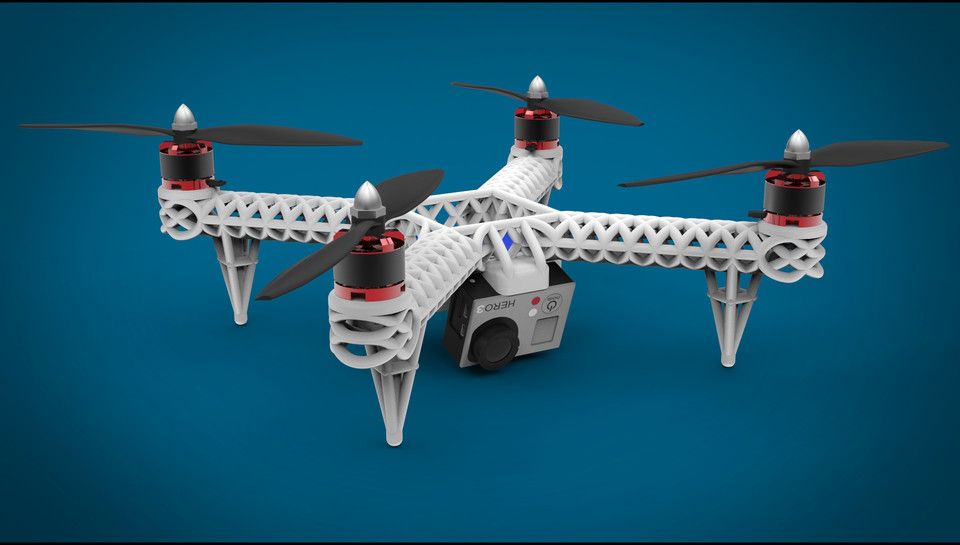

Drone frame 3d print

The Top 6 Frames to 3D Print for Your DIY Drone

On your way to building a DIY drone? Here are some of the best drone frames you can 3D print for free.

3D Printable Drone Frames

Making a sturdy and standard frame is a key part of the process of building your own DIY drone. Of course, you could also buy a frame, but that doesn't match the DIY spirit. Especially if you've already got access to a 3D printer.

One advantage of 3D printing your drone's frame is that you can do it again. This means that if you ever get in a flying accident and damage the frame, you won't have to go looking for spare parts as you can simply print them.

So if you plan on 3D printing a frame for your drone, there are plenty of models available for download and print online, and here are some of the best ones.

Building on the success of the original MHQ, the Hovership MHQ2 is a complete and functioning frame model designed for brushless rotors. This frame is designed to accommodate the rotors in an H shape, and the arms are foldable so that you can tuck them inside the body when you're not using the drone.

The MHQ2's design has room for plenty of auxiliary modules and sensors, though if you're planning on building your drone with Arduino, you're better off using a smaller board like the Arduino Nano.

The MHQ2 is easy and straightforward to print and doesn't have any tricky parts. It's best if you print the arms with an infill above 75% so that they don't snap in your first flying accident. You're going to need a handful of M3 bolts and nuts to put the frame together.

Related: What Is Arduino? What Can You Do With It? Explained

This Micro H-Quadcopter frame is designed for tiny brushed 8.5mm motors and is small enough to fit in the palm of your hand. The arms are attached in an H shape, and the frame houses a rubber band mount for a small 1S LiPo battery. It's also got a mount for attaching a tiny camera with double-sided tape.

The flight controller compartment is 30x37mm, so there isn't much room for extra modules, but you can easily fit a flight controller or a tiny Arduino board in there.

The Micro H-Quadcopter's frame model is easy to print and it's also a quick print as it's pretty small. Keep the infill above 60% to get a sturdy frame. You can put the frame parts together with M3 bolts, no glue required.

The Crossfire 2 might be the best true X-shape DIY frame out there. Sturdy and yet lightweight, and with a spacious three-story compartment to fit nearly every module you want, it’s a great choice for beginners and veterans alike.

This frame is large enough to house a 4S LiPo battery, a large flight controller (or Arduino Uno), and tons of modules. The electronic speed controllers are mounted on the arms and tightened with plastic clamps.

The entire frame weighs around 400 grams, which means the print will take quite some time, but it's a full package as it comes with numerous plates and even a GoPro cover. The Crossfire 2 has been standardized to work with M3 hardware and the designer MikeyB has included an extensive guide on how to print the frame and build a drone on it.

Related: The Best Cheap Drones With Cameras

Though most DIY drones show off their wirework, the PL1Q Vampire offers a different approach. The only visible parts in a drone with this frame are the motors and the propellers, and everything else is hidden inside the frame, or under the vampire's cloak if you will.

The model is designed to work with brushless motors, the arms are long enough to use 8" propellers, and the flight controller compartment is big enough for an Arduino Uno.

