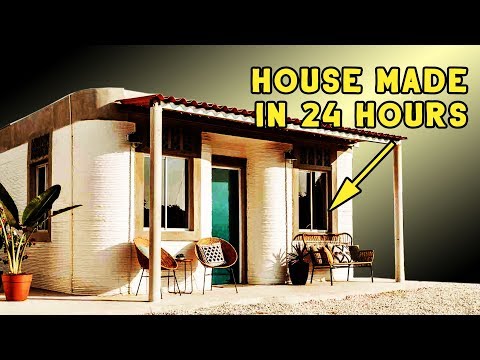

3D printers print ten houses in 24 hours

See How This House Was 3D Printed in Just 24 Hours

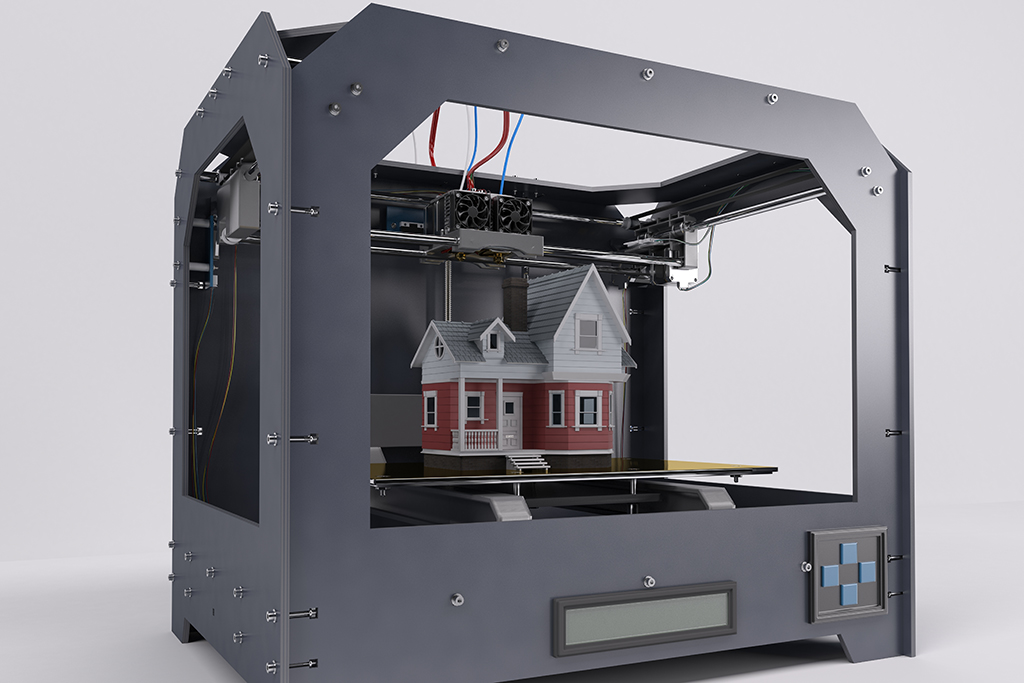

3D printing is being used to produce more and more novel items: tools, art, even rudimentary human organs. What all those items have in common, though, is that they’re small. The next phase of 3D printing is to move on to things that are big. Really big. Like, as big as a house.

In a small town in western Russia called Stupino, a 3D printed house just went up in the middle of winter and in a day’s time.

Pieces of houses and bridges have been 3D printed in warehouses or labs then transported to their permanent locations to be assembled, but the Stupino house was printed entirely on-site by a company called Apis Cor. They used a crane-sized, mobile 3D printer and a specially-developed mortar mix and covered the whole operation with a heated tent.

The 38-square-meter (409-square-foot) house is circular, with three right-angled protrusions allowing for additional space and division of the area inside. Counter-intuitively, the house’s roof is completely flat. Russia’s not known for mild, snow-free winters. Made of welded polymer membranes and insulated with solid plates, the roof was designed to withstand heavy snow loads.

Apis Cor teamed up with partners for the house’s finishing details, like insulation, windows, and paint. Samsung even provided high-tech appliances and a TV with a concave-curved screen to match the curve of the interior wall.

According to the company, the house’s total building cost came to $10,134, or approximately $275 per square meter, which equates to about $25 per square foot. A recent estimate put the average cost of building a 2,000 square foot home in the US at about $150 per square foot.

The homes of the future?

Since these houses are affordable and fast to build, is it only a matter of time before we’re all living in 3D printed concrete circles?

