my skin, which is often the case when I wear a regular bra“.

The stylist is now working with the Artec Eva Lite scanner, an accessible professional solution perfectly adapted to the digitisation of the human body. It all starts with a 3D scan of the client’s chest in a studio in Rotterdam – the stylist points out that no physical contact is made here. The scan consists of more than 20,000 data points. Then you can choose the model and read the bra fabric. Following this, the 3D printing process begins: using an Ultimaker machine, Lidewij Vera Arí van Twillert designs the first Curearis test: a curved structure that replaces the traditional underwire. The fabrics she has chosen are added so that the bra can be adjusted if necessary. The final manufacturing phase can then begin. The feedback so far has been very positive, as this testimonial shows: “It is soft and fits my body perfectly. There is no pressure or rubbing on my skin, which is often the case when I wear a regular bra“.

Credits: Lidewij Vera Arí van Twillert

You’ll need to be a little patient before you get your custom-made bra back, as it takes 6 to 9 weeks from the time the 3D scan is carried out. Please note that three fittings are included. As for price, the 3D scanning phase costs 95€ to which you will have to add the price of the chosen fabric. You can find more information HERE.

Please note that three fittings are included. As for price, the 3D scanning phase costs 95€ to which you will have to add the price of the chosen fabric. You can find more information HERE.

Fancy a 3D-printed bra? | Sciences Po School of Management and Impact

- Claire Chabaud ©Sciences Po

Claire Chabaud, a Master of Economics and Business student at Sciences Po, has just won first prize in the Bpifrance #PitchTonInno awards for students with her partner Anastasia Ruiz, a fashion design student at ESMOD. Thanks to the €30,000 FrenchTech grant this has earned them, the students' project for made-to-measure 3D-printed lingerie will be able to see the light of day. We talked to Claire.

Where did you get the idea of creating 3D-printed lingerie?

I've wanted to work in lingerie for a very long time. In 2011, during a trip to China with my grandmother for the World Expo, I noticed there was a problem in this area.

Chinese women are very slight with delicate figures. But they're trying to bring out the best in their morphology with Western brands that don't suit their measurements. Etam, for example, which had a strong presence on the market already back then, was selling the same models in China as in Europe without adapting its sizes. That was what made me think that lingerie should be created based on the woman herself and not on a standard. I though a lot about this problem without finding a good solution.

It was during a course at Sciences Po called Innovation and Disruptive Business that the light bulb went on. For our end-of-semester project we had to choose a favourite industry and work out a way to innovate in it. Rahaf Harfoush, our teacher, told us that to create a disruption in an industry you have to observe what's going in the opposite industry. Well, what could be more opposite to lingerie than the arms industry? This was when the first weapons were being created with 3D-printing.

A highly customizable technology that makes it possible to create unique, high quality pieces: that was just what I was looking for my project. So rather than printing weapons I thought "why not print underwear suited to women's bodies?"

How has your education at Sciences Po helped you (or not) start this business venture?

