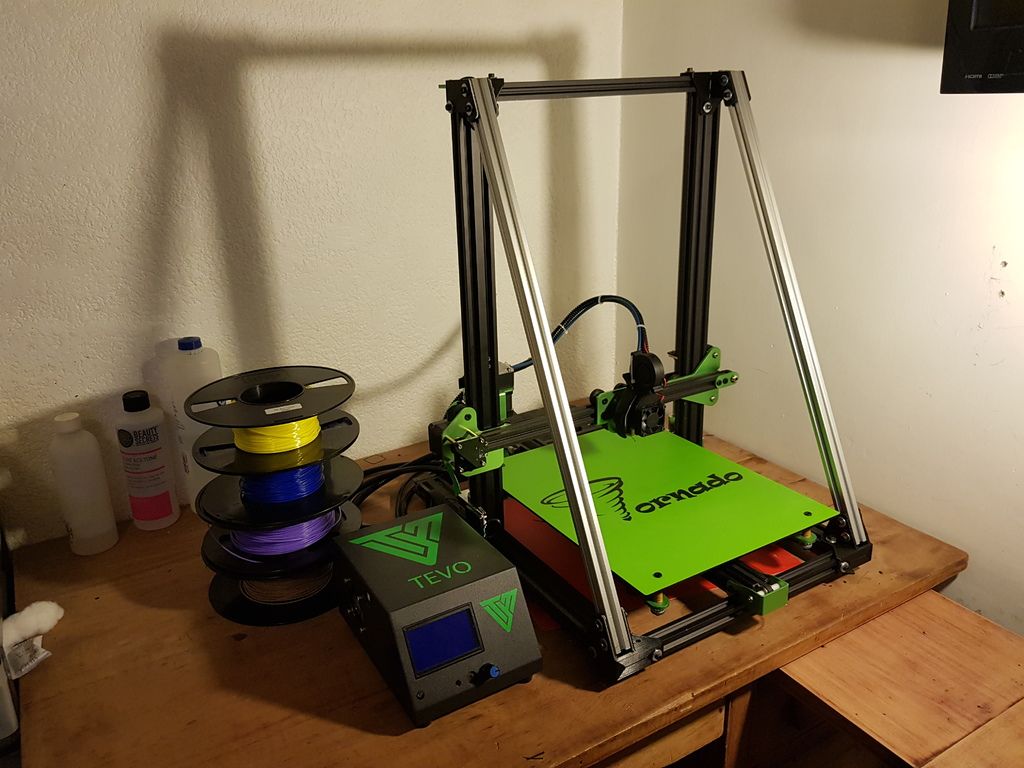

3D printer threaded rods

▷ m8 threaded rod 3d models 【 STLFinder 】

M8 Threaded Rod Cover

thingiverse

Plastic cover for M8 threaded rod. My filament and/or PTFE guide tube would always rub on my RepRap Prusa Mendel i2 top threaded rods, causing it to wear and leave dust etc. I initially taped the rods and this helped a bit. This is a more...

M8 Threaded Rod

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=193647 Instructions Using the following options: drive_type = phillips thickness = 2 countersink = 2 nut_height = 6 resolution = 0.5 slot_depth = 2 head_type = hex facets = 6 non_thread_length =...

Spool holder M8 threaded rod

thingiverse

Spool holder for M8 threaded rod. ...

M8 threaded rod Spool holder

pinshape

Summary Spool holder assembled from M8 threaded rod, 3D printed wheels and washers. ...ball bearing from roller skates

M8 Threaded Rod Test Object

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=193647 Instructions Using the following options: nut_diameter = 12 slot_depth = 2 drive_diameter = 5 socket_facets = 6 countersink = 2 thread_length = 25 inner_diameter = 8 head_diameter = 12...

M8 8x100mm threaded rod

thingiverse

http://www. thingiverse.com/apps/customizer/run?thing_id=193647 Instructions Using the following options: type = rod nut_height = 6.8 non_thread_length = 0 facets = 6 head_diameter = 13 nut_step_shape_degrees = 45 nut_type = normal nut_thread_step =...

thingiverse.com/apps/customizer/run?thing_id=193647 Instructions Using the following options: type = rod nut_height = 6.8 non_thread_length = 0 facets = 6 head_diameter = 13 nut_step_shape_degrees = 45 nut_type = normal nut_thread_step =...

M8 8x150mm threaded rod

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=193647 Instructions Using the following options: non_thread_length = 0 type = rod head_diameter = 13 socket_depth = 3.5 texture = exclude nut_diameter = 13 resolution = 0.5 facets = 6...

M8 30cm Threaded Rod

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=193647 Instructions Using the following options: type = rod thread_step = 1. 25 nut_height = 6 thickness = 2 step_shape_degrees = 45 head_type = hex inner_diameter = 8 wing_ratio = 1...

25 nut_height = 6 thickness = 2 step_shape_degrees = 45 head_type = hex inner_diameter = 8 wing_ratio = 1...

EGGBOT/SPHEREBOT FEET (M8 Threaded Rod)

thingiverse

Feet for M8 Threaded Rod used in assembly of Eggbot/Spherebot.

