Goengineer 3d printing lab

3D Printing Services | GoEngineer

Order custom 3D Printed Prototypes and Parts

800-688-3234

Previous Next

Custom 3D PRINTED PARTS

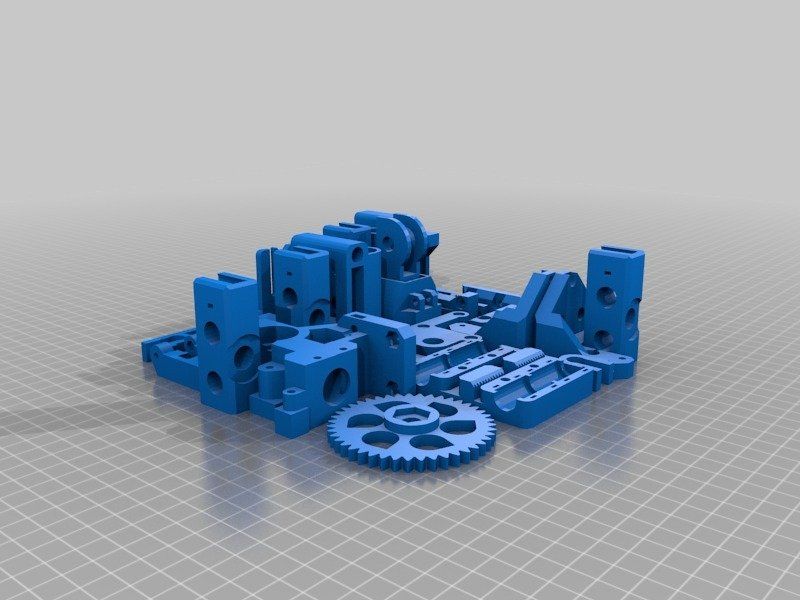

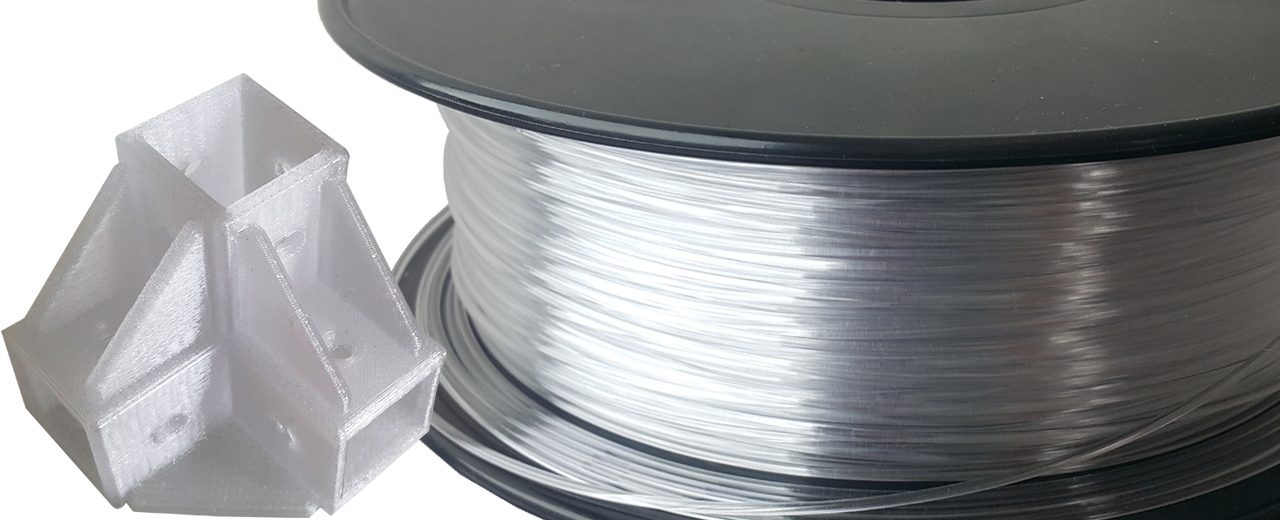

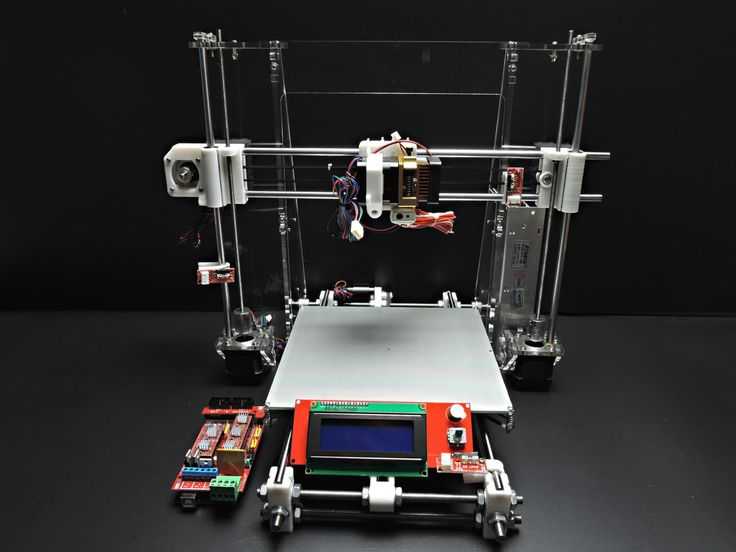

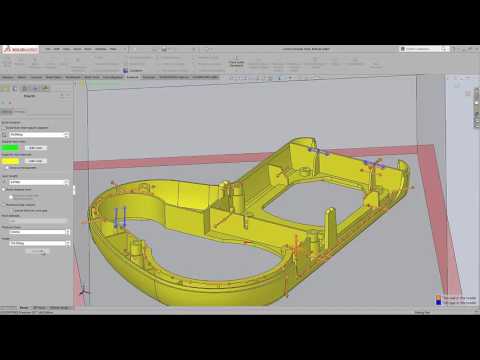

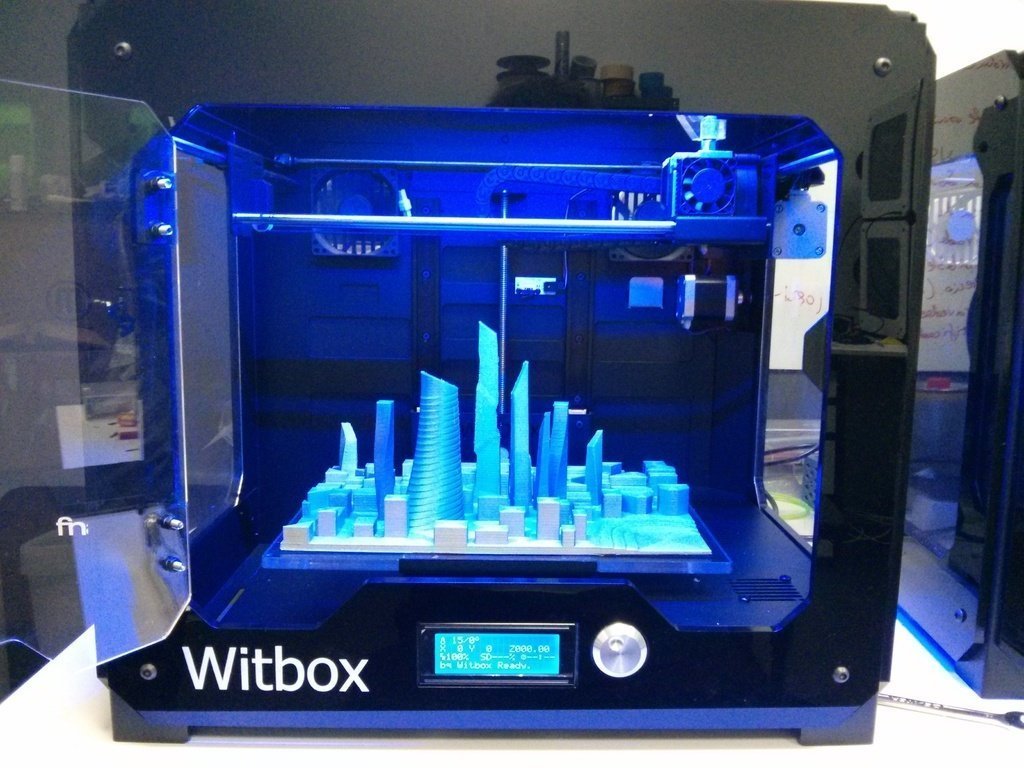

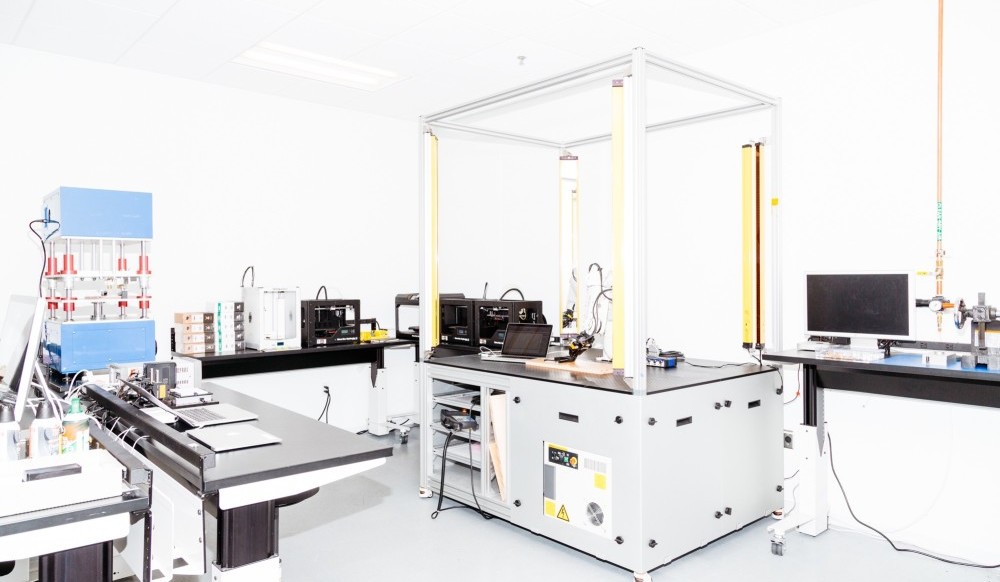

Whether you need a quick prototype for testing or a full-functioning production part, GoEngineer’s 3D printing services team can help you. Our 3D printing labs located throughout the U.S. contain the latest additive manufacturing technologies for printing FDM, PolyJet, SLA, and metal materials.

Request a Quote for 3D Printing Services

$250 minimum order*

10,000+ Parts

The GoEngineer 3D printing service bureau has been printing professional custom parts since 1999 and produces hundreds of parts per month for businesses throughout the U.S.

24/7 PrintingStratasys 3D printers can handle large print jobs for days or weeks at a time. No matter the size of your order, we can ensure the job will get done by your deadline.

No matter the size of your order, we can ensure the job will get done by your deadline.

Our 3D Printing labs are equipped with the latest technology in Additive Manufacturing. We can produce parts in FDM, PolyJet, SLA and Metal technologies, with over 50+ materials.

