3D printer plans open source

6 Best Open Source 3D Printers 2022 (With Links To Designs)

Open source previously meant users had permission to use and modify software code, and improve it however they wished. Today, the open source philosophy and community has grown immensely to include physical products, and open source software powers billions of devices worldwide.

Open source 3D printers helped launch the affordable 3D printer range we have now, starting from the RepRap movement more than a decade ago. Therefore, we ranked our favorite open source 3D printers, with links to the 3D printer source files, and where to buy them.

What is open source?

Open source encourages collaboration and the sharing of improvements with the community, leading to faster innovation and better technology for everyone. Without any IP holding people back from experimenting and improving open source 3D printer designs, fantastic new developments can occur.

- A number of open source software feature in our best free 3D software guide.

- Open source 3D printer software also feature in our best 3D printer software guide.

How can open source improve 3D printers?

An example of this is the development of the Olsson Block. Anders Olsson, in trying to get his Ultimaker 3D printer to print boron carbide, accidentally created a block that made switching a 3D printer’s nozzle far quicker. Now, Olsson Blocks are used by thousands of 3D printers to reduce nozzle switching time.

Best Open Source 3D Printers for all price ranges

| Name | Build Volume (mm) | Price | Best price available at: | Alternative purchase option: |

|---|---|---|---|---|

| Monoprice Mini Delta | 110 x 110 x 120 | $169 | Amazon here | |

| Anet A8 | 220 x 220 x 240 | $160 | Amazon here | |

| Creality CR-10 / V3 | 300 x 300 x 400 | $499 | Creality Store here | Amazon here |

| Prusa i3 MK3S+ | 250 x 210 x 200 | $749 / $999 | Kit available on Prusa store here | Fully assembled on Prusa store here |

| BCN3D Sigma D25 | 420 x 300 x 200 | $3,995 | Dynamism Store here | Matterhackers here |

| Ultimaker 3 / S3 | 215 x 215 x 210 | $4,080 | Dynamism Store here | Matterhackers here |

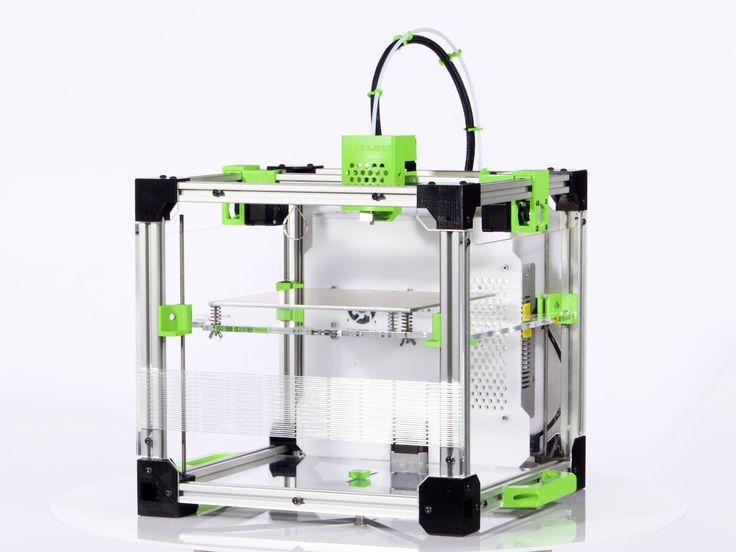

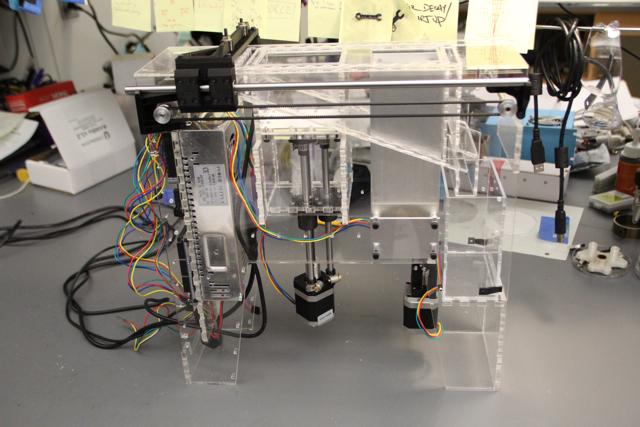

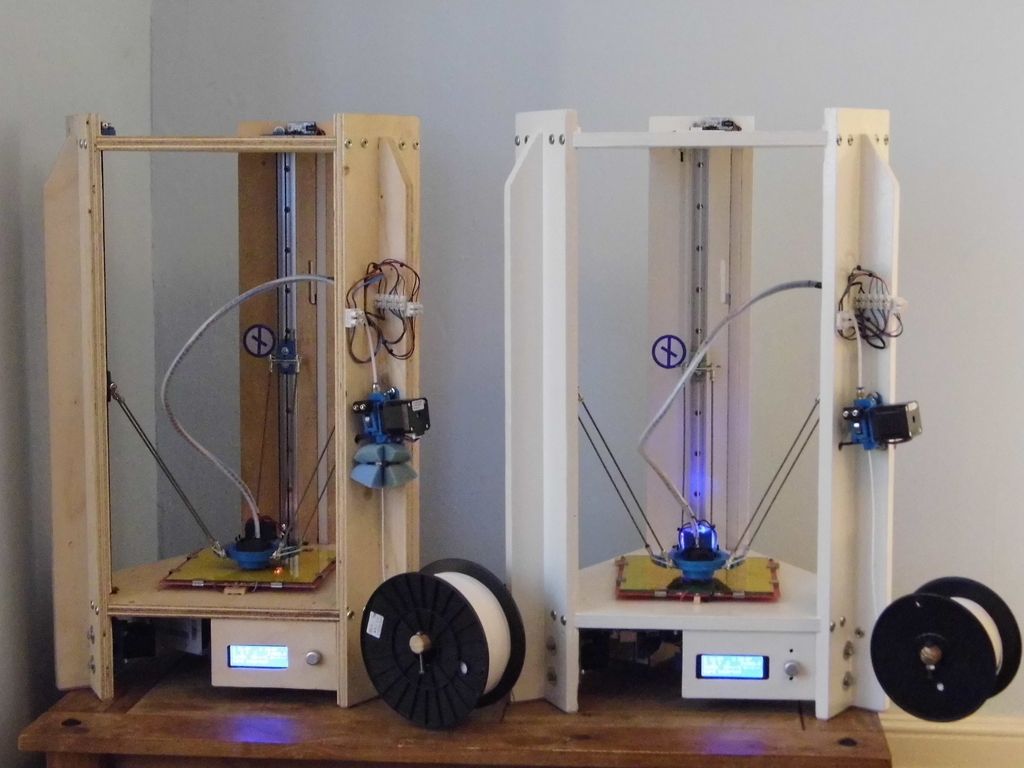

At the start of the consumer printing revolution, courtesy of RepRap 3D printers, open source 3D printers were the norm. Passionate makers across the world modified existing open source 3D printer designs or created their own for others to improve. They were effective yet cheap, costing just a few hundred dollars back when an equivalent 3D printer would cost thousands.

