3D printed wall panels

3d Wall Panels - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

Related to 3d wall panels

- 3d wall art

3D Wall Panels | Soelberg

3D WALL

PANELS

texture panel solutions

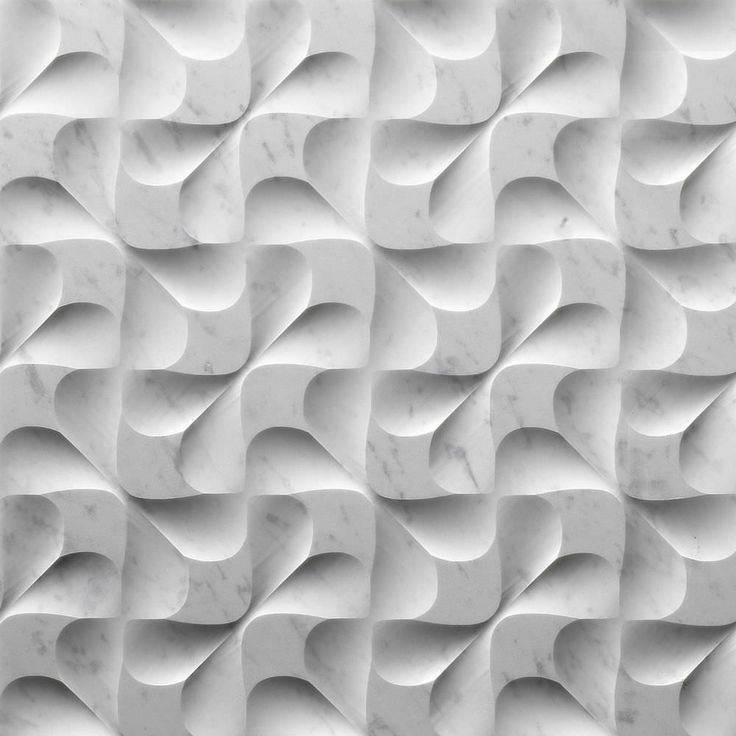

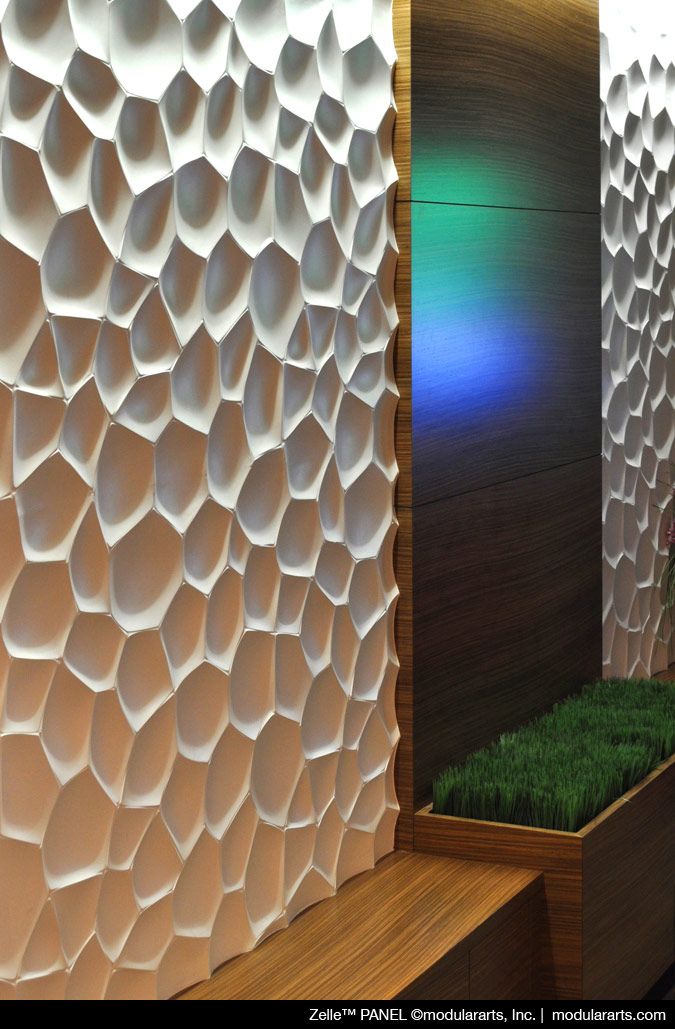

The world is not flat so why should our surfaces be? We offer a wide variety of deeply embossed texture patterns to add depth, dimension and drama to your interiors. Choose from small to large scale patterns with an assortment of 3D laminate finishes for endless texture options. And, since our patterns repeat from seam to seam, there is no end to how far your texture can go. Because we design everything we make, take advantage of our two week lead time and begin your life in 3D.

