Extra large 3d printer

Large Volume 3D Printers | MatterHackers

Bring your most ambitious prints to life with these large-volume 3D Printers! From the enormously large Modix 3D Printers to flexible & industrial-grade 3D printers from brands such as Raise3D, MakerGear, or BCN3D; MatterHackers has the right large-volume 3D printer to fit your needs.

Available for purchase as kits or ready to ship fully assembled, these large-volume 3D Printers will enable you to print BIG and explore product development and prototyping without the need to invest in costly, full-scale additive manufacturing systems.

Guides & Articles

What is 3D Printing?

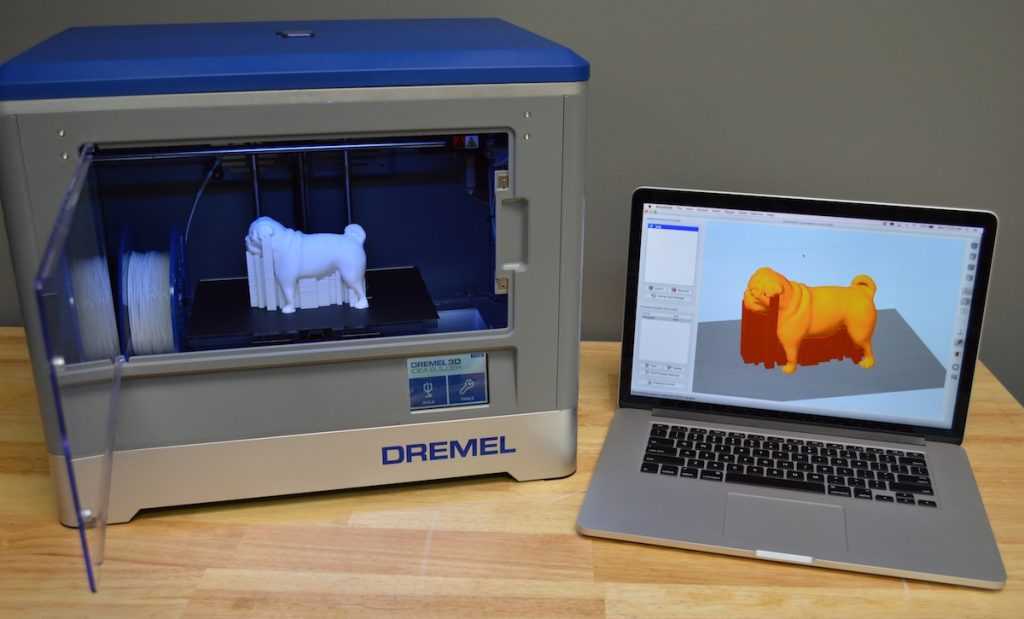

3D printing is a process where physical, three-dimensional objects, parts, or models are made layer-by-layer from Computer-Aided Design, or CAD, and digital files.

Anatomy of a 3D Printer

Get an understanding of how 3D printing works, from the inside and out. This guide will walk you through each of the critical components of a 3D Printer, answering the question: "How does a 3D printer work?"

The Top Ten Tips For Getting Started With 3D Printing

We were all noobs at one point! Here the ten best tips for getting started with 3D printing - whether it's your first time 3D printing or you need to brush up on the basics, this guide will help you out!

3D Printer Troubleshooting Guide

Use this guide to help you identify and solve the most common issues that may occur while 3D printing.

How To Calibrate Your 3D Printer's Extruder

This quick and informative guide will help you calibrate your extruder perfectly, resulting in accurate, quality prints.

3D Printing 101: How to Succeed with a Perfect First Layer for Every 3D Print

The first layer of your 3D print is the foundation of everything that comes after, which makes it such an important part of the 3D printing process.

How To Get The Best 3D Printed Parts By Understanding Extrusion Settings

Melting is a critical concept to 3D printing, and yet it hasn’t received a lot of in-depth attention. This article will teach you how to extrude your filament properly so it flows smoothly. Make filament jamming, delamination, and weak parts things of the past.

3D Printing Essentials: How to Succeed with Every Bed Surface Solution

Matching 3D printing filaments with the proper bed surface material is an important part of the 3D printing process. Read more to find out the best path to success.

Read more to find out the best path to success.

3D Printing Essentials: Filament Loading

Proper filament loading and unloading is a necessary part of 3D printing without trouble. Read on to learn the essential method you should be following.

3D Printing Essentials: Bed Leveling

For some, levelling a 3D printer's bed can be challenging, but it doesn't need to be. Read this essential guide to see what it takes to do it right.

Quick Tips: How To Get Started With Batch 3D Printing

Utilizing 3D printer time most efficiently is much easier once you start batch printing parts to maintain 3D printer uptime and minimize downtime.