Passionate makers across the world modified existing open source 3D printer designs or created their own for others to improve. They were effective yet cheap, costing just a few hundred dollars back when an equivalent 3D printer would cost thousands.

Open Source vs Closed Source 3D Printers

Makerbot, Printrbot, Lulzbot (by Aleph Objects), Ultimaker, BCN3D and several other 3D printer companies were formed championing the open source 3D printer movement. However, some have since struggled.

Printrbot closed down in July 2018 citing low sales, while Lulzbot laid off the majority of their staff in October 2019, facing closure before they were rescued and bought out. Makerbot, perhaps the most successful 3D printer company to emerge from the DIY 3D printer revolution, famously turned their back on the open source philosophy, and now their 3D printers are closed source and IP-protected. The company was acquired for $400M by Stratasys.Makerbot printers are now closed source and IP-protected.

However, some open source 3D printer companies continue to show strong growth and prove that open source is not only well-loved, but also a profitable strategy. BCN3D continue to produce high-quality printers including the Sigma D25 and Epsilon, while Ultimaker have grown to become one of the most respected 3D printer companies in the world.

We have a full list of open source 3D printers at the end of this article. First however, we have our recommendations of the best open source 3D printers with links for purchasing. We also include links to the open source 3D printer designs on GitHub.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Best Desktop Open Source 3D Printers

Monoprice Mini Delta — Introductory open source printer

- Price: $169 — Available on Amazon here

- Maximum print volume: 110 x 110 x 120 mm

- Accuracy: up to 50 microns

The Monoprice Mini Delta is known for being one of the best budget 3D printers around, with great precision (up to 50 microns), speed (up to 150 mm/s) — and it’s open source!

An open source delta 3D printer, this differing type of 3D printer allows for faster print speed, as with less weight on the print head, faster speeds and quicker acceleration can occur without overshooting. Higher print speeds can therefore be maintained without any loss of accuracy.

Higher print speeds can therefore be maintained without any loss of accuracy.

- We also have a ranking of the fastest 3D printers.

Unlike many delta printers, the Monoprice Mini Delta comes fully assembled, so you can get printing in less than an hour from opening the box. The heated bed means you can print ABS and other trickier 3D printer filaments, and you can print via WiFi as well as by USB or SD card. The sturdy metal frame improves part print quality by anchoring the printer down so external factors like vibrations don’t impact quality, and overall it’s a fantastic open source 3D printer for a low price.

