3D printer plug and play

Buy a plug-and-play 3D printer in USA | 3D printing experts

Creality 3D

CR-200B

Enclosed 3D printer with virtually no assembly required

- Build volume: 200x200x200mm

- Heated bed: Yes

- LCD+SD card: Yes

- Materials: PLA, PETG

- Filament diameter: 1.75mm

$ 310.50

In stock

Compare

FlashForge

Adventurer 3 Wifi

Very feature complete 3D printer with WIFI, network and a camera

- Build volume: 150x150x150mm

- Heated bed: Yes

- LCD+SD card: Yes

- Network: Ethernet and WIFI

- Camera: Yes

$ 349

In stock

Compare

FlashForge

Creator Pro

Dual extruder 3D printer for creative designing and prototyping!

- Build volume: 227x148x150mm

- Extruders: 2

- LCD+SD: Yes

- Filament diameter: 1.

75mm

- Auto bed leveling: Yes

$ 538.50

In stock

Compare

FlashForge

Creator Pro 2

Dual extruder 3D printer for creative designing and prototyping!

- 3.5” touchscreen

- Four 3D printing modes

- Spacious build volume

- Anti-scrape dual extruders

- Print a range of filament

$ 618. 50

50

In stock

Compare

FlashForge

Adventurer 4

The 3D printer for material experimentation and high productivity

- HEPA 13 air filter

- 3 nozzle options

- Resume printing

- Magnetic build plate

- Monitor your prints

$ 658.50

In stock

Compare

FlashForge

Inventor

The 3D printer for personal and professional prototyping

- Dual-extrusion

- 3.

5” touch screen

5” touch screen - Wi-Fi connectivity

- 240°C nozzles

- Flexible build plate

$ 852.50

In stock

Compare

Creality 3D

CR-5 Pro H

High-temperature version

Impressive plug-and-play high-temperature 3D printer for professional and at-home use.

- High printing temperature of 300°C

- Maximum bed temperature 110°C

- Ultra silent motherboard

- BLTouch auto bed leveling

- Superior master chip

$ 942

In stock

Compare

FlashForge

Guider II

Professional 3D printer with a spectacular sized build volume for small production

- Huge build space

- Auto-bed leveling

- Resume 3D printing

- Wireless 3D printing

- Touchscreen display

$ 1,162. 75

75

In stock

Compare

FlashForge

Creator 3

Industrial level 3D printing with dual extrusion & massive build space

- Fast printing

- Smart leveling

- 4 printing modes

- Flexible heated bed

- Max. temperature 300°C

$ 1,730.50

In stock

Compare

FlashForge

Creator 3 Pro

Improved version of the popular Creator 3

- Print Nylon or carbon fiber

- Smart leveling

- 4 printing modes

- Flexible heated bed

- Max.

temperature 320°C

temperature 320°C

$ 2,143.50

In stock

Compare

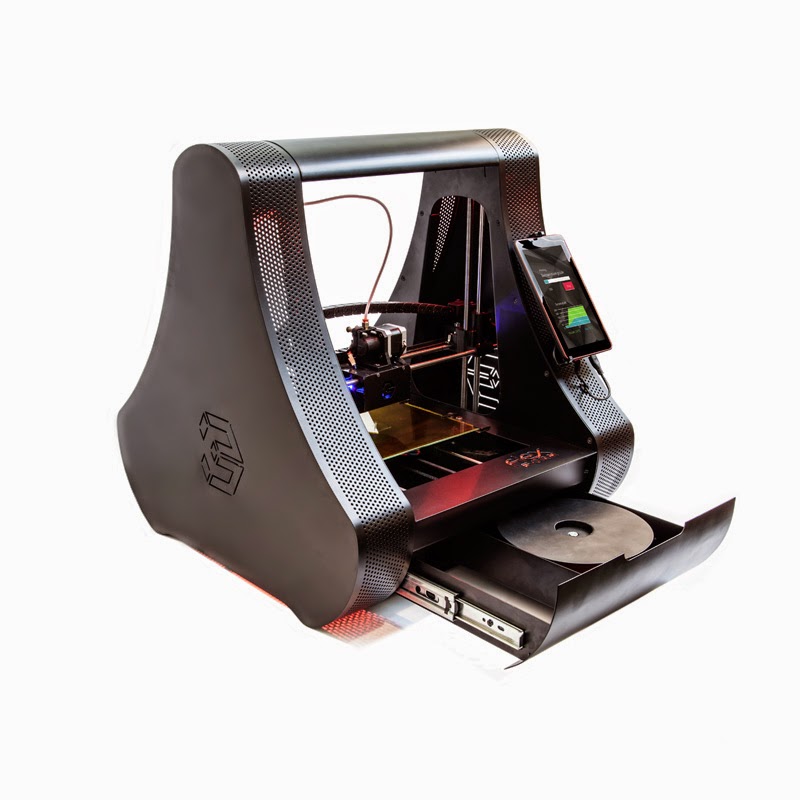

Zaxe

X3

Innovative compact and enclosed machine for industrial-grade 3D printing

- Heated chamber

- Flexible build plate

- 7” color touch screen

- E3D V6 titanium hot end

- Max. temperature of 280°C

$ 2,332. 50

50

In stock

Compare

Zaxe

Z3

Innovative enclosed 3D printer with a large build volume

- Heated chamber

- Flexible build plate

- 7” color touch screen

- E3D V6 titanium hot end

- Printing speed of 300 mm/sec

$ 4,126.50

In stock

Compare

FlashForge

Finder Wifi

Low cost plug and play 3D printer

- Build volume: 140x140x140mm

- Heated bed: No

- LCD+SD card: Yes

- Materials: PLA, PETG, FLEX

- Filament diameter: 1.

75mm

75mm - Auto bed leveling: No

Creality 3D

CR-5 Pro

Trustworthy plug-and-print 3D printer, ideal for both personal as professional use

- Print volume: 300x225x380mm

- Warmed bed: Yes

- LCD+SD Card: Yes

- Materials: PLA, PETG, ABS

- Filament diameter: 1.75mm

$ 960

Compare

View our selection of plug-and-play 3D printers. We have chosen high-quality 3D printers from the best brands that offer great printing results. With the 3D printers in this selection, you will be able to print right away. There is no assembly or setup required, and this will save time allowing you to focus on 3D printing. This collection of 3D printers is dedicated to all beginners and makers of all levels!

We have chosen high-quality 3D printers from the best brands that offer great printing results. With the 3D printers in this selection, you will be able to print right away. There is no assembly or setup required, and this will save time allowing you to focus on 3D printing. This collection of 3D printers is dedicated to all beginners and makers of all levels!

