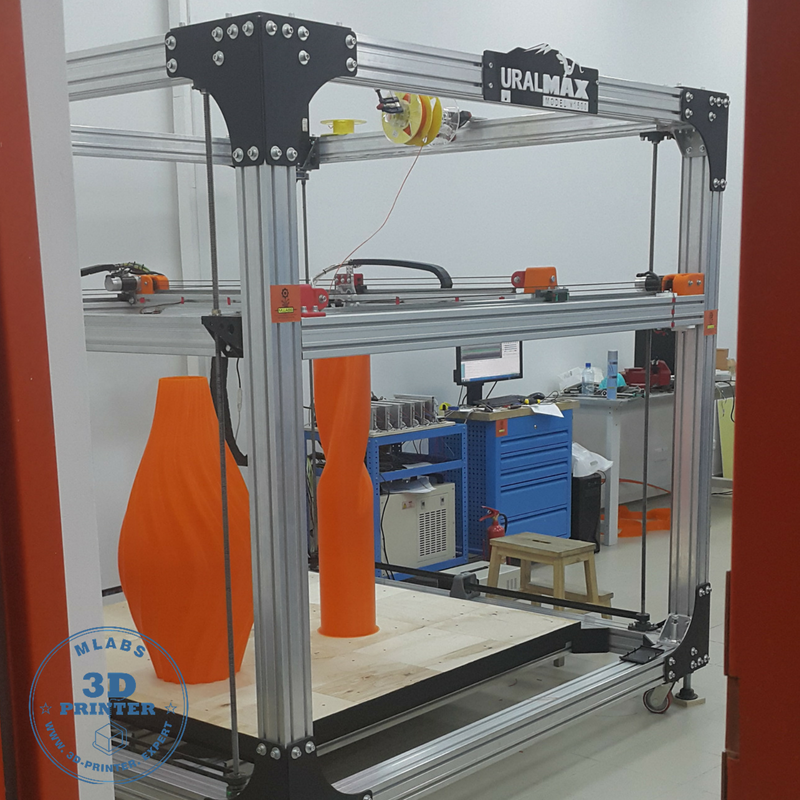

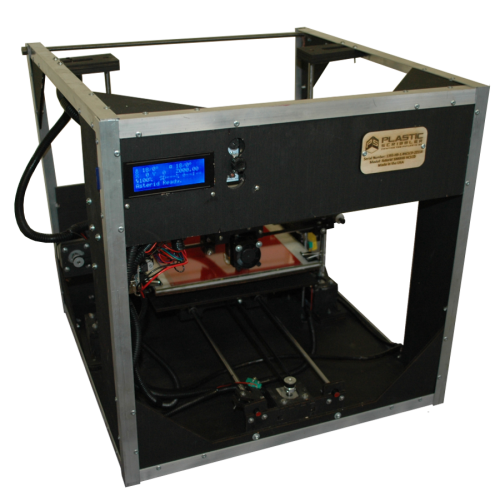

Asterid 1100 3d printer

Plastic Scribbler Introduces Its Newest Model of 3D Printer: The Asterid Model 1100

Plastic Scribbler -- Asterid Model 1100 3D Printer

Plastic Scribbler's 3D printers do not use proprietary filament and the end user is free to use and experiment with any 1.75mm plastic filament available on the market.

Cumming, GA (PRWEB) March 04, 2014

Starting with the Asterid 1000S $499 dollar base model 3D printer, Plastic Scribbler has added all the features even the most hardened veteran of 3D printing would need. The new model, Asterid 1100, includes a Smart Controller, a 12V 40W heater cartridge, a heated build platform with a borosilicate glass build surface and all the same great features as the 1000S model such as an 8” x 8” x 8” build volume, acme threaded rod for z-axis motion and geared extruder for more dependable extrusion.

The included Smart Controller adds a full size SD card reader in addition to a LCD display and allows for computer free 3D printing! With this standard option, the user is no longer tied to their office in order to use their 3D printer, the user can now take his 3D printer with him on a trip and doesn't even need to bring a computer! In addition, since the G-code is fed straight off the SD card, any latency or lag created by a personal computer and the USB interface would be completely eliminated. The included Smart Controller helps create the very highest quality of FFF (Fused Filament Fabrication) 3D printing that is possible today. The included slicer software would still be used to generate the g-code used for printing, but once the g-code file is on the SD card the Smart Controller does the rest. The user can auto-home all three axises, make small or large manual movements on each axis, all without the use of a PC. The Smart Controller also gives constant feedback on extruder and bed temperature, so the user can instantly monitor the status of their 3D prints.

In addition to the Smart Controller, Plastic Scribbler's newest model also includes a premium heater cartridge. When compared to the standard model 1000S power resistor, the heater cartridge out performs it in many ways. As plastic filament is extruded through the nozzle, heat is extracted. It is the job of the hot end heating element to return this heat loss back to the hot end extruder block. With a higher power density, the heater cartridge can restore heat loss more quickly which allows for more consistent extrusion and better 3D prints. In addition, since the heater cartridge heats up more quickly, the user can spend more time 3D printing instead of waiting.

In addition, since the heater cartridge heats up more quickly, the user can spend more time 3D printing instead of waiting.

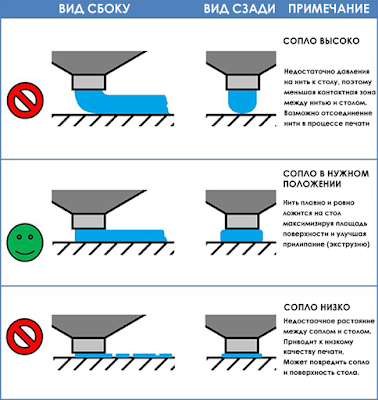

Whether the user chooses to print in ABS or PLA (the Asterid model 1100 supports both), the included heated build platform helps them achieve excellent results. The heated bed keeps the first couple of layers of the 3D model warm, to help prevent warping due to uneven part cooling. The heated bed thus helps reduce the chance the 3D printed model will pull-up at the corners and warp severely. In addition, the heated bed surface also helps the first layer adhere to the borosilicate glass or build plate which also helps create better 3D prints. Over the heated build PCB, Plastic Scribbler has supplied the model 1100 with a 10.5” x 9” x 1/8” thick piece of borosilicate glass. Borosilicate glass has a very low coefficient of thermal expansion, which allows the glass to be safely heated and cooled without worrying about breakage. Borosilicate glass is also one of the flattest man made materials. A flat build surface is critical for the first few layers since an uneven surface would cause sticking and part deformation issues.

A flat build surface is critical for the first few layers since an uneven surface would cause sticking and part deformation issues.

In addition to the new product offering, Plastic Scribbler has also been very busy on design side improvements. The z-axis motor mounts have been significantly strengthened and the y-axis guide plate bearing support has also been redesigned and upgraded. The new design strengthens the entire assembly and makes for a more robust 3D printer. The Plastic Scribbler team has also tweaked the slicer settings and improved the print quality. Finally, they have made small changes to the Y and Z axis limit switch mounts. The new mounts make it easy to tweak these two end points and give more clearance to the y-axis table and the z-axis limit switch. All these improvements have been incorporated into the existing 3D printer models the 1000S, the 1000HB and also in the newest model the 1100.