Anet A8 – Low cost open source 3D printer

- Price: $180 — Available on Amazon here

- Size: 220 x 220 x 240 mm

- Minimum layer thickness: 100 microns

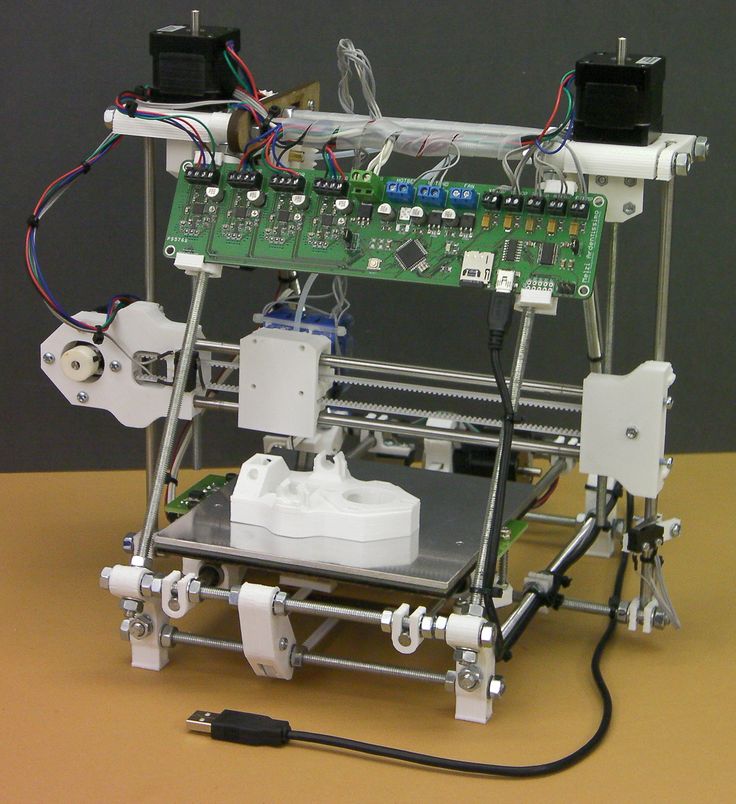

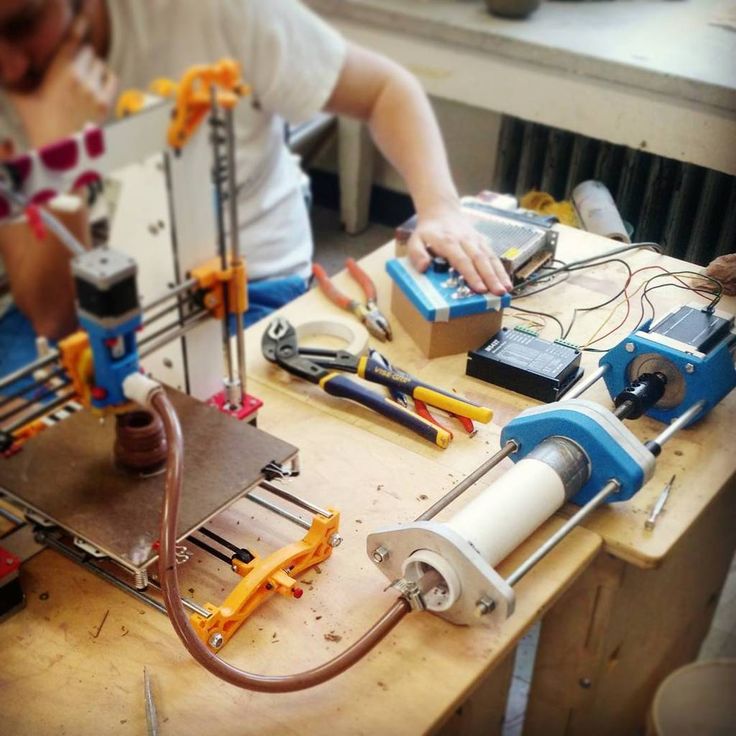

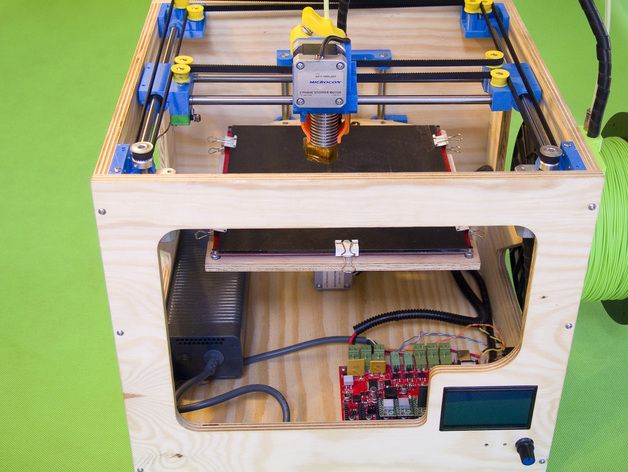

A low-cost open source 3D printer, the Anet A8 is a 3D printer kit that you will have to build yourself. It will take a few hours (up to six, actually), but once it’s up and running, not only will you be able to print magnificent 3D models, but you’ll also feel accomplished and appreciate it more having built it yourself.

Since it requires some tech know-how, this may not be the ideal 3D printer for beginners. But for those with enough experience to handle any issues and who can modify their open source 3D printer based on what they want to print, it’s fantastic for such a low price.

Once it’s up and running, it’s a fairly large 3D printer, able to print 220 x 220 x 240 mm parts without issue. It can print standard PLA and ABS, as well as wood-filled filaments and others including Nylon.

Overall, it’s reasonably reliable, accurate, and does everything you could possibly expect for such an affordable 3D printer. And with the open source firmware, you can unleash your creativity and change anything you want to improve.

Creality CR-10 / V3 — Great Open Source 3D Printer Kit

- Price: $369 for standard CR-10 / $459 for CR-10 V3 — Available on Amazon here / Available on Creality Store here

- Build volume: 300 x 300 x 400 mm

- Minimum layer thickness: 100 microns

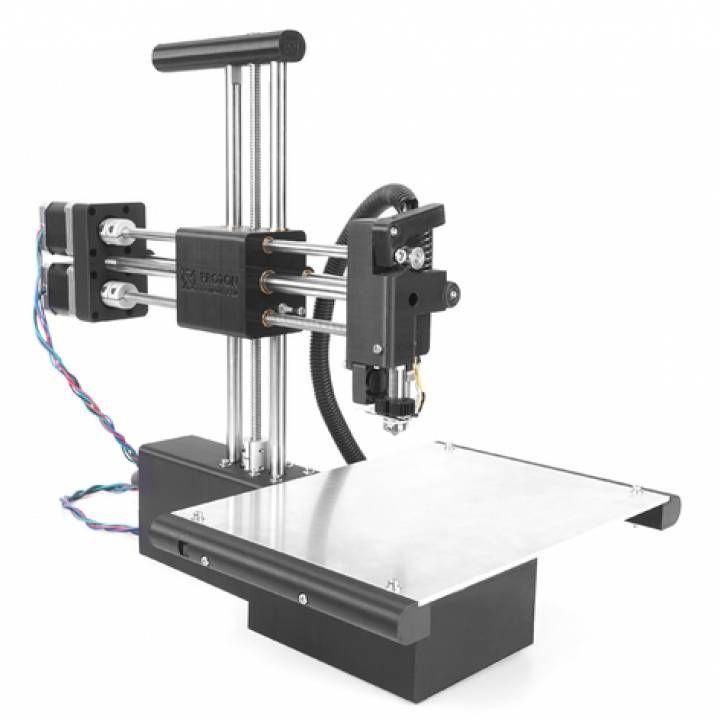

The Creality CR-10 has been one of the best-selling and highest-rated 3D printers under $500 of the last few years, with many iterations and updates continuing to build on the original CR-10’s success.

The original CR-10 is now fully open source, with Creality 3D having released all the files on their GitHub for anyone to view. Though this CR-10 is being phased out in favor of the newer CR-10 V2 models, many 3D printer parts will be identical across models, and the CR-10 V2 files are also available.

The open printing area means there is no protection from unpleasant fumes, and this open source 3D printer can also be fairly noisy, so you may want to keep it in a separate room from the one where you work or relax in. The quality and reliability of the Creality CR-10 however shines through and is the main reason for its popularity, and overall it’s a great open source printer.

Prusa i3 — best open source 3D printer under $1,000

- Price: $749 as a kit — Available on Prusa store here / $999 fully assembled — Available on Prusa store here

- Build volume: 250 x 210 x 200 mm

- Precision: 50 microns

Whereas some desktop 3D printer brands have turned their backs on open source, Prusa is still committed to the open source 3D printer philosophy, and you can access everything you need on their GitHub.

Known as one of the best 3D printer kits ever made, Prusa 3D printers have won boatloads of awards. Solid printing speed, accuracy, great reliability and compatibility with a variety of filaments (especially with the Multi-Material 2.0 upgrade) make it competitive with printers costing far more.

- The Prusa can be upgraded to print 5 colors simultaneously. You can read more in our color 3D printer ranking.

Designed to save you hassle and time, the Prusa i3 printers will save your current progress in the event of a power outage so you can resume where you left off, it will pause in the event of filament running out so the print doesn’t fail, and can even detect when the filament is clogging. Overall, it’s a fantastic open source 3D printer and we highly recommend it.

Professional Open Source 3D Printers

BCN3D Sigma D25

- Price: $3,995 — Available on Dynamism Store here / Available on Matterhackers here / 3DPrima Europe here

- Build volume: 420 x 300 x 200 mm

Barcelona, Spain-based BCN3D remain committed to open source 3D printing since their inception in 2012. All their printers have open source 3D printer files for firmware, process, software, and more published on the BCN3D GitHub.

All their printers have open source 3D printer files for firmware, process, software, and more published on the BCN3D GitHub.