Full PAntoneEnsure your prototype looks and feels as realistic as possible with Stratasys 3D printing technology. Get access to full-pantone palette options to bring your prototype to life.

Most 3D printed parts can be same business day. However, complexities, multi-materials and size could push your part out a couple days. Please reach out to us directly for a more detailed timeline for your order. 1-800-688-3234

Yes, we can accomodate rush orders and expedited delivery for your custom parts. Reach out today and let us help map out your needs as quickly as possible. 1-800-688-3234

We can produce parts in FDM, PolyJet, SLA and Metal technologies. With access to over 50+ different material options

With access to over 50+ different material options

Yes, for custom orders we do require a minimum of $250.

Native CAD, STL, 3MF, STEP and IGES.

Request More Information on GoEngineer 3D Printing Services

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

Online Store

FREE SOLIDWORKS Tools

Enjoy this collection of small ‘macros’ that were tailored to help our customers. These free SOLIDWORKS tools are for you to use, review, and modify. SOLIDWORKS Automation Tools

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing Services

3D Printing Services

3D Printing - Sales, Service and Support

SEE CURRENT 3D PRINTING PROMOTIONS

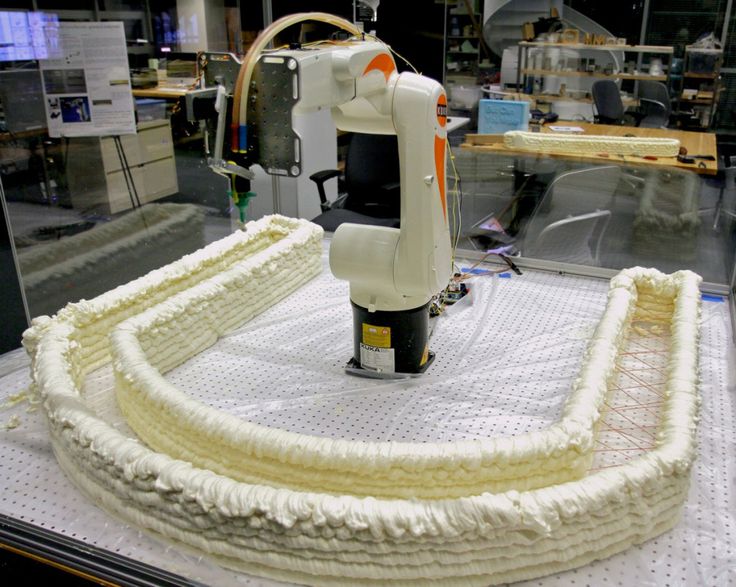

ADDITIVE MANUFACTURING Solutions and Technology

800-688-3234

Which 3D Printing Technology is Right For You?