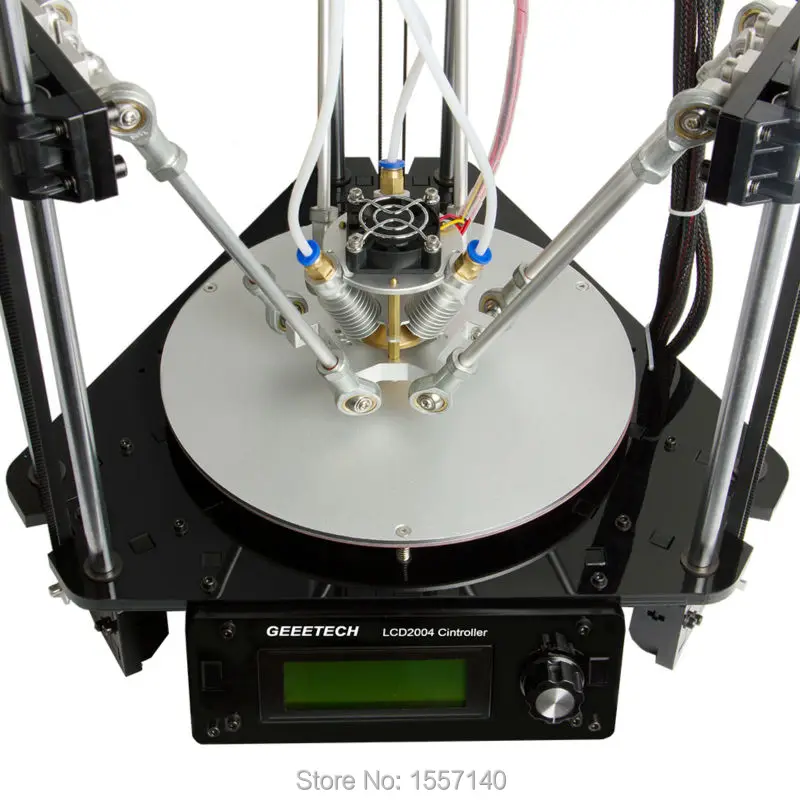

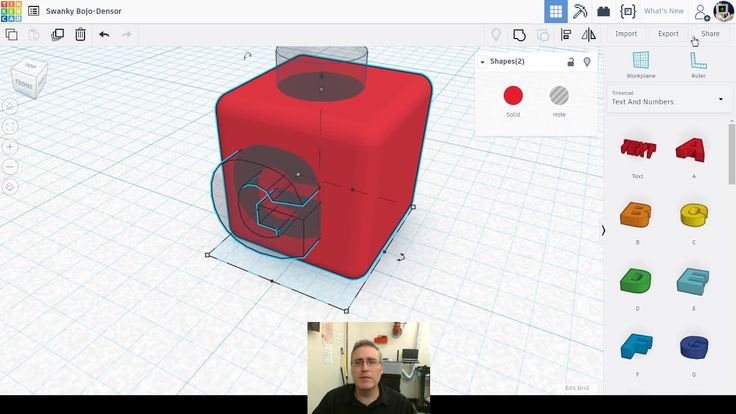

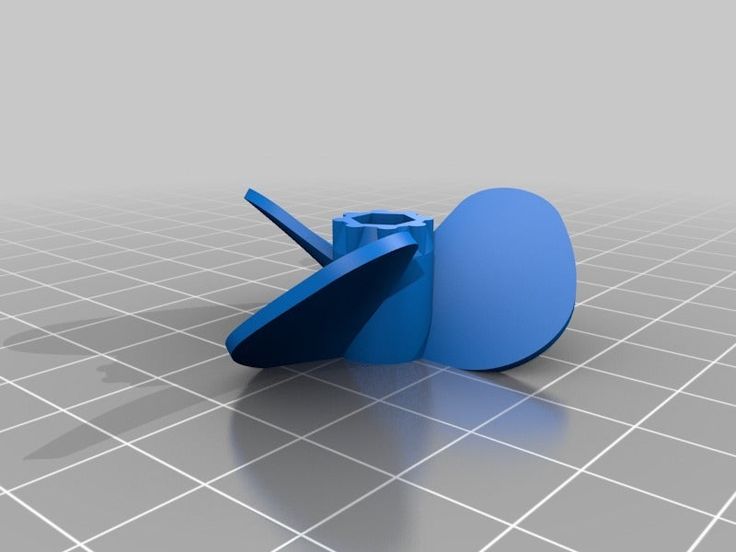

Rahaf Harfoush's course helped boost my creativity and be more open-minded so I could find new solutions. But after I got the idea, I had to admit the obvious: 3D printing was a complicated technology that I needed to understand better. So I signed up for a course offered by the Sciences Po Arts Bureau called "3D printing", where Jean Colladon taught us how it works. We used FDM printers [Fused deposition modeling, a 3D-printing method that works by depositing filament] and created files with a programme called SketchUp. Then just at the end of that semester I was looking for internships for my gap year. I received several offers to work for luxury or marketing companies but at the last moment I received an offer from Sculpteo, one of the three leading 3D-printing services worldwide.

Jean helped me with my application and I started working as a marketing assistant. In that position I was able to learn 3D technology, and a few months later I was put in charge of creating a collection of 3D-printed clothing.

This 3D-printed lingerie project is the result of collaboration with a fashion design student. How did you come to associate your respective skills? How do you complement each other?

I was really the project manager for creating this collection of 3D-printed clothing. Sculpteo had the technology with the printers and engineers but we were missing the artistic side. So I went to ESMOD, one of the best fashion schools in Paris, and proposed a competition to select a student. The principle was simple: the collection would be offered to the winning student. Anastasia Ruiz won the competition hands down. She had designed a collection called "Virus", a metaphor for the constantly changing world and technology's fast-paced development.

It's hard to imagine what it's like to wear a 3D-printed bra. Is it a comfortable material?