#WESPEAKFLUENTTEXTURE

REQUEST A QUOTE

3D WALL PANELS SPEC SHEET

core material

__________

MDF

finish

__________

3D laminate or paintgrade

core options

__________

Premium or Fire Rated

fire rating

__________

Class A – ASTM – E84

core thickness

__________

3/4″ – 1 1/4″

lead time

__________

2 weeks

panel size

__________

48″ x 96″

warranty

__________

5 years

Classic Collection

21 patterns to choose from

_____________________

The Classic Collection of texture provides a variety of patterns for every application from commercial and residential to healthcare and hospitality. The maximum core thickness is 3/4″ MDF which allows for both small-scale subtle texture patterns and just enough depth for decorative wavy walls.

The maximum core thickness is 3/4″ MDF which allows for both small-scale subtle texture patterns and just enough depth for decorative wavy walls.

ALBERO

BLOCCO

CANTENA

COLARE

COLONNA

LISCIO

ONDA ONE

ONDA TWO

PIOGGIA

SALDARE

SCOLPITO

SCULTURA

SERPENTE

SPACCATO

STRISCIA

TURBINE

Elevate Collection

12 patterns of distinctive texture

_____________________

Dramatic texture panels from our Elevate Collection will help you transform your interiors from flat to multidimensional. With a maximum core thickness of 1 1/8″ MDF, you have more freedom in scale and depth to create noteworthy 3D walls.

INCAVO

OCEANO

ONDATA

SCALPELLO

STATUA

STILLARE

STRISCIONE

TESSERE

VETRINO

Grande Collection

Select from 9 big bold patterns

_____________________

The Grande Collection of 3D wall panels takes texture to the next level. A maximum core thickness of 1 1/4″ MDF allows for larger scale texture patterns with more depth and shadow to create an even more monumental feature.

BLOCCATO

CESELLATO

DISTRUTTO

FLAUTO

SCIVOLO

FINISH

38 beautiful 3D laminate colors, grains & metallics to choose from or paintgrade material to be finished onsite

_____________________

3D Laminate (rigid thermofoil or RTF) is a thermoformed decorative surface that contours to our MDF textures . Please note: Delamination will occur when 3D laminated products are exposed to heat higher than 150 degrees.

Please note: Delamination will occur when 3D laminated products are exposed to heat higher than 150 degrees.

Color variation will occur from screen to sample

(contact your sales representative for swatch sample)

FROSTY WHITE

GLACIER WHITE

MATTE WHITE

WHITE HG

PORTUNA LIGHT

ANTIQUE WHITE

ALMOND

BLONDE MAPLE

CLEAR MAPLE

BIRDS EYE MATTE

CANDLELIGHT

OAK PALOMINO

NATURAL WALNUT

RUSTIC CHERRY

SUMMER FLAME

CHERRY BLOSSOM

JUBILEE CHERRY

AMATI WALNUT

OAK GIBRALTAR

OAK KODIAK

BOARDWALK

MALI WENGE

CHOCOLATE PEAR

PORTUNA DARK

LAUSANNE

OAK ARGENTO

TURMALIN MATTE

UMBRA MATTE

GAUNTLET GREY

SIENA MATTE

FLAT IRON

SHARK GREY

BLACK HG

BRUSHED STEEL HG

BRUSHED ALUMINUM

CANADIAN GREY

FASHION GREY

TO TEXTURE? OR NOT TO TEXTURE?

nobody does texture like SOELBERG

_____________________

Boring walls become beauitful walls with texture. Because we know manufacturing, we do texture differently. We offer continous pattern repeat, different core thickness and texture scales and we even cut to size to accommodate the site conditions of your project. With a variety of texture patterns and 3D lamiante finish options, to texture or not to texture is not the question. Rather, where else to texture?

Because we know manufacturing, we do texture differently. We offer continous pattern repeat, different core thickness and texture scales and we even cut to size to accommodate the site conditions of your project. With a variety of texture patterns and 3D lamiante finish options, to texture or not to texture is not the question. Rather, where else to texture?