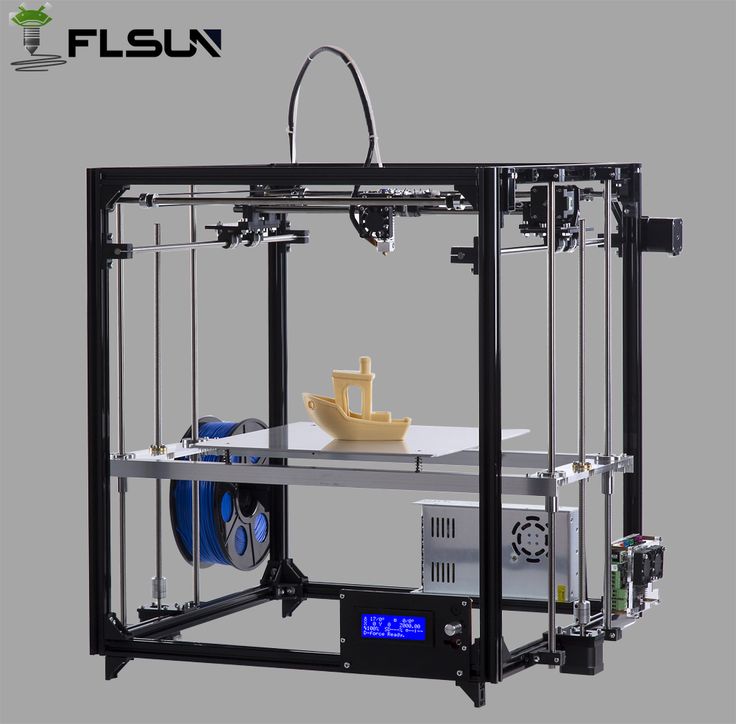

WHY SHOULD I SELECT A LARGE-VOLUME 3D PRINTER?The number of available large-volume 3D Printers is growing every day. Whether you are just getting started with 3D Printing, consider yourself an experienced hobbyist, or are a professional looking to take that next step into the world of large-scale production there is a large-volume 3D Printer to fit your needs.

Large-volume 3D Printers can range in price from as low as $500, such as the Creality Ender 5 Plus, while some can be as expensive as $15,000, such as the absolutely massive Modix Big-180X.

There are many other additional factors to consider when discussing the costs associated with large-volume 3D printers. It's important to thoroughly take into consideration things such as the type of 3D Printer Filament Or 3D Printer Resins you are planning to print with, the type of HotEnds and Nozzles required, as well as any other accessories such as Build Surfaces & Fume Extractors.

HOW LARGE CAN I PRINT?The Modix 3D Printer line easily takes the lead when it comes to print volume. Large, highly upgradable, and available exclusively as kits these printers are exceptional options for achieving ridiculously large prints.

- Modix BIG-40: 400mm x 400mm x 800mm, starting at $5,600

- Modix BIG-60 V3: 600mm x 600mm x 660mm, starting at $4,500

- Modix BIG-120X: 1200mm x 600mm x 640mm, starting at $7,550

- Modix BIG-120Z: 600mm x 600mm x 1200mm, starting at $7,450

- Modix BIG-180X: 1800mm x 600mm x 600mm, starting at $15,150

- Modix BIG-Meter: 1010mm x 1010mm x 1010mm, starting at $13,150

Large Scale 3D Printers Big Enough to Print Furniture

Home / 3D Printers / Large Scale 3D Printers Big Enough to Print Furniture

Use Cases

Just like all types of 3D printing, XL 3D printing has its own strengths and tradeoffs. Users are constantly finding more applications for these gigantic machines so the XL 3D printing space is getting bigger and bigger. Let’s have a closer look.

Users are constantly finding more applications for these gigantic machines so the XL 3D printing space is getting bigger and bigger. Let’s have a closer look.

Quick jump to:

- Request XL 3D printer quote

- Request XL service quote

When To Consider Large Scale 3D Printing

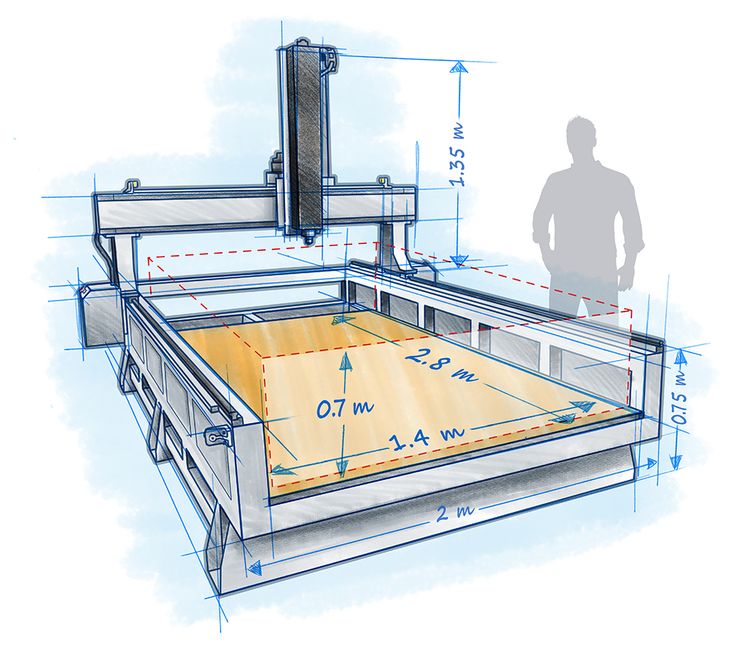

It takes a large scale 3D printer to print furniture, vehicle parts and architectural components. Obviously, size is the driving factor in choosing to use large-format printing but there’s more to it than that. Here’s a breakdown of some of the less-obvious considerations:

- Unibody Parts – Often, producers are already able to fabricate their large objects through traditional methods of assembly but those objects would perform better if they were produced as one solid piece, something only a large 3D printer can do efficiently.

- Weight Reduction – Large objects are usually made of wood, metal, or injection molded plastics.

Printing the same objects in plastic will make them much lighter, especially when factoring that users can easily adjust the density infill of 3D printed objects. Consolidating large assemblies into single components also reduces weight by eliminating the need for fasteners like nuts and bolts.

Printing the same objects in plastic will make them much lighter, especially when factoring that users can easily adjust the density infill of 3D printed objects. Consolidating large assemblies into single components also reduces weight by eliminating the need for fasteners like nuts and bolts. - Faster Development – The larger an object, the longer it takes to create and setup the tooling to fabricate it through traditional means. With 3D printing, there are essentially no setup steps so large prototypes are significantly faster to print than to make them any other way. A large object may take a while to print, but by cutting out the time-consuming tooling step, it may also be faster to do production runs of large objects, depending upon the specifics.

- Reduced Cost – 3D printed large parts can be cost competitive with conventionally-made parts almost entirely because of the tooling costs of the latter. Consolidated assemblies usually cost less as well because fewer materials have to be sourced from different places.

