3D printer strength

Optimizing Strength of 3D Printed Parts — 3DPros

Whether you are considering 3D printing for prototypes or end use applications, there are many factors you’ll need to consider to ensure the parts are strong enough for your application. In this article, we’ll take a look at the choices which have the greatest impact on part strength:

Note that this guide discusses specific considerations for FDM 3D printing; other 3D printing technologies have differing considerations.

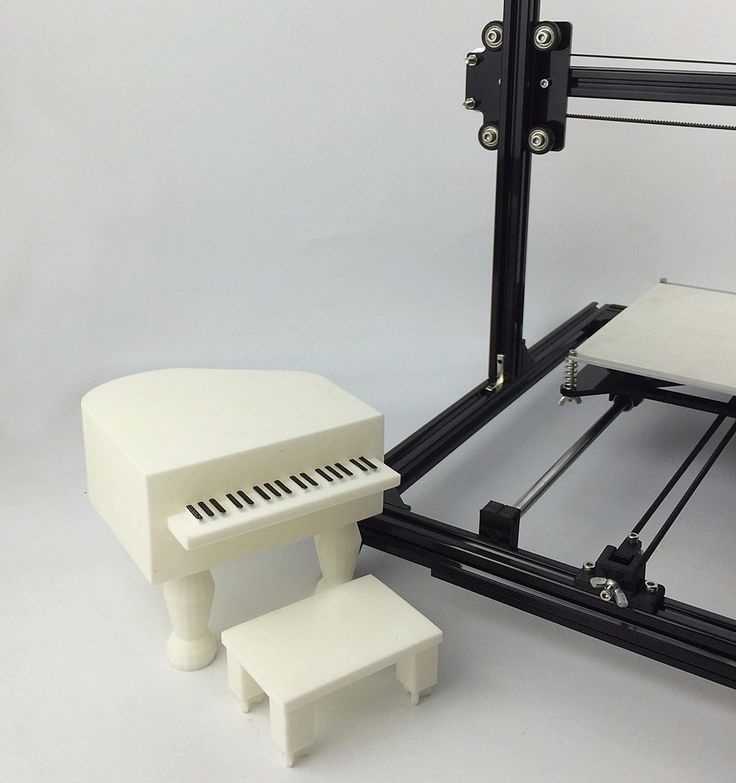

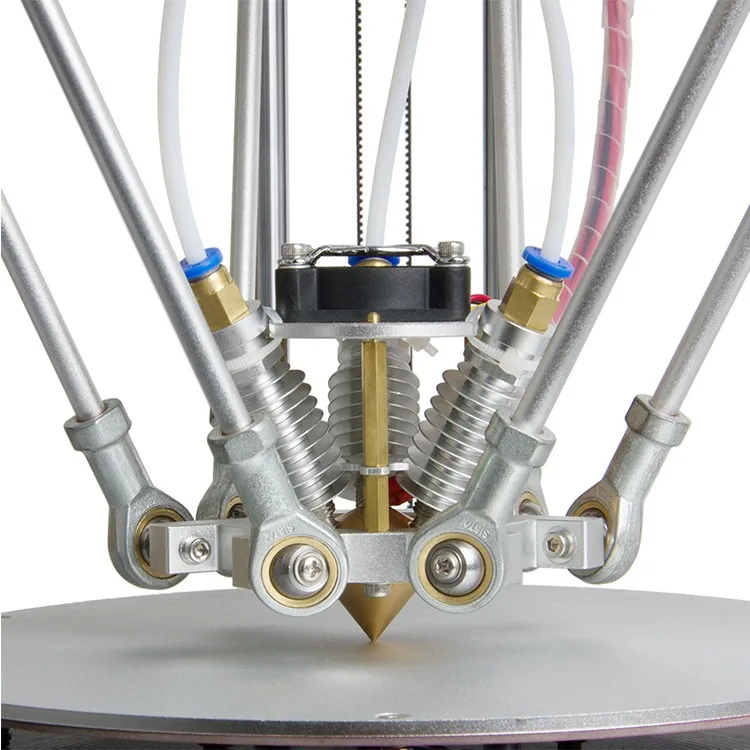

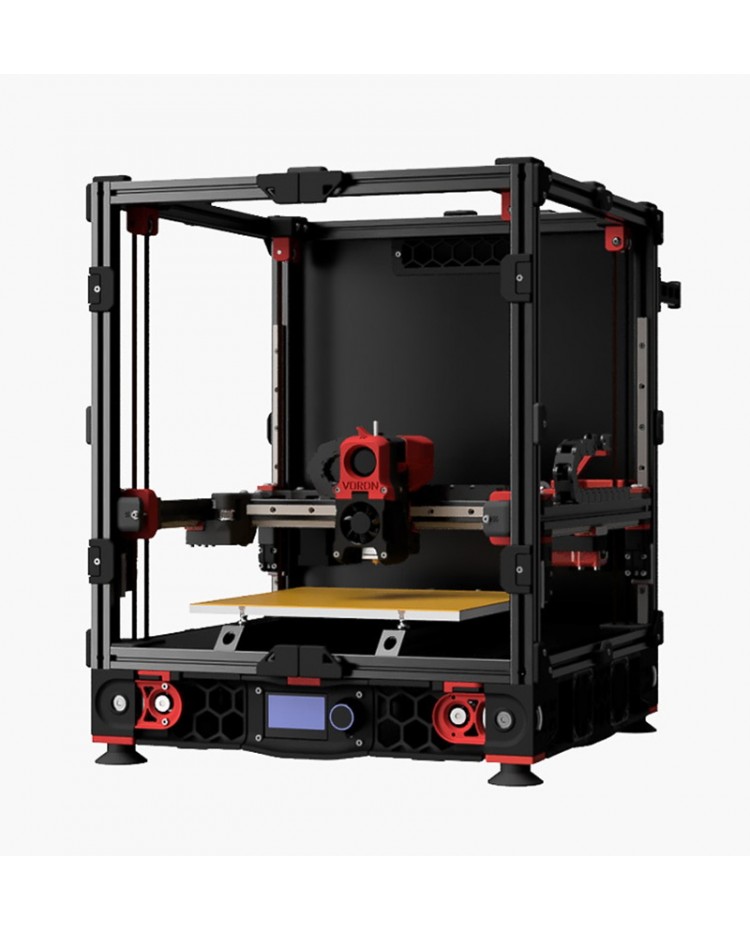

When 3D printing end use parts like this mounting bracket for the cement extruder for our client’s structural 3D printer, part strength is top priority. We used PETG with a high infill and shell thickness to ensure this part was up to the job.

3D Printer Settings

Infill Percentage

When ordering 3D printed parts, you will typically need to specify an infill percentage. Infill Percentage represents how dense the interior of the model will be. This setting ranges from 0%, a totally hollow model, to 100%, a totally solid model. Infill has the greatest impact of compression strength, since it acts to support the interior of the model.

It seems obvious that a totally solid model would be the best choice for strength, but in practice, choosing a value beyond 60-70% has very little impact on part strength and is usually not worth the additional cost and print time. Especially for larger models with large internal spaces, increasing the infill can have a drastic impact on both the cost and print time. It is important to consider whether the benefits outweigh the drawbacks for your application.

