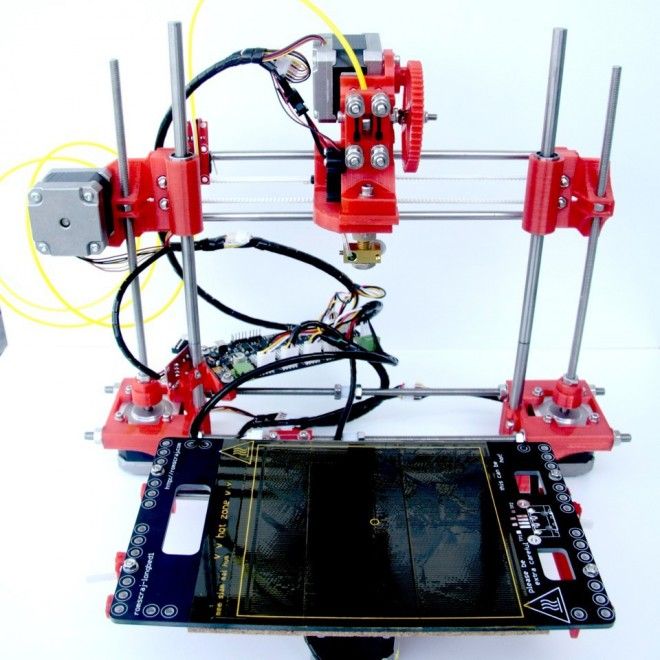

3D printer wired

Curious About 3D Printing? Here Are Some Tips Before You Dive In

What I intended to do with my 3D printer, I can’t remember. I vaguely remember wanting to print big things, but I was unsure what those might be. More abstractly, I was hoping the printer might combine several hobbies and interests into one: computer programming, additive and subtractive manufacturing, computer-aided design, tinkering, and an unyielding desire to create something, anything.

Expecting too much of my printer was my first mistake. I stumbled into dozens of other pitfalls after the printer arrived, up until the day I placed it on a shelf in my garage and solemnly declared across my family’s breakfast table that I was done (for now) with the 3D printer. The room virtually erupted in applause.

That’s because my hobby became an obsession, something I could have avoided had I understood the limitations of both my skill set and the capabilities of the printer. Meanwhile, since March 2020, additive manufacturing has been one of the few industries to grow despite the pandemic. The machines have proven their commercial mettle during disrupted supply chains and has offered rapid prototyping capabilities to at-home renaissance workers looking to aid the health care industry.

And with 3D printers (some available to consumers, others intended for industrial operations) now creating everything from concrete homes to organic biotech material, their popularity is unslowing.

Here are a few tips before starting your own foray into 3D printing.

Know Why You’re Buying

3D printers range in size, price, precision—and, because of those variables, cost. Do you plan to print toys for your children, or is it a way to introduce your kids to STEM? Do you have small do-it-yourself projects around the home for which 3D-printed parts could save you money? Or are you simply looking for a desktop hobby that'll let you print doodads and bric-a-brac like a toothpaste tube squeezer or bookshelf bracket?

