3D printer saves life

Saving Lives with 3D Printing

There is never a dull moment in 3D printing. From printing organs to helping prepare doctors for surgeries to trying to print fully formed organs, 3D printing may well enable a leap forward in human life expectancy. This article will recap some of what 3D printing has already done, and the new technology that is one step closer to making healthcare better.

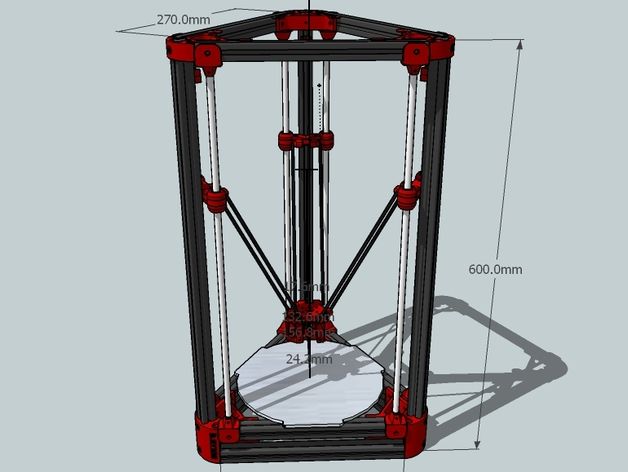

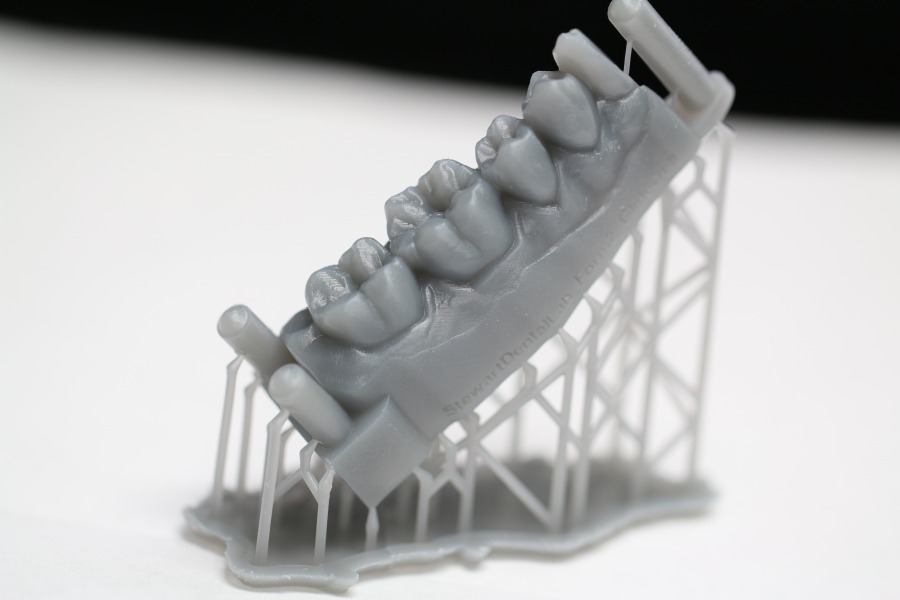

Recently, Sinterit launches a soft thermoplastic polyurethane (TPU) to be used in small selective laser sintering (SLS) 3D printers. At Formnext 2018, the company will show off its soft TPU powder intended for small SLS 3D printers, called Flexa Soft. With a hardness between 40-55 in Shore A type scale, the company thinks this material will help doctors perform mock surgeries.

Some materials are too hard to cut. When doctors are printing organs to prepare for surgery, they are often just a tangible reference. Extrude plastic printers are common, cost-effective, and accessible for most anyone. Unfortunately, an extruded plastic method might not provide material that is easy to cut. However, Sinterit claims this new soft SLS powder is more realistic feeling and cutting. Stratasys also has a BioMimics to print a replica or accurate, functional models for students and doctors to use with training. With a multi-jet process, users can control the durometer and color of the material to print sections of the body with more accurate soft, hard, or colored areas.

Despite this, I’ve only heard from one doctor who’s tried performing surgery on a printed organ, and he described it as lacking. While not knocking the benefits 3D printing is bringing to the medical industry, the doctor says without some type of fiber in the material, it just won’t feel the same as cutting human tissue, muscle, and organs. However, this has not slowed 3D printing in the medical industry.

Cardiologists Use 3D Printing to Save Tiny Lives

Sinterit also published the case of a pediatric cardiac surgery performed on Kordian, a three-week-old infant boy in Poland. It is unclear whether a soft or hard material was used in this case, but today the baby is 18 months old and reportedly doing well. And the doctors say the 3D-printed model did help.

It is unclear whether a soft or hard material was used in this case, but today the baby is 18 months old and reportedly doing well. And the doctors say the 3D-printed model did help.

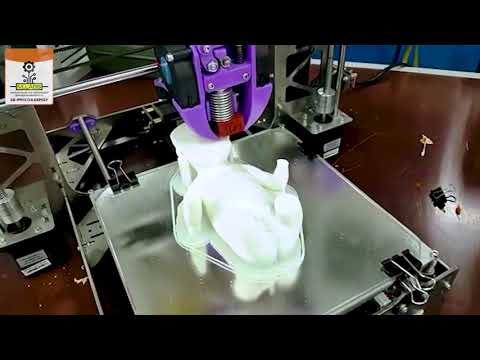

Most doctors can get an idea of what they are up against based on their experience or the popular methods like CT scan and MRI. The real challenge starts when the part is tiny, the disease is rare, or the case is otherwise atypical. In all of those examples, even sub-millimeters can make a life-or-death difference. To increase Kordian’s chance of survival, surgeons decided to 3D print his heart with a laser sintering desktop 3D printer.

