3D printer filament extruder

Felfil Filament Maker | Make your own 3D printing filament with Felfil Evo

Felfil Evo Extruder

The Perfect Match for your 3d printer

order now

Felfil Shredder

Crush your Plastic Wastes

order now

Felfil Spooler

Easier way to extrude

order now

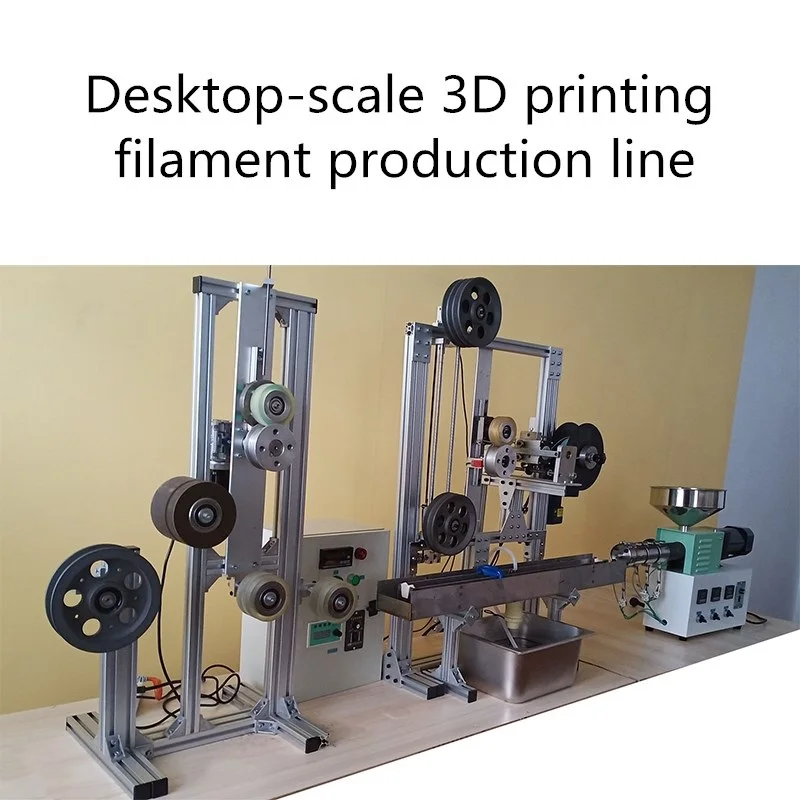

Our filament maker system

The Felfil filament extrusion line is composed by Felfil Evo, a 3d printer plastic extruder machine, Felfil Spooler which is a winding machine and Felfil Shredder that is a small plastic shredder. This extruding system allows anyone to make custom 3D printing filaments at home or in a lab, starting from industrial pellet or chopped wrong 3D prints, old models and plastic waste.

Using our desktop filament maker you will be able to choose your filament color, diameter and material, day by day, according to your creativity and your needs. In this way you will save over 80% of the price of filaments spools and help to protect the environment.

Recycle

Use failed 3D prints or plastic waste to create your filament

Save money

Save up to 80% of the spool costs starting from our pellets

Experiment

Make your custom 3D printing filament for any 3D printer

Get Your Desktop Filament Extruder

Choose between our different models and start to make your own filament

request a quote

This is the complete filament maker system by Felfil, that includes Felfil Evo Assembled and Felfil Spooler.

You will receive all assembled, ready to make your custom and DIY 3d filament.

A complete solution to make your own filament directly on your desktop.

That’s the full recycling system by Felfil. It includes a plastic shredder, the extruder and the winder. All arrives already assembled and tested.

All three products can be placed on your desktop, and you can start immediately to recycle your old 3d prints or plastic wastes.

The Felfil Evo Complete Kit is the solution for who want to build their own extruder, step by step. Then, it is shortly to begin to extrude.

Buying this package you will get all the components of Felfil Evo, you just have to assemble them following the instruction manuals.

This is the complete filament maker system by Felfil, that includes Felfil Evo Assembled and Felfil Spooler.

You will receive all assembled, ready to make your custom and DIY 3d filament.

A complete solution to make your own filament directly on your desktop.

This solution is perfect for who want to try immediately our extruder! An ideal choice for those who want to begin to extrude easily.

You will receive the filament maker already assembled, ready to make your custom and DIY 3d filament. You have just to unbox it and connect the plug.

The Felfil Evo Complete Kit is the solution for who want to build their own extruder, step by step. Then, it is shortly to begin to extrude.

Then, it is shortly to begin to extrude.

Buying this package you will get all the components of Felfil Evo, you just have to assemble them following the instruction manuals.

ONE SYSTEM, SEVERAL APPLICATIONS

Our filament extruder system is easy to use and suitable for different applications, find out yours

Fablab /Makers

Felfil Evo is an open source project and it is perfect for FabLabs and MakerSpace users: amatorial 3D printers and experts.

It is studied to help Makers recycle plastic waste from 3D printing activities, to save money and try different materials in order to stimulate creativity and innovative ideas.

