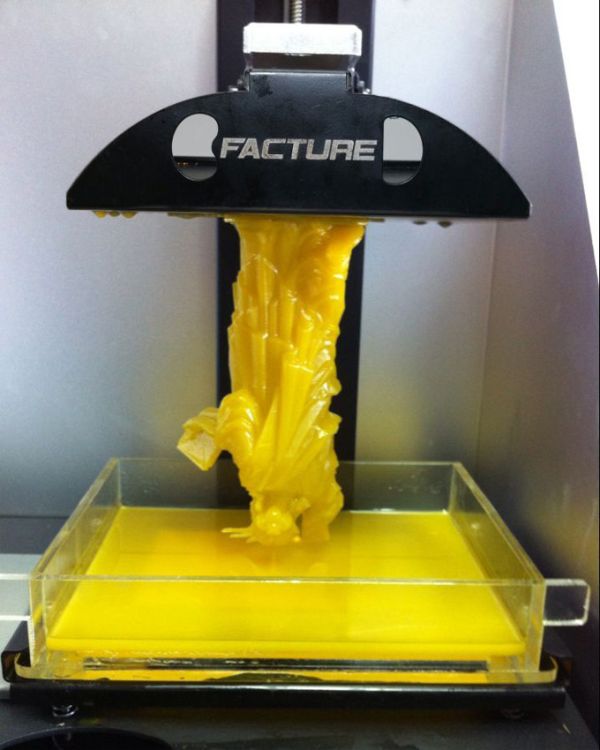

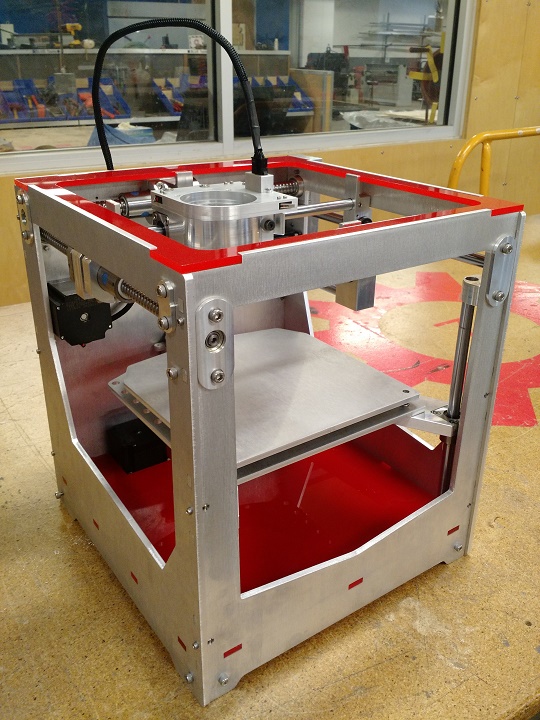

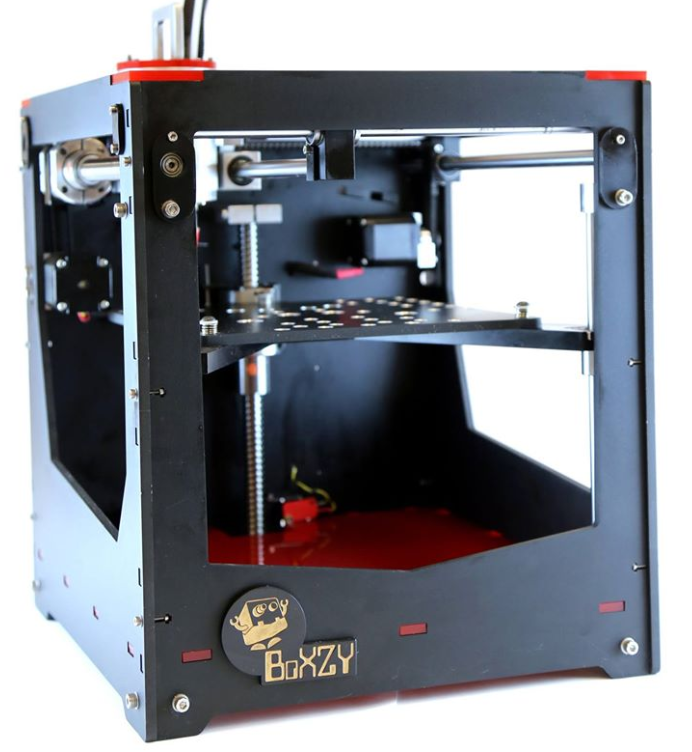

3D printer laser liquid

Best 3D Printer for 2022

In this article:

- What to Consider Before Buying a 3D Printer

- The Best 3D Printers

- Best 3D Printers for Beginners

- Midrange 3D printers

- High-end and professional 3D printers

- 3D Scanners

- 3D printing FAQs

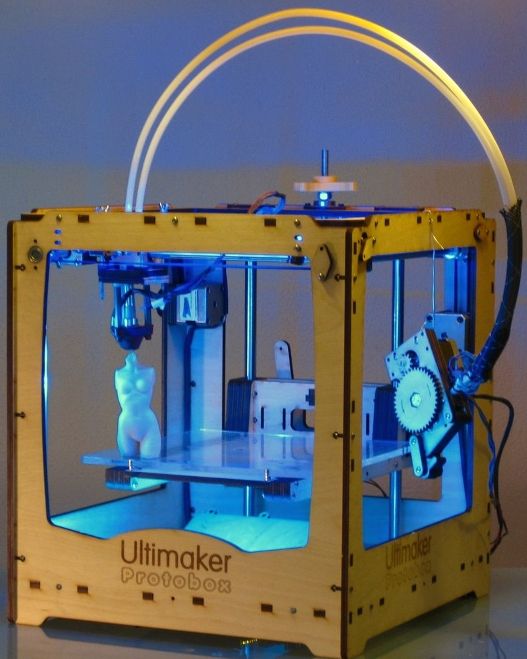

In the last few years, 3D printing has become much more commonplace and accessible for hopeful hobbyists. No longer do you have to make a trip to your local university or library to print out 3D objects as inexpensive machines have started to offer fantastic results straight out of the box.

Because 3D printing technology has come a long way in recent years, I've doubled down on being creative and gotten into 3D scanning and laser cutting as well, which lets you sculpt real-world designs from leather and wood. Advanced makers are also using resin machines that create amazingly detailed prints.

Current 3D printers, which range from affordable (under $300) to high-end (over $4,000), are great gifts for a creative person in your life. Even better, they're great for you to craft your own personalized designs if you're looking to open an Etsy shop or something similar.

These models by Fotis Mint are extremely detailed.

James Bricknell/CNETWe've taken a deep dive into many of the best 3D printers available today. This list includes both small and large 3D printers, with attention paid to print speed, the size of the build plate, the cost of PLA filament, the kind of print head included and other important details. And once you've decided to take the plunge into additive manufacturing -- that's what 3D printing essentially is -- there's an FAQ below.

What to Consider Before Buying a 3D Printer

Purchasing your first 3D printer can be nerve-wracking but don't worry; we are here to help. There are a few main areas that you should consider when choosing the best 3D printer and we have them covered here.

What am I 3D printing?

