3D printing building construction pdf

3D Printing of Concrete: State of the Art and Challenges of the Digital Construction Revolution

Selected type: Hardcover

Quantity:

Out of stock

$165.00

Arnaud Perrot (Editor)

ISBN: 978-1-786-30341-7 April 2019 Wiley-ISTE 176 Pages

-

E-Book

Starting at just $132.00

-

Print

Starting at just $165.

00

-

O-Book

E-Book

$132.00

Hardcover

Out of stock

$165.00

O-Book

Download Product Flyer

Download Product Flyer

Download Product Flyer is to download PDF in new tab. This is a dummy description. Download Product Flyer is to download PDF in new tab. This is a dummy description. Download Product Flyer is to download PDF in new tab. This is a dummy description. Download Product Flyer is to download PDF in new tab. This is a dummy description.

Description

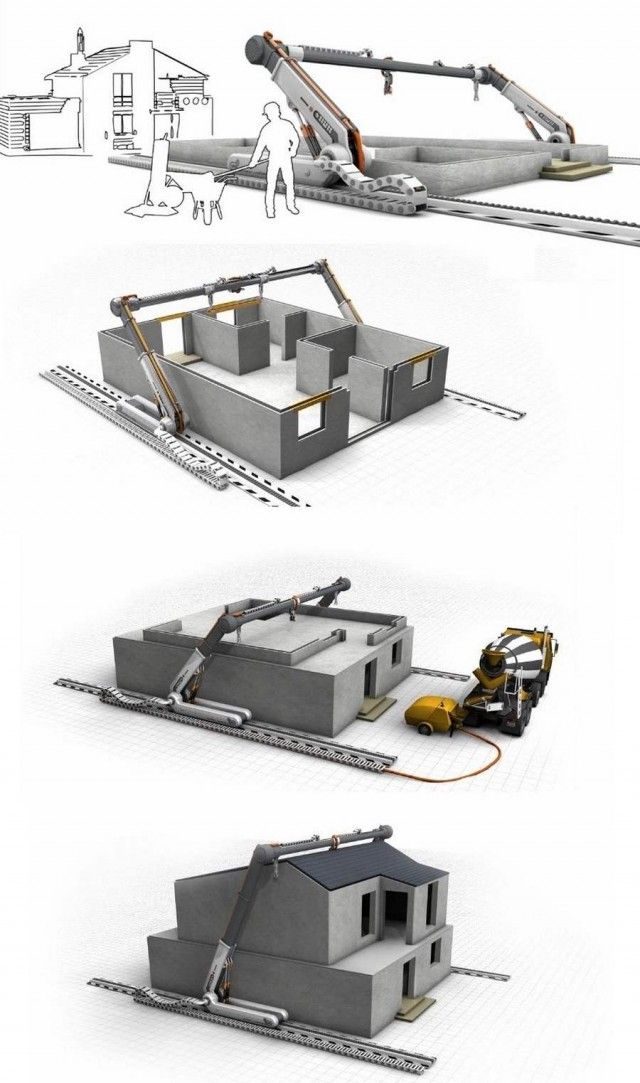

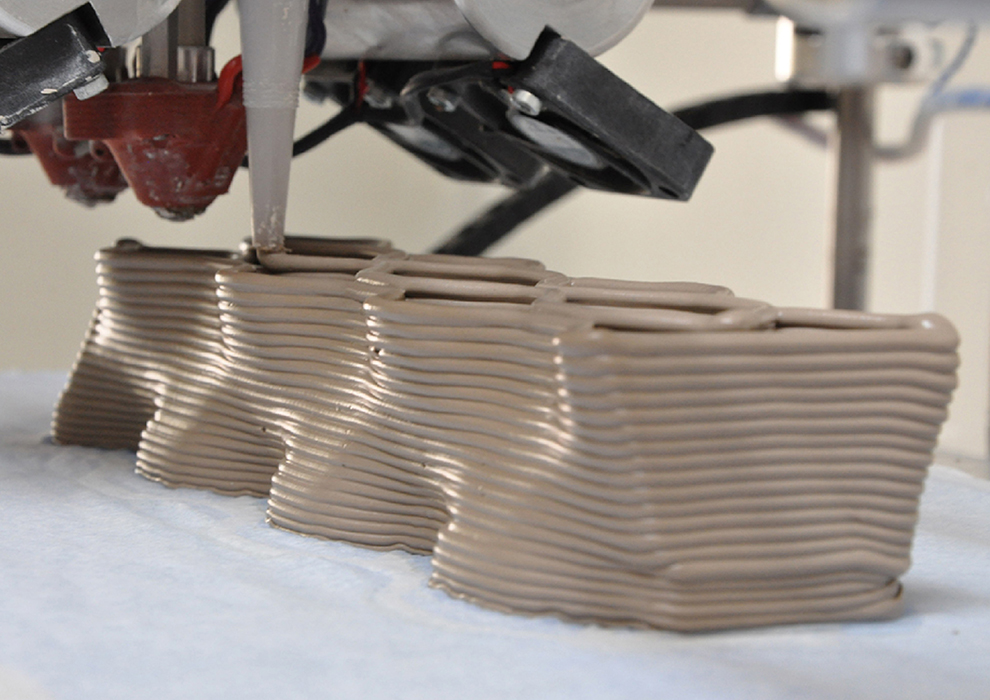

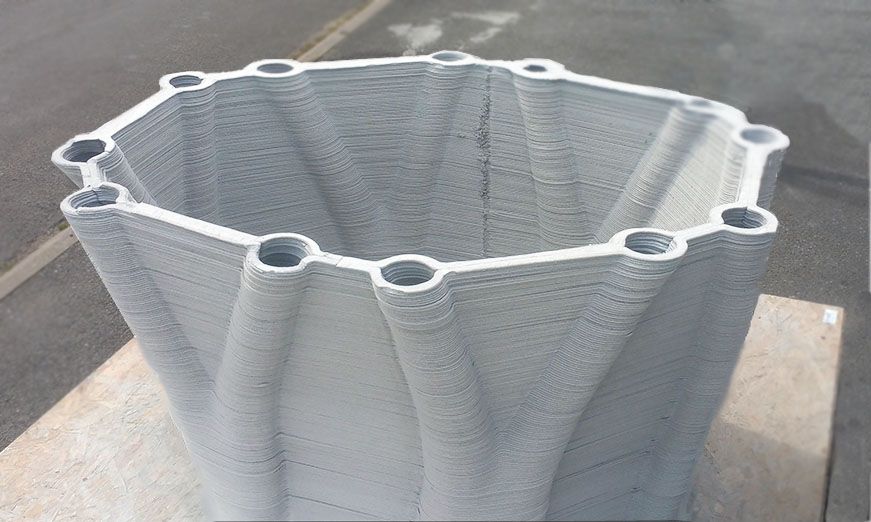

The introduction of digital manufacturing techniques, such as 3D printing applied to concrete material, opens up new perspectives on the way in which buildings are designed. Research on this theme is thriving and there is a high rate of innovation related to concrete. At the same time, the first life-size constructions made from printed concrete are emerging from the ground.

This book presents state-of-the-art knowledge on the different printing processes as well as on the concrete material that must adapt to these new manufacturing techniques, such as new hardware and new printers for concrete. The possibilities in terms of architectural design are discussed as well as the pathways that remain to be uncovered. The book also explores the challenges that researchers and companies expect to overcome as they get closer to democratizing this potential revolution that is the digital manufacturing of concrete.

About the Author

Arnaud Perrot has been Research Professor at Université Bretagne Sud, France, since 2007. He is the author of over 50 scientific articles in the field of the implementation and rheology of cement-based materials.

Permissions

Request permission to reuse content from this site

Table of contents

Introduction ix

Arnaud PERROT

Chapter 1. 3D Printing in Concrete: General Considerations and Technologies 1

3D Printing in Concrete: General Considerations and Technologies 1

Arnaud PERROT and Sofiane AMZIANE

1.1. Introduction 1

1.2. General considerations for 3D printing and additive fabrication 2

1.2.1. What is 3D printing? 2

1.2.2. Towards the 3D printing of cement-based materials 7