M8 threaded rod filament holder mount

thingiverse

This is our M8 threaded rod filament holder mount we designed for easily get our filament hung up above our printer.

M8 Threaded Rod Filament Mounting Kit

thingiverse

. .. made with Tinkercad. ...Edit it online https://www.tinkercad.com/things/997Waew2QYr BOM: 1 x Printed Mounting Kit 2 x M8 Threaded Rod (cut to desired length) 4 x M8 Nut 1 x 8mm Smooth Rod (cut to desired length) 8 x Wood Screw with 4mm countersunk head

.. made with Tinkercad. ...Edit it online https://www.tinkercad.com/things/997Waew2QYr BOM: 1 x Printed Mounting Kit 2 x M8 Threaded Rod (cut to desired length) 4 x M8 Nut 1 x 8mm Smooth Rod (cut to desired length) 8 x Wood Screw with 4mm countersunk head

Spoolholder support for m8 threaded rod

thingiverse

Top mounted spoolholder stand to be used in connection with thing 969358 (Wall-mount spool holder with quick release fastener) I made this bracket to fit m8 threaded rod. The thread for the rod to screw into is cut with a tap as this makes the best...

M8 threaded rod 1.25 mm pitch

myminifactory

This is a snappable 50 mm length version of an m8 threaded rod needed for the prusa i3 and other 3d printers. you can print multiple copies of this model and fit them into each other as per your lenngth requirements.

I haven't checked the...

you can print multiple copies of this model and fit them into each other as per your lenngth requirements.

I haven't checked the...

Wind vane (on M8 threaded rod)

thingiverse

... rod, in the tip of the vane, is for balancing the assembly. If the rod isn't in the tip, to much weight will lean on the tail section, causing the vane not to rotate smoothly. ...Miiiike's Vertical Windmill Mk2http://www.thingiverse.com/thing:948401

M8 Threaded Rod

thingiverse

Customized version of https://www.thingiverse.com/thing:193647 Created with Customizer! ...https://www.thingiverse.com/apps/customizer/run?thing_id=193647

M8 threaded rod holder

thingiverse

I use this to hold my spool holder in my leapfrog printer uses M4 x 30 screws if you want to screw this in 40x40 extrusion

M8 threaded rod, 21mm

thingiverse

Customized version of https://www. thingiverse.com/thing:193647 Created with Customizer! ...https://www.thingiverse.com/apps/customizer/run?thing_id=193647

thingiverse.com/thing:193647 Created with Customizer! ...https://www.thingiverse.com/apps/customizer/run?thing_id=193647

M8 threaded rod GoPro mount

thingiverse

nT

simple vice with M8 threaded rod and nut s

grabcad

simple vice with M8 threaded rod and nutsNot tested yet

Handle for M8 threaded rod (suitable for AEG angle grinder)

thingiverse

Ergonomic handle for M8 threaded rod. ... Designed for at least 180mm of M8 threaded rod. Handle itself has 131mm height and 116.5mm of usable grip area. ... I used in this case 4x M8 nuts (2x nylock for each end)

... Designed for at least 180mm of M8 threaded rod. Handle itself has 131mm height and 116.5mm of usable grip area. ... I used in this case 4x M8 nuts (2x nylock for each end)

M8 threaded rod to T8 lead screw nut adapter

thingiverse

Allows you to replace a T8 lead screw nut with an M8 nut Used this on my MPCNC Lowrider2 to use M8 threaded rods instead of T8 lead screws

CUBICON STYLE SPOOL-HOLDER, BEARINGS, M8 THREADED ROD

thingiverse

IMPROVED SMOOTH RUNNING 1 1/4" round x 3 1/2" DEEP SPOOL HOLDER WITH REMOVABLE HAND NUT RETAINER TOLERANCES ~+ . 01" USE SUPPORTS FROM BED ON PART X & PART Z 25 TO 75 % FILL 1 TO 2 MM WALL PRINT AS PALETIZED ASSEMBLY: + M8 X 130MM THREADED ROD...

01" USE SUPPORTS FROM BED ON PART X & PART Z 25 TO 75 % FILL 1 TO 2 MM WALL PRINT AS PALETIZED ASSEMBLY: + M8 X 130MM THREADED ROD...

Spool centerer on M8 Threaded Rod (from Anet A8)

myminifactory

Updated design :) HEY,this is a spool centerer for any M8 threaded rod, the thing is, if the filament isnt centered, there might be an ugly Z pattern in your prints, this fixes that. ... you need 2 M8 Nuts, to thread these properly, the filament then is...