Kordian was suffering from the heart disease called interrupted aortic arch. “The problem was that aorta, the biggest vessel that is coming out of the heart was suddenly interrupted,” says Jarosław Meyer-Szary, M.D. from the Department of Pediatric Cardiology and Congenital Heart Defects, University Clinical Center in Gdańsk, Poland.

SLS 3D Printing Offers a Hand

An interrupted aortic arch during surgery could be fatal. Jarosław Meyer-Szary, M.D. from the Department of Pediatric Cardiology and Congenital Heart Defecs, University Clinical Center in Gdańsk, Poland. made the decision to use a life-sized 3D-printed model of Kordian’s heart to study before the surgery. Plastic extrusion processes are normally good for printing parts and organs to show doctors anomalies up close and make a tangible model for the doctor. Unfortunately, for this case this technology wouldn’t work. Doctors had to imitate every little vein and artery that surrounds the heart. Plastic extrusion veins were either too thin to print or, because of the needed supports, could be easily torn apart during post-processing.

Jarosław Meyer-Szary, M.D. from the Department of Pediatric Cardiology and Congenital Heart Defecs, University Clinical Center in Gdańsk, Poland. made the decision to use a life-sized 3D-printed model of Kordian’s heart to study before the surgery. Plastic extrusion processes are normally good for printing parts and organs to show doctors anomalies up close and make a tangible model for the doctor. Unfortunately, for this case this technology wouldn’t work. Doctors had to imitate every little vein and artery that surrounds the heart. Plastic extrusion veins were either too thin to print or, because of the needed supports, could be easily torn apart during post-processing.

SLS technology met the requirements. Such SLS 3D-printed models can be used both for planning the cardiac surgery and interventional procedures, especially in complex and rare congenital heart diseases when the anatomy always varies from patient to patient. It is thus important for the patients—and in this case, parents—to understand the situation and give the permission to operate.

“As a head of a department I have to talk to parents, students and explain sometimes very complicated congenital heart defects to the people who are not doctors, not professionals in this area,” says Joanna Kwiatkowska M.D., Ph.D., from the University Clinical Center.

3D Printing Makes Surgery Safer, Easier, and Shorter

3D-printed medical models help to increase surgeon confidence in planning procedures and assist in the training of medical students. These tangible reproductions of a patient’s specific anatomy result in more accurate, hands-on planning, and enable safer procedures for patients with the potential for smaller incisions, less radiation, and/or less anesthetic.

Research published in The Cleft Palate-Craniofacial Journal has shown this technology can help hospitals save up to 31 minutes in the operating room per case, resulting in cost savings of $1,036 per operation. Implementing 3D printing operations as an in-house service in a hospital can also allow for greater automation, faster turnaround times, and more opportunity for collaboration and iterative work on complex cases.

“This was a difficult surgery, and such a model helped to see the heart more close then on the TV screen,” says Meyer-Szary of Kordian’s case. Today, the boy’s happy face and positive attitude toward new people belie the fact that just over a year ago, his life was in jeopardy.

3D printing can generate implants. This means the implant is generated from the patient’s CT or MRI scan that will provide a custom fit. This eliminates hours of hand-made customization with traditional processes that wouldn’t provide a fit as well as the 3D-printed implant.

Types of Models and the Future of 3D printing

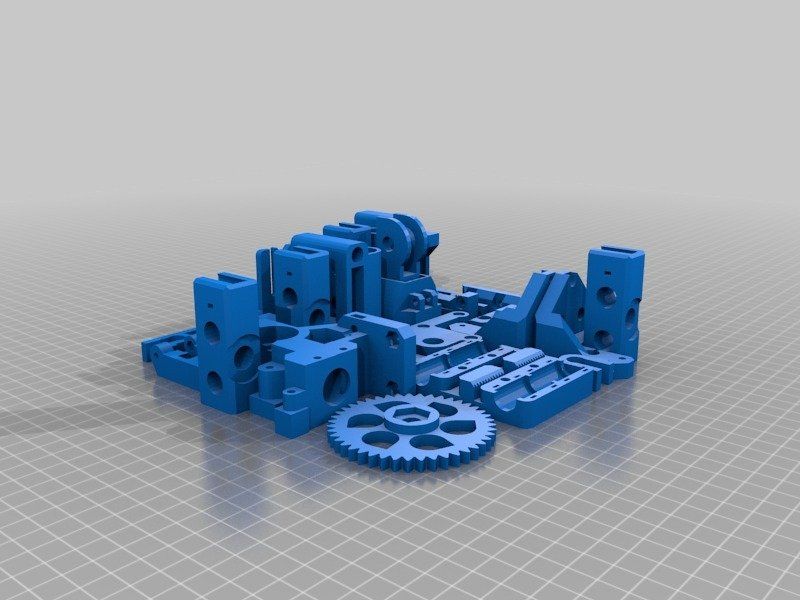

In the U.S. Drs. Bon Ku and Rob Pugliese of Thomas Jefferson University and Hospital in Philadelphia created a new laboratory with Ultimaker 3D printers, a plastic extrusion printer, for doctors to better hone their skills to perform better under pressure. This program also let students and doctors design tools for their own solutions.

