3D printer on the moon

Luyten Plans to Build Structures on the Moon With Its Platypus Galacticus 3D Printer

3D printing news Aerospace Luyten Plans to Build Structures on the Moon With Its Platypus Galacticus 3D Printer

Published on December 13, 2021 by Mikahila L.

It seems lately that the space race has been reignited. In recent years we have seen major moon projects from companies all over the globe — such as the Griffin lunar lander from Agile Space Industries, ICON, which is set to 3D print buildings on the Moon, and even China’s plans to 3D-print a base on the Moon. Recently, Australian 3D printer maker Luyten also unveiled its plans to conquer the last frontier. In partnership with the University of New South Wales, Sydney (UNSW), the company wants to build structures on the moon, as part of a project called Meeka.

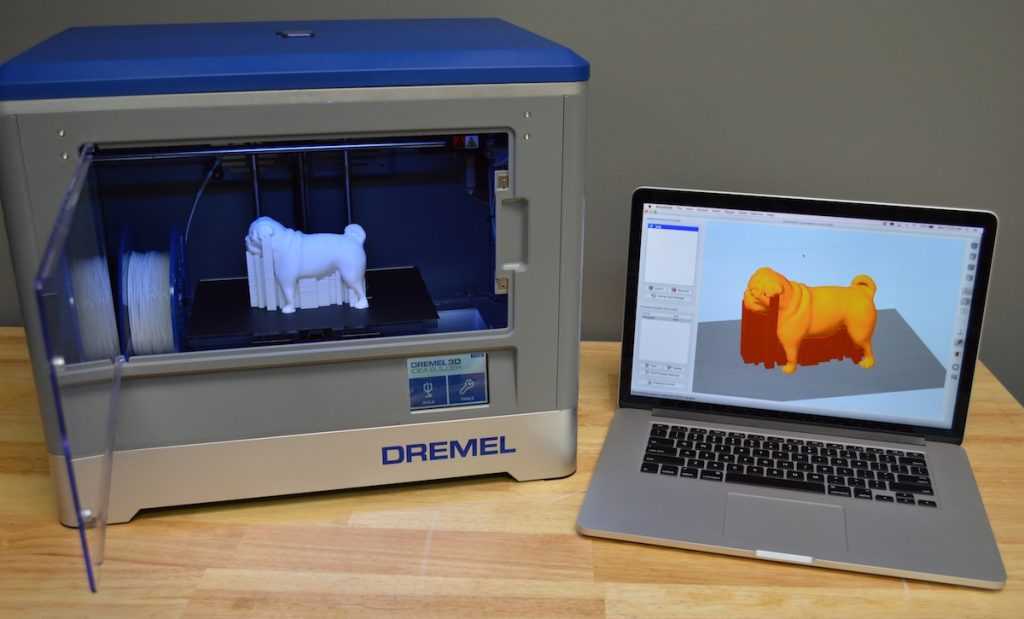

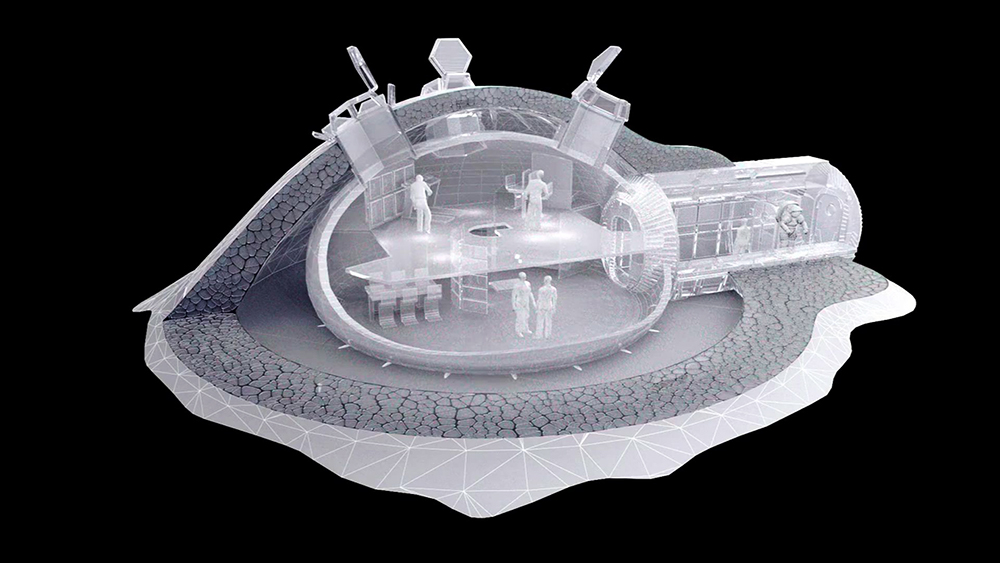

To achieve their space ambitions, the company has developed a 3D printer called Platypus Galacticus. Designed to make parts from regolith, a material available on the Moon, the Platypus Galacticus would offer many benefits in this endeavor. Matthias Hank Haeusler, one of the managers of the Meeka project managers, explained: “This information can become part of the Computational Design script and the design will respond to the specific material properties identified on-site. The knowledge we generate for building on the moon can be translated directly into building housing for extreme climates such as heat or for addressing housing issues in remote indigenous communities – both topics we investigate in parallel”.

Photo Credit: Luyten

Characteristics of the Platypus Galacticus 3D Printer