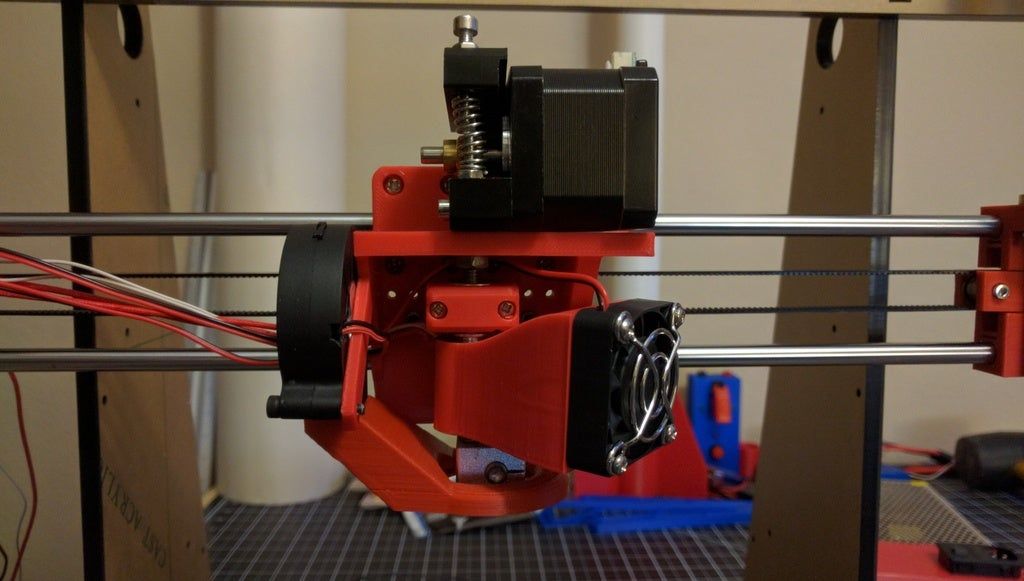

BCN3D printers are known for their reliability, and the Sigma D25, their newest printer, is no different. Featuring their signature IDEX dual extruder system which can print in two special modes, Mirror and Duplication, each extruder can function separately, as either a multi color 3D printer, or for printing with a soluble filament for supports that can be easily removed.

Whereas the Sigmax R19 has a completely closed, enclosed build chamber, the Sigma D25 is semi-open. It’s easy to use, reliable, durable with its high-quality stainless steel frame, and prints very consistently and accurately at up to 50-micron layer heights on E3D hot ends. D25 models now have access to WiFi 3D printing, and can automatically install new firmware updates to keep your printer up to date.

Any keen makers or small businesses looking to print fun projects or accurate plastic prototypes, that is also open source, may find the Sigma D25 the perfect 3D printer for you.

Ultimaker 3 / S3

- Price: $4,080 — Available on Dynamism Store here / Available on Matterhackers here

- Build volume: 215 x 215 x 210 mm

12 months after the Ultimaker 3’s release, the Dutch company released the hardware source files for both the Ultimaker 3 and Ultimaker 3 Extended here. This was no surprise; Ultimaker had previously released the files to other printers including the Ultimaker 2 Go, leading to innovation breakthroughs such as the Olsson Block. Ultimaker also develops Cura, the popular and open source 3D slicer.

Known as one of the best 3D printers of its generation, the Ultimaker 3 is incredibly accurate and widely adopted for rapid prototyping precise plastic parts. It comes fully assembled and almost ready to print; you can get it all started within just a few minutes.

It works with Ultimaker’s open source 3D printer software, Cura, and features a built-in camera for monitoring your print’s progress remotely. It’s not the fastest, but prints with flawless accuracy for an FDM 3D printer, and the dual extruder also adds to its offering.

Ultimaker has not yet (as of August 2021) released any source files for the Ultimaker S5 or S3, but some of the parts are near identical to the Ultimaker 3.

- BCN3D Epsilon

- Lulzbot Mini

- Taz Pro

- BigFDM

- Creatable 3D

- Hydra Research Nautilus

Other articles you may be interested in:

- How to get a free 3D printer

- Open source CAD software

6 Best Open Source 3D Printers (2022 Update)

- Last Updated: December 7, 2022

- Pat Nathaniel

If you’re a 3D printer enthusiast, you know an open source printer is the way to go. It allows you to modify hardware and keeps you from being attached to a manufacturer’s whims. Plus, the open source philosophy is crucial for encouraging constant improvement.

The best open source 3D printer is easy to use, easy to modify, and will create high-quality prints.

We’re here to help you figure out which one that is. But before we dig into 3D printer specs, let’s define “open source” and remind you of its advantages.

Table of Contents

- What Is Open Source?

- Open Source VS Closed Source

- Best Open Source 3D Printer Designs At A Glance

- 1. Creality Ender 3 V2 (Best Overall)

- 2. Prusa i3 MK3S+ (Premium Choice)

- 3. Monoprice Mini Delta (Best Budget)

- 4. Voron (Best for DIY-fans)

- 5. Anet A8 Plus (Best Value Alternative)

- 6. Prusa SL1 (Best Resin Open source)

- Final Thoughts

What Is Open Source?

The term “open source” originally comes from software developers who traditionally made their source code freely available. With access to the source code, professionals, hobbyists, and everyone in between could edit and redistribute the software.

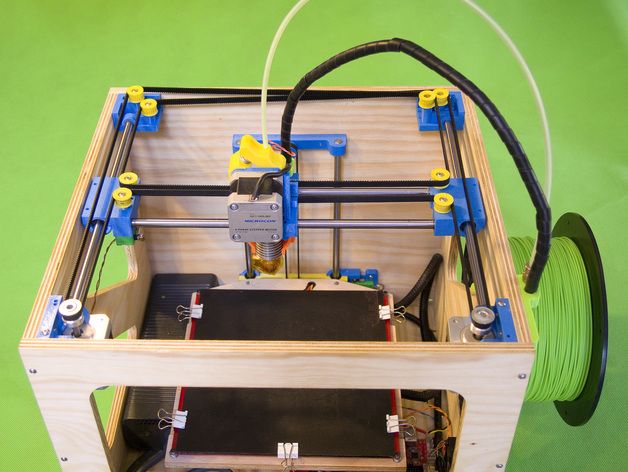

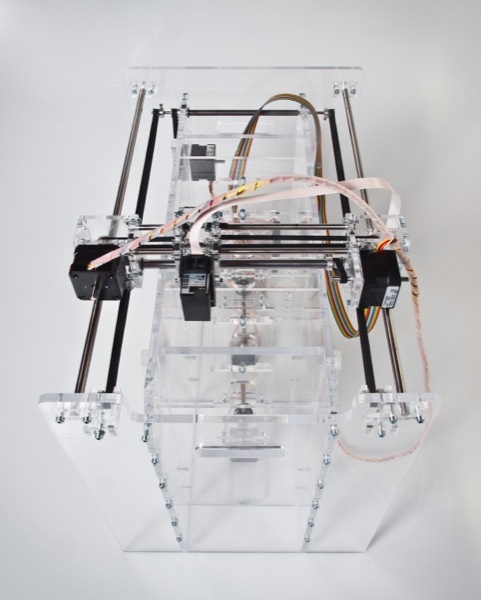

The open source philosophy carries over to the world of 3D printers, thanks in large part to the RepRap Project and community. The RepRap project created the first low-cost, self-replicating 3D printer with an open source design, meaning all of the project’s intellectual property is free to use and modify.