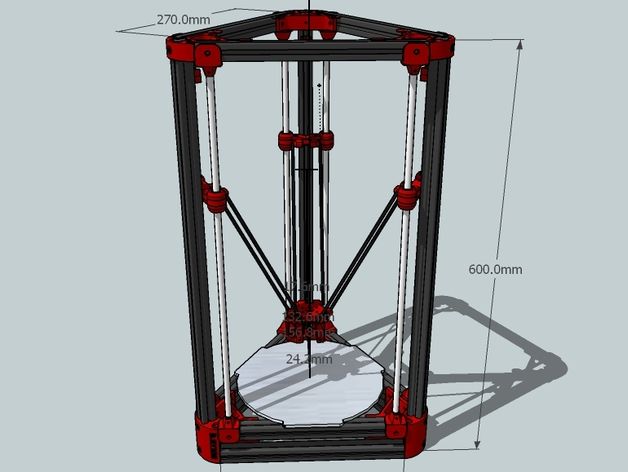

FDM

- Durable Parts

- Large Build Envelopes

- Prototype and Test

- Uninterrupted Builds FDM 3D Printers

POLYJET

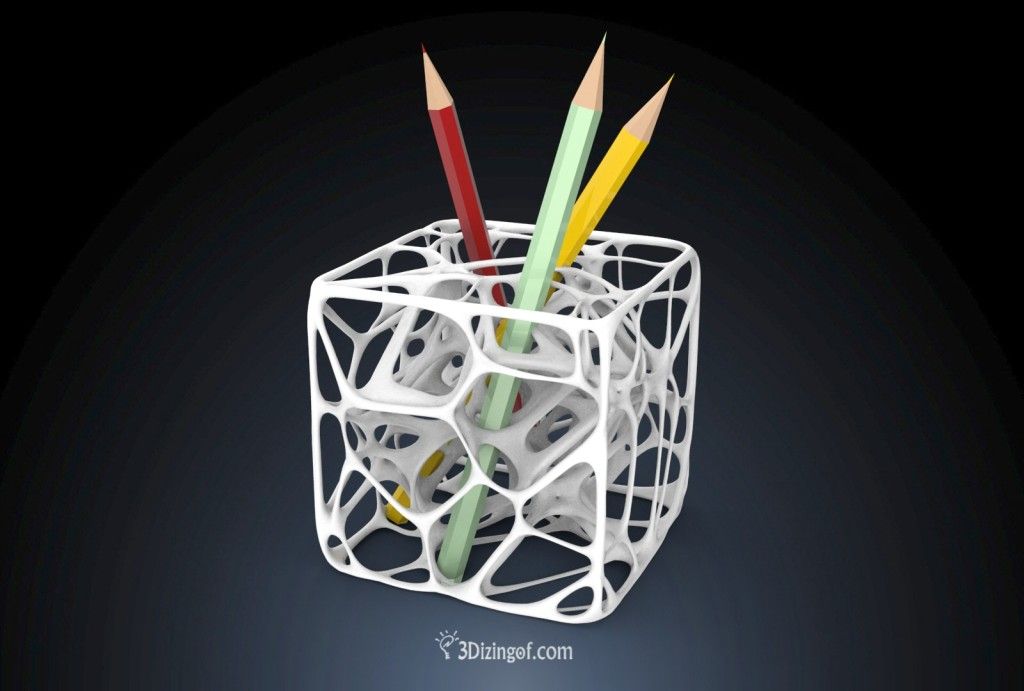

- Realistic Models

- Multi-Material Prints

- Full-Color Pantone

- High Run Quantities PolyJet 3D Printers

METAL

- SupportFree

- Production Level Parts

- Multiple Metal Materials

- Print Low Angles Metal 3D Printers

P3

- Programmable PhotoPolymerization

- High Output Resin

- High Performance Materials

- Repeatability Production P3 Printers

SAF

- Selective Absorption Fusion

- High Demand Output

- Accuracy and Repeatability

- Cut Hidden Costs Production SAF Printers

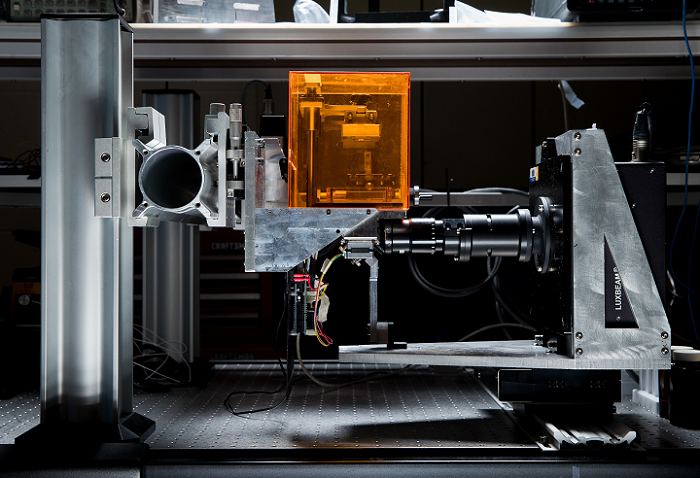

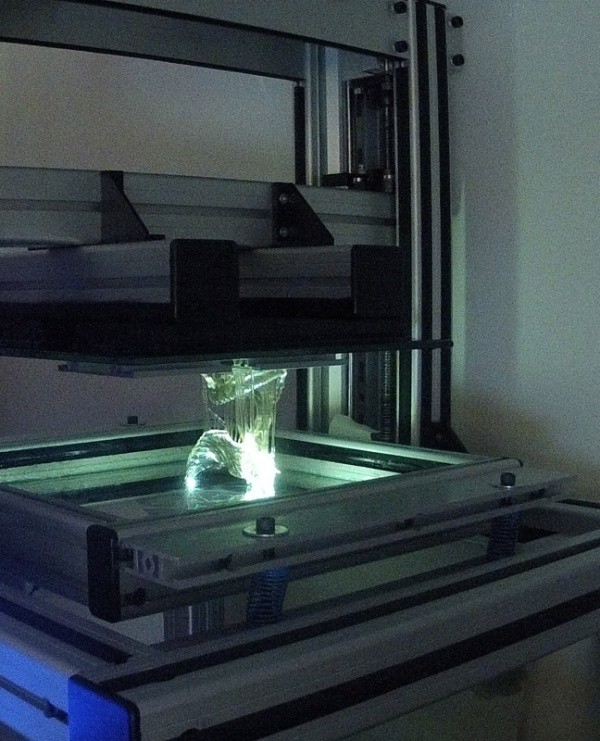

Stereolithography (SL)