Features of the plug-and-play DIY printer kits

We would like to highlight the different features and attributes of the plug-and-play 3D printers of this assortment. All the 3D printers have their own advantages and unique benefits. Select a 3D printer with the printing temperature and filament material options that you prefer most. This will be based on what kind of properties you would like your 3D objects to have. Be sure to also choose a print volume that will match your printing needs. The build volume is the full space available for the 3D model itself, which will determine the size of the parts that you will be able to create. If you are looking to create more complex prints with a combination of colors or support filament, have a look at the Flashforge Creator Pro 3D printer. Consider if you will find a wifi connection useful and whether you would prefer to have the auto-bed leveling feature. All our plug-and-play 3D printers are enclosed, providing safety and sound reduction. Use the left filter menu to easily select your plug-and-play 3D printer or the compare feature at the bottom of all 3D printers to place all specifications beside one another.

If you are looking to create more complex prints with a combination of colors or support filament, have a look at the Flashforge Creator Pro 3D printer. Consider if you will find a wifi connection useful and whether you would prefer to have the auto-bed leveling feature. All our plug-and-play 3D printers are enclosed, providing safety and sound reduction. Use the left filter menu to easily select your plug-and-play 3D printer or the compare feature at the bottom of all 3D printers to place all specifications beside one another.

Printing with a plug-and-play 3D printer

Print immediately with the literal plug-and-play 3D printers. From the moment you plug in your 3D printer, you should be able to print models straightaway. Make sure that you will be ready to print as soon as your plug-and-play 3D printer arrives. Have your filament material stored and prepared. To ensure a successful print, arrange to have sprays or Kapton tape ready for the foundation and adhesion of the 3D model. We also provide a series of tools to support you along the way. For some more guidance, view the tutorials online where you can perform 3D printing step-by-step with fellow makers.

We also provide a series of tools to support you along the way. For some more guidance, view the tutorials online where you can perform 3D printing step-by-step with fellow makers.

Plug-and-play 3D printers software

The plug-and-play 3D printers are delivered with software so that you can immediately start printing. The FlashForge 3D printers will come with the software FlashPrint and the Creality 3D printers will have the Creality Slicer Software. FlashPrint is easy to use and is great for both beginners and professional makers. The Crealtiy Slicer offers numerous settings and 3D printing features, however, it will only run on Windows. Both brands’ plug-and-play 3D printers are also compatible with alternative software that can easily be downloaded online.

Would you like to have more information about plug-and-play 3D printers? Feel free to reach out to our customer service, we are happy to be of assistance!

Ten 3D Printers that are Near Click-and-Print-Capable Right from the Box

We have coffee makers that can make a cup of joe right out of the box. We have smartphones that require little to no setup when bought new. We have printers that are plug-and-play, needing only a simple driver install before churning out print after print. So, why is it so tough to get 3D printers to do the same—function right out of the box with little to no setup beyond connecting to your device of choice and simply uploading your CAD model?

We have smartphones that require little to no setup when bought new. We have printers that are plug-and-play, needing only a simple driver install before churning out print after print. So, why is it so tough to get 3D printers to do the same—function right out of the box with little to no setup beyond connecting to your device of choice and simply uploading your CAD model?

Granted, many variables differ for each print—size, resolution dynamics, and choice of material all come into play for each print. However, there should be a standard when it comes to plug-and-play for these machines. Auto-find my file type and just print the object using the CAD data therein…is that so difficult? Can we not have a civilization? Certainly, technology has come a long way to be able to handle such a feat, and in this roundup, we’ll look at ten 3D printers that come close to the notion of “click-and-print” with minimal setup.

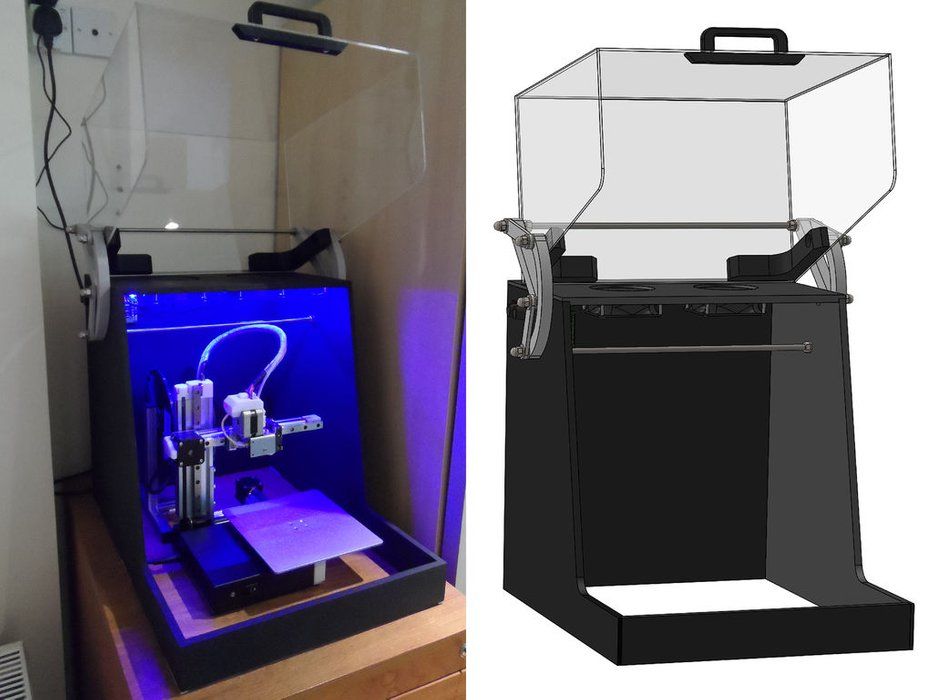

TierTime Upbox+ $1,899 (Courtesy of TierTime)

Metal frame? Check. Enclosed casing? Check. Heat print bed? Check. All three of those features make for a decent 3D printer, allowing for a more consistent print, and TierTime’s Upbox has them and more. It comes with a closed plastic casing, a modularized melted-extrusion-modeling (MEM) print head and has a build volume of 10 × 8 × 8 in. As far as filaments go, it can take advantage of ABS, ABS+, and PLA, but will support others in the near future.

Enclosed casing? Check. Heat print bed? Check. All three of those features make for a decent 3D printer, allowing for a more consistent print, and TierTime’s Upbox has them and more. It comes with a closed plastic casing, a modularized melted-extrusion-modeling (MEM) print head and has a build volume of 10 × 8 × 8 in. As far as filaments go, it can take advantage of ABS, ABS+, and PLA, but will support others in the near future.