Increasing the infill percentage improves the strength of 3D printed parts, especially impact resistance, but the benefits taper beyond 60%.

Refer to our Infill Percentage Guide for more details and other considerations for this setting.

Shell Thickness

Another lesser known setting, the shell thickness, also plays a significant role in part strength. Shell Thickness refers to the thickness of the outer surfaces of the part. Most 3D printing services use a standard thickness of about 1.0 - 1.5 mm, but increasing this setting can greatly increase the tensile strength and impact strength of your parts.

Shell Thickness refers to the thickness of the outer surfaces of the part. Most 3D printing services use a standard thickness of about 1.0 - 1.5 mm, but increasing this setting can greatly increase the tensile strength and impact strength of your parts.

Increasing the shell thickness of parts can significantly improve the strength of 3D printed parts, even with a lower infill percentage.

Material Choice

The material your parts are made from also has a significant impact on strength. Typically, 3D printed parts are made from PLA, ABS, or PETG plastics. Its important to consider the types of force that your parts will undergo when deciding on the most suitable material.

ABS, PETG, and PLA have differing strength characteristics which are important to consider when 3D printing end use parts.

For parts which need tensile strength to resist forces pulling on the object, PETG is the strongest option, followed by PLA. ABS is the least effective choice for resisting this type of force. PETG has especially strong bonding between layers and is stronger than other options, which is why it is an especially good choice for thin parts with high strength requirements.