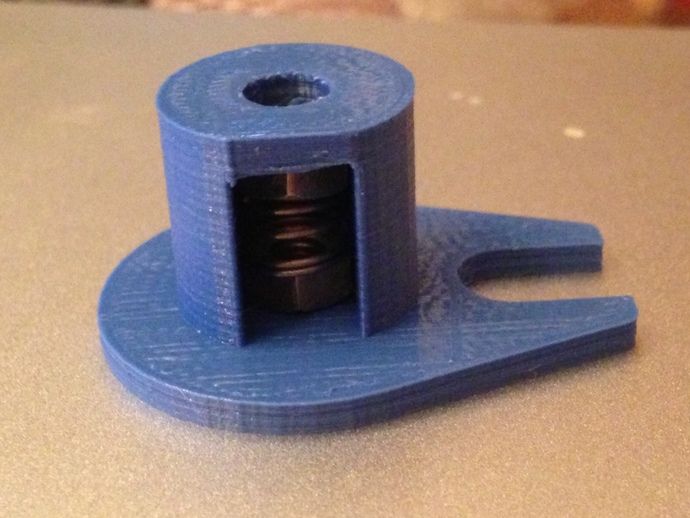

Flanged anti-backlash nut for m8 threaded rod

thingiverse

I am a cheapskate. ... I needed a cheap anti backlash mechanism for m8 threaded rod that works well. ... Those acme screw and nuts are like $5 a piece, and a few hundred millimetres of threaded rod is less than a dollar.

... I needed a cheap anti backlash mechanism for m8 threaded rod that works well. ... Those acme screw and nuts are like $5 a piece, and a few hundred millimetres of threaded rod is less than a dollar.

M8 threaded rod fan mount bracket for Prusa I3

thingiverse

A minimal approach to mounting a fan on some M8 threaded rod. If you have spare length of rod, it's worth manually bending the supports slightly immediately after printing to fit the rod exactly while its still slightly warm. The fan can be...

M8 threaded rod clip for vertical ball joint

thingiverse

Clips for mounting the vertical ball joints described here: https://www. thingiverse.com/thing:3412413 onto an M8 threaded rod - like the ones in your A8 ;). Both socket and ball version provided. Also added the latest max overhang vertical ball joint...

thingiverse.com/thing:3412413 onto an M8 threaded rod - like the ones in your A8 ;). Both socket and ball version provided. Also added the latest max overhang vertical ball joint...

Spool wall holder (console) for M8 threaded rod

thingiverse

Here is my design for spool wall holders using a M8 threaded rod. The spools sit on top of the rod and touch the wall with their backside. This design allows taking the spools easily off and on the shelf. It’s not a beauty but it works and it’s...

Anet A8 M8 Threaded Rod Filament Spool Holder Mk.I

thingiverse

Mine ended up costing 2. 50EUR for the M8 threaded rod (1 metre, so I was left with extra) and some filament.

It's super simple. Anyone can put this together and even printers with not-so-accurate calibration will manage parts this size with ease....

50EUR for the M8 threaded rod (1 metre, so I was left with extra) and some filament.

It's super simple. Anyone can put this together and even printers with not-so-accurate calibration will manage parts this size with ease....

M8 Threaded Rod End Force Transducer Inline Load cell

grabcad

M8 threaded inline load cell 1kN 2kN 3kN 5kN tension and compression force transducer.Force sensor model: FL34

300mm M8 Threaded Rod with bolt and washer .5mm resolution

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=193647 Instructions Using the following options: type = rod non_thread_length = 0 head_diameter = socket_depth = 3. 5 texture = exclude nut_diameter = 12 resolution = 0.5 facets = 6...

5 texture = exclude nut_diameter = 12 resolution = 0.5 facets = 6...