- Open-source Material Capability

- UV curing oven

- High Quality Parts

- 3-axis Dynamic Scanning SL 3D Printers

FDM

– Durable Parts

– Large Build Envelopes

– Prototype and Test

– Uninterrupted Build Times

FDM 3D Printers

POLYJET

– Realistic Medical Models

– Multi-Material Prints

– Full-Color Pantone

– High Run Quantities

PolyJet 3D Printers

METAL

– SupportFree

– Production Level Parts

–

Multiple Metal Materials

– Print Low Angles

Metal 3D Printers

Stereolithography

– Scalable Fabrication

– P

recision Parts

–

Open-source Material

– U

nprecedented Speeds

Stereolithography 3D Printers

DON'T MISS THese UPCOMING WEBINARs!

Leveraging Additive Manufacturing on the Factory Floor - Part 1

February 17, 2021, 11:00 AM - 12:00 PM, CDT

In this two-part webinar series, we talk about how 3D printing can help you produce more, increase the quality, and reduce the cost of your jigs, fixtures, and manufacturing aids. We will also discuss a few customer success stories, as well as the Stratasys printer and material portfolio.

We will also discuss a few customer success stories, as well as the Stratasys printer and material portfolio.

Leveraging Additive Manufacturing on the Factory Floor - Part 2

February 24, 2021, 11:00 AM - 12:00 PM, CDT

In this two-part webinar series, we talk about how 3D printing can help you produce more, increase the quality, and reduce the cost of your jigs, fixtures, and manufacturing aids. We will also discuss a few customer success stories, as well as the Stratasys printer and material portfolio.

3D Printing Services

AWARD WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

LEARN MORE

ADDITIVE MANUFACTURING TRAINING

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

LEARN MORE

3D Print and Part Design

No matter your size, quantity or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing and Part Design Services to help your organization produce the best parts and prototypes available on the market.

LEARN MORE

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

Online Store

FREE SOLIDWORKS Tools

Enjoy this collection of small ‘macros’ that were tailored to help our customers. These free SOLIDWORKS tools are for you to use, review, and modify. SOLIDWORKS Automation Tools

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing Services

3D Printing Services

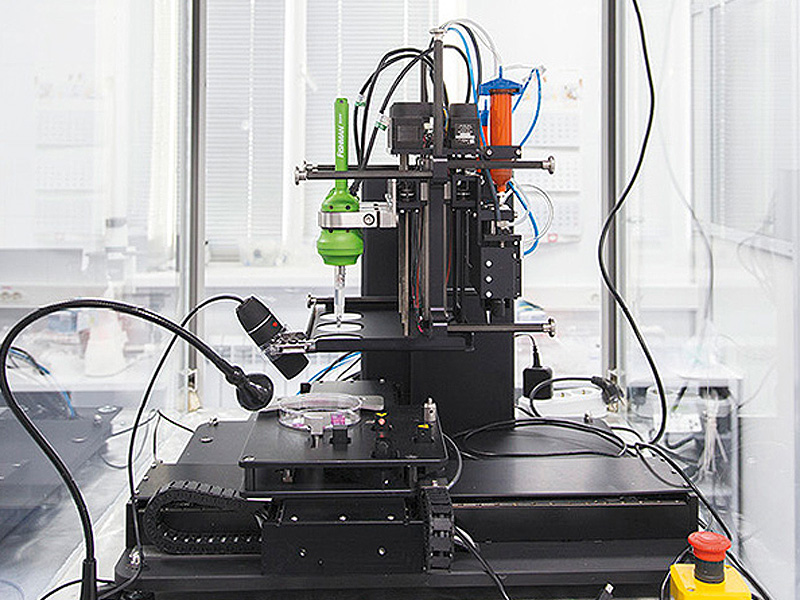

Application of 3D printers in medicine | 3D printing news

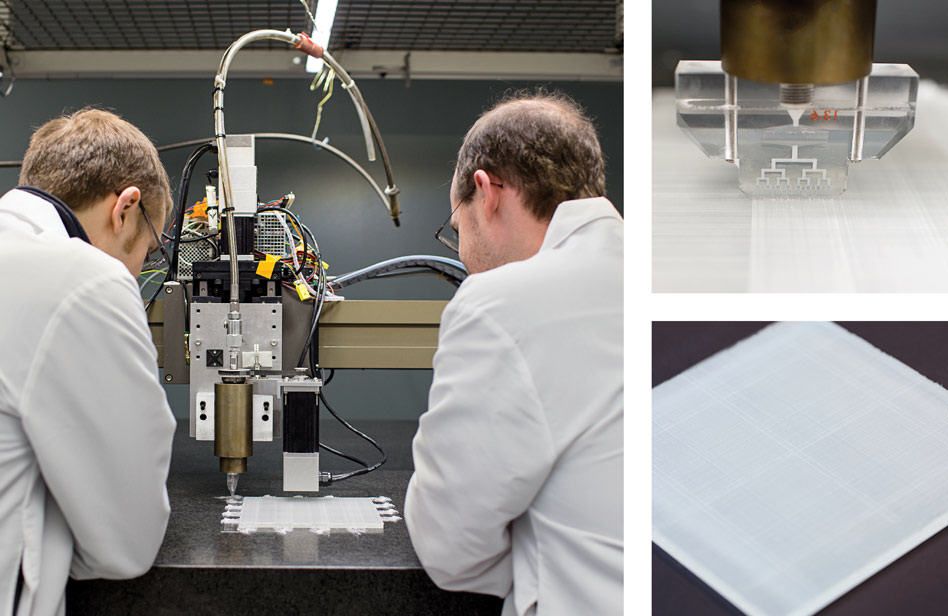

The development of technology forces us to analyze the tools we use every day again and again. Thus, classical manufacturing techniques are increasingly being replaced by automated production systems that optimize time and material costs.

It is the norm in dental laboratories to save time down to the second for maximum productivity. In this regard, a constant search for the best solutions for optimizing labor is required, the introduction of innovations, one of which was the use of CAD / CAM technology and milling machines. In a short period of time, this technology has become the standard for the manufacture of orthopedic structures with a high quality of the end result, which ensured its widespread popularity. nine0005 Today, we are on the verge of a new technological revolution, which, like the introduction of the assembly line at the beginning of the last century and the widespread use of personal computers at the end of the century, portends us to a different level of production. We are talking about professional 3D equipment that can free the hands and head of a dental technician to solve more creative tasks.

