3D printer steppers

3D Printer Stepper Motors & Stepper Drivers

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

-

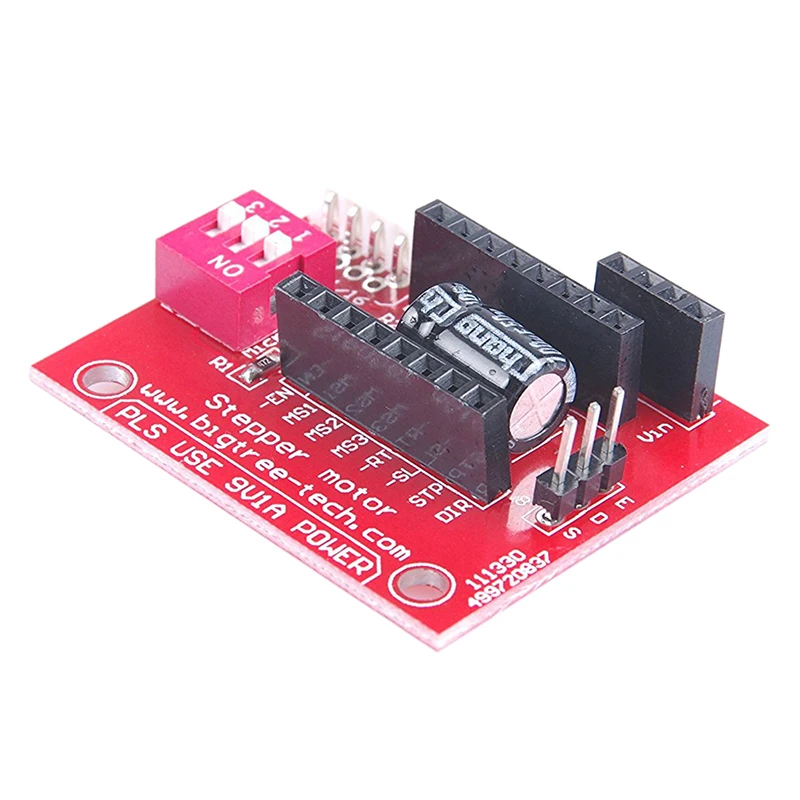

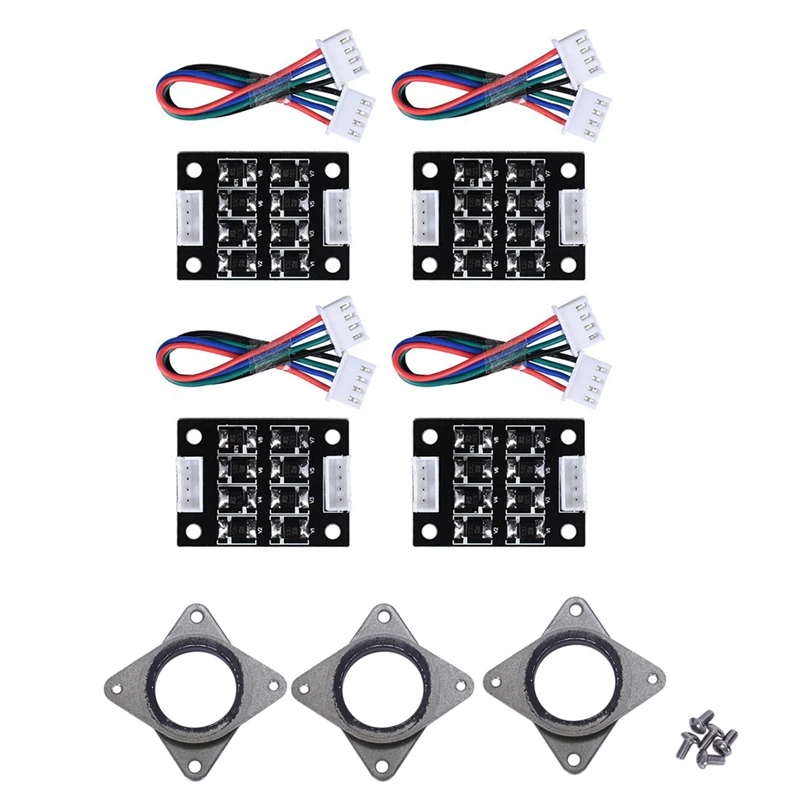

BIGTREETECH Stepper Motor Driver 9 Model types- High-quality

- Different versions available

- Upgrade option

-

BondTech NEMA17 Pancake Stepper 25mm- Removable cable

- High torque

- Original Bond Tech

-

BondTech Heatsink- Better heat dissipation

- Self-adhesive backing

-

Creality Stepper Motor 8 Model types- Original spare part

- From Creality 3D

-

Anycubic Stepper Motor 5 Model types- Original spare part

- By Anycubic

-

FLSUN Stepper Motor 3 Model types- Original spare part

-

BondTech NEMA17 Pancake Stepper 22mm- Fixed cable

- High torque

- Original Bond Tech

-

BIGTREETECH EZ Stepper Driver 2 Model types- 2-in-1 driver and heatsink

- Quiet movements

- Very durable

-

E3D Hemera XS Motor- Original spare part

- For E3D Hemera XS

- Including drive gear

-

BIQU Stepper Driver- Original spare part

-

BIGTREETECH EZ Driver Connector- Adapter for increased compatibility

-

Zortrax Extruder Motor Set- Original spare parts

-

E3D Hemera Motor- Original spare part

- For E3D Hemera

- Including drive gear

-

Artillery Stepper Driver- Original spare part

- From Artillery

-

Artillery Stepper Motor- Original spare part

- From Artillery

-

BondTech NEMA17 Geared Stepper- Planetary gear

- High torque

- Original Bond Tech

All prices incl. VAT.

What is the Best Stepper Motor/Driver for Your 3D Printer? – 3D Printerly

If you’ve wondering just which stepper motor/driver is best for your 3D printer, you’re in the right place. It’s a quite overlooked part of a 3D printer and it deserves a bit more of an informed decision rather than just sticking with what your printer came with.

Many people have reported prints improving after installing a better stepper motor on their 3D printer so which one is best for your 3D printer?

For such an essential part of a 3D printer, I’ve wondered which stepper motor is the best so I created this post to find that out so read along for the answers.

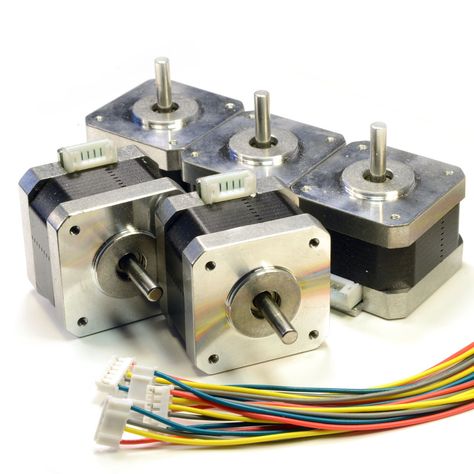

For the people that came for a quick answer, the best stepper motor for your 3D printer is going to be the StepperOnline NEMA 17 Motor. It’s highly rated on Amazon and is the #1 listing for Electric Motor Mounts. Low noise, long lifetime, high performance and no loose steps!

Many have described it as a plug-and-play motor but it does require a bit of know-how, but shouldn’t take too long at all to install. Once you install this stepper motor, any slip problems you’ve had previously should be dealt with easily.

Once you install this stepper motor, any slip problems you’ve had previously should be dealt with easily.