The PL1Q Vampire is harder to print than the other models in this list, and some parts will require supports to print properly. Use 100% infill on the motor mounts and 40% for the rest. Print the landing gear in 100% if you plan on making rough landings.

Yet another Micro-Quad, albeit this time with foldable arms. This Foldable Brushed Micro-Quad isn't as micro as you would expect, but it still fits in the palm of your hand if you tuck its arms inside. This frame is built in a stretched X shape which gives you more stability at high speeds.

You can build this quadcopter with 8.5mm brushed motors and a 1S LiPo. You'll be skipping the speed controllers since this model works with brushed motors. The frame is a bit too heavy for doing acrobatics, but since it's got a nice camera mount it's perfect for FPV flying.

The print process for this foldable Micro-Quad is simple, as the parts are small and you don't need any rafts or supports. You can put the frame together with M2 and M3 bolts and nuts.

Related: Essential Drone Photography Apps and Guides for Beginners

The idea behind Nanolongrange was to make a long-range lightweight drone that's designed around a single lithium battery and it does a great job at that, as the entire drone, with a camera, weighs under 45 grams. Having built the drone around a single lithium battery gives the frame a unique structure shape, which is neither an X and nor an H.

This frame is designed for brushless motors. However, it cannot accommodate external electronic speed controls, so you should use an AIO flight control. This makes building this drone with Arduino harder, compared to other frames.

This makes building this drone with Arduino harder, compared to other frames.

The print is a single file that you can print at above 40% infill with PLA or ABS filaments. This design uses lithium-ion batteries instead of the go-to LiPo batteries that most brushless drones use.

Related: Unique Ways That Drones Are Being Used Today

Print Your Own Drone Frame

Now that you've got a good array of frames to pick from and print, you can further customize the frames by changing the size, the material, the color, and more to build a truly unique drone. Be it an X or H shape, with brushed motors or brushless motors, you can build just about any sort of drone if you've got the right frame.

If you've recently gotten yourself into drones and want to start learning more, then you should start with the first step and first learn how drones fly.

Quadcopter Frame best 3D printing files・Cults

LED arm foot for racing drone (matek)

Free

Snapper7 4in1 frame replacement

Free

Snapper7 EXTREME PROtect frame

Free

Snapper7 motor mount replacement [UPDATE]

Free

Snapper7 carbon frame

Free

OSH 140S

Free

75mm micro quad frame

Free

TPU FPV Drone Frame - Indestructible

Free

Aomway FPV CAM protection

Free

115mm 2.

5" drone quadcopter frame

5" drone quadcopter frameFree

Tyro79 "Viper"

Free

Stubby Quadcopter

Free

Yet Another Quad Copter #YAQC

Free

Racing Quadcopter

Free

Garmin Ultra 30 Action Camera Frame

Free

FlyTime Quadcopter Skate Park Kit Wheels

Free

Komet, 75mm frame for 8520 motors

Free

Stiffener for Tiny whoop style chasis 65mm. and 6mm Motors

Free

Speddy 65mm. Frame for 7mm. Motors

Free

65mm Drone Frame

Free

Voltus Folding Drone

Free

Simple frame for CX-002 DIY Drone

Free

Eachine E010 lite frame

Free

Foldable drone frame (wider body, higher ground clearence,bottom access plate) Remix

Free

Foldable drone frame (Mavic look like)

Free

Foldable drone frame (Mavic look like, body & head alternative) Remix

Free

Brushless Shutter Bug

Free

Xterminator quadcopter

Free

MicroDrone 2s 3D printed Frame

Free

Battery Holder for RaGG-e Whoop frame

Free

Stingray Amphibious Tri-Copter Drone Model

Free

Brushless beecheese frame (Semi ducted micro brushless frame)

Free

Semi Ducted Micro Frame (Beecheese Frame V3)(cam mount integrated)

Free

Semi Ducted Micro Frame (Beecheese Frame V2)

Free

Semi Ducted Micro Frame (Beecheese Frame)

Free

Sweet awesome looking quad frames

Free

Semi Ducted Micro Frame (Cheese Frame)

Free

HD100mm BenAllen 3D printable Micro Drone / Mini quadcopter / Runcam Split HD

Free

Pg One Quadcopter

Free

Drone/Quadcopter frame - Arduino drone - Ludwik Drone

Free

h225 Micro Quad V1 -7mm/8.