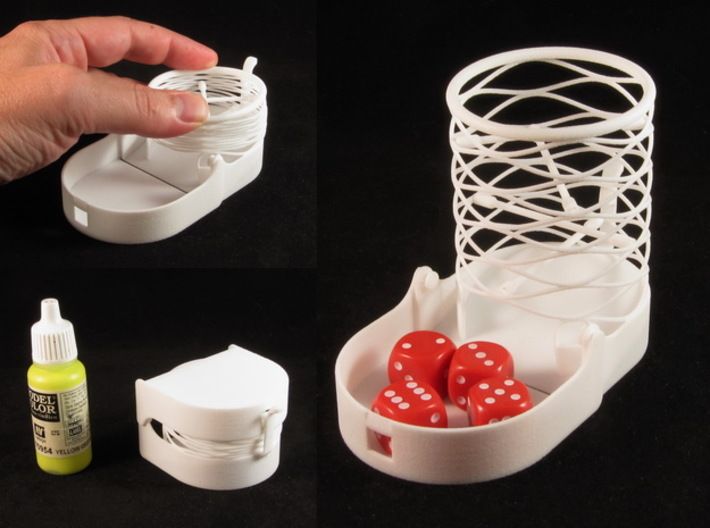

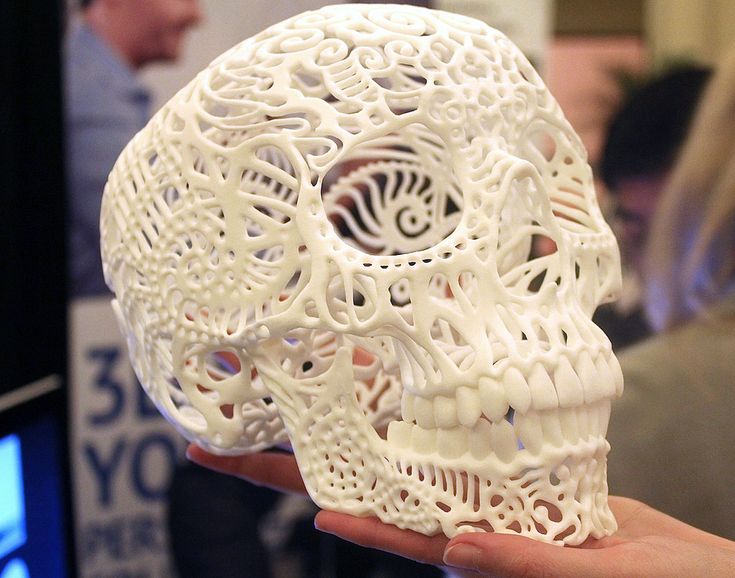

- Design Freedom – Using conventional manufacturing methods, many geometries are just not possible, such as internal channels and complex lattice structures. Many large objects, like furniture, benefit from such features and XL printers are the only way to realize those designs.

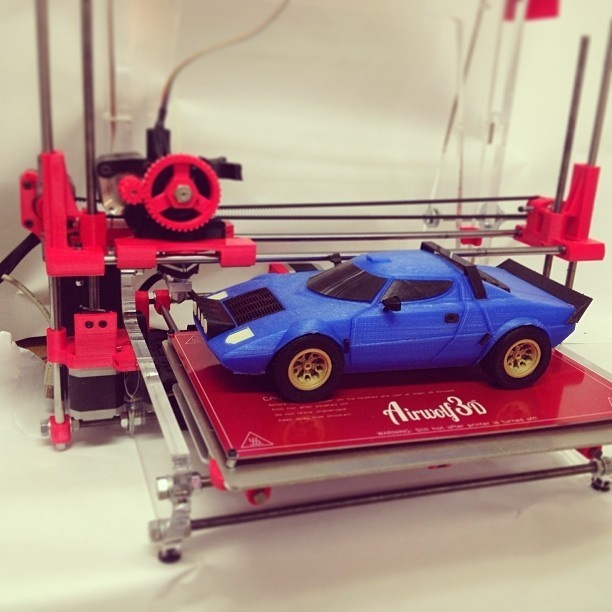

Large Scale 3D Printing Examples

- Restoration and replication – XL 3D printing has become rather popular among paleontologists as the technology allows them to both study and preserve the delicate fossils that they regularly handle.

- Furniture – Thanks to large-scale 3D printers it is now possible to create complex functional designs within a fully digitized process chain. From full-size prototyping to production of 3D printed furniture.

- Display advertising – XL 3D printers are perfect for making high-quality, modern signage and lettering for retail stores, businesses and exhibitions.

- Props – With the introduction of large scale 3D printers, designers can now produce enormous set pieces – overnight.

3D printing can help designers quickly manifest their wildest imaginations into the physical reality, and the Film & TV industry has taken notice.

3D printing can help designers quickly manifest their wildest imaginations into the physical reality, and the Film & TV industry has taken notice.

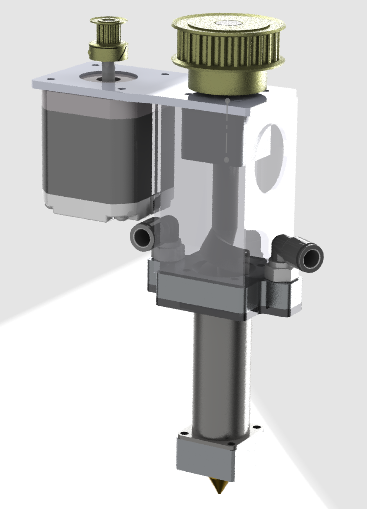

Pellet Extrusion

One of the differences between desktop-sized machines and XL printers is the possibility to utilize pellet extrusion systems on the large printers. Pellet extrusion doesn’t use spooled filament as feedstock but instead uses the same virgin plastic pellets that are used for injection molding, which are much cheaper than spooled filament. This makes it easy to mix different plastics to make custom polymer blends and colors. These systems can also take shredded plastics as feedstock, which enables users to directly recycle water bottles, milk jugs, and failed and unneeded prints into new objects. Such a degree of a circular ecosystem can not be achieved with any other form of manufacturing.

