High temp thermistor 3d printer

3D Printer Thermistors - 3DJake International

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

-

E3D Thermistor- Easy connection

- Cartridge style

- With extension cord

-

E3D Prusa Thermistor- Spare thermistor

- Especially for Prusa

-

E3D PT1000 Temperature Sensor- For high temperatures

- Accurate measurement

- Easy installation

-

BondTech PT1000 RTD Temperature Sensor- Platinum-based resistor

- Robust sensor in thin-film construction

- -50 ° C - 500 ° C

-

Slice engineering 300°C Thermistor- From room temperature to 300 ° C

- 3 mm connection

- High compatibility

-

BondTech DDX Thermistor Adapter- For Copperhead and Mosquito heating block

-

Qidi Tech Hotend Thermistor 6 Model types- Original spare part

- By Qidi Tech

-

Creality Thermistor Kit- Easy installation

- High precision

- For hotend & heated bed

-

Zortrax Thermocouple + Heater- Original spare part

-

E3D PT100 Temperature Sensor- Highest precision

- Suitable for high temperatures

- Up to 500 ° C

-

BondTech HeatLink Cable JST XHP-2- For numerous 3D printers

- Easy to use

-

BondTech HeatLink Cable JST XH-2- For numerous 3D printers

- Easy to use

-

BondTech HeatLink 300C Thermistor- Easy to use

- For numerous 3D printers

- Plug & Play

-

E3D 100k Ohm NTC Thermistor - Semitec- Spare part for V5 hot ends

-

3D Solex Temperature Sensor PT100 UM2 / +- Tested & Approved

- High-quality

- Length: 134 cm

-

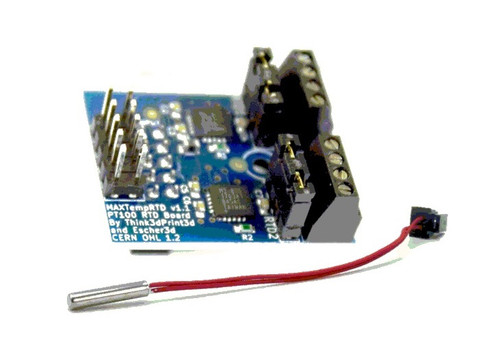

E3D PT100 Amplifier Board- Upgrade for PT100 sensor

- More accurate temperature measurement at high temperatures

-

E3D Thermistor Replacement Kit- Package for changing the thermistor

-

Qidi Tech High Temp Hotend Thermistor- Original spare part

- From Qidi Tech

-

BondTech HeatLink cable JST SMP-02V-BC- Easy to use

- For numerous 3D printers

- Plug & Play

-

BondTech Molex MX-50-57-9002 HeatLink Cable- Easy to use

- For numerous 3D printers

- Plug & Play

-

MINGDA Thermistor- Original spare part

- For MINGDA 3D printers

-

Creality Hotend Thermistor 3 Model types- Original spare part

- Available for various 3D printers

-

Artillery Thermistor 5 Model types- Original spare part

-

E3D V6 PT100 Upgrade Kit- High precision

- Temperatures up to 500 ° C

- Easy to use

All prices incl. VAT.

Slice Engineering High Temperature Hotend Thermistor - 300C

- Home

- Store

- 3D Printer Accessories

- 3D Printer HotEnds

- Hotend Accessories

The Slice Engineering High-Temperature Hotend Thermistor eliminates the need for a PT100 or having two separate thermistors to maintain accuracy at both the low and high end of the temperature spectrum. These are simply the highest performing thermistors on the market and are made right here in the USA! The Slice Engineering High-Temperature Hotend Thermistor is a standard sleeved thermistor at 3mm in diameter and features a 15 mm long cable. Each thermistor is attached to 2 meter bare leads making it universally adaptable and easy to install on virtually any printer. Use the Slice Engineering High-Temperature Hotend Thermistor in conjunction with Slice Engineering Boron Nitride Thermal Paste for the highest accuracy results! Compatible with the Mosquito Hotend, Mosquito Magnum Hotend, or any hotend that can fit a standard sleeved thermistor with a 3mm diameter.

Remove from wishlist Add to wishlist loading...