5mm Micro SciSky Based (under $50)

5mm Micro SciSky Based (under $50)Free

Simple, Easy Quadcopter/FPV Racing Drone

Free

Mini Quad Acro 120mm Micro Pico F3 Brushless 1103 2S 10.000kv

Free

Tiny Whoop X mode 68 mm Polycarbonate

Free

Tiny Whoop 68mm polycarbonate cross fashion

Free

Tiny Whoop 68mm polycarbonate cross fashion

Free

Hexantrix 80mm: Tiny Whoop Hexa based on spf3 brushed

Free

DC110 ABS FPV for SP F3 RACING EVO Brush Flight control

Free

BigRep Introduces DUSTER, a 2m 3D Printed Drone

News

Recently, BigRep, the German manufacturer of one of the largest FDM 3D printers in the world, has unveiled a huge 220 x 190 x 60 cm 3D printed drone DUSTER.

fusing. Its design is based on a frame reinforced with carbon thread, and therefore it turned out to be surprisingly light and reliable. In a word, it is an ideal device for industrial and agricultural applications.

fusing. Its design is based on a frame reinforced with carbon thread, and therefore it turned out to be surprisingly light and reliable. In a word, it is an ideal device for industrial and agricultural applications. DUSTER (official name of OIC Copter System #42 OT) is the result of a collaboration between BigRep and industrial designer and engineer Robert Reichert. Reichert is also the founder of OiC Drones, a full-featured drone supplier and one of the innovators in the flying robot industry.

The DUSTER 3D 3D printed drone is based on a helicopter frame, on which eight 3.8 kW electric motors are mounted. Its load capacity is 40-60 kg. Depending on the load, the flight time of the drone can reach 40 or even 70 minutes if you supply it with additional batteries.

To create such a massive and functional drone, BigRep and Reichert resorted to large-format 3D printing and used special materials. DUSTER was printed on the BigRep ONE, the world's largest 3D printer with a working volume of 1 m³, which can print whole pieces of furniture if desired.

“Without the BigRep ONE, building a drone of this size would be impossible,” says Reichert. “Large-scale 3D printing has helped us push the envelope. I am proud to have been involved in the development of DUSTER as it is a completely new generation drone.”

In terms of materials chosen, BigRep opted for their own Big Orange PLA filament, which holds pressure well but can break if stretched or bent. The creators of the drone found a way out by adding carbon filaments to the design of the drone. As a result, they have a frame that easily withstands traction and load both at rest and in the air.

“The combination of thin-walled, 3D-printed hollow parts and carbon filaments achieved the necessary stability. The result is a remarkably light drone of incredible size,” says a company spokesperson. “The different materials used in the work softened the shortcomings and highlighted the advantages of each other.”

3D printed drones find their way into a wide range of areas of our lives, from surveying emergency housing to military missions. BigRep and Reichert believe the DUSTER will be particularly useful in agriculture, as its huge design is great for controlled, semi-autonomous application of fertilizers and biological pesticides. It can also be useful in winemaking.

BigRep and Reichert believe the DUSTER will be particularly useful in agriculture, as its huge design is great for controlled, semi-autonomous application of fertilizers and biological pesticides. It can also be useful in winemaking.

2m wide FDM 3D Printed Drone Was Officially Introduced at Hannover Messe 2016 Production Technology Fair held in Germany on 25-29April.

Source

Follow author

Follow

Don't want

3

More interesting articles

eleven

Subscribe to the author

Subscribe

Don't want

Simon Fraser University scientists have developed a self-learning system that matches in real ...

Read more

5

Subscribe to the author

Subscribe

Don't want

Experts from the Institute of Light Materials and Technologies (ILMiT) of the united company RUSAL developed. ..

..

Read more

56

Subscribe to the author

Subscribe

Don't want

Dear friends!

3D printers, makers and just caring people in Russia connect...

Read more

Pair of drones share 3D printing duties

Engineers from four countries have developed a 3D printing system with two drones that perform different functions: one is responsible for printing itself, and the second makes sure that the printed object matches the plan. Article published in Nature .

A traditional 3D printer has a fundamental limitation: it has a printable area, and in general it is impossible to go beyond it. Although, there are ways to get around this limitation and construction printers with a working area of several meters on each side. There is another approach: you can install the print head on a movable platform and thus set the working area during the printing process, and not at the time of assembling the printer. Previously, it was proposed to use robots on mobile platforms for this, including for working in pairs, where each is responsible for his half.

Previously, it was proposed to use robots on mobile platforms for this, including for working in pairs, where each is responsible for his half.

Engineers from the UK, Germany, USA and Switzerland, led by Mirco Kovac of Imperial College London, proposed a different principle - to use two drones, and give them different roles. Also, the use of drones makes it possible to print structures in places inaccessible to ground-based robots.

The authors called the main drone BuilDrone. It has a large load capacity and a print head is installed on it, and the engineers created two types: a fixed head and a fixed head on a delta arm. The second option allows you to compensate for drone vibrations by moving the nozzle during printing so that it maintains a stable position relative to the structure being printed.

Drones are swapped after each printed layer. The second drone, dubbed ScanDrone, flies over the print site and scans the printed layers using a depth camera. This allows you to adapt the height of the next layer and check if the actual print matches the original 3D model.