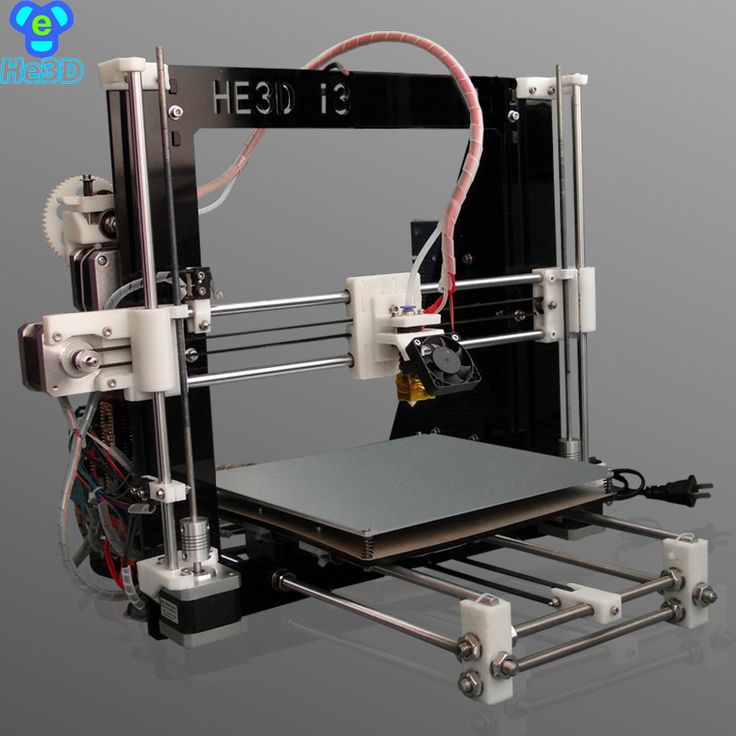

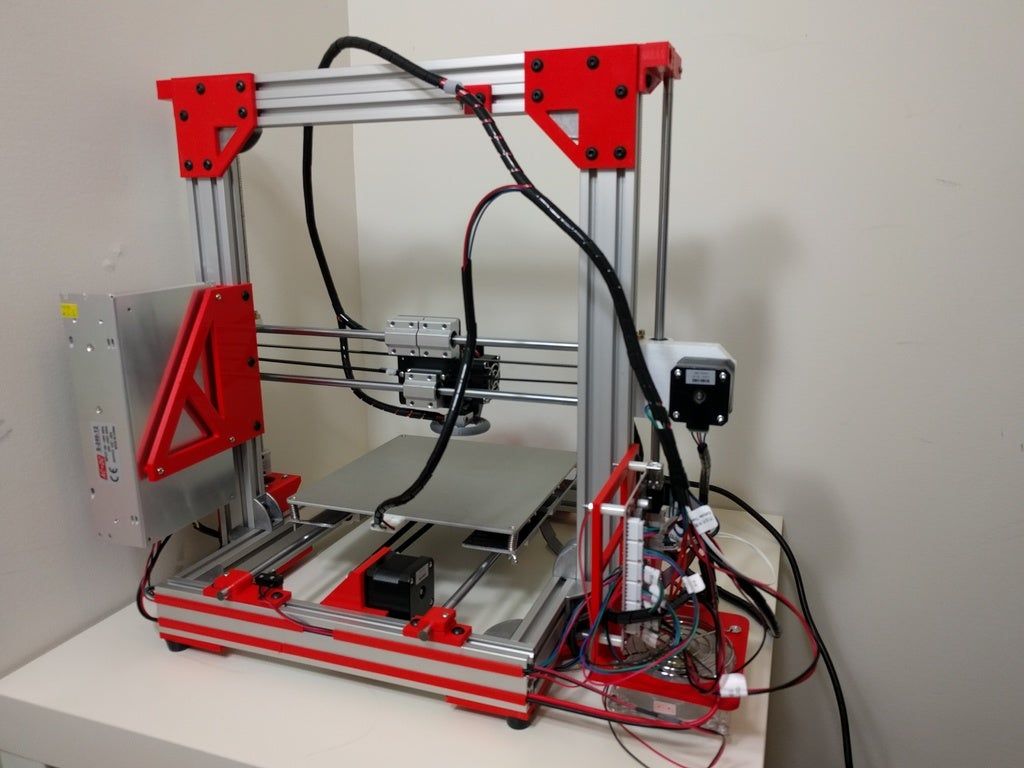

When deciding on what 3D printer to buy you first have to know what type of things you want it to print. Resin 3D printing is good for highly detailed models such as character busts, dental work or tabletop miniatures. Even jewelry can be made using a resin 3D printer.