#WESPEAKFLUENTTEXTURE

SEE MORE WALLS

LIFE IN 3D: MORE SOELBERG TEXTURE

SOLID SURFACE TEXTURE

MUTO TEXTURE

NATURA TEXTURE

STL File 3D GEOMETRIC DIAMOND WALL PANEL・3D Printing Idea for Download・Cults

3D GEOMETRIC DIAMOND WALL PANEL

9 €

3D GEOMETRIC DIAMOND WALL PANEL

9 €

3D geometric diamond wall panel

9 €

3D GEOMETRIC DIAMOND WALL PANEL

9 €

3D GEOMETRIC WALL PANEL

9 €

3D WALL PANEL

9 €

3D GEOMETRIC WALL PANEL

9 €

3D GEOMETRIC DIAMOND WALL PANEL

9 €

Best Files for 3D Printers in the Art Category

IFA MAZA

17. 51 €

51 €

StarWars Millennium-Falcon

4.79 €

Steampunk squid

1.29 €

LEXINGTON

16.39 €

Mother's Day gift - figurine - regalo dia de madres-estatua

2,50 €

Cute Platypus Articulated Print In Place No Support

2.34 €

Key hanger JACK Skellington Tim Burton

2 €

30" Snake, Spot Print, Basilisk, Boa, Python, Flexi Wiggle Pet Articulating Snake

3.84 €

Art category bestsellers

Cute skeleton with flexi print

2.83 €

GHOST ZU - GHOST WITH FEET

2,76 €

Gingerbread man ornament with flexi print

1,39 €

Cute flexi print frog

1. 87 €

87 €

Cute little fox with flexi print

2,40 €

Articulated toy "Python Snake", imprint body, snap head, cute flexi

3,79 €

Baby Crystalwing, Cinderwing3D, articulating Flexi Wiggle Pet, print on site, fantasy

3.84 €

Flexi Print-in-Place Dinosaur Brachiosaurus

2.83 €

Flexi-print Imperial Dragon

3,79 €

Triceratops on flexi printer

2.83 €

Cute squirrel with flexi print

2.41 €

Astronaut on flexi printer

2,83 €

Stitch Love (easy printing without support)

1,50 €

Archaeopteryx nibbler

3 €

Bearded Dragon toy, body with imprint, head with latch, cute flexi

3,34 €

Hannya wall masks

3,80 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

affiliation: Shop online by following our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Concrete 3D printing: still ahead

Back to Concrete Issues main pageAdditive manufacturing, more commonly known as 3D printing, has been around since 1980s. 3D printers have long been available for home use, so it's not surprising that industrial companies have begun to explore the possibility of using them in construction.

The use of 3D technology is widely and frequently discussed in the construction industry. Almost every week there is news of plans to 3D print structures ranging from bridges to houses that developers say can be built in one day. However, the initial enthusiasm in the media is quickly fading as there is less and less news of successful projects in this area. To shed some light on this topic, we asked a few experts for their opinions on the current state of 3D printing in construction.

However, the initial enthusiasm in the media is quickly fading as there is less and less news of successful projects in this area. To shed some light on this topic, we asked a few experts for their opinions on the current state of 3D printing in construction.

One approach to automation

There is a lot of hype in the construction industry around 3D printing technology, which, however, is still at an early stage of development. Concrete is a difficult material for 3D. A construction 3D printer works by applying concrete, layer by layer, through a nozzle, and in order to flow out of it, the concrete must be liquid. After printing, on the contrary, the material must quickly lose most of its fluidity in order to retain the printed form. However, at the same time, it should not harden too quickly to give the layers time to stick to each other. If layers are simply applied on top of others, without any connection between them, this will result in a weak structure, with no tensile strength. All this means that we cannot use ordinary concrete in 3D printing, and each structure needs a special type - always with different impurities.

All this means that we cannot use ordinary concrete in 3D printing, and each structure needs a special type - always with different impurities.

We must also take into account the complexity of the frame of the building that is being built. 3D printing is best for simple designs. Wall structures in Northern Europe, for example, are quite complex, and using 3D printing in them is quite problematic. The structure of the sandwich panel itself is a challenge for 3D printing: it has three layers - internal concrete, insulation, and external concrete. In addition, there are usually various wiring components inside the wall structure. Printing a three-layer structure and assembling electrical components during the printing process is not an easy task. The entire wall structure needs to be redesigned for 3D printing.

The current speed of 3D printers is incomparable with modern precast concrete factories. In addition, the quality of products from factories is much better than that obtained using additive technologies. 3D printing makes it possible to produce complex shapes, but in the case of typical concrete structures such as wall panels, its efficiency is far from that achieved by modern precast concrete technology.