That’s all great but what compels most users to opt for pellet extrusion is its blazing speed as the technology enables output of several kilograms per hour. Printing times scale exponentially with part size so having a high extrusion rate is pretty important for large-format 3D printing. One drawback of pellet extrusion systems is that they struggle with retraction, a feature that filament extruders employ to improve surface finish by pulling back on the filament during non-extrusion travel moves; retraction reduces or eliminates blobs, dots, and stringing on prints. Some XL printers can operate with both filament and pellet extrusion systems, allowing users to choose the best toolhead for their specific application.

Printing times scale exponentially with part size so having a high extrusion rate is pretty important for large-format 3D printing. One drawback of pellet extrusion systems is that they struggle with retraction, a feature that filament extruders employ to improve surface finish by pulling back on the filament during non-extrusion travel moves; retraction reduces or eliminates blobs, dots, and stringing on prints. Some XL printers can operate with both filament and pellet extrusion systems, allowing users to choose the best toolhead for their specific application.

Get a Quote

Large Scale 3D Printers

Looking to implement large scale 3D printers in your production process? Get a quote from Modix or Industry

Modix BIG Meter

With the Modix BIG Meter, you are now able to manufacture objects as large as 1010 x 1010 x 1010 mm in one go!

$13,500Modix

Request a Quote

modix big meter

- Benefits

- Applications

- - DIY self-assembly kit

- - Print Volume: 1010 x 1010 x 1010 mm

- - Printer Dimensions: 1300 x 1470 x 1830 mm

- - Shipping Weight: 200kg

- - Included: Dual print head, E3D Aero & Volcano 1.

75mm

75mm - - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - Automatic bed tilt calibration

- - Power Requirements: 32A, single phase, 208-240V

Mold Making, Prototyping, Research and Development, Restoration

Industry MAGNUM

Hailing from Sweden, Industry is a company that has made major waves in the world of 3D printing. The new MAGNUM large scale pellet 3D printer enables you to print parts measuring 1500 x 1200 x 1200 mm.

A powerful E25 extruder manufactured to handle shredded material, granules or pellets. The MAGNUM handles nozzles between 2-8mm and has an average output between 1-8 kg / hour & a maximum output of 15 kg / hour.

MAGNUM offers powerful control features based on Bosch Rexroth MTX system control. It comes with a camera and mail/text module for external monitoring. A large touch screen display allows for easy setup and agile control.

€159,000Industry

Request a Quote

Industry MAGNUM

- Benefits

- Applications

- - Large scale pellet 3D printer

- - XL build size: 1500 x 1200 x 1200 mm

- - Granular extruder, which reduces material costs

- - Fast build rate: up to 15 kg per hour

- - Touch screen display

- - High quality linear motion modules from Bosch Rexroth MTX

Mold Making, Production, Prototyping, Research and Development, Restoration

Modix BIG-180X

The BIG-180X features a print volume of 1800 x 600 x 600 mm and comes at a competitive price of $12,000 USD. The unique extra width of the build chamber is designed per request of customers working in the automotive industry.

$15,500Modix

Request a Quote

modix 180

- Benefits

- Applications

- - DIY self-assembly kit

- - Print Volume: 1800 x 600 x 600 mm

- - Printer Dimensions: 2170 x 1060 x 1430 mm

- - Shipping Weight: ~240kg

- - Included: Dual print head, E3D Aero & E3D Volcano 1.

75mm

75mm - - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - 4 X Z axis motors are controlled individually providing automatic bed tilt calibration.

- - Minimal Electricity requirements: 32A, single phase, 208-240V

Prototyping, Research and Development, Restoration

Modix BIG-120Z

The closed enclosure of the BIG-120Z is made of aluminum composite panels and polycarbonate doors. It incorporates a premium motion system including HIWIN motion rails, Gates timing belts and IGUS signal cables. This is a smart 3D printer providing several key reliability features including power-off resume, filament runout sensor, 120 probing points based automatic bed leveling, stall detection and more. The manufacturer offers an active air filter device as an add-on.

$7,500Modix

Request a Quote

BIG-120Z

- Benefits

- Applications

- - DIY self-assembly kit

- - XL print volume of 600 x 600 x 1200 mm

- - Z axis guides, HIWIN MGW Linear Rails

- - Duet 2 Wifi, 32Bit controller developed by Duet3D

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - Dual print head

- - E3D Titan Aero extruder with E3D Volcano hotend

Displays, Fashion, Mold Making, Prototyping

Modix BIG-120X

Modix BIG-120X Version 3 represents a major leap forward with regards to the printer reliability, print quality, ease of assembly and readiness to future advanced updates. Since Modix big60 and 120X share the same core design the new update is benefiting both models.

Since Modix big60 and 120X share the same core design the new update is benefiting both models.

$7,500Modix

Request a Quote

BIG-120X

- Benefits

- Applications

- - DIY self-assembly kit

- - XL print volume of 1200 x 600 x 660 mm

- - Duet 2 Wifi, 32Bit controller developed by Duet3D

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - Closed loop motion system (optional)

Mold Making, Prototyping, Research and Development, Restoration

Get a Quote

XL 3D Print Service

3D printing is a viable option for display advertising, large scale concept models, car parts, furniture, molds & tooling. We offer both cost effective solutions with thick layers and rough surfaces for rapid prototyping as well as highly detailed & post-processed end-use objects. Please contact — [email protected] — for any questions or complete the form below and we’ll answer you as soon as possible.

