3D printer for casting

Introduction to Metal Casting and Ways to Combine 3D Printing With Casting Workflows

Metal casting is an age-old metalworking process in which molten metal cools and solidifies in a mold to form metal parts. Despite its ancient roots, metal casting is still one of the most popular processes for companies looking to produce metal parts.

This article will cover what metal casting is, how it works, and walks you through the most common metal casting processes and the benefits manufacturers can attain by combining modern digital tools like 3D printing with traditional casting workflows.

White Paper

Get design guidelines for creating 3D printed patterns, walk through the step-by-step direct investment casting process, and explore guidelines for indirect investment casting and sand casting.

Download the White Paper

Metal casting step-by-step from the original design through final casting.

Since the advent of metal casting, the methods have evolved and varied. Its core techniques, however, have remained constant. Here is a general step-by-step process for metal casting:

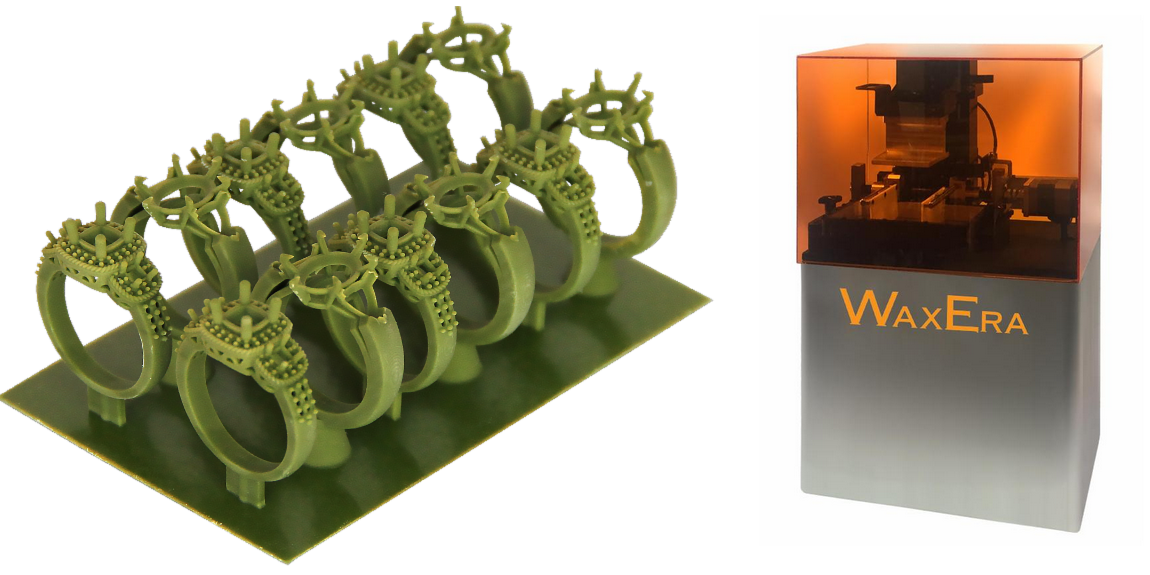

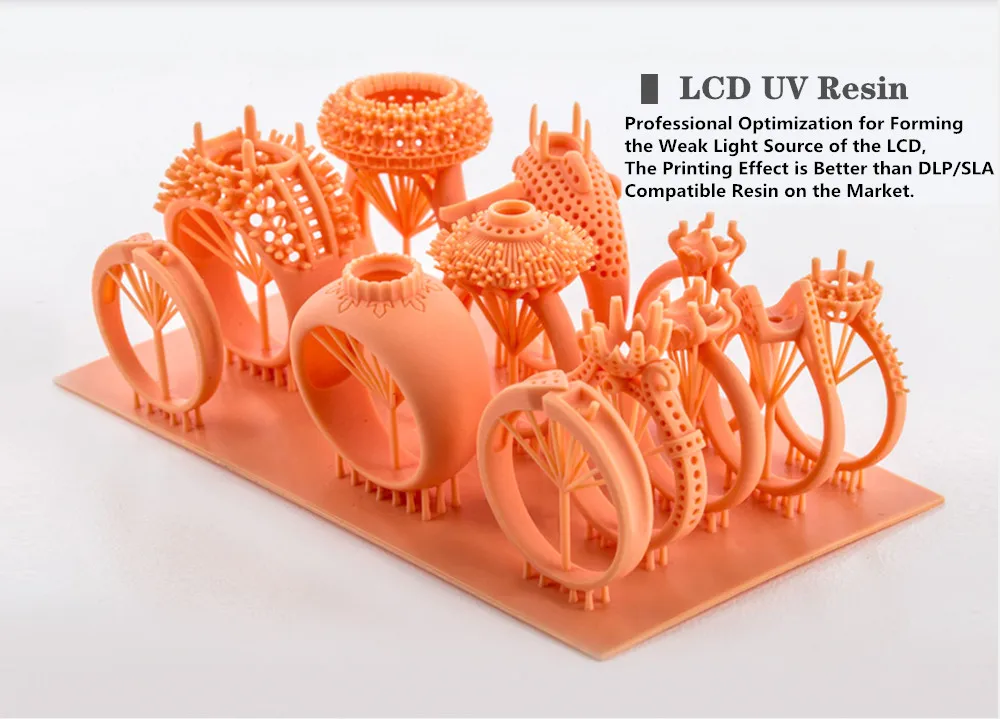

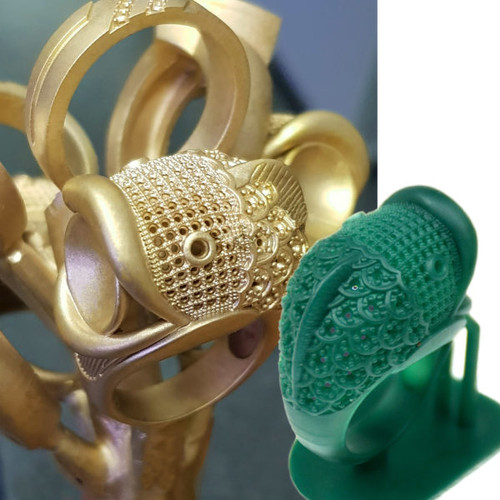

Ring patterns 3D printed in Castable Wax 40 Resin.

In order to begin the metal casting process, a manufacturer first must develop a representation of the desired pattern. This pattern is essential in designing the mold used for the cast. It is traditionally made from wood, foam, plastic, or wax and ensures that the mold accurately produces the finished metal part. Today, 3D printing is also a common method to produce patterns, which allows designers to create accurate patterns directly from digital CAD software tools.

A pattern is not an exact replica of the desired part. It has additional elements that make the casting process possible, including gates that allow molten metal to flow at a steady rate and vents for gas to escape. Additionally, patterns are also larger than the parts they represent to account for the shrinkage that occurs during cooling.

When the casting piece is hollow, the manufacturer also creates a core of sand or metal to shape the internal form. This core gets removed upon completion of the casting.

This core gets removed upon completion of the casting.

The next step is creating a casting mold, which can be either reusable (non-expendable) or non-reusable (expendable). Non-reusable molds are usually made out of sand, plaster, wax, or by 3D printing, and just as the name suggests, they get destroyed in the casting process. Reusable molds are made out of metal and other durable materials and can be reused for multiple casting cycles.

Ceramic shells after burnout and 3D printed patterns in Clear Resin.

Molten pewter poured into a High Temp Resin 3D printed mold for metal casting.