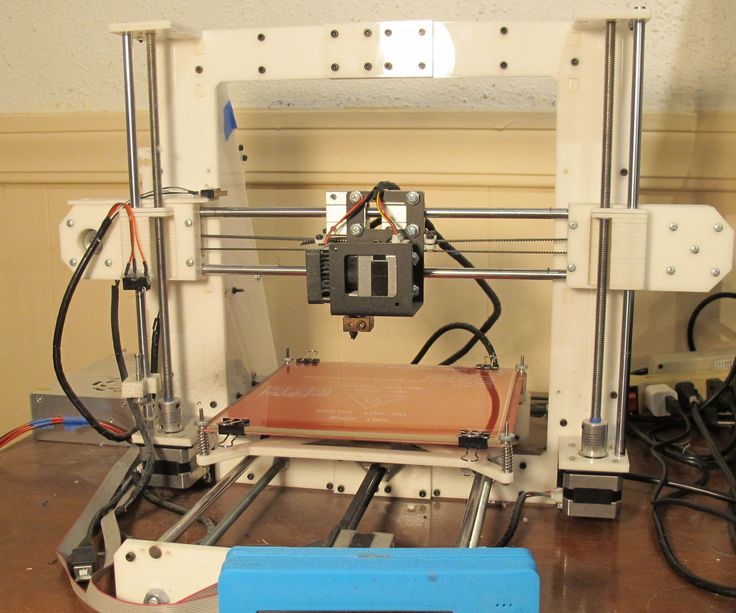

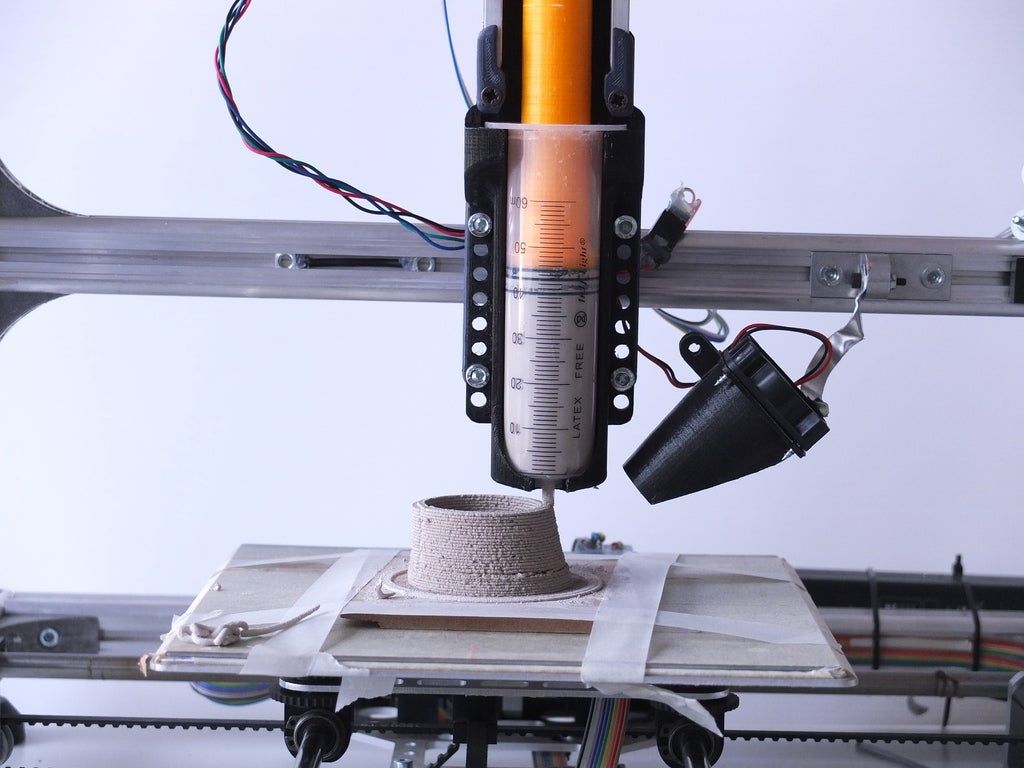

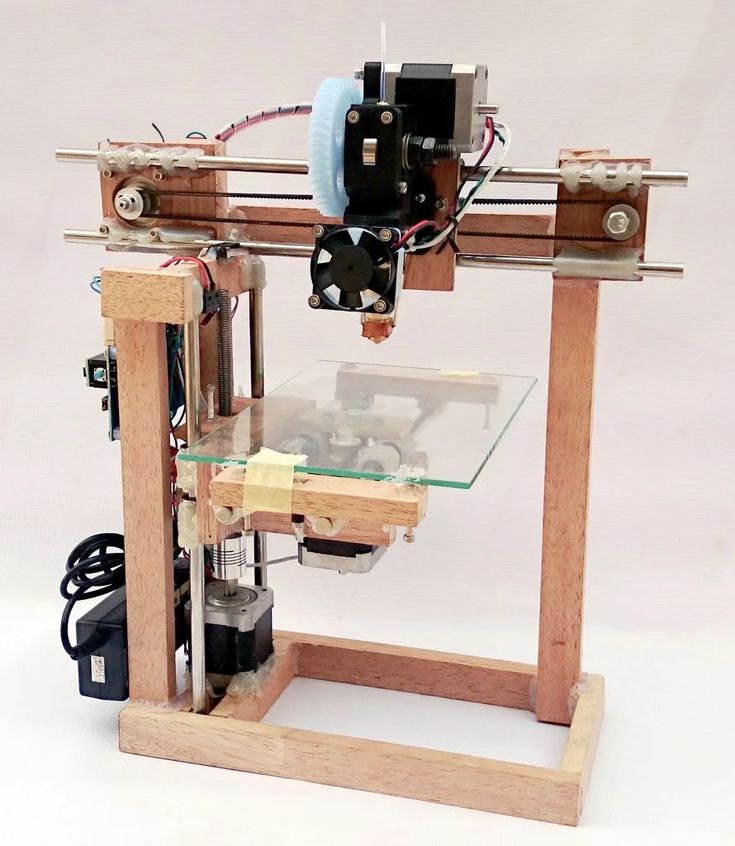

For almost every other application, an FDM, aka filament, 3D printer is likely the best choice. Filament 3D printing is versatile in the types of material you can use and offers much larger build volumes to work on models. Cosplay armor and helmets, practical parts and large-scale models are best printed on an FDM printer.

Read more: What is 3D Printing?

What is build volume?

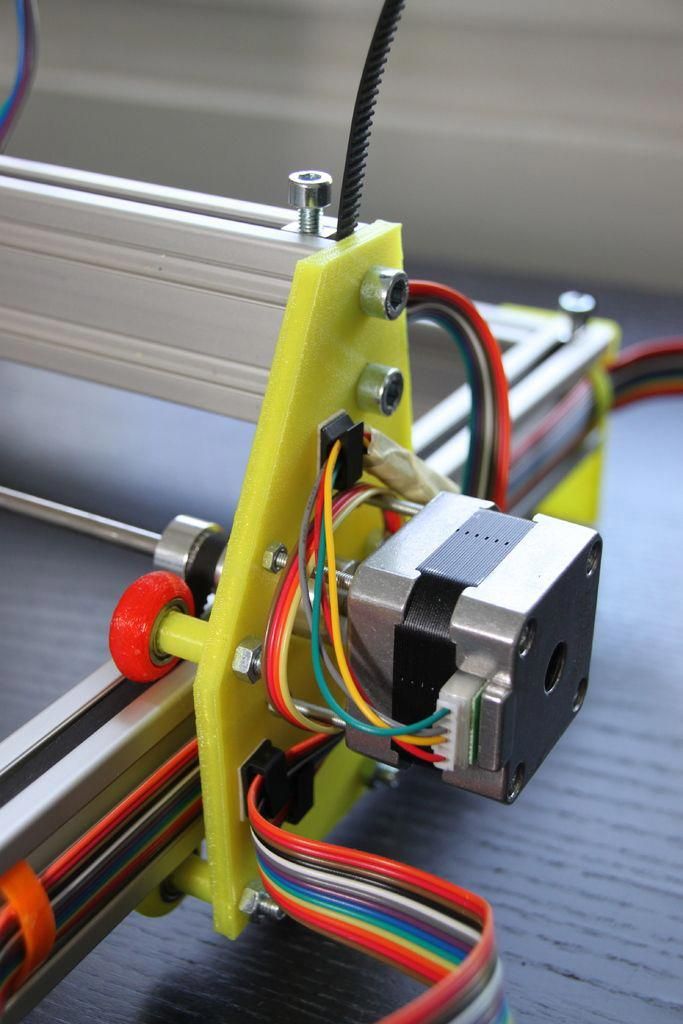

Build volume is the amount of space a printer has to produce a model. Often calculated in millimeters cubed, it is the combination of the width, height and depth that your printer's nozzle can reach. This is not always the same as the internal volume of a 3D printer because the wiring and other mechanical parts can get in the way of the nozzle, reducing the area available.

Most FDM printers have a build area of around 220 by 220 by 250mm, though some of the best 3D printers have larger and a few of the best budget 3D printers have smaller. I think the 220 by 220mm build plate is a good size for starting out as it has room for large, practical pieces or several smaller models at once.

Should I wait for a deal to buy a 3D printer?

3D printers are often available throughout the year at a discount price. Special days like Prime Day, Black Friday and Cyber Monday are great occasions to pick yourself up a new machine, but there are still plenty of deals to be had on a normal day. Make sure you stay fluid and choose your 3D printer deal based on the availability of the machine and what your research has told you is the best.

The Best 3D Printers

Dan Ackerman/CNET

Creality Ender-3 S1

Best 3D Printer for Beginners

I'd avoided Ender-3 printers for a long while, because they came in kit form and required many hours of assembly, setup and fine-tuning to use. For just a little more than the kit versions, the newer Ender-3 S1 comes nearly fully preassembled, and with high-end features like a direct drive extruder and self-leveling bed.

For just a little more than the kit versions, the newer Ender-3 S1 comes nearly fully preassembled, and with high-end features like a direct drive extruder and self-leveling bed.

Print quality even out-of-the-box was excellent, although a lot of that comes down to having good models to work from. I'd love it to have a touchscreen and Wi-Fi, but apart form those missing features, this is a great way to get polished results from a $400 3D printer.

Read our Creality Ender-3 S1 review.

$399 at Amazon

You're receiving price alerts for Official Creality Ender 3 S1 3D Printer with Direct Drive Extruder CR Touch Auto Leveling High Precision Double Z-axis Screw Silent Board Printing Size 8.6X8.6X10.6in, Upgrade Ender 3 V2 for Beginners

James Bricknell / CNET

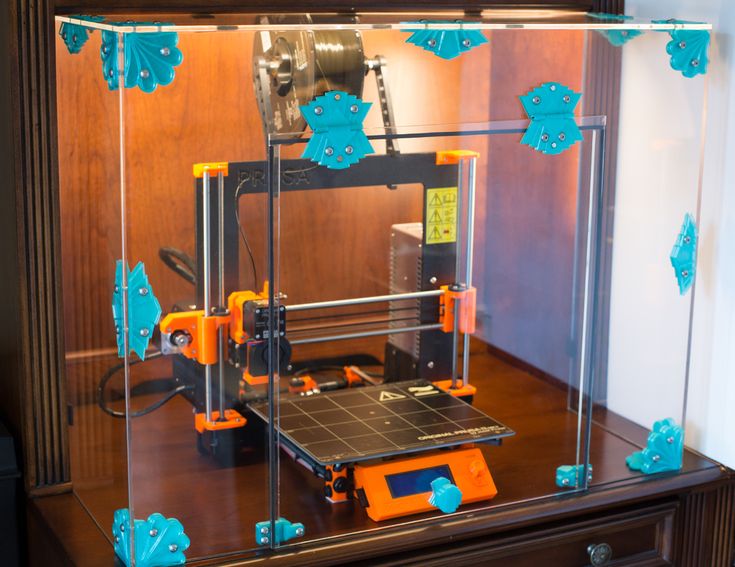

Prusa Mk3S Plus

The standard candle for home 3D printing

No best 3D printer list is really complete without the Prusa MK3S Plus. For nearly a decade it has dominated the market and continues to be the go-to printer for anyone looking to make a business from 3D printing. It is fast and creates quality prints every time. I can count the number of print fails from MK3 on one hand, and I have had it for nearly seven years. If you have the $800, you should buy one of these.