Designed from composite materials, the Platypus Galacticus is a compact 3D printer and is based on a proprietary extrusion technology called Luyten Turisops. According to the company, the machine will be able to print structures up to 12 meters long and 9 meters high (~39 feet long and 30 feet high). In order to identify buildable areas and collect materials on the Moon, Luyten plans for rovers to accompany the Platypus Galacticus. Some will therefore aim to penetrate the soil to assess the areas while others will harvest regolith.

Some will therefore aim to penetrate the soil to assess the areas while others will harvest regolith.

Though perhaps the realization of such a project still seems far out, one thing that is certain is that innovations follow one another in this sector and AM is certainly starting to make its mark. For example, in order to manufacture thrusters, NASA opted for 3D printing and called on the services of Agile Space Industries, showing the capabilities of AM in the sector at the beginning of the year. Since then, more and more companies are becoming involved in 3D printing in space in a variety of different ways, including 3D printing rockets, testing the capabilities of 3D printing in zero gravity and more. And projects like Meeka are becoming more numerous today. Indeed, it would not be surprising to see additive manufacturing playing an important role in the exploration of the Moon in the future. You can learn more about the Meek project HERE.

What do you think of the Meeka project from Luyten? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

Cover Photo Credit: Luyten

Winning ideas for 3D printing on the Moon

Enabling & Support23/01/2019 11110 views 127 likes

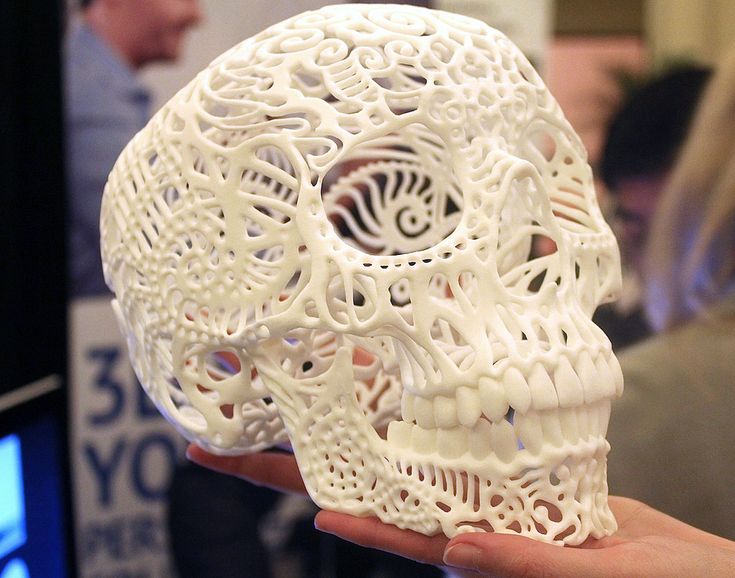

While studying lunar base concepts ESA ran a competition, asking: what would you 3D print on the Moon, to make it feel like home? Responses came from all across the globe, and now two winners have been selected, both with ideas linked to nature.