With all the professional features included in the price, the Asterid Model 1100 3D printer is a great way for artists, engineers, designers and students to get started in the world of 3D printing. In addition, all of Plastic Scribbler's 3D printers use standard 1.75mm plastic filament and do not use proprietary 3D printer filament. Some 3D printer manufacturers embed RFID tags or use other means to make sure the consumer is forced to purchase their brand of filament. Plastic Scribbler's 3D printers do not use proprietary filament and the end user is free to use and experiment with any 1.75mm plastic filament available on the market. This is a huge advantage and any 3D printer user should recognize the benefits right away. So, please visit Plastic Scribbler's website to check out all the great 3D printers they have to offer that start at just $499 dollars.

In addition, all of Plastic Scribbler's 3D printers use standard 1.75mm plastic filament and do not use proprietary 3D printer filament. Some 3D printer manufacturers embed RFID tags or use other means to make sure the consumer is forced to purchase their brand of filament. Plastic Scribbler's 3D printers do not use proprietary filament and the end user is free to use and experiment with any 1.75mm plastic filament available on the market. This is a huge advantage and any 3D printer user should recognize the benefits right away. So, please visit Plastic Scribbler's website to check out all the great 3D printers they have to offer that start at just $499 dollars.

ProX SLS 6100 3D Printer

The production-ready ProX® SLS 6100 features automated material handling and advanced 3D Sprint® software to deliver tough, high-resolution end-use parts and functional prototyping.

Production-Grade Materials

Produce tough, durable parts from a range of DuraForm® ProX production-grade nylon materials that have been optimized, validated and tested to ensure quality, with uniform 3D mechanical properties. The ProX SLS 6100 brings versatility to your applications, whether for functional prototyping or direct 3D production. Choose from industrial-grade, tough, impact and fatigue-resistant nylon 11 materials or strong, medical-grade, or flame-retardant capable nylon 12 thermoplastics, or filled nylons for advanced properties in terms of stiffness, temperature resistance, strength and surface finish.

The ProX SLS 6100 brings versatility to your applications, whether for functional prototyping or direct 3D production. Choose from industrial-grade, tough, impact and fatigue-resistant nylon 11 materials or strong, medical-grade, or flame-retardant capable nylon 12 thermoplastics, or filled nylons for advanced properties in terms of stiffness, temperature resistance, strength and surface finish.

ProX SLS 6100 Material Quality Control system

Unmatched Part Quality at High Throughput:

With faster build times than other SLS printers in its price point, high performance nesting and high density capability for a 25% larger build volume capacity, the ProX SLS 6100 delivers production quality parts in a fast and efficient process.

- Best surface finish

- Highest resolution and edge definition

- High accuracy and repeatability

- Uniform part properties

Predictive support through advanced 3D printing software increases uptime and SLS efficiency

Maximize Your Production with 3D Connect:

3D Connect™ Service provides a secure cloud-based connection to 3D Systems service for preventative support to enable better service, improved uptime and production assurance for your system. With 3D Connect Service, your system will automatically send alerts to 3D Systems' service team for immediate assistance in resolving printer-defined conditions or exceptions, solve problems remotely, pre-order parts, and schedule on-site services as required.

With 3D Connect Service, your system will automatically send alerts to 3D Systems' service team for immediate assistance in resolving printer-defined conditions or exceptions, solve problems remotely, pre-order parts, and schedule on-site services as required.

About this printer

-

Applications

-

Benefits

-

Tech Specs

Applications

- Impact and temperature resistant durable parts

- Covers, housings, enclosures

- Jigs and fixtures

- Reduced weight production parts

- Knobs, handles and other dashboard/interior parts

- Parts with snap fits and living hinges

- Machinery components

- Complex duct work

Benefits

- Manufacture strong end-use parts and functional prototypes faster

- Easily print any design without using supports or post-processing

- Integrated solution with expert application support

- Full automation of material handling frees valuable resource

- Streamline your workflow with automated production tools

- Lower cost of ownership with high throughput and material efficiency

- Smoothest surface finish, highest resolution and edge definition of any SLS system

Tech Specs

- Selective Laser Sintering (SLS) technology

- Max build envelope capacity (W x D x H): 15 x 13 x 18 in (381 x 330 x 460 mm)

- Broad range of production-grade nylon 11, nylon 12 and reinforced materials

- Consistent mechanical properties

- High production speed for its class of 2.

7 l per hour

7 l per hour - Streamlined production control, including 3D Sprint™ integrated additive manufacturing software, fully automated powder handling and optional 3D Connect capability

- Automated 3D part nesting

- Maximized build volume and density

-

Setting the New Standard in 3D Printing

Bring increased productivity and quality to your SLS production process with this exclusive additive manufacturing software with tools for file preparation, automatic 3D nesting, quality checks for pre-build verification, and efficient build planning,

-

A new level of management in 3D production

3D Connect Service provides a secure cloud-based connection to 3D Systems service teams for proactive and preventative support, enabling better service to improve uptime and deliver production assurance for your system.

-

3D printing with plastics offers many choices for engineering grade materials, elastomers and composites. Do you need flexibility? Strength? Bio-compatibility? More?

-

3D print with plastics to build almost anything - used for prototyping, manufacturing, anatomical models and more. Select a plastic material and 3D technology to deliver the characteristics you need.

Interested in purchasing this printer?

You must have JavaScript enabled to use this form.

First Name

Last Name

Business Email

Company

Country -- Select Country --AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua & BarbudaArgentinaArmeniaArubaAscension IslandAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia & HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBritish Virgin IslandsBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCanary IslandsCape VerdeCaribbean NetherlandsCayman IslandsCentral African RepublicCeuta & MelillaChadChileChinaChristmas IslandClipperton IslandCocos (Keeling) IslandsColombiaComorosCongo - BrazzavilleCongo - KinshasaCook IslandsCosta RicaCroatiaCuraçaoCyprusCzechiaCôte d’IvoireDenmarkDiego GarciaDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard & McDonald IslandsHondurasHong Kong SAR ChinaHungaryIcelandIndiaIndonesiaIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKosovoKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacao SAR ChinaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmar (Burma)NamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorth MacedoniaNorwayOmanOutlying OceaniaPakistanPalauPalestinian TerritoriesPanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandsPolandPortugalPuerto RicoQatarRomaniaRussiaRwandaRéunionSamoaSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia & South Sandwich IslandsSouth KoreaSouth SudanSpainSri LankaRepublic of Sudan (North Sudan)St. BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSurinameSvalbard & Jan MayenSwedenSwitzerlandSão Tomé & PríncipeTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTristan da CunhaTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluU.S. Outlying IslandsU.S. Virgin IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSurinameSvalbard & Jan MayenSwedenSwitzerlandSão Tomé & PríncipeTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTristan da CunhaTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluU.S. Outlying IslandsU.S. Virgin IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