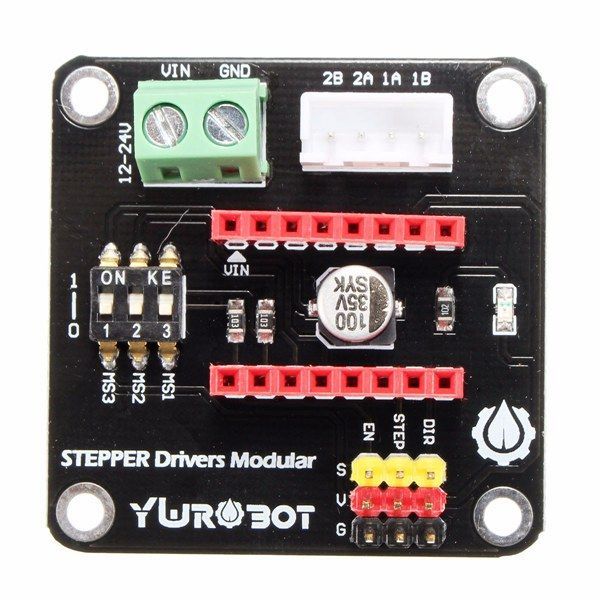

If you are looking for the best stepper motor driver, I’d go for the BIGTREETECH TMC2209 V1.2 Stepper Motor Driver from Amazon. It significantly reduces noise in 3D printers and produces much smoother movements overall.

Now let’s get into what makes a stepper motor so important.

What are the Key Functions of a Stepper Motor?

Under the hood of every 3D printer out there, you’ll find a stepper motor.

The proper definition of a stepper motor is a brushless DC electric motor that divides a full rotation into an equal number of steps. The position of the motor can be ordered to move and hold at certain steps and used at your desired torque and speed.

In simpler terms, stepper motor is what the motherboard uses to communicate to the motors of your 3D printer to make it move around the various axes. It gives the precision, speed and positioning of how things move so it’s a very vital component of a printer.

The reason stepper motors are used in 3D printers is because of their wide range of benefits such as low cost, high torque, simplicity, low maintenance while being highly reliable, and works in just about any environment.

Also on the technical side of things, they are very reliable because there are no contact brushes in the motor, meaning the life of the motor depends solely on the longevity of the bearing.

Stepper motors are also used in medical instruments, engraving machines, textile equipment, packaging machines, CNC machines, robotics and much more.

What Makes a Stepper Motor Better Than Others?

Now it’s important to know that there are many different sizes, styles and characteristics that a stepper motor can give you.

The factors that are important to us are the ones that work best for a 3D printer specifically. Since we need to consider how much work the motor is going to be doing, we take a few things into account.

The main factors that make a stepper motor better than another are:

- Torque rating

- Size of motor

- Step count

Torque Rating

Most stepper motors have a torque rating which roughly translates to how powerful the motor is. Usually, the bigger the size of the motor, the more torque rating you’ll have because they have a better ability to deliver power.

You do have smaller 3D printers such as the Prusa Mini which would require less torque than lets say, an Anycubic Predator Delta Kossel so do keep the size of your printer in mind.

Size of Motor

You have a wide range of sizes for stepper motors, but many can definitely be too strong for a simple 3D printer, which doesn’t require too much performance.

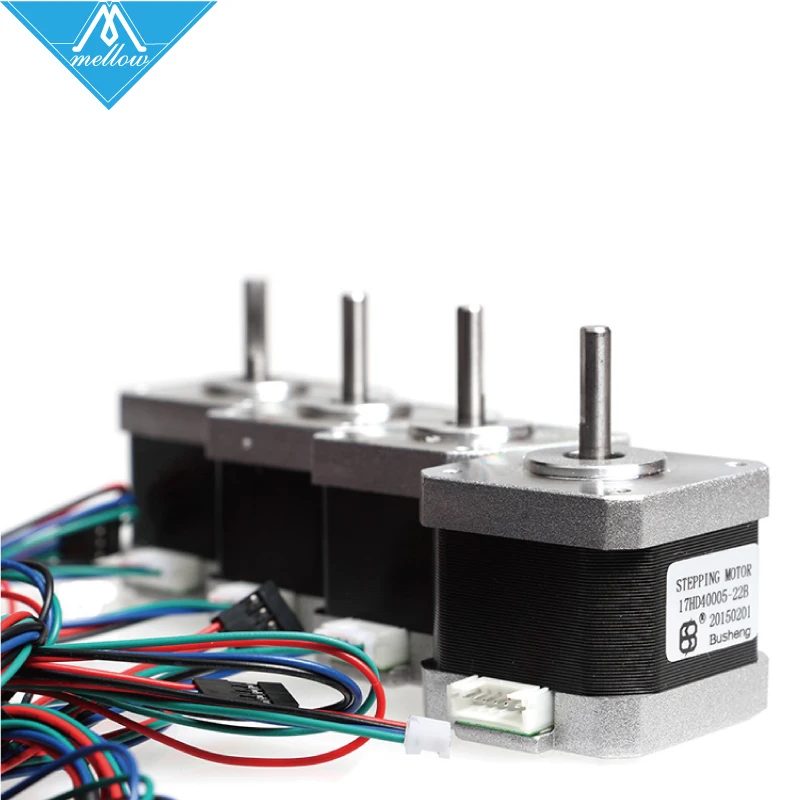

For 3D printers, we generally go for the NEMA 17 (face plate dimensions 1.7 by 1.7 inches) because they are large enough to get the job done.

You would usually use larger NEMA motors in products that require industrial applications or CNC machines. Do keep in mind that NEMA simply describes the size of the motor and not it’s other characteristics. Also, two NEMA 17 motors could be very different and are not necessarily interchangeable.

Do keep in mind that NEMA simply describes the size of the motor and not it’s other characteristics. Also, two NEMA 17 motors could be very different and are not necessarily interchangeable.

Step Count

The step count is what gives us the precision that we need in terms of movement or positioning resolution.

We call it the number of steps per revolution and it can range anywhere from 4 to 400 steps with the common steps counts being 24, 48 and 200. 200 steps per revolution translates to 1.8 degrees per step

For you to get a high resolution, you will have to sacrifice speed and torque. Basically, a high step count motor will have lower RPMs than another motor of a lower step count of comparable size.

If you need higher step rates to turn the motors efficiently, it will require more power so the torque comes in lower and vice versa. So if you want great precision of movement, you will need high step counts therefore reducing the amount of torque you have.

Best Stepper Motors You Can Buy Now

NEMA-17 Stepper Motor

StepperOnline NEMA 17 Motor as recommended at the start of this post is a great choice for a stepper motor. Thousands of happy customers have used this stepper motor with great success with its high quality and flexible customization.

Thousands of happy customers have used this stepper motor with great success with its high quality and flexible customization.

It comes neatly packaged and is a bipolar, 2A motor with a 4-lead and 1M cable/connector. The only downside here are the cables are non-detachable. Do note that the colors of the cables don’t necessarily mean they are a pair.

The way to determine wire pairs is to spin the shaft, then touch two wires together and spin it again. If the shaft was more difficult to spin, those two wires are a pair. Then the other two wires are a pair.

Once you do install this stepper motor, your performance should be second to none and smooth for years to come.

Usongshine NEMA 17 Motor is another choice that is well-liked between 3D printer users and is slightly smaller than the above choice. This high torque stepper motor is made of high quality steel and has great performance.

A few advantages of this stepper motor is its effective thermal conductivity and quality control for each stepper motor that’s sold. You get your stepper motor (38mm), 4pin cable and connector a strong/quiet device to assist you in your 3D printing journey.

You get your stepper motor (38mm), 4pin cable and connector a strong/quiet device to assist you in your 3D printing journey.

The wiring is better set out, with the black and red wires being A+ & B+ then the green and blue wires being A- & B-.