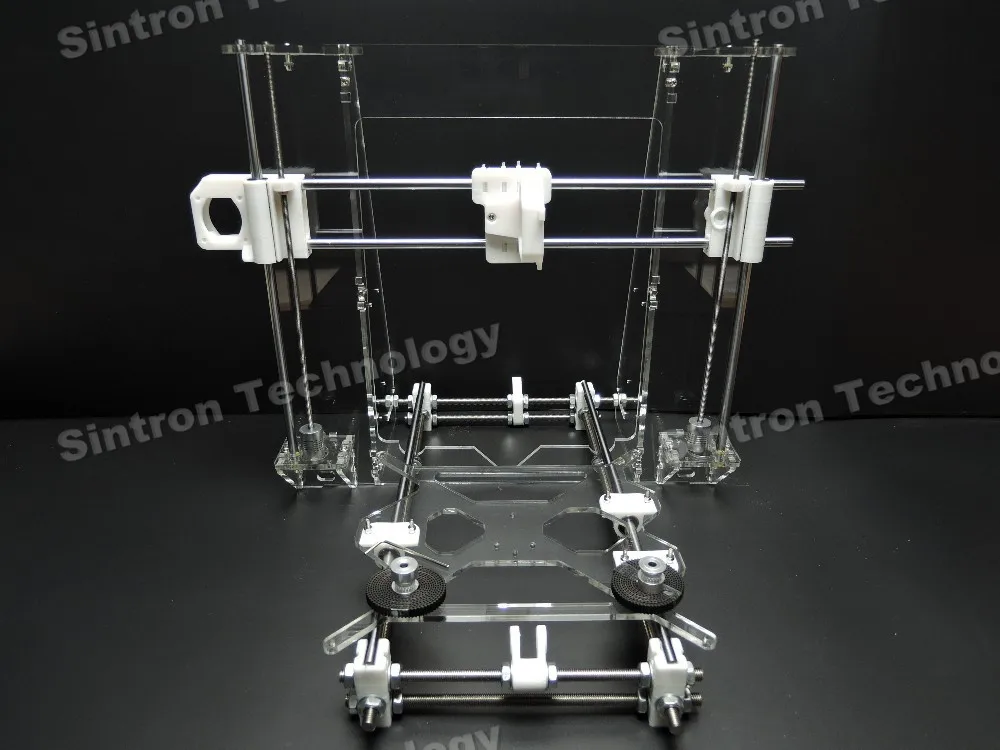

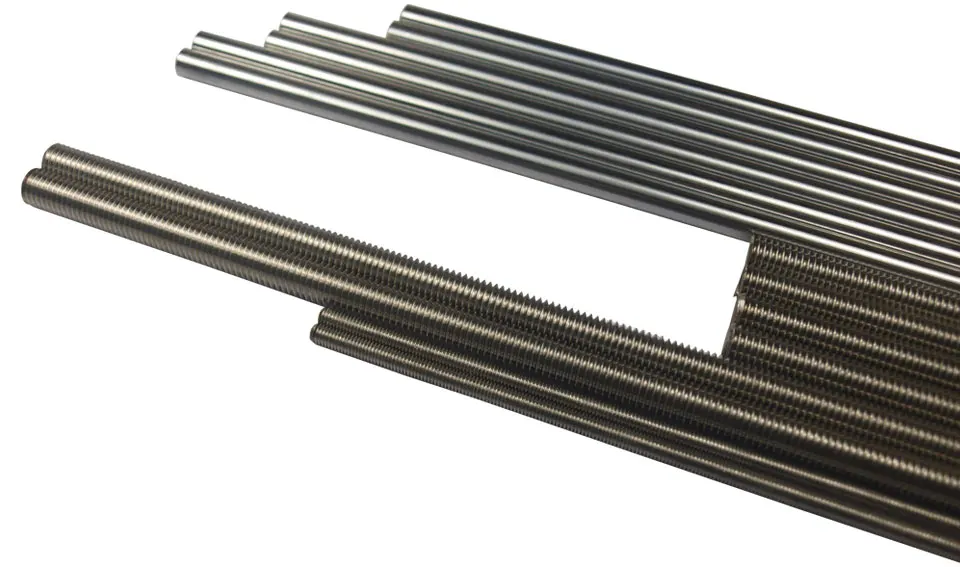

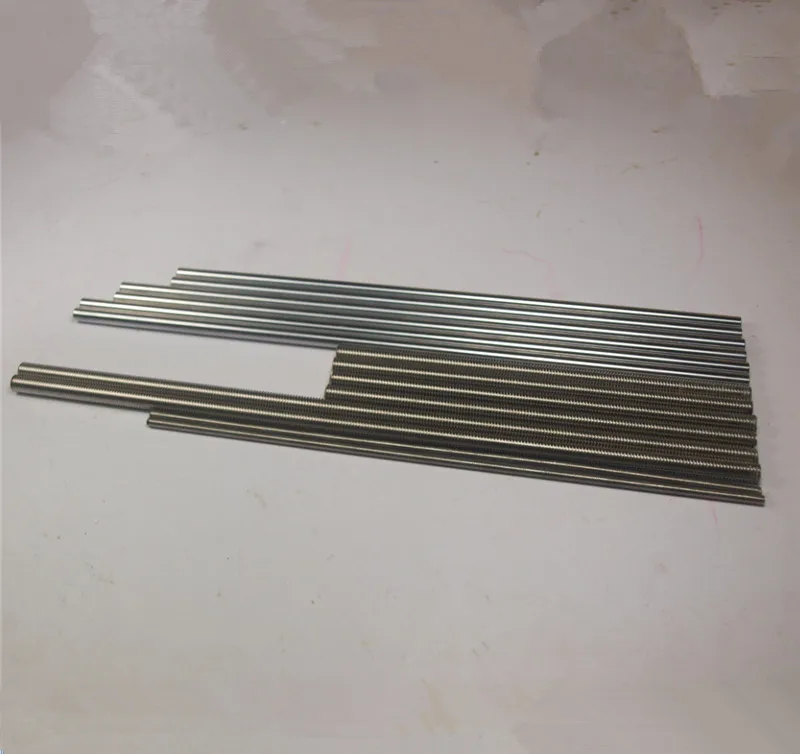

Shafts/ Threaded rods/ Lead Screws Archives

Showing all 7 results

Sort by popularitySort by average ratingSort by latestSort by price: low to highSort by price: high to lowShow products in stock first-

1000 mm M8 Chrome Plated Smooth Rod

د.ع 9,500شفت ناعم مطلي بالكروم بقطر 8 ملم وطول 1000 ملم (1 متر).

يستعمل في بناء الطابعات ثلاثية الابعاد ومكائن السي ان سي والاعمال الهيدروليكية والروبوتية.

These are the smooth rods used for 3D printer kits. They’re made of chrome-plated high-carbon steel and provide smooth, consistent motion when paired with linear bearings. These smooth rods are manufactured for use in 3D printers, Hydraulics as well as in CNC / linear motion applications, are stand up to frequent use without a problem.

