3D printer 20000

The $20k Difference: Understanding 3D Printer Value

Learn Blog

Charles Lu is an Application Engineer based out of Markforged HQ in Watertown, MA. When he isn't investigating new uses for additive manufacturing or diving deep into the weeds of material properties, you can usually find him hiking, biking, and/or searching for his next meal.

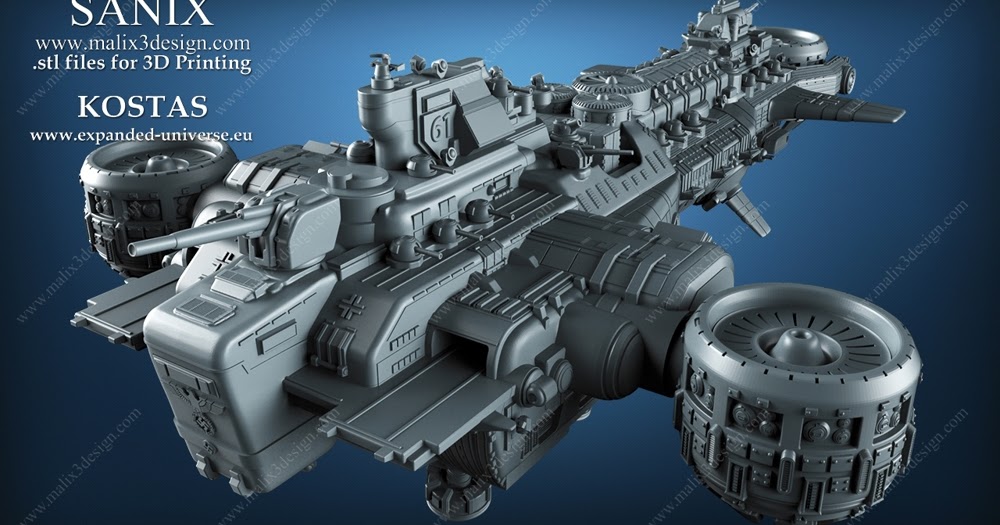

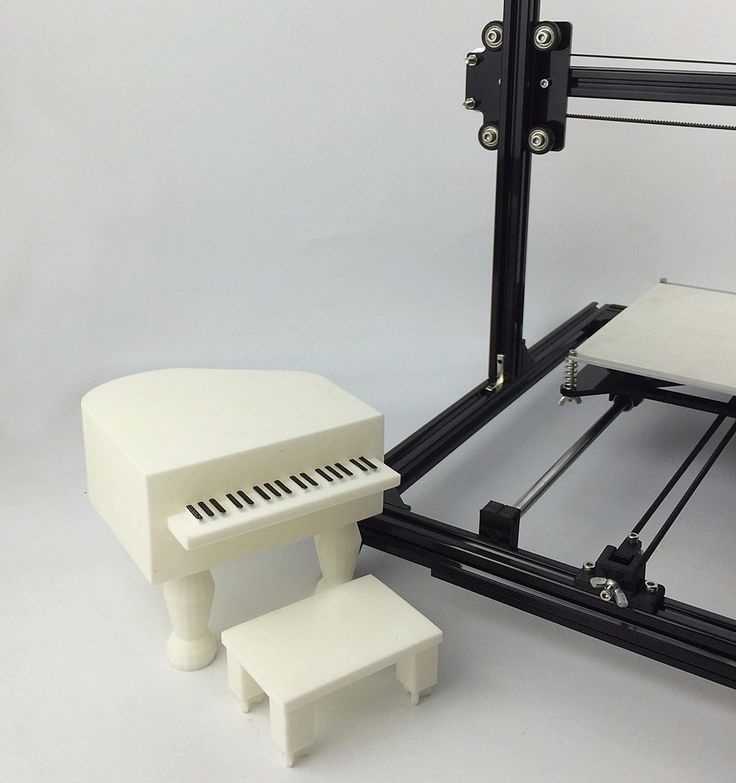

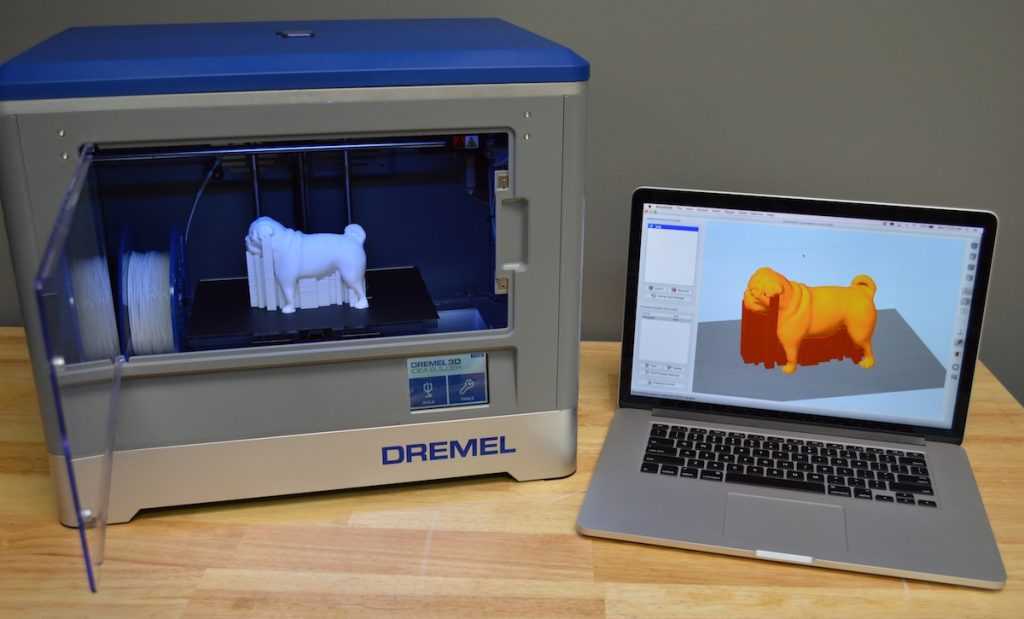

Hobbyist 3D printers have improved rapidly in the last decade, and market offerings are the best they’ve ever been. Today’s budget systems pack more capability per dollar than the founding fathers of extrusion-based 3D printing (think Scott Crump, Bre Pettis, and Adrian Bowyer) could have collectively imagined in an AIM chatroom, during the formative years of RepRap. The value of the hardware itself is so compelling today that the line between professional and hobbyist 3D printers might start to seem a bit blurry.

The low cost of a budget system from the likes of Prusa or Creality makes it easy for a mid-level manager to purchase on a credit card. Interns or co-ops are able to keep the thing running, so it seems like a manageable expense. More expensive systems require budgetary approval, and there’s always someone in management or finance who asks whether you really need a new tool if what you currently use isn’t broken.

So what exactly makes a Mark Two twenty times more expensive than a Prusa i3 Mk3S+? Or nearly one hundred times more expensive than a Creality Ender 3? You can’t answer these questions by comparing brochures.

I’ll give you a hint: it’s not just the hardware.

Take a minute to think back about your past experiences with 3D printing. Maybe you tried the MakerBot Replicator at the peak of 3D printing hype. Maybe you’ve been using a Lulzbot, made by a fun, humble business in Colorado whose revenue stream was devoured overnight by overseas competitors. Perhaps you’ve been busy with Stratasys for the better part of the last decade at work. You might even be a Markforged customer, and wondering if you should try something else. You could be totally new to 3D printing, but think it might solve a problem or scratch a creative itch.

Maybe you’ve been using a Lulzbot, made by a fun, humble business in Colorado whose revenue stream was devoured overnight by overseas competitors. Perhaps you’ve been busy with Stratasys for the better part of the last decade at work. You might even be a Markforged customer, and wondering if you should try something else. You could be totally new to 3D printing, but think it might solve a problem or scratch a creative itch.

But here we are in the present. It’s 2021, and despite the good value and good times in the industry, you’re finding limitations to the capabilities of your 3D printer, and looking for something more with Markforged.

- Maybe the promise of 10x stronger materials brought you here.

- Maybe you saw an Onyx part at a tradeshow once, and you still think about it sometimes...