For nearly a decade it has dominated the market and continues to be the go-to printer for anyone looking to make a business from 3D printing. It is fast and creates quality prints every time. I can count the number of print fails from MK3 on one hand, and I have had it for nearly seven years. If you have the $800, you should buy one of these.

$800 at Prusa Research

James Bricknell / CNET

AnkerMake M5

Speed and quality combined

The AnkerMake M5 is a new breed of 3D printer. Its speed is unrivaled on this list and the quality of the end product is on par with anything I've seen. When you can get this quality level in a 3D print job in around half the time of its closest competitor, it's hard to recommend anything else for someone with the money to buy one.

Read our AnkerMake 5 review

$799 at AnkerMake

Dan Ackerman/CNET

Anycubic Vyper

Best for out-of-the-box printing

The Anycubic Vyper FDM printer attempts to be both an affordable 3D printer and easy to use. It's a tricky needle to thread. Plenty of 3D printers offer automatic bed leveling and calibration to make sure prints come out even and firmly anchored to the print bed. This, however, is the first time I've seen a 3D printer run its bed leveling once, with zero manual input from me, and be totally good to go. I printed a 3D test file from the included SD card within minutes of powering on, and I've never seen a first print from a 3D printer come out so perfectly.

It's a tricky needle to thread. Plenty of 3D printers offer automatic bed leveling and calibration to make sure prints come out even and firmly anchored to the print bed. This, however, is the first time I've seen a 3D printer run its bed leveling once, with zero manual input from me, and be totally good to go. I printed a 3D test file from the included SD card within minutes of powering on, and I've never seen a first print from a 3D printer come out so perfectly.

Read our Anycubic Vyper review.

$359 at Anycubic

Anycubic

Anycubic Kobra Max

Best to make big projects easily

The Anycubic Kobra Max earned a 9 out of 10 in our recent review, in large part because it's one of the most enjoyable printers I've used in years. The build area is large enough to print entire helmets for cosplay, and the auto-bed-leveling system makes setting the machine up a breeze. The Kobra Max is the best choice for a large build area printer, bar none.

The Kobra Max is the best choice for a large build area printer, bar none.

Read our Anycubic Kobra Max review.

$529 at Anycubic

Best 3D Printers for Beginners

These 3D printers are excellent for anyone just starting out in 3D printing. Check out our expanded list of the best budget 3D printers for more in this category.

Prusa Research

Prusa Mini Plus

Small but mighty

The Mini Plus is one of the best small-footprint printers you can buy. It has everything you would expect from a Prusa machine: Auto bed leveling, crash detection and great print quality, all for under $450. Building it with my son gave us a lot of good insights into how a 3D printer works, and potentially how to fix one.

$429 at Prusa Research

Sarah Tew/CNET

Anycubic Mono

Best inexpensive resin 3D printer

Resin printers are the next step up in rapid prototyping design technology when you want your printing to look as high quality as possible. Just be warned: The liquid resin is harder to work with, and it requires both good ventilation and a portable UV light to properly cure. This model is extremely popular with board game hobbyists who want to print pro-looking miniatures, and sometimes you'll see it fall in price. Note that you can save $20 at Amazon by activating the instant coupon on the product page.

Just be warned: The liquid resin is harder to work with, and it requires both good ventilation and a portable UV light to properly cure. This model is extremely popular with board game hobbyists who want to print pro-looking miniatures, and sometimes you'll see it fall in price. Note that you can save $20 at Amazon by activating the instant coupon on the product page.

$250 at Amazon

You're receiving price alerts for ANYCUBIC Photon Mono 4K, Resin 3D Printer with 6.23" Monochrome Screen, Upgraded UV LCD 3D Printer and Fast & Precise Printing, 5.19" x 3.14" x 6.49" Printing Size

Dan Ackerman/CNET

Monoprice Mini Delta V2

Best for tiny desks

I had high hopes for this dirt-cheap 3D printer with a tiny footprint. It's usually under $200 and requires no additional assembly. And I do like it, but it's for a specific audience. This is not the great low-cost entry-level printer I was hoping for. It required some tweaking and troubleshooting to get up and running. The included microSD card was so cheap and corrupted it never worked, the built-in Wi-Fi was never able to connect to my network, and the machine's arms got caught on some poorly installed plastic wire covers (I just ripped the paper-thin covers off).

This is not the great low-cost entry-level printer I was hoping for. It required some tweaking and troubleshooting to get up and running. The included microSD card was so cheap and corrupted it never worked, the built-in Wi-Fi was never able to connect to my network, and the machine's arms got caught on some poorly installed plastic wire covers (I just ripped the paper-thin covers off).

But once I had all the problems ironed out, it was a reliable little machine for quick jobs. It would make a great second 3D printer, or if you need to fit one into a small space. I especially liked the auto-leveling, which worked well, and the color touchscreen, which is a feature that often gets chopped from low-cost models. If you're willing to put a little effort into getting it set up correctly, it's a great printer for the price.

$180 at Amazon

Midrange 3D printers

James Bricknell / CNET

Elegoo Saturn 2

The best resin experience right now

The Elegoo Saturn 2 is an almost perfect upgrade from the original Saturn. It is bigger and more powerful, with better quality prints than its predecessor and my No. 1 choice for a midrange resin 3D printer. If you are looking to print serious details or a lot of tiny models, this is simply the best choice. It's $671 on Amazon, but you can get it for $60 off when you apply a coupon at checkout.

It is bigger and more powerful, with better quality prints than its predecessor and my No. 1 choice for a midrange resin 3D printer. If you are looking to print serious details or a lot of tiny models, this is simply the best choice. It's $671 on Amazon, but you can get it for $60 off when you apply a coupon at checkout.

$671 at Amazon

You're receiving price alerts for ELEGOO Saturn 2 8K MSLA 3D Printer, UV Resin Photocuring Printer with 10-inch 8K Monochrome LCD, 8.62x4.84x9.84 Inch Larger Printing Size

James Bricknell/CNET

Flashforge Adventurer 4

Best 3D printer for ease of use

The Flashforge Adventurer 3 has long been one of CNET's favorite midprice 3D printers. The updated Adventurer 4 brings a handful of iterative improvements that make for a winning evolution. The Adventurer 4 is a fully enclosed unit, which helps control the temperature and block drafts. The build area is 220 by 200 by 250mm, and it has a system for easily swapping out nozzles -- all good features to have in a mid-level to high-end printer.

The build area is 220 by 200 by 250mm, and it has a system for easily swapping out nozzles -- all good features to have in a mid-level to high-end printer.

$749 at Amazon

You're receiving price alerts for Flashforge Adventurer 4

High-end and professional 3D printers

Creality

Creality CR-30

Best for small biz or pro cosplayers

A word of warning; the CR-30 is not for the beginners out there. It is a complicated machine, and you will need some 3D-printing knowledge to really get the hang of it. It's also a very different beast, and instead of printing on a static-sized build plate, it uses a conveyor belt to create an "endless Z-axis." That lets you print very long things or lots of things over and over again.