While printing tools, organs, and implants to help with surgeries, 3D bioprinting is speeding up drug screenings. Current 3D bioprinting approaches have demonstrated that 3D-printed tissues can be used as disease models for predictive drug screening. There has been an explosion in interest for 3D-printed human tissues; its global market size was estimated at $295 million in 2016, and is expected to grow to $1.8 billion by 2021. These values are based on the applications of 3D-printed tissues, which include disease tissue modeling, toxicology testing, tissue engineering, and skin transplants.

Current 3D bioprinting approaches have demonstrated that 3D-printed tissues can be used as disease models for predictive drug screening. There has been an explosion in interest for 3D-printed human tissues; its global market size was estimated at $295 million in 2016, and is expected to grow to $1.8 billion by 2021. These values are based on the applications of 3D-printed tissues, which include disease tissue modeling, toxicology testing, tissue engineering, and skin transplants.

For example, tumor cells extracted from biopsy samples can be printed and matured in the laboratory to create patient-specific tumor replicas, which can then be used to screen combinations of therapeutic drugs to create individualized cancer treatments. Although there are still several technical challenges, there is a bright future ahead for 3D bioprinting technology.

While 3D bioprinting is speeding up drug screenings to get through the FDA, it might be more difficult for other technologies to pass regulations. There are researchers that are trying to print parts, or entire organs. A Machine Design article by Joyce Laird discusses an instrument built by Tissue Genesis Corp. that allows you to put fat into the device; it sorts out the viable cells so they are ready to be implanted back into a patient, or else used to 3D print new hybrid organs and body parts.

There are researchers that are trying to print parts, or entire organs. A Machine Design article by Joyce Laird discusses an instrument built by Tissue Genesis Corp. that allows you to put fat into the device; it sorts out the viable cells so they are ready to be implanted back into a patient, or else used to 3D print new hybrid organs and body parts.

Researchers at the University of Louisville are already printing layer-by-layer cellular structures, but without a vascular supply, once the organ thickness gets beyond half a millimeter, there is a loss of oxygen or nutrients to the center of that material. This is stated in multiple 3D bioprinting research papers. However, The University of Louisville is currently developing structures that are pre-vascularized to keep these cells alive.

The researchers have developed a way to 3D print capillaries, the smallest blood vessels. By doing so, they are able to make very viable structures, particularly the ventricular walls of the heart, with the vascular supply built into it. One researcher, Stuart Williams, boldly said that he believes they are farther ahead of any other group.

One researcher, Stuart Williams, boldly said that he believes they are farther ahead of any other group.

“We are at the stage of doing implantation of pre-clinical models and are currently planning human clinical trials of pre-vascularized structures for a patch for the human heart,” Williams says. “We are not that far away. This would be used on a part of the heart that had very poor or damaged vascular flow for whatever reason, where a bypass graft or a stent will not solve the problem.

“You have to get to the level of the smallest blood vessels,” he continues. “Using bioprinting to do this is still several years in the future.”

Ukrainian Volunteers Use 3D Printers to Save Lives

The world of magic had Houdini, who pioneered tricks that are still performed today. And data compression has Jacob Ziv.

In 1977, Ziv, working with Abraham Lempel, published the equivalent of Houdini on Magic: a paper in the IEEE Transactions on Information Theory titled “A Universal Algorithm for Sequential Data Compression. " The algorithm described in the paper came to be called LZ77—from the authors' names, in alphabetical order, and the year. LZ77 wasn't the first lossless compression algorithm, but it was the first that could work its magic in a single step.

" The algorithm described in the paper came to be called LZ77—from the authors' names, in alphabetical order, and the year. LZ77 wasn't the first lossless compression algorithm, but it was the first that could work its magic in a single step.

The following year, the two researchers issued a refinement, LZ78. That algorithm became the basis for the Unix compress program used in the early '80s; WinZip and Gzip, born in the early '90s; and the GIF and TIFF image formats. Without these algorithms, we'd likely be mailing large data files on discs instead of sending them across the Internet with a click, buying our music on CDs instead of streaming it, and looking at Facebook feeds that don't have bouncing animated images.

Ziv went on to partner with other researchers on other innovations in compression. It is his full body of work, spanning more than half a century, that earned him the 2021 IEEE Medal of Honor “for fundamental contributions to information theory and data compression technology, and for distinguished research leadership. "

"

Ziv was born in 1931 to Russian immigrants in Tiberias, a city then in British-ruled Palestine and now part of Israel. Electricity and gadgets—and little else—fascinated him as a child. While practicing violin, for example, he came up with a scheme to turn his music stand into a lamp. He also tried to build a Marconi transmitter from metal player-piano parts. When he plugged the contraption in, the entire house went dark. He never did get that transmitter to work.

When the Arab-Israeli War began in 1948, Ziv was in high school. Drafted into the Israel Defense Forces, he served briefly on the front lines until a group of mothers held organized protests, demanding that the youngest soldiers be sent elsewhere. Ziv's reassignment took him to the Israeli Air Force, where he trained as a radar technician. When the war ended, he entered Technion—Israel Institute of Technology to study electrical engineering.