During this step, the metal gets heated in a furnace until it melts. Depending on the application, manufacturers can use a variety of different metals, with the most commonly cast metals being iron, aluminum, aluminum alloy, steel, copper, and zinc, as well as precious metals like gold and silver. Once the metal melts, the manufacturer pours it into the mold cavity and allows it to cool and solidify.

Metal casting post-production.

Once the metal cools down and solidifies, the parts get removed from the mold. Depending on the mold type, this can be done by vibrations in a shakeout process, washing away the investment material, or by ejector pins. Then, excess material, such as vents, gates, and feeders, are removed from the parts. Finally, the parts get filed, grated, machined, or sandblasted to smooth the surface and reach the final shape requirements.

Though all metal casting techniques share the same core process, there are various methods better suited for different applications. Some of the most common methods include die casting, investment casting, and sand casting.

Die casting uses a steel mold and high pressure. (Source: buhlergroup.com)

Die casting is a metal casting process in which a manufacturer pushes molten metal into a steel mold cavity at a high pressure to quickly produce metal parts. In die casting, the manufacturer fixes two halves of a die or reusable mold together and uses a nozzle to inject pressurized molten metal into the die. When the metal cools, the die opens, and ejector pins push out the cast.

When the metal cools, the die opens, and ejector pins push out the cast.

The two most common die casting processes are hot-chamber and cold-chamber casting. While the specifics of these processes vary, there are several shared characteristics of the die casting process as a whole.

Hot-chamber die casting is the most common of the two main die casting processes. Hot-chamber die casting machines have a built-in furnace to heat the metal within the machine. Once the metal reaches a molten state, the machine lowers a cylindrical chamber into the molten metal. The gooseneck shape of the metal injection system allows the chamber to quickly fill itself, and then push the material into the mold with air pressure or a piston.

Immersing the injection mechanism to fill it allows for rapid and streamlined mold injection in this casting process. Because the chamber is subject to direct heat from the molten metal, however, hot-chamber die casting systems are at risk for corrosion, making them a less viable option for metals with high melting points. Instead, it is better suited for materials with low melting points and high fluidity, like lead, magnesium, zinc, and copper.

Instead, it is better suited for materials with low melting points and high fluidity, like lead, magnesium, zinc, and copper.

By contrast, the cold-chamber die casting process works more slowly to avoid corrosion. With this method, a foundry worker ladles molten metal into the injection system. A piston then pushes the metal into the mold.

This process limits the corrosion that is more common in hot-chamber die casting. It is an ideal option for metals with high melting points, like aluminum and aluminum alloy.

The die casting process is rapid and produces highly detailed parts. It is ideal for the production of high volumes of complex parts and can also produce strong parts with smooth surface finishes. Die casting’s capacity to produce a high volume of parts makes it a crucial process in the automotive and aerospace industries.

As die casting tooling and equipment are expensive, this process is not cost-effective for smaller production runs. In addition, the malleability of metals used in the process can impact the complexity of the product.

Cast parts from SLA patterns printed in Clear Resin on a Formlabs 3D printer.

Investment casting, also known as lost-wax casting, is a process that uses wax, slurry, and molds to produce complex parts. It is one of the oldest metal casting techniques but is still valued for its ability to create precise metal parts with intricate shapes.

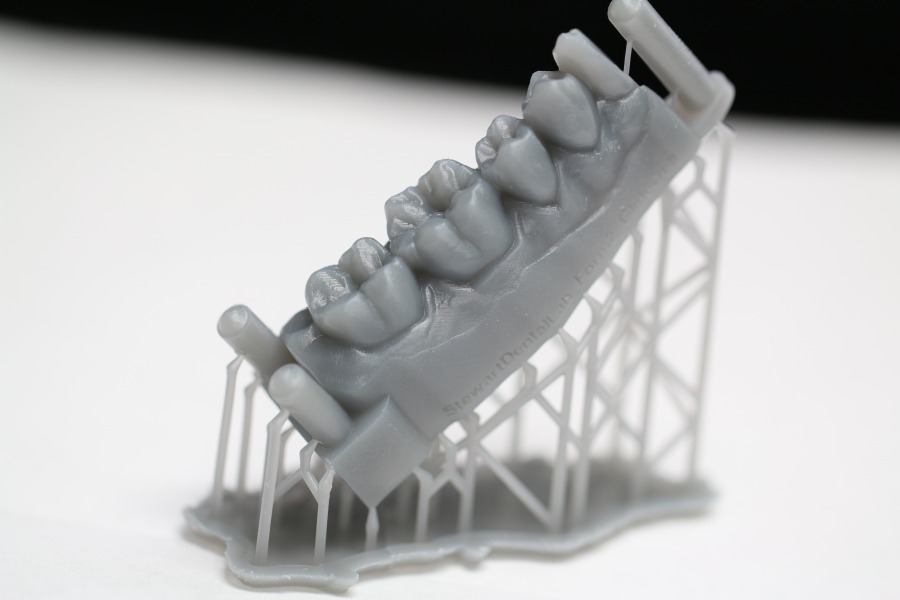

This process is still widely used for producing jewelry, dentistry, and art. Its industrial form, investment casting, is a common way to create precision metal parts in engineering and manufacturing.

Investment casting patterns are typically made out of wax or 3D printed polymers. The patterns are assembled into a tree-like structure and dipped into a slurry of silica, or put into a flask and surrounded by the liquid investment plaster. After the investment material dries, the flask is placed upside down into a kiln, which melts the pattern, leaving a negative cavity in the shape of the original model. Metal is melted and then poured, using gravity or vacuum pressure to pull the metal into the cavity. The casted parts are filed, ground, machined, or sandblasted to achieve final geometry and surface finish.

The casted parts are filed, ground, machined, or sandblasted to achieve final geometry and surface finish.

Sprue trees with cast rings.

Investment casting is a versatile process. It allows manufacturers to produce accurate and repeatable parts out of nearly any metal available for casting and complicated shapes that would be difficult or impossible with other casting methods. Casted parts also have excellent surface qualities and low tolerances, with minimal surface finishing or machining required.

These features make investment casting ideal for complex parts in automotive, aerospace, and industrial applications, medical tools, dental implants, as well as fine jewelry and art.

Investment casting is a complex and labor-intensive process. It requires specialized equipment, costly refractories and binders, as well many manual operations to make a mold. It can be difficult to cast parts that require cores and the process is better suited to small parts.

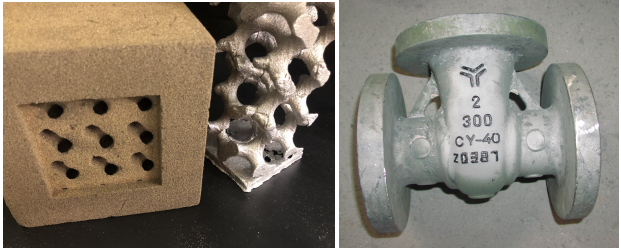

One half of a sand casting mold.