On the software side, the Upbox uses Up Studio, which is straightforward and supports STL and UP3, although others can be converted using third-party platforms. Setup is easy as well by connecting to your PC, Mac, or iOS device via USB or Wi-Fi.

Once the initial setup routine is complete, you can then upload your 3D file, manipulate the parameters needed (if required), and the Upbox does the rest. While it isn’t a simple plug-and-play machine, it does come pretty close, and with the myriad of features that come packed with it (blackout recovery, filament run-out recovery, HEPA filter, and more), it’s hard to pass this one up.

If you work for a company that needs a 3D printer or wants to try one, get this first. Printing parts in ABS will change how you prototype forever.

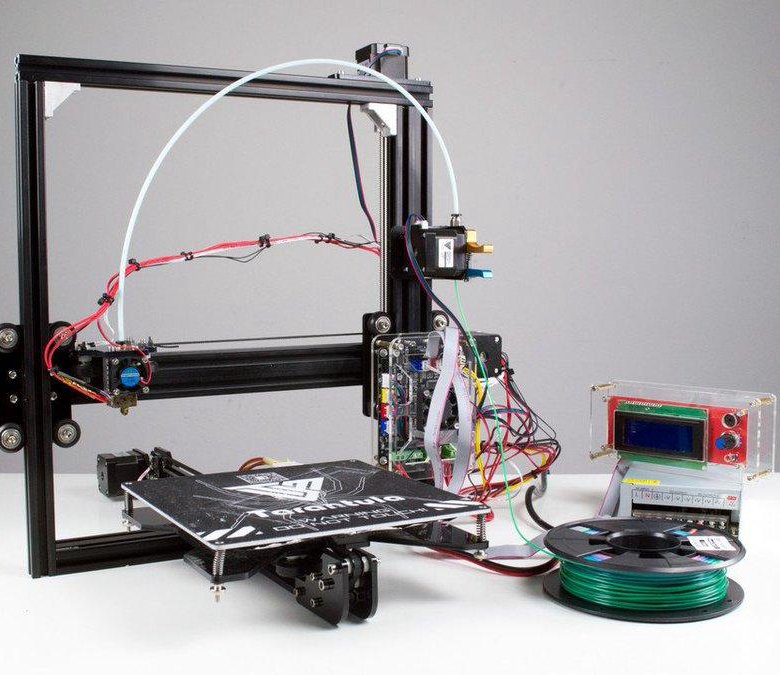

MakerGear M2 $1,825 (Courtesy of MakerGear)

The MakerGear M2 is similar to the Upbox in that it features a metal frame, heated print bed (110°C and up), and a build area of 8 × 8 × 10 in. However, it doesn’t have an enclosed case (although you could build your own) and comes with no software. Although they do recommend Simplify3D, you can use the modeling platform of your choice, such as Slic3er, Simplify3D, Blender, or SketchUp. Beyond the specs mentioned above, the M2 features 4-point leveling, single/dual extruder, and aluminum construction.

As far as filaments go, it can handle PLA, ABS, PET, HIPS, Poly and metal, wood, and carbon-fiber composites. When it comes to simplicity of use, MakerGear states, “open box, follow instructions, and beautiful prints will soon follow.” The M2 is probably the only 3D printer on this list that manages to get as close to plug-and-play or set-and-forget as possible—connect via USB (or use SD card), run initial setup, and upload your 3D model.

This is the printer used at my shop, to be honest. After much deliberation and searching models, this printer was found to produce amazing results… if everything is set just right. The metal frame was the first requirement, coming off of a plastic unibody printer I had before it. Since getting the MakerGear M2, an enclosure was built for it, one of those Ikea end-table mod enclosures. It consists of two end tables stacked on top of each other. The software driving it is Simplify3D. So far, the results are the best I have seen outside a quarter-million-dollar Objet printer.

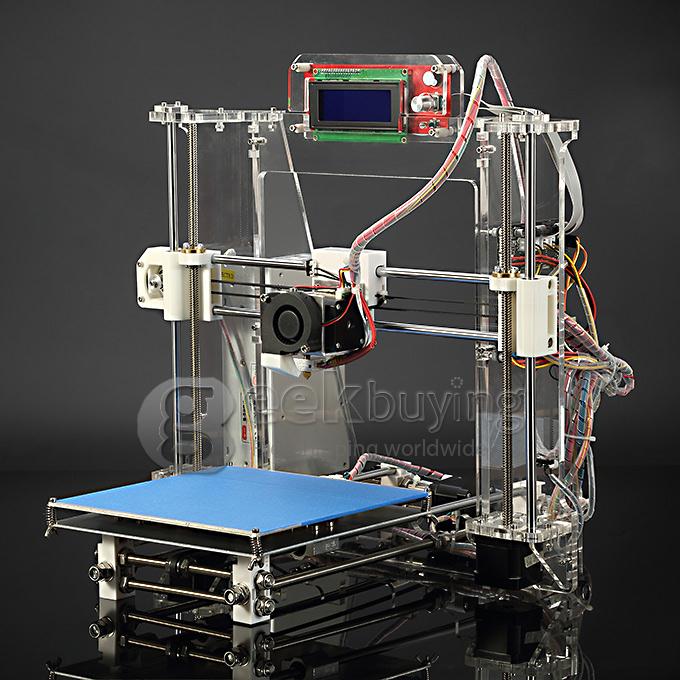

TEVO Tarantula I3 $237 and up (Courtesy of TEVO 3D Technologies)

The bare minimum is the phrase that best describes TEVO’s Tarantula I3 3D printer. This machine comes as a kit, and it’s a great platform for beginners (or even experts for that matter) as a starter printer for its ease of use and ultra-low cost.

Ease of use and low cost don’t make a great 3D printer by no means, nope. It must meet the criteria stated previously, and it does—it comes with a solid metal frame and heated bed with self-leveling capability, but it doesn’t have an enclosure, thereby negating consistent heat and allowing for ambient airflow (bad for repeated print consistency). That doesn’t mean it’s not worth of building your own.

That doesn’t mean it’s not worth of building your own.

Regardless of that drawback, the Tarantula I3 features (depending on the additional extras) an 8- × 8- × 8-in. build area, dual-color metal extruder, and can take advantage of ABS, PLA, PETG, wood and PVS filaments. It uses a TF card or USB port for connecting to a PC or Mac, and like the MakerGear M2, you can use your software of choice for uploading G-code.

This is another instance where an enclosure built around it is a must. Prepare for a little project before using this printer.