After completing his master's degree in 1955, Ziv returned to the defense world, this time joining Israel's National Defense Research Laboratory (now Rafael Advanced Defense Systems) to develop electronic components for use in missiles and other military systems. The trouble was, Ziv recalls, that none of the engineers in the group, including himself, had more than a basic understanding of electronics. Their electrical engineering education had focused more on power systems.

The trouble was, Ziv recalls, that none of the engineers in the group, including himself, had more than a basic understanding of electronics. Their electrical engineering education had focused more on power systems.

“We had about six people, and we had to teach ourselves," he says. “We would pick a book and then study together, like religious Jews studying the Hebrew Bible. It wasn't enough."

The group's goal was to build a telemetry system using transistors instead of vacuum tubes. They needed not only knowledge, but parts. Ziv contacted Bell Telephone Laboratories and requested a free sample of its transistor; the company sent 100.

“That covered our needs for a few months," he says. “I give myself credit for being the first one in Israel to do something serious with the transistor."

In 1959, Ziv was selected as one of a handful of researchers from Israel's defense lab to study abroad. That program, he says, transformed the evolution of science in Israel. Its organizers didn't steer the selected young engineers and scientists into particular fields. Instead, they let them pursue any type of graduate studies in any Western nation.

Its organizers didn't steer the selected young engineers and scientists into particular fields. Instead, they let them pursue any type of graduate studies in any Western nation.

“In order to run a computer program at the time, you had to use punch cards and I hated them. That is why I didn't go into real computer science."

Ziv planned to continue working in communications, but he was no longer interested in just the hardware. He had recently read Information Theory (Prentice-Hall, 1953), one of the earliest books on the subject, by Stanford Goldman, and he decided to make information theory his focus. And where else would one study information theory but MIT, where Claude Shannon, the field's pioneer, had started out?

Ziv arrived in Cambridge, Mass., in 1960. His Ph.D. research involved a method of determining how to encode and decode messages sent through a noisy channel, minimizing the probability and error while at the same time keeping the decoding simple.

“Information theory is beautiful," he says. “It tells you what is the best that you can ever achieve, and [it] tells you how to approximate the outcome. So if you invest the computational effort, you can know you are approaching the best outcome possible."

Ziv contrasts that certainty with the uncertainty of a deep-learning algorithm. It may be clear that the algorithm is working, but nobody really knows whether it is the best result possible.

While at MIT, Ziv held a part-time job at U.S. defense contractor Melpar, where he worked on error-correcting software. He found this work less beautiful. “In order to run a computer program at the time, you had to use punch cards," he recalls. “And I hated them. That is why I didn't go into real computer science."

Back at the Defense Research Laboratory after two years in the United States, Ziv took charge of the Communications Department. Then in 1970, with several other coworkers, he joined the faculty of Technion.

There he met Abraham Lempel. The two discussed trying to improve lossless data compression.

The state of the art in lossless data compression at the time was Huffman coding. This approach starts by finding sequences of bits in a data file and then sorting them by the frequency with which they appear. Then the encoder builds a dictionary in which the most common sequences are represented by the smallest number of bits. This is the same idea behind Morse code: The most frequent letter in the English language, e, is represented by a single dot, while rarer letters have more complex combinations of dots and dashes.

Huffman coding, while still used today in the MPEG-2 compression format and a lossless form of JPEG, has its drawbacks. It requires two passes through a data file: one to calculate the statistical features of the file, and the second to encode the data. And storing the dictionary along with the encoded data adds to the size of the compressed file.

Ziv and Lempel wondered if they could develop a lossless data-compression algorithm that would work on any kind of data, did not require preprocessing, and would achieve the best compression for that data, a target defined by something known as the Shannon entropy. It was unclear if their goal was even possible. They decided to find out.

It was unclear if their goal was even possible. They decided to find out.

Ziv says he and Lempel were the “perfect match" to tackle this question. “I knew all about information theory and statistics, and Abraham was well equipped in Boolean algebra and computer science."

The two came up with the idea of having the algorithm look for unique sequences of bits at the same time that it's compressing the data, using pointers to refer to previously seen sequences. This approach requires only one pass through the file, so it's faster than Huffman coding.

Ziv explains it this way: “You look at incoming bits to find the longest stretch of bits for which there is a match in the past. Let's say that first incoming bit is a 1. Now, since you have only one bit, you have never seen it in the past, so you have no choice but to transmit it as is."

“But then you get another bit," he continues. “Say that's a 1 as well. So you enter into your dictionary 1-1. Say the next bit is a 0. So in your dictionary you now have 1-1 and also 1-0."

So in your dictionary you now have 1-1 and also 1-0."

Here's where the pointer comes in. The next time that the stream of bits includes a 1-1 or a 1-0, the software doesn't transmit those bits. Instead it sends a pointer to the location where that sequence first appeared, along with the length of the matched sequence. The number of bits that you need for that pointer is very small.

“Information theory is beautiful. It tells you what is the best that you can ever achieve, and (it) tells you how to approximate the outcome."

“It's basically what they used to do in publishing TV Guide," Ziv says. “They would run a synopsis of each program once. If the program appeared more than once, they didn't republish the synopsis. They just said, go back to page x."

Decoding in this way is even simpler, because the decoder doesn't have to identify unique sequences. Instead it finds the locations of the sequences by following the pointers and then replaces each pointer with a copy of the relevant sequence.

The algorithm did everything Ziv and Lempel had set out to do—it proved that universally optimum lossless compression without preprocessing was possible.