- Maybe you’re working from home and tired of simultaneously watching your kids, the stove, and the printer the company sent home with you, and you are looking for a more reliable system so you can take regular lunch breaks.

- Maybe you are like Tom Sandladerer and love the aluminum unibody design.

But golly gee whiz, $20k to print carbon fiber? What gives? Is it worth it? (There’s an easy way to find out)

How risk and business impact changes as you improve materials and printer precisionThere’s never been a better time to buy a budget system, and despite unlimited access to our own machines and materials, plenty of Markforged engineers would agree. We’re not here to tell you that Markforged is the solution for every problem; frankly, it’s not. But if it could be the solution for your problem. If it is, we’d love to help.

Get the $200 vs $20,000 eBook

If you prefer the video format, check out the recording of our latest webinar on The $20k Difference: Strategies for Maximizing 3D Printer Value for a guided decision-making session on choosing your next 3D printer. It is a fun webinar - kind of like group fitness, a Ted Talk, and guided meditation, rolled into one. You’ll hear from a number of [Markforged] engineers who rock Mark Twos AND Creality or Prusa machines at home who can give you the pros and cons of each.

It is a fun webinar - kind of like group fitness, a Ted Talk, and guided meditation, rolled into one. You’ll hear from a number of [Markforged] engineers who rock Mark Twos AND Creality or Prusa machines at home who can give you the pros and cons of each.

All of the blogs and the information contained within those blogs are copyright by Markforged, Inc. and may not be copied, modified, or adopted in any way without our written permission. Our blogs may contain our service marks or trademarks, as well as of those our affiliates. Your use of our blogs does not constitute any right or license for you to use our service marks or trademarks without our prior permission. Markforged Information provided in our blogs should not be considered professional advice. We are under no obligation to update or revise blogs based on new information, subsequent events, or otherwise.

Never miss an article

Subscribe to get new Markforged content in your inbox

required required requiredSubmit

Largest 3D printers in 2022 for XXL prints

Large-scale 3D printers are able to print massive objects thanks to their gigantic build volumes. This guide covers some of the largest 3D printers in the world that are commercially available.

This guide covers some of the largest 3D printers in the world that are commercially available.

Last update June 23, 2022

We removed discontinued products and updated the BLB Industries The BOX lineup, which has been replaced by The Industry MAGNUM. We also added MASSIVit's latest solution, the Massivit 10000.

Table of contents

Handpicked related content

Large scale 3D printers (XXL): 2022 selection

BIG-Meter V4

F1000

BigRep ONE v4

400 Series WORKBENCH XTREME

T3500

MAGNUM

Massivit 10000

MAMA

3D printing furniture

3D printing large prototypes

3D printing production series

Customized large scale 3D printers

What are the best large scale 3D printers?

Large-scale 3D printers have been in the spotlight for quite some time. When we say large scale, we mean it– these machines can 3D print objects of over 1 square meter. They can be used to 3D print pieces of furniture, large prototypes, or several series of smaller objects in one go.

The professional 3D printers featured in our article are basically super-sized versions of ordinary desktop 3D printers. They almost all use extrusion 3D printing technology (FFF) and work the same way as regular desktop printers.

Our “largest 3D printers” selection does not include construction 3D printers, which fit into a different category.

Handpicked related content

If these large scale 3D printers (XXL) are too big, check out our other selections:

- Large format 3D printers (XL)

- Large volume 3D printers (L) for desktops/benchtops

- Large resin 3D printers (L)

Large scale 3D printers (XXL): 2022 selection

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Modix This brand is a certified partner from our network. | BIG-Meter V4 | 1010 × 1010 × 1010 mm39.76 × 39.76 × 39.76 in | Israel | $ 13,50013 723 €11,975 £2,012,256 ¥ | Buy |

| CreatBot | F1000 | 1000 × 1000 × 1000 mm39.37 × 39.37 × 39.37 in | China | $ 29,99930 494 €26,610 £4,471,531 ¥ | Buy |

| BigRep | BigRep ONE v4 | 1005 × 1005 × 1005 mm39.57 × 39.57 × 39.57 in | Germany | $ 30,00030 000 €26,611 £4,471,680 ¥ | Quote |