State -- Select State --Buenos AiresCatamarcaChacoChubutCiudad Autónoma de Buenos AiresCórdobaCorrientesEntre RíosFormosaJujuyLa PampaLa RiojaMendozaMisionesNeuquénRío NegroSaltaSan JuanSan LuisSanta CruzSanta FeSantiago del EsteroTierra del FuegoTucumánAustralian Capital TerritoryNew South WalesNorthern TerritoryQueenslandSouth AustraliaTasmaniaVictoriaWestern AustraliaBurgenlandKärntenNiederösterreichOberösterreichSalzburgSteiermarkTirolVorarlbergWienAcreAlagoasAmapáAmazonasBahiaCearáDistrito FederalEspírito SantoGoiásMaranhãoMato GrossoMato Grosso do SulMinas GeraisParáParaíbaParanáPernambucoPiauíRio de JaneiroRio Grande do NorteRio Grande do SulRondôniaRoraimaSanta CatarinaSão PauloSergipeTocantinsAlbertaBritish ColumbiaManitobaNew BrunswickNewfoundland and LabradorNorthwest TerritoriesNova ScotiaNunavutOntarioPrince Edward IslandQuebecSaskatchewanYukon TerritoriesAisén del General Carlos Ibañez del CampoAntofagastaAraucaníaArica y ParinacotaAtacamaBío-BíoCoquimboLibertador General Bernardo O'HigginsLos LagosLos RíosMagallanesMauleRegión Metropolitana de SantiagoTarapacáValparaísoAnhuiBeijingChinese TaipeiChongqingFujianGansuGuangdongGuangxiGuizhouHainanHebeiHeilongjiangHenanHong KongHubeiHunanJiangsuJiangxiJilinLiaoningMacaoNei MongolNingxiaQinghaiShaanxiShandongShanghaiShanxiSichuanTianjinXinjiangXizangYunnanZhejiangÎle-de-FranceOccitanieAuvergne-Rhône-AlpesBourgogne-Franche-ComtéBretagneCentre-Val de LoireCorseGrand EstHauts-de-FranceJuraNormandieNouvelle-AquitainePays de la LoireProvence-Alpes-Côte d'AzurBaden-WürttembergBayernBerlinBrandenburgBremenHamburgHessenMecklenburg-VorpommernNiedersachsenNordrhein-WestfalenRheinland-PfalzSaarlandSachsenSachsen-AnhaltSchleswig-HolsteinThüringenAndaman and Nicobar IslandsAndhra PradeshArunachal PradeshAssamBiharChandigarhChhattisgarhDadra and Nagar HaveliDaman and DiuDelhiGoaGujaratHaryanaHimachal PradeshJammu and KashmirJharkhandKarnatakaKeralaLakshadweepMadhya PradeshMaharashtraManipurMeghalayaMizoramNagalandOdishaPuducherryPunjabRajasthanSikkimTamil NaduTripuraUttar PradeshUttarakhandWest BengalCarlowCavanClareCorkDonegalDublinGalwayKerryKildareKilkennyLaoisLeitrimLimerickLongfordLouthMayoMeathMonaghanOffalyRoscommonSligoTipperaryWaterfordWestmeathWexfordWicklowAgrigentoAlessandriaAnconaAostaArezzoAscoli PicenoAstiAvellinoBariBarletta-Andria-TraniBellunoBeneventoBergamoBiellaBolognaBolzanoBresciaBrindisiCagliariCaltanissettaCampobassoCarbonia-IglesiasCasertaCataniaCatanzaroChietiComoCosenzaCremonaCrotoneCuneoEnnaFermoFerraraFirenzeFoggiaForlì-CesenaFrosinoneGenovaGoriziaGrossetoImperiaIserniaLa SpeziaL'AquilaLatinaLecceLeccoLivornoLodiLuccaMacerataMantovaMassa - CarraraMateraMedio CampidanoMessinaMilanoModenaMonza e BrianzaNapoliNovaraNuoroOgliastraOlbia-TempioOristanoPadovaPalermoParmaPaviaPerugiaPesaro e UrbinoPescaraPiacenzaPisaPistoiaPordenonePotenzaPratoRagusaRavennaReggio CalabriaReggio EmiliaRietiRiminiRomaRovigoSalernoSassariSavonaSienaSondrioSiracusaTarantoTeramoTerniTrapaniTrentoTrevisoTriesteTorinoUdineVareseVeneziaVerbano-Cusio-OssolaVercelliVeronaVibo ValentiaVicenzaViterboAichiAkitaAomoriChibaEhimeFukuiFukuokaFukushimaGifuGunmaHiroshimaHokkaidoHyogoIbarakiIshikawaIwateKagawaKagoshimaKanagawaKochiKumamotoKyotoMieMiyagiMiyazakiNaganoNagasakiNaraNiigataOitaOkayamaOkinawaOsakaSagaSaitamaShigaShimaneShizuokaTochigiTokushimaTokyoTottoriToyamaWakayamaYamagataYamaguchiYamanashiBusanDaeguDaejeonGangwonGwangjuGyeonggiIncheonJejuNorth ChungcheongNorth GyeongsangNorth JeollaSeoulSouth ChungcheongSouth GyeongsangSouth JeollaUlsanJohorKedahKelantanMelakaNegeri SembilanPahangPerakPerlisPulau PinangSabahSarawakSelangorTerengganuWilayah Persekutuan Kuala LumpurWilayah Persekutuan LabuanWilayah Persekutuan PutrajayaAguascalientesBaja CaliforniaBaja California SurCampecheChiapasChihuahuaCoahuilaColimaDurangoFederal DistrictGuanajuatoGuerreroHidalgoJaliscoMexico StateMichoacánMorelosNayaritNuevo LeónOaxacaPueblaQuerétaroQuintana RooSan Luis PotosíSinaloaSonoraTabascoTamaulipasTlaxcalaVeracruzYucatánZacatecasŚląskieŁódzkieŚwiętokrzyskieDolnośląskieKujawsko-pomorskieLubelskieLubuskieMałopolskieMazowieckieOpolskiePodkarpackiePodlaskiePomorskieWarmińsko-mazurskieWielkopolskieZachodniopomorskieAdygeya, RespublikaAltay, RespublikaAltayskiy krayAmurskaya oblast'Arkhangel'skaya oblast'Astrakhanskaya oblast'Bashkortostan, RespublikaBelgorodskaya oblast'Bryanskaya oblast'Buryatiya, RespublikaChechenskaya RespublikaChelyabinskaya oblast'Chukotskiy avtonomnyy okrugChuvashskaya RespublikaDagestan, RespublikaIngushetiya, RespublikaIrkutskaya oblast'Ivanovskaya oblast'Kabardino-Balkarskaya RespublikaKaliningradskaya oblast'Kalmykiya, RespublikaKaluzhskaya oblast'Kamchatskiy krayKarachayevo-Cherkesskaya