“At the time they published their work, the fact that the algorithm was crisp and elegant and was easily implementable with low computational complexity was almost beside the point," says Tsachy Weissman, an electrical engineering professor at Stanford University who specializes in information theory. “It was more about the theoretical result."

Eventually, though, researchers recognized the algorithm's practical implications, Weissman says. “The algorithm itself became really useful when our technologies started dealing with larger file sizes beyond 100,000 or even a million characters."

“Their story is a story about the power of fundamental theoretical research," Weissman adds. “You can establish theoretical results about what should be achievable—and decades later humanity benefits from the implementation of algorithms based on those results. "

"

Ziv and Lempel kept working on the technology, trying to get closer to entropy for small data files. That work led to LZ78. Ziv says LZ78 seems similar to LZ77 but is actually very different, because it anticipates the next bit. “Let's say the first bit is a 1, so you enter in the dictionary two codes, 1-1 and 1-0," he explains. You can imagine these two sequences as the first branches of a tree."

“When the second bit comes," Ziv says, “if it's a 1, you send the pointer to the first code, the 1-1, and if it's 0, you point to the other code, 1-0. And then you extend the dictionary by adding two more possibilities to the selected branch of the tree. As you do that repeatedly, sequences that appear more frequently will grow longer branches."

“It turns out," he says, “that not only was that the optimal [approach], but so simple that it became useful right away."

Jacob Ziv (left) and Abraham Lempel published algorithms for lossless data compression in 1977 and 1978, both in the IEEE Transactions on Information Theory. The methods became known as LZ77 and LZ78 and are still in use today.Photo: Jacob Ziv/Technion

The methods became known as LZ77 and LZ78 and are still in use today.Photo: Jacob Ziv/Technion

While Ziv and Lempel were working on LZ78, they were both on sabbatical from Technion and working at U.S. companies. They knew their development would be commercially useful, and they wanted to patent it.

“I was at Bell Labs," Ziv recalls, “and so I thought the patent should belong to them. But they said that it's not possible to get a patent unless it's a piece of hardware, and they were not interested in trying." (The U.S. Supreme Court didn't open the door to direct patent protection for software until the 1980s.)

However, Lempel's employer, Sperry Rand Corp., was willing to try. It got around the restriction on software patents by building hardware that implemented the algorithm and patenting that device. Sperry Rand followed that first patent with a version adapted by researcher Terry Welch, called the LZW algorithm. It was the LZW variant that spread most widely.

It was the LZW variant that spread most widely.

Ziv regrets not being able to patent LZ78 directly, but, he says, “We enjoyed the fact that [LZW] was very popular. It made us famous, and we also enjoyed the research it led us to."

One concept that followed came to be called Lempel-Ziv complexity, a measure of the number of unique substrings contained in a sequence of bits. The fewer unique substrings, the more a sequence can be compressed.

This measure later came to be used to check the security of encryption codes; if a code is truly random, it cannot be compressed. Lempel-Ziv complexity has also been used to analyze electroencephalograms—recordings of electrical activity in the brain—to determine the depth of anesthesia, to diagnose depression, and for other purposes. Researchers have even applied it to analyze pop lyrics, to determine trends in repetitiveness.

Over his career, Ziv published some 100 peer-reviewed papers. While the 1977 and 1978 papers are the most famous, information theorists that came after Ziv have their own favorites.

For Shlomo Shamai, a distinguished professor at Technion, it's the 1976 paper that introduced the Wyner-Ziv algorithm, a way of characterizing the limits of using supplementary information available to the decoder but not the encoder. That problem emerges, for example, in video applications that take advantage of the fact that the decoder has already deciphered the previous frame and thus it can be used as side information for encoding the next one.

For Vincent Poor, a professor of electrical engineering at Princeton University, it's the 1969 paper describing the Ziv-Zakai bound, a way of knowing whether or not a signal processor is getting the most accurate information possible from a given signal.

Ziv also inspired a number of leading data-compression experts through the classes he taught at Technion until 1985. Weissman, a former student, says Ziv “is deeply passionate about the mathematical beauty of compression as a way to quantify information. Taking a course from him in 1999 had a big part in setting me on the path of my own research. "

"

He wasn't the only one so inspired. “I took a class on information theory from Ziv in 1979, at the beginning of my master's studies," says Shamai. “More than 40 years have passed, and I still remember the course. It made me eager to look at these problems, to do research, and to pursue a Ph.D."

In recent years, glaucoma has taken away most of Ziv's vision. He says that a paper published in IEEE Transactions on Information Theory this January is his last. He is 89.

“I started the paper two and a half years ago, when I still had enough vision to use a computer," he says. “At the end, Yuval Cassuto, a younger faculty member at Technion, finished the project." The paper discusses situations in which large information files need to be transmitted quickly to remote databases.

As Ziv explains it, such a need may arise when a doctor wants to compare a patient's DNA sample to past samples from the same patient, to determine if there has been a mutation, or to a library of DNA, to determine if the patient has a genetic disease. Or a researcher studying a new virus may want to compare its DNA sequence to a DNA database of known viruses.

Or a researcher studying a new virus may want to compare its DNA sequence to a DNA database of known viruses.

“The problem is that the amount of information in a DNA sample is huge," Ziv says, “too much to be sent by a network today in a matter of hours or even, sometimes, in days. If you are, say, trying to identify viruses that are changing very quickly in time, that may be too long."