Probably not—or, at least, not until whole apartment buildings can be 3D printed. The Stupino house would be harder (though not impossible) to plop down in the middle of a city than in the Russian countryside.

The Stupino house would be harder (though not impossible) to plop down in the middle of a city than in the Russian countryside.

While cities like Dubai are aiming to build more 3D printed houses, what many have envisioned for the homes of the future are environmentally-friendly, data-integrated ‘smart buildings,’ often clad with solar panels and including floors designated for growing food.

Large-scale 3D printing does have some very practical applications, though. Take disaster relief: when a hurricane or earthquake destroys infrastructure and leaves thousands of people without shelter, 3D printers like Apis Cor’s could be used to quickly rebuild bridges, roads, and homes.

Also, given their low cost and high speed, 3D printed houses could become a practical option for subsidized housing projects.

The Stupino house interior. Image Credit: Apis CorIn the US, tiny houses have been all the rage among millennials lately—what if that tiny house could be custom-printed to your specifications in less than a week, and it cost even less than you’d budgeted?

Since software and machines are doing most of the work, there’s less margin for human error—gone are the days of “the subcontractor misread the blueprint, and now we have three closets and no bathrooms!”

While houses made by robots are good news for people looking to buy a basic, low-cost house, they could be bad news for people employed in the construction industry. Machines have been pouring concrete for decades, but technologies like Apis Cor’s giant printer will take a few more human workers out of the equation.

Machines have been pouring concrete for decades, but technologies like Apis Cor’s giant printer will take a few more human workers out of the equation.

Nonetheless, the company states that part of their mission is “to change the construction industry so that millions of people will have an opportunity to improve their living conditions.”

Banner Image Credit: Apis Cor

Look inside only large-scale 3D printed housing development in U.S.

- Just outside Austin, Texas, massive machines are squeezing out 100 three- and four-bedroom homes, in the first major housing development to be 3D-printed on site.

- One of the nation's largest homebuilders, Lennar, is partnering with ICON, a 3D printing company, to develop the project.

- "The promise of robotic construction is a promise of automation, reducing labor – therefore reducing labor costs," said ICON co-founder Jason Ballard.

watch now

It looks more like a project at NASA than a home construction site.

Just outside Austin, Texas, massive machines are squeezing out 100 three- and four-bedroom homes, in the first major housing development to be 3D-printed on site.

One of the nation's largest homebuilders, Lennar, is partnering with ICON, a 3D printing company, to develop the project. Lennar was an early investor in ICON, which has printed just about a dozen homes in Texas and in Mexico. These homes will go on the market in 2023, starting in the mid-$400,000 range.

"This is the first 100 homes, but we expect to be able to bring this to scale, and at scale we really bring cycle times down and we also bring cost down," said Stuart Miller, executive chairman of Lennar.

ICON claims it can build the entire wall system of the home, which includes mechanical, electrical and plumbing, two to three times faster than a traditional home and at up to 30% of the cost.

Read more real estate coverage

"We exceed code requirements for all the different kinds of strength, wind, compressive strength by about 4x. We're about two and a half times more energy efficient," said Jason Ballard, co-founder and CEO of ICON.

We're about two and a half times more energy efficient," said Jason Ballard, co-founder and CEO of ICON.

The printers are designed to operate 24 hours a day, but they don't because of area noise restrictions. They are almost fully automated, with just three workers at each home. One monitors the process on a laptop, and one checks the concrete mixture, which has to be adapted to the current weather conditions. Another works in support, misting the area with water or adding new material into the system.

"The promise of robotic construction is a promise of automation, reducing labor – therefore reducing labor costs," Ballard said.

ICON aims to get the number of operators down to two over the next 12 months, Ballard added. Eventually, he wants even fewer operators. "I think the sort of Holy Grail is where one person can watch a dozen systems you need one person to watch a dozen systems," Ballard said.

The main squeeze

An ICON 3D printer at a housing development in Georgetown, TX.

Diana Olick | CNBC

The way it works is a digital floor plan is loaded into the software system called Build OS, which then prepares it for robotic construction. It will automatically map out the structural reinforcement, placing the electrical and plumbing outlets during the print. The printers then squeeze out rows and rows of a proprietary concrete mixture that looks much like toothpaste, slowly building up the structure.

Other companies, like California-based Mighty Buildings, are also using 3D printing technology, but they print the homes in a factory and then move them on-site. ICON brings the factory to the site.

"With this project, we're improving our total house count 400%, and we expect to like continue at least doubling for the next three to five years," said Ballard. He said he already has plans to work with other large-scale builders. DR Horton is another of ICON's early investors.