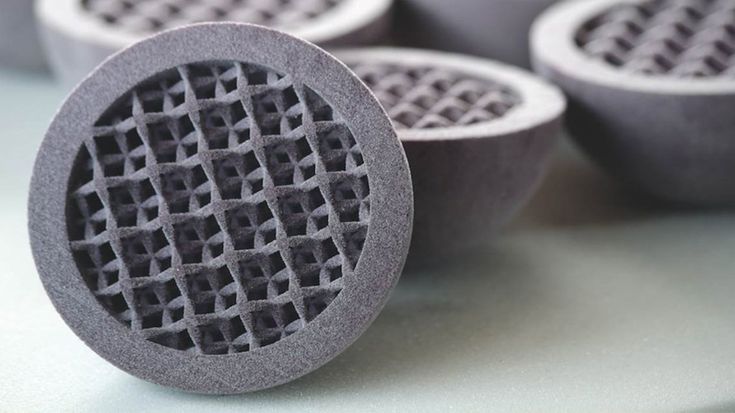

Sand casting is a metal casting method that was first in use 3,000 years ago but remains the most widely used casting method to this day. This process allows manufacturers to cast metal without relying on machining.

In the sand casting process, the manufacturer first creates a foundry pattern, or replica of the casting, most commonly from wood or plastic. The pattern is oversized to allow for shrinkage. Parts with features on one side only require an open-faced mold. For parts with multiple detailed surfaces, the manufacturer separates the foundry pattern into two mold boxes to form a closed cavity mold. The top half is called a cope and the bottom a drag.

Once the manufacturer creates the pattern, they tightly pack sand around the pattern. Then, they add sprues and gates to ensure that the molten metal flows smoothly through the mold cavity. The manufacturer removes the pattern then clamps the two halves of the sand mold together. Once the metal melts to a molten state, it is poured into the mold and left to cool. From here, the sand mold is removed using vibrations or high-pressure water. Finally, the manufacturer refines the part by removing sprues and gates, and polishing the cast metal part.

From here, the sand mold is removed using vibrations or high-pressure water. Finally, the manufacturer refines the part by removing sprues and gates, and polishing the cast metal part.

Sand casting is an adaptable process that functions outside the limitations of machinery. Because of this, it can create complex parts of virtually any size. Sand is inexpensive and plentiful, which lowers the setup cost and makes modifications possible. It is the only practical or economical way to produce very large castings. The lead time of sand casting is also short, making it a viable process for short production runs.

Sand casting’s versatility makes it a manufacturing option across a wide array of industries. It can produce medical equipment, automobile parts, electronic equipment, gas tanks, and engine blocks, and more.

Sand casting creates highly porous, textured metals. The shrinkage and rough surface finish also lower the dimensional accuracy of parts. This results in a low-strength final product that requires time-consuming post-processing to achieve a higher quality finish.

In order to choose the right industrial metal casting process, several factors must be considered. We’ve created this comparison table to help you compare die casting, investment casting, and sand casting in terms of types of metals, production volume, costs, production time, part complexity, and for which industries they are generally used.

| Die Casting | Investment Casting | Sand Casting | |

|---|---|---|---|

| Compatible metals | Aluminum, copper, lead, magnesium, zinc | Most metals | Most metals |

| Production volume | High volume | Low to high volume | One-off to medium volume |

| Unit costs | Low | Moderate to high | Moderate |

| Tooling costs | High | Moderate | Low |

| Cycle time | Rapid | Long | Moderate |

| Industries | Automotive, aerospace, consumer products, furniture, power tools | Automotive, aerospace, jewelry, medicine, dentistry, art | Automotive, aerospace, industrial equipment, electronics, consumer products |

3D printed jewelry ring pattern and cast metal part.

Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3D printing by combining castings processes like indirect investment casting, direct investment casting, pewter casting, and sand casting with 3D printed patterns or casting metal into 3D printed molds. Cast metal parts using 3D printed rapid tooling can be produced in a fraction of the time invested in traditional casting and at a significantly lower cost than metal 3D printing.

Stereolithography (SLA) 3D printers offer high precision and a broad material library that is well-suited for casting workflows and can produce metal parts at a lower cost, with greater design freedom, and in less time than traditional methods.

Webinar

In this webinar, we will look at how desktop stereolithography (SLA) 3D printers are being used to directly print patterns, how to work with SLA patterns for investment casting, and how the benefits of generative design are increasing the demand for printed patterns.

Watch the Webinar Now

A 3D printed mold in Clear Resin for wax injection.

The process of making patterns from molds or tooling is referred to as indirect investment casting because it requires creating molds for producing the patterns in addition to final investment molds.

Rigid molds for wax (often referred to as tools) are commonly fabricated by machining aluminum or steel. Machined metal molds cost thousands of dollars to produce and take weeks of machining and polishing work before first shots can be run and pattern parts evaluated within a casting process.

With 3D printing, manufacturers can directly 3D print the mold for their pattern using materials like High Temp Resin or Rigid 10K Resin, resins with high-temperature resistance. For an optimal surface finish of molded parts, treat the interior surfaces of the mold by sanding and polishing for a smooth look, or bead blasting if a uniform matte look is desired. To ensure the final cast parts are dimensionally accurate, compensate for shrinkage by scaling up the printed mold. The exact shrinkage of the wax and the casting process can be obtained from supplier specifications.

The exact shrinkage of the wax and the casting process can be obtained from supplier specifications.

3D printed molds for metal casting shorten the time between concept and first tests to a matter of days because manufacturers can directly print the tooling necessary for running and evaluating parts.

While molded pieces must follow design rules for moldability (e.g., no undercuts, draft is beneficial, etc.), you can achieve increased pattern complexity by using assembly jigs to combine multiple components into a single structure.

White Paper

Download our white paper to learn about six moldmaking processes that are possible with an in-house SLA 3D printer, including injection molding, vacuum forming, silicone molding, and more.

Download the White Paper

3D printed jewelry patterns and metal casted rings.

Direct investment casting is a version of investment casting where the process moves directly from pattern creation to surrounding the pattern with investment material. It is ideal for producing parts with geometries that are too complex to be molded or for parts with extensive undercuts and fine surface texture details, where molding is possible but carries high tooling costs.

It is ideal for producing parts with geometries that are too complex to be molded or for parts with extensive undercuts and fine surface texture details, where molding is possible but carries high tooling costs.

Traditionally, patterns for direct investment casting are carved by hand or machined if the part is a one-off or expected to be only a handful of units. With 3D printing, however, manufacturers can directly print the patterns, removing the design and time constraints common in other processes.

With 3D printing, engineers, designers, and jewelers can direct 3D print patterns in order to achieve shorter lead times and geometric freedom that exceeds the design for manufacturability constraints of molding processes. Formlabs developed a range of castable materials suitable for direct investment casting, in particular for the jewelry industry.

White Paper

The way jewelers work is changing, and castable photopolymer resins are leading the way. In this guide, learn how to cast fine jewelry pieces 3D printed on Formlabs printers.

In this guide, learn how to cast fine jewelry pieces 3D printed on Formlabs printers.