We are talking about professional 3D equipment that can free the hands and head of a dental technician to solve more creative tasks.

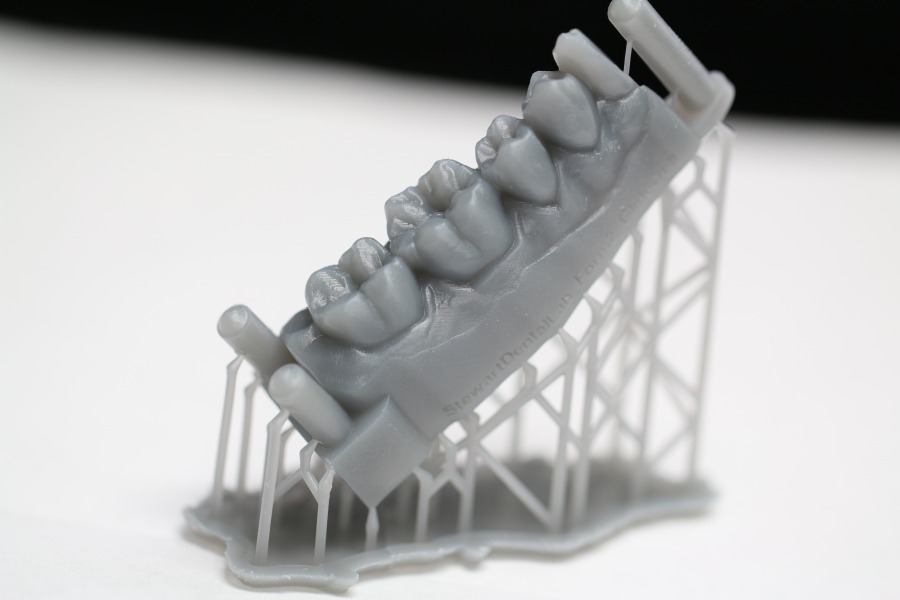

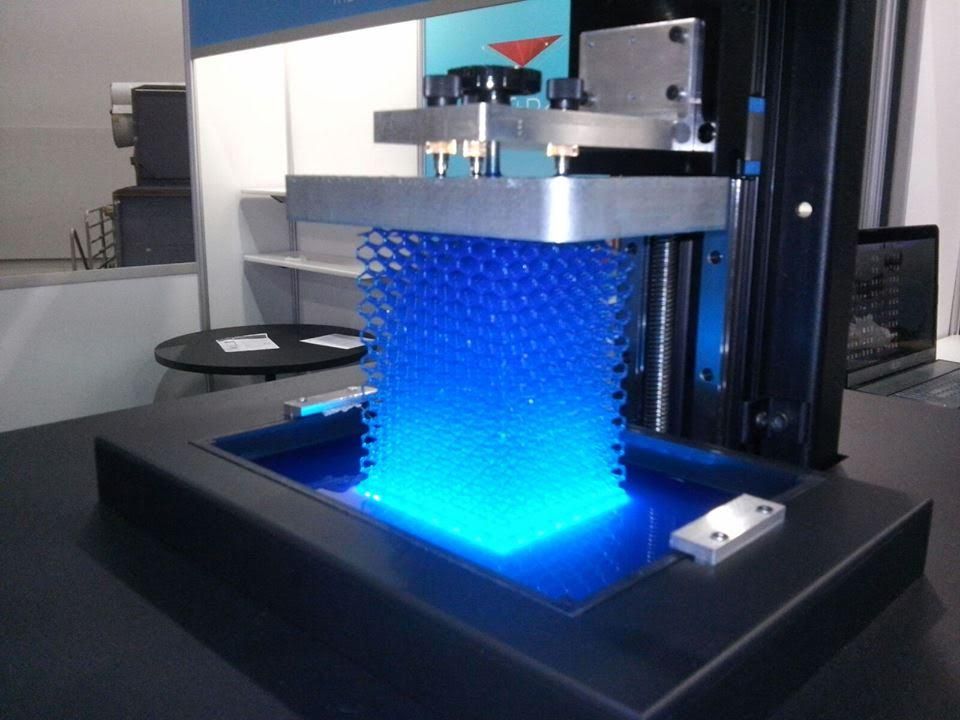

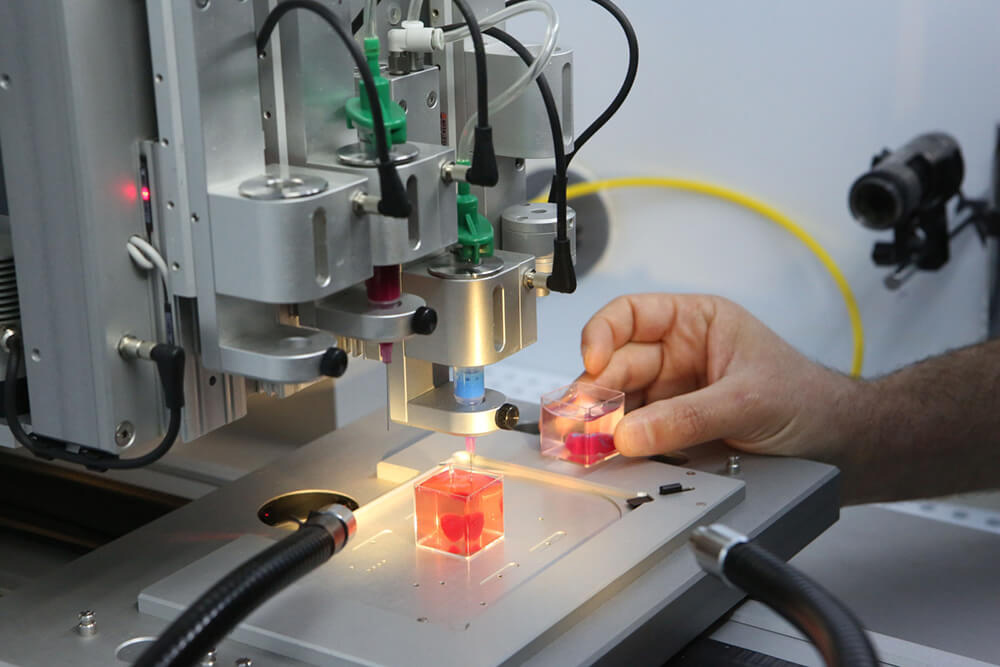

Of the vast array of existing 3D printing technologies in dentistry, stereolithography (SLA) and digital LED projection (DLP) have taken root. Both technologies have a similar principle of operation - the object is divided into flat layers of equal thickness, then the printer recreates the original object layer by layer with the help of alternate illumination. The difference between the above printing methods is the light source - UV laser for SLA and digital LED projector for DLP. nine0005 Both printing technologies use photopolymer resins, a liquid material cured by light.