Product No. loading...

Notify me when this item becomes available Success You will be notified when ... becomes available. Request A QuoteTo get an instant quote, add everything you need to your cart, and click "Download as quote".

Or use the form below and a MatterHackers expert will contact you within one business day to discuss available discounts, training, and maintenance options.

Product(s)

Email *

Phone

Full Name

Company/Organization

Questions

Success Thank you for your request. We will be in touch shortly.THE HIGH-TEMPERATURE HOTEND THERMISTOR FROM SLICE ENGINEERING DELIVERS ACCURATE RESULTS AT THE HIGHEST 3D PRINTING TEMPERATURES

300°C Thermistor

- Accurate from room temperature up to 300°C

- Robust construction

- Compatible with most 3D printer firmware, including Marlin and Duet*

- Perfect for expanding your 3D printer's material capabilities to the limits of open-air machines

450°C Thermistor

- Designed to weather the fiercest heat - accurately measures up to 450°C

- Robust construction

- Compatible with most 3D printer firmware, including Marlin and Duet*

- The only high-temperature 3D printing thermistor for high-performance polymers like PEEK and PEI (Ultem)

*NOTE: Installation of a new thermistor will require selecting the correct sensor in your firmware settings. Some printers may require an update of the RT table in the printer firmware, especially for the 450°C Thermistor. Not all 3D printers allow firmware updates. Please check to ensure your printer will allow firmware updates, otherwise, the thermistor will not work.

Some printers may require an update of the RT table in the printer firmware, especially for the 450°C Thermistor. Not all 3D printers allow firmware updates. Please check to ensure your printer will allow firmware updates, otherwise, the thermistor will not work.

The 450°C Thermistor should not be used with printers that use a RAMBo Mini V1.3a or any older version of this board. Common printers with this board include the Prusa MK2.5s, the Prusa MK2.5, the Prusa MK2s, and the Prusa MK2.

This item cannot be shipped to a PO Box or APO/FPO/DPO address. This item takes longer to ship due to its size and/or weight.

E3D V6 high temperature heating block for PT100 temperature sensor or thermistor in a sleeve (brass)

E3D V6 high temperature heating block for a PT100 temperature sensor or thermistor in a sleeve (brass) in the sleeve) and the heating element.

Mellow store E3D V6 equivalent

Goods Receipt Notification

Article: hblok-e3dv6-pt100-latun-mellow Categories: Mellow Store, Hot End Parts, 3D Printer Parts Tags: e3d, e3dv6, Heating block

- Description

- Details

- Origin of goods

- Reviews (0)

Description

Brass heating block e3d v6 with holes for PT100 temperature sensor (thermistor in a sleeve will do) and heating element. nine0005

nine0005

Similar to E3D V6 fuser manufactured by Mellow store.

The V6 heating block is a core part of the E3D ecosystem. This block type is used in most printers.

Compatible with all types of thermal barriers and nozzles having an M6 thread on the hot end.

Designed for use at temperatures up to 500°C.

Turned from a single piece of brass. Possesses high quality of surfaces and carvings.

Supplied with M3 gouge to fix the bulb thermistor and M3 screw to fix the heating element

This heating block is compatible not only with PT100 thermistors, but also with pocket temperature sensors. Suitable thermistors in a sleeve measuring 3x15 mm and 3x20 mm. In this heating block, the thermistor in the sleeve is securely fixed with a special clamping screw - guzhen.

Ceramic heating elements 6x20 mm must be used for this heating block. The heating elements are fixed in the heating block with a special screw.

Heating block dimensions 16x23x12 mm

Material - brass

Hole diameter for the heating element - 6mm

Hole diameter for the thermistor - 3mm

Thread for mounting the thermal barrier and nozzle - M6

Mir3D experience

This is not the first year we have been operating the high-temperature V6 heater block your 3D printer. Despite the fact that brass is heavier than aluminum, and the installation of such a heating block makes the 3D printer head somewhat heavier, there are a number of advantages:

Despite the fact that brass is heavier than aluminum, and the installation of such a heating block makes the 3D printer head somewhat heavier, there are a number of advantages:

- More stable heating and temperature retention, and as a result, more stable printing

- Brass is not as plasticine as aluminum heating blocks. I think that many have come across the fact that when replacing a nozzle on a standard aluminum block, the thread is licked. This does not happen with brass blocks

- Often, when the thermistor breaks and the Thermal Runaway is triggered, the heating block quickly heats up within a few seconds and, due to thermal expansion, the threads of the thermal barrier fastening are damaged. On aluminum heating blocks this is normal. This does not happen with brass heating blocks. nine0017

To sum up, brass heating blocks give a stable result when printing, are less subject to the risks of thermal deformation and thread damage when changing nozzles.