ABS is the least effective choice for resisting this type of force. PETG has especially strong bonding between layers and is stronger than other options, which is why it is an especially good choice for thin parts with high strength requirements.

If your parts are subjected to bending forces, ABS is typically the strongest option due to its ductility, followed by PETG. PLA is more rigid and brittle than the other options, which means it is not a good choice for applications that require flexural resistance.

If parts need to resist impact, such as being subjected to falls, ABS or PETG perform about equally. PLA is less suitable for this use due to its rigidity.

For more information on material options and other considerations, refer to our Materials Guide.

Part Orientation

Part Orientation, or how the part is positioned on the 3D printer, is a strength consideration unique to 3D printing. To understand why the orientation has such a significant impact, you need to know how parts are produced on an FDM 3D printer. Parts are 3D printed by depositing thin layers of melted plastic at gradually increasing heights in order to form a 3 dimensional part.

Parts are 3D printed by depositing thin layers of melted plastic at gradually increasing heights in order to form a 3 dimensional part.

3D printed parts are created by depositing thin layers of plastic, each slightly higher than the last.

Althought the plastic of each layer bonds to the previous layer, the interfaces between these layers are a weak point. When 3D Printed parts crack or break, it is typically between layer lines.

Considering this characteristic of 3D printed parts is especially useful when forces are subjected on the part in a specific direction. For example, if you were designing a bracket for a shelf, you know that the largest forces will be pushing downward where the bracket attaches to the shelf. Using this information, printing the bracket on its side will ensure that the force is not acting along the interfaces between layers.

In cases where you cannot avoid forces acting across layers, consider using PETG since it has the best layer bonding performance of the common materials.

We printed the same shelf bracket in two different orientations. Which of these do you think will perform better?

The part with a thin interface across layer lines (on the left in the first image) failed with relatively little force.

Keep in mind that other factors can also impact the best choice for part orientation. For example, part orientation affects which surfaces of the print will be smoothest. In some cases, part orientation can also affect the cost of the print because more support material may be required to enable a certain part orientation.

Other Considerations

While you can use the techniques in this guide to improve the strength of your parts, strength is just one of many factors you are likely thinking about when considering 3D printing for your project. Other requirements, such as the appearance of the parts, cost of production, and timeframe, can require you to make difficult trade-offs. If you aren’t sure how to proceed or just want to run your ideas by someone, we would love to hear about your project and help you figure out the best way to print it!

If you aren’t sure how to proceed or just want to run your ideas by someone, we would love to hear about your project and help you figure out the best way to print it!

Next Steps

Want to Learn more about buying your own 3D printer?

Our informational site www.crealityexperts.com is a great place to start! We have used Creality brand 3D printers for years and have been very happy with them

Looking to order 3D printed parts?

You can find a local vendor on Treatstock; a site for small 3D printing businesses to list their services. We have worked with them in the past and had great experiences, and we highly recommend them if you are looking to work with a small business

Are 3D Printed Parts Strong & Durable? PLA, ABS & PETG – 3D Printerly

Companies worldwide have recently turned to 3D printing to create technical parts quickly while saving some money in the process. But, developing 3D versions of pieces involves using new materials that might not be as durable. So, are 3D printed parts strong?

So, are 3D printed parts strong?

3D printed parts are very strong, especially when using specialized filament like PEEK or Polycarbonate, which is used for bullet-proof glass and riot shields. Infill density, wall thickness and print orientation can be adjusted to increase strength.

There’s a lot that goes into the strength of a 3D part. So, we’re going to be reviewing the materials used during 3D printing, how strong they really are, and what you can do to increase the strength of your 3D printed parts.

Are 3D Printed Parts Weaker & Fragile?

No, 3D printed parts aren’t weaker and fragile unless you 3D print them with settings that don’t give strength. Creating a 3D print with a low level of infill, with a weaker material, with a thin wall thickness and low printing temperature is likely to lead to a 3D print that’s weak and fragile.

How Do You Make 3D Printed Parts Stronger?

Most 3D printing materials are rather durable on their own, but there are some things that can be done to increase their overall strength. This mostly comes down to the minor details in the design process.

This mostly comes down to the minor details in the design process.

Most important would have to be manipulating the infill, wall thickness, and the number of walls. So, let’s take a look at how each of these factors can impact the strength of a 3D printed structure.