Customer service is also at the forefront of their product so you have good peace of mind after your purchase.

Even at print speeds of 120mm/s+ this stepper driver will deliver amazing performance every time.

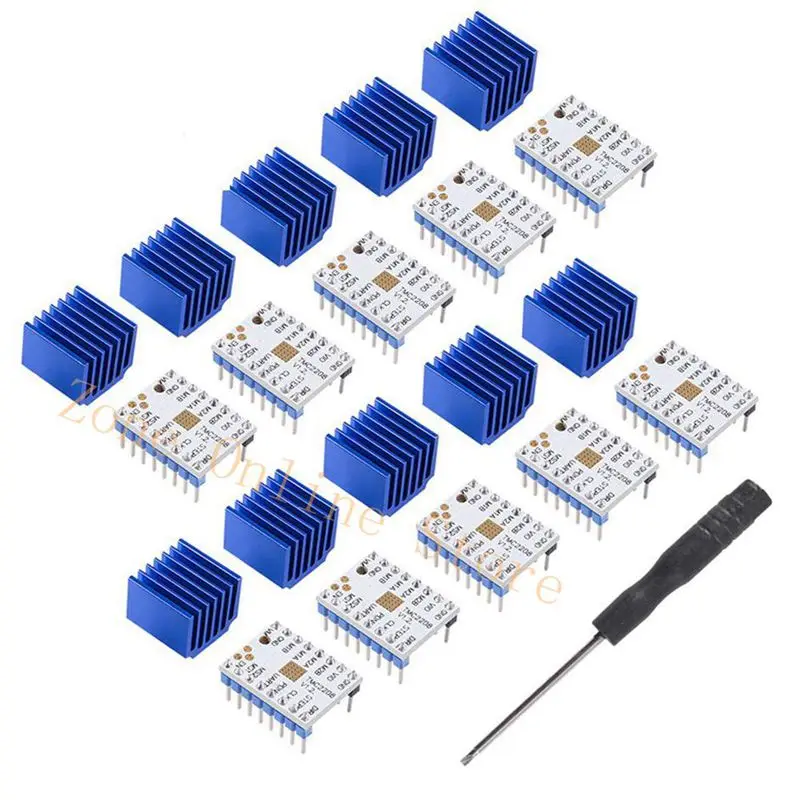

Best Stepper Motor Driver for 3D Printers (Upgrades)

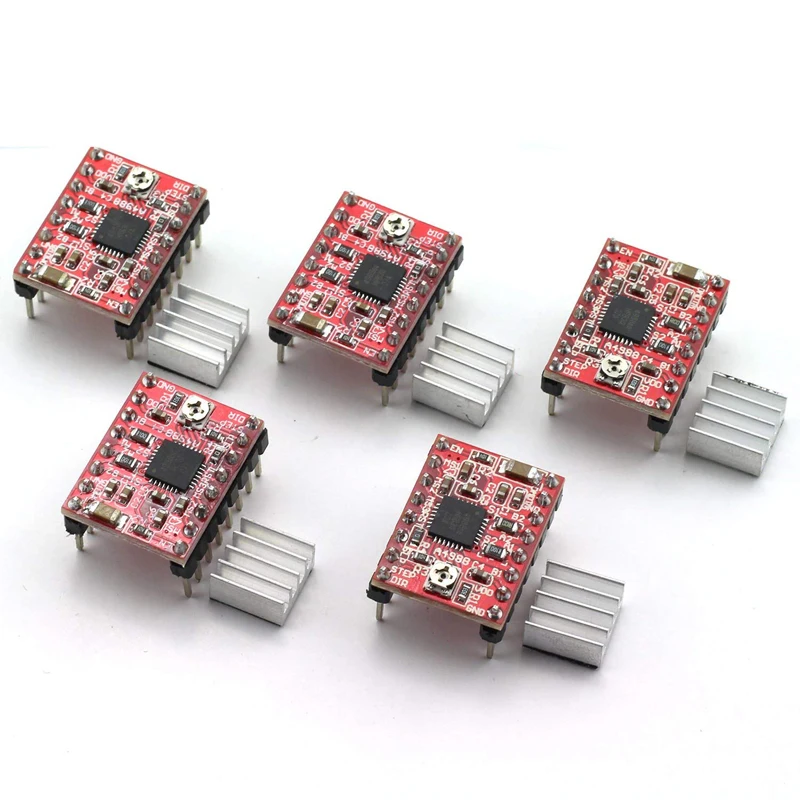

Kingprint TMC2208 V3.0

There are many stepper motor drivers out there you can get for your 3D printer, but you’ll want to get one that works well for your particular machine.

The Kingprint TMC2208 V3.0 Stepper Damper with Heat Sink Driver (4 Pack) from Amazon is a great choice that many users have loved using. One user said he went from using standard drivers to these, and the difference in noise and control was astounding.

Previously, he had a very noisy 3D printer that also had jitters throughout the printing process, but now, the printing is silent and really smooth. They have a good large exposed heatsink area, so the installation is made a little easier.

They have a good large exposed heatsink area, so the installation is made a little easier.

The difference between these and classic 4988 steppers are huge. Another nice feature that has been added to this is the pin headers for UART access, so you don’t have to solder them on yourself.

One user mentioned how she didn’t realize 3D printing could be so silent, making a really dramatic difference in noise. If your 3D printer vibrates a lot, even to the point where your table vibrates like another user, you’ll want to get these installed as soon as possible.

After installing this, the loudest thing on people’s 3D printers are the fans.

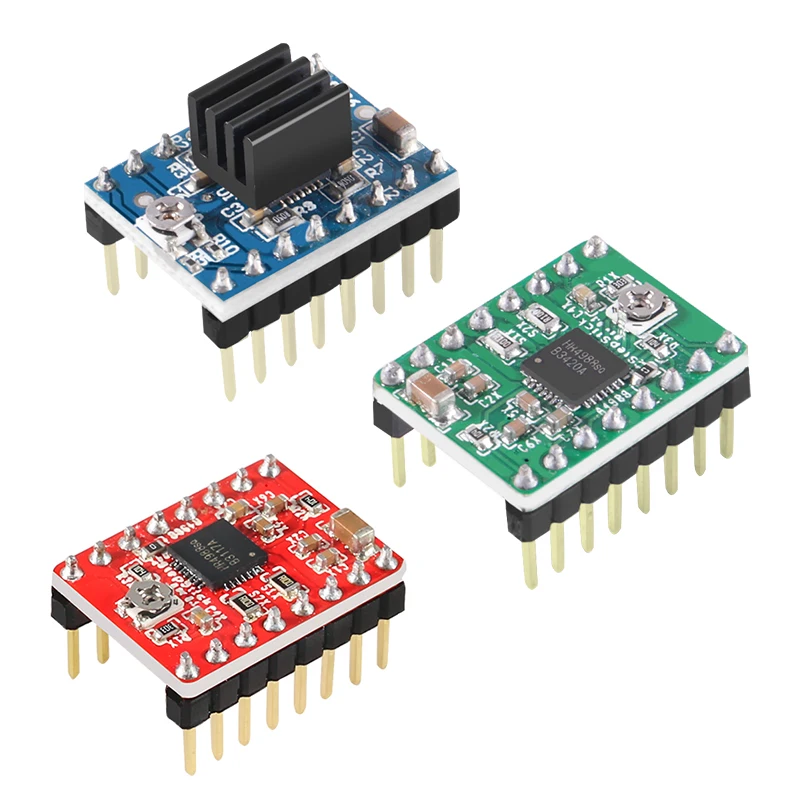

BIGTREETECH TMC2209 V1.2 Stepper Motor Driver

BIGTREETECH is a very well-known 3D printer accessories company that produces really reliable and useful parts. If you are looking for some of the best stepper motor drivers, you’ll want to look into getting yourself the BIGTREETECH TMC2209 V1.2 Stepper Motor Driver from Amazon.