If you are a cosplayer looking to make weapons or large armor pieces, the CR-30 gives you a lot of room to create. I've managed to print Squall's Gunblade from Final Fantasy VIII as well as the Whisper of the Worm from Destiny 2 (both were printed in two halves and attached together). It's great for small businesses looking to mass-produce small parts, and with just two CR-30s you could create a small empire on Etsy or Shopify. --James Bricknell

It's great for small businesses looking to mass-produce small parts, and with just two CR-30s you could create a small empire on Etsy or Shopify. --James Bricknell

$1,100 at Amazon

You're receiving price alerts for Creality CR-30

Sarah Tew/CNET

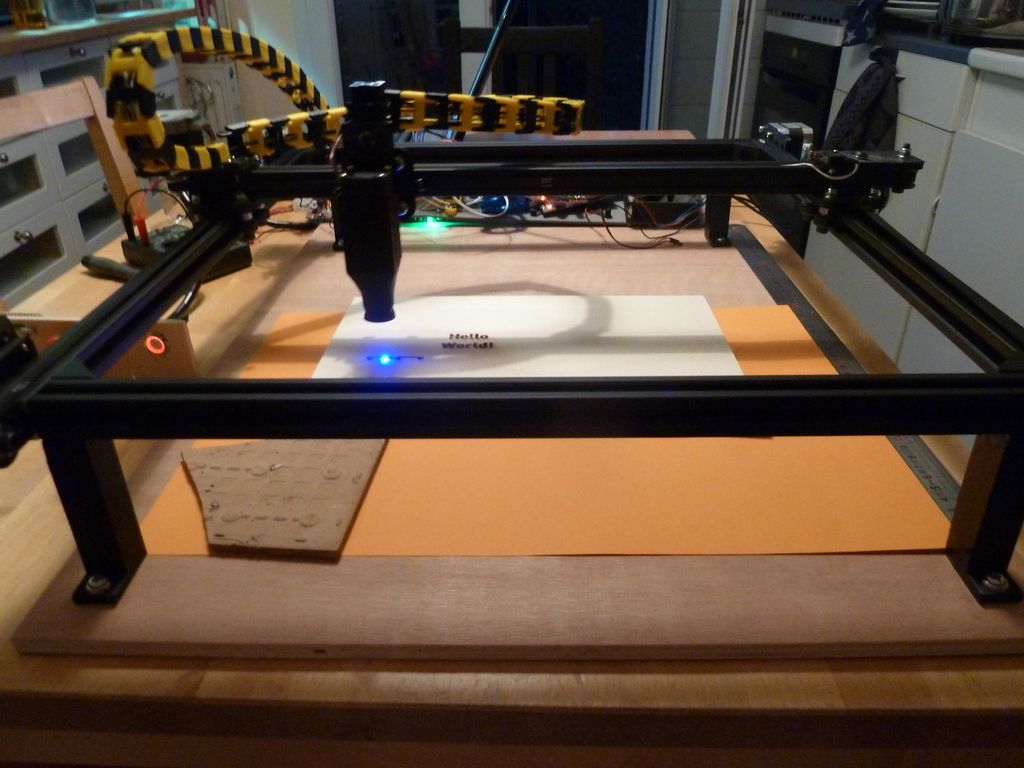

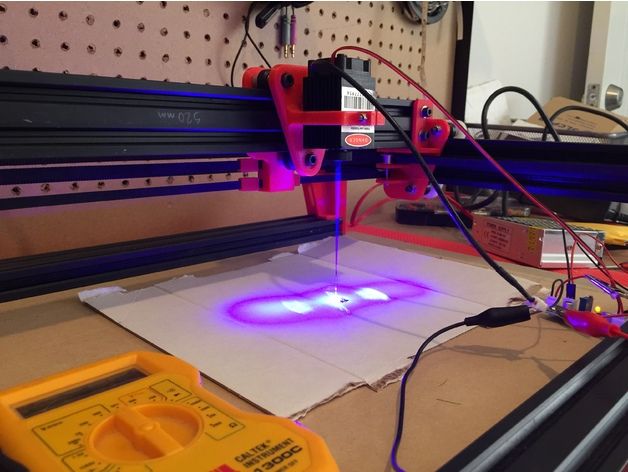

Glowforge 3D Laser Cutter

Best for woodworkers

I can't begin to tell you how much I love the Glowforge. Laser cutters can create projects from wood, leather, lucite and other materials, making it an interesting creation alternative to filament-based 3D printers. Even better, what would take a 3D printer hours to do takes just minutes in the Glowforge.

With it, I've created laser-etched LED lights, birch wood tool caddies, and even a three-tier box for my Nespresso sleeves. There's a robust community of makers creating and sharing files, but pretty much any line drawing you can create in something like Adobe Illustrator can be turned into a project.

The software is all cloud-based, which adds a layer of complication (you need internet service to use it), but the ability to create amazing gifts and more from simple 0.125-inch or 0.25-inch cheap plywood is pretty empowering.

See some of my laser cutter projects (and download my SVG files) here.

$3,995 at Glowforge (Glowforge Basic)

$4,995 at Glowforge (Glowforge Plus)

3D Scanners

Revopoint

Revopoint Pop 2

Incredible details

While the software has a pretty steep learning curve, the end result is extremely detailed. I've really enjoyed using the handheld version to scan larger models while the included turntable makes scanning smaller objects a breeze. If you are looking for a professional-grade scanner and can spend some time on the software, the Pop 2 is a great choice.

$669 at Amazon

You're receiving price alerts for Revopoint Pop 2

Sarah Tew/CNET

SOL Desktop Laser 3D Scanner

Best 3D scanner for easy replicas

Recreate pretty much anything by putting it on this 3D scanner, where a rotating base and built-in camera create a 360-degree copy, which is then editable in any 3D program and printable on your 3D printer. Simply scan the object, import the scan into your slicing software for cleanup, and print. The included software alerts you of next steps in the printing process with either sound or texts. Scan quality and print resolution are great, and setup is easy, although you might want to clean up your 3D model a bit in a 3D software app after.

Simply scan the object, import the scan into your slicing software for cleanup, and print. The included software alerts you of next steps in the printing process with either sound or texts. Scan quality and print resolution are great, and setup is easy, although you might want to clean up your 3D model a bit in a 3D software app after.

$649 at Amazon

You're receiving price alerts for SOL Desktop Laser 3D Scanner

Black Friday deals 2022

Black Friday deals are here! Check often for CNET's coverage on the best Black Friday deals this season.

3D printing FAQs

What material should I use to print with?

Most home 3D printers use PLA or ABS plastic. Professional printers can use all sorts of materials, from metal to organic filament. Some printers use a liquid resin, which is much more difficult to handle. As a beginner, use PLA. It's nontoxic, made mostly of cornstarch and sugarcane, handles easily and is inexpensive. However, it's more sensitive to heat, so don't leave your 3D prints on the dashboard of a car on a hot day.

Which brand of PLA is best?

Generally speaking, Hatchbox has never let me down and runs about $25 for a full 1kg spool on Amazon. Some of the printers I tested only accommodate narrower 0.5kg spools. In those cases, I sometimes used a larger Hatchbox roll with a separate spool-holder. Other times, I had good luck with AIO Robotics 0.5kg spools, which are a little more expensive, at $14 for 0.5kg. Amazon Basics and Monoprice can also be good, but for any brand, weird colors like metallic or glow-in-the-dark filament can be hit-or-miss. Note that a 1kg roll prints a lot of stuff.

What settings should I use?

Most 3D printers include or link to recommended software, which can handle converting 3D STL or other files into formats supported by the printer. Stick with the suggested presets to start, with one exception. I've started adding a raft, or bottom layer of filament, to nearly everything I print. It has cut down dramatically on prints that don't adhere to the bed properly, which is a common issue. If you continue to have problems, rub a standard glue stick on the print bed right before printing.

If you continue to have problems, rub a standard glue stick on the print bed right before printing.

What are supports?

Your 3D models probably need some help to print properly, as these printers don't do well with big overhangs -- for example, an arm sticking out from a figure. Your 3D printer software can usually automatically calculate and add supports, meaning little stands that hold up all those sticking-out parts of the model. After the print is done, clip the supports off with micro cutters and file down any nubs or rough edges with hobby files.

Where do I find things to print?

Thingiverse.com is a huge online repository of 3D files for anything and everything you can think of. Pokemon chess set? It's there. Dyson vacuum wall mount? You bet.

When you're ready to create your own designs, there are a ton of software packages to choose from, but it's easiest to start with the browser-based free TinkerCad app from Autodesk.