You can create incredible and original objects from your old 3D prints.

Lean more

Laboratories

With our system it is possible to experiment new material, test their features and study their application. Felfil Evo and Felfil Spooler can be used in many sectors for prototyping activities.

Felfil Evo and Felfil Spooler can be used in many sectors for prototyping activities.

With our desktop filament maker, research laboratories can be independent creating and testing small quantities of filament and have an immediate experience with the new materials.

Lean more

Education

Felfil helps students to learn about new technologies and additive manufacturing.

Thanks to our filament recycler system it is possible to learn about plastic materials for 3D printing and their potential for reuse culture.

The educational potentials of Felfil project concerns recycling and reuse, maker philosophy and application sectors of 3D printing.

Lean more

Our Clients

Born as open hardware but ready to make filament easily and safely at home. It’s a desktop 3d printer filament extruder able to produce custom filaments for your 3D printer.

Meet Felfil Evo

Meet

Make your choice

You can choose between three different version of Felfil Evo filament maker

DIY Project

Discover how to customize Felfil Evo

More

Felfil Evo | Filament Extruder Kit or Assembled for 3D printers

Felfil Evo

Filament Extruder

The Perfect match

for your 3D printer

Make your filament and personalize

your prints with the Felfil Evo filament extruders

Order now

Tech Specs

Felfil Evo

Filament Extruder

The Perfect match

for your 3D printer

Make your filament and personalize

your prints with the Felfil Evo filament extruders

Order now

Despite a small delivery problem, which was fixed immediately, everything worked fine and quickly.

This is the service as you expect from some big company.

This is the service as you expect from some big company.Gerhard

Number 1 extruder on the market. High quality job, worth the money paid. I wish to see more innovative products in near future from Felfil Srl.

Anonymous

All the machines work perfectly. I already mixed up coffee beans, scissor powders but I see no problem so far. I'm really happy!

Shintaro

Goo customer service and transparency. I used the Felfil Evo for a Master Thesis in mechanical engineering and I got support to every question I asked them.

Theodor

"The assembling process is very easy"

Takawo (client) - takawo.hatenablog.com

"Your extruder kit works excellent!"

Glassy (Kickstarter Backer)

"An excellent and very cool looking design, that will be a great addition to any desktop: the Felfil Evo."

3ders.com - 3ders.com

Felfil Evo is a safe and easy to use plastic filament extruder, able to produce custom and recycled filament for 3D printers starting from pellet or wrong prints.

With Felfil Evo you can choose from many different plastic materials and make your 3D printing filament.

A desktop filament extruder

Felfil Evo is a small 3d printer filament maker and is designed to be used by every user, professional or amateur. Indeed, its compact design and small dimensions are suitable for every desktop.

With Felfil Evo you can make both filament diameter, 1.75mm and 2.85mm, just by changing the nozzle.

Felfil Evo interface is intuitive and make the extruder easy to use.

In particular, through it is possible to set manually the correct temperature and gearmotor speed, then start to make high quality custom filament for your 3D printer.

Moreover, Felfil Evo is available in four colors: yellow transparent, transparent, white or black.

THE FILAMENT EXTRUDER MADE FOR YOU

Felfil Evo is a safe and easy to use plastic filament extruder, able to produce custom and recycled filament for 3D printers starting from pellet or wrong prints.

With Felfil Evo you can choose from plastic materials and make your 3D printing filament.

A DESKTOP EXTRUSION SYSTEM

Felfil Evo is a domestic filament maker and is designed to be used by every user, whether 3D print expert or beginner. Indeed, its compact design and small dimensions are suitable for every desktop.

With Felfil Evo you can make two different filament diameter, 1.75mm and 2.85mm, just by changing the nozzle.

Felfil Evo interface is intuitive and make the extruder easy to use.

Through it is possible to set manually the correct temperature and gearmotor speed, then start to make high quality custom filament for your 3D printer.

Felfil Evo is available in four colors: yellow transparent, transparent, white or black.

Technical Specifications

Extrusion speed

100-150 gr/hour

Temperatures

250°C or 300°C

Extrusion screw

Specifically made screw

Licence

Open Hardware

Tolerance

up to +/- 0. 07mm

07mm

Multi Materials

PLA - ABS - HIPS - TPU and more

Open Source

Felfil Evo is an open source project, which means that you can see how it was designed.

For this reason Felfilino, our special PCB board, uses the same processor of Arduino.

Download the source files from here.

Industrial Solutions

We made specific components for specific objectives. The screw, nozzle and melting chamber design reports some industrial solutions. The screw is realized with durable materials and its precision guarantees a high-quality extrusion of plastic materials.

Awesome Design

The mechanical components are made in Italy with durable materials, ensuring the product quality.

Thanks to its design, Felfil Evo is easy to maintain and is suitable for different uses.

Three Faces of Felfil Evo Filament Maker

Choose your favourite filament extruder kit and let’s make at home your custom 3D filament with Felfil Evo.

shop now

This solution is perfect for who want to try immediately our extruder! An ideal choice for those who want to begin to extrude easily.