The adult category was won by visual artist Helen Schell from the UK, proposing a ‘magic Moon garden’, printed from recycled coloured plastics.

“What’s missing on the Moon?” wrote Helen. “Colour and living plants. This is an idea for a colourful carpet of interchangeable colour and design, which can be moved and the scale changed wherever you want to site it in your lunar habitat.”

3D-printed Moon gardenLike real flowers and plants, their 3D printed equivalents would be aromatic, to freshen the air, and perform the work of an air recycling unit changing carbon dioxide to oxygen. They would also ‘grow’ as each plant would be made up of smaller components that could be rearranged or added to over time, as if growing in nature.

The under 18 category was won by Judith de Santiago, a 17-year-old student from Madrid, Spain, who presented a dodecahedron (or 12-sided) plant pot – ideally for a real plant – that also incorporates symbols of distant Earth.

Plant pot for the Moon“The blue curves of the bottom represent the waves of the sea,” wrote Judith, “and the green badge with a small plant located at the centre, inspired by Disney’s movie WALL·E, represents the Earth in general. ”

”

Judith ensured her design was 3D printable by actually designing it in a 3D printing format.

The competition received more than a hundred entries from adults and children across the world with other ideas including a mobile lampshade to generate Earth-like colours, an hourglass filled with lunar dust, a glass model of Earth including realistic night lighting, proposals for statues and game boards – not to mention a few suggestions to print a 3D printer.

The idea for the competition came from an ESA-led project studying all the ways 3D printing could be used for the construction, operations and maintenance of a future lunar base: how could the various types of 3D printing meet those needs?

“This competition was a very good initiative to connect our study to the public, and gain insight into human factors involved in lunar settlement,” comments Advenit Makaya, overseeing the lunar 3D printing study.

“These entries give us an idea of what people living on the Moon would want from their everyday surroundings. Common themes that recur, such as to print items that resemble objects from nature, items linked to terrestrial hobbies and musical instruments, as well as reminders of loved ones back home – to help connect back to Earth and diminish any sense of isolation.”

Global space agencies are considering a lunar base as a possible next step in human space exploration, explains Advenit: “3D printing is one of the key building blocks for future space settlement, if we can find ways to make the stuff we need as we go along, rather than rely on costly resupply from Earth.

“And the Moon, at just a few days away from Earth, represents an ideal test case. Nobody else has run such a detailed system level study, looking at lunar 3D printing of everything from large infrastructure and building blocks down to tiny electronic components. ”

”

Supposed through ESA’s Basic Activities, this ‘Conceiving a Lunar Base Using 3D Printing Technologies’ project was run by the URBAN consortium led by Germany’s OHB System AG, with extreme environment specialist Comex in France, Austrian space design company Liquifer Systems Group and spacecraft structure manufacturer Sonaca Space in Germany.

Thank you for liking

You have already liked this page, you can only like it once!

NASA begins testing a 3D printer that works in the conditions of the Moon

Trends

TV channel

Pro

Investments

Events

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating club

Research

Credit ratings

Franchises

Newspaper

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Politics

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

Photo: Redwire

NASA delivered to the ISS a 3D printer capable of printing from regolith in microgravity on the Moon

What's happening

- As part of the latest ISS resupply mission, the Northrop Grumman Cygnus spacecraft delivered to the station a machine designed to 3D print regolith on the Moon and other extraterrestrial surfaces.

- The unit, called Redwire Regolith Print (RRP), will work in tandem with the ManD printer system installed on the ISS. The RRP is reported to be comprised of several extruders and printing platforms specifically designed to work with regolith.