1.3. The digital and additive fabrication of cement materials 7

1.3.1. Introduction 7

1.3.2. Printed methods using extrusion and deposition 9

1.3.3. Methods of printing by injection into a particle bed 22

1.3.4. Alternative printing methods 25

1.4. A classification of 3D printing methods for concrete 29

1.4.1. Philosophy 29

1.4.2. Classification parameters 30

1.4.3. Example of classification 33

1.5. References 35

Chapter 2. 3D Printing in Concrete: Techniques for Extrusion/Casting 41

Arnaud PERROT and Damien RANGEARD

2.1. Introduction 41

2.2. Breakdown of the process into stages 43

2. 3. Behavior during the fresh state and the printing stage 46

3. Behavior during the fresh state and the printing stage 46

2.3.1. Rheology of cement-based materials 46

2.3.2. Pumping 52

2.3.3. Extrusion 54

2.3.4. Stability of an elemental layer during deposition 56

2.3.5. Overall stability of the printed structure in a wet state 58

2.4. Other problems occurring during concrete extrusion printing 62

2.4.1. Elastic deformation and accuracy of the deposition 62

2.4.2. Shrinkage and cracking during drying 63

2.4.3. Bonding between layers – weakness at the interface between layers 65

2.4.4. Concept of time windows 66

2.5. Conclusion 67

2.6. References 68

Chapter 3. 3D Printing by Selective Binding in a Particle Bed: Principles and Challenges 73

Alexandre PIERRE and Arnaud PERROT

3.1. Introduction 73

3.2. Classification of selective printing processes and strategies 75

3.2.1. Selective cement activation 77

3.2.2. Selective paste intrusion 80

3. 2.3. Injection of the binder 82

2.3. Injection of the binder 82

3.3. State of the art of selective printing and major achievements 82

3.4. Scientific challenges 84

3.4.1. Selective cement activation and the effect of water penetration 84

3.4.2. Selective intrusion and penetration by cement paste 89

3.4.3. Towards modeling in 3D 94

3.5. Conclusion 96

3.6. References 96

Chapter 4. Mechanical Behavior of 3D Printed Cement Materials 101

Mohammed SONEBI, Sofiane AMZIANE and Arnaud PERROT

4.1. Introduction 101

4.2. Mechanical performance of the cement materials printed using the extrusion/deposition method 102

4.2.1. Effect of extrusion on the mechanical characteristics of cement-based composites 103

4.2.2. Mechanical behavior of 3D printed cement materials 105

4.3 Effects of the additive fabrication method on the mechanical behavior of cement-based materials 116

4.3.1. Printed concrete = anisotropic stratified materials: possible causes 116

4. 3.2. Effects of the printing process parameters on the mechanical properties 116