| 3D Platform | 400 Series WORKBENCH XTREME | 1000 × 1500 × 700 mm39.37 × 59.06 × 27.56 in | United States | $ 49,99950 823 €44,351 £7,452,651 ¥ | Quote |

| Tractus3D | T3500 | ⌀ 1000 x 2100 mm | Netherlands | $ 59,00049 900 €52,335 £8,794,304 ¥ | Quote |

| The Industry | MAGNUM | 1500 × 1200 × 1200 mm59. 06 × 47.24 × 47.24 in 06 × 47.24 × 47.24 in | Sweden | $ 135,000129 990 €119,750 £20,122,560 ¥ | Quote |

| MASSIVit 3D | Massivit 10000 | 1420 × 1110 × 1500 mm55.91 × 43.7 × 59.06 in | Israel | upon request | Quote |

| Modix This brand is a certified partner from our network. | MAMA | 2000 × 5000 × 1000 mm78.74 × 196.85 × 39.37 in | Israel | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Build volume | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|

| Modix This brand is a certified partner from our network. | BIG-Meter V4 | 1010 × 1010 × 1010 mm39.76 × 39.76 × 39.76 in | 1030.3 L | Israel | $ 13,50013 723 €11,975 £2,012,256 ¥ | Buy on Modix |

| CreatBot | F1000 | 1000 × 1000 × 1000 mm39.37 × 39.37 × 39.37 in | 1000 L | China | $ 29,99930 494 €26,610 £4,471,531 ¥ | Buy on CreatBot |

| BigRep | BigRep ONE v4 | 1005 × 1005 × 1005 mm39.57 × 39.57 × 39.57 in | 1015.08 L | Germany | $ 30,00030 000 €26,611 £4,471,680 ¥ | Get a quote |

| 3D Platform | 400 Series WORKBENCH XTREME | 1000 × 1500 × 700 mm39.37 × 59.06 × 27.56 in | 1050 L | United States | $ 49,99950 823 €44,351 £7,452,651 ¥ | Get a quote |

| Tractus3D | T3500 | ⌀ 1000 x 2100 mm | 1649.34 L | Netherlands | $ 59,00049 900 €52,335 £8,794,304 ¥ | Get a quote |

| The Industry | MAGNUM | 1500 × 1200 × 1200 mm59. 06 × 47.24 × 47.24 in 06 × 47.24 × 47.24 in | 2160 L | Sweden | $ 135,000129 990 €119,750 £20,122,560 ¥ | Get a quote |

| MASSIVit 3D | Massivit 10000 | 1420 × 1110 × 1500 mm55.91 × 43.7 × 59.06 in | 2364.3 L | Israel | upon request | Get a quote |

| Modix This brand is a certified partner from our network. | MAMA | 2000 × 5000 × 1000 mm78.74 × 196.85 × 39.37 in | – | Israel | upon request | Get a quote |

Overview of the best large scale professional 3D printers

The Modix BIG-Meter offers over one cubic meter of build volume. As all Modix printers do, the BIG-Meter is delivered as a self-assembly kit, which contributes to the printer’s relatively low price point.

This large scale 3D printer comes with a dual extruder (E3D Aero and E3D Volcano print heads), full automatic bed leveling (bed tile and bed mapping), a Wi-Fi controller, and a range of industrial-grade components. The print bed heats up to 120°C.

The print bed heats up to 120°C.

Buy on Modix Get a quote Add to comparison

The F1000 from CreatBot offers a full cubic meter of fully enclosed and heated (60°C) build volume. There’s also a filament chamber that can hold two spools of up to 5kg each and heat up to 45°C or 65°C.

Its dual nozzles are able to heat up to 420°C, while the print bed heats up to 100°C. Compatible materials range from standard PLA and ABS to PETG and carbon fiber-filled and flexible materials.

Buy on CreatBot Get a quote Add to comparison

The BigRep ONE, currently in its third generation of upgrades and updates, is one of the only large-sized 3D printers to provide independent dual extrusion (IDEX). IDEX can cut production times in half thanks to duplication or mirror modes.

