3D printer planter

🌱 Best 3D print files for 3D printing of planters・Cults

🌱 Best 3D print files for 3D printing of planters

Download 3D files of planters

If you like plants, flowers and decoration, this selection is for you. Here you will find the best STL files for your flower pots that are perfectly 3D printable. Whether it is cactus, climbing plants, flowers or aromatic plants, 3D printing will allow you to magnify your plantations. These 3D creations can take on geometric shapes, cling to your windows or look like pop-culture heroes. The perfect touch for your interior decoration!

Self-Watering Planter (Small)

Free

Plantygon - Modular Geometric Stacking Planter for Succulents

Free

Minion stone age planter

Free

Baby groot (remixed) head planter

Free

Bucky Bowls

Free

"Molcajete" Flowerpot Line

Free

Bonsai Planter

Free

Geodesic Planter Pot

Free

Mario Boo

Free

Video Game Planter Collection

Free

Octopus Planter

Free

CactusHotel

Free

Nefertiti Bust [Hollow]

Free

Voronoi Planter

Free

Customizable Yin-Yang Planter / Container

Free

Concrete Planters Mold

Free

Turtle Planter

Free

Wall Organizer

Free

Ghost Pacman Planter

Free

Space Explorer reworked Planter

Free

Hanging Flower Pot - Flower Pot

Free

Hanging Flower Pot - Flower Pot

Free

Cat Plant Pot

Free

Faceted Modular Wall Planter

Free

Oddish Planter Remix

Free

Brain Planter

Free

Criss Cross Planter

Free

Low Poly Planter

Free

Boot Planter

Free

honeycomb planter #2

Free

Kirby Whispy Woods Plant Pot

Free

Planter

Free

Planter

Free

Castle Planter

Free

Campbell Planter - Fully 3D Printed Self-Watering Planter

Free

Multi-Color Self-Watering Planter

Free

Planter - 3D Printable Mold or Planter

Free

Mini Middle Eastern Villas Planter (3-in-1)

Free

honeycomb planter #1

Free

Hoppip Planter

Free

Star Spectrum Planter

Free

Sprout - Self-Watering Desktop Planter for small plants and succulents

Free

Mini Middle Eastern Villa Planter

Free

Geometric planter

Free

Planter #3

Free

Blossy: Planter

Free

Little Planter

Free

Anti-gravity Planter

€1

Zigzag Planter

Self-Watering planter (1-5 in 1)

Bonsai Planter

Video Game Planter Collection

Here is our selection of the best flowerpot 3D files, all these beautiful designs are from the 3D file library Cults and are perfectly 3D printable designs.

This collection includes free 3D files of planters of all kinds. You will of course find the classic planters and simple pots, but also some very surprising inspirations. 3D designers are inspired for example by architecture so that their plants find their place in a real urban setting.

There are also pop-culture characters 3D printed to which plants have been grafted. Your cactus and succulents will love becoming the hair of Mario, a Minion or a Pokémon!

Launch your 3D printer, make great 3D printed planters and give them to your friends. This is an excellent gift idea that will surprise and be completely unique!

3d Printed Planter - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

Related to 3d printed planter

- 3d printed jewelry

- 3d printed vase

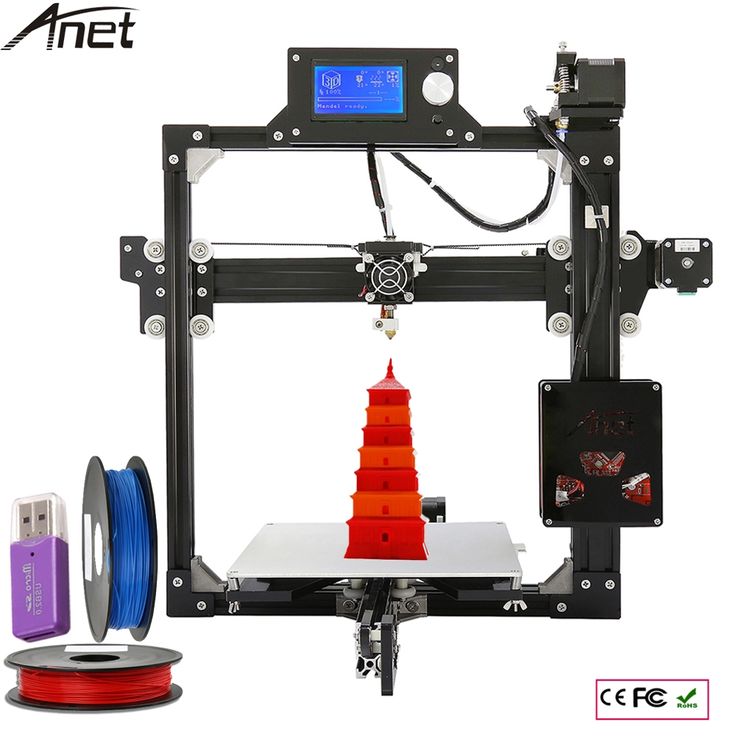

How a 3D printer works, what can be printed on a 3D printer

The 3D printer is a technology that allows you to create real objects from a digital model. It all started in the 80s under the name "rapid prototyping", which was the goal of the technology: to create a prototype faster and cheaper. A lot has changed since then, and today 3D printers allow you to create anything you can imagine.