Open Source VS Closed Source

The open source idea is vital to 3D printers because collaboration allows for faster technological gains. Many 3D printers come as a DIY kit; users have to build the printer from scratch and often modify the design as they go. As hobbyists and professionals tinker with 3D printer hardware, they find new ways to improve the design.

For a consumer, open source technology means you’ll always have control. It doesn’t matter if the original manufacturer shuts their doors; your machine can keep on printing. You can replace any worn or broken parts using the original design because it’s open source.

With closed source hardware, modifying or copying parts of the machine will void any warranty, and you’ll be infringing on intellectual property, which is against the law.

Monoprice Mini Delta

Build Volume: 110 x 120 x 120 mm

Check Latest Price

Creality Ender 3 V2

Build Volume: 220 x 220 x 250 mm

Get Discount (Official Store)

Check Latest Price

Prusa I3 MK3S+

Build Volume: 120 x 68 x 150 mm

Check Official Website

Check Latest Price

Check For Kit

Best Open Source 3D Printer Designs At A Glance

A genuinely open source 3D printer is something to appreciate. You can build it, tear it down, and change it to suit your needs, all without infringing on any intellectual property. That’s not to mention all the epic things you can print!

So, what are the best open source 3D printers?

We’re glad you asked. Below we review our six favorites in thorough and honest detail. We cover ease of use, quality of printing, and who each printer is best suited for. We’ll also discuss access to community support because rest assured each printer on this list is fully open source.

We’ll also discuss access to community support because rest assured each printer on this list is fully open source.

1. Creality Ender 3 V2 (Best Overall – Editor’s Choice)

2. Prusa I3 MK3S+ (Premium Choice)

3. Monoprice Mini Delta (Best Budget)

4. Voron (Best for DIY-fans)

5. Anet A8 Plus (Best Value Alternative)

6. Prusa SL1 (Best Resin Open Source)

1. Creality Ender 3 V2 (Best Overall)

3D Printer Type: FDM | Layer Resolution: 0.1mm – 0.4mm | Materials: PLA, ABS, PETG, TPU | Build Volume: 220 x 220 x 250 mm | Max Print Speed: 180 mm/s

For an affordable, high-quality, beginner-friendly 3D printer, look no further than the Creality Ender 3 V2. The level of quality this machine prints at is comparable to much more expensive models, and it comes mostly pre-assembled, though there are some technical steps you’ll need to take to make it run.

Unlike its predecessor, the Ender 3 Pro, the Ender 3 V2 has built-in screw-driven belt tensioners, which allow for easy and exact adjustments. It also has a much better screen interface than the Ender 3 pro had. The console provides a seamless user experience, making the V2 better for beginners.

The Ender 3 V2 features a self-developed silent motherboard as well. That means it’s quiet while it prints, which may be ideal if you’re trying to focus on other projects. And it has a glass bed which makes for smooth, shiny prints. Of course, glass beds are heavier, which may lead to print ringing (the wavy pattern that can appear when a printer bed vibrates).

With its built-in tool drawer, you can easily store necessary tools like tweezers or an Allen wrench with your machine. If you’re new to 3D printing, you might not understand, but we promise, having a few tools close at hand can be a huge advantage!

Maybe the biggest plus to the Ender 3 V2 is the huge community that’s formed around Creality machines. They’re not always the easiest to put together if you’re not so mechanically inclined, but with such a vast support network, assembly advice isn’t hard to come by.

They’re not always the easiest to put together if you’re not so mechanically inclined, but with such a vast support network, assembly advice isn’t hard to come by.

- Great value given the price point

- Huge support community

- Beginner-friendly printer operation

- Silent Motherboard

- Takes some technical knowledge to assemble initially

- Heavy glass bed could cause print ringing

Get Discount (Official Store)

Check Latest Price

2.

Prusa i3 MK3S+ (Premium Choice)

Prusa i3 MK3S+ (Premium Choice) 3D Printer Type: FDM | Layer Resolution: 0.5-0.35mm | Materials: Any thermoplastic including Nylon and Polycarbonate | Build Volume: 250 x 210 x 210 mm | Max Print Speed: 200 mm/s

The Prusa i3 MK3S+ provides outstanding print quality without fuss and tinkering on the user’s part. Though it’s on the pricey side of things, this 3D printer is one of our favorites for beginners or those who don’t want to spend too much time modifying their machine. You can purchase it as a DIY kit or as a fully assembled product.

Whether you put it together yourself or buy it ready to go, you can rest assured that the Prusa i3 MK3S+ will create high-quality, error-free prints every time. Prusa designed the extruder on this model to sit closer to the x-axis, providing less resonance and higher quality prints, even when using flexible materials.

The open-frame design means you shouldn’t run this printer around kids or pets, at least not unsupervised. You also need to keep materials that could ignite or melt away from the machine. That’s because there’s no covering for the extruder, which will reach high temperatures during use.

You also need to keep materials that could ignite or melt away from the machine. That’s because there’s no covering for the extruder, which will reach high temperatures during use.

Fortunately, Prusa designed this printer to cool down automatically when it’s finished. That’s not a feature you see in every 3D printer!

Also somewhat unique to Prusa is the community behind them. Not only is the software for this printer straightforward to use, but it’s also backed by 24/7 customer support via Prusa’s professional team. If the professionals don’t have an answer, there are plenty of unofficial support groups on Facebook and other social media hubs.

- Beginner-friendly setup and use

- Excellent print quality even with default settings

- Incredible manufacturer and community support

- Relatively expensive

- Open frame design not ideal around kids or pets

- Mediocre user interface

Check For Official Website

Check Latest Price

Check Fo Kit Price

3.

Monoprice Mini Delta (Best Budget)

Monoprice Mini Delta (Best Budget) 3D Printer Type: FDM, Delta | Layer Resolution: 0.5-0.3 mm | Materials: ABS, PLA, PETG | Build Volume: 110 x 120 x 120 mm | Max Print Speed: 150 mm/s

The printers we’ve discussed so far are cartesian style printers, meaning they run along the Cartesian plane, or X, Y, and Z axes. Delta-style 3D printers work differently. They support the extruder with three arms attached to three vertical posts that sit in a triangle. The arms can move vertically and allow the extruder to move in every direction while printing.