The printer’s large touchscreen grants access to the webcam and allows users to resume prints even after a power outage. The filament holder is able to hold multiple spools of up to 8kg.

Contact manufacturer Get a quote Add to comparison

This large format 3D printer with dual extrusion is customizable. Various extruders are available, and it’s possible to add an enclosure. The enclosure can be heated and/or include an air filter as well.

Various extruders are available, and it’s possible to add an enclosure. The enclosure can be heated and/or include an air filter as well.

It’s possible to choose from two different control systems; with Wi-Fi or with Ethernet connectivity. The automatic leveling probe touches over 400 points on the print bed to ensure optimal calibration.

Contact manufacturer Get a quote Add to comparison

The T3500, a huge delta 3D printer, offers a massive build size that can 3D print to an exact scale of 1:1 up to 2.1 meters high.

The large-scale Tractus3D T3500 can 3D print exotic materials with its hot-end extruder capable of reaching up to 300°C. This 3D printer features a heated bed and can be equipped with an optional dual extruder.

Contact manufacturer Get a quote Add to comparison

The Industry MAGNUM is a very large format 3D printer by The Industry (previously called BLB Industries), a manufacturer based in Sweden. This XXL 3D printer offers a build volume of 2. 16m³ and comes with a set of nozzles ranging from 2 to 8mm in diameter. The MAGNUM is based on the company’s previous model, the BLB Industries THE BOX.

16m³ and comes with a set of nozzles ranging from 2 to 8mm in diameter. The MAGNUM is based on the company’s previous model, the BLB Industries THE BOX.

Contact manufacturer Get a quote Add to comparison

The Massivit 10000 is an industrial large format 3D printer produced by MASSIVit 3D. MASSIVit 3D is a 3D printer manufacturer based in Israel. This 3D printer offers a build volume of 1420 x 1110 x 1500 mm.

Contact manufacturer Get a quote Add to comparison

Modix has nicknamed their printer “Personal Car Factory”, a quick way to indicate how big the MAMA (Modular Additive Manufacturing Assembler) system really is. It’s equipped with a high-speed pellet extruder, and is also capable of 3D printing with spools of filament.

This huge FFF 3D printer isn’t available yet.

Contact manufacturer Get a quote Add to comparison

Applications for large scale 3D printing

3D printing furniture

The largest 3D printers can be used to 3D print furniture in one go. This includes tables, chairs, and even bathtubs. 3D printing furniture can also generate unique, complex pieces that would be difficult to create otherwise.

This includes tables, chairs, and even bathtubs. 3D printing furniture can also generate unique, complex pieces that would be difficult to create otherwise.

Hence, customized furniture is becoming more and more accessible thanks to extra-large 3D printers.

The BigRep One is in action. Source: QMES3D printing large prototypes

The professional large-scale 3D printers featured in our article can also be used to 3D print large prototypes. This enables businesses to test out their products before actually launching production. Industrial designers and engineers are able to perform more revisions in significantly less time.

They can test their future products extensively while at the same time reducing the production-to-market time.

3D printing production series

Large-scale 3D printers don’t have to exclusively 3D print large objects and prototypes. Their huge build platform also enables 3D printing big series of smaller objects.

Customized large scale 3D printers

There are several manufacturers that mainly offer tailored solutions rather than standardized 3D printer models. Tobeca, for instance, is a French team that builds 3D printers from scratch and is based entirely on their customers’ needs and requirements.

US-based Erectorbot also provides on-demand builds, although they do have a lineup of standard models. Then there’s Colossus, a company in Belgium that constructs 3D printers within shipping container-like structures. CNC Barcenas, a Spanish manufacturer, also offers tailored, large-scale 3D printers with a range of options to choose from.

How much does a 3D printer cost?・Cults

How much does a 3D printer cost? This question is asked by many beginners, hobbyists and enthusiasts. While the answer may be a little complicated, our goal is to simplify the process and help you choose the right printer for your skill level. There are many different 3D printers on the market. Some are small, cheap, and designed for do-it-yourselfers, others are full of features and cost much more.

While the answer may be a little complicated, our goal is to simplify the process and help you choose the right printer for your skill level. There are many different 3D printers on the market. Some are small, cheap, and designed for do-it-yourselfers, others are full of features and cost much more.