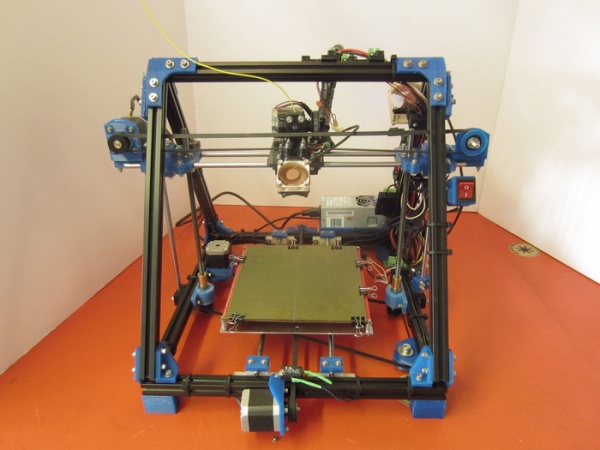

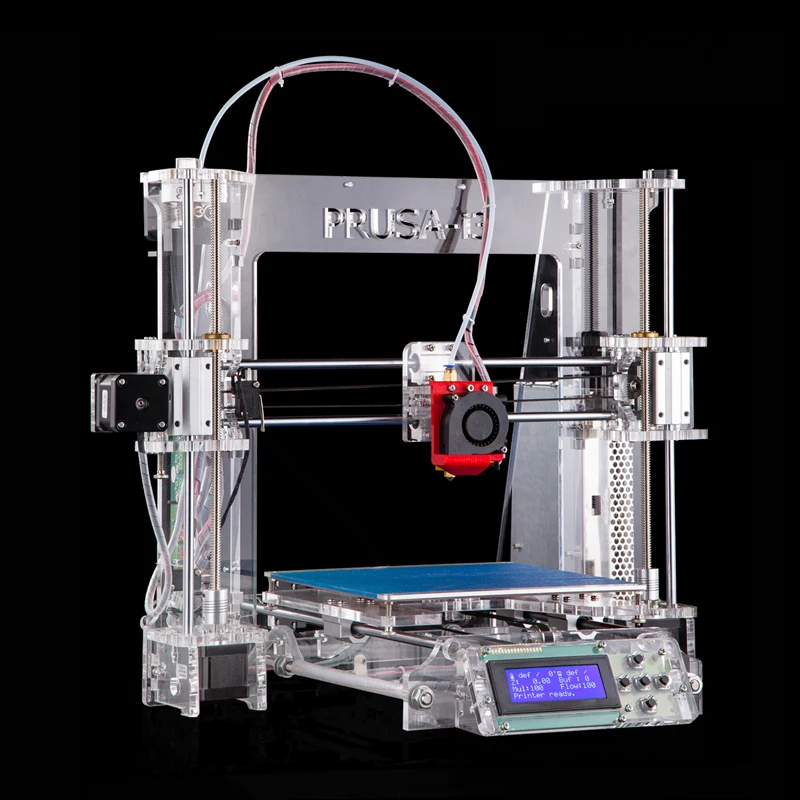

Prusa Research Prusa i3 $699 (Courtesy of Prusa Research)

Like the Tarantula, the Prusa i3 is based on the RepRap Project to produce a low-cost 3D printer that can make its own components. As such, this machine also comes in kit form. However the design is a little more refined than the Tarantula, and includes an aluminum frame, heated bed with auto-leveling, and integrated LCD and SD card controller. Nope, no case with this one as well; however, with most open platforms, you can make your own thermal-controlled box to keep things consistent.

The Prusa i3 also features an 8- × 8- × 8-in. build area, RepRap-based open-source electronics, and comes with the company’s version of Slic3r to get things up and running. It also runs the entire gamut of filaments, ranging from ABS, PLA, and PET to NinjaFlex, nylon, and bamboofill—all of which pass through an E3D V6 extruder.

Makerbot Replicator+ $2,499 (Courtesy of Makerbot)

Makerbot is known for its quality 3D printers, and the Replicator+ is a testament to that reputation, considering it has been around forever. Surprisingly, this 3D printer meets only two of the desirable qualities wanted for great prints: A powder-coated metal frame with an ABS case, but there’s no heated print bed! Instead, the Replicator+ features the company’s bendable Flexible Build Plate with kung-fu grip, which keeps prints from moving and pop off when done.

With that caveat in mind, the machine boasts many good features, and it’s easy to use. The printer comes with a hot-swap Smart Extruder+, which can be replaced quickly if problems arise. It also includes an internal camera that allows you to view your prints remotely to monitor progress, as well as an intuitive LCD display that lets you change settings, view files, and access cloud-based models.

It also includes an internal camera that allows you to view your prints remotely to monitor progress, as well as an intuitive LCD display that lets you change settings, view files, and access cloud-based models.

The main feature, though, is its connectivity options, being able to connect over USB, Wi-Fi, Ethernet, and even remotely over the Makerbot app. As for software, it uses Makerbot Print, which lets you easily upload your own 3D models or imported from those taken from the cloud. You can even control a series of Makerbot prints through other connected machines if there’s a need. The only real drawback (besides the heated bed issue) is you’re limited on what filaments can be used, in this case only PLA.

Community is a huge draw for this printer. Their library of 3D models, prints, etc. is hard to ignore.

Ultimaker 3 $3,495-$4,295 (Courtesy of Ultimaker)

If you can afford it, the Ultimaker 3 (standard and extended versions) is an easy-to-use 3D printer that produces consistent quality prints and exceeds the requirements for a solid machine. Solid metal frame, heated glass print bed, and case are all present on this machine. What’s more, it features dual extrusion so that you can print in different colors and with the different filament at the same time.

Solid metal frame, heated glass print bed, and case are all present on this machine. What’s more, it features dual extrusion so that you can print in different colors and with the different filament at the same time.

Like the Replicator+, it features an internal camera for monitoring prints and has swappable print heads. It also features active leveling, which alters the bed automatically, depending on the job. Build volume measures-out at 8.5 × 8.5 × 7.8 in. (for the standard version), and it uses all standard filaments—ABS, PLA, PVA, Nylon, and CPE. What’s interesting is that the 3D printer utilizes NFC tags that read what the filament is when installed, and then adjusts the settings accordingly.

Connection options include USB and Wi-Fi and files can be uploaded with a flash drive. On the software end, the Ultimaker 3 uses the company’s version of Cura to get prints optimized and ready for manufacturing, utilizing both basic and advanced settings. Turn on, connect, and print; it doesn’t get any easier than this.