3.2. Effects of the printing process parameters on the mechanical properties 116

4.4. Mechanical behavior obtained with other methods of 3D printing of cement-based materials 119

4.4.1. Production using robotic sliding castings (“Smart Dynamic Casting”) 119

4.4.2. Printing using the method of injection into a particle bed 119

4.5. Conclusion 120

4.6. References 121

Chapter 5. 3D Printing with Concrete: Impact and Designs of Structures 125

Arnaud PERROT and Damien RANGEARD

5.1. Introduction 125

5.2. Freedom of forms: architectural liberation and topological optimization 126

5.2.1. 3D printing with concrete: a boon for architects? 126

5.2.2. Towards the creation of structures with optimized shapes? 128

5.2.3. Could 3D concrete printers go through a transition similar to the transition from black and white to color? 130

5.3. Design of structures: reinforcement strategies and design codes 131

5. 3.1. The use of fibers 132

3.1. The use of fibers 132

5.3.2. External reinforcements 133

5.3.3. Steel wire placed within the extruded material 133

5.3.4. Dedicated spaces acting as lost formworks 134

5.3.5. Wrapping of reinforcement elements set in place beforehand 135

5.3.6. Towards a specific design code? 136

5.4. Impacts of 3D printing 136

5.4.1. Environmental impact 136

5.4.2. Societal impact 138

5.4.3. Economic impact 139

5.5. Conclusion 140

5.6. References 141

List of Authors 145

Index 147

3D-Printing Technology in Construction: Results from a Survey

Abstract

Purpose

The purpose of this paper is to study the introduction of 3D-printing of concrete in the construction sector.

Design/Methodology/Approach

A survey was conducted to collect professional view on ongoing innovations in the construction sector, including 3D-printing. Participants were selected among the members of Norwegian networks for project and construction management research.

Participants were selected among the members of Norwegian networks for project and construction management research.

Findings

The survey highlighted effective leadership, collaboration with partners and industry-academia collaboration as primary enablers of innovation. Few of the respondents to the survey have used 3D-printing technologies.

Research Limitations/Implications

It is difficult to obtain representative samples in this type of research, including this study. The study can be seen as a snapshot of attitudes in the sector.

Practical Implications

3D-printing appear as a potentially interesting technology, especially for unstandardized construction components. Further work is needed to materialise the expectation for technological development in the construction sector.

Originality/Value

Most research on 3D-printing has focused on demonstrating technical potential. This study adds a practitioners’ perspective, with a large dose of pragmatism.

This study adds a practitioners’ perspective, with a large dose of pragmatism.

Keywords

- 3D-printing

- Concrete

- Implementation

- Additive

- Hybrid additive/Subtractive manufacturing

- HINDCON

Citation

Olsson, N.O.E., Shafqat, A., Arica, E. and Økland, A. (2019), "3D-Printing Technology in Construction: Results from a Survey", Lill, I. and Witt, E. (Ed.) 10th Nordic Conference on Construction Economics and Organization (Emerald Reach Proceedings Series, Vol. 2), Emerald Publishing Limited, Bingley, pp. 349-356. https://doi.org/10.1108/S2516-285320190000002044

Publisher

:Emerald Publishing Limited

Copyright © 2019, Nils O. E. Olsson, Ali Shafqat, Emrah Arica, Andreas Økland.

E. Olsson, Ali Shafqat, Emrah Arica, Andreas Økland.

License

Published in the Emerald Reach Proceedings Series. Published by Emerald Publishing Limited. This article is published under the Creative Commons Attribution (CC BY 4.0) licence. Anyone may reproduce, distribute, translate and create derivative works of this article (for both commercial and non-commercial purposes), subject to full attribution to the original publication and authors. The full terms of this licence may be seen at http://creativecommons.org/licences/by/4.0/legalcode

1. Introduction

This paper studies 3D-printing of concrete in the construction sector. As an innovative technology, 3D-printing offers interesting opportunities for the construction industry, such as increased flexibility and reduced operational costs. However, it is important to analyse and use the previous innovation experiences to increase the success potential of implementing the 3D-printing technology in the construction industry. The study is a part of the EU-funded research project HINDCON (2018).

The study is a part of the EU-funded research project HINDCON (2018).

The aim of this study is to investigate the implementation of 3D-printing in the construction sector. The following research questions are set up:

2. On 3D-printing as an innovation in construction

The construction industry has evolved from a craftsmanship to an industrialised and service-oriented business, owing to the significant efforts in development and implementation of technological and organisational innovations over the past 70 years. Nevertheless, it is questionable if the introduced innovations have yielded their full potential and promises in the construction industry. Many studies show that construction industry has failed to adopt innovations to improve its performance as in other industries (World Economic Forum, 2016). The lack of stakeholder's involvement, high initial innovation costs, lack of risk funding, inherent conservative behaviour of organisations and initial non-profitability of innovations are some examples of barriers leading to fails in innovation (Ozorhon et al. , 2013). As an innovative technology, 3D-printing and hybrid additive/subtractive manufacturing offers significant opportunities for the construction industry, such as increased flexibility and reduced operational costs. However, it is important to analyse and use the previous innovation experiences to increase the success potential of implementing the 3D-printing technology in the construction industry.

, 2013). As an innovative technology, 3D-printing and hybrid additive/subtractive manufacturing offers significant opportunities for the construction industry, such as increased flexibility and reduced operational costs. However, it is important to analyse and use the previous innovation experiences to increase the success potential of implementing the 3D-printing technology in the construction industry.