Photopolymer resins are graded according to application. Using the DETAX Freeprint® materials as an example, we highlight three key groups used in dentistry.

Freeprint® model is a material for making dental models. Suitable for creating jaw models or other solid objects. It has three colors: gray, sand and ivory.

It has three colors: gray, sand and ivory.

Freeprint® cast is a burn-out material for precision casting technology. Finished printing products are placed in the investment mass and cast from the required metal. nine0005 Freeprint® splint is a biocompatible material for the manufacture of surgical templates, mouth guards and other objects in contact with the patient.

The above DETAX Freeprint® materials have a registration certificate for use in dentistry on the territory of the Russian Federation.

Having appeared on the Russian market more than 5 years ago, modern photopolymer printers using stereolithography technology have found their application in the jewelry industry, where the accuracy of design reproduction in accordance with the developed layout is extremely important. In addition to precision, the use of 3D printers has made it possible to reduce the production time of burn-in jewelry models by moving from classical technology with hand-modeling to digital and further printing. A significant advantage is the possibility of modeling a unique shape of the final product at the stage of digital modeling, giving the most complex shapes and their exact reproduction during casting. We have similar requirements for products in the production of dental structures. nine0003

A significant advantage is the possibility of modeling a unique shape of the final product at the stage of digital modeling, giving the most complex shapes and their exact reproduction during casting. We have similar requirements for products in the production of dental structures. nine0003

Examples of work performed at the 3D printing center of MyDent24 LLC.

Made from DETAX Freeprint® materials on Asiga PICO2 and Way2Production SolFlex 650 printers

The main question is what do we print in a dental laboratory?

The answer to this question is key when choosing equipment. Today, there are three key areas of using 3D printing in this direction:

• production of demonstration and collapsible models of the jaw, sectoral reproduction of the upper and lower jaws in bite; nine0005 • production of ashless constructions, caps, bases for crowns and bridges, clasp prostheses;

• production of surgical templates for implantation, guides for maxillofacial surgery, individual mouthguards.

The printing of temporary and permanent orthopedic structures, as well as the production of bases for removable dentures, is actively developing. In the near future, these biocompatible materials will become available on the Russian market.

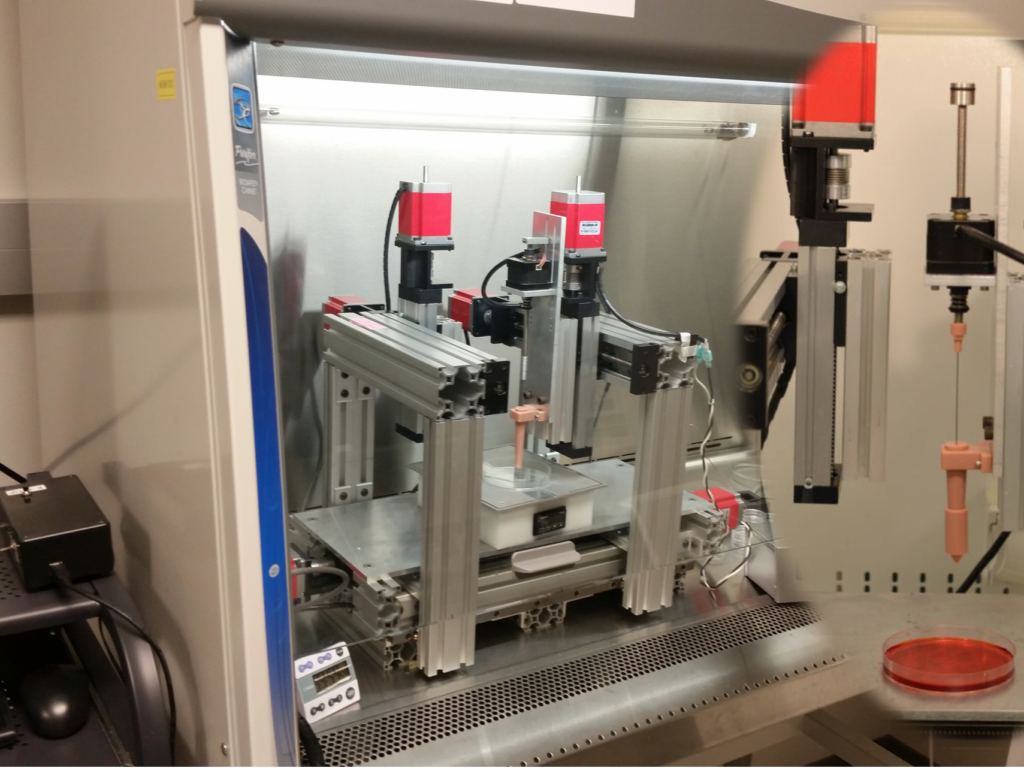

In our 3D printing center we use Way2Production SolFlex 650 (Austria) and Asiga PICO 2 (Australia) DLP printers. Both printers cure materials with 385 nanometer (UV) wavelength radiation. nine0005 DLP printers are distinguished by light intensity and print accuracy, depending on the projector resolution and layer thickness. For example, for printing crowns, bridges, the base of clasp prostheses and other structures that require an exact fit, you should choose a layer thickness in the range of 25 - 50 microns. For the manufacture of surgical templates, jaw models and other volumetric tasks, a layer thickness of 100 microns is optimal.

The range of tasks solved with the help of 3D printing is growing every day due to the emergence of new technologies and an increase in the level of skill in using existing ones. Today, 3D printing has ceased to be the lot of professionals and has moved into the consumer market. nine0005 It is important not to miss the time now, to get the necessary skills and opportunities, so that tomorrow, when we cannot imagine our life without 3D printing, to be at the top. 3D modeling, understanding print preparation processes, studying the properties of materials and their applicability - start with any of these questions and the world of 3D printing will suck you in.

Today, 3D printing has ceased to be the lot of professionals and has moved into the consumer market. nine0005 It is important not to miss the time now, to get the necessary skills and opportunities, so that tomorrow, when we cannot imagine our life without 3D printing, to be at the top. 3D modeling, understanding print preparation processes, studying the properties of materials and their applicability - start with any of these questions and the world of 3D printing will suck you in.