Origin of goods

Country of origin: China

Importer in the Republic of Belarus:

IP Shalashenko Evgenia Alexandrovna

Minsk obl. Dzerzhinsky district, Shatili village, st. Central, 4

Only registered customers who have purchased this item can post reviews.

You might also be interested...

-

Quick View

-

Quick View

-

Quick View

-

Quick View

-

Quick View

High temperature 3D printing - to the masses / Sudo Null IT News0001

There is an impressive variety of thermoplastics that can be printed on consumer grade desktop 3D printers. But, despite this, most often users turn to polylactide (PLA) threads. This is not only the cheapest of materials, but also the easiest to work with. Its extrusion can already be carried out at a temperature of 180 °C, and good results can be obtained even without preheating the table. The disadvantage of PLA-printed objects is that they are relatively brittle and do not tolerate high temperatures well. For prototyping or printing low-stress components, PLA is great. However, many users quickly go beyond its capabilities. nine0005

But, despite this, most often users turn to polylactide (PLA) threads. This is not only the cheapest of materials, but also the easiest to work with. Its extrusion can already be carried out at a temperature of 180 °C, and good results can be obtained even without preheating the table. The disadvantage of PLA-printed objects is that they are relatively brittle and do not tolerate high temperatures well. For prototyping or printing low-stress components, PLA is great. However, many users quickly go beyond its capabilities. nine0005

Polyethylene terephthalate (PETG) is usually the next step. It is not much harder to work with compared to PLA, while it is more reliable and can withstand higher temperatures. In general, it is better suited for creating mechanically loaded parts. But if you need to make even stronger and more heat resistant parts, you can switch to acrylonitrile butadiene styrene (ABS), polycarbonate (PC) or nylon. And this is where the problems begin. These materials are extruded at temperatures over 250°C and closed chambers are recommended for best results. These printers are at the top of the budget range that hobbyists are willing to work with. nine0032

These printers are at the top of the budget range that hobbyists are willing to work with. nine0032

Industrial 3D printers like this one, the Apium P220, start at around $30,000. (PAEK, PEEK, PEKK). Components made from these plastics are suitable for aerospace applications as they can replace metal while remaining much lighter.

These plastics need to be extruded at temperatures in the order of 400°C and require a hermetically sealed chamber that is constantly above 100°C. The cheapest printers of this kind cost tens of thousands of dollars, and some models even cost six figures. nine0005

Of course, not so long ago, the same could be said about all 3D printers. Once used only by well-equipped research labs, these machines now sit on the workbenches of hackers and hobbyists the world over. It is difficult to predict whether the same price-cutting race will start for high-temperature 3D printers, but the first steps to democratize the technology have already been made.

Engineering difficulties

Simply put, a machine that supports these so-called. "engineering plastics", you need to be a hybrid of a 3D printer and a stove. This, of course, is the main problem. The printer itself - of the type and quality we are accustomed to seeing on our desks - will not survive in such conditions. In order for a consumer printer to produce PEI and PEEK plastic parts, it needs to be seriously redesigned. This is exactly what NASA did with the LulzBot TAZ 4 in 2016. nine0005

LulzBot TAZ 4 redesigned to support high temperature printing

The first step was to design an insulated housing to fit the TAZ 4 and install a set of 35W infrared lamps for heating. Under such conditions, the printer's electronics would naturally overheat - so it had to be taken outside.