They have a 2.8A peak driver, made for SKR V1.4 Turbo, SKR V1.4, SKR Pro V1.2, SKR V1.3 Motherboard, and comes with 2 pieces.

- The motor makes it very hard to lose steps; ultra-quiet mode

- Has a large thermal pad area to reduce the temperature of the work

- Prevents motor shake

- Supports stall detection

- Supports STEP / DIR and UART mode

The TMC2209 is an upgrade over the TMC2208 in that it has an increased current of 0.6A-0.8A, but also increases the function of stall detection. It has some cool technology within the part such as SpreadCycle4 TM, StealthChop2TM, MicroPlyer TM, StallGuard3TM & CoolStep.

These do things such as give more control, reduce noise, and provide a smoother operation.

One user said they paired these stepper motor drivers with the SKR 1.4 Turbo, along with a new screen and now their 3D printer is smooth and silent. You won’t regret making this great upgrade if you are facing issues of noise and large vibrations.

Answers to questions on stepper

Questions about stepper motors, a type of motor commonly used in 3D printers.

- Stepper motor broken? Faced with extreme under extrusion on my Anycubic i3 Mega, I first cleaned the nozzle and ended up replacing the entire hotend + nozzle. As this didn't help and I didn't see any…

- Confusing Stepper Motor Behavior I'm trying to control stepper motors for a 3D printer with a RAMPS 1.4 screen connected to an Arduino Mega 2560. I've uploaded the Marlin firmware to the board and am currently using Pronterface for…

- Marlin 2.0.x bug fix: how to determine which driver to use when controlling a particular stepper motor? I'm using TriGorilla 2560 and Marlin bugfix 2.0.x and two stepper motors that I use as two z-axes For some reason, both the Z port and the E1 port are controlled by the same...

- A jerk causing vibration and shearing of the Y layer.

.. Bad stepper? This issue is very recent; I'm not sure if this is related to the specific part I'm printing or if something is going wrong with the printer. Until now, I have printed all kinds of details without any…

.. Bad stepper? This issue is very recent; I'm not sure if this is related to the specific part I'm printing or if something is going wrong with the printer. Until now, I have printed all kinds of details without any… - Z-axis does not work only during printing Problem: Z-axis does not work during printing. He tries to work, maybe climbs along the Z axis, but unscrews back. He whines too. But the Z axis WORKS without printing. Doesn't matter…

- Stepper motor only moves one way after reset I'm going through this post by rescuing a problem with my printer. It uses an Arduino 2560 Mega, RAMPS 1.4 and Marlin 1.1.9 which configured it like this: on the RAMPS the Y axis is connected to the pins of…

- Diagnosing Broken Steppers (Ender 3) I upgraded my (already highly modified) Ender 3 to a geared extruder, and instead of flashing, why not switch the phase of the extruder on the cable? I accidentally shorted two coils.

..

.. - Is the Y-stepper very hot on the 4.2.2 board? Is there a known issue where the Y-stepper gets very hot (e.g. 70-80°C) on a Creality 4.2.2 board, but the Y-stepper stays at 40°C on a 4.2.7 board? (two different printers) … nine0008

- Stepper motors on the extruder and Z axis freeze during any fast movements Okay, here is some background to the problem: Symptoms: All retractions on the extruder produce a grinding noise. The rest of the time the extruder extrudes normally. Any fast movement...

- How do I adjust the longer LK5 Pro for smoother printing? I need to print parts that fit together really well on a longer LK5 Pro. However, after printing Benchy, I noticed that everything I print has many flaws. Is there…

- Ender 3 - extruder step skipping I have a problem, most likely very similar to some of the other users' posts: the extruder stepper visually skips a step at times. It rotates rapidly in the direction.

..

.. - Adjust E-step on Ender 3 I felt a little weird extruding and noticed that the gear on the extruder was a little tired. I decided to replace it with a dual drive extruder, but that makes the E-step far from the best...

- Dual Z axis has different speed (out of sync) Z axis has two stepper motors, I am using MKS GEN L V2.1 motherboard with TMC 2209 drivers. My problem is motors are out of sync. How can I make them work together?…

- Is it possible to turn on an external stepper driver without connecting a motor? I haven't used external stepper drivers yet, but I'm using them in a new build. I have an additional stepper drive that will connect to a stepper motor for a rotating attachment. … nine0008

- Closed loop stepper motors I'm thinking of using closed loop stepper motors to prevent step loss and make the machine more accurate. What options (preferably low cost) exist for: …

- Stepper motor current MKS-SBASE V1.

3 Marlin I have an MKS-SBASE V1.3 with integrated stepper motor drivers, but they don't have a physical way to change the current. I know there is a way to update the DRV8825 stepping current through Marlin but I don't…

3 Marlin I have an MKS-SBASE V1.3 with integrated stepper motor drivers, but they don't have a physical way to change the current. I know there is a way to update the DRV8825 stepping current through Marlin but I don't… - Will a 12V stepper motor run at 24V? I have a Prusa MK2.5 that runs on 12V, a Prusa MK3 runs on 24V. I noticed on the Prusa web page they list stepper motors as compatible with both MK2 and MK3,…

- Is there a way to change the direction of the motor using GCode instead of the firmware in Marlin Is there a way to change the direction of the motor using GCode instead of reconfiguring the Marlin firmware? nine0008

- X axis sometimes stops working on my Tronxy X5SA This is related to the circuit of my Tronxy X5SA stepper motor for X axis 3D printer. I had an observation: It has a cooling fan (40X10 24V) which has been having problems lately - it is…

- What is the name of this stepper motor connector? I'm struggling to find the name of the connector I just broke so I can order a new one.

This is a six-pin nylon terminal that connects to the header pin set of the stepper motor...

This is a six-pin nylon terminal that connects to the header pin set of the stepper motor... - The large constant layer is shifting in the x-axis, it looks like something is holding the stepper motor, but it's not I have an Ender 3 with a 32-bit controller board version 4.2. This is a video of what he does while aligning the MBL on the mesh table (9 points): …

- Can I make this extruder work by changing the motor? I have a remote direct drive Flex3Drive extruder that I bought for my Ender 3 (with the original extruder motor) and I'm quite happy with it, except for the terrible...

- Eryone Thinker SE ignores Stopswitch and only moves down I just got an Eryone Thinker SE and went through a lot of trouble getting it to even work. My first major problem was that it would keep trying...

- Ender 3 Pro Extruder Stepper Skipping fragment sounds I have a relatively new Ender 3 Pro except for the addition of a tempered glass table.

So far I've fed about 3kg of PLA filament, all Solutech brands. Towards the end of the last reel I...

So far I've fed about 3kg of PLA filament, all Solutech brands. Towards the end of the last reel I... - How to install TMC2209 on MKS GEN L V2.1 How to install TMC 2209 drivers on MKS GEN L V2.1 board? I don't need a home sensorless, I just want my dual z-axis motors to be cool and in sync. - Thanks.

- Stepper motors get very hot I installed MKS Gen L V2.1 with TMC 2209 drivers on my Creality Ender-3 printer and updated the software to marlin 2, the stepper motors got very hot. What should I do to…

- Does not move in X and Y axes TL;DR I moved the printhead slightly without shutting down the system, and now only the Z-axis stepper motors work. I recently bought an Ender 5 Plus. I managed to make three prints, and then...

- X-axis motor print problem Here's an idea of what's going on. Here is a picture of the progress during the first layer: I'm printing a simple gauge square, and as you can see, my x-axis doesn't move as it should.