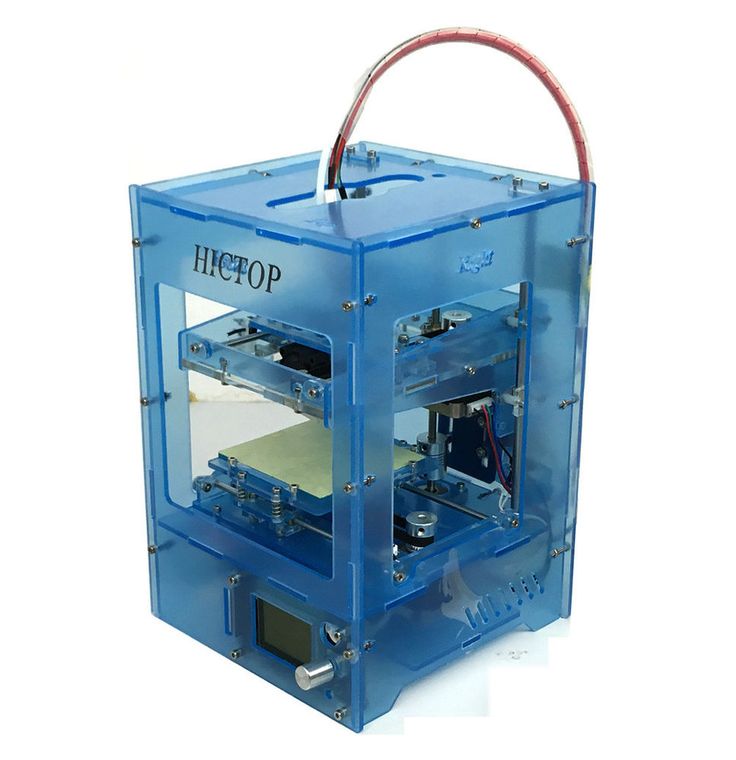

Low-cost, desktop printers range from $100 to $400, with more accurate and larger printers costing north of $1,000. Professional and enthusiast printers—some of which can print ceramics, metals, sand, and other materials beyond plastics—can cost up to $10,000. Anything beyond that would be considered industrial and could easily cost up to $250,000.

Professional and enthusiast printers—some of which can print ceramics, metals, sand, and other materials beyond plastics—can cost up to $10,000. Anything beyond that would be considered industrial and could easily cost up to $250,000.

For the purposes of this guide, I’m assuming you’re looking for desktop consumer printers. With the recent explosion in the availability of printers, anything less than $500 is sufficient for household jobs. This range will all meet similar standards of accuracy and speed, and maintain options to upgrade.

Choosing a Type of Printer

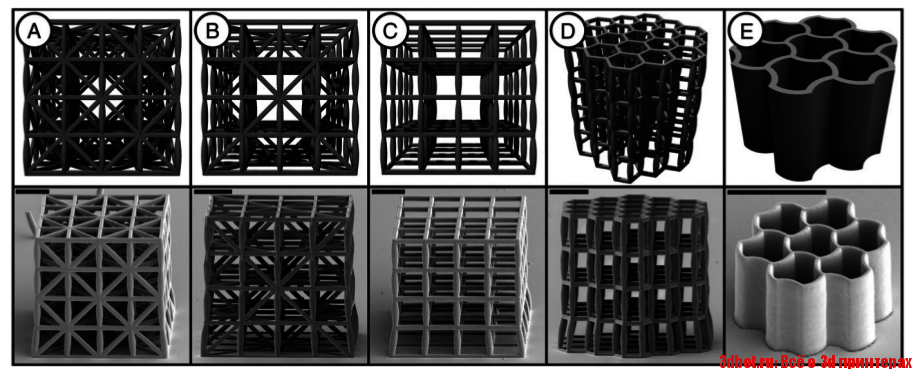

3D printers have existed since 1983. The one method of 3D printing back then has today become nine different types of printers. For the first-time buyer, however, fused deposition modeling (FDM) and stereolithography (SLA) are the easiest to learn and require the least know-how to get started.