- Technologies: FDM, SLA, GDP

- Materials: From PLA to CF composites & more

- Maximum print size: 1450 x 1100 x 1800 mm

- Post-processing: Spray paints, metal coatings, assembly & many more

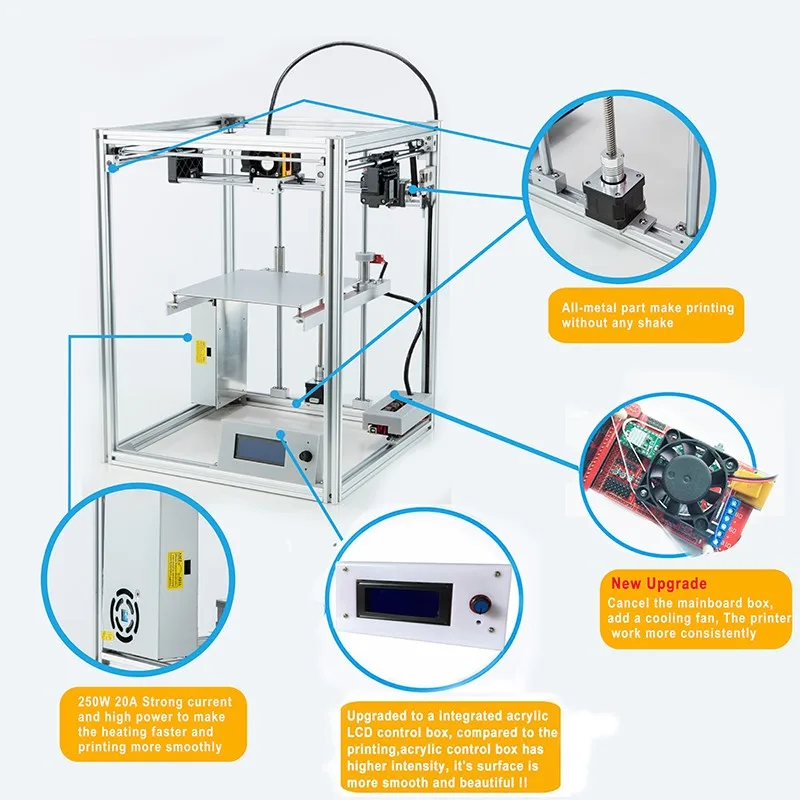

CreateBot D600 Large Professional 3D Printer

Hello everyone, the company 3Dtool is with you. Today in our review is an impressive 3D printer that takes professional 3D printing to a new level.

It proudly bears the name CreatBot D600 and comes in a fairly sturdy wooden box.

Let's start unpacking it

The printer is packaged just fine, with foam padding on all sides, all glasses sealed with packaging film to avoid scratches, and inside the moving parts are fixed with nylon ties.

CreatBot D600 , it is no coincidence that it has these numbers in the name, because the size of its working area is 600 mm x 600 mm x 600 mm and the usable volume is 216 liters.

Also, its main advantage (besides the size) is the dual print unit with two separate extruders

The size of the working area is impressive, because there are not many FDM 3D printers on the market that can compete with the D600 in this indicator. At the same time, the dual print unit can print supports using soluble materials. Such capabilities allow CreatBot D600 to create complex models of large size. That in itself is a rare combination and is highly demanded in the market of professional 3D equipment.

Housing

The body of the printer is all metal and its overall dimensions are 915 x 845 x 1085 mm . The weight of the printer is 125 kg , which, coupled with a rather impressive rigidity, has a beneficial effect on reducing vibration during printing.

There are many opening doors and windows on the body, providing access from any side to the printed model.

With a fully closed housing, the possibility of external interference in the operation of the printer is eliminated, the noise level during operation is reduced, and the temperature inside the chamber is maintained at a constant temperature so that the product does not deform during printing. Thanks to this, the printer allows you to print with high shrinkage plastics, such as ABS derivatives or nylon, without problems.

Thanks to this, the printer allows you to print with high shrinkage plastics, such as ABS derivatives or nylon, without problems.

The location for installing the material spools is at the back of the housing.

Kinematics

Designed as a single unit with a belt, rail guides provide a high degree of positioning accuracy, higher than not only their counterparts, but even some optical printers available on the mass market. The classic kinematic scheme allows you to print, albeit a little slower than analogues at H-Bot and Core-XY systems, but much more reliable due to the direct drive of the motor along the axes. By the way, along the axis Y the printing unit moves due to the movement of two belts (one per rail), but one powerful stepper motor with a through drive

Along the axis Z , the heating table is moved by two ball screws installed at the side walls. As guides for the table, there are four cold-rolled shafts with a diameter of 16 mm .

As guides for the table, there are four cold-rolled shafts with a diameter of 16 mm .

Along the X and Y axes, block rail guides with an integrated belt are installed.

Extruder

As standard, the printer has a dual print unit with two extruders. Optionally, it is possible to install a third. The extruders are equipped with a gearbox with a gear ratio of 1:10 .

The pull mechanism is completely metal. This allows you to confidently print with any materials, which is also provided by the nozzle heating limit, right up to 400°C . The printing unit itself is made according to the classic direct extruder scheme, has an extruder tube and heating blocks similar to the Vulcan. The cold zone (ColdEnd) is forcibly blown by two small fans, the speed of which can be adjusted.

Nozzles with a diameter of 0. 4 mm are installed by default. They are interchangeable and, if necessary, you can always install other diameters suitable for your tasks (0.3, 0.5, 0.6, 0.8, 1.0 mm) .

4 mm are installed by default. They are interchangeable and, if necessary, you can always install other diameters suitable for your tasks (0.3, 0.5, 0.6, 0.8, 1.0 mm) .

When the power is suddenly turned off, the printer automatically remembers the current position and saves the print data, lowers the build platform and retracts the nozzle.

The platform of a heating table is made of glass ceramics. Can heat up to 100 - 110 °C . This is not as much as, for example, MarkForged printers, but allows you to use any of the most common materials for 3D printing. The adhesive on the platform is a BuildTak-like surface that securely holds even very large objects made of high shrinkage materials (eg ABS).

The calibration screws are located at the bottom of the heating table.