However, this does not mean that you have to spend a fortune to get a good printer. The cost of 3D printers has come down a lot over the years and you can now find good 3D printers for under $300. While they may not have some of the features found on a $20,000 printer, you can still use them to create interesting projects. Many of these cheap printers are for beginners, hobbyists, or those who want to learn how to 3D print.

So how much does a 3D printer cost? Basically, you can find starter models for $200. Mid-range consumer models start at around $700, while commercial or high-end consumer models will set you back thousands of dollars. In this article, we will answer some questions about 3D printers and provide you with an informative guide to choosing the best printer for your skill level.

If you're an engineer, artist, inventor, hobbyist, or just a tinkerer, a 3D printer is definitely worth it. 3D printers are very useful for creating models of machines, parts, fixtures, gears, and other complex shapes. This technology is used in many areas, including aerospace, medicine, all kinds of mechanical engineering, etc.

If you love building, fixing and fiddling with things, a 3D printer can be a great addition to your equipment. However, if you're not into any of the above areas or hobbies, getting a 3D printer might not be worth it. In addition, before purchasing a printer, you need to make sure that you are technically literate enough to operate it. This is because such printers require regular updates/upgrades and the learning curve can be quite steep.

You will need to regularly buy filaments, learn how to design in 3D CAD or use other modeling software. Also, you may have to fiddle with your machine settings before you find the right fit. If you are completely new, using a 3D printer will take you a lot of time and you may end up spending a lot of money on filaments and other materials. However, once you get the hang of it, 3D printing can quickly turn into one of the most enjoyable activities or hobbies one can indulge in.

However, once you get the hang of it, 3D printing can quickly turn into one of the most enjoyable activities or hobbies one can indulge in.

In addition to the initial purchase cost, the cost of using a 3D printer can quickly increase depending on the model you purchase. For the cheapest models, you will have to constantly buy printer upgrades. Therefore, it is recommended to purchase a high-quality printer with better specifications so that you do not have to upgrade from time to time.

Another item that can increase the cost of a 3D printer is filaments. They usually sell for around $25 per kilo, so beginners are advised to buy them in small quantities. This is because you will need multiple colors to create models, and buying a kilo of each can quickly add up to hundreds of dollars. Another thing you will waste is time. If you're just getting started, you'll have to take the time to learn about your printer, how to make great 3D prints, the right software and updates, color combinations, material composition, and many other important factors.

Definitely yes. In fact, there are many different ways to make money with 3D printers. Below are the top four ways to make money with these printers:

- Prototyping and Selling : You can make money by offering to prototype for local engineering firms. Since 3D printing involves learning how to create 3D designs, you can sell your designs or create designs for engineering firms.

- Sell your prints : You can sell your printed objects online. Create a website or social media campaign and sell your designs. You can also create custom prints for your clients; they will provide you with the design and you will print it for them.

- Sell your designs : You don't have to print to make money. You can just sell your 3D designs and skip the whole printing process.

- Teach others : Many people are interested in the knowledge you have about printing. Engineers, students, DIYers and hobbyists will be happy to learn from you.

You can just charge them and teach them how to use and set up their own printers, what materials to use, how to print, and so on.

You can just charge them and teach them how to use and set up their own printers, what materials to use, how to print, and so on.

As we noted above, the cost of 3D printers has dropped significantly because there are now models that have few features but are cheaper. Basically, there are five different types of 3D printers based on price. These are entry-level printers for hobbyists, enthusiasts, professional and industrial printers. The price of machines in each category depends on the functions, size and capabilities of the machine. Let's take a closer look at each of these categories:

Entry level 3D printers

Entry-level 3D printers designed for beginners. They are mainly used to climb the learning curve. You can buy these to learn how to 3D print before moving on to higher models. While you won't be able to create complex prints, you will be able to understand how a 3D printer works.

This type of printer has its limitations. First, you won't be able to print more than 3-4 inches in any dimension, be it height, width, or length. Also, many of these printers do not allow you to use more than one media at a time. In addition, they are slow and noisy, and the quality of their products is not as beautiful as that of expensive models. Also, the highest resolution that most entry-level printers offer is 100 microns.