Increase Infill Density

Infill is what’s used to fill in the walls of a 3D printed part. This is essentially the pattern within the wall that adds to the density of the piece overall. Without any infill, the walls of a 3D part would be completely hollow and rather weak to outside forces.

Infill is a great way to increase the weight of a 3D part, also improving the strength of the part at the same time.

There are plenty of different infill patterns that can be used to improve the strength of a 3D printed piece, including a grid infill or a honeycomb infill. But, just how much infill there is will determine the strength.

For regular 3D parts, up to 25% is likely more than enough. For pieces designed to support weight and impact, closer to 100% is always better.

Increase Number of Walls

Think of the walls of a 3D printed part as the support beams in a house. If a house only has four exterior walls and no support beams or interior walls, just about anything can cause the house to collapse or give under any amount of weight.

In the same way, the strength of a 3D printed piece will only exist where there are walls to support weight and impact. That’s exactly why increasing the number of walls inside a 3D printed piece can increase the strength of the structure.

This is an especially useful strategy when it comes to larger 3D printed parts with a greater surface area.

Increase Wall Thickness

The actual thickness of the walls used in a 3D printed piece will determine how much impact and weight a part can withstand. For the most part, thicker walls will mean a more durable and sturdy piece overall.

But, there does seem to be a point at which it’s difficult to print 3D printed parts when the walls are too thick.

The best part about adjusting the wall thickness is that the thickness can vary based on the area of the part. That means the outside world probably won’t know that you’ve thickened the walls unless they cut your piece in half to dissect it.

Generally speaking, extremely thin walls will be quite flimsy and won’t be able to support any exterior weight without collapsing.

Generally, walls that are at least 1.2mm thick are durable and strong for most materials, but I’d recommend going up to 2mm+ for a higher level of strength.

The Strength of Materials Used to Create 3D Parts

3D printed parts can only be as strong as the material that they’re made of. With that said, some materials are a lot stronger and more durable than others. That’s exactly why the strength of 3D printed parts varies so greatly.

Three of the more common materials used to create 3D parts include PLA, ABS, and PETG. So, let’s discuss what each of these materials is, how they can be used, and how strong they really are.

PLA (Polylactic Acid)

PLA, also known as Polylactic Acid, is perhaps the most popular material used in 3D printing. Not only is it quite cost-effective, but it’s also very easy to use to print parts.

That’s why it’s often used to print plastic containers, medical implants, and packaging materials. In most circumstances, PLA is the strongest material used in 3D printing.

Even though PLA has an impressive tensile strength of about 7,250 psi, the material does tend to be a little brittle in special circumstances. That means it’s a little more likely to break or shatter when placed under a powerful impact.

It’s also important to note that PLA has a relatively low melting point. When exposed to high temperatures, the durability and strength of PLA will severely weaken.

ABS (Acrylonitrile Butadiene Styrene)

ABS, also known as Acrylonitrile Butadiene Styrene, isn’t quite as strong as PLA, but that doesn’t at all mean that it’s a weak 3D printing material. In fact, this material is much more capable of withstanding heavy impact, often flexing and bending rather than shattering completely.

In fact, this material is much more capable of withstanding heavy impact, often flexing and bending rather than shattering completely.

That’s all thanks to the tensile strength of about 4,700 PSI. Given the lightweight construction yet impressive durability, ABS is one of the best 3D printing materials out there.

That’s why ABS is used to make just about any type of product in the world. It’s quite a popular material when it comes to printing children’s toys like Legos, computer parts, and even piping segments.

The incredibly high melting point of ABS also makes it able to withstand just about any amount of heat.

PETG (Polyethylene Terephthalate Glycol-Modified)

PETG, also known as Polyethylene Terephthalate, is usually used to develop more complex designs and objects when it comes to 3D printing. That’s because PETG tends to be much denser, more durable, and more rigid than some of the other 3D printing materials.

For that exact reason, PETG is used to make plenty of products like food containers and signage.

Why Use 3D Printing at All?

If 3D printed parts weren’t at all strong, then they wouldn’t be used as an alternative production method for many supplies and materials.

But, are they as strong as metals like steel and aluminum? Definitely not!