In fact, when you start working in the 3D-printing industry you go through a long phase of disillusionment when you realise that not everything can be printed in 3D. But that disappointment helped me get over seeing 3D printing as an end and start seeing it as a means. We prototype our bras by scanning the bust measurements, then using the 3D scan we create a structure that looks like underwire but has neither the same shape nor function. But over this structure we'll be adding fabric; it's 3D-printing that gives the made-to-measure, but then we add normal fabric.

We've also won the competition run by CETI. The prize is six months of research and development with their teams to create 3D-printed lace, which could make it possible for us to create 100% 3D-printed bras! But like any innovation, that won't be for another two or three years.

..

Do you see bras as purely practical objects or should they be "attractive"?

In fact I've noticed something rather amusing: when women are asked what matters to them about their bra, they are often asked to choose between a comfortable, sexy or practical piece of lingerie. I don't think a woman should have to choose between these three aspects. The Endeer project really aims to try and develop a product that will bring together all three. Currently, our prototyping is focused on the practical aspect of the bra, then we want to create a comfortable garment, and I trust Anastasia to perfect the aesthetic side.

- Master's programmes at Sciences Po

- Endeer's website

STL file Wooden bra・3D printing idea for download・Cults

The best files for 3D printers in the Tools category

Deactivated

eSUN 口罩松紧调节器 e-Free respirator regulator

Free

Handle vase with spur gear

Free

Inkynato

6 €

Embroidery Hoop

Free

Trail Marker Square

0. 64 €

64 €

TinyLoom cnc/laser

Free

Sleeve Case for BeagleBone Black

Free

Bestsellers in the Tools category

Armadillo - flexible wire conduit

1.69 €

Phone holder

2.46 €

Quick Print Paint Bottle Rack (6 sizes)

2.83 €

Fire Hydrant Storage Container

1.90 €

UNIVERSAL BED LEVELING INDICATOR FOR VERY ALL PRINTERS

2,84 €

PRECISION CALIPER 3D PRINT DIY

3,12 €

3D printed wave transmission (harmonic drive)

4. 99 €

99 €

ENDER 3 S1, S1 PRO, SPRITE, HOT END DUCT 4020 OR 5015 FAN, PROBE NO Y OFFSET

€2.28 -20% 1.83 €

Cooling system Minimus Hotend

2.72 €

INDICATOR FOR BETTER BED LEVELING FOR ENDER 3 V2

2.84 €

SUPERBOX

1,50 €

nine0008 Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct/fang. CR-10, Micro Swiss direct drive and bowden compatible. No support required for printing1.58 €

Quick print stackable parts containers / storage boxes

2.83 €

Ender 3 S1 BEST cable guide - vertical

2,50 €

nine0008 Tool holder for 3D printer V3. 0

0 1.05 €

ARTEMIS -> Shop for Alligator 2 || 6.5" arrows || Repeating crossbow

6.25 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so support us at maintaining the activities of and creating future developments of is very simple. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here. nine0006

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Stephanie Santos 3D Printed Couture