Download the White Paper

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

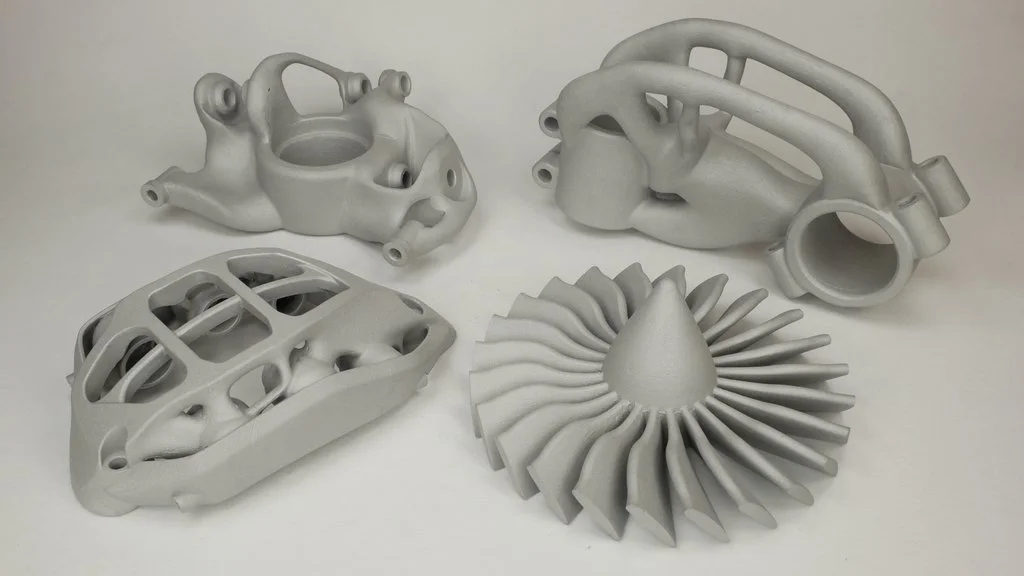

Grey Resin printed pattern and finished aluminum casting from an open-faced sand mold.

Similar to investment casting, 3D printing can be used to create patterns for sand casting.

In comparison to traditional materials like wood, 3D printing allows manufacturers to create complex shapes and go straight from digital design to casting.

Metal Miniatures made with pewter casting and 3D printing.

Pewter is a malleable metal alloy with a low melting point that can be used for making fully metal objects for decorative applications such as detailed metal miniatures, jewelry, scale models, and replicas of antiques.

With recent developments in temperature-resistant 3D printing materials, like High Temp Resin for Formlabs SLA 3D printers, it’s now possible to 3D print molds for direct pewter casting.

There are two options for mold designs: a sacrificial or pull-apart mold. In a sacrificial mold, there is a shell designed to be broken apart in the process. Pull-apart molds function with separate halves so the mold can be reused.

Compared to directly printing metal, the casting pewter in 3D printed molds offers significantly better detail and surface finish at a small fraction of the cost. Compared to wax casting, directly 3D printing a mold has fewer steps and requires less manual effort, while preserving the most possible detail.

Webinar

Watch our webinar to learn how moldmaking using 3D printed masters and reusable or sacrificial molds can allow you to produce parts in porcelain, precious and non-precious metals, silicone and biocompatible flexible materials, and more.

Watch the Webinar Now

Jewelry investment casting process with 3D printed patterns.

Businesses looking to boost design freedom or cut costs and lead times have a strong solution in metal casting with 3D printing.

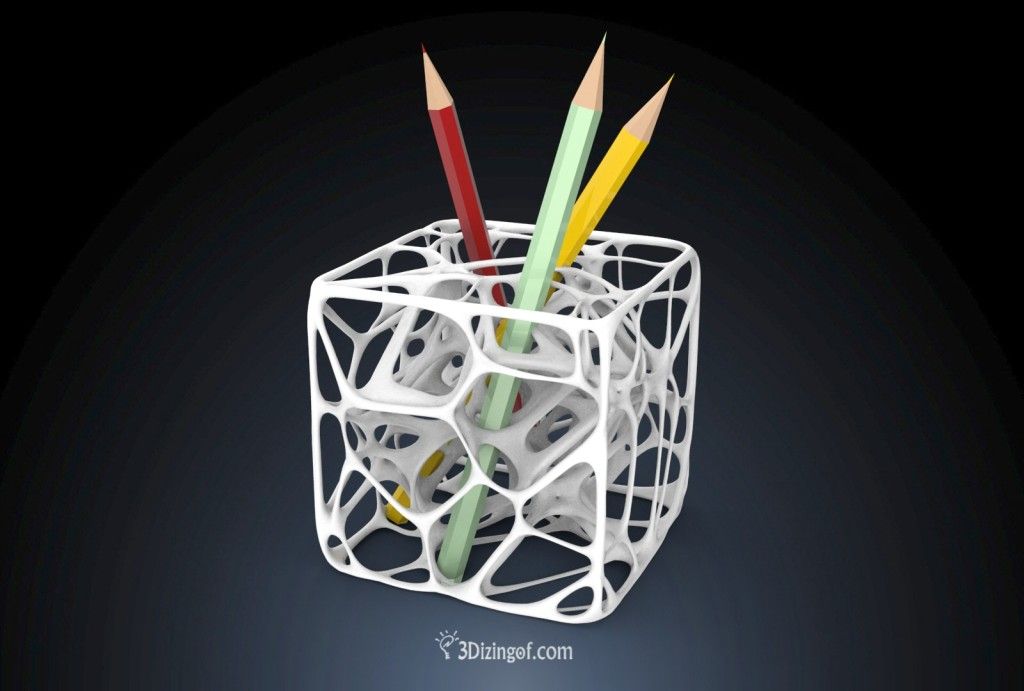

Certain types of complex metal castings, such as large shapes with cross-sections and pieces with multiple cores, are difficult to create using traditional metal casting methods. 3D printing allows manufacturers to produce these complex designs. For example, jewelers can create intricate and custom designs that might be impossible without a 3D printed pattern.

3D printing also eliminates reliance on multiple machines or service providers to create parts. Instead, companies just need a digital file, a 3D printer, and printing material. This can cut costs and waste, as all the material used goes into the final product.

Finally, the combination of 3D printing with metal casting can cut costs and lead time. Rather than waiting weeks for expensive tooling before being able to cast a final product, a 3D printer can create a pattern or mold in hours.

Rather than waiting weeks for expensive tooling before being able to cast a final product, a 3D printer can create a pattern or mold in hours.

Metal casting combined with 3D printing help companies quickly and efficiently create metal parts. With a Formlabs SLA 3D printer, you can expedite the metal casting process and cut costs along the way.

Learn more about the Form 3 desktop SLA 3D printer and request a free sample part to evaluate the quality firsthand.

See the Form 3Request a Free Sample Part

Custom 3D-Printed Casts and Splints

You Have Casting Options!

When you have a broken bone, you can choose a custom fit, waterproof 3D printed cast for the remainder of your healing, just as soon as your fracture is stabilized and your swelling goes down.

Your Clinic Can Provide ActivArmor Today!

No equipment or inventory to buy. Get started now with our free iPhone app!

What is ActivArmor™?

ActivArmor is the only waterproof, breathable, sanitizable custom plastic cast in the U. S. consumer marketplace. It empowers patients with the freedom to be able to stay safe and maintain their active lifestyles.

S. consumer marketplace. It empowers patients with the freedom to be able to stay safe and maintain their active lifestyles.

No rubbing or slipping. Custom fabricated to within 1mm of your body map.

Clips are locked on like a cast or easily removable like a splint, per doctor’s orders.

Kids love the colorful options and comfort. It’s breathable and does not trap bacteria.

Shower, bathe or swim as you normally would. Easy to clean dirt, sweat and grime.

ActivArmor™ allows you to continue to be active while you are healing from your injuries, and can reduce downtime in your active lifestyle and/or training.

ActivArmor™ is covered by most insurance plans and is affordable or even free depending on your individual coverage.

ActivArmor™ is the only commercially available, 3D printed custom splint in the United States and is FDA listed.

Participate in daily activities such as bathing and showering; convenient for children or those with mobility problems.

No need for a 3D printer in the doc’s office. All you need is an Rx pad and you can prescribe from the comfort of your own desk.

Listed with FDA as a Class 1 splint, doctors love the patient outcomes and patients love the faster recovery. ISO-10993 certified for biocompatibility.