However, they are quite useful when it comes to designing new pieces, printing them at a lower cost, and getting a good amount of durable use out of them. They’re also great for small parts and have a generally decent tensile strength given their size and thickness.

What’s even better is that these 3D printed parts can be manipulated to increase their strength and overall durability.

Conclusion

3D printed parts are definitely strong enough to be used to make common plastic items that can withstand great amounts of impact and even heat. For the most part, ABS tends to be much more durable, though it does have a much lower tensile strength than PLA.

But, you also need to take into consideration what’s being done to make these printed parts even stronger. When you bump up the infill density, increase the number of walls, and improve the wall thickness, you’re adding to the strength and durability of a 3D printed piece.

When you bump up the infill density, increase the number of walls, and improve the wall thickness, you’re adding to the strength and durability of a 3D printed piece.

What is the most durable material for 3D printing?

3DPrintStory 3D printing process What is the most durable material for 3D printing?

While the 3D printing process seems like a great alternative to traditional manufacturing methods, the parts produced can be fragile and unusable. As a rule, this is the result of using standard materials that are not designed for strength and durability. But there is a solution: use durable materials! Durable 3D printing materials can greatly enhance your options, as you can print parts and assemblies for small projects without fear of breakage.

In this article, we'll take a look at the three most durable types of 3D printing materials. However, before that, we will take a closer look at what strength means in terms of filament materials.

What is strength and how do we evaluate it?

The strength of a material can be measured and evaluated in different ways. In this article, we will mainly use tensile strength (stress before something breaks). We will list the tensile strength of each 3D printing material in pounds or pounds per square inch (PSI).

Despite the obvious number of pounds the material can support, there is still a margin of error depending on how the part was printed. We've compiled research from a variety of sources to make sure these three materials are the strongest.

You must also understand that the material itself is not the only factor that affects the strength of the finished product. The design itself, post-processing and the 3D printing process also affect the strength of the part.

Polycarbonate

Polycarbonate (PC) is considered by many manufacturers and reviewers to be the strongest 3D printing filament available. In particular, it is possible to achieve high strength of polycarbonate products by 3D printing with an all-metal hot end and a 3D printer in a case that is isolated from the influence of the external environment.

Some Numbers

Airwolf 3D has come to the conclusion after many filament tests that polycarbonate is the best choice of durable filaments for desktop 3D printers. They were able to hang up to 685 pounds on a polycarbonate printed hook and found that this material had a tensile strength of 9800 psi. In contrast, the same part printed in PLA could only support 285 pounds.

Using a similar test, MatterHackers studied the tear strength of this type of thread, as well as a number of other materials. They were able to hang an average of 409 pounds on the polycarbonate hook, while the PLA parts had a significantly lighter average weight of just 154 pounds.

Finally, renowned 3D printing YouTuber Thomas Sunladerer reviewed several polycarbonate materials and gave very positive feedback on the strength of the material.

3D printing with polycarbonate

It is worth noting that the quality of 3D printing with polycarbonate is not very good. Compared to other materials, protrusions and small details may not turn out as well as using the same PLA.

According to Rigid.Ink, polycarbonate is mostly sold in clear. This 3D printing material has excellent heat resistance as well as impact resistance. But note that you will have to print at high temperatures. As mentioned above, it is better to use an enclosed 3D printer and a solid metal hotend.

Pros of polycarbonate : extra strong, excellent thermal and impact resistance.

Cons of polycarbonate : does not cope well with protrusions and small details of a 3D model, requires a body and an all-metal hot end, a limited number of colors.

Nylon

Next on our list of durable 3D printing materials is nylon. This material is considered by many to be the most reliable for desktop 3D printers. Nylon is inferior in strength to polycarbonate, but still clearly stronger than other competitors such as PLA and ABS.

Some numbers

A hook printed with nylon (910) thread had a breaking strength of 7,000 psi, while the same ABS hook only had a strength of 4,700 psi, according to Airwolf 3D. Airwolf 3D also noted that the nylon filament-printed clip holds 485 pounds.

MatterHackers posted similar results and noticed that a hook printed with their NylonX material can hold an average of 364 pounds before it breaks. Rigid.Ink also reviewed some nylon threads and gave them a four out of five rating for strength and a five for durability. For comparison: the strength and durability of PLA is three conventional units.