RespublikaKareliya, RespublikaKemerovskaya oblast'Khabarovskiy krayKhakasiya, RespublikaKhanty-Mansiyskiy avtonomnyy okrug-YugraKirovskaya oblast'Komi, RespublikaKostromskaya oblast'Krasnodarskiy krayKrasnoyarskiy krayKurganskaya oblast'Kurskaya oblast'Leningradskaya oblast'Lipetskaya oblast'Magadanskaya oblast'Mariy El, RespublikaMordoviya, RespublikaMoskovskaya oblast'MoskvaMurmanskaya oblast'Nenetskiy avtonomnyy okrugNizhegorodskaya oblast'Novgorodskaya oblast'Novosibirskaya oblast'Omskaya oblast'Orenburgskaya oblast'Orlovskaya oblast'Penzenskaya oblast'Permskiy krayPrimorskiy krayPskovskaya oblast'Rostovskaya oblast'Ryazanskaya oblast'Sakha, RespublikaSakhalinskaya oblast'Samarskaya oblast'Sankt-PeterburgSaratovskaya oblast'Severnaya Osetiya-Alaniya, RespublikaSmolenskaya oblast'Stavropol'skiy kraySverdlovskaya oblast'Tambovskaya oblast'Tatarstan, RespublikaTomskaya oblast'Tul'skaya oblast'Tverskaya oblast'Tyumenskaya oblast'Tyva, RespublikaUdmurtskaya RespublikaUl'yanovskaya oblast'Vladimirskaya oblast'Volgogradskaya oblast'Vologodskaya oblast'Voronezhskaya oblast'Yamalo-Nenetskiy avtonomnyy okrugYaroslavskaya oblast'Yevreyskaya avtonomnaya oblast'Zabaykal'skiy krayCentral SingaporeNorth EastNorth WestSouth EastSouth WestA CoruñaÁlava / ArabaAlbaceteAlicante / AlacantAlmeríaAsturiasÁvilaBadajozBalearsBarcelonaBurgosCáceresCádizCantabriaCastellón / CastellóCiudad RealCórdobaCuencaGironaGranadaGuadalajaraGuipúzcoa / GipuzkoaHuelvaHuescaJaénLa RiojaLas PalmasLeónLleidaLugoMadridMálagaMurciaNavarra / NafarroaOurensePalenciaPontevedraSalamancaSanta Cruz de TenerifeSegoviaSevillaSoriaTarragonaTeruelToledoValencia / ValènciaValladolidVizcaya / BizkaiaZamoraZaragozaAargauAppenzell AusserrhodenAppenzell InnerrhodenBasel-LandschaftBasel-StadtBernFribourgGenèveGlarusGraubündenJuraLuzernNeuchâtelNidwaldenObwaldenSankt GallenSchaffhausenSchwyzSolothurnThurgauTicinoUriValaisVaudZugZürichChanghua CountyChiayi CityChiayi CountyHsinchu CityHsinchu CountyHualien CountyKaohsiung CityKaohsiung CountyKeelung CityMiaoli CountyNantou CountyPenghu CountyPingtung CountyTaichung CityTaichung CountyTainan CityTainan CountyTaipei CityTaipei CountyTaitung CountyTaoyuan CountyYilan CountyYunlin CountyŞırnakŞanlıurfaİstanbulİzmirAğrıAd?yamanAdanaAfyonkarahisarAksarayAmasyaAnkaraAntalyaArdahanArtvinAydınBalıkesirBartınBatmanBayburtBilecikBingölBitlisBoluBurdurBursaÇanakkaleÇankırıÇorumDenizliDiyarbakırDüzceEdirneElazığErzincanErzurumEskişehirGaziantepGiresunGümüşhaneHakkâriHatayIğdırIspartaKırşehirKırıkkaleKırklareliKahramanmaraşKarabükKaramanKarsKastamonuKayseriKilisKocaeliKonyaKütahyaMalatyaManisaMardinMersinMuşMuğlaNevşehirNiğdeOrduOsmaniyeRizeSakaryaSamsunSiirtSinopSivasTekirdağTokatTrabzonTunceliUşakVanYalovaYozgatZonguldakCrimeaCherkasyChernihivChernivtsiDnipropetrovskDonetskIvano-FrankivskKharkivKhersonKhmelnytskyiKirovohradKyivLuhanskLvivMykolaivOdesaPoltavaRivneSumyTernopilVinnytsiaVolynZakarpattiaZaporzhzhiaZhytomyrAberdeen CityAberdeenshireAngusAntrimArgyll and ButeArmaghAvonBanffshireBedfordshireBerkshireBlaenau GwentBordersBridgendBristolBuckinghamshireCaerphillyCambridgeshireCardiffCarmarthenshireCeredigionChannel IslandsCheshireClackmannanshireClevelandConwyCornwallCumbriaDenbighshireDerbyshireDevonDorsetDownDumfries and GallowayDurhamEast AyrshireEast DunbartonshireEast LothianEast RenfrewshireEast Riding of YorkshireEast SussexEdinburghEssexFalkirkFermanaghFifeFlintshireGlasgowGloucestershireGreater ManchesterGwyneddHampshireHerefordshireHertfordshireHighlandHumbersideInverclydeIsle of AngleseyIsle of ManIsle of WightIsles of ScillyKentLancashireLeicestershireLincolnshireLondonLondonderryMerseysideMerthyr TydfilMiddlesexMidlothianMonmouthshireMorayNeath Port TalbotNewportNorfolkNorth AyrshireNorth East LincolnshireNorth LanarkshireNorth YorkshireNorthamptonshireNorthumberlandNottinghamshireOrkneyOuter HebridesOxfordshirePembrokeshirePerthshire and KinrossPowysRenfrewshireRhondda, Cynon, TaffRoxburghshireRutlandShetlandShropshireSomersetSouth AyrshireSouth LanarkshireSouth YorkshireStaffordshireStirlingSuffolkSurreySwanseaTorfaenTyne and WearTyroneVale of GlamorganWarwickshireWest DunbartonshireWest LothianWest MidlandsWest SussexWest YorkshireWiltshireWorcestershireWrexhamAlabamaAlaskaAmerican SamoaArizonaArkansasCaliforniaColoradoConnecticutDelawareDistrict of ColumbiaFederated MicronesiaFloridaGeorgiaGuamHawaiiIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarshall IslandsMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaNorthern Mariana IslandsOhioOklahomaOregonPalauPennsylvaniaPuerto RicoRhode IslandSouth CarolinaSouth DakotaTennesseeTexasUnited States Minor Outlying IslandsUS Virgin IslandsUtahVermontVirginiaWashingtonWest VirginiaWisconsinWyoming