It all started in the 80s under the name "rapid prototyping", which was the goal of the technology: to create a prototype faster and cheaper. A lot has changed since then, and today 3D printers allow you to create anything you can imagine.

Contents:

- What is 3D printing?

- How does a 3D printer work?

- What can be printed?

The 3D printer allows you to create objects that are almost identical to their virtual models. That is why the scope of these technologies is so wide.

What is 3D printing?

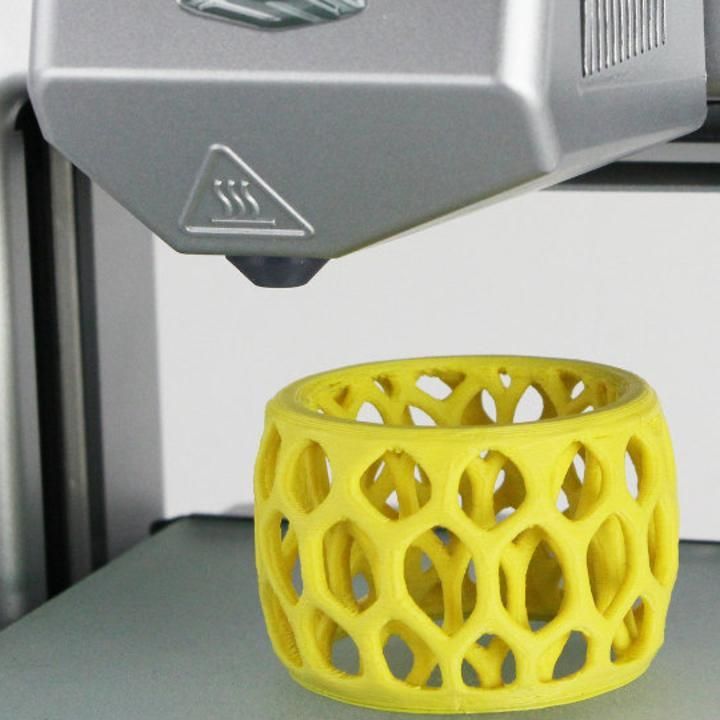

3D printing is an additive manufacturing process because, unlike traditional subtractive manufacturing, 3D printing does not remove material, but adds it, layer by layer - that is, it builds or grows.

- In the first step of printing, the data from the drawing or 3D model is read by the printer.

- Next is the sequential overlay of layers.

- These layers, consisting of sheet material, liquid or powder, are combined with each other, turning into the final form.

With limited production of parts, 3D printing will be faster and cheaper. The world of 3D printing does not stand still and therefore there are more and more different technologies competing with each other on the market. The difference lies in the printing process itself. Some technologies create layers by softening or melting the material, then they provide layer-by-layer application of this same material. Other technologies involve the use of liquid materials, which acquire a solid form in the process under the influence of various factors.

In order to print something , you first need a 3D model of the object, which you can create in a 3D modeling program (CAD - Computer Aided Design), or use a 3D scanner to scan the object you want print. There are also easier options, such as looking for models on the internet that have been created and made available to other people.

Once your design is ready, all you need to do is import it into the Slicer, a program that converts the model into codes and instructions for a 3D printer, most of the programs are open source and free. The slicer will convert your project into a gcode file ready to be printed as a physical object. Simply save the file to the included SD card and insert it into your 3D printer and hit print.

The slicer will convert your project into a gcode file ready to be printed as a physical object. Simply save the file to the included SD card and insert it into your 3D printer and hit print.

The whole process can take several hours and sometimes several days. It all depends on the size, material and complexity of the model. Some 3D printers use two different materials. One of them is part of the model itself, the other acts as a prop that supports parts of the model hanging in the air. The second material is subsequently removed.

How does a 3D printer work?

Although there are several 3D printing technologies, most create an object by building up many successive thin layers of material. Typically desktop 3D printers use plastic filaments (1) which are fed into the printer by the feeder (2) . The filament melts in the print head (3) which extrudes the material onto the platform (4) creating the object layer by layer. Once the printer starts printing, all you have to do is wait - it's easy.

Once the printer starts printing, all you have to do is wait - it's easy.

Of course, as you become an advanced user, playing with the settings and tweaking your printer can lead to even better results.

What can be 3D printed?

The possibilities of 3D printers are endless and they are now becoming a common tool in fields such as engineering, industrial design, manufacturing and architecture. Here are some typical usage examples:

Custom Models

Create custom products that perfectly match your needs in terms of size and shape. Do something that would be impossible with any other technology.