Flashforge Creator Pro $899 (Courtesy of Flashforge)

It’s not the cheapest or most expensive 3D printer on the market, but the Flashforge Creator Pro is easy to use and built like a tank, making it perfect for this roundup. Beyond its solid steel frame, heated aluminum auto-leveling print bed, and PVC case are a dual extruder print head, an 8.9- × 5.9- × 5.7-in. build area and front-mounted LCD display for changing settings.

ABS, PLA, Nylon, composites (metal and wood), and dissolvable filaments can all be used with the Creator Pro. The company states that the extruders can be modified to handle flexible materials if they decide to release them in the near future. For software, Flashforge ships this with an SD card pre-loaded with the ReplicatorG open-source platform, which is easy to use, even for beginners. The card also contains the manual as well as design ideas if you get stuck on what to print.

XYZprinting da Vinci 1.0 Pro $699 (Courtesy of XYZprinting)

XYZprinting also offers a sturdy 3D printer with its da Vinci 1. 0 Pro and comes complete with solid metal frame, heated bed, and plastic enclosure. What makes this printer different from the others is that it has a unique calibration system that’s adjusted using knobs and onboard software that guides you using the printer’s LCD display.

0 Pro and comes complete with solid metal frame, heated bed, and plastic enclosure. What makes this printer different from the others is that it has a unique calibration system that’s adjusted using knobs and onboard software that guides you using the printer’s LCD display.

Like some of the other models mentioned previously, the printer utilizes Wi-Fi, USB, and a mobile app to upload models as well as accessing other cloud-based designs. While you can only use either ABS or PLA filament, you are not restricted to the in-house material. That means you can use your filament of choice regardless of manufacturer.

Another interesting feature of the da Vinci 1.0 Pro is that you can swap out the print head with a laser engraver for etching designs on almost anything, including wood, leather, and cardboard. XYZware rolls the software show and is easy to use to manipulate models, although you can simply upload an STL file and hit print.

Qidi Technology X-One $499 (Courtesy of Qidi Technology)

There’s nothing overtly exceptional to Qidi Technology’s X-One 3D printer; it’s not going to win an award for being flashy as simplicity is the name of the game here. It is solidly built, though, with an all-metal design, and uses the same FDM manufacturing method like most other entries in this list. Beyond its construction, it was designed more as a child-friendly teaching tool and features a single fan-cooled extruder, able to print objects from 100 to 500 microns with a volume up to 5.5 × 5.5 × 5.5 in.

It is solidly built, though, with an all-metal design, and uses the same FDM manufacturing method like most other entries in this list. Beyond its construction, it was designed more as a child-friendly teaching tool and features a single fan-cooled extruder, able to print objects from 100 to 500 microns with a volume up to 5.5 × 5.5 × 5.5 in.

PLA and ABS are the only options here for filament choices, but as a learning tool, that’s all you really need. Like some of the other 3D printers here, it features an intuitive touchscreen for adjusting settings—resolution, temperature, material, etc. It is also pretty limited regarding connecting options, which include USB and SD card only with no Wi-Fi support.

The SD card comes pre-loaded with Cura, but others can be used depending on your preferred platform. While X-One may seem underwhelming on all fronts, it is really well constructed and a great option for those looking for a “set it and forget it” option.

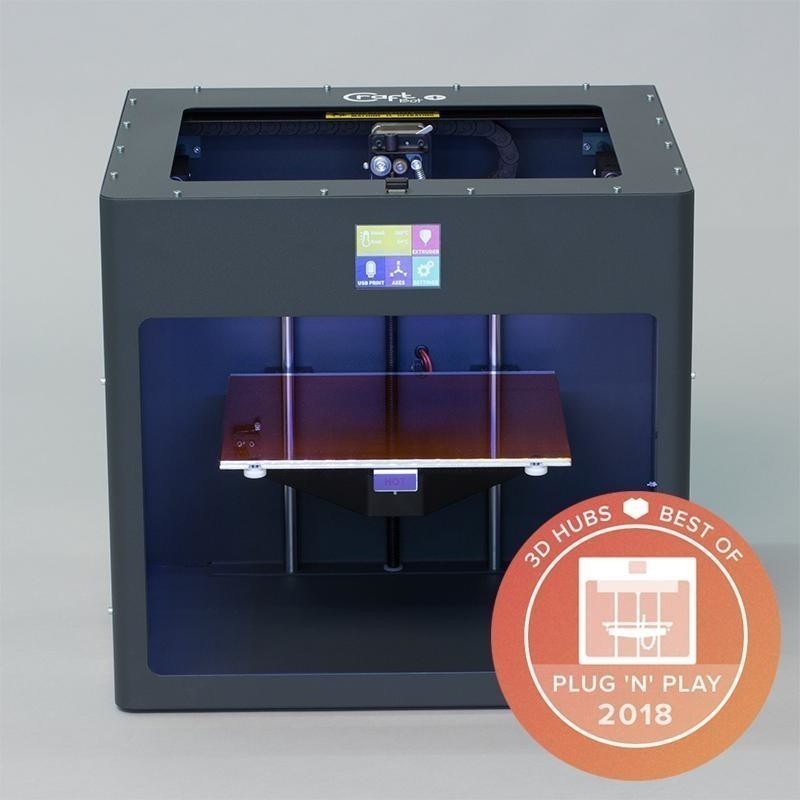

Zortrax M200 $1,800 (Courtesy of Zortrax)

The last entry in this roundup was voted best plug-and-play 3D printer by 3D Hubs last year in 2016, and for good reason. Zortrax’s M200 has a great build quality with a full-metal frame encased in an all-aluminum housing, providing great stability while printing. Good looks aside, it features a perforated heated, auto-leveling bed with a build area of 8 × 8 × 7.2 in.

Zortrax’s M200 has a great build quality with a full-metal frame encased in an all-aluminum housing, providing great stability while printing. Good looks aside, it features a perforated heated, auto-leveling bed with a build area of 8 × 8 × 7.2 in.

While it only uses a single direct-feed extruder, it makes up for it with a detailed resolution of up to 400 microns, providing a high level of detail to any print. Like most of the others, this 3D printer can either tether to your PC or Mac via USB or access files from an SD card. Sadly, there is no Wi-Fi option, but no printer is perfect.

It does feature a small LED screen for navigating settings as well as a myriad of filament options, including ABS, PLA, Nylon, and many others. Zortrax’s Z-Suite software is easy to use and offers settings for beginner to advanced users, or you can simply upload an STL, OBJ, DXF, or 3MF file and hit print, then walk away.