Nylon 3D printing

Nylon is slightly easier to print than polycarbonate, but it's still not PLA. Nylon filament is quite hygroscopic, so it must be kept dry and requires a high printing temperature of 220-270°C. This material is prone to slight warpage, but is also resistant to impact, fatigue, and high temperature.

Nylon filament is quite hygroscopic, so it must be kept dry and requires a high printing temperature of 220-270°C. This material is prone to slight warpage, but is also resistant to impact, fatigue, and high temperature.

Nylon pros: impact resistance, fatigue resistance, heat resistance, easier to print than polycarbonate.

Nylon 9 cons0042 : hygroscopic, warping, very high hot end temperature required.

Composites

Finally, composite threads, although not essentially one material, can be extremely strong. Composites are threads with certain additives that affect the properties of the material, including to increase strength. The names of these threads usually have the words "pro", "reinforced" (reinforced) or "infused" (infused), since they are usually a mixture of different materials.

For this reason, it is impossible to assess where the composite fibers are compared to the two previous materials. Some composites, such as Carbonyte, can compete with nylon threads for strength, while some composites are less durable.

It all depends on what the composite thread consists of. Durable is usually a high strength material such as nylon impregnated with another high strength material such as carbon fiber or glass.

Speaking of carbon fiber, this is also a very strong filament that is sometimes used for 3D printed bicycles. However, some composite fibers are stronger than many pure carbon fibers, so they are not in the top three, but deserve special mention as composite fibers.

Some numbers

We will use carbon fiber nylon and glass fiber nylon threads as examples. MatterHackers has determined that hooks printed on these materials can hold an average of 349and 268 pounds respectively.

Rigid.Ink gave the fiberglass nylon filament four out of five ratings for strength and five for durability. They also gave the carbon fiber nylon a five out of five rating for both strength and durability. In comparison, PLA and ABS were in the top three for strength.

3D printing with composites

Composites vary in the way they are 3D printed, but they are generally relatively similar to their base material. Durable composite fibers are usually made from nylon, so you'll have to print at fairly high temperatures. These threads are also quite expensive.

Durable composite fibers are usually made from nylon, so you'll have to print at fairly high temperatures. These threads are also quite expensive.

Advantages of composites : This is a combination of several materials to achieve the best possible properties, durable.

Cons of composites: Expensive, requires high 3D printing temperatures.

90,000 strength of 3D printer products-Studia3D05/10/2018 in the expert blog, instructions

UDC 67.02, 620.172.2, 004.9

Study of the strength characteristics of the model material obtained by the FDM printing using ABS-plastic.

Kamonichkina Natalia Vladimirovna

Master of the 1st year N.E. Bauman

Supervisor: I.V. Kocheshkov

Candidate of Technical Sciences, Associate Professor of the Department of Materials Processing Technology”

Additive technologies are currently one of the most dynamically developing areas of "digital" production. This type of technology has great prospects in the production of engineering products and repair work. Additive technologies are based on the use of 3D printers [1]. Of the seven basic principles of the 3D printing process noted in [1], today the most widespread is the extrusion of a material that is selectively fed through a nozzle or jet. This type of 3D printing in the technical literature is called FDM printing (Fused Deposition Modeling).

This type of technology has great prospects in the production of engineering products and repair work. Additive technologies are based on the use of 3D printers [1]. Of the seven basic principles of the 3D printing process noted in [1], today the most widespread is the extrusion of a material that is selectively fed through a nozzle or jet. This type of 3D printing in the technical literature is called FDM printing (Fused Deposition Modeling).

The widespread use of FDM printing is due to the relative cheapness of this type of 3D printers and wide technological capabilities in the production of various types of products. However, it cannot be argued that the strength characteristics of the material of parts obtained using FDM printing correspond to the strength properties of the material of the threads that are used in this case. The application of alternating layers by sequential deposition of filaments leads to the formation of a multilevel physical structure of the material. The formed structure may differ in the anisotropy of properties relative to the direction of laying the threads, the difference in the thicknesses of the stacked layers, the presence of various types of defects, and the peculiarity of the mechanisms of material destruction. The factors listed above affect the strength characteristics of the resulting materials.

The formed structure may differ in the anisotropy of properties relative to the direction of laying the threads, the difference in the thicknesses of the stacked layers, the presence of various types of defects, and the peculiarity of the mechanisms of material destruction. The factors listed above affect the strength characteristics of the resulting materials.