The approach he and Cassuto describe involves using known sequences that appear commonly in the database to help compress the new data, without first checking for a specific match between the new data and the known sequences.

“I really hope that this research might be used in the future," Ziv says. If his track record is any indication, Cassuto-Ziv—or perhaps CZ21—will add to his legacy.

This article appears in the May 2021 print issue as “Conjurer of Compression."

Related Articles Around the Web

- An introduction to Generative Art: what it is, and how you make it ›

- Creating Art With Code ›

Animals whose lives were saved using a 3D printer

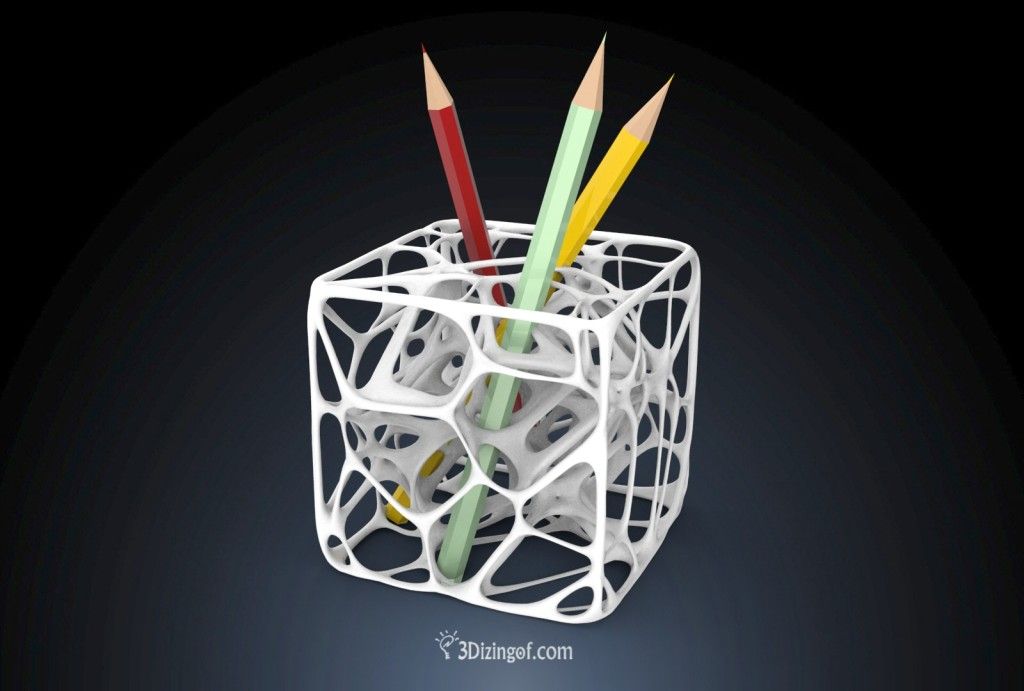

3D printing is a unique technology that allows you to create almost any detail or figure quickly, accurately and from a wide variety of materials: plastic, metal, wax, and so on. As a result, manufacturers do not need to reconfigure machines or "cut" prototypes manually - it is enough to entrust this task to the printer. You can print a variety of things: superhero figures for children, pizza for astronauts, special shoes for a hacker, as well as medical prostheses for people and even animals. nine0003

As a result, manufacturers do not need to reconfigure machines or "cut" prototypes manually - it is enough to entrust this task to the printer. You can print a variety of things: superhero figures for children, pizza for astronauts, special shoes for a hacker, as well as medical prostheses for people and even animals. nine0003

In the 3D printing market, helping our little brothers is not only an act of charity, but also a great way to showcase what new technologies can do. For animals, 3D printers create not only prostheses, but also special splints, splints and other medical devices. When the patient recovers, they can be removed and reused.

New legs for the dog

The front paws of the dog named Derby were underdeveloped from birth, so the dog did not run all his life, but crawled. He would have ended up in a shelter if Tara Anderson, director of 3D Systems, had not adopted him and made this dog the face of an advertising campaign for 3D printing technologies. Finally standing on all fours, Derby quickly learned to run. He liked this activity so much that now he goes on a daily five-kilometer jog with his new owner, Tara's husband. nine0003

Finally standing on all fours, Derby quickly learned to run. He liked this activity so much that now he goes on a daily five-kilometer jog with his new owner, Tara's husband. nine0003

3D Systems has tried more than one type of prosthesis. The first models did not allow the dog to keep his back straight, which increased the load on the spine and could lead to injury in the future. A simple increase in the size of the prosthesis did not solve the problem - such legs interfered with walking more than helped. The developers had to change the design, pick up a new material and create a kind of functional semblance of a knee. The result is prostheses that don't look like dog paws, but that doesn't stop Derby from happily running around with his tongue hanging out. nine0003

Titanium-jawed turtle

Most species of sea turtles are in danger of extinction, so scientists are trying to save every affected animal. In 2014, an adult male sea turtle met the propeller blades of a motor boat, and the meeting ended tragically: the upper and lower jaws of the animal were partially crushed, which made it unable to feed on its own.