Previous

Next

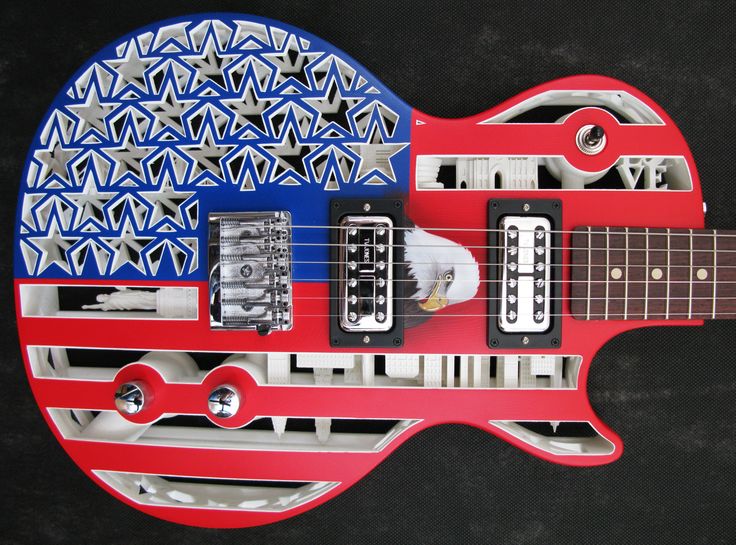

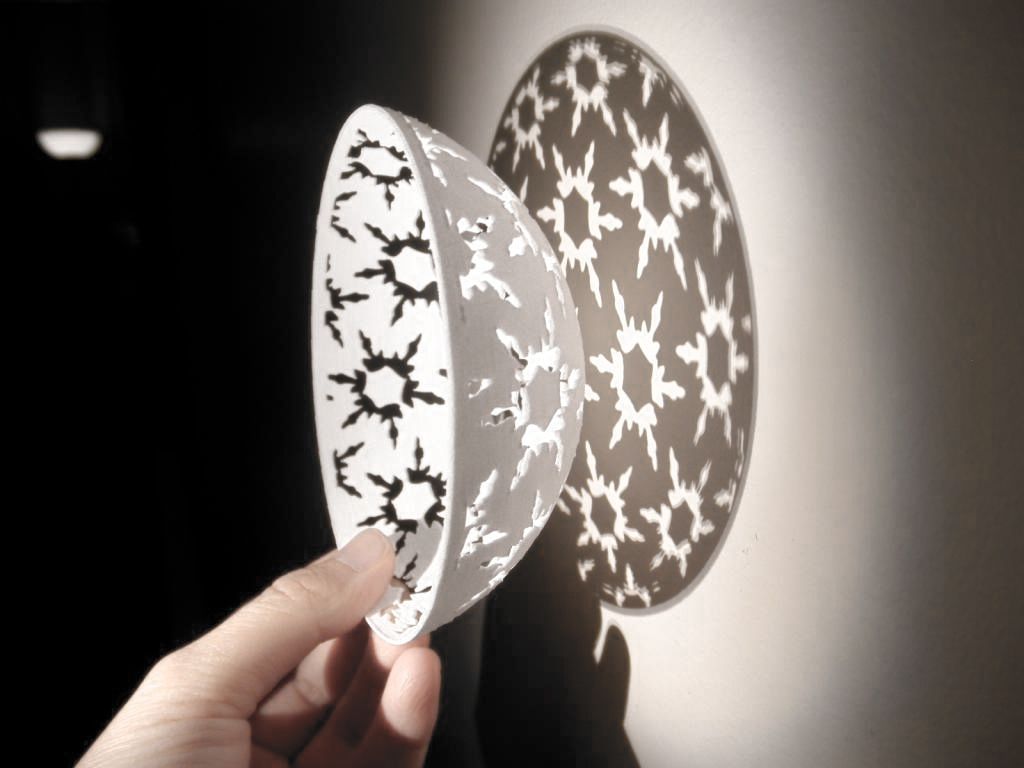

Stephanie Santos offers a new vision of lingerie and fashion, the intersection of design and technology. The designer combines traditional Haute Couture clothing construction with new digital and 3D printing technologies. The seams are 3D printed. All lingerie pieces are unique and handmade to order by the FashionTech designer in her workshop in Portugal. nine0006

The designer combines traditional Haute Couture clothing construction with new digital and 3D printing technologies. The seams are 3D printed. All lingerie pieces are unique and handmade to order by the FashionTech designer in her workshop in Portugal. nine0006

Read more

About the designer Stephanie Santos 3D printed fashion

Stephanie Santos was born in Luxembourg to Portuguese parents. She studied various fields of art and design in France and abroad (at TextileLab in Amsterdam). The designer admires what nature offers us, especially the wonders of flora. In her work, she combines modern techniques with fundamental ones to create her own interpretation of aesthetics and create unique pieces of lingerie. Stephanie Santos specializes in textile technology, and more specifically FashionTech 3D printing, which offers new innovative possibilities for the design and production of clothing and textiles. nine0006

"The idea is to work with a material that has a sustainable production and life cycle: each piece I print can be cut again into small pieces and melted down into threads that can be reused by the machine for other industries," explains she.

Man is only a product of his thoughts. What they think is what they become. -Mahatma Gandhi

The designer takes some inspiration from nature, biomimicking aspects of the botanical kingdom, especially plants. Designed with the ergonomics of the female body in mind to create a unique, natural and elegant shape. To feel comfortable in clothes, form and function must coexist. Nature has already cracked the code of perfection. Overall, the founder believes in the symbiotic relationship of clothing created using nature's codes. nine0006

3D printing enables a greener and much less polluting production. The brand is also inspired by the principles of "Slowfashion". Stephanie Santos uses 3D technologies such as 3D pens, 3D printers and 3D software to create 3D digital designs and translate them into 3D printed clothing, textiles and accessories. Working with a 3D pen opens up many more possibilities that have not yet been explored. Bringing ideas to life and creating unique textiles with a 3D pen is incredible.