Control screen

For convenience, the printer is equipped with a 4. 3” touch screen with an English menu. There are separate menus for preheating and movement along the axes. It is quite easy to handle. Intuitive icons allow you to quickly understand the tools and manage the printer, with almost one touch.

3” touch screen with an English menu. There are separate menus for preheating and movement along the axes. It is quite easy to handle. Intuitive icons allow you to quickly understand the tools and manage the printer, with almost one touch.

Interfaces

3D printer CreatBot D600 is equipped with a USB 1.0 port. This allows you to pair with a computer and send print jobs from it directly. However, we recommend using the USB flash drive slot to the right of the display in order to take full advantage of the device's capabilities.

Software

The printer comes with free software CreatWare based on the popular and well-known Cura 1.5.4, which can be downloaded from the manufacturer's website.

It is very simple and easy to learn, so there should not be any problems in working with this software.

This 3D printer is designed to solve serious problems of printing large-sized models. The quality of workmanship and ease of use allow the CreatBot D600 to be used in professional 3D printing studios, various design and design offices 24/7. The build quality of the 3D printer is factory. All components of the 3D printer are made of high quality components. Significant advantages of CreatBot D600 include:

1) The ability to heat the extruder up to 400 degrees (Important for 3D printing with engineering plastics)

2) Reliable and accurate kinematics for a working area of this size.

3) The presence of 2 extruders in the base.

4) Factory assembly

If you need a printer with a large print area, we recommend 100% for consideration.

You can order the CreatBot D600 3D printer from our company. Delivery time 6 weeks.

Link to equipment: https://www.3dtool.ru/product/3d-printer-creatbot-d600/

Large 3D printer - big 3D problems.

Lately, I've been getting a lot of questions about large 3D printers. It is understandable why print parts in parts, if you can print out the whole thing, simplify your life. And often people say, why is there, you take Prusa, increase the size and voila.

Large 3D printers are produced by not so many companies (they can literally be counted on the fingers). And there are a number of good reasons for that.

And so today I would like to talk about the problems of large printers, and methods of dealing with it, in examples.

Let's go in order.

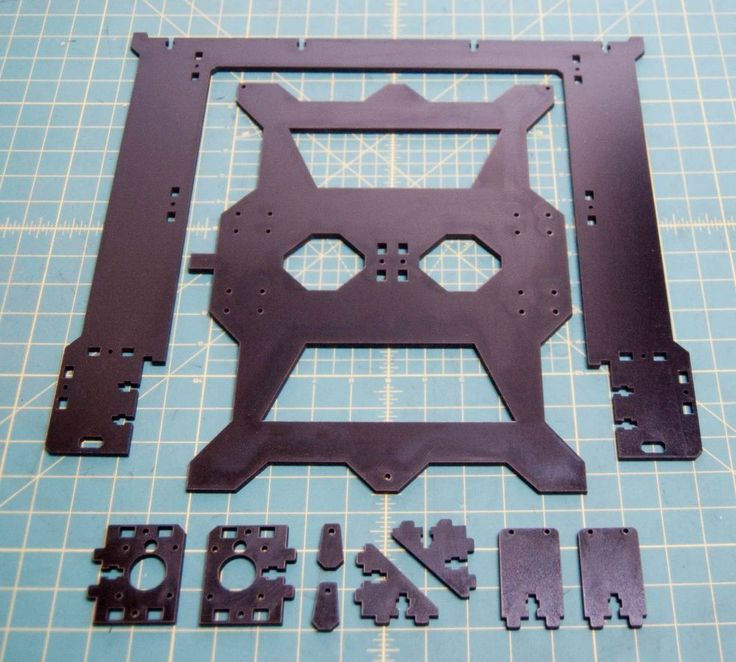

1) Frame.

As you know, the moment of force is force * shoulder , so the larger the dimension, the greater the load must be taken by the structural elements. (strong simplification) We add vibration and internal resonance here and it turns out that the strength and rigidity of the structure must be significant, this seriously affects the mass of moving parts and the cost of the frame. Moreover, due to the increase in mass, the printing speed inevitably decreases, but more on that later.

Also, for obvious reasons, it is not advisable to take the Prusa i3 frame as a basis, a spatially rigid frame is needed. But what is it made of? Steel, aluminum, fiberglass? How to fasten it, rivets, welding, glue? I will not give you an answer to these questions, but you need to know those well. process to make an even frame.

2) Mechanics and kinematics.

Okay, let's calculate the frame, weld it, and mill it. But what kinematics to take as a basis? What should be the axis drive, what should such a printer look like?