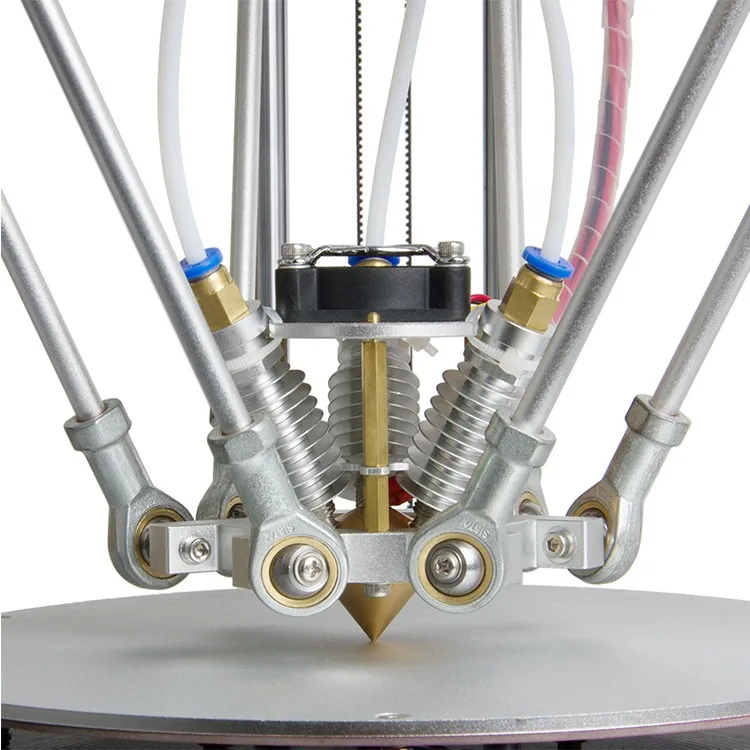

2.1. About 3D-printing and additive manufacturing

3D-printing is an automated, additive manufacturing process for producing 3D solid objects from a digital (i.e. CAD) model, where the 3D CAD model is sliced into a series of 2D layers that are later deposited by the printer to construct the model (Boothroyd, 1994). A more recent definition for 3D-printing is "the fabrication of objects through the deposition of a material using a print head, nozzle, or another printer technology" (American Society for Material and Testing 2009). The term "additive manufacturing" (AM) is more generally defined as: "the process of joining materials to make objects from 3D model data, usually layer upon layer" (American Society for Material and Testing, 2009). Additive manufacturing can deliver parts of intricate and complex geometries, built from tailored materials with near-zero material waste, while being applicable to a variety of materials (Bikas et al., 2016).

Additive manufacturing can deliver parts of intricate and complex geometries, built from tailored materials with near-zero material waste, while being applicable to a variety of materials (Bikas et al., 2016).

Three important aspects of additive manufacturing are: material, process, and design. The main categories of 3D-printing have been detailed by (Labonnote et al. 2016) solid-like, viscous-like, powder-like and liquid-like. More complete overviews on previous and current additive construction experiences can be found in (Perkins and Skitmore, 2015; Labonnote and Rüther, 2016 and Wu, Wang et al., 2016).

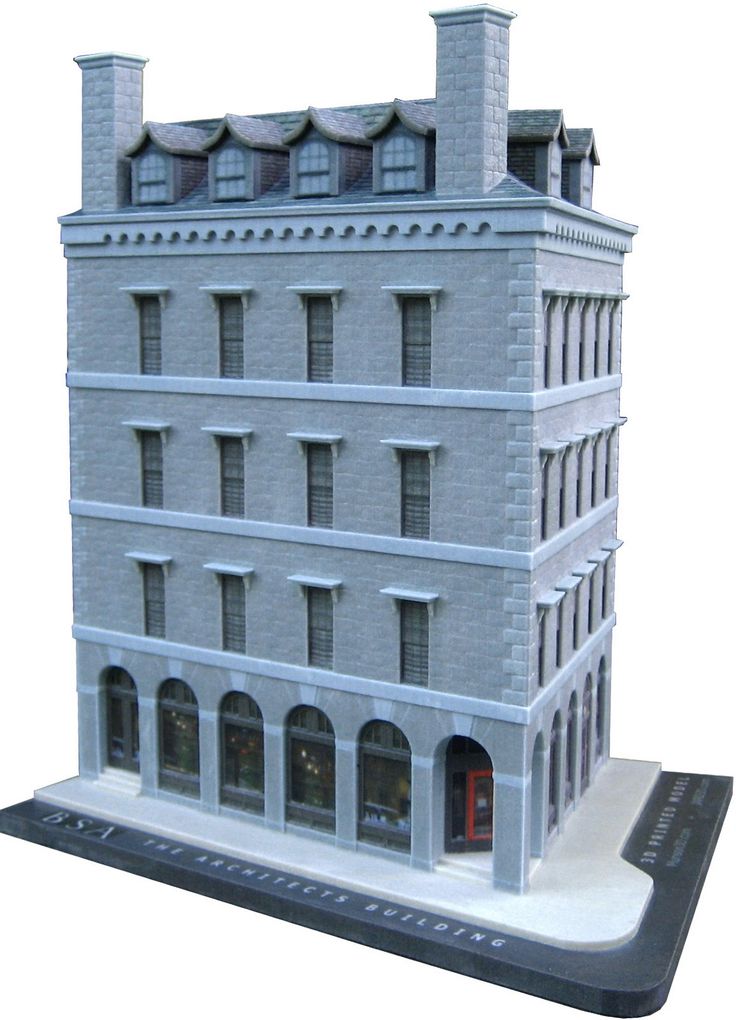

PWC (2014) did a general about use of 3D-printing in manufacturing. It showed that about 25% of the companies were involved in prototyping using 3D-printing and 29% were experimenting how they can use it.