You will receive the filament maker already assembled, ready to make your custom and DIY 3d filament. You have just to unbox it and connect the plug.

This kit includes only the main components that are specifically made and are very expensive when handcrafted in single pieces.

All other parts, like heaters an electronics, are easily reachable on the market and are the same used in 3D printers. Complete the extruder following our guides.

The Felfil Evo Complete Kit is the solution for who want to build their own extruder, step by step. Then, it is shortly to begin to extrude.

Buying this package you will get all the components of Felfil Evo, you just have to assemble them following the instruction manuals.

This is the complete filament maker system by Felfil, that includes Felfil Evo Assembled and Felfil Spooler.

You will receive all assembled, ready to make your custom and DIY 3d filament.

A complete solution to make your own filament directly on your desktop.

This solution is perfect for who want to try immediately our extruder! An ideal choice for those who want to begin to extrude easily.

You will receive the filament maker already assembled, ready to make your custom and DIY 3d filament. You have just to unbox it and connect the plug.

The Felfil Evo Complete Kit is the solution for who want to build their own extruder, step by step. Then, it is shortly to begin to extrude.

Buying this package you will get all the components of Felfil Evo, you just have to assemble them following the instruction manuals.

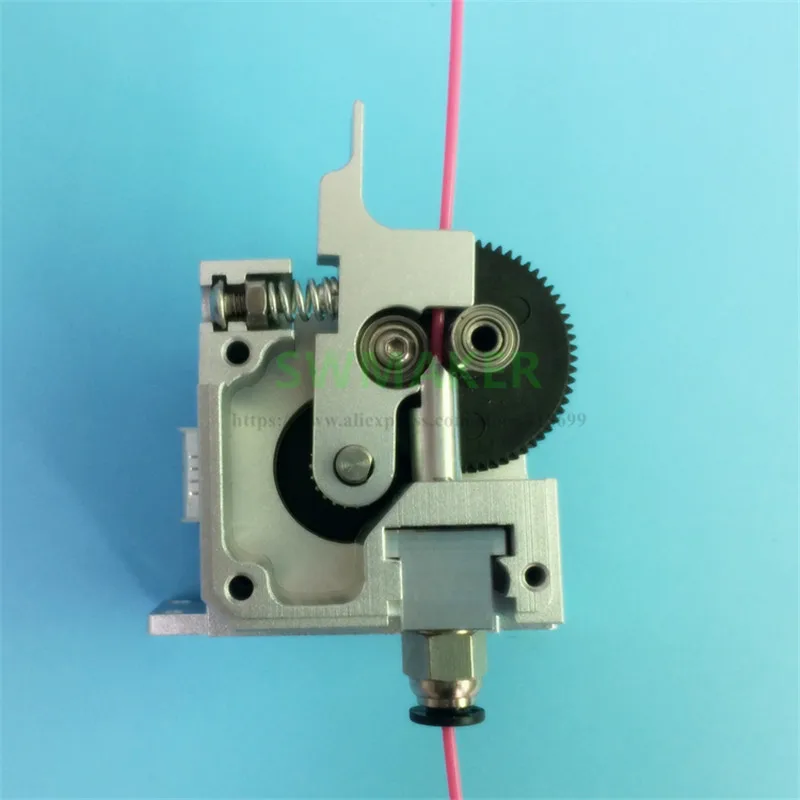

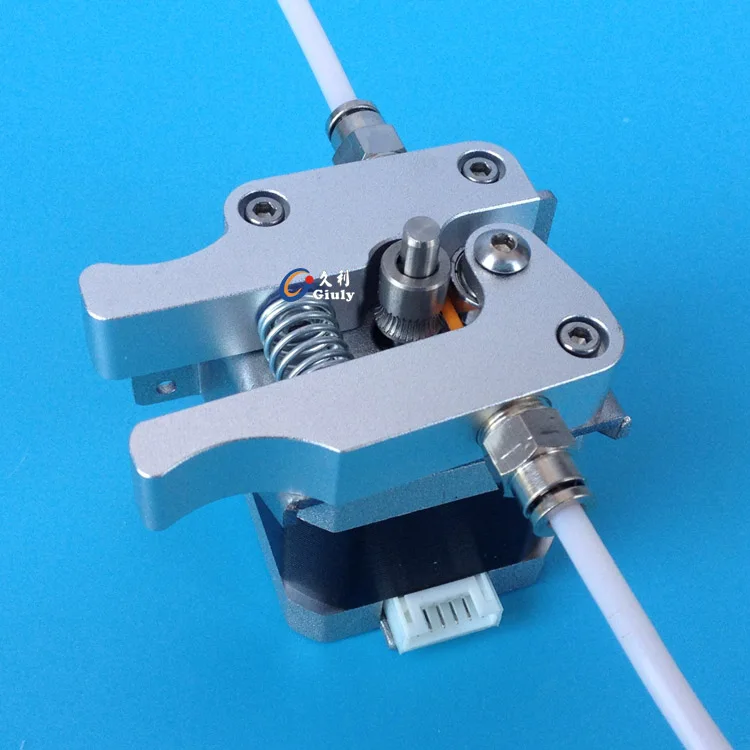

Powerfull Gearmotor

The Felfil Evo gearmotor has been selected for its reliability and power quality. It allows to Felfil Evo to work in a excellent way with many materials