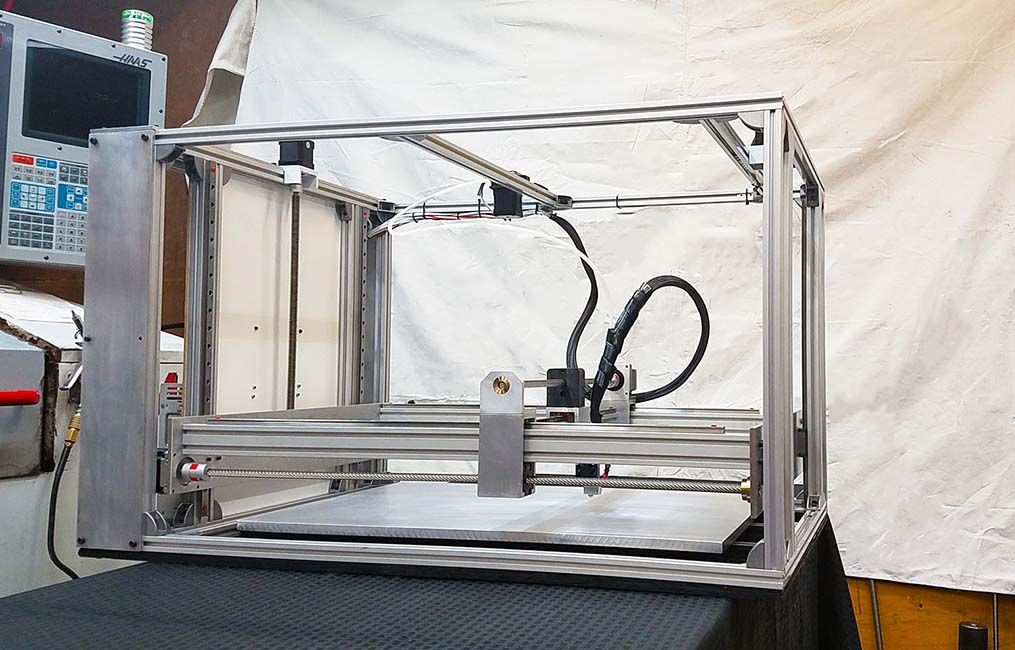

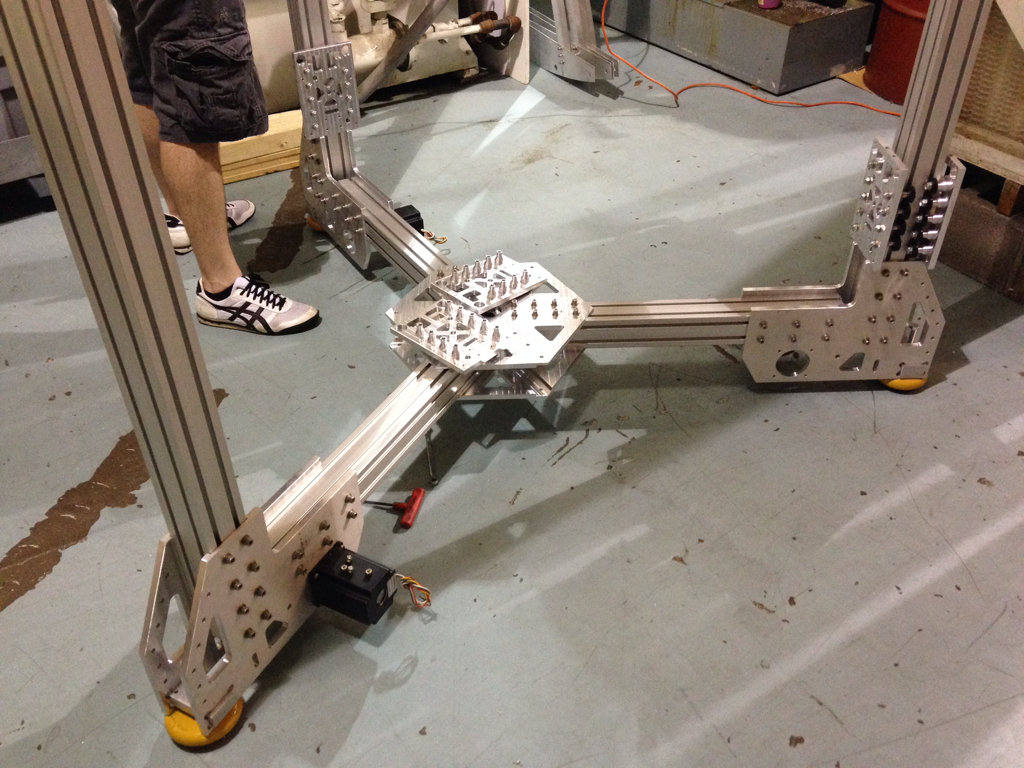

And let's look at existing printers - BigRap and Tsar Printer :

Yes, the printers are very similar, and please note that the table of such printers is not movable, the print head moves along all axes, and this is reasonable. Firstly, the mass of the table itself in this case is greater than the head drive, in addition, this mass will constantly increase during printing, and it will not be evenly distributed. (printed part can be in different positions)

(printed part can be in different positions)

Well, what kinematic scheme should I choose then? H-Bot/CoreXY do not fit, they have a very long strap, it needs to be pulled tight. Musicians are well aware that the strings on the guitar are tightly stretched, and vibrate beautifully, and stretch over time, and then completely break. All the same effects will be on the belt.

Ultimaker mechanic? It also does not fit, it is good for dimensions of 200 * 200 - 300 * 300 maximum, then a lot of difficulties arise. (rotating shafts on large spans will have a noticeable runout, but this problem can be circumvented, but the structure will be heavily piled up)

The most reasonable solution is to take as a basis the mechanics of MarekBot (for sure there is some official name, but I could not find it in free sources, designations like: XY head, Z bad - also does not reflect the essence)

This mechanics is bad because the Y-axis motor moves along with the carriage, which adversely affects print quality at high speeds, but in our conditions this is not a bad decision. (By the way, it is not necessary to use shafts as guides, this mechanics does not limit us in anything)

(By the way, it is not necessary to use shafts as guides, this mechanics does not limit us in anything)

3) Electronics and drives.

We have increased the load on moving elements and therefore we need to use more powerful drive motors and powerful drivers for them. Ideally, I would like to add feedback here. More recently, such hybrid servo-stepper motors Leadshine :

appeared on free sale. What is feedback for? Strictly speaking, this set compensates for missing steps, but does not give the values of absolute coordinates to the controller. In principle, this solution is quite suitable for 3D printers. The main snag is only in switching this controller with the same Ramps1.4 (or any other electronics typical for printers).

As far as I know no one has used them before. Moreover, the most modern boards have a maximum of 6 pins for drivers (Rumba), this number may not be enough. (Pay attention to the Tsar Printer, there are only 4 motors along the Z axis, plus two for each axis and at least one for the extruder, this is no longer enough. Therefore, they need to be somehow reduced or hung on one channel.)

Therefore, they need to be somehow reduced or hung on one channel.)

There is another option . Connect all this electronics to standard CNC boards + computer with LinuxCNC (EMC2), because all we need is to play G-Code, and although this method will not be very convenient, it is still workable.