Add to cart

Quick View

-

1000 mm M12 Chrome Plated Smooth Rod

د. ع 13,500

ع 13,500شفت ناعم مطلي بالكروم بقطر 12 ملم وطول 1000 ملم (1 متر).

يستعمل في بناء الطابعات ثلاثية الابعاد ومكائن السي ان سي والاعمال الهيدروليكية والروبوتية.

These are the smooth rods used for 3D printer kits. They’re made of chrome-plated high-carbon steel and provide smooth, consistent motion when paired with linear bearings. These smooth rods are manufactured for use in 3D printers, Hydraulics as well as in CNC / linear motion applications, are stand up to frequent use without a problem.

Add to cart

Quick View

-

1000 mm M8 Zinc Plated Threaded Rod

د.ع 4,000شفت لولبي مطلي بالزنك بقطر 8 ملم وطول 1000 ملم (1 متر).

يستعمل في بناء الطابعات ثلاثية الابعاد ومكائن السي ان سي والاعمال الهيدروليكية والروبوتية.

Add to cart

Quick View

-

1000 mm M10 Zinc Plated Threaded Rod

د.ع 5,000شفت لولبي مطلي بالزنك بقطر 10 ملم وطول 1000 ملم (1 متر).

يستعمل في بناء الطابعات ثلاثية الابعاد ومكائن السي ان سي والاعمال الهيدروليكية والروبوتية.

Add to cart

Quick View

-

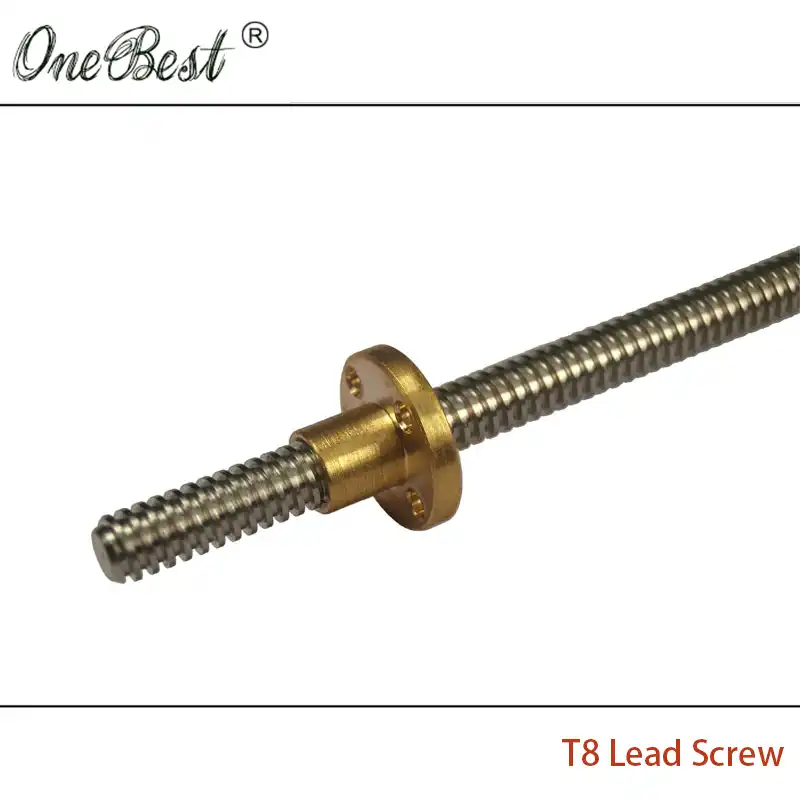

350 mm T8 Lead Screw with Brass Nut – 2 mm Pitch

د.ع 16,000Lead screw (8mm) suitable for: industrial automation equipment, stepper motor rails; such as 3D printers; engraving machine; XYZ module; slider; lifts, etc.

Add to cart

Quick View

-

400 mm T8 Lead Screw with Brass Nut – 2 mm Pitch

د.ع 19,000Lead screw (8mm) suitable for: industrial automation equipment, stepper motor rails; such as 3D printers; engraving machine; XYZ module; slider; lifts, etc.

Add to cart

Quick View

-

500 mm T8 Lead Screw with Brass Nut – 2 mm Pitch

د.ع 24,000Lead screw (8mm) suitable for: industrial automation equipment, stepper motor rails; such as 3D printers; engraving machine; XYZ module; slider; lifts, etc.