Stepper motors would also overheat. But instead of taking them out, the team at the Langley Research Center decided to build cooling shrouds on each of the motors through which the compressed air must circulate. nine0005

nine0005

Like many desktop 3D printers, the TAZ 4 uses several printed components. Since they are ABS, they would quickly break down in a chamber designed to support PEEK. They were printed from PC, but even this material was not resistant enough for permanent use. In classic RepRap tradition, the team printed the last, third set of components on their most modified printer, in PEI plastic, commercially named Ultem.

Surprisingly, the team had no trouble changing the printer's nozzle to one that could extrude plastic at 400°C. The popular E3D-v6 extruder costs less than $100 and has been shown to be able to maintain this temperature. True, the team had to replace the thermistor with a better one, as well as edit the Marlin firmware so that it allowed it to reach high temperatures. For conventional printers, too high a temperature should cause an emergency shutdown. nine0005

Printing results from Ultem 1010 plastic on a remanufactured LulzBot TAZ 4.

In the end, the NASA report indicated that the LulzBot TAZ 4 rework was a complete success. They noted that an attempt to print PEI with infrared lamps turned off ended in failure - delamination and distortion of the model, which was to be expected. They did not specify the cost of the conversion, but given that at that time the TAZ 4 cost $2200, the entire project could cost 10 times cheaper than similar commercial proposals. nine0005

They noted that an attempt to print PEI with infrared lamps turned off ended in failure - delamination and distortion of the model, which was to be expected. They did not specify the cost of the conversion, but given that at that time the TAZ 4 cost $2200, the entire project could cost 10 times cheaper than similar commercial proposals. nine0005

Starting from zero

A NASA experiment has shown that an existing desktop 3D printer can be converted to print with high-temperature engineering plastics, and quite inexpensively. But hardly anyone believes that this approach is the ideal solution. There are too many repetitive operations involved here, and NASA engineers had to abandon some of the decisions made by the LulzBot developers. Still, the experiment provided a valuable baseline for other projects built from scratch. nine0005

In September 2020, a team from Michigan Technological University demonstrated the Cerberus, an open-source, high-temperature 3D printer capable of creating objects from PEI and PEKK that costs as little as $1,000 to build. Without trying to adapt existing designs, the team started development from scratch, aiming for high temperature printing. All electronics are housed separately from the sealed chamber, which uses a kilowatt heating element to quickly raise the temperature in the chamber to operating temperature. nine0005

Without trying to adapt existing designs, the team started development from scratch, aiming for high temperature printing. All electronics are housed separately from the sealed chamber, which uses a kilowatt heating element to quickly raise the temperature in the chamber to operating temperature. nine0005

All stepper motors are also outside the chamber. Because of this, the kinematics become more complex than in desktop 3D printers, but Cerberus no longer requires a special motor cooling system.

Building a Cerberus is quite affordable for the aspiring hobbyist. It has a simplified circuit, ready-made control electronics based on the Arduino Mega 2560 and RAMPS 1.4, and the same E3D-v6 extruder as the TAZ 4. In addition, the team posted clear and detailed instructions for assembling the printer - this is not in the NASA report. meet. nine0005

Expanding possibilities

Whether it's NASA's redesign of the TAZ 4, or the new Cerberus-type circuits, it's clear that the technical capabilities of PEI and PEEK printing in the home workshop are already available for those who really need them. So far, it's not as easy as buying a $200 3D printer on Amazon, but if there is demand, cheaper machines based on the same principles will appear on the market. The situation is not much different from the current wave of affordable laser cutters hitting the markets in the past few years. nine0005

So far, it's not as easy as buying a $200 3D printer on Amazon, but if there is demand, cheaper machines based on the same principles will appear on the market. The situation is not much different from the current wave of affordable laser cutters hitting the markets in the past few years. nine0005

Fans from all over the world print PPE

Is there a demand for such machines? A year ago, the answer might have been different from today. But in the fight against the coronavirus pandemic, there is a new demand for the rapid production of personal protective equipment (PPE) that no one could have foreseen.

print PPE that can be sterilized at high temperatures. The team believes that masks printed from PEKK can be reused rather than thrown away. nine0005

Components that can be printed and re-sterilized will obviously have other potential medical applications. A portable, low-cost machine capable of producing such components has the potential to save lives in places on the planet where supplies and equipment cannot be quickly accessed.