Crazy things I've made on a 3D printer

+15 more See all photosMore creative recommendations

- Best 3D Printer Filament

- Best Budget 3D Printer

- Best Laptops, Desktops and Tablets for Designers and Creatives in 2022

- Best Vlogging Camera for 2022

- The Best 3D Printer Resin

Guide to Resin 3D Printers

There are many 3D printing processes on the market. Getting familiar with the nuances of each helps to clarify what you can expect from final prints to ultimately decide which technology is suitable for your particular application.

Getting familiar with the nuances of each helps to clarify what you can expect from final prints to ultimately decide which technology is suitable for your particular application.

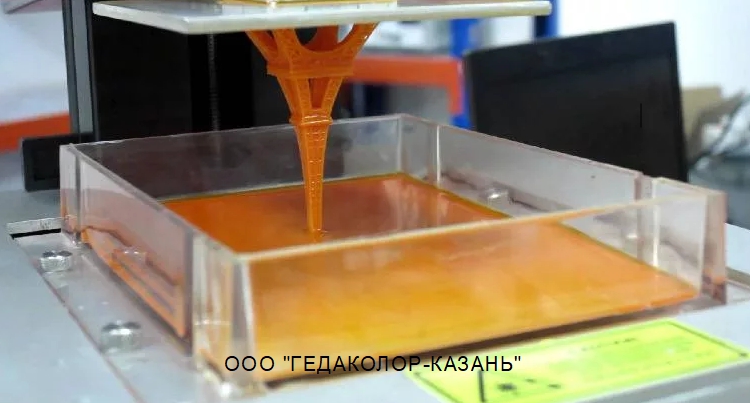

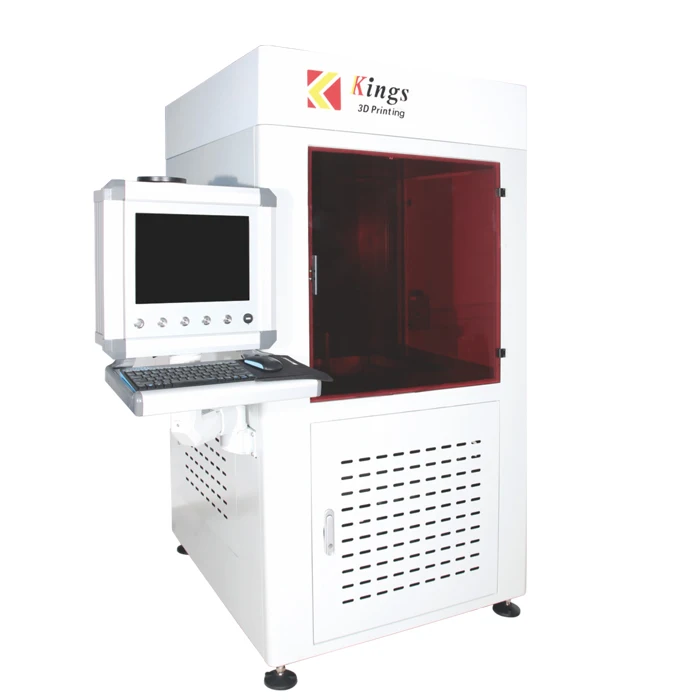

Stereolithography (SLA) and digital light processing (DLP) 3D printing are the two most common processes for resin 3D printing. Resin printers are popular for producing high-accuracy, isotropic, and watertight prototypes and parts in a range of advanced materials with fine features and smooth surface finish.

While these technologies were once complex and cost-prohibitive, today’s small-format desktop SLA and DLP resin 3D printers produce industrial-quality parts at an affordable price point and with unmatched versatility thanks to a wide range of materials.

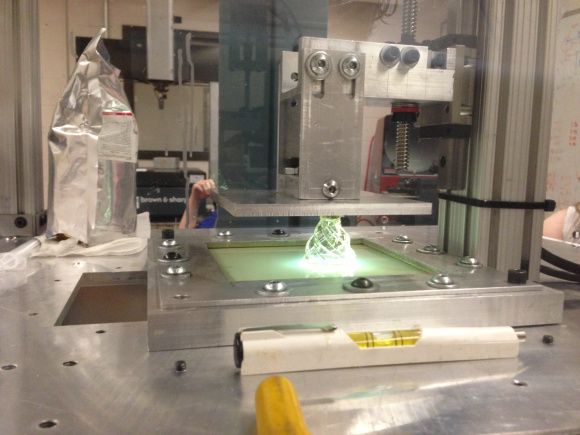

Both processes work by selectively exposing liquid resin to a light source—SLA a laser, DLP a projector—to form very thin solid layers of plastic that stack up to create a solid object. While very similar in principle, the two technologies can produce significantly varying outputs.

In this in-depth guide, we walk through the details of the two resin 3D printing processes and explore how they compare in terms of resolution, accuracy, build volume, speed, workflow, and more.

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

Desktop SLA 3D printers contain a resin tank with a transparent base and non-stick surface, which serves as a substrate for the liquid resin to cure against, allowing for the gentle detachment of newly-formed layers.

The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or the last completed layer, and the bottom of the tank. A laser points at two mirror galvanometers, which direct the light to the correct coordinates on a series of mirrors, focusing the light upward through the bottom of the tank and curing a layer of resin.

The cured layer then gets separated from the bottom of the tank and the build platform moves up to let fresh resin flow beneath. The process repeats until the print is complete.

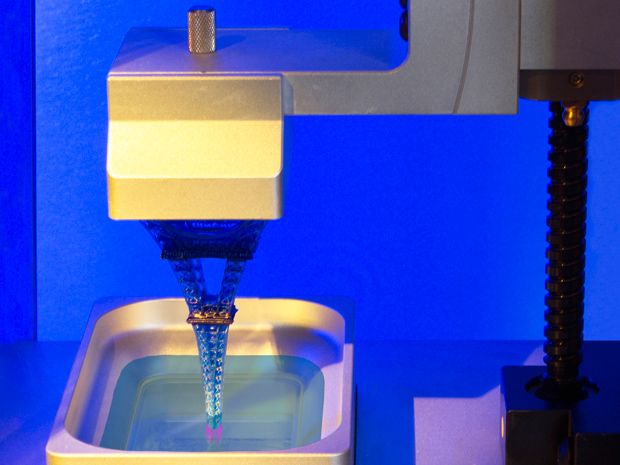

Low Force Stereolithography (LFS) technology, used by the Form 3+ and Form 3L, is the next phase in SLA 3D printing.

In LFS 3D printers, the optics are enclosed in a Light Processing Unit (LPU). Within the LPU, a galvanometer positions the high-density laser beam in the Y direction, passes it through a spatial filter, and directs it to a fold mirror and parabolic mirror to consistently deliver the beam perpendicular to the build plane and ensure accurate, repeatable prints.

As the LPU moves in the X direction, the printed part is gently peeled away from the flexible bottom of the tank, which drastically reduces the forces exerted on parts during the print process.

LFS 3D printing drastically reduces the forces exerted on parts during the print process, using a flexible tank and linear illumination to deliver incredible surface quality and print accuracy.

This advanced form of stereolithography delivers vastly improved surface quality and print accuracy. Lower print forces also allow for light-touch support structures that tear away with ease, and the process opens up a wide range of possibilities for future development of advanced, production-ready materials.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

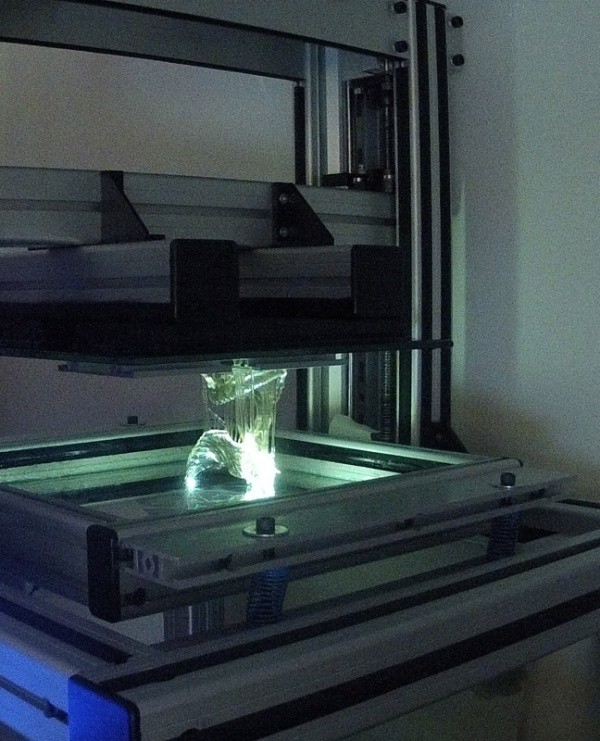

Just like their SLA counterparts, desktop DLP 3D printers are built around a resin tank with transparent bottom and a build platform that descends into a resin tank to create parts upside down, layer by layer.