Rapid Prototyping

3D printing allows you to quickly create a model or prototype, helping engineers, designers and companies get feedback on their projects in a short time.

Complex geometry

Models that are hard to imagine can be easily created with a 3D printer. These models are good for teaching others about complex geometry in a fun and useful way.

Cost reduction

The cost of 3D printing end-use parts and prototypes is low due to the materials and technology used. Reduced production time and material consumption as you can print models multiple times using only the material you need.

How to choose and buy a 3D printer? →

ProJet 4500: Full Color Plastic 3D Printer

The ProJet 4500 is currently the world's only full color 3D printer capable of printing with plastic. It is able to create parts with excellent surface quality, ready to use flexible and durable colored products. The ProJet 4500 is highly productive and has an intuitive control console.

ProJet 4500 Benefits

- Capable of producing durable full color plastic models directly from the build chamber without any post-processing.

- A unique feature of the 3D printer is the ability to print in different colors up to a million shades, and each pixel of the model can have its own color, which gives designers and designers a wide scope for creativity.

- High print speed.

- Material Saving: The ProJet 4500 does not use any backing materials, the build material can be reused for printing.

- Combination of ergonomics and reliability: The ProJet 4500 fits perfectly in a typical office, it does not require special conditions and is easy to operate.

- Eco-Friendly: This 3D printer does not require a water connection or the use of any chemicals.

Applications

The capabilities of the ProJet 4500 are used in a wide range of applications. It is actively used by professionals in various industries, wherever it is necessary to obtain high-quality color products in a short time.

ProJet 4500 Applications:

- design;

- architecture and construction;

- fashion industry;

- production of souvenirs;

- advertising production and marketing communications;

- development of consumer goods;

- health care.

The manufacturer can always be sure of the quality of the printed models. The ProJet 4500 creates durable, full color plastic products.

The ProJet 4500 creates durable, full color plastic products.

Printing technology

The ProJet 4500 creates models using CJP technology, which uses two components in its work: the base material of construction and the binder. The build material is spread over the chamber in a thin layer, then the inkjet printheads apply a coloring binder in accordance with a given geometry, which causes the material to harden. The working platform is lowered with each layer applied until the model is completely built.

Using the VisiJet C4 Spectrum material, the ProJet 4500 3D printer allows you to quickly create prototypes that match the original model, transfer its most important characteristics, and also receive finished products made to order and with high resolution.

Materials

The ProJet 4500 is the first 3D printer in its class to produce full color plastic products using color inkjet technology. The 3D printer uses VisiJet C4 Spectrum acrylate-based heat-curable materials and has a pixel-by-pixel coloring feature that allows you to produce strong, flexible plastic products and paint them in almost one million unique user-selectable colors. If necessary, a simple additional processing can enhance the brightness of the colors.

The 3D printer uses VisiJet C4 Spectrum acrylate-based heat-curable materials and has a pixel-by-pixel coloring feature that allows you to produce strong, flexible plastic products and paint them in almost one million unique user-selectable colors. If necessary, a simple additional processing can enhance the brightness of the colors.

VisiJet C4 Spectrum is a plastic material with excellent flexibility and strength for long-term testing of concepts, prototypes, and final products. The material is ideal for manufacturers in a wide range of applications requiring wear resistant parts. From homewares and toys to healthcare, science and design accessories.

ProJet 4500 or ProJet 660Pro: Which Should You Choose?

In the 3D hardware market, you can often find machines with similar features. For example, the specifications of the ProJet 4500 3D printer are very similar to the ProJet 660Pro. Which of these 3D printers is best for your needs?

The main difference between these two printers is the materials they use: the 660Pro is a gypsum-based powder, while the 4500 is a resin compound (plastic). Due to the strength of the modeling plastic, the ProJet 4500 is able to print products that are more durable than those made on the plaster 660Pro. However, the detailing of plaster prototypes is better, and the heat resistance is higher, which allows you to create molds with the ProJet 660Pro.

Due to the strength of the modeling plastic, the ProJet 4500 is able to print products that are more durable than those made on the plaster 660Pro. However, the detailing of plaster prototypes is better, and the heat resistance is higher, which allows you to create molds with the ProJet 660Pro.

Increased product strength gives the ProJet 4500 a wider range of applications than models built on the 660Pro. Given the quality of the surfaces, the ProJet 4500 3D printer is more versatile and finds application in many areas of manufacturing and design.

Some businesses are successfully using both models of these 3D printers. According to Steve Corey (Objex Unlimited), the ProJet 4500 is the perfect complement to the 660:

“With the ProJet 4500, we can complete any model that would be too complex for the Projet 660Pro. It allows you to create products that are more durable, with thin walls and geometry that is not always available to gypsum.”

Cory also notes that the 4500 is more reliable and does an excellent job of printing thin-walled complex structures for mechanical and architectural needs.