I…

I… - Stepper motor for homemade DIY 3D printer I am making a DIY 3D printer. And I need which stepper motor to use. So, I am planning to make the maximum print size 18x18x18 or 20x20x20. I have only one z axis like prusa...

- How can I check that the stepper motors are functioning and compliant? I bought a set of 5 stepper motors from Trianglelab official Aliexpress store. Only one of these engines received any kind of protective bubble wrap for…

- Can closed loop steppers be used for extruders? I am relatively new to 3D printing but have some experience with industrial equipment and test machines. An important part of setting up the printer is setting the speed correctly…

- Anet A8 extruder motor moves back and forth Here's what's going on with my motor. Any suggestions would help. 1. I tried to adjust the trimpot. 2. Rewire the connector to match the connector on the motherboard.

3. All…

3. All… - What are the effects of backlash from the geared stepper motor used to drive the filament extruder? Question background: I'm building an extruder/hotend combo for use with 2.85mm filaments. The extruder I chose is Bondtech's QR extruder which comes with a stepper…

- CR10-S5 Y-axis stepper motor I need to replace this stepper motor with the following product ID: This is the Y axis for the CR10-S5 and is labeled JD42HS60-1500A-02F. What is a stepper motor? nine0008

- Can steppers of different sizes be used for different axles? So basically I have 3 different types of steppers. NEMA 23 stepper motor for Z axis, good quality NEMA 17 for Y axis and even lower quality NEMA 17 for the X axis. …

- Stepper motors make noise after stepping/idling Why, if I run a gcode command that causes the stepper motor to rotate in the reverse direction (any negative movement in the x-axis), after this step it will emit a high-pitched squeal,…

- Are stepper flexible couplings important? How important is it? TL;DR: Regarding my particular printer design, it definitely seems like the company went from flexible couplings to rigid couplings specifically to improve the printer and hinder… -3-pro-extruder-stepper-skipping-with-a-chunk-sound .

After reassembling the extruder, I found that the extruder pitch does not move,…

After reassembling the extruder, I found that the extruder pitch does not move,… - Steppers don't work properly while printing I have a problem with my RepRap 3D printer steppers I'm making. I assembled the car and calibrated the limit switches. when the machine is not typing, the steppers move like...

- Is 12V and 15A enough to make a RAMPS 1.6 Plus and two stepper motors work? I want to place an order with this configuration Arduino MEGA 2650 R3 RAMPS 1.6 Plus 2 TMC2130 2 stepper motors 17hs3401 1 Fan But I'm not sure what voltage and current...

- I can set the voltage and current of the TMC2130 driver manually. But in what cases can some components burn out? I need to know if something burns out in advance, I connect all the circuits: RAMPS 1.6+ Arduino Mega 2560 Power supply 12 V, 15 A 2 TMC2130 V3.0 Stepper motor driver 2 stepper motors…

- How to calculate Vref and X_CURRENT for TMC2130 stepper driver knowing stepper motor rated current? I posted a question about this but I found new information in this video and I want to get to the point.

My motor "nominal current" is 1.4V. I'm assuming this is the maximum current … nine0008

My motor "nominal current" is 1.4V. I'm assuming this is the maximum current … nine0008 - How do I connect a NEMA 17 stepper motor to RAMPS 1.4? I have a NEMA 17 17HS4401 stepper motor and a RAMPS 1.4 driver. Engine outputs: RED A+ BLUE A- GREEN B+ BLACK B- while the RAMPS board has the following: 2B 2A 1A 1B …

- Anet A8 Installing a second extruder without changing the board I'm wondering if it's possible and safe to add a second extruder to my Anet A8 without changing the main board. I was thinking about splitting my Z motor wires to free up the connector...

- X carriage "vibrates" on small segments Following the question I asked here: Replace the X axis motor with another model I have a problem with my new motor. My X axis is now moved by the 17HS3401S motor instead of the motor...

- Why do 3D printers use stepper motors? Stepper motors in 3D printers are used to move and position the extruder.

But why shouldn't printers use servo motors or any other type of motor? Why usually…

But why shouldn't printers use servo motors or any other type of motor? Why usually… - New use for extruder port Is there a way to change the use of the extruder port on the 3D printer motherboard to move the stepper motors (on the y axis) on the 3D printer? This is for a school project and we replaced…

- The extruder makes shimmy, how can I fix it? Printer: Monoprice Maker Select V2 3D printer Problem: Extruder not working Story: My extruder was clogged and I didn't realize it at first and I opened the extruder and pulled out the stuck one...

- Extruder stepper motor problem, what could be wrong? I bought a homemade Reprap Prusa Mendel 3 printer, modified to build with cheaper materials, and immediately after the transaction I had various problems. I fixed most of them, but...

- Using stepper motors with built-in controllers I just pulled stepper motors out of an old laser printer.

They have built-in controllers. I would like to use them without dismantling the controllers. I currently have 4, 6 and 9…

They have built-in controllers. I would like to use them without dismantling the controllers. I currently have 4, 6 and 9…