3D printing makes it possible to produce complex shapes, but in the case of typical concrete structures such as wall panels, its efficiency is far from that achieved by modern precast concrete technology.

Despite the limitations, we must be open to the possibilities that 3D printing brings. It can be considered as one of the approaches to increase the level of construction automation. If you look objectively, the future of 3D printing in construction is not clear. It may be one of the tools to help develop automation in construction, but certainly not the only one.

We must keep in mind that one of the main advantages of concrete is that it can be cast into shapes, create images and structures of varying complexity. Various types of concrete surface treatment are also currently available. Concrete construction is based, as a rule, precisely on its flexibility. With the help of 3D printing, we will completely change this. 3D printing certainly gives us new opportunities, but at the same time we lose some of the benefits of using concrete.

Jouni Punkki

Professor of Practice (Concrete Technology)

Aalto University, Helsinki, Finland

Jouni Punkki

Professor of Practice (Concrete Technology)

Helsinki Aalto University6

Financial viability is a big issue in the use of 3D printing in construction

We should consider 3D printing in construction as a very interesting technology that has some potential in the future. From a safety point of view, there are rules governing construction of any kind, and of course there are requirements for adding reinforced bars as supports in 3D framing. Since this technology is new and regulatory practices are constantly changing, these rules can be difficult to comply with. But I don't think there is any reason to be concerned about the safety of 3D printed structures.

Concrete 3D printing faces the same challenges as other industries embracing this technology. Using molds to make components by casting will be much faster because with 3D printing you need extra time to make sure the previous layer can support the structure before adding the next one.

One advantage that 3D printed structures can provide over conventional building methods is that they are much easier to incorporate smart technologies such as sensors, making them easier to integrate into the smart city concept. From this point of view, it is much more difficult to modernize existing houses built using traditional building technologies.

Development of new technologies takes time. It's about testing, learning, and trying to figure out all the different variables. 3D printing of concrete structures is likely to become more commonplace. However, what role it will take in the construction industry, we cannot yet predict.

The big question, of course, is can we make it financially viable? Is this technology something that customers will pay for? Will the cost of acquiring special 3D technologies be competitive, or at least comparable to what is on the market? There are other ways to achieve similar results, and these options are cheaper and more readily available to the construction industry.

Jouni Partanen

Head of Department (Advanced Manufacturing)

Faculty of Mechanical Engineering

Aalto University, Helsinki, Finland

CONCRETE EXPERIMENT 01 Design: Ashish Mohite, Michal Trpak Concrete Printing done by: Hyperion robotics Photographer: Umění ve městě 2019CONCRETE EXPERIMENTS Design: Ashish Mohite, Kunal Chadha Concrete Printing done by: Hyperion robotics Photographer: Ashish MohiteLots of claims, but not much evidence yet

There are several companies in the US and Europe that claim to be 3D printing concrete, but in the last two to three years they have only completed small projects such as private homes. One Russian company was erecting a three-story building in Dubai, and another company, already in Estonia, is now building a house using 3D printing. We help them make it a reality, but the project is still far from being completed.

Construction is a highly regulated industry, and one of the reasons why 3D printed concrete is no longer commercially available is the time it takes to get permits. In addition, the concrete used for 3D printing is more expensive than traditional concrete materials due to the admixtures needed to ensure the correct composition.

In addition, the concrete used for 3D printing is more expensive than traditional concrete materials due to the admixtures needed to ensure the correct composition.

However, this technology continues to evolve. When a wall is 3D printed, it looks like a sandwich with two sublayers to make room for pipes and ventilation. In Zurich, it was possible to build a three-story house using various technologies. They invented a "smart stove" that had all the heating elements inside, however very expensive 3D printed molds were used for this. It was a pilot project to prove that the concept could be implemented.

Most companies involved in 3D printing in construction, of course, say that this technology is better than precast concrete, but in reality this has not yet been proven.

Ashish mohit

Doctor

Mechanical Engineering Faculty

Aalto University, Helsinki, Finland

Ashish Mohita

Doctor

Faculty of Mechanical Engineering

University of Aalsinka

3D printing: promising, but it has a long way to go

The current technology used in construction is pouring concrete. To make it financially viable, you must keep the structure simple and standardized. If you don't, the price will go up as you have to make and customize different molds. In addition, simple products are not only visually unattractive, but also require a large amount of concrete in the manufacture. With 3D printing, we can reduce the amount of concrete used by about 50% by focusing, for example, on where the wall bears the load. We can print lines to make a slab and only use materials where we really need them. However, this means that we must also develop new design methods to benefit from the technology. Unfortunately, this takes time.