Industry - None -Academic & ResearchAerospace & DefenseDentalHealthcareManufacturing & PrototypingTransportation & Motorsports

Sub-Industry - Select -Medical Device ManufacturersMedical Contract ManufacturersHospital or Medical ClinicMedical SchoolsOther HealthcareDental ClinicsDental Equipment ManufacturersDental LabsDental SchoolsOther DentalMilitary AviationCommercial AviationDefenseSpace & UAVOther Aerospace & DefenseAutomotiveTruck, Bus & RailMotorsportsAftermarket & ServiceRecreation & MarineOther Transportation3D Printing Service BureausFoundriesElectronics & ConnectorsSemiconductorTurbomachineryJewelryConsumer & Durable GoodsOther Manufacturing

Address

Postal Code

Job Level -- Select Job Level --C-LevelPresident or VPDirectorManagerProfessional StaffConsultant or ContractorIntern or StudentHobbyist

Job Function -- Select Job Function --Engineering - SoftwareEngineering - HardwareManufacturingFinanceITLegalMarketingPurchasingSalesService Technician - HardwareService Technician - SoftwareOther

Level of Interest -- Select Your Level of Interest --Beginning ResearchEvaluating Solutions and CompetitorsInterested in Buying in 1-3 MonthsInterested in Buying in 3-6 MonthsInterested in Buying in 6-12 MonthsI would like to speak with a Solutions SpecialistI have a Support Issue or Question

Area of Interest - Select -Printers• Professional Printer (ColorJet, MultiJet)• Production Printer (SLA, SLS, Metal/DMP)• Figure 4• Titan Additive• OtherSoftwareHaptics• HapticsHealthcare• Virtual Surgical Planning• Anatomical Modeling• Kumovis Additive

3D Printer - Select -MJP• ProJet 2500• ProJet 2500 Plus• ProJet 2500W• ProJet 2500 IC• ProJet 3600• ProJet 5600CJP• ProJet 260 Plus• Projet 360• ProJet 460 Plus• ProJet 660Pro• ProJet 860ProDMP• DMP Flex 100• ProX 200• DMP Flex 200• DMP Flex 350• DMP Factory 350• DMP Factory 500• ProX 100• ProX 300SLS• SLS 6100• SLS 380• sPro 140• sPro 230SLA• SLA 750• ProJet 6000• ProJet 7000• ProX 800• ProX 950Figure 4• Figure 4 Standalone• Figure 4 Modular• Figure 4 Production• Figure 4 JewelryNextDent• NextDent 5100Kumovis• Kumovis R1Atlas• Atlas H• Atlas HSMaterialsBioprinter

Software product - Select -3D Connect Manage3D Connect Service3D Modeling Services3D Sprint3D Sprint Pro for SLA3DXpertGeomagic Control XGeomagic Design XGeomagic for SOLIDWORKSGeomagic FreeformGeomagic SculptGeomagic TouchGeomagic Touch XGeomagic WrapOpenHapticsPhantom Premium

Area of Interest - Select -Medical Device Design and ManufacturingMedical SimulatorsAnatomical ModelsD2P SoftwareDental Manufacturing and Design Services

I consent to receive 3D Systems CommunicationsWould you like to receive special offers, product updates, and event news from 3D Systems? By clicking "Yes", you agree to receive follow-up communications from 3D Systems or our partners. You can also choose to opt out of communications at any time. Please click here to view our Privacy Policy or click here to manage your Preferences.

You can also choose to opt out of communications at any time. Please click here to view our Privacy Policy or click here to manage your Preferences.

Area of Interest - None -Appearance ModelsCast UrethaneCJPCNCCNC MetalCNC PlasticDie CastingDigitalization/ScanningDMPEngineering ProjectsFDMInjection MoldingInjection ToolingInvestment CastingInvestment Casting PatternJigs and FixturesMetal CastingMJPMJP-ElastomersQuick Cast PatternsRIMSheet MetalSLASLSToolingVacuum castingVacuum forming

Custom Area of Interest

PPP

PST

Software

Healthcare

ODM

Area of interest Required

This site is protected by reCAPTCHA. The Google Privacy Policy and Terms of Service apply.

You Might Also Be Interested In

sPro 140

High repeatability and throughput of SLS production parts

sPro 230

Large capacity SLS printer for high throughput of tough and durable thermoplastic parts

10 most unexpected directions of 3D printing

As professionals say, the main problem with 3D printing is that no one knows why it is needed. But the portal 3Dtoday knows. Therefore, they have prepared for us a cool material about the areas for which 3D printing is actively used in our time. So, the ten most striking applications of 3D printers in everyday life and industry are in front of you!

But the portal 3Dtoday knows. Therefore, they have prepared for us a cool material about the areas for which 3D printing is actively used in our time. So, the ten most striking applications of 3D printers in everyday life and industry are in front of you!

Oleg Nechay

For most people, additive technologies are still something mysterious and incomprehensible, despite their growing popularity around the world. In fact, household 3D printers are quite easy to operate, and quite successfully produced by Russian companies at quite affordable prices. Industrial devices, in turn, are very expensive, but their potential cannot but impress. Go! nine0003

Do not self-medicate! In our articles, we collect the latest scientific data and the opinions of authoritative health experts. But remember: only a doctor can diagnose and prescribe treatment.

Medical

The most promising direction for 3D printing in general is piece or small-scale production. If consumer goods are easier and cheaper to cast and stamp, then customized products are more profitable to print, since 3D printing allows you to go from a digital model directly to production without requiring the manufacture of expensive tooling. Sometimes, one-piece production simply cannot be dispensed with. Children’s prostheses are great examples, and they need to be constantly replaced as the child grows. The idea of prosthetics has become widespread around the world, with some fully functional 3D printed mechanical versions costing as little as $50, while classic custom prostheses can cost as much as $50,000. Designers are being helped by 3D scanners used to obtain a three-dimensional drawing of a limb. Then the prosthesis is printed according to the obtained dimensions and outlines. The pioneer in this area was Aaron Brown and his project E-Nabling The Future. He came up with children's prostheses in the shape of the hands of superheroes - Wolverine, Iron Man, and so on. They play not only a mechanical, but also a serious psychological role in the rehabilitation of children who have lost limbs or were born without them.

If consumer goods are easier and cheaper to cast and stamp, then customized products are more profitable to print, since 3D printing allows you to go from a digital model directly to production without requiring the manufacture of expensive tooling. Sometimes, one-piece production simply cannot be dispensed with. Children’s prostheses are great examples, and they need to be constantly replaced as the child grows. The idea of prosthetics has become widespread around the world, with some fully functional 3D printed mechanical versions costing as little as $50, while classic custom prostheses can cost as much as $50,000. Designers are being helped by 3D scanners used to obtain a three-dimensional drawing of a limb. Then the prosthesis is printed according to the obtained dimensions and outlines. The pioneer in this area was Aaron Brown and his project E-Nabling The Future. He came up with children's prostheses in the shape of the hands of superheroes - Wolverine, Iron Man, and so on. They play not only a mechanical, but also a serious psychological role in the rehabilitation of children who have lost limbs or were born without them. nine0003

nine0003

But dentures are just the beginning. There is a special area in additive manufacturing called bioprinting. Its essence lies in the 3D printing of volumetric structures with living cells and biodegradable materials that serve as a scaffold or "matrix" for the cell mass. Of course, it is possible to grow a cell mass in a test tube, but only bioprinting can create a fully functional organ from several tissues and with a network of blood vessels, and even suitable for transplantation. Work in this direction is already underway, although complex organs have not yet been obtained. The most advanced example can be considered the experiments of the Russian company 3D Bioprinting Solutions, which printed the thyroid gland, which was then successfully implanted in an experimental mouse. But the American company Organovo already produces liver tissue used as samples for testing new drugs for efficacy, toxicity and side effects without the participation of bipedal test subjects. nine0003

nine0003

Sometimes it is not necessary to print a new organ to save a life. You can fix an existing one. A vivid example was the operation performed by surgeons of the St. Petersburg State Pediatric Medical University. Doctors had to save a baby born with a complicated heart defect. In order to understand the structure of the defect, the doctors printed an exact model of the heart from tomographic images and worked out all the details before proceeding with two complex operations. The story ended happily: the boy went to a quick recovery. nine0003