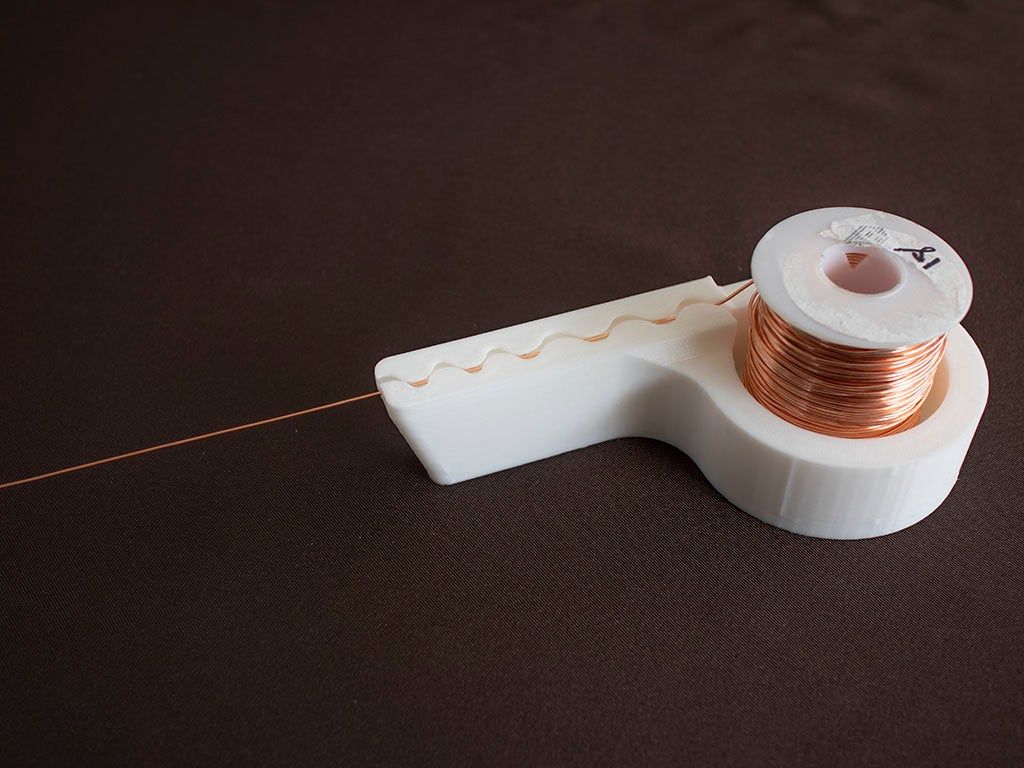

FDM works like this: Thermoplastics (are forced through a nozzle heated to over 200 degrees. The plastics, known as filaments, come in a variety of types: polylactic acid (PLA), polyamide (PA), acrylonitrile butadiene styrene (ABS), polyethylene terephthalate glycol (PETG), or some with wood and carbon laced into the plastic. The most common nozzles are .4 mm in diameter (the smaller they are, the higher the resolution), and they hover over a build plate or heated platform at about the thickness of a Post-it Note. The build plate, sometimes also heated, helps the plastic stick and cool down as layers accumulate and harden. The nozzle moves on tracks or gantries (some have two axes, some more), assisted sometimes by actuators, servo motors, rack-and-pinion structures, or slide guides. The final print usually needs to be cleaned of excess plastic with a hobby knife or wire brush, but this isn't always necessary.

The most common nozzles are .4 mm in diameter (the smaller they are, the higher the resolution), and they hover over a build plate or heated platform at about the thickness of a Post-it Note. The build plate, sometimes also heated, helps the plastic stick and cool down as layers accumulate and harden. The nozzle moves on tracks or gantries (some have two axes, some more), assisted sometimes by actuators, servo motors, rack-and-pinion structures, or slide guides. The final print usually needs to be cleaned of excess plastic with a hobby knife or wire brush, but this isn't always necessary.

3d Printing | Latest News, Photos & Videos

3d Printing | Latest News, Photos & Videos | WIREDSkip to main content

Story SavedTo revisit this article, visit My Profile, then View saved stories.