ActivArmor is designed and made in Pueblo, Colorado in a United States EDWOSB, and was developed by an American entrepreneur.

When you no longer have a need for your ActivArmor™ custom splint, rest assured you can recycle it and help keep our planet beautiful.

Doctors Love ActivArmor™

ActivArmor saves physicians time and increases clinic efficiencies by reducing cast removals, material inventory, recasting, and skin irritation complaints.

Custom RX Pad

Scan with your iphone in your office, or just write a script to have our certified staff fill your patient’s DME order.

Very Easy to Prescribe

it really is…

You can also become an ActivArmor partnering clinic

Learn More

Increase Traffic to Clinics

Your patients become walking billboards for your practice, marketing for you while they heal.

Zero Upfront Costs

Help more patients

Clinics are viewed as innovative, and are given the opportunity to provide patients with the latest in high tech healing options with no upfront equipment cost.

Learn More

Advanced Treatments

Provide your patients with the latest in high-tech immobilization, custom adapted for advanced healing technologies like ultrasound, bone and muscle stimulators and TENS units.

Advanced Treatments

Any doctor can do it

Because ActivArmor™ devices are custom designed and fabricated, physicians and patients now have an infinite number of unique design options.

Learn More

Improve Patient Satisfaction

Patients prefer ActivArmor™ over traditional casting and splinting options.

Patient Satisfaction

Patients can stay active

Referring physicians for ActivArmor™ have reported that their patients prefer it over traditional casting and splinting options.

Learn More

Actor

ActivArmor has changed my life! When I was diagnosed with severe never damage by my doctor and needed to be put into a cast, it really hurt me because I knew what they meant. My nerve damage is extensive and will take a year or more to heal, but I still wanted to work out, shower, wash. This is making my healing process so much more enjoyable and while I have a long road of healing ahead, I’m very happy with the cast I have, seeing what I can do with it! These should be all across America and replace fiberglass casts everywhere!

Pro Circuit Rider

"My brace has given me the freedom to do things I couldn't do with a standard cast while giving me the support I need to protect my wrist fracture. I love it and would recommend it to anyone with any problem requiring extra support!"

Mother

"My son, Robert, is a very active child: water skiing, climbing, baseball, swimming, you name it and as such he injured his arm the first week of summer vacation. Knowing his injury required a cast, we assumed Robert would miss out on all of the summer fun with his friends. He was going to have to wear a stinky itchy cast like his sister did before him. given that Robert had just been invited to a pool party, I asked the doctor if there were any options. When the doctor prescribed an ActivArmor™ cast we were thrilled! ActivArmor™ was the answer to what would've been a dreary summer otherwise. My son said it was very comfortable to wear. He loved being able to shower with the cast on. No smell, no discomfort, and no irritated/itchy skin."

Knowing his injury required a cast, we assumed Robert would miss out on all of the summer fun with his friends. He was going to have to wear a stinky itchy cast like his sister did before him. given that Robert had just been invited to a pool party, I asked the doctor if there were any options. When the doctor prescribed an ActivArmor™ cast we were thrilled! ActivArmor™ was the answer to what would've been a dreary summer otherwise. My son said it was very comfortable to wear. He loved being able to shower with the cast on. No smell, no discomfort, and no irritated/itchy skin."

Patient

"Out and about with my ActivArmor™ cast... I have sent more people to your site than you can believe. Everyone asks about it and I love telling your story. Thank you for giving me back my summer. I have been boating, swimming everyday, paddleboarding, kayaking, and rafting since I got my cast. I am able to shower, and unfortunately do dishes. I can wash my dogs, and hose down my hogs. If when I am throwing hay, it shakes out of the cast. It is not smelly either. My baby Toy Chihuahua loves to chew on it. I just wish I had more than one color to coordinate with my clothes. But I am always answering questions about it and sending people to your site."

It is not smelly either. My baby Toy Chihuahua loves to chew on it. I just wish I had more than one color to coordinate with my clothes. But I am always answering questions about it and sending people to your site."

MD

"The ActivArmor™ brace is the next generation of patient immobilization. Custom fit, 3D printed, waterproof, and breathable! All of the previous problems of inability to shower, swim or workout, itching, hygiene, and incision exposure are solved. Patients will love the comfort and convenience of going back to a more normal life!"

19

"After breaking my wrist and having to have surgery, I thought I wouldn't be able work as a lifeguard this summer. But thanks to ActivArmor™, I'm able to be in a cast to heal my wrist and still be able to lifeguard and get in the water whenever, and however many times needed!"

Ironman World Championships Competitor

"Literally couldn't do it without you!!!"