2.3. Drivers and barriers to use of 3D-printing in construction

A driver that supports the use of 3D-printing in construction is the significant customisation opportunities (Labonnote et al. 2016). Minimisation of waste (Berman, 2012) and improved carbon footprint (Achillas et al., 2015) are also interesting possibilities. There is a potential for cost-efficiency through high automation and reduced manpower requirement (www.3ders.org, 2014). Automation such as 3D-printing can reduce danger for human workers in harsh environments (Millsaps, 2015). 3D-printers also have quick deployability (Peter, 2015).

2016). Minimisation of waste (Berman, 2012) and improved carbon footprint (Achillas et al., 2015) are also interesting possibilities. There is a potential for cost-efficiency through high automation and reduced manpower requirement (www.3ders.org, 2014). Automation such as 3D-printing can reduce danger for human workers in harsh environments (Millsaps, 2015). 3D-printers also have quick deployability (Peter, 2015).

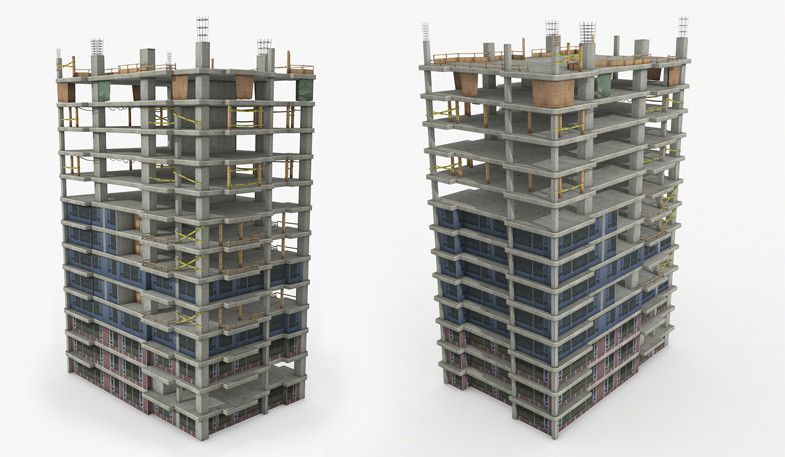

Issues that may serve as barriers include uncertainty regarding the size of demand for mass customisation and availability of high-strength printing materials. The literature also find it unclear whether 3D-printing could lead to reduced or increased construction cost (Wu, Wang et al., 2016). Owing to size limitation of existing 3D printers, it is difficult to print a multi-story building at a time (Gibson et al., 2002). However, users can print structural components piece-by-piece and then assemble them together as a real-scale building (Feng and Yuhong, 2014). Intellectual property issues have been raised in particular in connection with concerns that digital objects (including a digital file describing the construction of a given structure) can easily be copied and re-sold (Berman, 2012). There are also cyber security risks (Campbell et al., 2014).

Intellectual property issues have been raised in particular in connection with concerns that digital objects (including a digital file describing the construction of a given structure) can easily be copied and re-sold (Berman, 2012). There are also cyber security risks (Campbell et al., 2014).

3. Research approach

The paper presents findings from a questionnaire on use and expectations for 3D-printing in construction industry. Based on initial literature studies, the first version of the questionnaire was developed, which involved several workshops with the authors and the HINDCON team members. The result presented here is related to the 3D-printing experiences and expectations in the construction sector. In the second phase of the survey, the questionnaire was piloted in three companies with follow-up interviews. The questionnaire was adjusted after the feedback. The third phase of the survey was to collect an e-mail list of potential respondents. Survey participants were mainly selected among the members of Norwegian networks for project and construction management research. The types of companies involved in the survey are engineering and construction management consultants, clients, building owners, architects and suppliers of pre-assembled modules. The list of potential respondents included 235 persons. The fourth stage of the survey was to launch the final version of the questionnaire. A total of 36 valid responses were received. The results of the survey are entered in Excel format for analysis and graphical presentation.

The types of companies involved in the survey are engineering and construction management consultants, clients, building owners, architects and suppliers of pre-assembled modules. The list of potential respondents included 235 persons. The fourth stage of the survey was to launch the final version of the questionnaire. A total of 36 valid responses were received. The results of the survey are entered in Excel format for analysis and graphical presentation.

The formal response rate was 15%. However, it was not realistic to receive answers from all as several organisations had more than one person listed, and the list covered a wide array of actors. We estimate that the response rate among realistic respondents was between 25 and 30%. The results are largely based on Norwegian companies, with a bias towards large actors in the construction industry and those with an interest in research and development. Reliability can be influenced by the selection criteria of respondents. However, the study can hopefully give indications of present thinking about 3D-printing, even though the quantifications are not based on a representative sample. Validity in the study was a main concern in the development for the survey and in the piloting with three companies.

Validity in the study was a main concern in the development for the survey and in the piloting with three companies.

4. Results about the use of 3D-printing

The results address two aspects of 3D-printing in construction. The first aspect is about present and expected degree of implementation, while the second aspect is about expected cost issues.