The difference is the light source. DLP 3D printers use a digital projector screen to flash an image of a layer across the entire platform, curing all points simultaneously.

The light is reflected on a Digital Micromirror Device (DMD), a dynamic mask consisting of microscopic-size mirrors laid out in a matrix on a semiconductor chip. Rapidly toggling these tiny mirrors between lens(es) that direct the light towards the bottom of the tank or a heat sink defines the coordinates where the liquid resin cures within the given layer.

Because the projector is a digital screen, the image of each layer is composed of square pixels, resulting in a three-dimensional layer formed from small rectangular cubes called voxels.

Resolution shows up more often than any other value in 3D printer spec sheets, but it’s also a common ground for confusion. The basic units of the SLA and DLP processes are different shapes, making it difficult to compare the different machines by numerical specifications alone.

In 3D printing, there are three dimensions to consider: the two planar 2D dimensions (X and Y) and the third vertical Z dimension that makes 3D printing.

Z resolution is defined by the layer thicknesses a 3D printer can produce. Resin 3D printers like SLA and DLP offer some of the finest Z resolutions—thinnest layers—of all 3D printing processes and users can normally choose from a range of layer height options between 25-300 microns, allowing designers to strike a balance between detail and speed.

In DLP 3D printing, XY resolution is defined by the pixel size, the smallest feature the projector can reproduce within a single layer. This depends on the resolution of the projector, the most common being full HD (1080p), and its distance from the optical window. As a result, most desktop DLP 3D printers have a fixed XY resolution, generally between 35 to 100 microns.

For SLA 3D printers, XY resolution is a combination of the laser’s spot size and the increments by which the laser beam can be controlled. For example, the Form 3 LFS 3D printer features a laser with an 85 micron spot size, but because of the constant line scanning process, the laser can move in smaller increments and the printer can consistently deliver parts with 25 micron XY resolution.

However, resolution in itself is often just a vanity metric. It offers some indication, but it doesn’t necessarily correlate directly with accuracy, precision, and print quality.

Learn more about resolution in 3D printing in our in-depth guide.

Because 3D printing is an additive process, each layer introduces an opportunity for inaccuracy, and the process by which layers are formed affects the level of precision, defined as the repeatability of the accuracy of each layer. Accuracy and precision depend on many different factors: 3D printing process, materials, software settings, post-processing, and more.

In general, both SLA and DLP resin 3D printers are among the most accurate and precise 3D printing processes. Differences in accuracy and precision are often better explained by the differences between machines by various manufacturers than differences between the technologies themselves.

For example, entry-level SLA or DLP printers might use off-the-shelf projectors, lasers, or galvanometers, and their manufacturers will try to get the best performance possible out of these parts. Professional SLA and DLP 3D printers, like the Formlabs Form 3, feature a custom optical system adapted to the specifications required by professional customer applications.

Professional SLA and DLP 3D printers, like the Formlabs Form 3, feature a custom optical system adapted to the specifications required by professional customer applications.

Accuracy and precision are crucial for parts like dental splints (left) and surgical guides (right).

Calibration is also crucial. With DLP projectors, manufacturers need to deal with the non-uniform light distribution on the build plane and optical distortion of the lenses—meaning that pixels in the middle are not the same size or shape as pixels on the edges. SLA 3D printers use the same light source for every part of the print, which means it’s uniform by definition, but they still require extensive calibration to account for distortions.

Even a 3D printer with the highest quality components and degree of calibration can produce widely varying results depending on the material. Different resins require optimized material settings to perform as intended, which might not be available for off-the-shelf materials or resins that are not thoroughly tested with a specific 3D printer model.

The takeaway? Accuracy and precision are almost impossible to understand from the technical specifications alone. Ultimately, the best way to evaluate a 3D printer is to inspect real parts or ask the manufacturer to create a test print of one of your own designs.

With DLP 3D printers, there’s a direct trade-off between resolution and build volume. The resolution depends on the projector, which defines the number of pixels/voxels available. If one moves the projector closer to the optical window, the pixels get smaller, which increases the resolution, but limits the available build area.

Some manufacturers stack multiple projectors next to each other or use a high-definition 4K projector to increase the build volume, but this leads to substantially higher costs that often price these machines out of the desktop market.

As a result, DLP 3D printers are generally optimized for specific use cases. Some have a smaller build volume and offer high resolution to produce small, detailed pieces like jewelry, while others can produce bigger parts but at a lower resolution.

The stereolithography process is inherently more scalable, since an SLA 3D printer’s build volume is completely independent of the resolution of the print. A single print can be any size and any resolution at any location within the build area. This makes it possible to 3D print large parts at high resolution or a large batch of detailed small parts to increase throughput with the same machine.

The other main barrier to increasing build volume in both SLA and DLP 3D printers is the peel force. When printing larger parts, the forces exerted on the parts increase exponentially as a cured layer separates from the tank.

In LFS 3D printing, the flexible film at the base of the resin tank gently peels away as the build platform pulls the part up, significantly reducing the stress on the part. This unique feature has made it possible to substantially increase the build volume for the first accessible large format SLA 3D printer, the Form 3L.

The Form 3L is the first affordable large format SLA 3D printer with a build volume of 30 cm x 33. 5 cm x 20 cm.

5 cm x 20 cm.

Webinar

Want to learn more about the Form 3L and Form 3BL ecosystem, and the new large format post-processing machines?

In this demo, Kyle and Chris will expain how to navigate the Form 3L end-to-end workflow, including post-processing.

Watch Now

SLA and DLP resin 3D printers both known for creating parts with the smoothest surface finish of all 3D printing processes. When we describe the differences, in most cases these are only visible on tiny parts or highly detailed models.

Because objects are made of layers in 3D printing, 3D prints often have visible, horizontal layer lines. However, because DLP renders images using rectangular voxels, there is also an effect of vertical voxel lines.

DLP 3D printers render images using rectangular voxels, which causes an effect of vertical voxel lines. In this image, see the vertical voxel lines as they appear naturally on the left, and then outlined to more easily identify on the right.

Because the unit is rectangular, voxels also have an effect on curved edges. Think of building a round shape out of LEGO bricks—the edges will appear stepped on both the Z axis and the X-Y plane.

The rectangular shape of voxels makes curved edges appear stepped. Removing the appearance of voxel and layer lines requires post-processing, such as sanding.

In LFS 3D printing, layer lines are close to invisible. As a result, surface roughness is reduced, which ultimately leads to smooth surfaces, and for clear materials, more translucent parts.

When thinking about speed in 3D printing, it’s important to consider not just raw print speed, but also throughput.

Raw print speed for SLA and DLP resin 3D printers is comparable in general. As the projector exposes each entire layer all at once, print speed in DLP 3D printing is uniform and depends only on the height of the build, whereas, SLA 3D printers draw out each part with a laser. As a rule of thumb, this results in SLA 3D printers being comparable or faster when printing small or medium-size single parts, while DLP 3D printers are faster to print large, fully dense prints, or builds with multiple parts that fill up much of the platform.