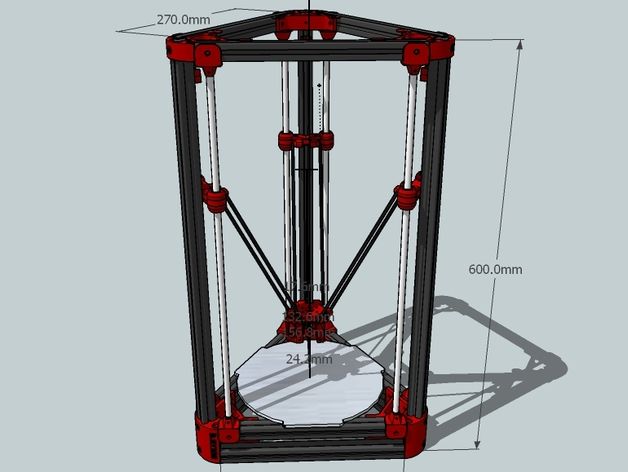

3D printers for foundries

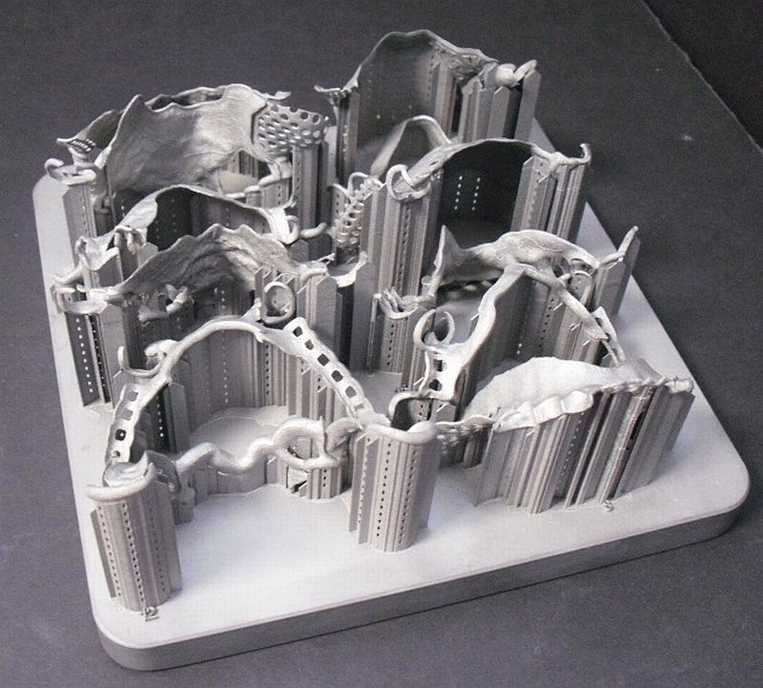

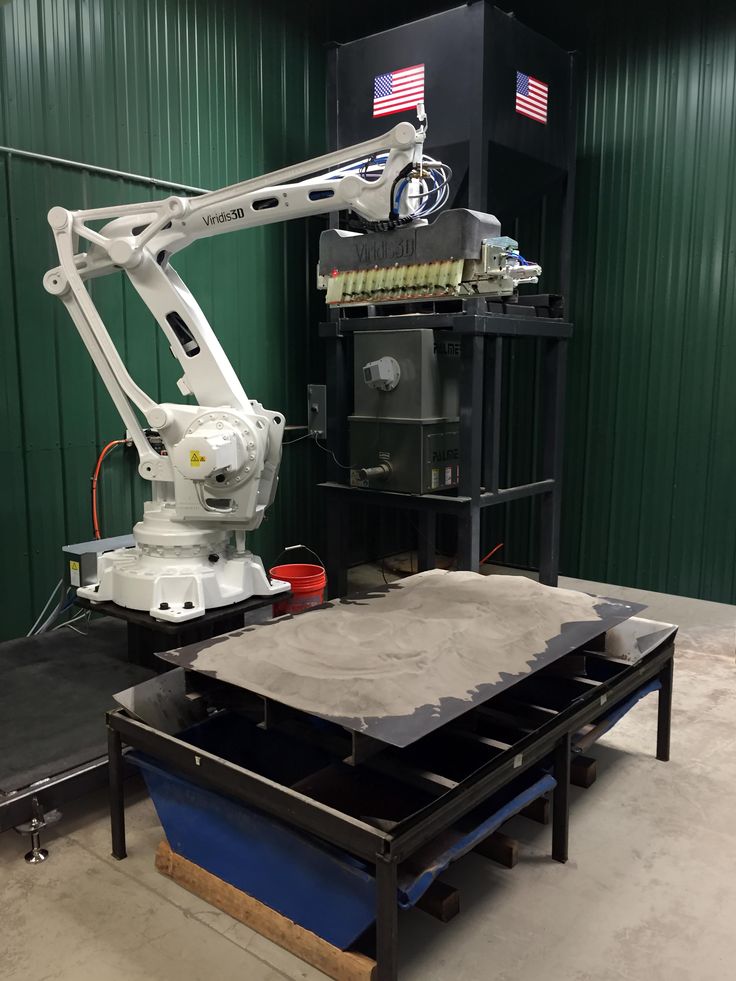

3D printing allows you to print master models for making molds from CAD files. The time to create a master model on a 3D printer is much less than the time to produce a casting sample using traditional methods.

The time to create a master model on a 3D printer is much less than the time to produce a casting sample using traditional methods.

- Cons of traditional injection molding

- Benefits of 3D printing

- Choosing a 3D printer0006

Disadvantages of traditional casting

Conventional mold making techniques include 3D modeling and making a master model using milling, manual labor, or other types of machining. All these methods are quite laborious and have obvious disadvantages:

- long production time,

- high cost,

- Error probability due to factor,

- is not very accurate. nine0011

- long production time,

- high cost,

- Error probability due to factor,

- is not very accurate.

-

- Creating a mold on a 3D printer guarantees rapid production of part prototypes from drawings or 3D file data.

- the ability to print molds of any complexity.

- ease, convenience, cleanliness and low cost of mold creation.

In addition, when using a 3D printer for foundry production in Moscow and other cities of Russia, it became possible to refine the master model in a new way. Under the complex geometric design, grooves are made on the mold, into which the missing pieces of durable material made using 3D printing are glued. The use of this technology significantly reduces labor costs for manual refinement, and also reduces the time for preparing the mold for casting. nine0003

Before starting production, 3D prototyping can optimize the working steps of the casting process. For example, after trial tests of injection molds, you can check the parts made in them and correct the molds without any difficulties, without creating a new model equipment each time.

-

-

-

- Creation of a mold on a 3D printer guarantees rapid prototyping of parts from drawings or 3D file data.

- the ability to print molds of any complexity. nine0006

- ease, convenience, cleanliness and low cost of mold creation.

How the process of casting on the burned workshops

How the process of casting for burned mastermodes

selection of the foundry 3D printer

Uniontech RSPRO 600 9000 9000

9000 9000 9000 9000 9000 9000 WUnionTech RSpro 600

Flashforge WaxJet 400

3D Systems ProJet 2500 W

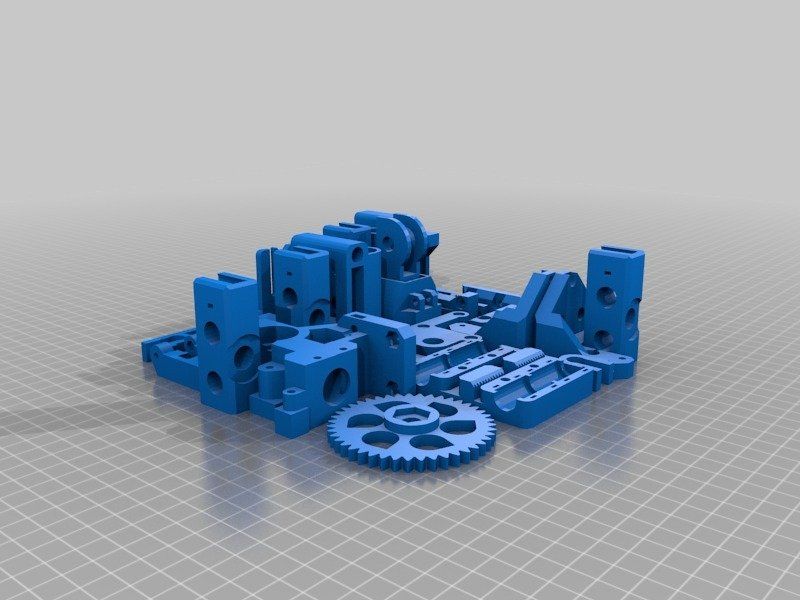

How to use 3D printing for injection molding

Today, most plastic products in the world are made using injection molding. However, creating molds can be time consuming and costly. Fortunately, molds can not only be obtained on a metal milling machine, but also printed on a 3D printer.

Stereolithographic (SLA) 3D printing is an affordable alternative to milling aluminum molds on a machine. The 3D printed models are hard and isotropic, and the materials used have a thermal distortion temperature of 238°C at 0.

45 MPa. This means that they can withstand the temperature and pressure of injection molding. nine0003

45 MPa. This means that they can withstand the temperature and pressure of injection molding. nine0003 Download our free white paper to learn how to 3D print injection molds.