4.1. Implementation of 3D-printing

The questionnaire addressed the use and implementation of 3D-printing. Figure 1 indicates that most of the respondents had not used 3D-printing. Those who had used the technology had mainly used it for piloting and prototyping.

Figure 1

Is your company involved in 3D-printing technology? N = 36 (more than one alternative could be selected)

Figure 2 shows the expected areas of application of 3D-printing. Most respondents expected that 3D-printing would mainly be applied for small or complex parts, including decorations. However, some also believed in the production of building blocks.

Figure 2

In the near future (5 to 10 years), what do you expect to be the primary area for application of 3D-printing products in your company? N = 36 (more than one alternative could be selected)

Figure 3 indicate collaboration within the construction sector as a key success factor for implementation of 3D-printing, along with R&D funding.

Figure 3

How can 3D-printing technology be successfully implemented in the construction industry? N = 34 (more than one alternative could be selected)

Most of the respondents expect that it will take more than eight years for 3D-printing to be widely in use, as shown in Figure 4.

Figure 4

In how many years do you expect 3D-printing technology to be used widely in construction projects? N = 36

4.2. Cost issues

The survey also included questions about cost issues of 3D-printing. Figure 5 show that most respondents expected a high initial investment related to 3D-printing.

Figure 5

Do you think 3D-printing technology involves high initial investment? N = 35

In spite of the expected high investment, a majority of the respondents believed that 3D-printing would eventually be cost efficient (see Figure 6).

Figure 6

Do you think the use of 3D-printing technology in construction projects will be cost -efficient? N = 35

5. Conclusions

We have investigated the implementation of 3D-printing in the construction sector. The first research question addressed the status of implementation of 3D-printing technology in construction industry. Despite the positive expectations from 3D-printing technology, it has so far only been applied to a limited extent in the Norwegian construction industry, and mainly for piloting and prototyping. The study shows that 20% of the respondents use 3D-printing for prototyping, while a smaller part of the companies uses 3D-printing for ordinary production. In terms of materials, plastic and ceramic are now not only widely used in 3D-printing, but also a big development in 3D-printing of metals. In comparison, the study by PWC (2014) found that some years ago, 25% of manufacturing companies were involved in prototyping using 3D-printing. Our results imply that the Norwegian construction industry is behind but still on somewhat the same level as for manufacturing.

The second research question is related to expectations for 3D-printing in construction industry. The respondents expected not only high initial investments, but also that 3D-printing would prove to be cost efficient in the long run, with an implementation time of more than eight years. The reviewed literature was not conclusive about the future cost efficiency of 3D-printing (quite naturally, as the technology is in an early stage of development).

The companies in the survey believe that research and development funding for the 3D-printing technology along with collaboration between suppliers and contractors will facilitate its wide future implementation of 3D-printing in the construction sector. Regarding future use, the survey pointed to production of small or complex parts, including decorations as key potential applications of 3D-printing. This is in accordance to the literature, which highlighted the significant customisation opportunities, even though the literature also addressed uncertainty regarding the size of demand for mass customisation. Overall, the study conveys the impression of 3D-printing as a potentially interesting technology, especially for unstandardized construction components. The technology appears to still be at a testing stage. However, there is interest in the industry and we expect to hear more as the technology matures, and we gain more experiences.

Overall, the study conveys the impression of 3D-printing as a potentially interesting technology, especially for unstandardized construction components. The technology appears to still be at a testing stage. However, there is interest in the industry and we expect to hear more as the technology matures, and we gain more experiences.

References

Achillas, Aidonis, Iakovou, Thymianidis, and Tzetzis, 2015Achillas, C., Aidonis, D., Iakovou, E., Thymianidis, M. and Tzetzis, D. (2015). “A methodological framework for the inclusion of modern additive manufacturing into the production portfolio of a focused factory.” Journal of Manufacturing Systems 37(1): 328–339.

American Society for Material and Testing, 2009American Society for Material and Testing (2009). “Standard terminology for additive manufacturing technologies”. West Consholhocken, US, ASTM International. F2792-12a.

Berman, 2012Berman, B. (2012). “3-D printing: The new industrial revolution.” Business horizons 55(2): 155–162.

(2012). “3-D printing: The new industrial revolution.” Business horizons 55(2): 155–162.

Bikas, Stavropoulos, and Chryssolouris, 2016Bikas, H., Stavropoulos, P. and Chryssolouris, G. (2016). “Additive manufacturing methods and modelling approaches: a critical review.” The International Journal of Advanced Manufacturing Technology 83(1-4): pp. 389–405.

Boothroyd, 1994Boothroyd, G. (1994). “Product design for manufacture and assembly”. Computer-Aided Design, 26(7), pp 505–520.

Campbell, Tibbits, and Garrett, 2014Campbell, T. A., Tibbits, S. and Garrett, B. (2014). “The next wave: 4D printing - Programming the material world”. Atlantic Council, Washington DC.https://www.researchgate.net/publication/262818283_The_Next_Wave_4D_Printing_-_Programming_the_Material_World/download (accessed on 20 August 2018).

Feng, and Yuhong, 2014Feng, L. and Yuhong, L. (2014). “Study on the status quo and problems of 3d printed buildings in china.” Global Journal of Human-Social Science Research.

and Yuhong, L. (2014). “Study on the status quo and problems of 3d printed buildings in china.” Global Journal of Human-Social Science Research.