To make it financially viable, you must keep the structure simple and standardized. If you don't, the price will go up as you have to make and customize different molds. In addition, simple products are not only visually unattractive, but also require a large amount of concrete in the manufacture. With 3D printing, we can reduce the amount of concrete used by about 50% by focusing, for example, on where the wall bears the load. We can print lines to make a slab and only use materials where we really need them. However, this means that we must also develop new design methods to benefit from the technology. Unfortunately, this takes time.

The industry is focused on using currently available material. I think if you're going to change something, you'd better look at it from a social perspective and from a sustainability perspective. I saw an opportunity when working with digital concrete: everyone supports changing the composition of concrete because 3D printing is not perceived as a threat to the traditional construction industry.

I think 3D printing opens up a lot of possibilities for making smart materials. Why not tie the conductive materials directly into the concrete so that you no longer have to insert wires into concrete structures after they are made? With 3D printing, you can add inches, make material changes, make electrical connections in the right place, make concrete transparent where you want. It's about combining 3D printed concrete with smart technology to ultimately benefit us as a society.

One of the barriers is economic viability. A technology such as 3D printing will not be widely adopted unless there is a visible economic benefit at some point. Thus, manufacturers could consider expanding their business model so that construction is valued not only by the price of the house or structure being built, but also by the impact it has on our ecosystem and its sustainability.

However, there is a big difference between 3D printing a bridge and a house. We announced a 3D printed house project in Eindhoven two and a half years ago, and the first house has yet to be built. The complexity becomes apparent already when compared with the first printing bridge, which was opened within half a year after the start of the project.

The complexity becomes apparent already when compared with the first printing bridge, which was opened within half a year after the start of the project.

We found this to be terribly difficult because building a home involves complex systems - HVAC, electricity, internet connections - that you have to consider. It took us a long time to figure out how to do this, and I think it will be many more years before we can print houses or buildings on a larger scale. Bridges are much easier to build using 3D printing, as they have fewer details.

Theo Sale

Dean of the Faculty of Built Environments

Professor of Structural / Concrete Design

Technical University of Eindhoven, The Netherlands

Theo Sale

Dean of the Faculty of Built Environments

Professor of Structural / Concrete Design

Technical University of Eindhoven, The Netherlands

Ideal for decorative elements, but not yet for structures

3D printing is a very interesting manufacturing system that we are following closely. It is already used in many industries such as steel and plastics, as well as in aeronautics, and especially in the production of aircraft parts. However, it is not widely used in the construction industry.

It is already used in many industries such as steel and plastics, as well as in aeronautics, and especially in the production of aircraft parts. However, it is not widely used in the construction industry.

According to experts, there are still many barriers that need to be removed before 3D printing will leave its mark on construction, but I believe that it is the future of our business - it's just a matter of time. Now 3D printing is mainly used to create decorative items. Some cruise ships, for example, use 3D printed plastic and cellulose fibers as part of their interior design.

Although concrete is not yet widely used in 3D printing, it offers many advantages: fire resistance, strength and the ability to withstand heavy structural elements. This is what makes it an ideal material for 3D printing items such as statues or columns, especially since each of us needs something beyond the usual box-like prefabricated structures.

Decorative elements, of course, can also be molded from concrete, but this requires workers - craftsmen to equip the molds. One of the practical applications of 3D printing in construction is mold making. In complex precast concrete projects, mold tooling is always a challenge as it requires a lot of manpower and precision. If the molds were 3D printed, the process would be easier and less labor intensive.

One of the practical applications of 3D printing in construction is mold making. In complex precast concrete projects, mold tooling is always a challenge as it requires a lot of manpower and precision. If the molds were 3D printed, the process would be easier and less labor intensive.

Tested to 3D print entire frames using concrete for projects such as small single-family cottages. It is good that these tests are being carried out, but at the same time it is already clear that 3D printed concrete still has a long way to go. There are technical and quality issues that need to be addressed, especially when we start thinking about 3D printing large structures such as multi-story buildings. Building with 3D printed concrete also faces an economic challenge. The additives required for concrete to be used with 3D printing technology are very expensive.

Construction entirely based on 3D printed concrete – where all reinforcement, RAC and sewerage systems are integrated rather than installed separately as is done today – is simply not possible at present.