3d-printing

SearchSearchScience

A 3D-Printed Chicken Breast Was Cooked With Frickin’ Lasers

By Jennifer Ouellette, Ars Technica

Science

3D Printing Helps Ultracold Quantum Experiments Go Small

By Karmela Padavic-Callaghan

Science

The Squishy, Far-Out New Experiments Headed to the ISS

By Max G. Levy

Gear

This Lamp Is 3D-Printed From Orange Peels

By Jeremy White

Science

Coming Soon: A Nuclear Reactor—With a 3D-Printed Core

By Daniel Oberhaus

Gear

These Sleek Lamps Illuminate the Promise of 3D Printing

By Boone Ashworth

Science

These Plastic Bunnies Got a DNA Upgrade. Next up, the World?

By Megan Molteni

Transportation

Elon Musk's ‘Pedo Guy’ Trial, Uber’s Crime Report, and More

By Aarian Marshall

Transportation

3D Printing Can Keep Aging Air Force Aircraft Flying

By Alex Davies

Science

Massive, AI-Powered Robots Are 3D-Printing Entire Rockets

By Daniel Oberhaus

Science

Robot ‘Natural Selection’ Recombines Into Something Brand New

By Matt Simon

Gear

The Perfect Pair of Pants Is Just a 3D Body Scan Away

By Arielle Pardes

Science

Bio-Printers Are Churning out Living Fixes to Broken Spines

By Eric Niiler

Science

A 'Roadless Trip' in a 3D-Printed Solar-Powered Snow Rover

By Megan Molteni

Science

Eyes and Ears 3D-Printed From Flesh Could Boost Our Senses

By Rebecca Heilweil

Security

Cody Wilson Resigns, But the DIY Gun Machine Rolls On

By Andy Greenberg

Science

Scientists 3-D Print Mouse Ovaries That Actually Make Babies

By Nick Stockton

Trianglelab® / Dforce® M8 Inductive Proximity Sensor DC5V 3-wire 2mm for 3D Printer Z Probe with Auto Bed Leveling CR10 ENDER3 3D Printer Reviews

Trianglelab® / Dforce® M8 Inductive Proximity Sensor DC5V 3-wire 2mm for 3D printer Z-probe with auto bed leveling CR10 ENDER3 3D printer Reviews - Banggood UK Online ShoppingCustomer reviews

- 5 star3 (100.0%)

- 4 star0 (0%)

- 3 star0 (0%)

- 2 star0 (0%)

- 1 star0 (0%)

Write a review You'll get double Banggood points for a review if you're one of the first 3 to leave it!

- All reviews (3)

- Image (0)

- Video (0)

- All Stars

- All sprockets (3)

- 5 Star (3)

- 4 Star (0)

- 3 Star (0)

- 2 Star (0)

- 1 Star (0)

Sort by:

evaluation

- estimate

- utility

- date

Reviews only from your country (Russian Federation)

|

Show original

Part of the review is translated automatically.

General 0 page

Go to page

Go

Recommended

-

58.12€

Dual Z-Axis Creativity® MGN12C Linear Guide with Mounting Bracket Kit Ender-3/3S / PRo CR Parts Kit

(0)

-

20.57€

235mm X 235mm 3D Printing Heating Block Square Surface Sticker Sheet for 3D Printer Hot Bed

(0)

recommendation for you

How to choose a 3D printer?

Recently, everyone has become interested in the possibilities of 3D printing - this is not surprising, because they are really impressive. 3D printing is carried out using a 3D printer, a device that produces volumetric physical products based on a three-dimensional layout. The equipment is widely used in various fields of activity - in medicine, machine and instrument making, jewelry, etc.

3D printing is carried out using a 3D printer, a device that produces volumetric physical products based on a three-dimensional layout. The equipment is widely used in various fields of activity - in medicine, machine and instrument making, jewelry, etc.

Working area size

There is a technique with a very small (length, width and height - 100 mm) and a very large (length, width and height - 1 meter) working area. But such equipment is capable of solving only highly specialized tasks. For example, the first devices are suitable for making miniature parts, while the second ones are suitable for the production of huge prototypes.

For 95% of tasks, a device with a working area of 200 x 200 x 200 mm will do. Even if one day you have to make a larger product, you can divide its 3D model into parts in a special editor, print each part separately, and then glue them together.