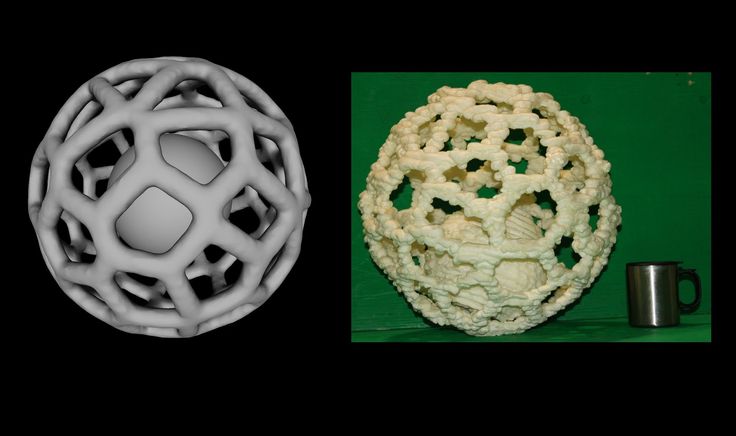

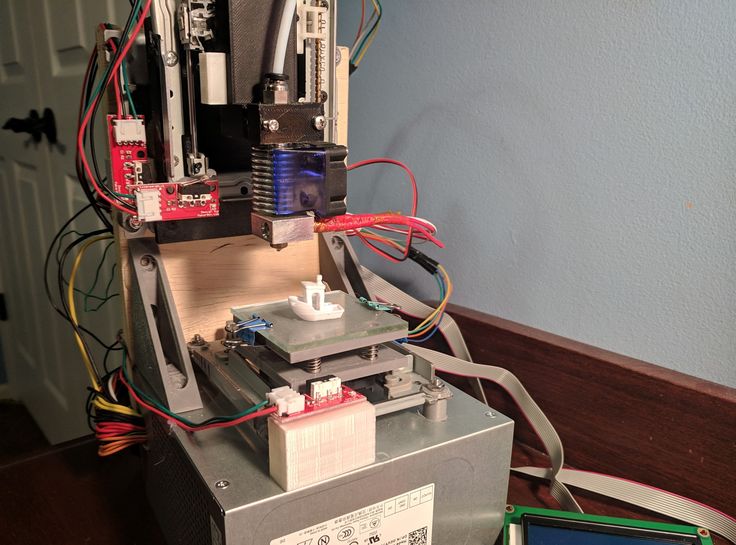

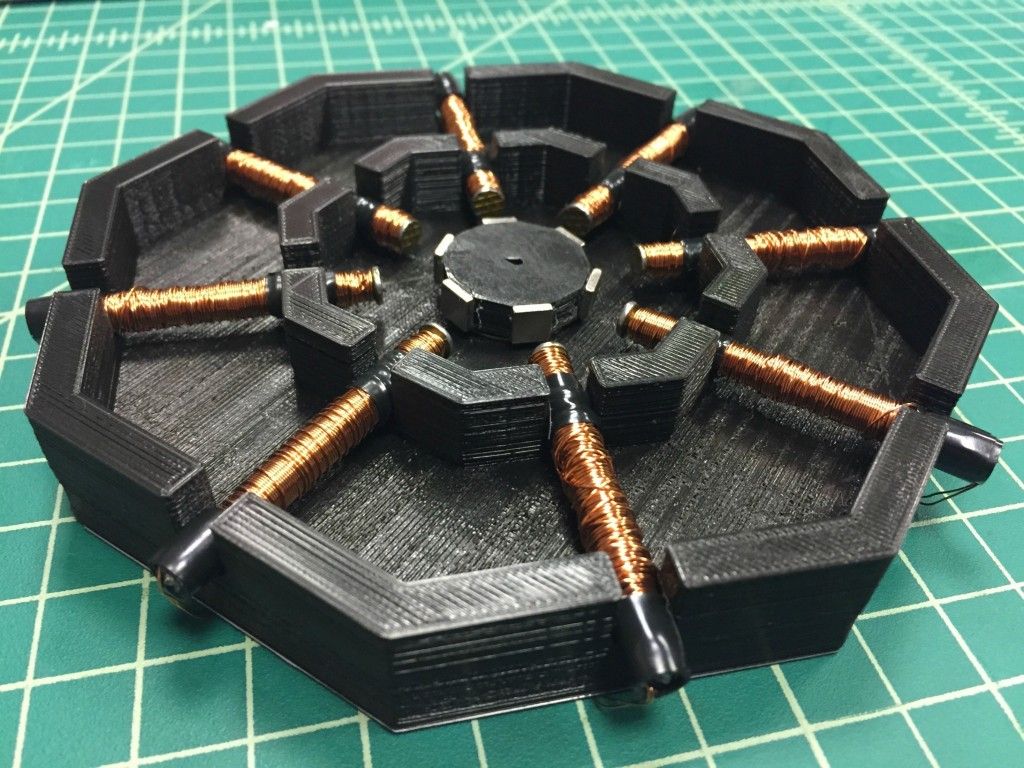

I saw, I plan, I collect a 3d printer from trash and sticks / Sudo Null IT News

I have long wanted to have a 3d printer. A year and a half - exactly, maybe even more. I even learned how to model a little in DesignSpark Mechanical and occasionally drew all sorts of useful and not very things in it, for example, I redid the buttons on my Logitech G27 steering wheel to make it easier to press with gloves: G27 Button Plates. The flight of fancy in the manufacture of all sorts of different things was limited only by the lack of a printer, because printing somewhere else is long, inconvenient and not too cheap. Only one thing stopped me - I needed money for my printer, and for some reason they are always chronically lacking. After much deliberation, I decided to assemble the printer myself, and, given the above circumstance, to make the most of any rubbish lying around at work. nine0210

nine0210

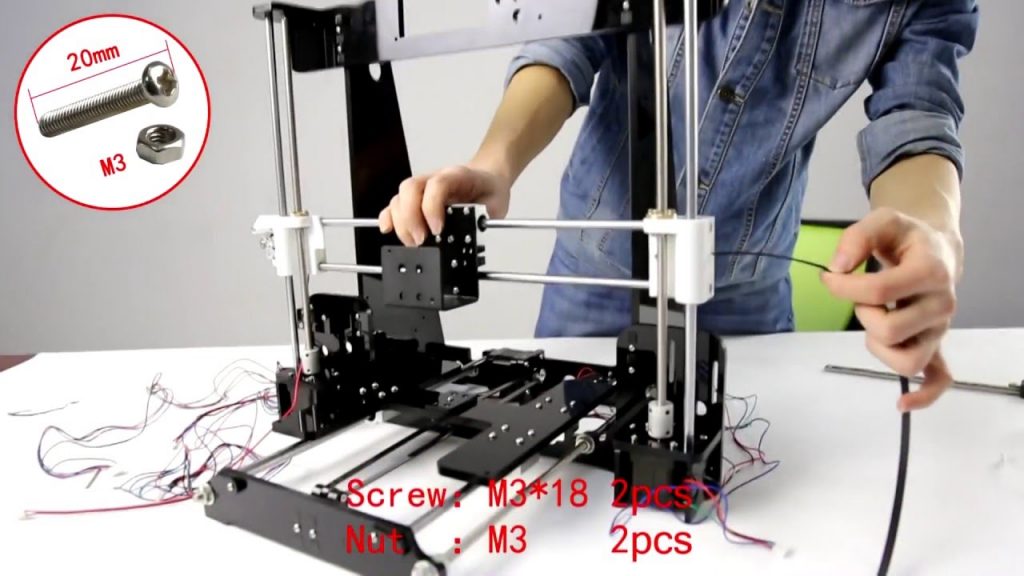

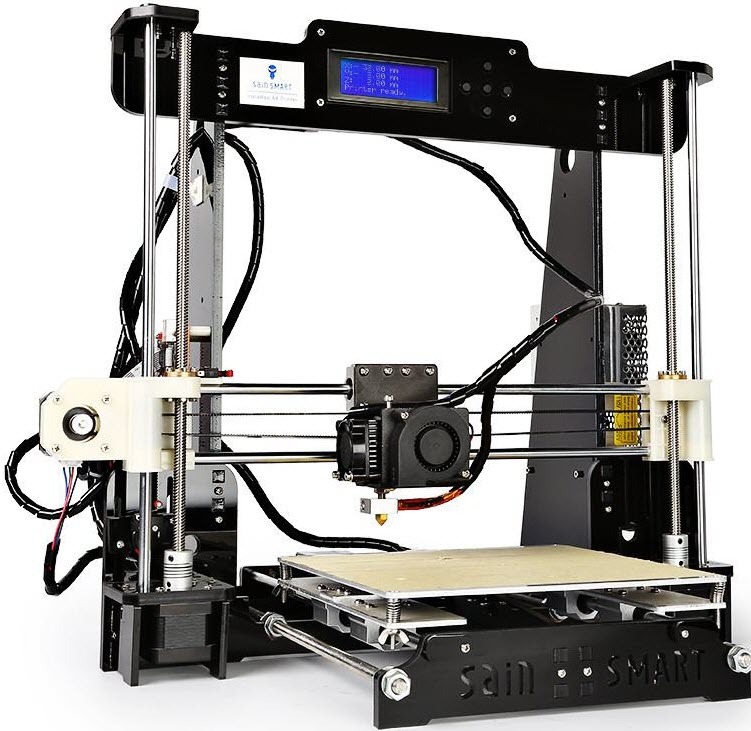

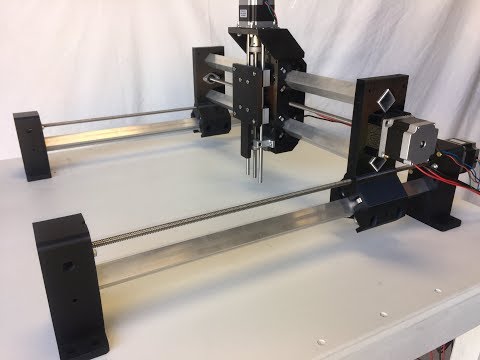

Since before that I had only seen 3D printers from afar and had a very rough idea about them, I began preparations by studying the forums, while the best one I found from Russian speakers on this topic is the section on 3D printing on roboforum.ru (http://roboforum. ru/forum107/). Local elders recommend assembling the first Mendel90 printer from dibond (aluminum composite sheets), by this time I had already begun to assemble Prusa i3 from 12 mm plywood. Looking ahead, I’ll say that this is not the best choice, it was necessary either to order a ready-made aluminum frame, or to do all the same Mendel90, it is much more rigid, which will increase print speed and reduce noise and vibration.