Also, many of these printers do not allow you to use more than one media at a time. In addition, they are slow and noisy, and the quality of their products is not as beautiful as that of expensive models. Also, the highest resolution that most entry-level printers offer is 100 microns.

In addition, entry-level printers are not very durable. However, they are a great learning tool and can serve as a good stepping stone to dive deeper into the world of 3D printers. Now to answer the question, how much does a 3D printer cost? A typical entry-level printer will cost between $200 and $400.

3D printers for hobbyists

Hobbyists are those who have plunged into the world of 3D printing a little, fell in love with it and were carried away by it. They just want to improve their 3D printing skills by making models just for fun. Although 3D printers in this category are slightly better than entry-level models, they still cannot offer a result that goes beyond fun creativity. Their build volume is larger and you will be able to make more models with these printers. 3D printers for hobbyists allow you to create designs as small as 5-6 inches. Prints are thinner than entry-level printers and usually have better software.

Their build volume is larger and you will be able to make more models with these printers. 3D printers for hobbyists allow you to create designs as small as 5-6 inches. Prints are thinner than entry-level printers and usually have better software.

They are faster than entry-level models and allow more flexibility in material selection. This means that with machines in this category you can be even more creative. However, it is important to note that while they may be better than entry-level models, they are not very durable and their performance is not reliable. This means that they may not be able to withstand too much load, and you will not be able to use them for a long time. So how much does a 3D printer cost? They usually cost between $300 and $1500. There are many different products on the market in this price range and choosing the right one can be a daunting task. We recommend taking a look at this guide to 3D printers under $500 from HotRate.

3D Printers for Enthusiasts

Becoming a 3D printing enthusiast means you've decided to level up and now consider it more than just a hobby. This is a big leap that requires better and more powerful hardware than those in the hobbyist category. Printers in this category are known for their reliability and high build volume. They are quieter and slightly faster than hobbyist machines. In addition, they can print up to 12 inches in any dimension and allow for a wider choice of materials.

This is a big leap that requires better and more powerful hardware than those in the hobbyist category. Printers in this category are known for their reliability and high build volume. They are quieter and slightly faster than hobbyist machines. In addition, they can print up to 12 inches in any dimension and allow for a wider choice of materials.

However, they also have their downsides. Some of them only work with branded media, which means you can't just buy any type of media and run it into the printer. Also, while their prints and output are usually better than hobbyist printers, they cannot be used for production. This is because they are not professional machines and cannot be used for a long time.

You will need regular maintenance and repairs. Enthusiast 3D printers are ideal for regular use, but can break down with constant use. How much does a 3D printer in this category cost, you ask? Be prepared to spend $1500 to $3500.

Do you consider yourself experienced enough and would like to monetize your 3D printing skills? Or maybe you just want to take your hobby to the next level by creating professional models? Be that as it may, a professional 3D printer is one that is capable of working for you. The print quality on them is first class and they are capable of printing up to 12 inches in any dimension. In addition, they are flexible regarding materials. You can use a variety of media in the machine without worrying about color or texture. They can also print faster than the categories we talked about earlier without sacrificing quality.

The print quality on them is first class and they are capable of printing up to 12 inches in any dimension. In addition, they are flexible regarding materials. You can use a variety of media in the machine without worrying about color or texture. They can also print faster than the categories we talked about earlier without sacrificing quality.

The price of a printer for a professional printing press is quite high. Therefore, to ensure that you are purchasing the best 3D printing machine, be sure to read real user reviews. Consider the pros and cons of the machine you want to purchase. Read up on how to maintain it, what materials to use, how best to set it up, etc. Make a list of important factors and go through them one by one.

The price of a printer for machines in this category is expensive, so checking all the right boxes before making a purchase decision is very important. So back to our original question, how much does a 3D printer cost in this category? A typical professional 3D printer costs between $3,500 and $6,000. They are commonly used by robotics clubs, schools, and businesses large and small.

They are commonly used by robotics clubs, schools, and businesses large and small.

