Prox 500 3d printer price

ProX™ 500 Plus - Protocom s.r.o.

Manufacture strong, functional parts and assemblies faster than ever

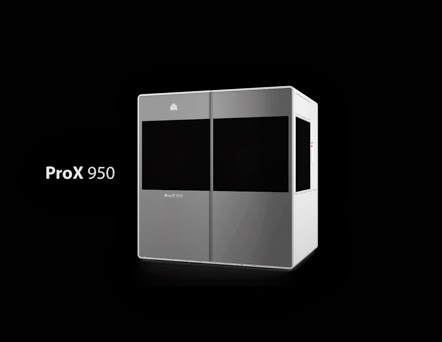

The ProX™ 500 and 500 Plus are cutting-edge Selective Laser Sintering (SLS®) production 3D printers from 3D Systems that create injection molding-grade parts without expensive tooling. Designed for smooth integration with your manufacturing workflow, these production printers empower you to rethink entire production and supply chain strategies, allowing for advanced product performance, lower total manufacturing costs, and localized on-demand manufacturing.

The ProX 500 prints in DuraForm® ProX plastic material to produce parts with superior mechanical properties, precision, resolution, surface finish and edge definition compared to any other SLS system. The ProX 500 Plus prints in additional materials, including glass filled and aluminum + fiber filled, and offers faster and higher resolution modes. The included state-of-theart Material Quality Center (MQC) module ensures unrivaled material recyclability for efficient, clean and automated production.

- ProX SLS Series.pdf (pdf - 342 kB)

Technical Specifications

| Dimensions (W×D×H) | |

|---|---|

| 3D Printer Uncrated | 1744 × 1226 × 2295 cm (68.7 × 48.3 × 90.3 in) |

| Weight | |

| 3D Printer Uncrated | 1360 kg (3000 lbs) |

| Compatible Materials | DuraForm ProX DuraForm ProX GF DuraForm ProX AF+ |

| Print Envelope Capacity | 381 × 330 × 457 mm (15 × 13 × 18 in) |

| Powder Layout | Variable Speed Counter Rotating Roller |

| Imaging System | ProScan™ DX Digital High Speed |

| Laser Power/Type | 100 W / CO2 |

| Electrical Requirements | |

| Printer | 208 VAC/7,5 kVA, 50/60 Hz, 3 PH |

| MQC | 100-240 VAC, 50/60 Hz, 1 PH |

| Standard Print Mode | |

| Layer thickness | Range: 0. 08 - 0.15 mm (0.003 - 0.006 in) 08 - 0.15 mm (0.003 - 0.006 in)Typical: 0.10 mm (0.004 in) |

| Volume build rate | 2 l/h |

| High-resolution print mode | |

| Scanning speed | TBD |

| Layer thickness | TBD |

| Volume build rate | TBD |

| High-speed print mode | |

| Scanning speed | TBD |

| Layer thickness | TBD |

| Volume build rate | TBD |

| Accessories | ProX Material Quality Center (MQC) for automated material handling and recycling |

Video

3D Systems Reduces Price on ProX SLS 500 to Expand 3D Printing Market and Gain Market Share - 3D Sys (NYSE:DDD)

ROCK HILL, S. C., April 13, 2017 (GLOBE NEWSWIRE) -- 3D Systems DDD today announced a price drop of more than 30 percent1 of its production-ready ProX® SLS 500 3D printing system in North America and Europe, an aggressive move to increase market share and drive adoption of the technology as companies look to shift production to additive manufacturing. New system pricing for customers starts at $270,000 and €250,000.1

C., April 13, 2017 (GLOBE NEWSWIRE) -- 3D Systems DDD today announced a price drop of more than 30 percent1 of its production-ready ProX® SLS 500 3D printing system in North America and Europe, an aggressive move to increase market share and drive adoption of the technology as companies look to shift production to additive manufacturing. New system pricing for customers starts at $270,000 and €250,000.1

| |||||

A photo accompanying this announcement is available at http://www.globenewswire.com/NewsRoom/AttachmentNg/7674c5e6-2ccc-42f9-85ba-35d5745495f8

Featuring one of the broadest portfolios of materials available, 3D Systems' SLS technology delivers exceptional versatility for printing a wide range of parts and build sizes from interior components for airplanes to large production tooling for high-volume manufacturing to small patient-specific medical devices.

With the price reduction, the ProX SLS 500 has market leading total cost of operations (TCO) for durable, end-use parts compared to competing systems.