The Monoprice Mini Delta is an excellent delta-style machine that is reasonably priced. It’s great for those who have some technical background but are just getting into 3D printing. As an entry-level 3D printer, it’s both versatile and simple to use.

It’s speedy too. We tend to value delta-style printers because they’re far faster than their cartesian cousins, and this one’s no exception. Unfortunately, the unique design of a delta-style printer has a downside, one that’s magnified in the Monoprice Mini Delta– a tiny build area.

Unfortunately, the unique design of a delta-style printer has a downside, one that’s magnified in the Monoprice Mini Delta– a tiny build area.

The build space on any delta-style printer is limited, but on the Monoprice Mini, that’s exceptionally true. It also has a thin build sheet surface that may stick to and then rip finished prints, though it’s nothing a little 3D printer tape can’t fix.

Assuming you’re not trying to maximize printing capacity, this is a great machine to enter the 3D printing world with. It works right out of the box and is small enough to take on the go! As long as there’s a power outlet, you can print anywhere you want.

- Very Affordable

- Delta-style design means faster prints

- Compact size means you can take and store almost anywhere

- Tiny build area

- Thin build sheet surface

Check Latest Price

4.

Voron (Best for DIY-fans)

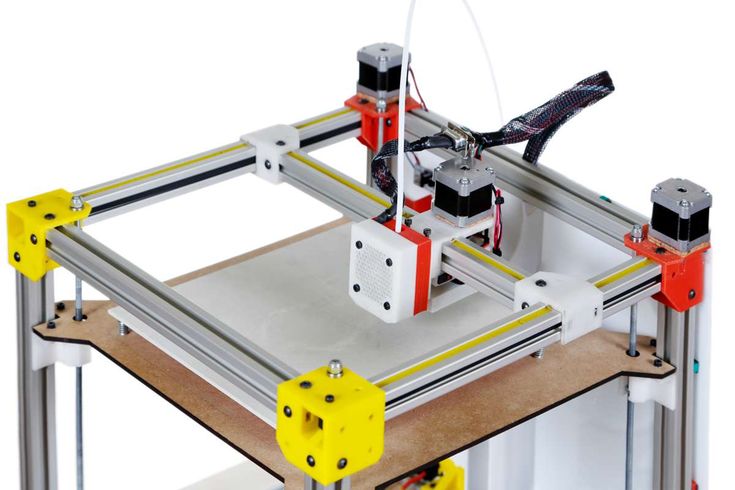

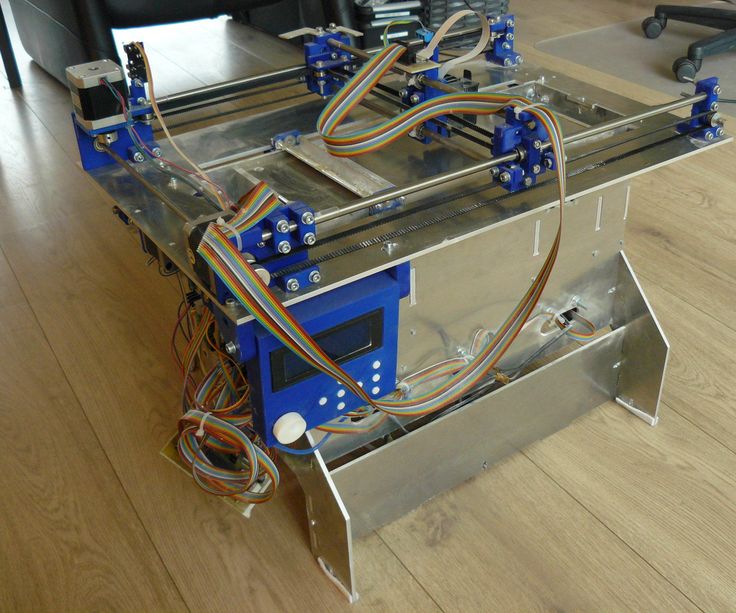

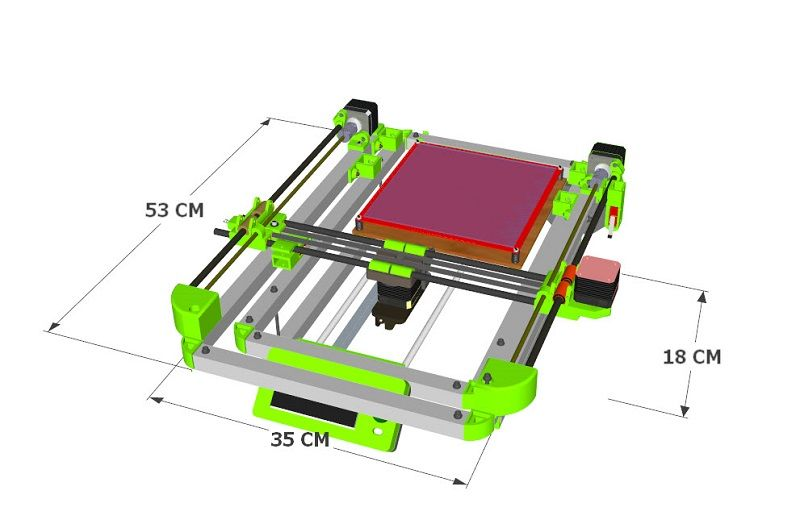

Voron (Best for DIY-fans) 3D Printer Type: FDM, CoreXY | Layer Resolution: 0.5-0.3 mm | Materials: ABS, PLA, PETG | Build Volume: 250 x 250 x 250 mm / 300 x 300 x 300 mm / 350 x 350 x 350 mm | Max Print Speed: 250 mm/s

If you enjoy building machines and want a speedy, efficient 3D printer, you should consider Voron. Voron makes three versions of their 3D printer design: version 0, version 1, and version 2. All of them use a CoreXY motion system which separates them from other cartesian-style 3D printers.

CoreXY motion systems have a few advantages. The belts move in different planes, reducing undesirable twisting, and it can hold the X and Y motors stationary, which reduces the weight of the machine’s moving parts.

These machines are small and fast without sacrificing quality. They have a higher build capacity relative to the machine’s size and move faster than other 3D printer designs. Voron also features a stationary print bed, so vibrations can’t ruin your print. And, they have HEPA filters built-in, which we love from a user-health standpoint.

Voron also features a stationary print bed, so vibrations can’t ruin your print. And, they have HEPA filters built-in, which we love from a user-health standpoint.