Gatich Artyom

head of the development department of MyDent24 LLC

0023

Tags:

3D printing in medicine, dental laboratory, CAD/CAM, milling machine, 3D equipment, SLA, DLP, dentistry, UV laser, LED projection, layer by layer, photopolymer resin, photopolymer printer, jewelry production, 3D

Other materials:

- 3D printing for the design of components and blocks of rocket and space systems

- Additive manufacturing is gaining momentum

- Additive technologies in mechanical engineering

- REC.

3D Printing Strength Test

3D Printing Strength Test - AM Quality

Attention!

We accept news, articles or press releases

with links and images. [email protected]

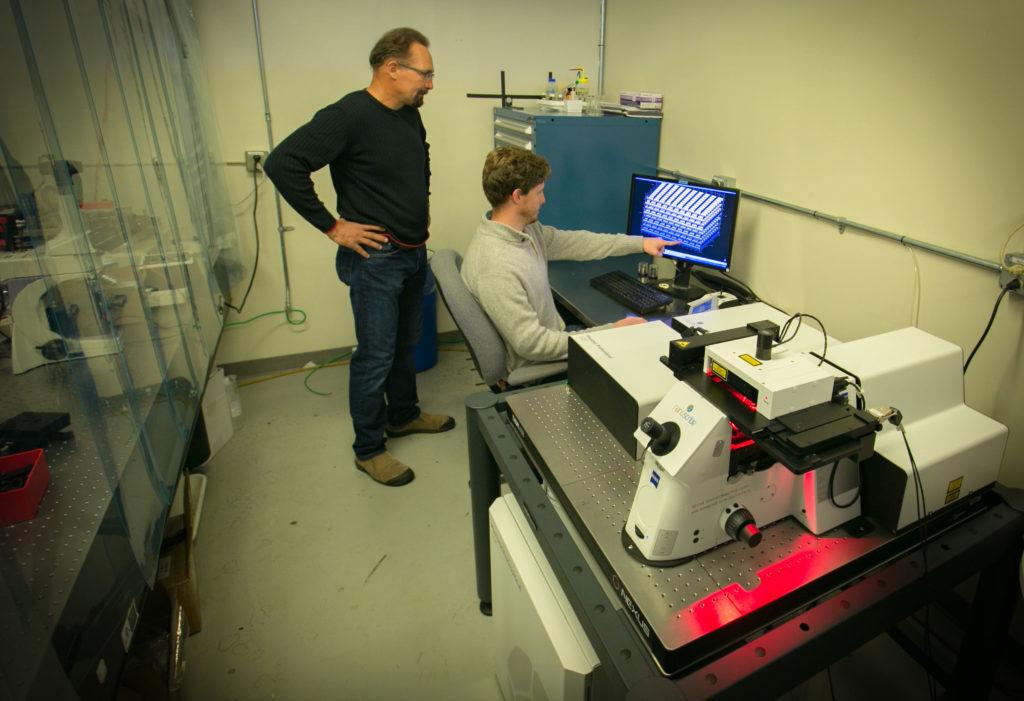

Overview of Creaform Metrascan 3D scanners / Sudo Null IT News

Let's talk about Creaform Metrascan - professional 3D scanners for industrial applications, including part geometry control, and reverse engineering. Learn more from this article. nine0003

About Creaform

Source: coarchitecture.com

In 2002, Bank of Canada invested $200,000 in a 3D scanner startup led by Martin Lamontagne. From that moment began the history of Creaform. Two years later, Lamontagne was named the "Best Young Entrepreneur of Quebec." His business brought in $5,000,000 and grew by 50% annually.

Source: pressreader. com

com

Creaform creates and markets 3D measurement equipment and participates in the development of innovative solutions in partnership with other companies. nine0003

Manufacturer specialized in 3D scanning, non-destructive testing, reverse engineering, quality control and digital modeling (FEA/CFD) tools.

Creaform equipment is in demand in various fields:

- In heavy engineering;

- In healthcare organizations;

- In the manufacture of household appliances;

- In the automotive industry;

- In the aerospace industry; nine0054

- In mining and processing industries;

- In the production of electricity;

- In educational and scientific institutions.

In 2013, Creaform became part of AMETEK Ultra Precision Technologies, a division of AMETEK Inc., a world renowned manufacturer of electronic tools and electromechanical devices with over $4 billion in annual sales.

Source: trends.directindustry.com

On 01.03.2018, Fanny Truchon took over the Creaform business unit. For the previous 5 years, she served as the company's vice president of customer service.

Creaform's headquarters and manufacturing facilities are located in Quebec. Scientific and technical centers operate in Grenoble and Levis. Sales centers operate in Europe, Asia and America: Italy, France, Germany; China, Korea, Japan, Thailand, Singapore, USA and Brazil.

Creaform Metrascan 9 3D scanners0079

Source: industryarena.com

Creaform's 3D scanner principles are:

TRUaccuracy - Accurate data in all conditions.

Protect measurements from adverse environmental conditions. Vibrations, unstable lighting, temperature fluctuations and inexperience of the operator do not affect the accuracy of the result. Creaform scanner algorithms are aimed at facilitating the measurement process and increasing the accuracy of the information received

TRUporability - 3D scanning anywhere.

Compact size, light weight, easy transport - everything you need to work 3D scanners almost anywhere.

TRUsimplicity - simple workflow.

It takes less than 5 minutes to collect information, process data, visualize and display a grid for objects of almost any size, color and material. To work with the device does not require pre-configuration or special user experience. nine0003

How it works

Source: creaform3d.com

The laser beams of the 3D scanner are directed at the subject, the camera captures the intersection points of the beams and the object. A laser tracker or accessory monitors the spatial position of the scanner. To connect parts of the image, small stickers of a given size, called marks, are used.

Source: creaform3d.com

MetraSCAN, Go! SCAN, HandySCAN - three models, three ways to collect data. nine0003

Each device determines its location in space in relation to the scanned object using different algorithms.

MetraSCAN is the most accurate device in this range. The principles of operation are similar to those of HandySCAN. MetraSCAN can operate as a stand-alone handheld device. However, it was originally designed to work with the C-track device. More about it in the paragraph "Optional equipment".

METRASCAN 750 (Elite)

Source: creaform3d.com

Specifications

Price METRASCAN 750 on request

METRASCAN 750 ELITE price on request

METRASCAN 350 (Elite)

Source: creaform3d.com

Price METRASCAN 350 on request

METRASCAN 350 ELITE price on request

Scope of supply

Source: aniwaa

Scope of supply:

- MetraSCAN 3D scanner nine0053 VXelements software

- Stand

- Calibration sphere

- FireWire cable

- Flight case

- 1 year labor and parts warranty

Optional equipment

C-Track

Source: aniwaa. com

com

The MetraSCAN handheld scanner is housed in a frame with marks to determine its location in space. The work of the scanner is to process data about the shape and surface of the scanned object, it is not tied to reference marks. They are searched for by the C-track, which is equipped with two cameras spaced apart to "capture" a large amount of space. nine0003

To obtain a coordinate reference system for the scanner, at least 4 marks, the C-track tracks an area up to 16.6 cubic meters in front of it. To bind the coordinate system to the object, marks can be placed on the part under study. When changing the relative position of the C-track and the object, the relationship between the scanner and the object is preserved.