23 9

Nm Rpm

Powerfull Gearmotor

The Felfil Evo gearmotor has been selected for its reliability and power quality. It allows to Felfil Evo to work in a excellent way with many materials

It allows to Felfil Evo to work in a excellent way with many materials

23 9

Nm Rpm

Special Extruding Screw

The screw has been designed to transform the plastic scraps into a brand new filament. Thanks to its design you can easily make colored filament. The extrusion screw is made by K100 steel machined from a solid base on a five-axis milling machine

12,7 1,47

L/D ratio Comp ratio

Special Extruding Screw

The screw has been designed to transform the plastic scraps into a brand new filament. Thanks to its design you can easily make colored filament. The extrusion screw is made by K100 steel machined from a solid base on a five-axis milling machine

12,7 1,47

L/D ratio Comp ratio

Interchangeable Nozzles

Felfil Evo nozzle allows to cool down the filament in output and to keep a constant filament diameter thanks to its internal processing. Easy to change, it’s available in two diameters.

Easy to change, it’s available in two diameters.

1,75 2,85

Ø mm Ø mm

Dedicate Electronic Brain

Felfilino project is totally opensource and Arduino based.

Our PCB run the Felfil Evo interface and the filament extruder functioning. Moreover, the PCB manage also security system that allow to use Felfil Evo in the domestic environment.

12V 150W

Safe Powerfull

Interchangeable Nozzles

Felfil Evo nozzle allows to cool down the filament in output and to keep a constant filament diameter thanks to its internal processing. Easy to change, it’s available in two diameters.

1,75 2,85

Ø mm Ø mm

Dedicate Electronic Brain

Felfilino project is totally opensource and Arduino based.

Our PCB run the Felfil Evo interface and the filament extruder functioning. In addiction, the PCB manage also security system that allow to use Felfil Evo in the domestic environment.

In addiction, the PCB manage also security system that allow to use Felfil Evo in the domestic environment.

12V 150W

Safe Powerfull

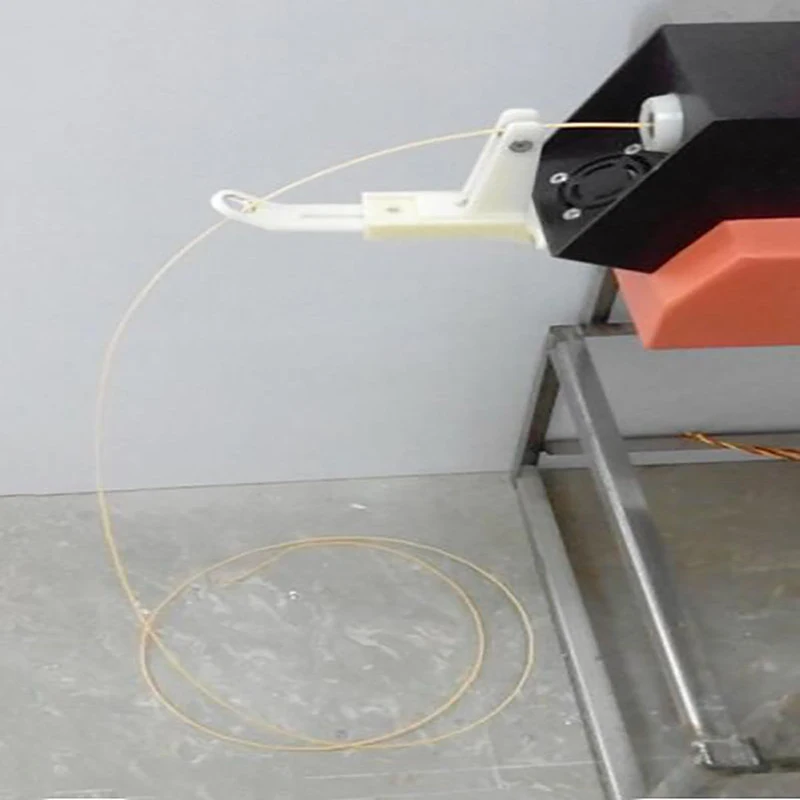

Make extrusion easier

Felfil Evo can work alone, but we developed Felfil spooler in order to make the extrusion process easier. See how Felfil Spooler works.

discover

Felfil Evo

Make your own 3D printing filament

order now

3d filament extruders in Russia

- Home

- Sale

- Extruders and extrusion lines

- 3d filament extruder

You can quickly compare 3d filament extruder prices and choose from over 5769 offers