Conclusion

There are a ton of 3D printers on the market that will cover just about any project aspect you have—some with high resolutions, others capable of using nearly any material, and still more offering a myriad of connection options and easy-to-use software packages. When it comes to plug-and-play or “set it and forget it” options, the list dwindles down. Still, they can be found, and at nearly every price-point. However, there really should be “standards” across all of them that makes them as easy to use as a PC-connected laser printer. Onward, to a 3D printer-in-every-garage world.

When it comes to plug-and-play or “set it and forget it” options, the list dwindles down. Still, they can be found, and at nearly every price-point. However, there really should be “standards” across all of them that makes them as easy to use as a PC-connected laser printer. Onward, to a 3D printer-in-every-garage world.

As a beginner I bought a 3D printer. Choosing, setting up, problems and solving practical problems / Sudo Null IT News

A few months ago, I was thinking about purchasing such a device because I wanted to print a broken part of my robot vacuum cleaner. About a month ago I bought a device I liked on eBay. That's what was important to me when choosing a 3D printer.

Which printer was needed?

Considering that I knew almost nothing about 3D printers (except for a few articles read here, on Habré), the important points were:

- Printer performance out of the box. I have seen several articles describing how long it takes to set up a "simple Chinese printer".

It needs to be assembled from a large number of parts, and it is not a fact that there will not be defective ones among them. Once assembled, you can mess around with the device for a couple of days, and then it turns out that for some reason it does not work. In short, I needed a printer that didn't need to be assembled and that could work right out of the box.

It needs to be assembled from a large number of parts, and it is not a fact that there will not be defective ones among them. Once assembled, you can mess around with the device for a couple of days, and then it turns out that for some reason it does not work. In short, I needed a printer that didn't need to be assembled and that could work right out of the box. - It shouldn't be too expensive. Seriously, I'm new, I was not sure that after a couple of days I would not abandon the device. And a printer for 500-600 euros would be too expensive a toy. So I was willing to spend a couple of hundred, no more.

- It must not be too large. Before buying, I allocated a little space for installing the printer, somewhere around 50 * 50 cm. Therefore, the printer had to stand on the allocated area without any problems.

- It shouldn't be too difficult to maintain. This point is closely related to the first. I didn’t want to spend a lot of time on operation and maintenance work - there is sorely not enough time, so constantly eliminating emerging glitches is not an option.

- I wanted to get a printer with WiFi, it was not critical, but important.

What did I end up buying?

Model Geeetech E180. It was shown by Google after the query “3D printer for beginners”. There were other models in the search results, but this one was liked by the design and the presence of WiFi.

The developers of this printer raised money for it with the help of Kickstarter and a couple of years ago it appeared on the free market. Its price is from 200 to 350 euros, depending on the company that sells it and the store.

Bought on eBay, starting price was 200 euros, but the seller agreed to drop 50 euros, so the total price is 150.

Printer specifications:

- Print technology: FDM

- Working space dimensions: 130 x 130 x 130 mm

- Printing accuracy: 0.05 mm

- Positioning accuracy: X / Y 0.11 mm, Z 0.0025 mm

- Print speed: 80-110 mm/s

- Thread diameter: 1.

75 mm

75 mm - Nozzle diameter: 0.4 mm

- Supported material: PLA declared by the manufacturer, but can work with other materials

- Operating system: Windows

- Management software: EasyPrint 3D

- File format: .STL, G-code

- Maximum extruder temperature: 230 °C

- Power supply: DC 12V 6A

- Connectivity: WiFi, USB, TF card (offline printing support)

- Display: 3.2" full color touchscreen

- Chassis: metal plate + injection molding (portable console 3D printer)

- Work table: aluminum alloy plate

- XYZ Rods: wear resistant, stainless steel screw and lead (Z axis)

- Stepper motors: 1.8 degree stepped angle with 1/16 micro stepping

Unpacking and setup

Before setting up, I looked at several reviews and tests of the printer. If not for them, I would not have done it myself, the explanation in the instructions is slurred. The setup is simple, but not for a beginner.

The setup is simple, but not for a beginner.

The printer "wound up" as soon as I connected it to power and a laptop. I calibrated the position of the table - it turned out to be simple - inserted a microSD card into the slot, found the contents through the menu on the printer screen, inserted the fiber into the channel and started printing. The printer made a noise and started printing. Or rather, I thought that he started typing, in fact it was not so.

Problems

The printhead moved, the temperature reached 205 degrees Celsius, but there was almost no plastic - in the first few seconds, a few plastic “hairs” came out and that was it. The printer continued to work, but the plastic was not squeezed out of the head.

I wasted several Saturday hours trying to figure out why. I tried to look for an explanation on the net, but solutions to similar problems did not suit me.

The joy of buying disappeared in the first couple of hours of fuss. I wanted a printer that “just works”, but it didn’t work out. As a result, I realized that the fiber was not being fed - the feed mechanism hidden under the plastic cover simply did not work. It did not work because the constituent elements did not rotate. There was no movement at all.

I wanted a printer that “just works”, but it didn’t work out. As a result, I realized that the fiber was not being fed - the feed mechanism hidden under the plastic cover simply did not work. It did not work because the constituent elements did not rotate. There was no movement at all.

I have decided that the printer has a defective electric motor that is responsible for feeding, and I cannot repair it. The next step is to click the Return to Seller button on eBay. After clicking the button and describing the problem, I decided to pack the printer for shipping. Before sealing it in a foam box, just in case, I decided to carefully examine those “insides” that are visible through the holes in the case.

And the reason was immediately found - the assembler at the factory simply forgot to connect the power supply to the engine. Seriously, the cable just dangled inside the case. I connected it to the right connector with tweezers without disassembling the printer. Then I turned on the device again and this time everything was fine, the plastic feed worked as it should.

Then a few more minor problems arose:

- Misaligned table. This caused the table to skew and the print head was pressed against the surface in one place. As a result, the plastic could not be squeezed out of the head, which led to solid print defects;

- Unable to directly print models downloaded from the Internet. Being a beginner, I thought that everything works like with a regular printer - I downloaded a document, sent it to print. It turns out that slicing is also needed. I will not repeat what it is and why it needs to be perfectly described in this article on Habré;

- Slicers are not compatible with the printer model. The slicer needs to set the printer desktop size. Some slicers for some reason did not want to work with the dimensions of my printer (13*13*13 cm). Some even crashed (including the printer's native application), some did not "understand" the dimensions. As a result, I settled on ideaMaker;

- No WiFi.