Scanning starts immediately after the C-track finds several marks to create a reference frame in space. C-track keeps track of marks on the device so as not to lose its position in the working coordinate system. Collaboration of devices provides ample opportunities to scan large objects, such as aircraft and cars, in automatic mode and using a relatively small number of tags. nine0003

nine0003

CUBE-R

Source: creaform3d.com

The CUBE-R intelligent scanning system includes several devices: robotic arm, turntable, C-Track, C-Track, managing computer complex.

System features:

- High performance: checks up to hundreds of objects per day, including details of complex geometric shapes;

- Multifunctionality: simultaneously collects and analyzes information; nine0054

- Reduced footprint: 4.1m x 4.1m x 3.1m;

- Processing of large and heavy parts: weighing up to 1.5 tons, volume - up to 3 m along any coordinate axis;

- Ready to work: the system is completed, does not require integration;

- Automatic calibration mode during continuous data processing;

- Industrial design: adapted to the production environment.

Software

Source: creaform3d.com

Creaform offers several software license options:

- Computer license;

- Hardware key license;

- Network license.

Creaform software features comparison:

VXelements

Source: creaform3d.com

VXelements is an integrated software platform for combining all Creaform 3D scanning and measurement technologies. It is a working environment for other software modules (VXscan, VXprobe, VXshot, etc.) and a convenient, simple user shell. nine0003

VXmodel

Source: www.youtube.com

VXmodel is an easy-to-use program for preparing a 3D scan mesh for reverse engineering or 3D printing. Software options:

- Screen cleaning;

- Filling voids;

- Grid alignment;

- Mesh simplification;

- Create mesh-based surfaces.

VXinspect

Source: youtu.be

VXinspect - The software integrates the results of digital information processing and photogrammetric measurements. Solves the following tasks:

Solves the following tasks:

- Comparison of the resulting digital models in CAD with the original objects;

- Control of parameters of received models and original parts and tools;

- Control of conformity of manufactured parts to originals or standard;

- Checking the tool and its fixtures; nine0054

- Alignment;

- Deformation tracking;

- Dynamic measurement.

VXtrack

Source: creaform3d.com

VXtrack is designed to solve the following tasks:

- Robot calibration and orientation;

- Track and control complex assembly processes;

- Real-time correction of inaccuracies that occur during data processing; nine0054

- Deformation tracking during testing.

Comparison with Shining Freescan Trak

Both devices: Shining Freescan Trak and Creaform Metrascan operate on a similar principle: a symbiosis of a 3D scanner with a tracking tracker that determines the position of the scanner in relation to the digitized object.

Specification comparison:

Application examples

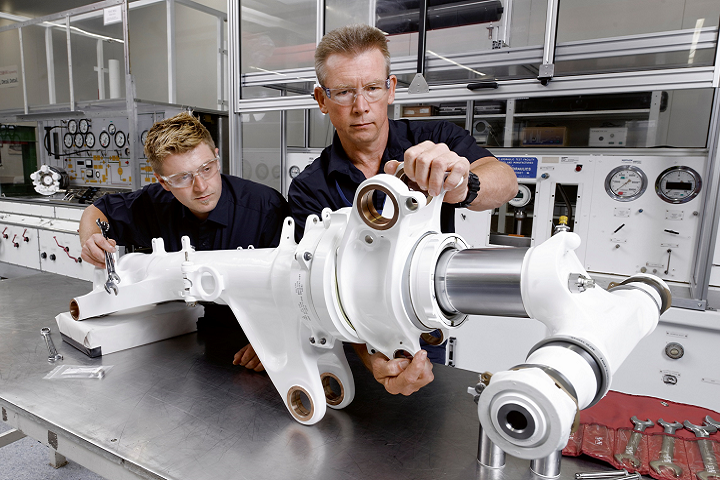

Product quality control at MDC DESIGN srl

Source: creaform3d.com

MDC DESIGN srl is a rapidly growing company and a leading supplier of control systems and sensors for process automation in the automotive and aerospace industries. The work of MDC DESIGN srl is based on strict compliance with quality standards. The company produces a wide range of devices, from simple instrument stands to innovative systems with complex electronic components.

Source: creaform3d.com

During the production of large equipment, the company was faced with the task of finding a device for measuring and creating models of parts in three-dimensional space. The tool had to process information and transform data with maximum accuracy.

MDC DESIGN management said they chose Creaform because their values matched. Accuracy and speed are priority principles of both companies. MDC DESIGN was pleased with the choice of supplier, also due to the high level of staff training and high-quality technical support. nine0003

Accuracy and speed are priority principles of both companies. MDC DESIGN was pleased with the choice of supplier, also due to the high level of staff training and high-quality technical support. nine0003

The Creation of American Magic, New York Yacht Club

Source: sail-world.com

The American Magic is the United States candidate for the 2020 America's Cup, considered by yachting enthusiasts to be the most prestigious international event. The history of the competition began in 1851, forty-five years before the Olympic Games.

Source: creaform3d.com

Creaform is the official 3D technology provider for the nearly 23m American Magic. The yacht develops a speed of more than 92 km/h thanks to innovative technologies and modern materials used by Airbus engineers to create a hydrofoil yacht.

Source: creaform3d.com

Working with sailing experts and engineers, Creaform's metrology team scanned the carbon fiber hull of the yacht. We analyzed the influence of the geometry of parts on the streamlining of the vessel, studied the possibilities of improving the characteristics of the hull. The Creaform team was delighted to be part of the evolution of American Magic and are proud to have helped improve the yacht's design features. nine0003

We analyzed the influence of the geometry of parts on the streamlining of the vessel, studied the possibilities of improving the characteristics of the hull. The Creaform team was delighted to be part of the evolution of American Magic and are proud to have helped improve the yacht's design features. nine0003

24 Hours of Le Mans

Source: sport.ru

To control the cars of the race participants, the FIA used the Creaform MetraSCAN 3D scanner.

Source: creaform3d.com

The task before the experts was to check the compliance of each car with the rules of racing. Each test was to take no more than 10 minutes. The problem was solved using MetraSCAN scanners.

https://youtu.be/bJPw8UEuoNA

Conclusion

Source: creaform3d.com

3D laser scanners are high-precision, high-speed equipment for use in various fields where accuracy and speed of obtaining three-dimensional models of physical objects are required.