But once again, it’s worth considering the trade-off between resolution and build volume for DLP printers. A small DLP 3D printer can print a small part or a (small) batch of smaller parts fast, at high resolution, but the build volume limits the part size and the throughput. A different machine with a larger build volume can print larger parts or a batch of smaller parts faster, but at a lower resolution than SLA.

SLA 3D printers can produce all of these options in one machine and offer the user the freedom to decide whether she wants to optimize for resolution, speed, or throughput.

SLA 3D printers offer a larger build volume, allowing users to batch parts and print overnight to increase throughput.

Speed can also depend on the material choice. Printing four times faster than Formlabs standard materials, Draft Resin fast-printing resin that is ideal for initial prototypes, rapid iterations, as well as dental and orthodontic models. From fast print initiation speeds to minimal support removal, wash, and cure times, Draft Resin has an optimized workflow to truly maximize efficiency.

100 microns | 200 microns |

|---|---|

100 microns | 200 microns |

|---|---|

100 microns | 200 microns |

|---|---|

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

Just like with accuracy and precision, the workflow and available materials differ more from machine to machine than technology to technology.

Most SLA and DLP 3D printers are “plug and play,” with easily swappable build platforms and resin tanks. Some more advanced models also come with a cartridge system to automatically refill the tank with liquid resin, which requires less attention and facilitates printing overnight.

Some printers come with proprietary software to prepare 3D models for printing, such as PreForm for Formlabs SLA 3D printers, while other manufacturers offer off-the-shelf solutions. Features differ by software tool, for example, PreForm offers one-click print setup, powerful manual controls to optimize support density and size, adaptive layer thickness, or functions to save material and time. Luckily, the software can be easy to download and test before purchasing a 3D printer.

Resin 3D printers offer a variety of materials for a wide range of applications.

One of the most significant benefits of resin 3D printing is the variety of materials that make it possible to create parts for diverse applications. Resins can feature a wide range of formulation configurations: materials can be soft or hard, heavily filled with secondary materials like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance.

Resins can feature a wide range of formulation configurations: materials can be soft or hard, heavily filled with secondary materials like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance.

However, the range of supported material options depend on the 3D printer model, so we recommend inquiring with the manufacturer before purchase.

Parts printed with both SLA and DLP technologies require post-processing after printing. First, the parts need to be washed in a solvent to remove excess resin. Some functional materials like engineering or biocompatible parts also require post-curing. For SLA 3D printers, Formlabs offers solutions to automate these steps, saving time and effort.

At last, 3D printed parts printed on supports require these structures to be removed, a manual process that is similar for both SLA and DLP 3D printers. LFS 3D printing simplifies this step by offering light-touch support structures that use very small touchpoints to enable easy removal with minimal support marks left behind.

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Recommend Me a Material

After sorting out the differences in technology and outcomes, we hope it’s much easier to select a resin 3D printer that best matches your workflow and output needs.

To explore the next generation of SLA 3D printing, learn more about the Form 3 and Form 3L LFS 3D printers.

Curious to see the quality firsthand? Order a sample part shipped to your office.

Request a Free Sample Part

| 3DNews Technologies and IT market. The most interesting in the reviews 12/01/2021 [12:43], Gennady Detinich Today, we are not surprised by compact laser printers, although in the early days of technology and for many years after the introduction of laser printers into the market, laser printers were surprising in size and weight. The situation is similar with laser 3D printing. These are high-precision additive modeling devices, but the dimensions of the devices remain relatively large - about the size of a voluminous suitcase or so. New German technology will help reduce such printers to the size of a shoebox. On the left is an image of a 3D printed structure under an electron microscope, on the right - under an optical one. Image Source: Professor Rasmus Schröder, University of Heidelberg, Vincent Hahn, KIT Modern laser printing as part of a 3D printer is a complex optical system that, in a pulsed femtosecond pulse mode, causes the chemical polymerization of a material at a focal point. Scientists in the journal Nature Photonics published an article in which they talked about the innovative design of a laser printer head for 3D printing with nanoscale precision. In a conventional laser 3D printer, the polymerization of a light-sensitive liquid occurs when two photons simultaneously excite a molecule of the liquid - this is the so-called two-photon absorption. In order for the two-photon (simultaneous) absorption reaction to occur, the laser system must be complex, matched, and therefore unwieldy. German scientists proposed to divide the excitation of light-sensitive liquid molecules into two stages and perform them in turn, which would radically reduce the laser head and the design of the 3D printer. In particular, researchers at the Karlsruhe Institute of Technology (KIT) and the University of Heidelberg have proposed a two-stage absorption that works with inexpensive and small blue laser diodes. The first photon transfers the molecule to an intermediate state. At the second stage, the second photon transfers the molecule from the intermediate state to the desired excited state and starts the chemical reaction. Absorption of two photons does not have to occur simultaneously, which was the key to the breakthrough. “Compact and low-power CW laser diodes, , can be used for this process,” said Vincent Hann, first author of the study at KIT's Institute of Applied Physics (APH). - The laser power required is much lower than conventional laser pointers. However, not everything is so simple. The breakthrough would not have been possible without the development of a new composition of photosensitive fluid. The new composition of the liquid was developed for several years together with chemists, until the desired result was obtained. “In my opinion, in the coming years it is possible to create a device the size of a shoe box. It will be even smaller than the laser printer on my desktop at KIT, - said another author of the work, Professor Martin Wegener. Source: If you notice an error, select it with the mouse and press CTRL+ENTER. Related materials Permanent URL: News Hardware, nanotechnology, printers, print servers, scanners, copiers, MFPs, on the cutting edge of science, 3D technologies, Tags: 3d printing, nanotechnology, scientists ← В past To the future → |

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- Overview of SLA materials

- SLA standard resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Biocompatibility class I vs biocompatibility class IIa

- Cast SLA resins

- Cast resin for jewelry making

- Generalized rules flexible ) , dental ( dental ) and castable ( castable ) .

The information from the article will help you choose a photopolymer resin for your needs.

The information from the article will help you choose a photopolymer resin for your needs. Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

Stereolithography allows you to print plastic parts with high resolution, good fine detail and smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries:

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning.

SLA 3D Printing Resin Overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - StandardStandard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface.

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (similar to ABS)Tough resin was developed for models that need to withstand high loads and be durable.

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes.

Refractory Photopolymer Resin - Formlabs High Temp ResinThe heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance.

Pros:

Cons:

Flexible ResinRubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips.

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping.

Ceramic photopolymer resin - Rigid ResinThis resin is reinforced with glass, which provides very high rigidity and a polished surface.

The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

The polymer is very resistant to deformation and is excellent for 3D printing thin elements. Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models.

Durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material.

Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon. tough ( tough ) resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness.

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o C, but has poor toughness and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity.

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media.

Image courtesy of Formlabs.

Image courtesy of Formlabs. Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs

Comparative chart of material properties of various technical resins. Image credit: Formlabs.

Dental and medical resins

Photopolymer resin for medical devices - Custom Medical Appliances 9 Class 1 biocompatible resins can be used to make medical equipment such as surgical guides. Parts printed on this resin can be steam sterilized in an autoclave for direct use in the operating room.Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A Biocompatible)These resins are specially formulated for long term dental fixtures.

Class 2A biocompatible resins can come into contact with the human body for up to a year.

Class 2A biocompatible resins can come into contact with the human body for up to a year. High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resinsThis material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.

Learn more

-

News printers, print servers, scanners, copiers... German scientists figured out how to make 3...

News printers, print servers, scanners, copiers... German scientists figured out how to make 3...  The large dimensions and prohibitive high cost of such printers do not allow them to become a product for widespread use. Can this be changed? Quite, said researchers from the German profile cluster 3D Matter Made to Order.

The large dimensions and prohibitive high cost of such printers do not allow them to become a product for widespread use. Can this be changed? Quite, said researchers from the German profile cluster 3D Matter Made to Order.

- Thus, laser 3D nanoprinters can become affordable for many populations. Experts are already talking about the democratization of laser 3D printing technology.”

- Thus, laser 3D nanoprinters can become affordable for many populations. Experts are already talking about the democratization of laser 3D printing technology.”