The most common materials for FDM printing are plastics. An example of a plastic commonly used in 3D printing is ABS plastic. Therefore, the purpose of this work is to study the strength characteristics of the material obtained by FDM printing using ABS plastic.

Description of the procedure and conditions for the preparation of samples.

The material obtained by FDM printing may have a different structure, but it will necessarily consist of a set of volumes with unidirectionally laid threads. This is determined by the technological features of the implementation of FDM printing. Therefore, in order to determine the strength properties of the material obtained by FDM printing, it is necessary first of all to study the strength of the model material with unidirectionally laid threads. In order to evaluate the strength characteristics of the material and the anisotropy of the properties of the test, it is necessary to carry out tests along and across the direction of laying the threads.

In order to evaluate the strength characteristics of the material and the anisotropy of the properties of the test, it is necessary to carry out tests along and across the direction of laying the threads.

The shape and dimensions of specimens for tensile tests were taken in accordance with GOST 11262-80 “Plastics. Tensile test method”. For research, a sample of the second type was chosen (Fig. 1). 3D printing was carried out using ABS+ plastic monofilament from StrimPlast, supplied according to the Specifications - TU 2291-001-24687042-2016. In accordance with these specifications, the monofilament must have a tensile strength of at least 47 MPa and printing must be carried out in the temperature range of 220-250 0 C.

Fig.1 Sketch of a specimen for tensile testing.

3D printing allows you to immediately produce samples for testing tensile strength, bypassing the stages of obtaining a primary blank and subsequent cutting of samples from it. The thread laying order (G-code) was prepared in the Simplify3D version 4.0 program according to GOST 20999-83 “Numerical control devices for metalworking equipment. Coding information of control programs”, taking into account the location of the threads in the working part of the sample along or across the direction of stretching. FDM printing was carried out on a PicasoDesignerPro250 3D printer with an extruder nozzle diameter of 0.3 mm.

The thread laying order (G-code) was prepared in the Simplify3D version 4.0 program according to GOST 20999-83 “Numerical control devices for metalworking equipment. Coding information of control programs”, taking into account the location of the threads in the working part of the sample along or across the direction of stretching. FDM printing was carried out on a PicasoDesignerPro250 3D printer with an extruder nozzle diameter of 0.3 mm.

Before printing, to improve the adhesion of the material, the table was covered with a special The3D binder. The temperature of the table was 110 0 C, and the temperature of the extruder nozzle was 240 0 C. Printing was carried out in three modes:

- stacked layer of thread h sl =100 microns;

- Mode 2 : at extruder nozzle speed V s =45 mm/s and the thickness of the stacked layer of thread h sl =150 µm;

- Mode 3 : at the speed of movement of the extruder nozzle V s =60 mm/sec and the thickness of the stacked layer of thread h sl =200 µm;

The obtained specimens were tested for tension at the rate of extension of the clamps of the testing machine corresponding to 1±0. 5 mm/sec (the minimum rate of extension of the clamps of the testing machine provided by GOST 11262-80).

5 mm/sec (the minimum rate of extension of the clamps of the testing machine provided by GOST 11262-80).

Discussion of the obtained experimental data.

Experimental data on the results of testing the material obtained by FDM printing using ABS, along and across the filament laying, are shown in fig. 2. From the presented data, it can be seen that the tensile strength of the material obtained by all three 3D printing modes in the direction of laying the threads is close in its values and is at the level of 31-33.5 MPa. If we use the manufacturer's data on the strength of the monofilament used in FDM printing (47 MPa), then these values are approximately 31% lower. However, in order to conduct a more correct comparison of the strength levels of these two materials, it is necessary to clarify to what extent the conditions for testing monofilaments coincide with the conditions for their loading in the model material.

The strength of the model material across the threads is much lower and depends more on the FDM printing modes (Fig. 2). The speed of movement of the extruder nozzle in combination with the thickness of the laid layer affect the adhesion strength of the threads. This is due to the spread of heat from the nozzle into the material. At high print speeds, less heat is transferred to the plastic at any given point in time than at low speeds. If you print a small layer at a low speed, then too much heat may be given off. This will increase adhesion, but there will be a possibility of defects in the form of plastic sagging. Conversely, if you are 3D printing with a thicker layer at high speed, there may not be enough heat to form good adhesion between the filaments.