- If the experiment is successful, the ISS crew will measure the strength of the resulting material based on ASTM (Additive Manufacturing Technology Standards) standards to see if it can withstand harsh conditions off Earth.

- Successful implementation of the RRP project could bring researchers closer to astronauts printing the items they need on space bodies, which will reduce the amount of materials that NASA delivers to the Moon and Mars.

- The project is part of NASA's Artemis lunar program, which also plans to land humans on the moon in 2024. It is assumed that the astronauts will stay on its surface for about a week.

What does it mean

It is believed that the colonization of the Moon and Mars is the next stage of space exploration. The technologies that will make this possible are being developed not only by public but also by private space companies. For example, the conquest and colonization of extraterrestrial space attract the founder of SpaceX, Elon Musk. The entrepreneur plans to take a man to Mars for the first time in six years, and the company's long-term plans include sending 1 million people to the planet by 2050.

The technologies that will make this possible are being developed not only by public but also by private space companies. For example, the conquest and colonization of extraterrestrial space attract the founder of SpaceX, Elon Musk. The entrepreneur plans to take a man to Mars for the first time in six years, and the company's long-term plans include sending 1 million people to the planet by 2050.

In this context, the development of 3D printing technologies on extraterrestrial surfaces seems to be an extremely topical issue — the future of human colonies on the Moon and Mars depends on it.

Earlier, the American architectural bureau AI SpaceFactory presented a project of buildings for construction on Mars as part of the NASA 3D-Printed Habitat Challenge. Despite the fact that architects currently use basalt fiber and bioplastics as materials, if the RRP project is successful, Martian soil could be used in construction.

Video: AI SpaceFactory

Updated on 08/17/2021

Text

Ksenia Yanushkevich

Top of the trend

Related materials

Moon dust 3D printer

CosmonauticsTechnology

09/08/2019

3,782 2 min read

Building a moon base is a real challenge. To avoid the transfer of heavy materials from the earth, scientists are developing the possibility of using lunar dust in special 3D printers. They should be able to print building blocks directly on the spot - the so-called additive manufacturing.

To avoid the transfer of heavy materials from the earth, scientists are developing the possibility of using lunar dust in special 3D printers. They should be able to print building blocks directly on the spot - the so-called additive manufacturing.

Ross Friel, senior lecturer at Halmstad University, leads a team of researchers working on autonomous additive manufacturing (also called 3D printing) that can be used on the moon.

Earth's resources are limited, so our continued existence requires that we look beyond our planet. There are endless resources in space. To be able to explore, both inside and outside, our solar system, a lunar base is needed that can serve as a "springboard" for space travel. According to Ross Friel, it is economically and technically advantageous to use the Moon as a launch pad because of its low gravity, extremely thin atmosphere and clear skies, and the ability to use hydrogen and oxygen from lunar ice for rocket fuel.

The task of building a moon base

Building a moon base is not an easy task. The building material must withstand and protect people and scientific instruments from harmful cosmic radiation and meteoroids. It is impossible to transport heavy concrete from the Earth to the Moon - it is too expensive. Therefore, being able to use materials already on the Moon to create building blocks and other useful components such as spare parts could be a better solution.

The building material must withstand and protect people and scientific instruments from harmful cosmic radiation and meteoroids. It is impossible to transport heavy concrete from the Earth to the Moon - it is too expensive. Therefore, being able to use materials already on the Moon to create building blocks and other useful components such as spare parts could be a better solution.

Lunar dust, i.e. fine gravel on the Moon called lunar regolith, is a natural ceramic material - much like volcanic ash on Earth. In our study, we used material from the earth with properties similar to moon dust. Real dust is hard to come by, says Ross Friel.

3D printer on the moon

By melting moon-like material from the earth, various types of structures can be printed on a specially designed 3D printer, such as cubes, filter elements and screws, directly on the surface of the moon.

By melting material from the earth, which has properties similar to moon dust, various types of textures can be printed using a specially designed 3D printer.