However, Voron isn’t great for beginners (check our article here if you’re looking for a beginner 3D printer) or anyone who doesn’t want to tinker with their printer. You have to purchase whichever model you choose as a DIY kit, and printing additional parts can be expensive. Plus, if there are any inaccuracies in your printed pieces, it will affect the machine’s ability as a whole.

- CoreXY Motion System is fast and efficient

- Stationary print bed eliminates vibrations

- HEPA Filter part of the design

- Not beginner-friendly

- Printing additional parts gets expensive

Check Latest Price

5.

Anet A8 Plus (Best Value Alternative)

Anet A8 Plus (Best Value Alternative) 3D Printer Type: FDM | Layer Resolution: 0.1-0.4 mm | Materials: PLA, ABS, HIPS, WOOD, TP | Build Volume: 300 x 300 x 350 mm | Max Print Speed: 120 mm/s

The Anet A8 Plus comes as a DIY kit or as a partially assembled machine. Though it doesn’t offer the best out-of-the-box experience, it is affordable and easy enough for someone with moderate skills to assemble, modify, and use.

It features an eye-pleasing minimalistic design and an admirably large build area. If you plan on printing at various sizes, the Anet A8 provides that flexibility. It’s also great at dimensional accuracy. However, it lacks the ability to print super sharp details.

The price point is exceptional, and there are lots of upgrades you can make on the Anet A8 to create more functionality. It may not produce the best of the best when it comes to quality prints, but it’s worthy of consideration.

- Very affordable

- Ample build area

- Minimalistic design

- Takes skill to assemble and modify

- Poor at printing details

Check Latest Price

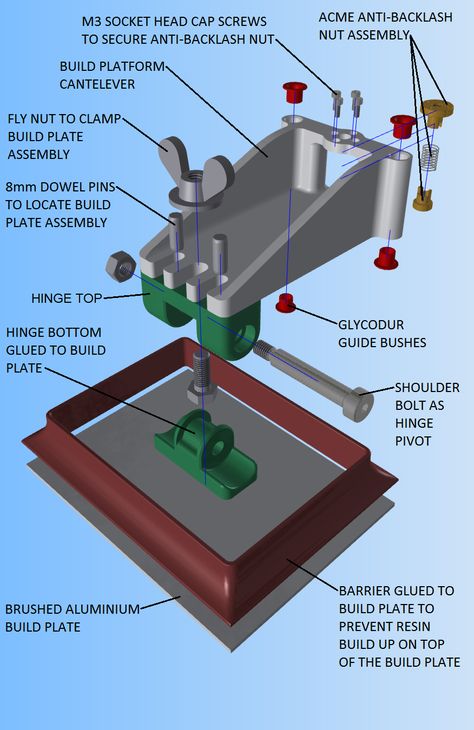

6. Prusa SL1 (Best Resin Open source)

3D Printer Type: SLA | Layer Resolution: 025-.1mm | Materials: Resin | Build Volume: 120 x 68 x 150 mm | Max Print Speed: 6 seconds per layer

The Prusa SL1 is an SLA (stereolithographic) printer, meaning it uses liquid resin rather than filament to produce 3D prints. There are pros and cons to this, but Prusa sticks to its overarching goal. They want to create affordable, easy-to-use 3D printers, and the Prusa SL1 is precisely that.

There are pros and cons to this, but Prusa sticks to its overarching goal. They want to create affordable, easy-to-use 3D printers, and the Prusa SL1 is precisely that.

You can purchase the Prusa SL1 pre-assembled or as a DIY kit. The pre-assembled version is a cinch to use right out of the box, and if you opt for the DIY version, the instruction manual is top-notch. Novice users will have no problem setting up this machine.

This printer handles details without an issue and works well with 3rd party resins. Unfortunately, with resin printers, the first few layers are the most crucial. If they don’t set correctly, your entire print is a bust.

Some resin printers allow you to pause and raise the print bed to ensure the first few layers look right. With the SL1, you can pause things, but you can’t raise the bed to check.

Resin printers also are notorious for letting off noxious fumes. That’s unavoidable given the materials you’re working with, but the SL1 does, at least, have a carbon filter to help with bad smells.

- Minimal setup required

- Clean and appealing design

- 3rd party resins supported

- Small print bed

- Cannot raise bed mid-print to check progress

Check Latest Price

Final Thoughts

If we had to choose one printer on this list, we’d go with the Ender 3 V2. It’s the best in terms of value and ease of use. Plus, it has vast community support.

The Prusa models are great as well, especially the SL1, if you’re looking to print with resin.

That said, the best open source 3D printer is the one you’ll use most readily. For some, that will be a machine that they can build from scratch and modify to their heart’s content, like the Voron models. For others, the best 3D printer is one that will work right out of the box.

Either way, you’ll benefit from open source technology. It makes modifying and updating your 3D printer an absolute breeze!

Geohot Open Source Autopilot for Cars At the age of 17, he managed to hack the iPhone, three years later he released a jailbreak for the Sony PlayStation 3. Moreover, Hotz managed to avoid a lawsuit with the corporation. A couple of years ago, he took on a more serious project - the creation of an autopilot for cars. nine0003

And after all, he managed to carry out his plan almost single-handedly. He built a self-driving car in his garage, after which he demonstrated the system's capabilities to many technology and financial media journalists. As reported, the system is based on a neural network self-learning process. A little later, Geohot announced its intention to launch its system for sale at a price of $999. But it didn't work out.

A little later, Geohot announced its intention to launch its system for sale at a price of $999. But it didn't work out.

At the end of October of this year, George Hotz received an official request from the National Highway Traffic Safety Administration (NHTSA). The request specifies a requirement for Hotz to provide detailed information about the developed automatic vehicle control system. The letter specifically stated that the autopilot manufacturer is subject to section 301 of the Safety Act and regulation by the National Highway Traffic Safety Administration. nine0003

If Hotz does not send a product response by November 10 of this year, he will face a fine of $21,000 per day. As a result, the developer decided to abandon the idea of selling the autopilot in the United States and left for China.

For several weeks nothing was heard from him. But the other day, he made himself felt, saying that a decision had been made to open the Comma One project (that's what the autopilot is called). Autopilot source code for passenger cars has been released to the public. Both the code and detailed information about the hardware of the system have been published. All materials are supplied under the MIT license. nine0003

Autopilot source code for passenger cars has been released to the public. Both the code and detailed information about the hardware of the system have been published. All materials are supplied under the MIT license. nine0003

On Wednesday morning, Hotz held a press conference in San Francisco, where he revealed the details of the upcoming changes in the activities of his startup Comma.ai.