Add to cart

Quick View

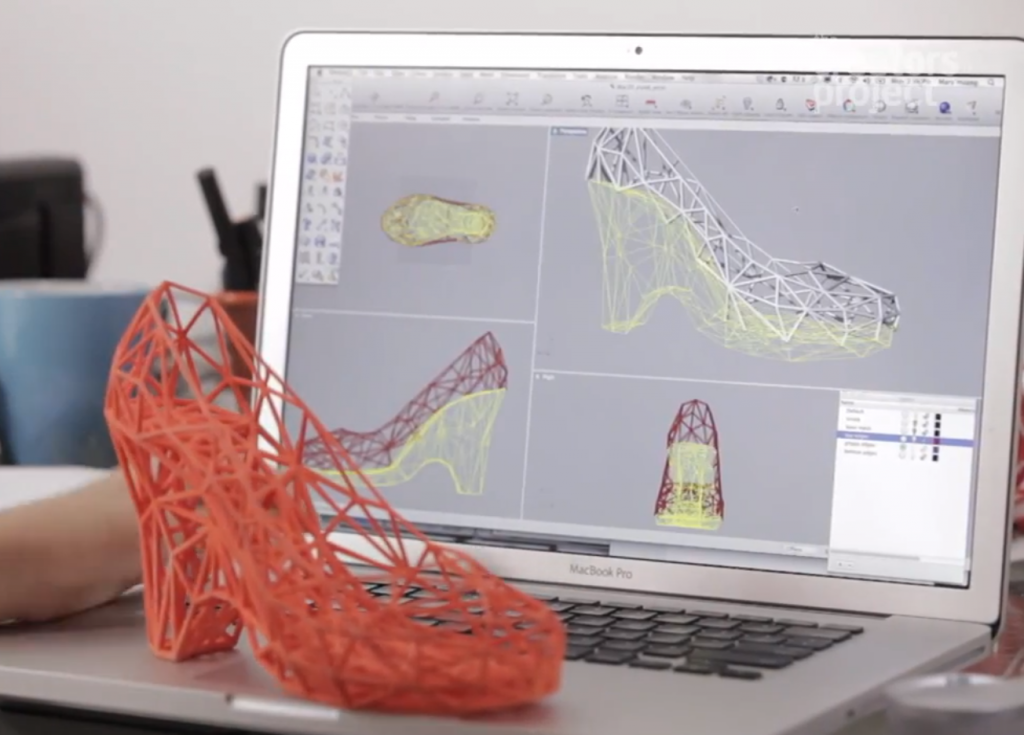

3D Printer Threads and Thread Inserts for Plastic

At Formlabs, we design various functional parts for printing on our stereolithographic (SLA) 3D printers such as the Form 3. These parts include prototypes used for our own R&D, clamps and fasteners to be used on our production lines, models to check the design before casting the final product in the appropriate material, such as nylon.

Regardless of the application, we often need to connect 3D printed components with screws and threaded fasteners. As the catalog of versatile and reliable engineering polymers grows, the differences between "imitation" prototypes and functional prototypes diminish.

This article is a guide to threading and threading 3D parts with a 3D printer. There are many ways to connect multiple 3D printed parts together, but if you need the ability to repeatedly connect and disconnect components and secure mechanical fastening, there is no real substitute for metal screws.

Do you like to see everything with your own eyes? Watch a video about 3D printing threaded connections and threaded inserts for 3D plastic parts.

White Paper

Download our white paper on stereolithography to find out how SLA printing works, why thousands of professionals use it today, and how this 3D printing technology can be useful in your work.

Download white paper

Let's take a look at some of the threading options for 3D parts we've put together based on years of Formlabs experience and your suggestions. We've ranked these options, starting with the one we think is the best, with the pros and cons of each option for different use cases.

Experience Formlabs print quality firsthand. We will send a free 3D printing sample directly to your office.

Request a free sample

Benefits: Strongly connects 3D printed parts without the use of glue. The metal threads are durable and reusable.

Drawbacks: Inserts may loosen as temperature rises.

3D print a sleeve blank with a depth and diameter that matches the insert specifications. Rinse with isopropyl alcohol (IPA) and allow to dry without final polymerization. Insert the insert into the sleeve with a screwdriver and use the screw to secure it completely into the plastic. Then finish curing the part to reduce the creep effect and fix the insert in the plastic even better. Performing this step last reduces the chance that the insert will break the sleeve when screwed in.

Benefits: Connects 3D printed parts very securely. The metal threads are durable and reusable.

Cons: Adhesive required (don't try to use a soldering iron!).

Threaded inserts with heat setting are designed for installation in thermoplastics using a soldering iron with a soldering tip. They can be used in acrylic models and Fused Deposition Models (FDM), but cannot be installed in SLA photopolymer parts, which bend but do not melt when heated.

Check out our detailed guide comparing FDM vs. SLA 3D printers to see how they differ in terms of print quality, materials, application, workflow, speed, cost, and more.

However, the notches and ridges on the heat set inserts make them a very effective thread fastener if you bond them with a two part epoxy or cyanoacrylate adhesive. Determine the bushing size by the largest diameter of the insert and apply some adhesive before installation. For best results, the part must be completely dry and cured.

Benefits: Nuts are easy to match to any required screw size.

Drawbacks: Side nut slots can eliminate the need for glue, but can make it harder to support the model during printing.

Adding a hexagon socket to the nut press-fit end creates a reusable strong metal-to-metal connection. To increase the twisting force, you can choose a square nut. This nut can also be plastic or have blocking elements. If necessary, a drop of cyanoacrylate glue will help hold the nut in place, but if the design includes a side socket, there is no need for glue. Use a 0.1 mm offset around the press-in nut and clearance around the screw itself.