"The ProX SLS 500 is winning deals today because of its superior capabilities; the new price point makes it accessible to additional customers, which we believe will enable us to increase our installed base faster and be more competitive in the market," said Jim Ruder, Senior Vice President and General Manager, Plastics, 3D Systems. "We will continue to invest in SLS to expand our leadership position and help accelerate the shift to 3D printing production."

3D Systems' ProX SLS 500 uses a wide range of DuraForm® materials from tough nylon for production parts, to high-temperature resistant fiber-reinforced engineering plastic, to glass-filled engineering plastic for excellent stiffness. DuraForm plastics have been optimized, validated and tested to offer an exceptional combination of surface detail, part strength, and durability for end-use parts.

Additionally, the ProX SLS 500 has high materials recyclability. Up to 95 percent2 of material used in a build is turned into parts, resulting in minimal waste and lower part cost. Automated material handling and production tools streamline workflows, producing parts up to 7 times faster than comparable FDM systems.

More information on 3D Systems' ProX 500 SLS 3D printer is available here.

Forward-Looking Statements

Certain statements made in this release that are not statements of historical or current facts are forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements involve known and unknown risks, uncertainties and other factors that may cause the actual results, performance or achievements of the company to be materially different from historical results or from any future results or projections expressed or implied by such forward-looking statements. In many cases, forward looking statements can be identified by terms such as "believes," "belief," "expects," "may," "will," "estimates," "intends," "anticipates" or "plans" or the negative of these terms or other comparable terminology. Forward-looking statements are based upon management's beliefs, assumptions and current expectations and may include comments as to the company's beliefs and expectations as to future events and trends affecting its business and are necessarily subject to uncertainties, many of which are outside the control of the company. The factors described under the headings "Forward-Looking Statements" and "Risk Factors" in the company's periodic filings with the Securities and Exchange Commission, as well as other factors, could cause actual results to differ materially from those reflected or predicted in forward-looking statements. Although management believes that the expectations reflected in the forward-looking statements are reasonable, forward-looking statements are not, and should not be relied upon as a guarantee of future performance or results, nor will they necessarily prove to be accurate indications of the times at which such performance or results will be achieved. The forward-looking statements included are made only as the date of the statement.

Forward-looking statements are based upon management's beliefs, assumptions and current expectations and may include comments as to the company's beliefs and expectations as to future events and trends affecting its business and are necessarily subject to uncertainties, many of which are outside the control of the company. The factors described under the headings "Forward-Looking Statements" and "Risk Factors" in the company's periodic filings with the Securities and Exchange Commission, as well as other factors, could cause actual results to differ materially from those reflected or predicted in forward-looking statements. Although management believes that the expectations reflected in the forward-looking statements are reasonable, forward-looking statements are not, and should not be relied upon as a guarantee of future performance or results, nor will they necessarily prove to be accurate indications of the times at which such performance or results will be achieved. The forward-looking statements included are made only as the date of the statement. 3D Systems undertakes no obligation to update or review any forward-looking statements made by management or on its behalf, whether as a result of future developments, subsequent events or circumstances or otherwise.

3D Systems undertakes no obligation to update or review any forward-looking statements made by management or on its behalf, whether as a result of future developments, subsequent events or circumstances or otherwise.

About 3D Systems

3D Systems provides comprehensive 3D products and services, including 3D printers, print materials, on demand manufacturing services and digital design tools. Its ecosystem supports advanced applications from the product design shop to the factory floor to the operating room. 3D Systems' precision healthcare capabilities include simulation, Virtual Surgical Planning, and printing of medical and dental devices as well as patient-specific surgical instruments. As the originator of 3D printing and a shaper of future 3D solutions, 3D Systems has spent its 30- year history enabling professionals and companies to optimize their designs, transform their workflows, bring innovative products to market and drive new business models.

More information on the company is available at www. 3dsystems.com

3dsystems.com

___________________

1 Pricing may vary and is not available in all geographies. New pricing will be available in the United States and Europe. It excludes Asia Pacific, Japan, Africa, India and the Middle East.

2 Using DuraForm PA material

Investor Contact: Stacey Witten Email: [email protected] Media Contact: Diane Parrish Email: [email protected]

© 2022 Benzinga.com. Benzinga does not provide investment advice. All rights reserved.