Sketch of the Comma Neo system

The project is now called Open Pilot and can be used by any person or company. The system is adapted to work with Honda Civic 2016 Touring Edition and Acura ILX 2016 cars. The autopilot does not turn on immediately, but when a certain speed is reached. For Acura it is about 40 km/h and for Honda it is 25 km/h. nine0003

Geohot also spoke about the creation of a new prototype called Comma Neo. Here, however, we are talking about a "hardware platform for research activities." As far as one can understand, the developer decided to circumvent the restrictions of American regulators by changing the positioning of the system.

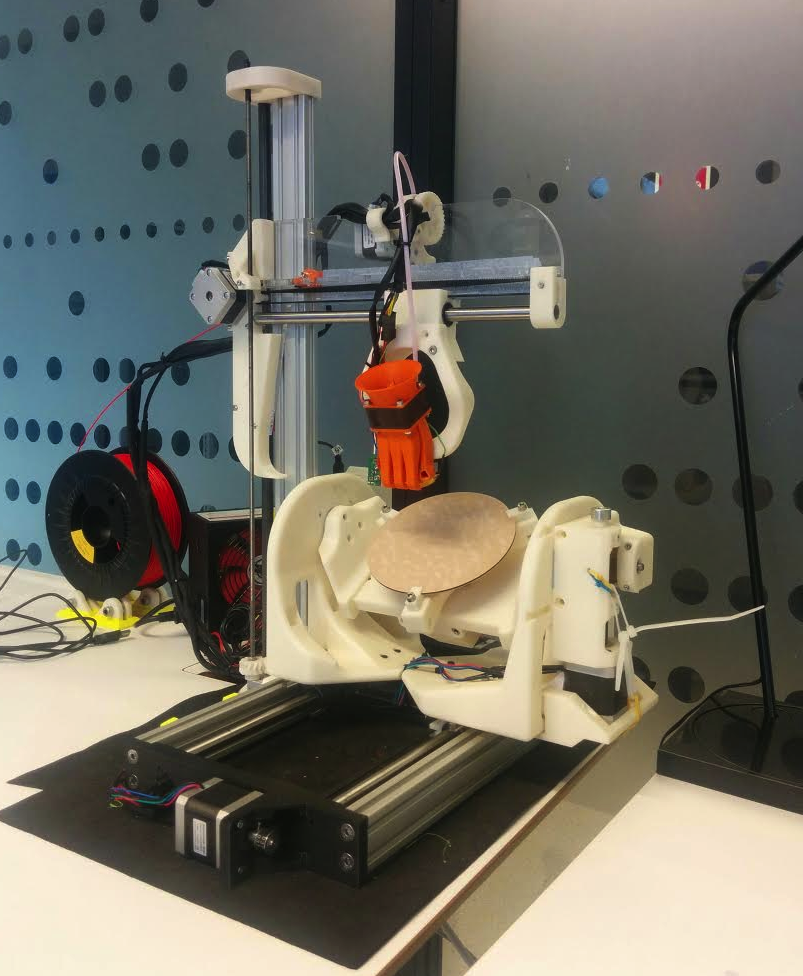

Comma Neo Working Prototype

Comma Neo can be assembled by yourself, it will require parts from a OnePlus 3 smartphone, a 3D printer and soldering skills. At the conference, Hotz avoided answering questions about whether the new system is planned to be released to the US or other markets. "We don't supply the product," was the only thing he replied. “We only distribute pre-release software for research purposes only. We make no guarantees." nine0003

When asked if the startup Comma.ai plans to start making money, Hotz replied: “How do you make money? Our goal is to create our own network. We want to have a network of autonomous cars.”

It is worth noting that the startup receives funding from various investors. In particular, Comma.ai previously received about $3 million from Andreessen Horowitz, a venture capital fund founded by Mark Andreessen and Ben Horowitz. Incidentally, the same company invested $50 million in Skype for a 2% stake in September 2009. of the year.

of the year.

Hotz compared Open Pilot to Android, saying that it is a project that will be of interest to "researchers and people who like" automatic control technology. This is a project "for people who want to go into the future."

More and more new developers are joining the startup, among which there are quite famous people. For example, a former employee of Tesla, who developed Autopilot, started working at Comma.ai earlier. Last month, ex-Google employee Michael Graczyk joined the startup. If the company manages to solve the problem with the authorities, then it is quite possible that in the near future, cars from many manufacturers will drive on the roads of different countries on their own, with minimal driver participation in the process of driving a car. nine0003

In Stavropol, students created a house using a giant 3D printer

December 02, 2022 16:33 Julia Rudy

The students who worked on the project will continue to work in the company that has acted as an industrial partner of the innovative project. nine0007 Photo of NCFU.

nine0007 Photo of NCFU.

In Stavropol, students built the first one-story house using a 3D construction printer. In this they were assisted by a team of developers from among the designers of the construction equipment plant.

Students of the Engineering Faculty of the North Caucasus Federal University (NCFU) tested the innovative technology of building a house.

The 3D printer was designed by a construction equipment company. However, NCFU students were also invited to participate in the development. nine0003

"I worked on the design of the printer, creating 3D models, drawings and subsequent operation of the development," said Alexei Nosenko, a student at the NCFU Engineering Institute.

Modified fine concrete was used as the printing material. "Print" is a layer-by-layer application of a building mixture according to a given three-dimensional computer model.

Construction 3D printer allows you to build houses, buildings and other structures faster. Due to the use of additive technologies (layer-by-layer building), the construction period of the building is reduced to several days. As the creators of the technology note, a house with an area of 100 square meters is built in 36 hours. nine0003

In addition, this technology generates less construction debris, and each square meter of new premises costs the developer less.

"Before starting the construction of the first one-story house, we made two uniform projects. We built one house in the classical way, and the other in an additive way, using a printer. We were convinced that the second way of working is much more profitable and faster - the savings turned out 36 %," said Dmitry Moskvitin, director of the NCFU partner enterprise. nine0003

The cooperation between the federal university and the construction equipment plant took two years: this is how much work on the project took in total from the idea to the first erected building.

Having received the necessary knowledge in this innovative area, many students then continued to work in the company.

At the moment, a two-story building is being built using 3D printing. Reportedly, in three working days, taking into account weather conditions, it was possible to build the entire first floor. nine0003

"Now we are directly engaged in the construction of buildings, residential premises, warehouses, which will be rented out to people and perform their direct function," said Alexey Nosenko.

In the meantime, NCFU is planning to open a new research and education center for additive technologies.

In it, students and their mentors will study and improve concrete mixtures, develop special software and industrial controllers. It is also necessary to create and develop new methods for designing buildings and building structures, adapted specifically for building 3D printing. nine0003

Previously, we talked about how Russian engineers create devices to print large parts of a carbon fiber car body, and how wasps inspired scientists to print houses out of mud and clay.