Download white paper

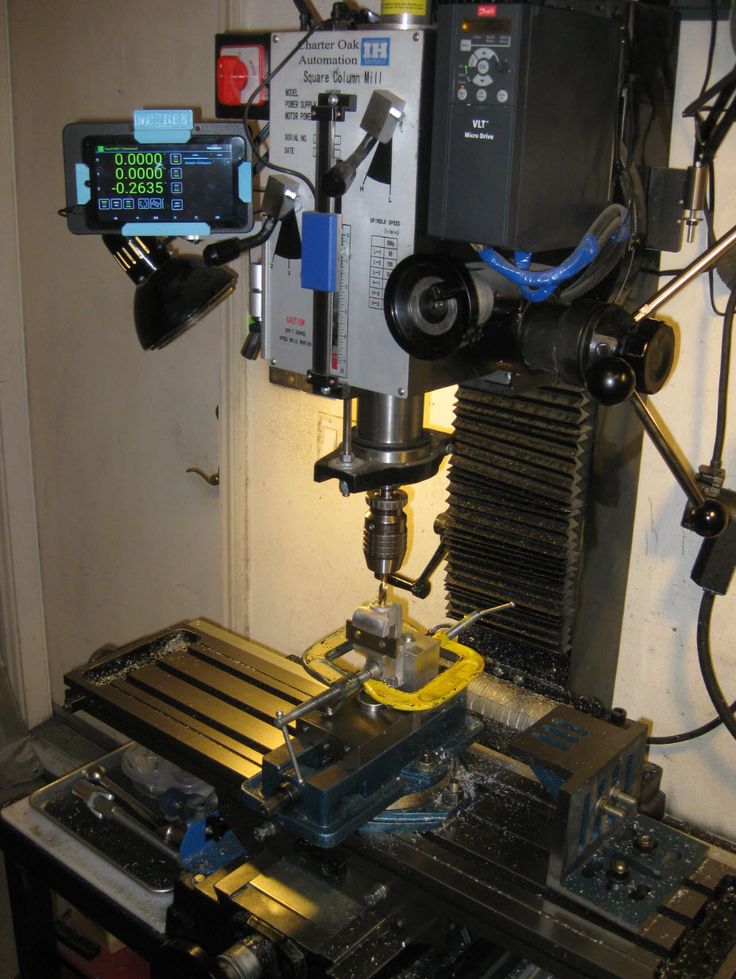

3D printed aluminum frame molds and die-cast model.

With affordable desktop 3D printers, heat-resistant 3D printing materials and injection molding machines, you can create molds yourself to produce functional prototypes and small models from industrial plastics. In the case of small-scale production (approximately 10-1000 models), injection molds created using 3D printing save time and money by eliminating expensive metal molds. They also provide a more flexible approach to manufacturing, allowing engineers and design professionals to prototype injection molds, test mold configurations, or easily modify molds while continuing to iterate, thanks to short order lead times and turnaround times. nine0003

Stereolithography (SLA) technology is a great solution for injection molding.

It is distinguished by the fact that it allows you to create molds with a smooth surface and high precision, giving these qualities to the finished model, as well as simplifying the process of removing from the mold. SLA 3D printing provides chemical bonding, density and isotropy of the manufactured models, which makes it possible to produce functional molds of a quality that cannot be achieved with Fused Deposition Modeling (FDM) printers. Desktop stereolithography printers, such as those offered by Formlabs, simplify your workflow because they are easy to implement, use, and maintain. nine0003

It is distinguished by the fact that it allows you to create molds with a smooth surface and high precision, giving these qualities to the finished model, as well as simplifying the process of removing from the mold. SLA 3D printing provides chemical bonding, density and isotropy of the manufactured models, which makes it possible to produce functional molds of a quality that cannot be achieved with Fused Deposition Modeling (FDM) printers. Desktop stereolithography printers, such as those offered by Formlabs, simplify your workflow because they are easy to implement, use, and maintain. nine0003 Formlabs created High Temp Resin for small production runs of injection molded models. It has the highest heat distortion temperature on the market and one of the highest among Formlabs resins: 238°C at 0.45 MPa. High Temp Resin can withstand high casting temperature and shorten the cool down time. Our white paper provides a case study from Braskem. She completed 1,500 casting cycles using a single 3D printed High Temp Resin profiling insert to make the face mask neck straps.

The company printed the insert and placed it in a conventional metal mold integrated with the injection molding system. This is an effective solution for the production of medium batches of models. The printed insert can be replaced as the project parameters change or if it breaks. This solution allows molds to be created as needed with complex geometries that are difficult to create with traditional methods, and also provides the possibility of multi-stage casting. nine0003

The company printed the insert and placed it in a conventional metal mold integrated with the injection molding system. This is an effective solution for the production of medium batches of models. The printed insert can be replaced as the project parameters change or if it breaks. This solution allows molds to be created as needed with complex geometries that are difficult to create with traditional methods, and also provides the possibility of multi-stage casting. nine0003 However, High Temp Resin is quite brittle. In the case of more intricate shapes, it is easily deformed and cracked. For some models, it is difficult to complete more than a dozen cycles. To solve this problem, the young French company Holimaker used Gray Pro Resin. This polymer has a lower thermal conductivity than High Temp Resin, which increases the cooling time. However, it is softer and able to withstand hundreds of cycles.

Formlabs recently released Rigid 10K Resin, an industrial grade material with a high fiberglass content.

It can convey a variety of geometric features and withstand injection molding processes. Rigid 10K Resin has a thermal distortion temperature of 218°C at 0.45 MPa and an elastic modulus of 10,000 MPa, making it strong, incredibly stiff and heat resistant. Novus Applications has cast hundreds of structurally complex threaded caps with just one Rigid 10K Resin mold. As more companies start using Rigid 10K Resin, we believe this resin will be a great help in 3D printing complex injection molds. nine0003

It can convey a variety of geometric features and withstand injection molding processes. Rigid 10K Resin has a thermal distortion temperature of 218°C at 0.45 MPa and an elastic modulus of 10,000 MPa, making it strong, incredibly stiff and heat resistant. Novus Applications has cast hundreds of structurally complex threaded caps with just one Rigid 10K Resin mold. As more companies start using Rigid 10K Resin, we believe this resin will be a great help in 3D printing complex injection molds. nine0003 Download our free white paper to learn about practical use cases and how to make your own injection molds using 3D printing.

Download white paper

Based on our customers' internal testing and case studies, we recommend selecting a 3D printing resin based on the criteria shown in the table below. Three stars mean that the polymer is very effective, one star means that it is not very effective. nine0203

★ ★★ ★★★ The more complex the model and mold design, the more difficult the injection molding process.

Using 3D printed molds, models can be molded from various materials such as polypropylene, polyethylene, thermoplastic elastomer, TPU or polyamide. Low viscosity material can reduce pressure and increase mold life. Polypropylene and thermoplastic elastomers are easy to process. Using them, you can perform a large number of cycles. In contrast, more technical plastics such as polyamide allow for fewer cycles. A release agent makes it easier to separate the model from the mold, especially for flexible materials such as TPU or thermoplastic elastomers. nine0003

Using 3D printed molds, models can be molded from various materials such as polypropylene, polyethylene, thermoplastic elastomer, TPU or polyamide. Low viscosity material can reduce pressure and increase mold life. Polypropylene and thermoplastic elastomers are easy to process. Using them, you can perform a large number of cycles. In contrast, more technical plastics such as polyamide allow for fewer cycles. A release agent makes it easier to separate the model from the mold, especially for flexible materials such as TPU or thermoplastic elastomers. nine0003 The type of injection molding machine does not greatly affect the process. If you have little experience with injection molding and would like to try this method at no extra cost, we recommend using a desktop injection molding machine such as the Holipress or Galomb Model-B100.

White paper

Download our white paper to learn how to use 3D printed molds for injection molding to help you cut costs and order lead times, and see real world application examples 3D printed by Braskem, Holimaker, and Novus Applications.

nine0003

nine0003 Read White Paper

We recommend that you follow the design rules for additive manufacturing as well as the general design rules for injection molding, such as two or three degrees taper, uniform model wall thickness, and rounded edges. Here are some helpful tips from users and professionals regarding resin printed molds:

To optimize dimensional accuracy:

- Plan the mold allowance for post-processing and dimensional changes. nine0006

- Print one batch of the mold to learn about deviations from the specified dimensions and take them into account for the mold model in CAD.

For longer mold life:

-

Open the sprue to release pressure in the cavity.