Feeding the turtle in the laboratory was also not easy: the animal could hardly swallow small fish and was on the verge of exhaustion. Therefore, specialists from the Center for the Study, Rescue and Rehabilitation of Turtles at the University of Pamukkale in Turkey modeled and 3D printed a titanium prosthesis, which completely replaced the turtle's lost jaw. nine0003

By the way, it is worth noting that metal 3D printing is now considered one of the most promising technologies. Most used to associate 3D printing with plastic products, mainly ABS plastic. Fusion-printed parts made of such plastic are cheap, but not very strong, and most importantly, this method does not allow creating complex products with sufficient accuracy. Plastic is not suitable for creating a turtle jaw.

Most used to associate 3D printing with plastic products, mainly ABS plastic. Fusion-printed parts made of such plastic are cheap, but not very strong, and most importantly, this method does not allow creating complex products with sufficient accuracy. Plastic is not suitable for creating a turtle jaw.

Metal 3D printing, on the other hand, allows you to create stronger and more precise parts with small elements. Developers have worked long and hard to create a 3D printer capable of printing metal of the proper quality. Now metal clay is used for this, consisting of a mixture of metal shavings, an organic binder and water (the last two components burn out during firing, due to which, in fact, a solid metal object is obtained). nine0003

Two in one: a masterpiece of architecture and an artificial house for a hermit crab

Hermit crabs use the empty shells of various mollusks as shelter and regularly change them - either when they grow out of an old shell, or when a stronger and more aggressive competitor kicks the occupant out of the house he occupied. The population of these animals directly depends on the availability of a sufficient number of shells of suitable shapes and sizes nearby. Some hermit crabs don't even molt until they find a new home. nine0003

The population of these animals directly depends on the availability of a sufficient number of shells of suitable shapes and sizes nearby. Some hermit crabs don't even molt until they find a new home. nine0003

Japanese designer Aki Inomata decided to combine art and caring for hermit crabs. Having carefully studied the structure of their favorite shells, Inomata began to print unique houses, identical to the clam shell from the inside. Well, from the outside they look like crystal buildings: cities, mills, churches and famous masterpieces of architecture. Cancers seem to appreciate her concern.

Toucan beak

A group of teenagers in Costa Rica attacked a young toucan. The bird survived the attack but lost the top of its beak. Unfortunately, the injury meant only a slow, painful death for her: without a beak, toucans are not able to forage and eat. The beak is also involved in heat exchange processes. In addition, the female toucan chooses her mate based on the color of her partner's beak, so this injury would prevent the victim of child aggression from reproducing. nine0003

The beak is also involved in heat exchange processes. In addition, the female toucan chooses her mate based on the color of her partner's beak, so this injury would prevent the victim of child aggression from reproducing. nine0003

Activists launched a fundraising campaign to help the bird and made a new beak with the money raised. The required amount - about $ 5,000 - was collected in less than 48 hours.

A similar story happened to another toucan named Tieta. The bird was rescued from an illegal poultry market in Brazil. The female toucan has lost the top of her beak. Most likely, she was injured by smugglers. Experts from three Brazilian universities worked together for three months to design and 3D print a special prosthesis for Tieta. Now the toucan can eat on its own. nine0003

Drake's foot

A duckling named Buttercup was born and lived with a defective foot turned backwards. The situation changed for the better when a young drake ended up in a shelter for abandoned geese and ducks Feathered Angels. Here, veterinarians advised to remove the flawed foot, and the founder of the shelter turned to NovaCopy, a 3D printing company, for help.

The situation changed for the better when a young drake ended up in a shelter for abandoned geese and ducks Feathered Angels. Here, veterinarians advised to remove the flawed foot, and the founder of the shelter turned to NovaCopy, a 3D printing company, for help.

After scanning the left paw of Buttercup's friend, Minnie the duck, NovaCopy specialists made a prosthesis for a drake, followed by several more copies, including a festive New Year's version and a special prosthesis for swimming. By the way, Dandelion has now become a Facebook star and a symbol of the Feathered Angels shelter. nine0003

Tibia for a cat

Vincent the cat was born without tibia, that is, he could not walk. He got new "bionic" paws thanks to Dr. Merry Berg, an employee of the State University of Iowa.

Merry couldn't figure out how to help Vincent for a long time until she got colleagues from Biomedtrix involved in the project. As a result of the joint work, titanium prostheses were created and printed. Conventional prostheses are extensions of a limb, but Vincent had no hind legs at all, so the printed parts were implanted directly into the cat's bones so that the bone could later grow around the metal base. According to the treatment plan, gradually the prostheses will be made longer and longer until they are equal to the front paws. Now the cat is more than three years old, and he is doing well. nine0003

Vincent's experiment with titanium prostheses is considered unique, and the experience will be very useful in the treatment of animals suffering from similar diseases.

Wheels for disabled dogs

Chihuahua TurboRu's touching story changed the life of not one dog, but many animals at once. Like many other dogs, this puppy was born with underdeveloped front paws. The owners did not dare to euthanize the baby: they made several home-made devices on wheels that support his chest and help the puppy move around. They posted their research on the Web, and the TurboRu story caused a great resonance. nine0003

Among the sympathizers were representatives of the 3dyn company, who made a special gift for the dog - a special cart on wheels. TurboRu quickly got used to the new device and now runs along the street on a par with his peers.

TurboRu was one of the first puppies to get 3D printed wheels, but not the last.![]() Similar devices are now being created for many disabled dogs. One such lucky person was Narcissus, who was found as a puppy in a box in the middle of the street. The owners wanted to get rid of the dog with underdeveloped forepaws and simply threw it away. nine0003

Similar devices are now being created for many disabled dogs. One such lucky person was Narcissus, who was found as a puppy in a box in the middle of the street. The owners wanted to get rid of the dog with underdeveloped forepaws and simply threw it away. nine0003

A passer-by took pity and adopted the puppy, and then turned to the SFSPCA charity organization, where specialists made special wheels for little Narcissus. In the video below, you can see how the first acquaintance of the puppy with this device went.