Industrial 3D printers designed for serious print businesses. They are simply the best and fastest cars in all categories. Their characteristics are at the highest level, they are very durable, as they are made of metal. In addition, their interfaces are user-friendly and they are very efficient. Industrial 3D printers are large and can accommodate many different types of custom prints. They also come with a hefty price tag, but that's to be expected given the fact that they're made for businesses and their construction is top-notch.

Industrial 3D printers are large and heavy, which can be a problem if you don't have enough space. In addition, the cost of 3D printing with these machines can run into the thousands of dollars over time. Obviously, these machines consume more electricity, materials and require a high level of maintenance than printers in other categories. That is why they are recommended only for enterprises and manufacturers. So how much does a 3D printer in this category cost? The price of a printer for industrial 3D machines ranges from $20,000 to $100,000.

So how much does a 3D printer in this category cost? The price of a printer for industrial 3D machines ranges from $20,000 to $100,000.

This page has been translated using machine translation. Suggest the best translation

The world's first printed five-storey building and villa

As early as March 29, 2014, ten printed houses, each with an area of 200 square meters, appeared in Shanghai. The buildings were created from concrete using giant construction 3D printers. The cost of each house was $4800.

On January 18, 10 months after the first project, Shanghai WinSun Decoration Design Engineering Co announced that they have taken 3D printing to a whole new level: they built the world's tallest 3D printed building, a 5-story residential building, and printed the first villa in the world. The area of the villa is 1100 square meters and is rented with internal and external finishing.

In 12 years of operation, WinSun has registered 98 national patents for building materials. The company started its innovative path in construction back in 2004, when it developed a 3D nozzle for automatic supply and spraying of building materials, and in 2008 the first wall was printed.

The company started its innovative path in construction back in 2004, when it developed a 3D nozzle for automatic supply and spraying of building materials, and in 2008 the first wall was printed.

More than 300 representatives of construction and investment companies gathered at the press conference. WinSun's CEO said the company's success is due to the uniqueness of the presented method. Firstly, an exclusive building material, which is a mixture of recycled construction waste, fiberglass, steel, cement and special additives. Secondly, the construction 3D printer itself is 6.6 meters high, 10 meters wide and 150 meters long. Such dimensions make it possible to increase the efficiency of construction by 10 times.

The company believes that thanks to 3D printing technology, it is possible to save up to 60% of materials and reduce construction time by 50-70% while reducing labor costs by 50-80%. In the future, the company plans to build bridges and high-rise office buildings using a 3D printer.

Presented today, the villa was designed for the Taiwanese company Tomson Group, the largest real estate agent in Taiwan, and the total construction costs amounted to $161,000 and there are already 10 pre-orders.

The director of the company hopes that with their 3D technology they will be able to undermine the usual picture of a construction site where noise and dirt reign. The new construction method is more compact and efficient.

The villa and the five-story house, which were printed by a giant 3D printer, comply with local construction standards, while the company notes that in addition to developing the method itself, it is necessary to carry out comprehensive work to introduce new standards, taking into account modern realities.

The presentation also featured a one-story house, an order for which was placed by the Egyptian government. The house was printed in one day and is part of an overall production plan for 20,000 units.

Today's display site also featured a one-story house pre-ordered by the Egyptian government, which will soon be shipped to Egypt. As Ma explained, "This house was printed in one day, and is part of a total order of 20,000 units."

As Ma explained, "This house was printed in one day, and is part of a total order of 20,000 units."

WinSun has announced a partnership with Egypt's Nile Sand Material Technology Co. Ltd. Within two years, the companies together plan to set up 12 factories in the desert. Solutions are currently being sought for the use of sand for printing. Already, they have discovered that sand is great for creating walls that prevent the spread of the desert.

Contracts have also been signed with Winsun Global, a joint venture between American and Chinese companies. Over the next three years, factories will be established in Saudi Arabia, the United Arab Emirates, Qatar, Morocco, Tunisia and the United States, as well as in more than 20 countries. In particular, the program is aimed at developing the countries of the Middle East and African countries - providing low-income people with cheap housing. The first batch of 3D printers is ready to ship.

Finally, Winsun announced a joint venture with China Railway 24th Bureau Group.