2). The speed of movement of the extruder nozzle in combination with the thickness of the laid layer affect the adhesion strength of the threads. This is due to the spread of heat from the nozzle into the material. At high print speeds, less heat is transferred to the plastic at any given point in time than at low speeds. If you print a small layer at a low speed, then too much heat may be given off. This will increase adhesion, but there will be a possibility of defects in the form of plastic sagging. Conversely, if you are 3D printing with a thicker layer at high speed, there may not be enough heat to form good adhesion between the filaments.

This assumption is confirmed by the obtained experimental data (Fig. 2). In mode 1 (minimum printing speed and thickness of the stacked layer), the strength of the model material across the laying of threads is maximum and amounts to 20.2 MPa (67% of the material strength along the laying of threads), in mode 2 - 14 MPa (41% of the material strength along laying of threads) and in mode 3 - 15. 9 MPa (51% of the strength of the material along the laying of threads). That is, when switching from mode 1 to mode 2 of 3D printing, there is a decrease in tensile strength of samples with cross-laid filaments, as a result of a stronger influence of the increased thickness of the stacked layer of filaments than an increase in printing speed. And when switching from mode 2 to mode 3, the increase in printing speed has a predominant effect, which leads to a slight increase in the strength of the material (Fig. 2).

9 MPa (51% of the strength of the material along the laying of threads). That is, when switching from mode 1 to mode 2 of 3D printing, there is a decrease in tensile strength of samples with cross-laid filaments, as a result of a stronger influence of the increased thickness of the stacked layer of filaments than an increase in printing speed. And when switching from mode 2 to mode 3, the increase in printing speed has a predominant effect, which leads to a slight increase in the strength of the material (Fig. 2).

Fig. Fig. 2 Dependence of tensile strength σ р of the model material with longitudinal and transverse filament laying, obtained in different modes of 3D printing (Mode 1 – V s =30mm/sec, h sl =100 µm; Mode 2 – V s =45 mm/s, h sl =150 µm Mode 3 - V s =60 mm/s, h sl =200 µm have a different type of tensile diagram and fracture surface. If the tensile diagram of samples with transverse filament laying has a characteristic form for brittle fracture, then on the tensile diagram of samples with longitudinal fiber laying, after a slight decrease in the tensile force, after reaching a maximum, its gradual decrease is observed until the moment of sample failure.

Fig. 3 The nature of the destruction of samples with transverse (a) and longitudinal (b) laying of threads.

Samples with transverse fiber laying (Fig. 3a) have an absolutely flat fracture surface, while specimens with longitudinal fiber laying (Fig. 3b) have a developed fracture surface. When examining these fractures with an optical microscope, it can be seen that the destruction of the material with transversely laid fibers occurs in one plane (Fig. 4a) along the surface of the laid filaments. The fracture of the model material with the longitudinal laying of fibers (Fig. 4b) has a developed character. Fracture proceeds in different planes, and both areas of damage accumulation and flat zones characteristic of the main crack propagation are observed at the fracture.

Fig. Fig. 4 Fracture view of samples with transverse (a) and longitudinal (b) laying of threads.

Conclusion

- For the model material obtained by FDM printing using ABS plastic, when laying threads along the load application direction, no dependence of tensile strength on 3D printing modes was revealed.

The strength in all printing modes was 31-33.5 MPa, which is approximately 31% lower than the strength of monofilaments declared by the manufacturer.

The strength in all printing modes was 31-33.5 MPa, which is approximately 31% lower than the strength of monofilaments declared by the manufacturer. - The strength of cross-laid pattern material is 41-67% of the strength obtained when tested along the fibers. This strength depends on the modes of 3D printing. The maximum value - 20.2 MPa - was obtained in mode 1, at the speed of movement of the extruder nozzle V s = 30 mm/sec and the thickness of the stacked layer of thread h sl = 100 μm, and the minimum value - 14 MPa - is observed in the mode 2, at V c =30 mm/sec and h sl =100 µm.

- Samples of model material with longitudinal and transverse laying of threads have a different nature and type of fracture surface:

- during their transverse laying, an absolutely flat fracture surface is observed along the junction of the deposited threads, and, therefore, the amount of adhesion between them is the most important factor affecting the strength value;

- during their longitudinal laying, the fracture of the material has a developed character, both with areas of damage accumulation and with zones of main crack propagation.

Learn more