3D printer 3D Systems Prox 500 (134000)

Home »3D Equipment

Type

Laser

Press Type

Monochrome

Press technology

SLS

90009000

l/h

Scan speed

12 m/s

Working area

381 x 330 x 457

3

0002 Customer rating

3D Systems

Best Price, Warranty, Service

| Hardware Consultant: | ||

| Nikita: | 694403397 | 9007|

| Key features | |

| Manufacturer: | 3D Systems |

| Device: | 3D printer |

| Type: | laser |

| Purpose: | 3D printing |

| Seal | |

| Print type: | monochrome |

| Print technology: | SLS |

| Print speed: | 2 l/h |

| Scan | |

| Scan speed: | 12 m/s |

| Additional | |

| Materials used: | DuraForm ProX |

| Work area size: | 381 x 330 x 457 mm |

| Radiator type: | CO2 laser, 100 W |

| Electrical requirements: | 208V 50/60Hz 3 phase |

| Dimensions, weight, equipment | |

| Dimensions: | 1744 x 1226 x 2295 mm |

| Weight: | 1360 kg |

| Official warranty: | 1 Year |

Techno Print 3D Company

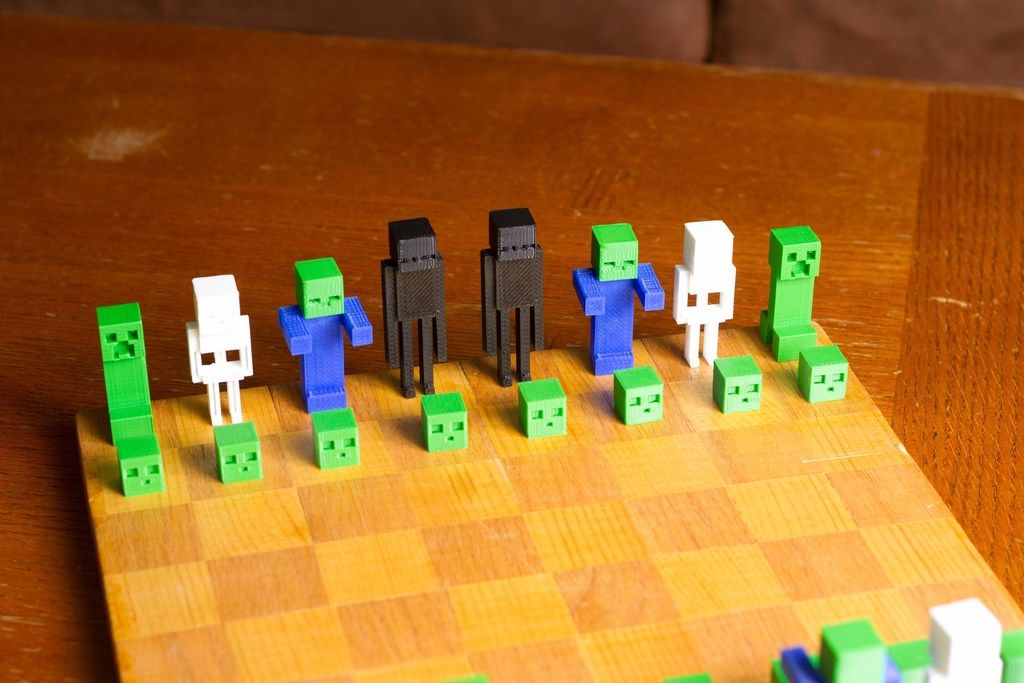

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with.

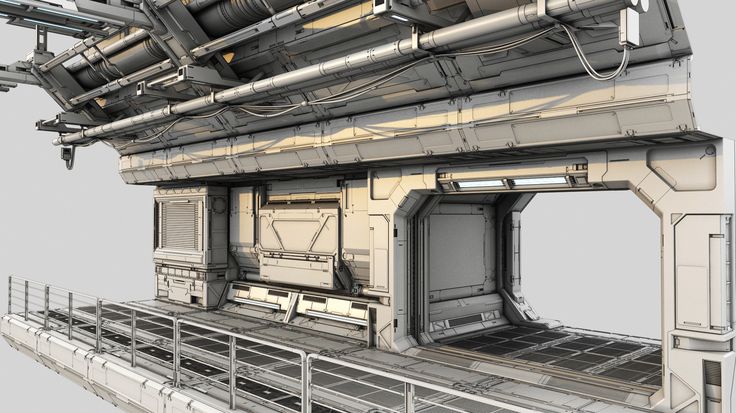

The printer is specially designed for the needs of production and at the output it creates both separate functional parts and ready-to-use already assembled models for various industries: aerospace, automotive, medical, textile (fashion accessories, mobile devices), etc.

The printer is specially designed for the needs of production and at the output it creates both separate functional parts and ready-to-use already assembled models for various industries: aerospace, automotive, medical, textile (fashion accessories, mobile devices), etc.

This technology allows you to quickly produce various parts from powdered polymers using a CO2 laser.

This technology allows you to quickly produce various parts from powdered polymers using a CO2 laser.