Gibson, Kvan, and Wai Ming, 2002Gibson, I., Kvan, T. and Wai Ming, L. (2002). “Rapid prototyping for architectural models.” Rapid prototyping journal 8(2): pp 91–95.

HINDCON, 2018HINDCON (2018) “Hybrid INDustrial CONstruction” http://www.hindcon3d.com, (accessed on 20 August 2018).

Labonnote, Rønnquist, Manum, and Rüther, 2016Labonnote, N., Rønnquist, A., Manum, B. and Rüther, P. (2016). “Additive construction: State-of-the-art, challenges and opportunities.” Automation in Construction 72, Part 3: pp. 347–366.

Labonnote, and Rüther, 2016Labonnote, N. and Rüther, P. (2016). “Additive manufacturing: an opportunity for functional and sustainable constructions”, Smart and Sustainable Manufacturing. Lisbon, Portugal. https://www.researchgate.net/publication/309430330_Additive_manufacturing_An_opportunity_for_functional_and_sustainable_constructions, (accessed on 20 August 2018).

Lisbon, Portugal. https://www.researchgate.net/publication/309430330_Additive_manufacturing_An_opportunity_for_functional_and_sustainable_constructions, (accessed on 20 August 2018).

Millsaps, 2015Millsaps, B. B. (2015). “The Swarmscapers: Students create 3D printing robots capable of building in outlying areas”. www.3DPrint.com, (accessed on 20 August 2018).

Ozorhon, Abbott, and Aouad, 2013Ozorhon, B., Abbott, C. and Aouad, G. (2013). “Integration and leadership as enablers of innovation in construction: Case study”. Journal of Management in Engineering, 30(2), pp. 256–263.

Perkins, and Skitmore, 2015Perkins, I. and Skitmore, M. (2015). “Three-dimensional printing in the construction industry: A review.” International Journal of Construction Management 15(1): pp 1–9.

Peter, 2015Peter, B. J. (2015). “Spiderbot: Large Scale 3D Printer.” Retrieved November 2015, from http://www.bnpeters.com/spiderbot.html (accessed on 20 August 2018).

J. (2015). “Spiderbot: Large Scale 3D Printer.” Retrieved November 2015, from http://www.bnpeters.com/spiderbot.html (accessed on 20 August 2018).

PWC, 2014PWC (2014). “Technology forecast: The future of 3-D printing”, http://usblogs.pwc.com/emerging-technology/the-road-ahead-for-3d-printing/pp (accessed on 20 August 2018).

World Economic Forum, 2016World Economic Forum (2016). “Shaping the future of construction a breakthrough in mindset and technology”. http://www3.weforum.org/docs/WEF_Shaping_the_Future_of_Construction_full_report__.pdf (accessed 20 August 2018).

Wu, Wang, and Wang, 2016Wu, P., Wang, J. and Wang, X. (2016). “A critical review of the use of 3-D printing in the construction industry.” Automation in Construction 68: pp. 21–31.

www.3ders.org, 2014www.3ders.org. (2014). “Loughborough University teams up with Skanska to build commercial 3D concrete printing robot.” http://www.3ders.org/articles/20141121-loughborough-university-skanska-to-build-commerical-3d-concrete-printing-robot.html, (accessed on 20 August 2018).

“Loughborough University teams up with Skanska to build commercial 3D concrete printing robot.” http://www.3ders.org/articles/20141121-loughborough-university-skanska-to-build-commerical-3d-concrete-printing-robot.html, (accessed on 20 August 2018).

developers talked about 3D printing of new buildings in St. Petersburg

Vladimir Svinin / Photo: okhta.com

The use of digital technologies in construction is being closely studied in the USA, France, the United Arab Emirates, China and a number of other countries around the world. The construction market of St. Petersburg does not lag behind world trends. ABN spoke with representatives of St. Petersburg developers about BIM technologies and 3D printers.

Last week, St. Petersburg hosted a session on “Construction, municipal services and housing and communal services”, the main topic of which was the planning of the digital transformation of the city.

Vice Governor Stanislav Kazarin, following the meeting, said that the development of additive technologies is one of the priority projects, in particular, we are talking about the construction of buildings using a 3D printer.

“St. Petersburg is carefully studying world experience and is striving to gradually start implementing pilot projects for printing buildings and structures in the foreseeable future,” said Kazarin.

General Director of the non-profit partnership "Association of Builders of St. Petersburg" Alexei Belousov, in an interview with ABN, explained that digitalization in construction is primarily BIM technologies (from the English "Building Information Modeling" - building information modeling).

According to the expert's estimates, today they are used in one way or another in 20% of projects on the St. Petersburg real estate market. Most often, developers work with documentation and design in digital models.

Sergey Yaroshenko / Photo: fisherclub.ru

Digital project management can be implemented quite quickly from the foreman to the general contractor. The digital advantage here is that all construction participants have a conditional tablet on which a digital model of the future project is displayed. As Aleksey Belousov explains, he controls and notes the progress of work step by step.

As Aleksey Belousov explains, he controls and notes the progress of work step by step.

According to the expert, a number of regions are now piloting this approach. In the future, developers will, of course, have to spend some money on equipping construction sites with equipment, but all this is already happening.

CEO and co-owner of KVS Group Sergey Yaroshenko confirmed that the developer is actively implementing and successfully using BIM design at its sites.

As for the prospects for the development of 3D printing of buildings, Russia and St. Petersburg in particular will enter this market at some point, the co-owner of KVS is sure, but it is too early to talk about the timing.