Every year 3D printing becomes more and more accessible, and although 3D printers are unlikely to appear in every home, we do not have to go far to print a toy or even a paw for a pet - it will be enough just to download model from the Internet and walk to the nearest workshop. By then, these technologies will become even more interesting, gain even more possibilities - and who knows what else we will be able to print on such printers. nine0003

By then, these technologies will become even more interesting, gain even more possibilities - and who knows what else we will be able to print on such printers. nine0003

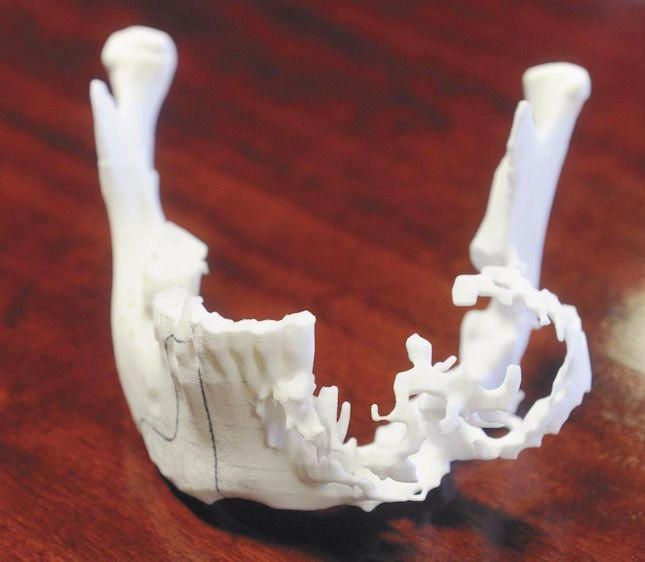

Scientists 3D-printed a skull and saved a child's life

Any surgical operation requires extreme caution from doctors - one wrong move can cause the patient's death. You have to be especially careful with newborn children, because their bones are not formed, and their internal organs are very poorly protected from external influences. In February 2022, in one of the maternity hospitals in the Polish city of Rzeszow, a girl was born, the fifth lobe of the bone part of the head of which was not formed. Due to the fact that one of the areas of the child's skull was practically absent, her brain tissue remained partially exposed - if damaged, the girl was at risk of acquiring many health problems. Fortunately, the company Sygnis came to the rescue, which printed on a 3D printer an exact copy of her skull based on photographs. The layout literally saved the girl's life, but how? Is the skull of a child half made of plastic? nine0003

The layout literally saved the girl's life, but how? Is the skull of a child half made of plastic? nine0003

A 3D-printed skull saved the life of a newborn girl

A child with an underdeveloped skull

A newborn girl from Poland did not have an occipital bone. It is located below, on the back of the head, and is needed to protect many parts of the brain - for example, under the occipital bone is the cerebellum. This part of the brain is responsible for coordinating body movements, regulating balance and muscle tone. The volume of the cerebellum is only 10% of the volume of the entire brain, but it contains most of all cells of the nervous system. nine0003

Location of the bones of the skull

Based on the above, it turns out that a girl without an occipital bone could easily damage the cerebellum and in the future have problems with coordination of movements. The defect was not diagnosed during the mother's pregnancy - they learned about it only closer to the birth. The child was born, but was in a very dangerous position, so he was quickly transferred to a hospital in Krakow.

The child was born, but was in a very dangerous position, so he was quickly transferred to a hospital in Krakow.

Related article: Scientists have found that appetite is controlled by the cerebellum

3D printed skull

Polish hospital specialists already knew that bone reconstruction was needed to save the girl's life. As noted at the beginning of the article, operations on children require meticulous care - surgeons needed to know exactly what shape the patient's brain has to within millimeters. Pictures cannot provide such accurate data, so the specialists turned to Sygnis, which has been engaged in 3D printing for a long time. It is reported that the firm has abandoned all its activities to make a model of the girl's head and help doctors save her life. nine0003

3D-printed skull helped save girl's life

Sygnis said they started printing as soon as they received scan data from a newborn baby's head. To avoid mistakes, they created two models at once on two 3D printers using two different materials. The best option turned out to be polyamide, which has great strength and is not damaged by contact with surgical instruments. All this took them only 24 hours - speed in this matter was very important, because in order to save the girl's life, the operation had to be carried out as soon as possible. nine0003

The best option turned out to be polyamide, which has great strength and is not damaged by contact with surgical instruments. All this took them only 24 hours - speed in this matter was very important, because in order to save the girl's life, the operation had to be carried out as soon as possible. nine0003

Surgeons have inserted a 3D-printed eye for the first time in history. Here are the details

How doctors saved a girl's life

A 3D printed model of the girl's skull showed the surgeons what they would have to deal with. Needless to say, she did not become part of the child's head, because with age, her skull will grow. On the created model, the surgeons conducted preoperative testing and, so to speak, "knocked their hand." Thanks to this training, the specialists successfully performed a bone reconstruction operation. More than six months have already passed since then, and it is known that everything is fine with the girl. This is another case where technology was able to save a person's life.