The first step I tried to imagine what exactly I will collect. DS Mechanical was fine for a quick first sketch:

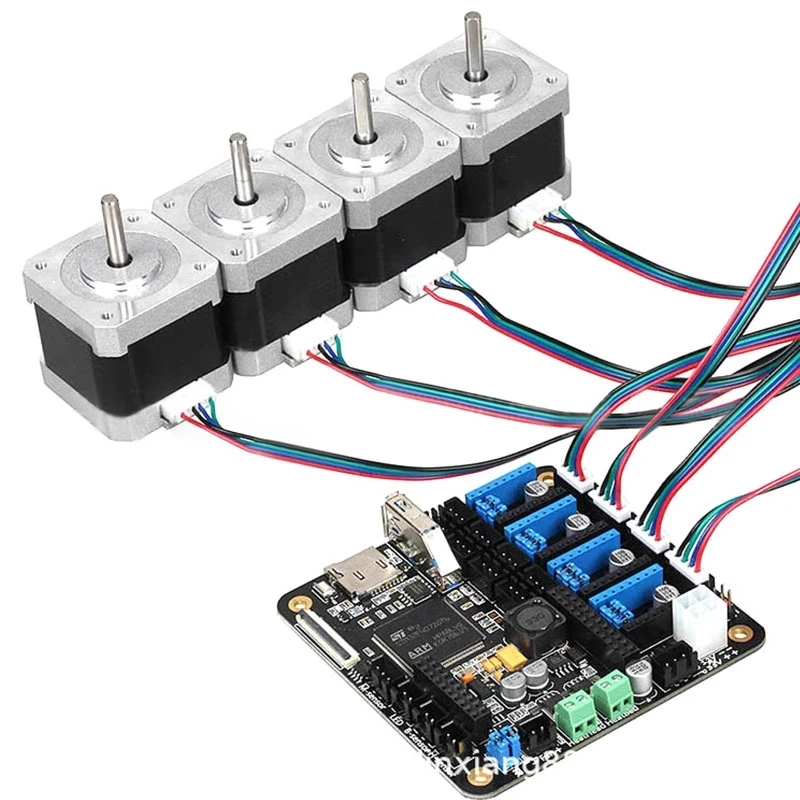

A sample shopping list originally looked like this:

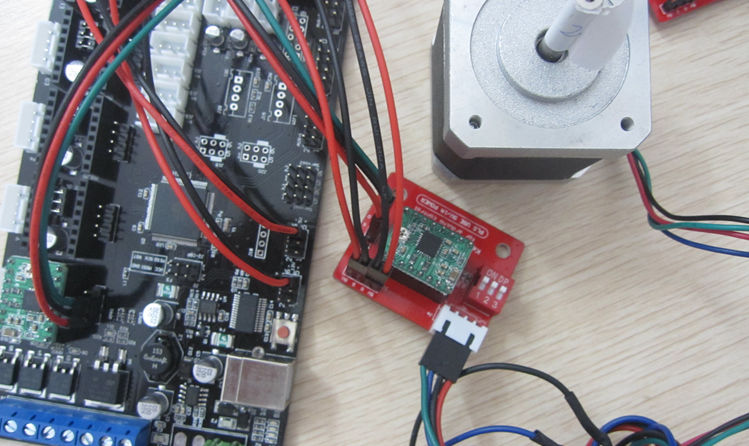

- 3D Printer Controller RAMPS 1.4 + Mega 2560 R3 + 5pcs A4988 For Arduino RepRap + 3 endstops goo.

gl/trkdsM $ 40.00

gl/trkdsM $ 40.00 - 12V 24V 3D Printer Heatbed MK2B RepRap PCB Hot Plate Heat Bed For Prusa & Mendel goo.gl/4nS4ry $ 12.00

- (2)8mm Bearing CNC Aluminum Rail Linear Motion Shaft Support Series Slide SK-8 goo.gl/Dzwxtr $ 4.00

- 12v Extruder for 3D Printer goo.gl/rOonr5 $ 60.00

- SC8UU SCS8UU 8mm Linear Motion Ball Bearing Slide Bushing Linear Shaft — 4 pcs goo.gl/T36aYa $ 13.00

- 8x400mm Outer Diameter Shaft Optical Axis Cylinder Linear Rail Series - 1 goo.gl/XlLMtN $ 5.00

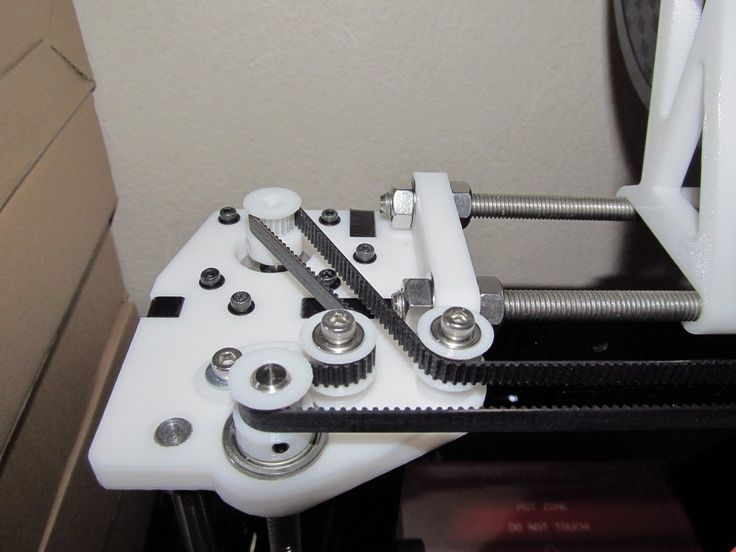

- 2 Meters Of GT2 Belt goo.gl/M2q7VH $7.00 nine0006 GT2 20 tooth Timing Pulley - 2 pcs goo.gl/M2q7VH $ 4.00

- 20T 5mm Bore 6mm GT2 Timing belt Idler Pulley 1 pcs goo.gl/gtNVeE $ 10.00

- 4pcs NEMA 17 1.8° 2.6 kg.cm flat shaft Stepper Motor goo.gl/8KBxcg $ 60.00

- Mounting Bracket for 42mm NEMA17 stepper motor 3 pcs goo.gl/G2eg7A $ 18.00

- 2pcs Coupler 5 x 8 mm for 3D Printer Z Axis NEMA17 Stepper Motor RepRap goo.

gl/PJkouI $ 4.00

gl/PJkouI $ 4.00 - 10pcs Spring for 3D Printer Extruder Heated Bed For Ultimaker Makerbot $ 2.00

- 2 Pcs 8mm Zinc Alloy Pillow Block Bore Inner Diameter Metal Ball Bearing goo.gl/tUYyZp $ 6.50

The printed parts were not supposed to be used at all, the steppers were to be hung on metal corners, the vertical feed was on M8 construction studs, the frame and table were made of 12 mm plywood, the guides were 8 mm with SC8UU plain bearings, clamped into SK-8 brackets (all searched on eBay by name). I made a preliminary list of parts and started looking on ebay for what you can buy at auctions cheaper. While choosing where to buy cheaper - I drew a sheet of plywood:

Sawed by hand, no laser cutting, only electric jigsaw, only hardcore!