4) Plastic.

There are so many problems here.

Any plastic shrinks, and because of this, such effects occur as: cracking of the model in layers ( both during printing and after printing ), as well as peeling off from the platform. How to deal with it? Definitely need a thermostatic chamber, where a constant temperature is constantly maintained. This technology has long been used in industrial printers Stratasys Dimension:

The hot air in them blows at the level of the nozzle and constantly circulates.

I can also say from my own experience that after printing massive parts made of ABS plastic, pushing it into the oven for half an hour at 150 degrees helps to remove internal deformations and harden the part.

The second problem with is the plastic coming off the platform. and if the thermostatic chamber gives us uniform shrinkage, then it will not help with sticking to the platform itself. Perhaps this question is a stumbling block in general for all printers.

Definitely the platform needs to be warmed up for better adhesion. We only remember from the lessons of physics that any material expands when heated. An aluminum or steel platform will constantly warp, so here you either need to scan the surface map (one of the auto calibration methods), or use a material with a low thermal expansion coefficient, you can use ceramics for example, here is an application example. But the problem will not be completely solved, it is still necessary to use some means of increasing adhesion, for example, adhesives or PEI film, to be sure.

The third problem with is the plastic on the spools. ( I will omit the question of the quality of the plastic itself, it is understandable anyway ) Very often the plastic overlaps on the reel and the plastic supply stops. This phenomenon is impossible to predict. Moreover, under the order, you can purchase a maximum of coils of 3 kg. For BigRap and Printer Tsar it is one tooth, the best option would be to extrude the plastic directly from the pellets. For example BAAM ( Big Area Additive Manufacturing ) uses just such a method, here are a couple of links to direct extruder designs: Pollen Pam, Universal Pellet Extruder for 3D Printing, Erecto-Struder 24v5) Power supply and print time.

This phenomenon is impossible to predict. Moreover, under the order, you can purchase a maximum of coils of 3 kg. For BigRap and Printer Tsar it is one tooth, the best option would be to extrude the plastic directly from the pellets. For example BAAM ( Big Area Additive Manufacturing ) uses just such a method, here are a couple of links to direct extruder designs: Pollen Pam, Universal Pellet Extruder for 3D Printing, Erecto-Struder 24v5) Power supply and print time.

My maximum continuous print time is 40 hours. The second longest is 20 hours. During this time, I can use up a maximum of one spool of plastic (as a rule, such a print takes about 300 grams). And if suddenly something goes wrong, I lose 40 hours and one coil. Of course it's a pity, but not fatal. For large orders, I take a stock of at least three days.

Why am I? Oh yes, it follows that the maximum reasonable print time varies within this limit. But everything that goes beyond this interval greatly increases the risk of printing failure, which means failure to meet deadlines, a huge waste of plastic and loss of money.

How can I reduce print time? Print in thick layers, thick nozzle. The surface will be rough, but you will get volume. It is not reasonable to increase the printing speed (travel speed), thus we overload the mechanical part and the extrusion process is also worse.

Further, if mechanically the printer will be able to print more than 100 hours without interruption. However, the risk of a power outage remains. In this case, you need to install either a UPS or an emergency print pause system. For example, such a system is not ideal, but still implemented on the Raise printer. A tablet is installed there as the main device, and when the power is turned off, it remembers the position of the head and continues printing.

And the last one related to the previous point. When the power goes out, the thermostatic chamber will cool down, and quickly, just like a heated table. Which can lead to delamination and peeling of the part. The only way out is to make a thermos from our cell.

6) Mentality and background.

Everyone wants to get the most for the least amount of money, and that's understandable. But there is a catch, but do we need it? I often met stupid customers who buy machines 'for the future', but suddenly they need it. This is a bad approach, since you can’t sit on two chairs, it’s better to focus on a narrow range of tasks and make / buy equipment for them. Don't make a 1 cubic meter printer, if you need to print tall vases, build or buy a tall printer.

In addition, it is often possible to print parts in parts, it is more rational to print the same bumper upright, dividing it in half. Since it takes less support, here is an example:

As you can see, 'standing' splitting the part in half prints easier and uses less support material. So think again, maybe a smaller printer will do?

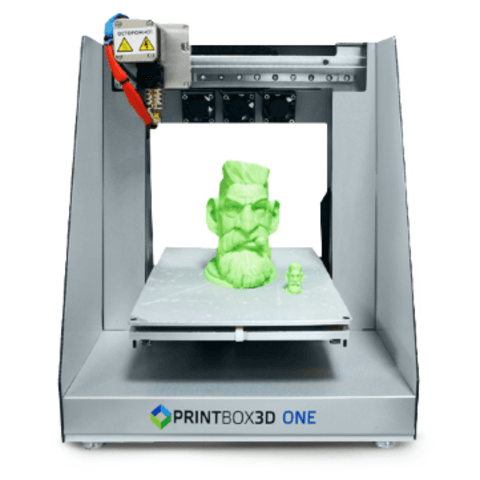

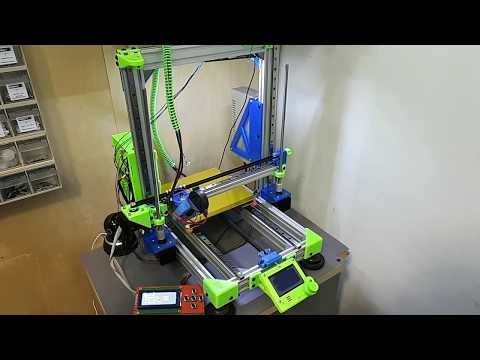

Finally, a few links to large 3D printers: THE BOX, Additive Machine 1, BigRep ONE v3, DeltaWASP 3MT, ErectorBot EB 2076 LX, Builder Extreme 2000, Moebyus M3, Tsar Printer And, as usual, your affectionate and gentle Tigeer.