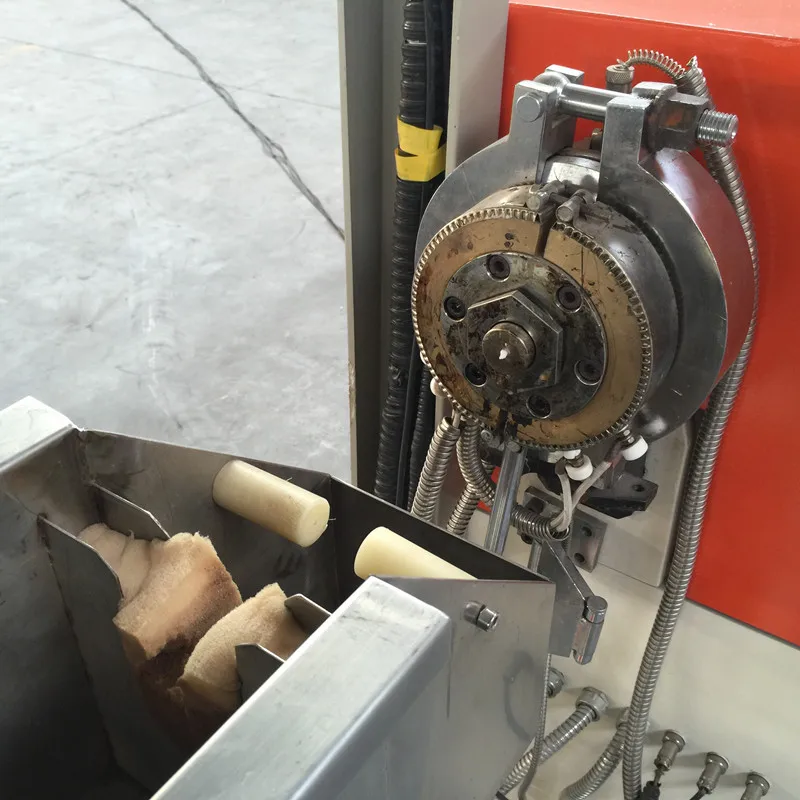

AFE25 3D filament production line

Condition: New Manufacturer: China

Characteristics: Model: AFE25 Raw material used: PAL ABS Productivity: 1 - 2 kg/hour 3D filament diameter: 1. 75 mm, 3 mm (can be customized according to customer requirements) 3D filament accuracy: ±...

75 mm, 3 mm (can be customized according to customer requirements) 3D filament accuracy: ±...

09/02/2022 Moscow (Russia)

Line for the production of 3D thread AFE28

Condition: New Manufacturer: China

Characteristics: Model: AFE28 Raw material used: PAL ABS Productivity: 3 - 5 kg/hour 3D thread diameter: 1.75 mm, 3 mm (can be customized according to customer requirements) 3D thread accuracy: ±...

02.09. 2022 Moscow (Russia)

Filament extruder for 3D printer

Condition: New Year: 2014

In stock

Extrusion line for the production of filaments for a 3D printer, new, fully equipped, ready for operation, consisting of an extruder, a dryer, a cooling bath, a water tank with pumps, a head ...

17.05.2015 Omsk (Russia)

1,500,000

PP thread extruder

Condition: Used Year: 2000 Manufacturer: Taiwan

PP thread production area: 1. Extruder brand CH-100 W made in Taiwan with a head for the production of PP film - 1 pc.2. Mixer PP granules - 1 pc.3. PP film cooling bath – 1 pc.4....

Extruder brand CH-100 W made in Taiwan with a head for the production of PP film - 1 pc.2. Mixer PP granules - 1 pc.3. PP film cooling bath – 1 pc.4....

11/19/2019 Cheboksary (Russia)

3,000,000

Thread extruder

Condition: Used Year: 2015 Manufacturer: SJPL (China)

I sell equipment Made in China. Productivity is 150kg/hour. 2015 release. In excellent condition.

06/01/2018 Krasnoyarsk (Russia)

7 000 000

Line for production 3D GSD-45

Status: New Manufacturer: China

Characteristics: GSD-45 FEAL: 220/380 / 480 V. , 50 / 60 Hz, 3 fTotal power: 30 kWActual power: 20 kWAir pressure: 0.6 - 0.7 MPa Average output: 15 - 30 kg/h ±...

06/21/2022 Moscow (Russia)

Flat thread extruder

Condition: used Year: 2012 Manufacturer: Taiwan (Taiwan)

I will sell an extruder for raffia. Auger 80. It turns out a thread from 600 to 1900 den. Number of winders 88 pieces Other information by phone.

Auger 80. It turns out a thread from 600 to 1900 den. Number of winders 88 pieces Other information by phone.