While I was processing pieces of wood, I was picking up an old scanner at work, a couple of matrix printers, a card embosser, I managed to get hold of one long 8 mm shaft, two short 10 mm, a steep aluminum rail along which a steel plate with holes rode on wheels. From there, I broke out the fastenings of the print head of the matrix, they had bronze plain bearings. As a result, already at the frame assembly stage, small changes were made to the project and the frame already differed from the first picture:

From there, I broke out the fastenings of the print head of the matrix, they had bronze plain bearings. As a result, already at the frame assembly stage, small changes were made to the project and the frame already differed from the first picture:

One of the 8 mm shafts still had to be ordered, the hope of finding suitable steppers in the printers did not materialize, NEMA 17 still comes across in the matrix, but with insufficient torque and a tightly mounted gear, which I could not remove. Since I ditched the 8mm x guides in favor of the embosser rail, I drastically reduced the number of SC8UU bearings needed, in the final version, three were enough. By the way, the bearings are shit, when I put them on the shaft - balls flew from one to the floor, they slide badly too, they have no lubrication at all from the factory. I ordered extended LM8LUU to replace, I'll see how they behave. In general, the people of the carriage and on rolling bearings collect, they say that it turns out much better. nine0003

nine0003

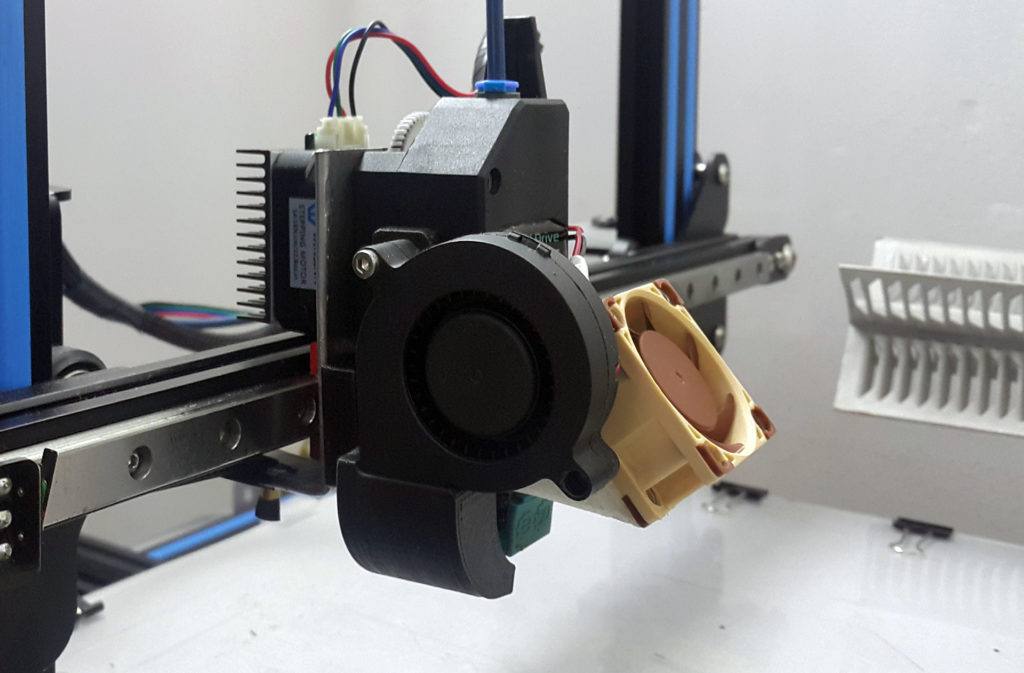

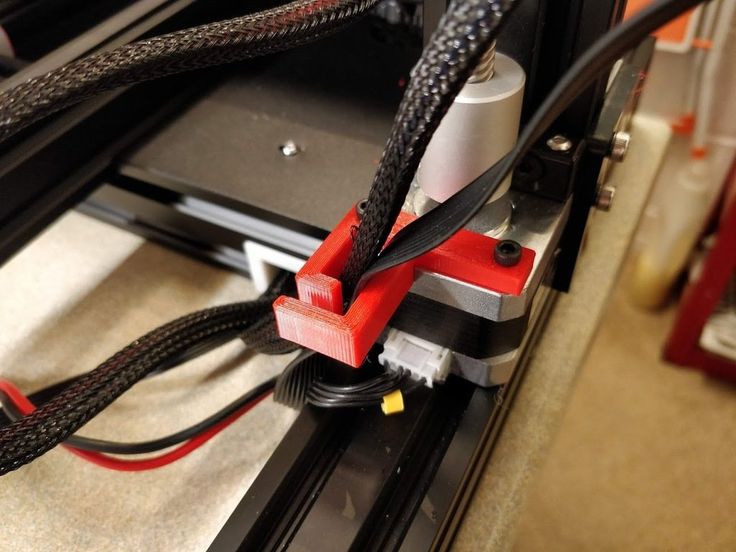

The plywood frame is not too rigid, so I decided to use a Bowden extruder to increase the print accuracy. The lighter the head, the less the frame will swing during acceleration, the higher the print accuracy. I managed to find a small and light hot end, with a very successful fastening at the bottom with a copper plate, and not with a clamp at the top, like most:

frames. In general, it is better to immediately assemble a reinforced version of the frame, such as this one:

Separately, I want to mention the plywood hot table - never do that! I was tormented to put it evenly, 12 mm plywood easily bends when tightening the fastening of the heating element, on the third attempt I managed to achieve relief fluctuations on the printed surface within 1 mm over the entire area, but it was not easy. It’s better to take a ready-made aluminum one, on eBay in the region of $ 30, but how much nerves you will save is beyond words.

The second interesting point is that the parts from the children's iron constructor were very useful, while the printer itself cannot print yet - a lot can be assembled from it. Here, for example, the belt roller along the Y axis:

Here, for example, the belt roller along the Y axis:

Another way to save money is the power supply. The savings, however, are so-so, the power supply for LED strips for 12 volts 30 amps on eBay costs not at all space $ 30. I decided to go my own way again and used a 500W power supply from an HP Proliant server, which delivers the same 30 amps on the 12 volt line, but at the same time it makes quite a noticeable noise. The power is enough, but I'd rather change it to something quieter.

I decided to use the cheapest electronics - RAMPS 1.4 + Mega R3, however, I took more powerful drivers - DRV8825. Radiators were included with them, they were of little use, they warmed up so that it hurt to hold your hand, I hung a 60 mm fan with a diameter of 0.2 A opposite, now they almost do not heat up even without radiators. By the way, I am very surprised that many people advise using microstepping 1/16, I even had skipped steps at 1/8, everything was fine at 1/4. The direct drive extruder works without microstepping at all, it is noisy, but there are no feed problems. Carefully insert drivers into RAMPS !!! Insert it upside down or with an offset - the arduina will rise beautifully and go to the trash, I have both chips burned out :(((

Carefully insert drivers into RAMPS !!! Insert it upside down or with an offset - the arduina will rise beautifully and go to the trash, I have both chips burned out :(((

As a result, after a couple of months of finishing with a hacksaw, jigsaw, needle files, soldering and twisting, the printer looked like this:

I am printing a raft…

There were no problems with the mechanics right away, a box with a thickness of 1 layer 0.2 mm was printed immediately evenly and with the correct dimensions, except that the upper layers settled due to lack of cooling. True, I almost immediately replaced the roller from the designer with a normal bearing with a self-printed mount:

Did I manage to save money? Yes, probably 30 percent of the cost of the Chinese Prusa i3 kit with shipping. Everything works, I print with a layer of 0.2 with good quality, there is a slight wobble along the Z axis, I think it will be possible to remove it by changing the fastening of the studs, perhaps by switching to thinner studs.