Lennar's Miller said his primary focus is on bringing more affordable homes to the market, and he sees this as one way to do that. But he knows it's also still the early stages.

But he knows it's also still the early stages.

"This is all about innovation. If you go around the country and speak to officials at the local and state level, the single biggest question is: How do we provide workforce housing, affordable housing," he said.

Lennar began plans on the project with ICON when the housing market was still red-hot, driven by strong demand and record-low mortgage rates. Now mortgage rates are more than double what they were at the start of the year, and demand has fallen off sharply, suggesting their could be added risk to this project.

"We still focus on our core business, making the trains run on time, building homes across the country, and as the market cycles up and cycles down we adjust our business," said Miller. "Innovation is a cycle as it sits on the side of our business because we know, looking forward, there's a housing shortage out there."

WATCH LIVEWATCH IN THE APP

WATCH LIVEWATCH IN THE APP

3D printing technology for residential buildings becomes a reality in 24 hours

From space exploration to robotics and medicine, 3D printing has huge potential in all areas, but especially it is starting to make a real impact in the world of affordable housing. The latest example of this is a slightly augmented project for the homeless in Texas, USA, which began with the construction of a stylish new 3D-printed administrative block in just one day.

The latest example of this is a slightly augmented project for the homeless in Texas, USA, which began with the construction of a stylish new 3D-printed administrative block in just one day.

The construction company behind the new 3D printed homes goes by the name ICON. The company presented its first prototype during the Texas media conference SXSW 2018, and after that it set about building an entire village - the world's first 3D-printed neighborhood, in a poor area of South America. Its Vulcan II 3D printer is designed to build simple boxes of houses, while the installation of roofs, doors and window openings is carried out by builders. The company is able to build housing much cheaper and more efficiently, and its concept shown at SXSW took just 48 hours to complete and cost just $10,000.

The Village of 3D Printed Homes aims to instill hope for a secure future for low-income people whose income does not exceed $200 a month, while promoting this concept of affordable housing solutions around the world.

Participation in a new project in Austin, Texas called Community First! Village was the next step for ICON. The project is led by local non-profit organization Mobile Loaves & Fishes for the homeless and will include more than 500 homes on 20 hectares when completed. In this social settlement of more than five hundred houses, additional addresses will appear - six objects made using the 3D construction method. Designed by Texas-based Logan Architecture, Icon will print three houses at once for the first time to showcase their build efficiency and focus on cost reduction. According to the company, all six houses will be rented out before the end of the year, but construction of the 46 sq. m. welcome center building is already completed at this stage. m for the future village, which was printed in just 27 hours. These 3D houses are among the affordable ones and will be ready to move in in just a few weeks.

How does it work?

The façade of the building is erected on the Vulcan printer developed by the company. The device prints walls with a mortar of concrete that retains its shape as it cures. Such technology allows them not to collapse. After erecting the facade, the builders install the necessary infrastructure, a wooden roof and windows. It takes a little more than 24 hours to fully build a finished house, depending on the building area, the maximum figures of which are about 75 square meters. The company installed the first such house in the American city of Austin.

The device prints walls with a mortar of concrete that retains its shape as it cures. Such technology allows them not to collapse. After erecting the facade, the builders install the necessary infrastructure, a wooden roof and windows. It takes a little more than 24 hours to fully build a finished house, depending on the building area, the maximum figures of which are about 75 square meters. The company installed the first such house in the American city of Austin.

This development has a number of advantages, such as relative cheapness, construction time, and the ability to build houses in conditions with limited resources and harsh climatic conditions. In addition, the walls of the building have an air gap that retains heat in cold weather. The estimated cost of building a dwelling is $4,000.

The second generation of this printer, the Vulcan II, is designed specifically for the production of reliable one-story buildings - quickly, inexpensively and with great variability. The printing area has been increased to 186 square meters. m, the width of the walls is adjustable for different sizes of panels. You can transport the printer in a special trailer; no assembly is required before starting work.

The printing area has been increased to 186 square meters. m, the width of the walls is adjustable for different sizes of panels. You can transport the printer in a special trailer; no assembly is required before starting work.

As ICON assures, anyone who has been instructed will be able to operate this printer. All functions are intuitive and displayed on the tablet screen. The printer itself is 3.5 meters high and 10 meters wide. It prints walls up to 2.5 meters high on a foundation up to 8.5 meters wide. It prints a part 0.3 high and 0.6 m wide at a speed of 1.5 - 2 meters per second.