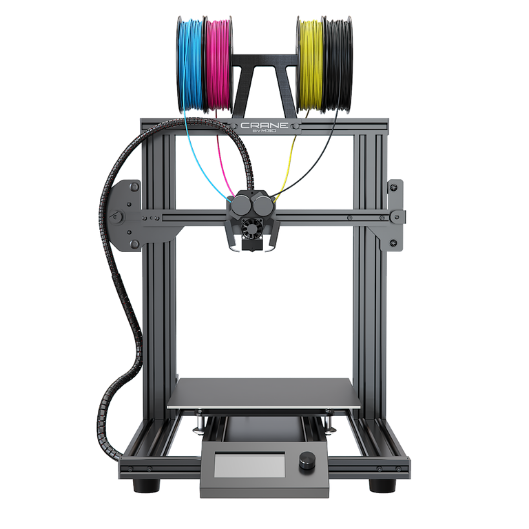

Number of extruders

An extruder is a piece of equipment that produces products by forcing a viscous material through a forming device.

A 3D printer can be equipped with one or two extruders.

The dual extruder technique prints two materials (or one material but different colors). It is needed if you are working with complex parts (for example, they have a lot of elements “suspended” in the air, or there are angles greater than 30 degrees). In other situations, you can get by with a more affordable option with one extruder.

Materials that the machine can handle

-

If you plan to work with ABS, Nylon, HIPS, PC or other materials that shrink a lot, choose a technique with a heated table and a closed case (an open case will not be able to form a thermal contour around the product).

-

To work with PLA plastic, these structural elements are not needed. However, models with a heated table are more functional.

-

There are also printers that work with flexible materials (Flex, Rubber). Such devices are expensive, and the printing process is very laborious and slow. Therefore, such a device should be purchased only when you know for sure that you will use this option.

Chamber

-

The open models are equipped with a table that moves horizontally. They are cheaper but slower. The technique involves complex settings. In addition, you will not be able to work with materials that shrink a lot (ABS, Nylon).

-

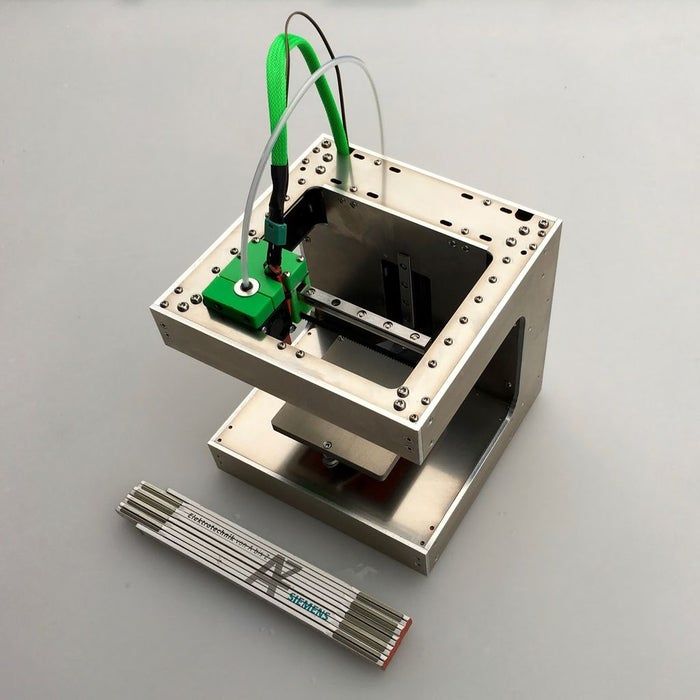

printers with closed chambers are referred to as dice. Devices provide high speed printing and its quality, allow the use of materials with shrinkage. The print head in such equipment can move in different ways.

Nozzle change

If you are solving standard tasks, then a nozzle with a diameter of 0.