-

If possible, design one side of the floor flat and the other as designed. This will reduce the chance of blocks shifting and splashing.

nine0005

Create large air ducts from the edge of the cavity to the edge of the mold.

This will improve the flow of material into the mold, minimize pressure, and reduce the chance of splashing in the sprue for faster cycle times.

This will improve the flow of material into the mold, minimize pressure, and reduce the chance of splashing in the sprue for faster cycle times. - Creation of a mold on a 3D printer guarantees rapid prototyping of parts from drawings or 3D file data.

-

Avoid thin cross-sections: under the influence of temperature, a surface with a thickness of less than 1-2 mm may be deformed.

-

Modify the back of the mold to minimize the amount of material used: reduce cross-cuts in areas that do not support the cavity. This will save resin and also reduce the chance of printing errors or warping. nine0003

-

Add a beveled edge to remove the product from the work platform.

-

Add centering holes at the corners to align both models.

- Thermoforming and vacuum forming

- Silicone molding (including multilayer and insert molding)

- Molded using vulcanized rubber

- Jewelry casting

- Metal casting

For print optimization:

If you have any questions about the workflow, please read our article in the FAQ section titled "Injection Molding in 3D Printed Molds". For full details of the workflow and recommended practices, download our technical white paper.

nine0064

nine0064 3D printed injection molds can withstand side loads.

By combining mold making with desktop 3D printing, engineers and designers can expand their 3D printer's range of materials and capabilities beyond rapid prototyping into industrial manufacturing.

3D printed molds, dies and samples to complement molding and casting processes are generally faster and cheaper than CNC milled models and easier than silicone molds. nine0003

In addition to injection molding, 3D printed molds can be used for the following molding and casting processes:

To download our technical reports with specific recommendations for each process, use the appropriate links. nine0003

White paper

Are you interested in other uses for 3D printed molds? Download our white paper which also talks about thermoforming and injection molding of elastomers.

Learn more

-

-

- Creating a mold on a 3D printer guarantees rapid production of part prototypes from drawings or 3D file data.

Special features, such as embossed markings on flat and conical parts of the product, are very difficult to achieve with these methods.

The situation is the same with the wooden master models. To obtain a mold, they are covered with a special mixture of betonite and sand, due to which the method is called "casting into the ground. " Such an operation requires a huge amount of labor and time, and most importantly, it is quite expensive and does not provide the required accuracy of the finished product.

" Such an operation requires a huge amount of labor and time, and most importantly, it is quite expensive and does not provide the required accuracy of the finished product.

Disadvantages of traditional casting

Conventional mold making techniques include 3D modeling and the production of a master model using milling, manual labor or other types of machining. All these methods are quite laborious and have obvious disadvantages:

Special features, such as embossed markings on flat and conical parts of the product, are very difficult to achieve with these methods. nine0003

The situation is the same with the wooden master models. To obtain a mold, they are covered with a special mixture of betonite and sand, due to which the method is called "casting into the ground. " Such an operation requires a huge amount of labor and time, and most importantly, it is quite expensive and does not provide the required accuracy of the finished product.

" Such an operation requires a huge amount of labor and time, and most importantly, it is quite expensive and does not provide the required accuracy of the finished product.

3D printing and injection: why it's worth it

3D printing speeds up the mold creation cycle many times over. It takes only a few hours to produce a high-precision master model using a 3D printer (as opposed to long and painstaking manual work). In addition, the master can be sure that he will receive a product that matches the digital model by 100%. nine0003

3D printing allows you to make casting master models from different materials

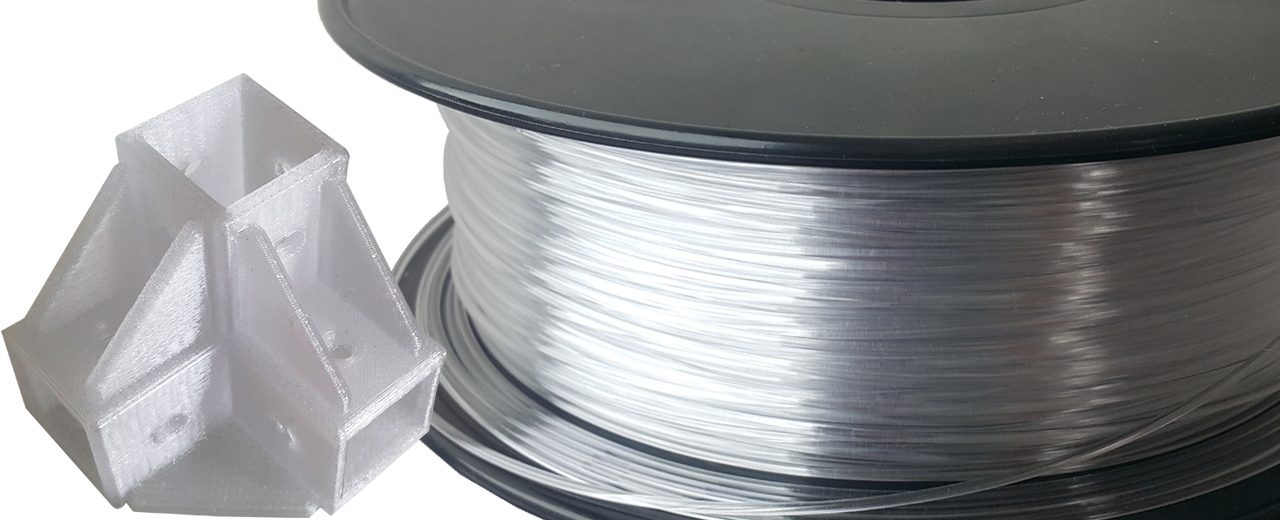

Wax. This material produces blanks for creating molds with a melting point of about 60 degrees, smooth surfaces and excellent detail. 3D stencils are most widely used in industry, dentistry, and jewelry.

3D printing and injection: why it's worth it

3D printing speeds up the mold creation cycle many times over. It takes only a few hours to produce a high-precision master model using a 3D printer (as opposed to long and painstaking manual work). In addition, the master can be sure that he will receive a product that matches the digital model by 100%. nine0003

It takes only a few hours to produce a high-precision master model using a 3D printer (as opposed to long and painstaking manual work). In addition, the master can be sure that he will receive a product that matches the digital model by 100%. nine0003

3D printing allows you to make casting master models from different materials

Wax. This material produces blanks for creating molds with a melting point of about 60 degrees, smooth surfaces and excellent detail. 3D stencils are most widely used in industry, dentistry, and jewelry.

3D Wax Printers >>

Photopolymer. Burnout master models (burnout temperature from 600 degrees) with an ash content of 0.01% are created from this material, as well as high-precision samples for creating silicone molds. nine0003

Wax 3D printers >>

Photopolymer. Burnout master models (burnout temperature from 600 degrees) with an ash content of 0.01% are created from this material, as well as high-precision samples for creating silicone molds.

Resin burnout

3D printed silicone mold

Resin burnout

3D printed silicone mold

In addition, when using a 3D printer for foundry production in Moscow and other cities of Russia, it became possible to refine the master model in a new way. Under the complex geometric design, grooves are made on the mold, into which the missing pieces of durable material made using 3D printing are glued. The use of this technology significantly reduces labor costs for manual refinement, and also reduces the time for preparing the mold for casting.

Before starting production, 3D prototyping can optimize the working steps of the casting process. For example, after trial tests of injection molds, you can check the parts made in them and correct the molds without any difficulties, without creating a new model equipment each time. nine0003