Especially for the operation of the machine, the company has developed and patented a recipe for concrete-lime material Lavacrete. It has passed all strength tests and is recognized as safe for residential construction.

This is not the first attempt at 3D printing living spaces. Recall that in the spring of 2017, researchers from the Massachusetts Institute of Technology presented a similar construction technology.

Not only American startups are going to solve the problem of affordable housing with printing. A similar project is planned in India. Tvasta promised the first printed houses this year. Indian technology takes more time: the startup plans to print the components of a 30-square-meter house in about three days, and assemble it “under the roof” within a week.

Source: New Atlas

90,000 Three and a Half Houses in Four Days

COBOD and PERI showcased super-fast home building at Bautec. Photo: 3dprintingmedia.network

One 3D printed house per day

Visitors to the Bautec International Building Exhibition, held from 18 to 21 February 2020 in Berlin, were given a unique opportunity to see the process of creating a residential building in one day, thanks to 3D printing technology. Danish 3D printing construction company COBOD has teamed up with PERI Group on an ambitious project to demonstrate how a 3D construction printer can print a house in less than 24 hours.

During the exhibition, COBOD and PERI successfully printed 3.5 houses of 64 square meters each. The fourth house was not completed because the partners also had to create two 3D printed logos for the Bautec exhibition. Overall, COBOD claims that 3D logo printing is equivalent to printing 8 square meters of a house per hour.

Visitors to Bautec could watch the BOD2 large format printer in operation from 9:00 am to 5:00 pm. Time-lapse video from each press day is now available for those who were unable to attend the event in person.

Henrik Lund-Nielsen, COBOD CEO:

to the world market because it has the quality, speed, reliability and stability to run smoothly, hour after hour, day after day, and with incredible productivity that surpasses traditional construction methods. We planned to print 4 small houses in 4 days, and we almost reached our goal. Every day we printed one small house, but on the last day, at the request of the organizers of the exhibition, we decided to print a couple of company logos on a large scale, which subsequently did not allow us to complete the construction of the last, 4th house.

Every day we printed one small house, but on the last day, at the request of the organizers of the exhibition, we decided to print a couple of company logos on a large scale, which subsequently did not allow us to complete the construction of the last, 4th house.

With a modular print design up to 15m wide and 10m high, the BOD2 3D printer has an unlimited build length, allowing it to build full-featured homes on site. For Bautec, partners COBOD and PERI installed a relatively small BOD2 configuration of 5 x 5 x 5 meters, which is smaller than the rest of the BOD2 printers that COBOD sold to various customers.

Source: 3dprintingmedia.network

In terms of speed, the BOD2 is theoretically capable of printing up to 100 cm/sec, but due to the limited materials available for construction 3D printing and the complexity of the pumping mechanisms, the printer can only print at speeds of 40 cm/sec . At the COBOD exhibition, they refused to demonstrate the maximum speed for safety reasons.

At the COBOD exhibition, they refused to demonstrate the maximum speed for safety reasons.

Tilmann Auch, COBOD Product Development Engineer:

“Of course, we would like to show people a more powerful 3D printer for construction, but full-fledged printing on the exhibition site turned out to be impossible for a number of reasons. Therefore, we could only print small houses with a perimeter of 4 × 4 meters and with one bedroom. As for speed, here we have already limited ourselves. During the Bautec exhibition, we printed at a speed of no more than 25 cm/sec. This is due to EU requirements for machinery and robotics, which require the construction of a protective fence around the printer if we decided to print faster. We certainly didn't want to put up a fence at the show, as that would prevent visitors from seeing the printer in action."

Despite the limitations, COBOD and PERI were able to successfully print houses within the first three days, demonstrating the technology's ability to build the walls of a small house in about eight hours. At this print speed, a 150-square-meter house can be reproduced in less than 24 hours, according to COBOD representatives.

At this print speed, a 150-square-meter house can be reproduced in less than 24 hours, according to COBOD representatives.

Dr. Fabian Meyer-Brötz, manager 3D printing department at PERI Group:

“At Bautec, we proved to visitors that with a minimum number of workers, we can print houses with rounded walls at an average speed of 8 m2 per hour. It is important to note that these possibilities for creating arbitrary shapes allow not only to embody any imagination of the architect, but also to increase the functionality of the walls, to create improved designs of buildings and houses. We are not aware of any other technology that could provide the same result.”

The German construction company PERI Group has been investing in COBOD projects for a long time. In 2018, the company acquired a minority stake in COBOD, and in April last year, PERI Group was named the official distributor of the COBOD construction 3D printer.

Source: 3DPRINTINGMEDIA.

Learn more