As it turned out, there are two varieties of E180 - one with an integrated WiFi module, the second - without a module, you need to buy it in addition. At the seller, the inscription "need a separate module" was applied to one of the photos of the printer, small and in French (everything else was in English). Not a scam, but close to it. The module decided not to buy more, it is not really needed;

As it turned out, there are two varieties of E180 - one with an integrated WiFi module, the second - without a module, you need to buy it in addition. At the seller, the inscription "need a separate module" was applied to one of the photos of the printer, small and in French (everything else was in English). Not a scam, but close to it. The module decided not to buy more, it is not really needed; - Long printing time. I thought it would take several tens of minutes to print. I was not ready for the fact that large models can be printed for 6-8 hours. This is my own fault - I did not carefully look at the reviews.

Practical use

I didn’t buy a printer for a game, I wanted to get a device that would allow me to create things I need in everyday life, and not run to the store. Before buying, I outlined what I wanted to create:

The lever for separating the water tank in the iRobot Scooba robot vacuum cleaner, the repair review of which I published on Habré. His native pen broke, he did not want to spend money on buying a new one (they are relatively rare, since Scooba is no longer produced and expensive).

His native pen broke, he did not want to spend money on buying a new one (they are relatively rare, since Scooba is no longer produced and expensive).

Finally found a suitable model on Thingiverse and printed it. To my surprise, everything fell into place the first time, the pen still works quite normally (it's been about a month since this part was printed).

Chinese electron microscope stand. I needed it for soldering small parts. I do not want to buy a professional microscope for 400 euros, since I myself do not do repairs very often. A Chinese microscope connected to a laptop is quite an option. But his native tripod is just terrible. Therefore, I wanted to make a new, normal one with my own hands.

Soldering iron stand. I just need a comfortable stand that won't let the soldering iron fall off, like from a Chinese stand that I once bought.

Paste tube squeezer. Yes, the thing is not the most necessary, but practical.

iPhone stand. Convenient, there is a hole for the cable, sound amplification.

Toys for children. Why buy another small doll or dollhouse piece when some things can just be printed out?

Stylus for Nintendo DS Lite. I had a game console bought at a flea market for a long time. The stylus was lost and I (and my daughter) played using the PDA stylus. Recently I found a stylus model for the console, printed it out - it turned out perfectly. It fits into the connector like a factory one.

Extractor for printed parts stuck to the table. Nearly all parts stick to the printer's desktop backing. You can’t do without a special device - an ordinary knife will scratch and cut a special sticker. I found a model that is compatible with the blades of a standard utility knife - works great.

The printer lived up to my expectations. It was possible to print almost everything that is indicated above. All these things fulfill their purpose, and most importantly, I am not afraid that any of them may fail. You can always print a new one.

You can always print a new one.

There are a lot of ready-made models on the net. If you need some detail or thing, in 90% of cases you can find everything you need.

Troublesome little things

Printed parts are far from perfect. In some cases, deformation of some elements occurs and it is necessary to “finish” manually, using a knife and, in fact, a file. It doesn't happen that often, but I wish the printed part didn't need to be reworked (yes, I know you can get it by buying a professional 3D printer).

Sometimes details are printed, but for some reason the real and declared size do not match. So, I tried several times to print different dispensers for AA and AAA batteries, but for some reason the ready-made dispensers did not fit. The diameter of the holes into which the batteries are inserted was always somewhat smaller than the diameter of the batteries themselves. I still do not understand whether the problem is on my part, or the model is problematic. As a solution, you can simply increase the scale of the part in the slicer, by 10 percent. But it’s a pity for the spent plastic - after all, you can find out whether a quality part will turn out or not only after a solid part of it is ready.

As a solution, you can simply increase the scale of the part in the slicer, by 10 percent. But it’s a pity for the spent plastic - after all, you can find out whether a quality part will turn out or not only after a solid part of it is ready.

It takes a long time to print a part. Some printouts take hours to complete, so making a simple car phone stand can take half a day.

In order to develop something of your own, you need knowledge of CAD , at least at an elementary level. Otherwise, you will have to look for ready-made objects on sites that host models created by someone. In the end, I never found a battery cover for one of the remotes. I am not able to develop it myself - there is almost no time to master CAD.

My printer desktop is small . Not all objects that I would like to print can be implemented. In particular, I wanted to get a different microscope stand model. But it did not work out, because it is larger than the printer table. The same problem with the handle of a robot vacuum cleaner (not the one in the photo, another one).

The same problem with the handle of a robot vacuum cleaner (not the one in the photo, another one).

Fin

Am I satisfied, as a beginner, with the printer? Yes very. It met my expectations almost completely. True, it must be borne in mind that I got the printer relatively inexpensively. If I had bought it for, say, 300-400 euros, I would have been less satisfied with the purchase. The main thing is that with the help of a 3D printer you can solve practical problems, this is far from just a toy. The opinion about the “toy” had to be heard from many.

Well, now the question is - what useful for everyday life or work do you print on your printers?

3d printers. Overview of achievements in 2013 / Sudo Null IT News

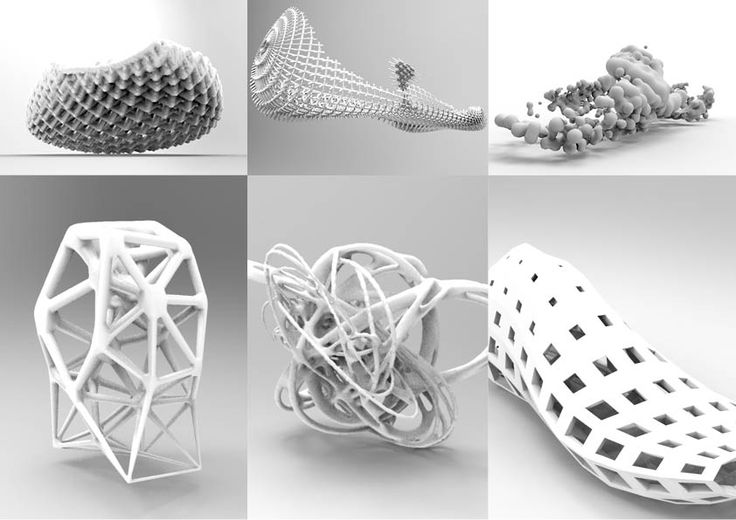

Prostheses for humans and animals, 3D printing of space structures, food and shoes, improved printing accuracy, new materials, new software.

A bunch of projects on crowdfunding platforms.

Well, pistols, where would we be without them.

China, Japan, Australia, USA, Netherlands, Africa and Haiti, 3D printing seems to be everywhere in the world.

In 2014, 3D printing will go into space.