09/06/2021 Togliatti (Russia)

6 800 000

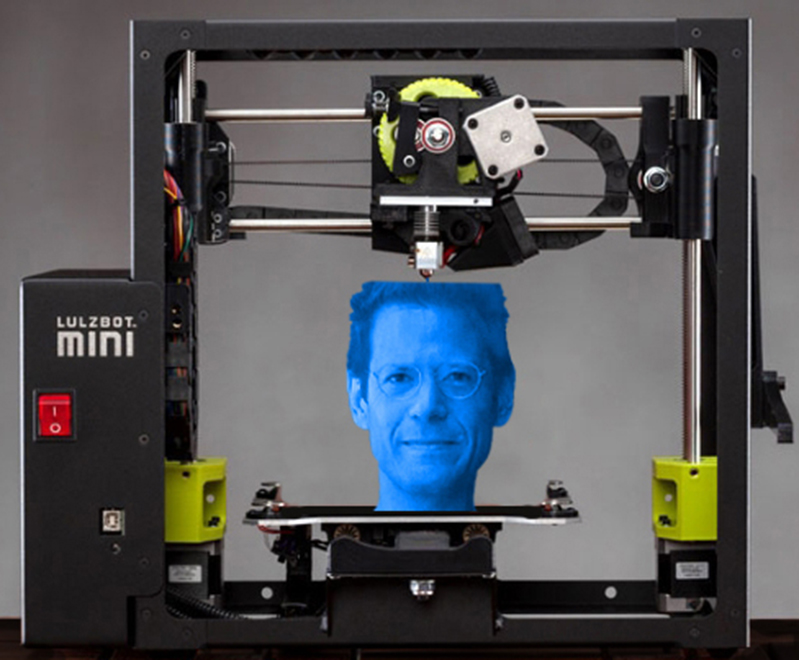

3D printer Wanhao I3

Status: New Manufacturer: Wanhao (China)

In the stock in the stock of the Wanhao Duplicat printer. It comes assembled, configured and tested! Without exception, all components are made of metal, and not with...12/07/2021 Samara (Russia)

29 000

3D printer Picaso Designer Classic

Condition: New

Available

Designer Classic is a basic 3D printer for an easy introduction to 3D printing technology. Clear management and customized profiles for popular materials will help you easily master new technology....

10/26/2022 Kazan (Russia)

3D printer Picaso 3D Designer X

Condition: New

In stock

3D printer Picaso 3D Designer X is a novelty from the Russian manufacturer Picaso 3D, which combines industrial-level technologies and the availability of a desktop device. This gadget is built on...

This gadget is built on...

10/26/2022 Kazan (Russia)

3D printer Picaso 3D Designer X Pro

Condition: New

In Stock

D printer Picaso 3D Designer X Pro is the latest development of the famous Russian brand Picaso 3D, presented in November 2016. The process of creating this printer is marked by another...

10/26/2022 Kazan (Russia)

3D printer Picaso 3D Designer XL

Condition: New

Picaso 3D Designer XL is a desktop 3D printer that combines all the advantages of an industrial machine with the simplicity of a personal machine. The main distinguishing feature of the device from all...

10/26/2022 Kazan (Russia)

3D printer Picaso 3D Designer XL PRO

Condition: New

Designer XL PRO - ease of maintenance, minimum calibrations and maximum printing - this is one of the key ideas that we kept in our head when we created Designer XL PRO. That's why we...

That's why we...

10/26/2022 Kazan (Russia)

3D printer Hercules Strong 19

Condition: New

Available

Hercules Strong 19 is a version of the 3D printer that has become larger and more accurate. The printable area has grown by an additional 10 cm in height, making it easier to print large models without...

10/26/2022 Kazan (Russia)

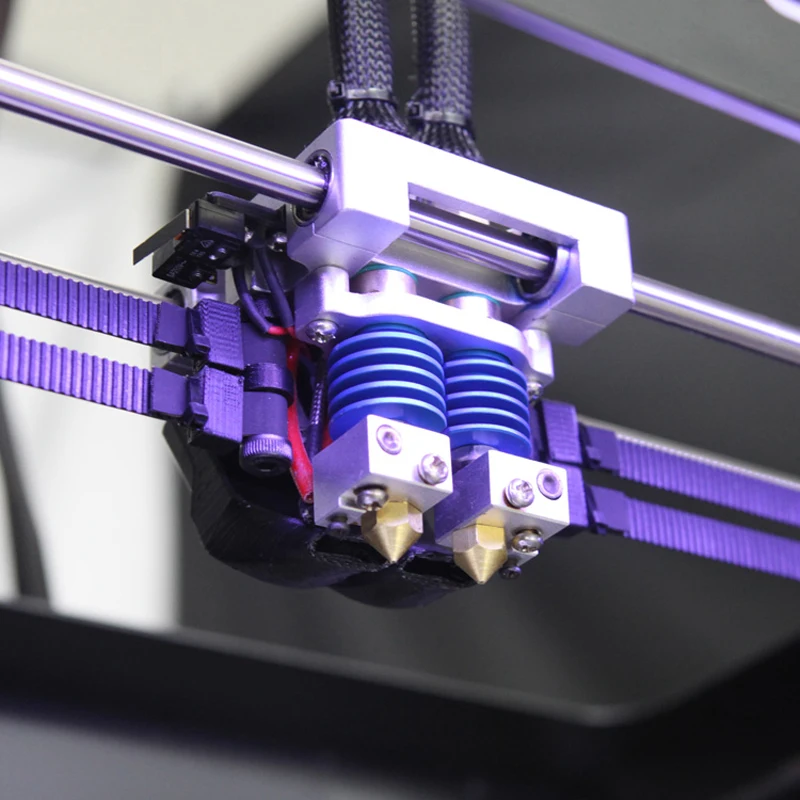

3D printer Hercules G2

Condition: New

Hercules G2 - a characteristic feature of this model is an extruder that heats up to 410 degrees Celsius, thanks to which the device is able to print with the widest range of...