Aleksey Belousov agrees with this opinion. According to him, the prospects for using 3D printers to print building panels still look far away.

“First of all, they will be used in individual housing and low-rise construction projects. If they prove their effectiveness, reliability and do not differ greatly in cost, then in this case you can think about their use in the construction of apartment buildings.

But this is not a question of the next few years, ”the expert says.

Arkady Skorov / Photo: Dalpiterstroy

Arkady Skorov, CEO of Dalpiterstroy, confirmed this state of affairs, noting that 3D printing of buildings is more suitable for low-rise construction.

“So far there is no corresponding centralized market in St. Petersburg. Such projects are mainly undertaken by small companies, while large investors pay attention mainly to large-scale projects,” the developer said.

Okhta Group Chairman of the Board Vladimir Svinin, in a commentary for ABN, said that innovative construction methods will be developed when the construction process becomes cheaper than usual, and the result will win in quality. But in his opinion, there is no talk about the use of 3D construction in St. Petersburg practice yet.

Meanwhile, abroad, 3D printing technologies are developing rapidly, however, as a rule, they are single objects.

For example, in the spring, a couple from Germany, 70-year-old Elise Lutz and 67-year-old Harry Dekkers, became the first residents in the European Union to live in a house completely printed on a 3D printer. They formally issued the necessary documentation for housing.

The project of a whole village of houses partially built by automated means also exists in the USA. It was named 3 Strands.

The developer promises that thanks to 3D printing of the ground floors, the buildings are characterized by a high level of energy efficiency and durability. The developer's website says that several houses have already been sold.

Source

BIM technologies, 3D printer, construction 3D printer, 3D printing of new buildings in St. Petersburg

2.2 billion tons of garbage. 3D printers can solve the problem, which allow you to build houses with little or no waste. We tell who organizes their work

Who is a 3D printing designer in construction

A 3D printing designer in construction is an architect who creates buildings using 3D printers. He selects materials and develops the forms of future houses, taking into account the needs of the customer, location and climate. The specialist models the project in the program, and then the machines print it in full size.

He selects materials and develops the forms of future houses, taking into account the needs of the customer, location and climate. The specialist models the project in the program, and then the machines print it in full size.

Today, 3D printed houses are popping up all over the world. For example, they are in the UAE, the Netherlands, Italy, China, Mexico and even Russia. Research shows that 3D construction simplifies supply chains, design, and makes the whole process more efficient and greener.

3D printing designer in construction is one of the professions of the future that RBC Trends collects in a separate selection. To find out who will be in demand in 5-10 years, follow the link above.

Printing an eco-friendly house from natural materials in Italy

(Video: 3D WASP / YouTube)

What does a 3D printing designer do in construction

The main task of such a specialist is to take into account and organically combine the possibilities of modern 3D printing in one project, natural terrain restrictions and customer desires.

First of all, the designer needs to decide how the building will be erected. It depends on the plans of customers and logistics. For example, walls and individual parts of a house can be printed separately, and then the finished elements can be assembled together at the construction site. Another option is to place the printer right on the spot and "grow" the house from scratch.

In addition, 3D printers are filled with various "inks" to build houses. These can be eco-friendly bioplastics, various mixtures of natural raw materials such as clay combined with rice husks or fiber-reinforced concrete. The availability of materials and their stability in different environmental conditions will influence the choice of the designer.

When everything is decided with the approach and building materials, the specialist needs to draw the project in 3D modeling software and program the printer. After that, the construction itself begins, which must be controlled at different stages.

Transport of 3D printed building modules (Photo: SOM)

Required skills

Engineering or architectural education is a necessary basis for working in the profession. Also, a 3D printing designer in construction needs to be able to handle modern modeling programs and techniques. At the same time, such a specialist cannot do without “flexible” skills.

- Customer focus is essential to get the most out of your customer experience.

- Project Management is useful for tracking deadlines and planning the construction stages correctly.

- Lean Skills and Green Thinking will help you choose economical and environmentally friendly approaches and materials.

- Systems thinking and cross-industry communication skills will be useful in organizing processes and work of different contractors.

Trends and professions

The use of 3D printing technologies in construction allows you to get rid of many problems of modern development. Therefore, we should expect that it will be increasingly integrated into our lives.

The amount of waste generated by the construction industry will grow to 2.2 billion tons by 2025, according to the Construction Waste Market. 3D construction often uses local natural materials and generates little to no debris.

In the United States, according to the Department of Labor, up to 15 workers die every day as a result of work-related injuries on construction sites. Automation and the maximum use of robotics can significantly reduce human losses in the development industry.

3D printed houses could be a solution for fast construction in case of natural disasters. Modern devices are able to create 1 m2 of wall in just five minutes. At the same time, some printed buildings withstand earthquakes of magnitude up to 8 points.

Where and when did the profession come from

The first version of ArchiCAD 3D modeling software appeared in 1984. Two years later, the first patent for a 3D printer was filed. The more perfect these technologies became, the more opportunities they gave to the world. Today, we are increasingly witnessing targeted projects in this area, but their success suggests that they will soon become part of everyday life.

The first 100% 3D printed building in the world is the "Office of the Future", built in the UAE in 2016. At the same time, in China, housing, partially constructed using this technology, was presented a year earlier. In Russia, the first house entirely printed on a 3D printer appeared in 2017.

How to Become a Construction 3D Printer

There are many bachelor's programs to start a career in the industry. Among them are architecture, design, construction and the use of modern technologies in these areas. In addition, there are short-term specialized courses.