Robotics

We already mentioned prostheses, but what about full-fledged robots? Easy. There are actually a lot of options, but the development of Siemens is interesting because it is based on 3D printed robots that act as 3D printers! As conceived by the creators, such devices should act as a production swarm like ants or bees. A group of machines follows common algorithms by printing new objects using onboard 3D printers. nine0003

nine0003

These "robo-spiders" work on batteries, remembering their position in space and relative to each other. When the batteries are low, the spider robot calls a fully charged shifter, and he goes to rest and recharge. The developers believe that the industrial version of such a swarm will be able to produce truly large-sized objects like buildings or ship hulls.

Construction

Buildings, however, can be printed now. There are still few construction 3D printers, but they show very interesting results. The essence of the process, as a rule, comes down to layer-by-layer printing of walls from a specially formulated cement mixture. The recipe for the mix is very important as it needs to set fast enough to not get crushed by subsequent layers. On the other hand, drying too quickly will prevent the layers from setting to each other. The resulting hollow walls serve as a kind of non-removable formwork, into which you can insert insulation, reinforcement, conduct communications, and for greater strength, fill the remaining cavities with concrete and get a monolithic structure. The advantage of this technology over the usual formwork is the ability to create all sorts of hitherto unthinkable shapes - rounded, spiral, etc.

The advantage of this technology over the usual formwork is the ability to create all sorts of hitherto unthinkable shapes - rounded, spiral, etc.

An excellent example is the work of Andrey Rudenko, who printed a miniature castle on an illustration. Andrey recently took on a serious project by printing an extension to a hotel complex in the Philippines. And the dexterous Chinese from WinSun have already printed a five-story building, although they carried out this project in parts, assembling the printed panels at the construction site.

Automotive

In just a few years, you'll notice a new car pulling out of your neighbor's garage every time. How can this be? The answer is simple: he prints them. The production of spare parts for automobiles quickly became one of the favorite directions among do-it-yourself printers or "makers". Is it worth waiting for delivery or scouring the shops in search of a broken handle or a hood ornament torn off by a bully when they can be printed? At the same time, printed products cost mere pennies, while spare parts from dealers can be quite expensive. For printing, you can use ABS plastic - the same one from which most plastic trim elements are made. But the automotive 3D printing career didn't end there. nine0003

For printing, you can use ABS plastic - the same one from which most plastic trim elements are made. But the automotive 3D printing career didn't end there. nine0003

When MarkForged introduced a special 3D printer that allows printing with plastic and carbon fiber composites, 3D printed parts began to appear even on Formula 1 cars. And the American company Local Motors went even further and created a car with a 3D printed body. Now even Toyota is working on its own version of a 3D printed machine.

Space

Those born to fly should not crawl, and astronauts love high-tech gadgets. A space 3D printer suggests itself! The first such device, similar to bar desktop machines available on Earth to anyone, was launched into orbit in September 2014. The Made in Space 3D printer has been successfully tested in zero gravity and has already returned to its home planet, and it has been replaced by a more advanced version. nine0003

nine0003

And yes, like motorists, astronauts intend to use 3D printing to produce spare parts. The logic here is simple: why carry a full set of parts and tools into orbit when they can be printed as needed from a relatively small stock of materials on board the station? The latest Made in Space project, which is still conceptual, involves 3D printing of engines and onboard equipment on asteroids using improvised materials. What for? To deliver a huge block of valuable raw materials to near-Earth orbit, where it can be used to build new orbital structures or lowered to Earth. nine0003

Although everyone has their own worries: Italian astronauts do not start their day without a cup of espresso brewed using a special coffee machine. And in order to prevent the drink from spreading throughout the station, 3D-printed cups of a special shape are used to hold the liquid due to surface tension. And quite recently, a Russian satellite manufactured by specialists from the Tomsk Polytechnic University arrived on board the ISS. The design of the satellite is partially made using 3D printing.

The design of the satellite is partially made using 3D printing.

Aircraft

Wait, what other 3D printed engines? Is it possible? Quite, and additive manufacturing is successfully used in many areas of mechanical engineering, including the aviation and space industries, where 3D printed engine parts are quickly becoming commonplace. It's all about 3D printing methods such as selective laser sintering (SLS) and deposition welding (SLM). These methods allow you to create high-precision parts consisting entirely of metals and alloys. nine0003

Fine powders are used as raw materials, which are heated almost to the melting point and then sintered or alloyed along predetermined contours using ultra-precise lasers. Although there were initially certain doubts about the strength of such products, numerous experiments dispelled fears: the density of the parts obtained is almost similar to cast counterparts, and the ability to manufacture the most complex components as a whole makes it possible to avoid the formation of weak zones that usually appear at the site of welding seams. nine0003

nine0003

3D printed engine parts, up to nozzles, are already being used on SpaceX devices, Airbus is actively and successfully testing 3D printed engine parts and supporting structures of airliners, and 3D printed swirlers created by the All-Russian Scientific Research Institute of Aviation materials (VIAM) for advanced PD-14 engines currently undergoing flight tests.