(Review of 3D printing achievements 2012 here) We read what we achieved for 2013 under the cut ( 54 photos ).

January

The Chinese printed a 5 meter one-piece aircraft part from titanium

more pictures

This is what a laser 3D printer looks like

Selective laser sintering technology in action

Smaller parts

Here's a plane that uses 3D printed parts

BioCurious hackerspace offers a self-assembly bioprinter based on HP 5150 inkje

(the first inscription where instead of ink - "Escherichia coli")

The European Space Agency is conducting experiments to build a shelter on the moon using a 3D printer

one and a half ton building block

February

A team of scientists from Scotland, for the first time, using a 3D printer, print three-dimensional tissue from stem cells

Article PDF

3D printed Urbee 2 is ready for production

change the way we make most things. ”

”

In February, the hype began with 3doodler - a 3D pencil that can "draw in the air."

In just a few hours, they raised over a million dollars on Kickstarter.

Articles on Habré about this:

With the 3Doodler pen, you can draw three-dimensional objects directly in the air

Our answer is 3doodler. Assembled in 20 minutes

3Doodler is in a hurry to you! (Bonus: clone review)

In November, the "pencil" was delivered to Russia - the first (and last) review

Scientists print artificial ear

original article

Nike introduced the world's first 3D printed football boot

4D printed. Self-transforming objects

4D printing video at TED

March

The government of Singapore intends to invest $500 million in the development of the 3D printing industry.

3D printing makes it possible to create low-cost implants taking into account the anatomical features of patients0005

April

Oxford University scientists say their 3D printer is capable of creating materials with some of the properties of living tissue

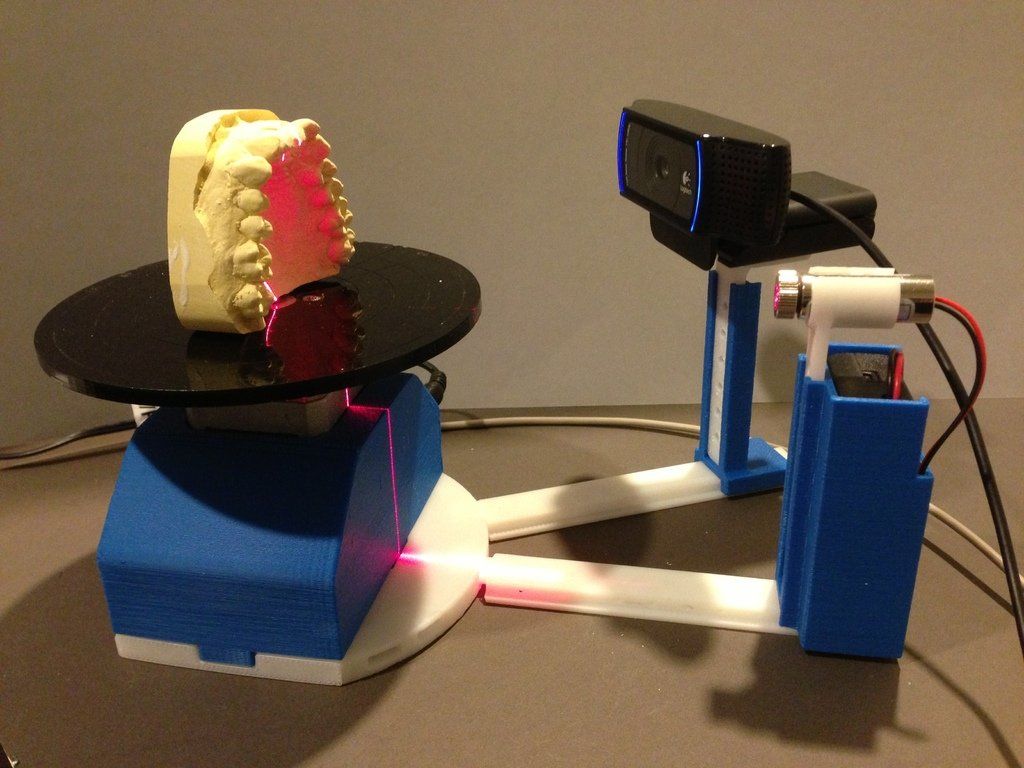

A 3D scanner has been created that can capture images from a distance of 1 km

The Chinese government intends to invest $ 6. 5M in the development of 3D printing technologies

5M in the development of 3D printing technologies

GE prints fuel injectors for aircraft engines

May

Liberator pistol: 100,000 downloads in two days

Printed ear capable of capturing radio frequencies

NASA awarded a $125K grant to develop a 3D food printer for astronauts who will fly into deep space

Saved the life of a child by printing a trachea

NASA plans to send a printer to the ISS August 2014

The Japanese have printed a carbon bunny the size of a bacterium0005

June

British government invests £14.7m in 3D printing projects

Polymers create 'artificial bone' that is 22 times stronger than its composite component

Microsoft builds 3D printer support into Windows 8.1

Foot printed for injured duck

July

MIT develops software that makes it easier to work with composite materials

British children will learn robotics and 3D printing from the age of 5

Telegraph article

August

3D printed rocket engine passes NASA test, setting the stage for many innovations to reduce the cost of manufacturing parts Stem Cell Knee Joint Using 3D Printer

MIT scientists have developed a lightweight structure whose smallest details can be 3D printed and assembled like a Lego set. The intended use is in the construction of aircraft, spacecraft, dams and bridges.

The intended use is in the construction of aircraft, spacecraft, dams and bridges.

The world's first full-scale architectural installation Echoviren

September

Breakthrough technology - printing with dissimilar materials, both organic and inorganic materials: ceramics, metal, plastic and even biological cells

Developers from Disney introduced software that will allow you create and print mechanical toys on a 3D printer

3D printer for $100 - The Peachy Printer

Scientists from Australia created a model of the Leaning Tower of Pisa using a hand-held 3D scanner

Scientists from the Netherlands created reproductions of paintings by Rembrandt and Van Gogh using a 3D scanner and 3D printer

October

UK provides £500K grant to equip 60 schools with 3D printers

HP plans to enter the 3D printing market in mid-2014

Scientists have discovered that natural components (vitamin B2) can be used in the 3D printing process to create implants

In Haiti 3D printer

Microsoft offered a technology that can turn any smartphone into 3D scanner

November

The program for encryption of 3D models

Despilatin Biocellors for the press

The first in the world is fully metal gun printed on a 3D printer

Scientists printed 20 layers of liver tissue that lived for 40 days

article on Habré

Revolution in the textile industry

Desktop metal 3D printer

Progress in the manufacture of lithium-ion batteries using 3D printers.