If necessary, a drop of cyanoacrylate glue will help hold the nut in place, but if the design includes a side socket, there is no need for glue. Use a 0.1 mm offset around the press-in nut and clearance around the screw itself.

Benefits: Prototyping uses the same metal products as mass-produced injection molded parts. Sleeve blanks made from Tough (and Durable) polymer are unlikely to crack if you follow the screw manufacturer's sleeve design guidelines.

Disadvantages: The screws will hold tight, but the threads will not be as resistant to repeated use as metal threads. Standard resins can be used, but the bushing is more likely to crack.

Follow manufacturer's recommendations for core sizes and print with high impact engineering resins (such as our Tough Resin and Durable Resin). Before using the screws, complete the final curing. If you are prototyping an injection molded part that will use tapping or tapping screws in its final assembly, this is a good option for testing.

Benefits: No need to buy special plastic screws.

Disadvantages: The screws will hold tight, but the threads will not be as resistant to repeated use as metal threads.

We have tested screws in our Tough Resin product and found that their use is identical to that of threading screws designed for plastics. The size of the hole diameter of the threaded bushing must be in the range between the main (threaded) diameter of the screw and the inner diameter. The screw shown is a #8 screw in a 0.16" diameter hole.

Benefits: Can be used for prototyping large and custom threaded designs.

Disadvantages: Not a durable or reusable fastening solution, especially for smaller thread sizes.

3D printed threads from standard resins are better than Tough Resins because they are much harder. 3D printed threads remain relatively brittle, depending on the size of the thread, and are not recommended if the fastening system is to be used continuously and repeatedly.

Thread sizes ¼-20 or larger are generally functional without the need for post-processing. For smaller screws, the threads must be modified to provide better fastening. For example, printing a round thread profile (on a screw and a nut) and using a 0.1mm offset results in a better thread fit and improved wear characteristics. For all screw sizes, it is best to orient the parts so that the supporting structures do not touch the threads.

White Paper

Tolerance and fit design reduces post-processing time and simplifies assembly, as well as reduces material costs per iteration.

Learn more

We hope this guide has provided you with useful information about the mechanical mounting options that can be used for 3D printed components! If you are interested in seeing the model we use for testing, please download the STL file.

Download STL file

Parts mentioned in this manual can be ordered from McMaster using the links below:

- M3 insert with heat setting for plastic

- Brass M3 screw-in insert for plastic

- Galvanized steel hex nut M3

- Galvanized steel hex nut M4

- Threading screw 4-20 for plastic

Want to try Tough Resin, Durable Resin or any other Formlabs 3D printing material in action? Request a free sample!

Request a free print sample SLA

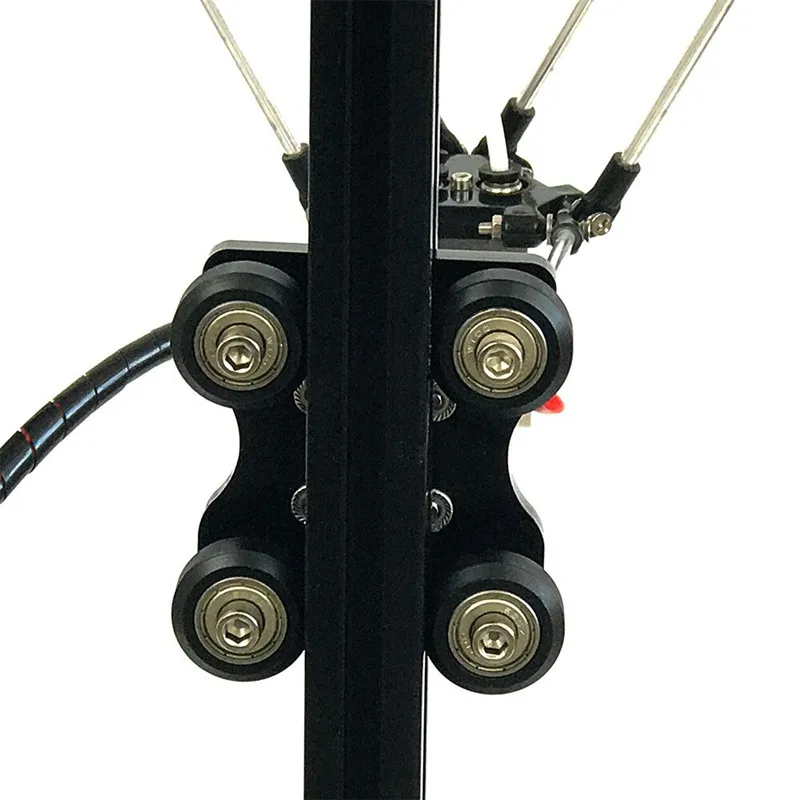

Lead screw

FAQLead screws are an excellent replacement for

threaded rodsFrom RepRap Wiki: Threaded Rod

Lead screws are threaded rods used to enter a component, such as an X-axis assembly to a Z-axis.

For most repraping, a regular (straight!) threaded rod is sufficient, but for higher accuracy and reduced wobble, you can use real lead screws.

There are two main thread profiles for lead screws, both of which are trapezoidal: trapezoidal and Acme. An important but subtle difference is the angle of the thread flange. Be sure to buy the right nuts.