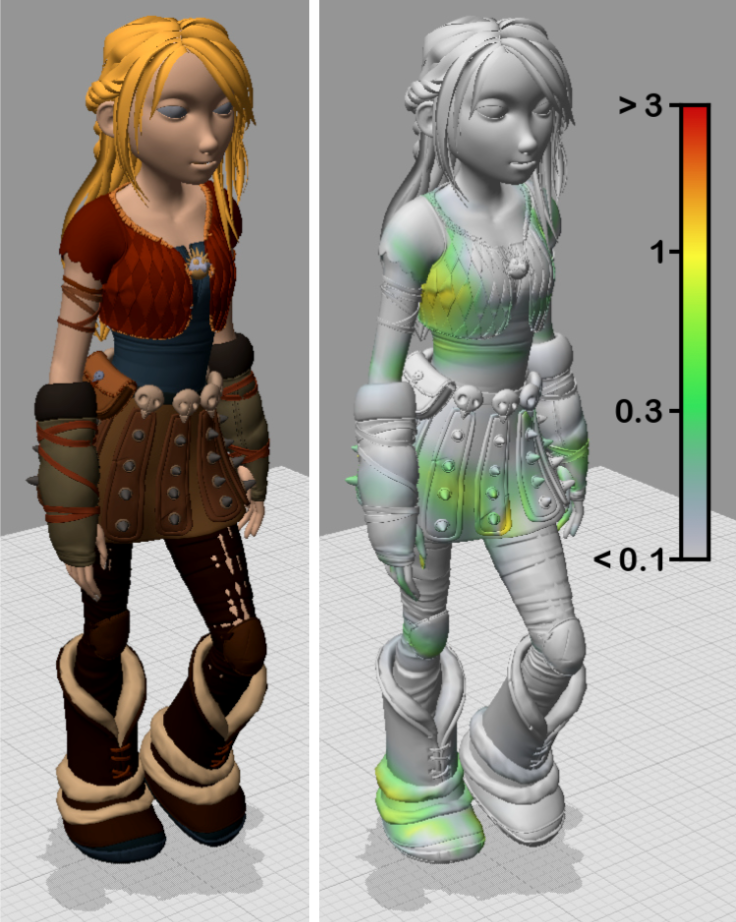

Industrial design

Although complex, expensive metal-printing systems are used to manufacture engines, 3D printers that print plastics are the most used in the industry. They are used not so much for the manufacture of finished products as for prototypes. Initially, 3D printing technology was called that - rapid prototyping. 3D printers make it possible to produce high-precision prototype parts, gadget cases, architectural models, and even shoes. Finished products not only serve for visual visualization, but also allow you to try on the components to be assembled. The latter option is used by the developers of the Armata tanks. Because prototyping requires no custom tooling, and the design itself can be quickly digitally modified and reprinted, 3D printing for prototyping results in significant time and cost savings for R&D. nine0003

The latter option is used by the developers of the Armata tanks. Because prototyping requires no custom tooling, and the design itself can be quickly digitally modified and reprinted, 3D printing for prototyping results in significant time and cost savings for R&D. nine0003

At the same time, 3D printing is for all ages. While serious engineers are designing tanks and aircraft, their young colleagues are increasingly using 3D printing to teach modeling and design skills. Inexpensive user-level 3D printers are increasingly being used in schools and circles, and youth creativity centers are being created throughout Russia, where future engineers can try out additive manufacturing technologies on their own experience.

Weapons

Of course, 3D printing has also caught on with gun enthusiasts, causing a lot of headaches for regulators around the world. It all started with the Liberator project by an American gun fighter named Cody Wilson. A simple plastic gun can be printed on any home 3D printer, the only metal element is a nail used as a striker, and the probability of an explosion and resulting injury to the shooter is higher than the chance of a successful shot. nine0003

A simple plastic gun can be printed on any home 3D printer, the only metal element is a nail used as a striker, and the probability of an explosion and resulting injury to the shooter is higher than the chance of a successful shot. nine0003

It turned out to be almost impossible to fight against the distribution of free files with a 3D model of a pistol, but these were just flowers. Berries followed in the form of a 3D-printed receiver for AR-15 automatic carbines, the actual analogues of the M-16 assault rifle, which is in service with the United States and many other countries of the world. The fact is that it is the lower part of the receiver that is subject to registration and accounting, since the serial number is stamped on it, and all other parts can be bought at any weapons store. The box, on the other hand, does not carry high loads, and it is quite possible to print it from plastic, and then assemble an unaccounted, unregistered rifle. Gun printing quickly fell under a local ban, and the aforementioned MarkForged company even refused to sell Cody their printer that prints with high-strength composites. nine0003

nine0003

Although, sometimes there are quite legal projects, such as fully functional 3D printed replicas of the Colt 1911 pistol, released in a limited edition by the California arms company Solid Concepts. Be that as it may, 3D printing of weapons in Russia will result in at least a criminal article for illegal storage and distribution, and therefore the experience of Cody Wilson should not be adopted.

Jewelry

What about fake weapons? This option is allowed by law and is quite available even on consumer 3D printers. And not only weapons, but also all kinds of armor, jewelry and accessories. From the glowing "plasma" swords from the popular game Halo to full-fledged Star Wars stormtrooper costumes, cosplay fans create the most colorful examples illustrating the possibilities of 3D printing. nine0003

In fact, MakerBot founder Bree Pettis demonstrated the feasibility of large-scale 3D printing with the Replicator Z18 3D printer in the most graphic way possible by wearing a fully printed helmet on his head in front of an enthusiastic audience of printers.

But with the help of 3D printing, you can create not only toy decorations, but also real ones. Jewelers around the world are increasingly turning to 3D modeling and printing blanks, which are used to make molds for casting precious metal jewelry. For such projects, high-precision stereolithographic printers are used that print with resins that harden under the influence of lasers or light projectors. nine0003