10/26/2022 Kazan (Russia)

Imprinta Hercules Strong Duo 3D printer

Condition: New

The Imprinta Hercules Strong Duo 3D printer is an improved version of the large-format Hercules Strong. From the previous model, it has a print chamber of the same volume (36 l), but mechanics and electronics...

From the previous model, it has a print chamber of the same volume (36 l), but mechanics and electronics...

10/26/2022 Kazan (Russia)

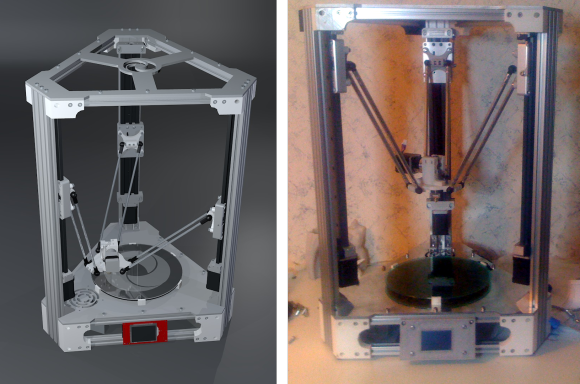

Zenit Z1 3D printer

Condition: New

Available

Zenit 3D printer is a Russian-made Zenit printer that meets all modern requirements for quality and convenience of 3D printing. It has extensive functionality and is used for...

10/26/2022 Kazan (Russia)

3D printer Zenit Z DUO

Condition: New

Available

The Zenit DUO 3D printer is a Russian-made device that meets all modern requirements for quality and convenience of 3D printing, has extensive functionality and is used for...

10/26/2022 Kazan (Russia)

3D printer Zenit DUO SWITCH

Condition: New

Available

The Zenit DUO SWITCH 3D printer is a Russian-made device that meets all modern requirements for quality and convenience of 3D printing, has extensive functionality and is used for. ..

..

10/26/2022 Kazan (Russia)

3D printer Raise3D Pro2

Condition: New

In Stock

The Raise3D Pro2 3D printer is a new industrial-grade model designed specifically for small-scale production and organization of 3D printed farms. The appearance of the device strongly resembles...

10/26/2022 Kazan (Russia)

Popular categories0014

3d filament extruder video

3D printer filament extruder

Technician

Good afternoon!

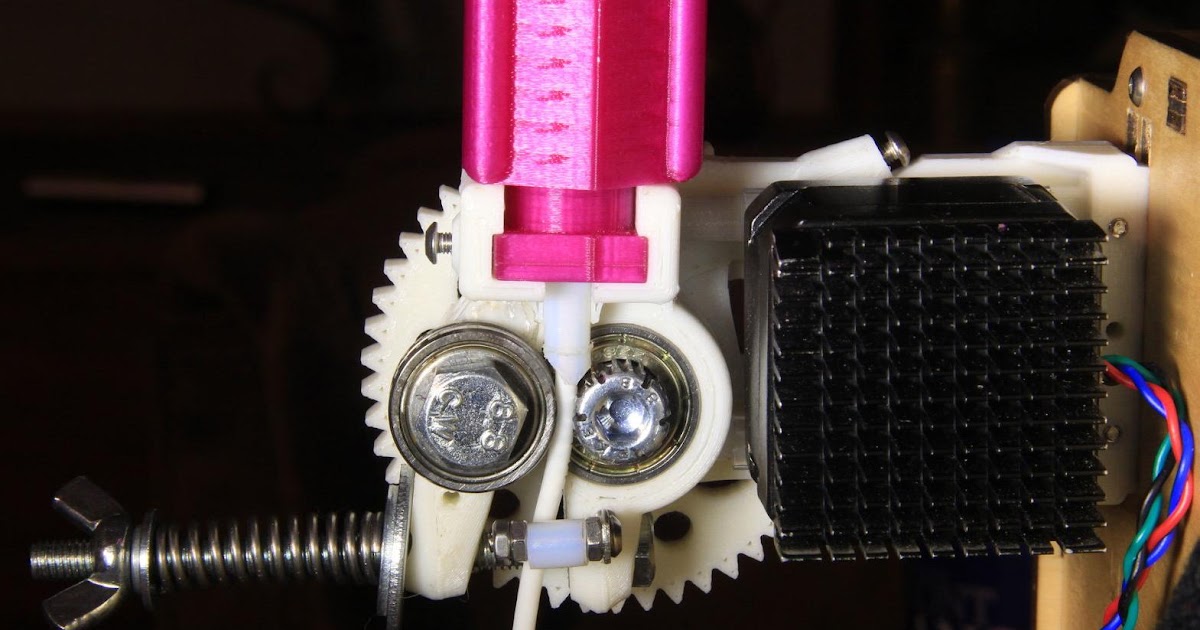

I want to share my experience in assembling a filament extruder for a 3D printer. I must admit that I collected slowly due to various circumstances. Just a colossal number of mistakes were made :)) As a rule, some mistakes cost both money and time. First of all, the mechanics turned out to be the most difficult for me. Due to the lack of centering of the auger, the grinding on the sleeve completely upset me and forced me to redo the mechanics every time. The most optimal for me was the installation of the auger directly into the gearbox without any additional bearings.