See also Wikipedia: Lead screw:

A lead screw (or lead screw), also known as a power screw1 or lead screw2, is a screw used as a lever in a machine to convert rotational motion into linear motion. Due to the large area of sliding contact between their female and female elements, screw threads have a high frictional energy loss compared to other connections. They are not typically used for high power transmission, but rather for intermittent use in low power actuators and positioners. Common applications are linear drives, mechanical slides (eg in machine tools), vices, presses and jacks.

3

Lead screws are made in the same way as other thread forms (they can be rolled, cut or sharpened).

There are three types of thread used with lead screws:

- Area

- Buttress

- Akme

Advantages and disadvantages:

The advantages of lead screw are as follows:

- Heavy duty

- Compact

- Easy to design

- Easy to manufacture; no special equipment required

- Great mechanical advantage

- Precise and accurate linear motion

- Smooth, quiet and low maintenance

- Minimum number of parts

- Most are self-locking

The disadvantage is that most of them are not very effective. Due to their low efficiency, they cannot be used in continuous power transmission systems. They also have a high degree of friction on the filament, which can wear out the filaments quickly. For square threads, the nut must be replaced; for trapezoidal threads, a split nut can be used to compensate for wear.

- Leadscrew orientation Wouldn't it be better to mount the leadscrews with the motor on top and free bottom end? Compared with the conventional way (motor at the bottom), the lead screw will be under constant voltage,…

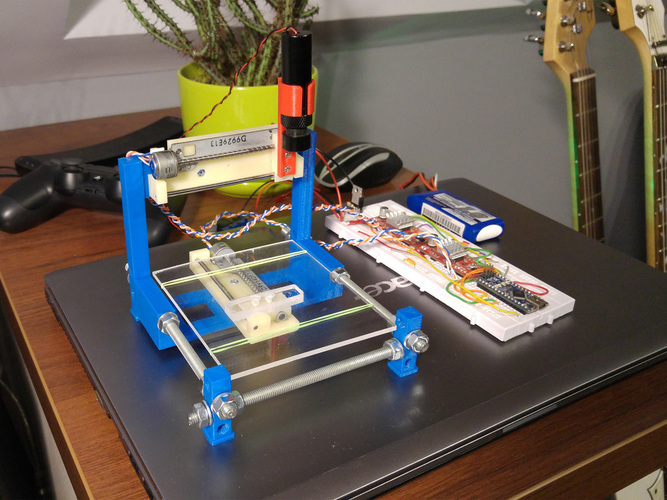

- Lead screw 3D printing I want to build a mini CNC machine, and I need some lead screws. I was wondering if I could just 3D print them. There are several 3D models, but I want to know if it's enough...

- Does anyone know the thread size (pitch and lead) of the Anet A8 lead screw? I bought a new printer and unfortunately the left lead screw nut is not tightened. Does anyone know the thread size including the pitch and lead of the lead screws?

- Lead selection for the lead screw This video brought my attention to the Ender 3 8mm Z-Axis screw lead, which seems to be an extremely poor choice in terms of accuracy with respect to general mesh alignments in…

- When to use an anti-backlash bolt for a Z-drive gear? I'm building a HEVO printer with a 300x300 mounting plate and the project includes two T8 lead screws, 8mm lead ("Tr8x8(p2)").

I have read that such a long lead can worsen backlash problems,…

I have read that such a long lead can worsen backlash problems,… - Calculation of the gear ratio for the lead screw My calibration on the printer is fine. When I try to move 10mm, it comes out exactly 10mm. But I want to know what is my precision for z-axis? (without posting a link to the product, perhaps…

- Are stepper flexible couplings important? How important is it? TL;DR: As far as my particular printer design goes, it certainly seems like the company switched from flexible couplings to rigid couplings specifically to improve the printer and hinder… ? By "better" I mean "more accurate"... As for the RepRap P3Steel or Wilson II, I get about 330mm of T8 lead screws for z movement. Apparently, there is a choice between lead…

- Lead screw holder - should I buy the metal one or just use the printed one? I'm on my way to build my own printer using 2020 profiles, TR8*500mm lead screw for z-axis. Still wondering if it'll be h-bot or CoreXY, but that's another one.

..

.. - Is there a reason on which drive nut M5 with z-axis is too loose on the lead screw? So I bought a prusa i3 kit from folger tech on ebay. I put it together and even printed out a few parts, but I noticed that a lot of the noise seemed to happen only when the engine…

- Why not use the GT2 instead of a Z threaded rod or lead screw? Having just re-read Tom's excellent answer to my question about the advantages of GT2 over a rack, my comment reflects 1: Why is a threaded rod or lead screw used for…

- Lead screws - M8 instead of M5? I'm building a Prusa i3 MK2S (cart). I'm having a really hard time finding M5 rods for the Z axis, I have an M8 screw with an 8mm lead so I figured since M8 is widely available online I might just…

- What size is the lead screw So I'm pretty new to 3d printing and I have a question that is probably stupid. I put together a 3D printer kit some time ago, but now I need a big printer to play with.

Learn more