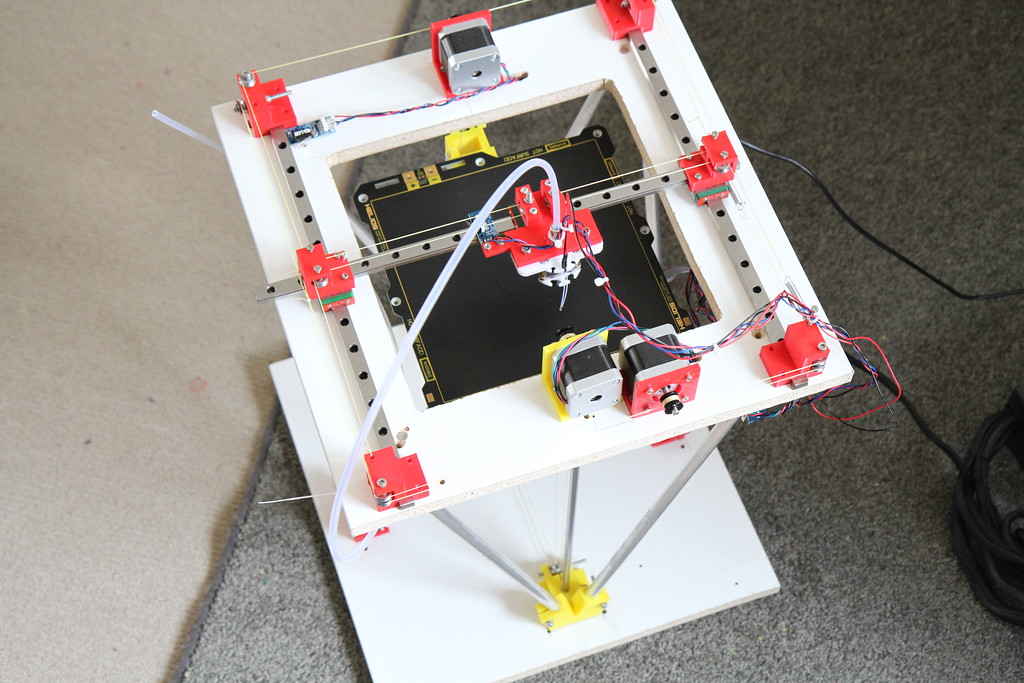

3D Printers

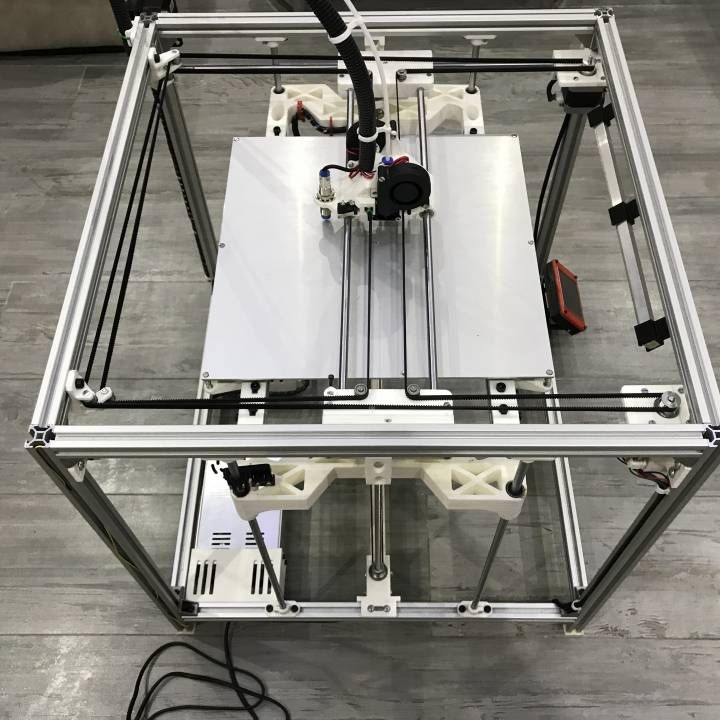

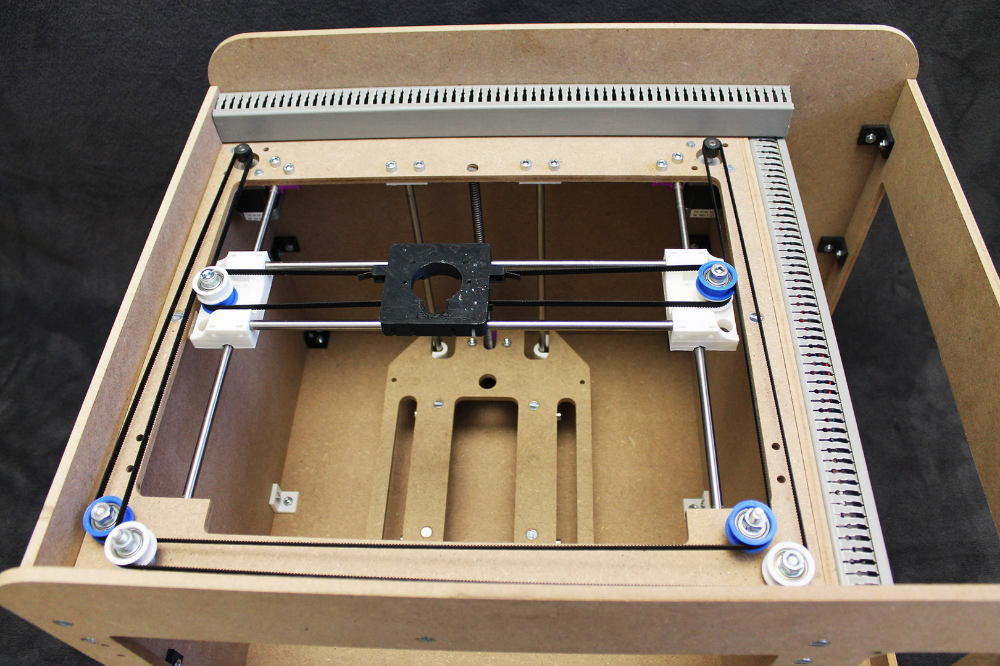

Finally, 3D printers can print... 3D printers! Among makers, there is the term RepRap, which stands for something like "self-replicating 3D printer." In fact, the simplest 3D printer is nothing more than a machine with numerical control - a set of guides, bearings, mounts and printheads controlled by a relatively simple computer controller.

Many of the structural elements (mounts, legs, corners and even printhead housings) are made of plastic, so why not print them on another 3D printer? This is exactly what real makers do, and many of the leading companies like MakerBot, Ultimaker or the Russian PICASO grew out of such home-made projects and still use 3D printed parts in the design of their branded printers. nine0003

nine0003

3D printer Magnum RX-3

3D printers for printing large models with low shrinkage plastics, including 3D printers for printing large models with low shrinkage plastics, including PLA, PETG, ASA, glass-filled and carbon-filled composites, etc.

Experimental use of such plastics as ABS, HIPS, PET and others is possible.

Magnum RX-3 3D printers are available in versions with

print chamber sizes from 700 x 700 mm to 1500 x 1100 mm. nine0003

Application area

Despite the limitations imposed by the material, models printed from it are widely used:

- Models for making molds used for casting metals, polymers

- Models-templates for gluing with fiberglass and receiving body parts

- Prototyping of devices, housings, parts

- Making decorative objects, figures, etc.

- Manufacture of technological equipment and tools

- Manufacture of working parts and parts where PLA, PET, ASA, etc.

plastics are applicable.

plastics are applicable.

Also recently there are more and more new materials that can be used on models of the RX-3 series without alterations and upgrades. Almost all filled materials (composites) such as Ultran, Total, etc. using glass or carbon fiber are suitable for printing on this printer.

General specifications:

- 3D Printing Technology: FFF (Fusion Fusion)

- Up to 4 extruders with different characteristics and nozzle diameters

- Basic nozzle diameter: 0.6 mm

- Layer thickness with 0.6 mm nozzle: 0.2-0.5 mm

- Additional nozzles: diameter 0.4 to 1.4 mm, material hardened steel, brass, sapphire

- Positioning accuracy on each axis: ±0.05 mm

- Real-time print monitoring camera

- Maximum extrusion temperature: 285°C

- Maximum working table temperature: 120°C

- Plastic sensor: bar detection, feed rate analysis

to detect stuck nozzle - Table calibration automatic, with surface mapping

- Automatic nozzle height calibration by sensor

- Built-in cabinet with optional feeder, can load up to 25 kg of plastic at one time

All printers of the RX-3 line are equipped with a closed print chamber, a heated desktop, reliable modern 32-bit ARM Cortex M7 300Mhz electronics, Trinamic TMC 5160 / TMC 2209 drivers, connecting to an Ethernet local area network.

3D printer control, model loading, heating, etc. is performed using a touch screen or via a WEB-interface built into the printer electronics. The extruder heads are controlled via the CAN bus.

Printable area dimensions Magnum RX -1 and dimensions:

| Model | Print size, mm (width x length x height) | Printer dimensions, mm (width x length x height) | Printer weight (kg) |

| RX-3.1 | 700 x 700 x 850 | 1700 x 1150 x 1600 | 330 |

| RX-3.2 | 1100 x 500 x 500 | 2100 x 950 x 1400 | 480 |

| RX-3.3 | 1100 x 700 x 850 | 2100 x 1150 x 1600 | 520 |

| RX-3.4 | 1100 x 1100 x 850 | 2100 x 1550 x 1600 | 590 |

RX-3. |