The most optimal for me was the installation of the auger directly into the gearbox without any additional bearings.

And so let's see what happened:

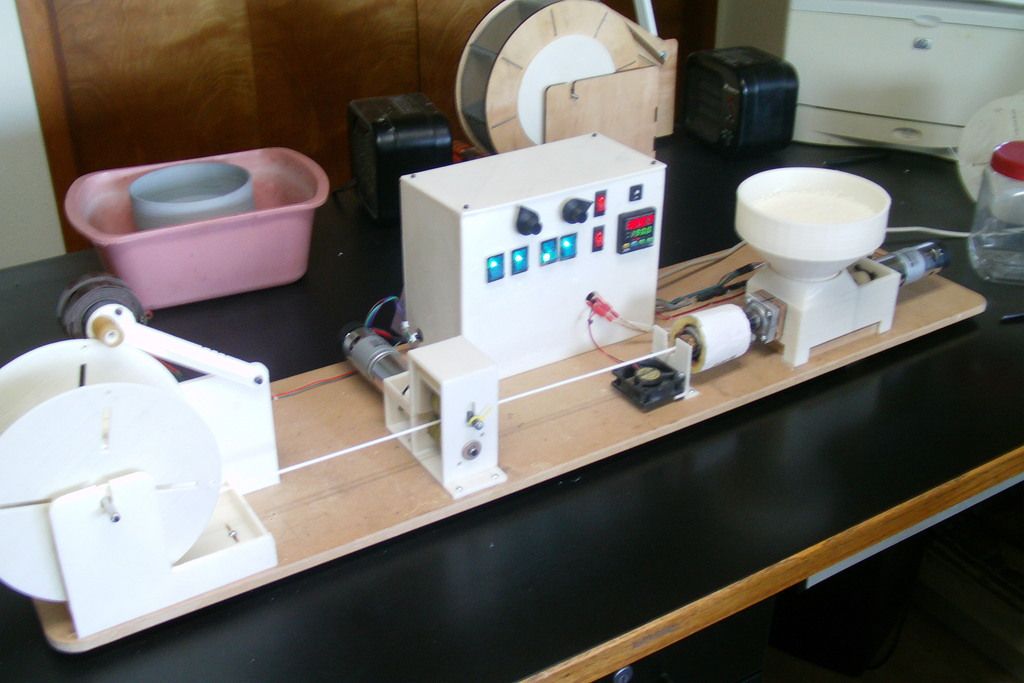

As you can see from the photo, I tried to make it as compact as possible. Placement of nodes carefully thought out.

A nema34 motor and gearbox was used. When working with such capacities, you need to be careful and make such mistakes

Later, accidents and other shutdowns were laid to prevent accidents

The first attempts to assemble the extruder were with many buttons, lights, switches and the like. I was especially annoyed by their installation, placement - this is another headache for me, since I had to redo the extruder so many times. As a result, I decided that there would not be a single button in my extruder! Many of my comrades did not like it, but still this is my extruder and I had just such a desire. Many guys who assembled the extruder used a Chinese PID controller for heating, but the presence of a display in the extruder did not fit into my concept, so the PID controller was programmed with my own.

Many guys who assembled the extruder used a Chinese PID controller for heating, but the presence of a display in the extruder did not fit into my concept, so the PID controller was programmed with my own.

On the bottom graph, you can see the problems that I encountered - namely, the pickup. max6675 let me down and had to convert it to a thermistor like on a 3d printer and as you can see the results are better.

Temperature control was carried out using again the application

I would like to pay special attention to the selection of coefficients for heating the extruder. The selection of good odds turned out to be not an easy task for me and it was spent sparingly for about one day.

I also attach a visual diagram of the extruder connection. On the diagram, you can see the main elements connected to the extruder control board, as well as a not tricky circuit.

A bit about management. As you can see from the diagram - I used esp8266-01. It uses the standard mqtt connection library. I did not plan to transfer important tasks under her control. Previously, I tried to use the hc-06, hc-12, 433mhz modules but nothing good came of it. It seemed to work, but in a couple of ways - the channel was not quite targeted and * clogged *. The mqtt protocol provides more targeted delivery and messaging, so I opted for it.

The Android application had implementations of the mqtt protocol, which made my life much easier.

The operation of the nodes can be seen on the video

44

Subscribe to the author

Subscribe

Don't want

Hi all.