3D printer items

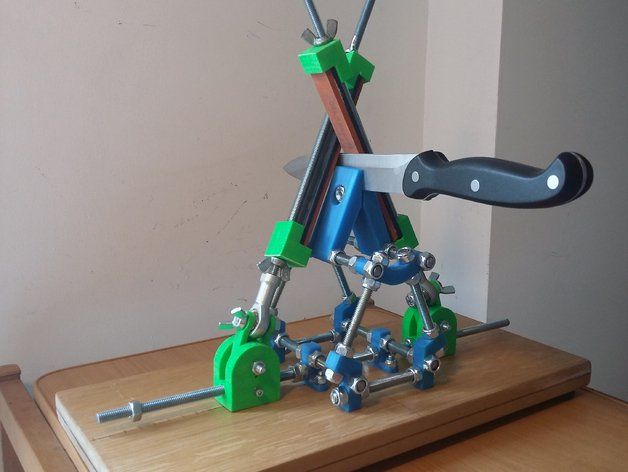

67 Cool Things to 3D Print

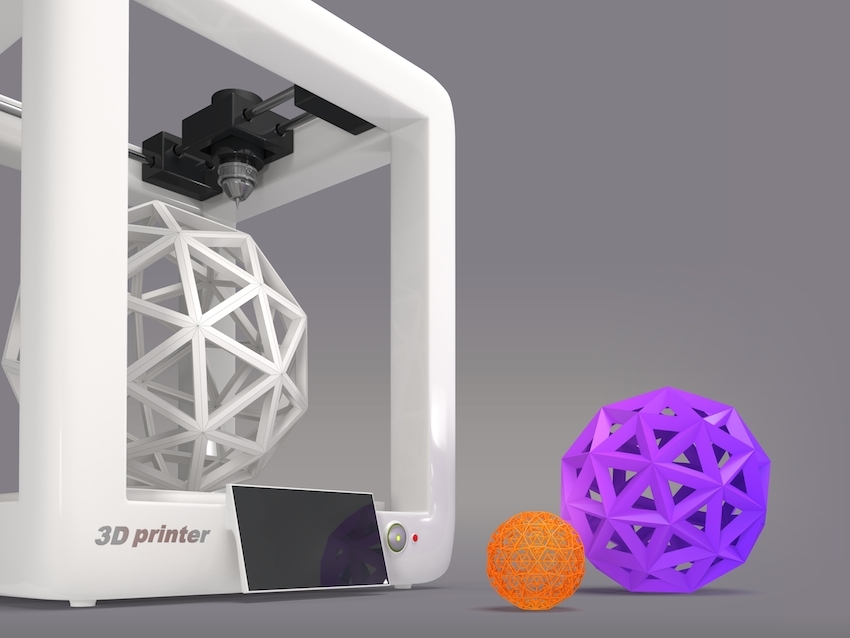

3D printing is such a fun way to produce creative work—and it has totally taken off. Now, creators are using this amazing new technology to create all kinds of wild and wonderful 3D printer projects that were previously all but impossible to make at home.

These 3D printer projects are a great addition to your online design portfolio. This is such a hot space that shows your mastery of this chic craft could win you some big new clients. You can showcase a collection of cool things to 3D print and some of your best 3D printings too.

Want to get in on this cool 3D prints trend? We’ve compiled a list of 67 inspiring 3D printing ideas to fuel your next 3D printer design. So, what can you make with a 3D printer? Well, there’s something cool for everyone!

Next in our list of cool things to 3D print is a simple project that can be completed in approximately one hour and will produce a whistle. It can produce an eye-popping 118db sound, perfect for camping or sporting events.

If there’s one thing we can all agree on, it’s that earbud cords are a pain in the butt to keep organized. They constantly get tangled and eventually produce the dreaded earphone-crackle, rendering your treasured music-makers useless. This is a great example of what you can make with a 3D printer that can improve your everyday life.

A simple toy originally created for Settlers of Catan, this project is durable and (in our opinion) cute. This is one of those 3D printer projects you could use in a few ways: gaming, office desk decoration, children’s toy, you name it! Plus, T-Rexes are (always!) cool.

Organize your desk, and add a little flair at the same time! With these simple 3D printer designs, you’ll have all you need to generate truly unique desktop organizers that not only keep your stuff where it needs to be but look cool as well. You can 3D print a pencil holder that is unique to your own personality and have others mistaking your pencil holders again.

You can 3D print a pencil holder that is unique to your own personality and have others mistaking your pencil holders again.

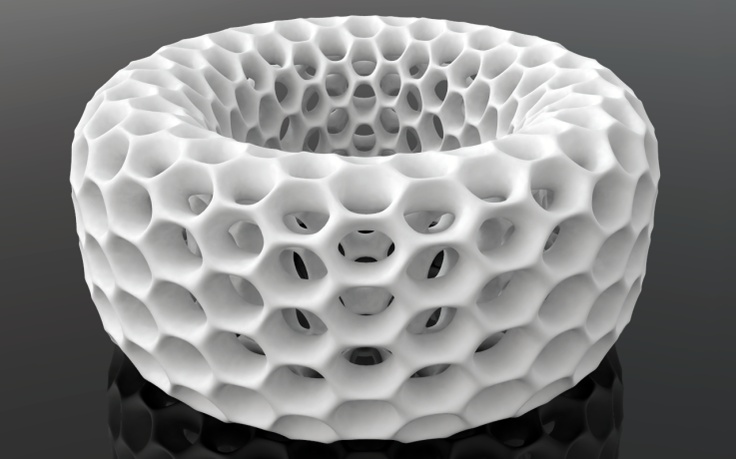

With a 3D printer you’ll be able to replace your dinnerware with new and original 3D printer designs in no time at all. Take this blueberry-themed bowl, for example. Why stop there? There are numerous other designs for plates and bowls out there to make eating at home a unique experience.

One of the cool things to 3D print is an abstract planter for your succulents and cacti. Why use traditional planters to hold your plants? There are cool 3D prints out there that don’t allow you to skip the traditional clay pots. These modular little guys are modern and fresh and guaranteed to make your mini-garden more attractive.

Get rid of those 72 measuring spoons from your utensil drawer and replace them all with a single implement! One of the most immediately useful and cool 3D prints in this list, it’ll make for an interesting tool that others will want when they see it.

Stop the tyranny of cords taking over your desk and entertainment unit and 3D print some space-saving cable management devices. You’ll cut back on desk clutter and all that cord-related aggravation. These are the blessed 3D printed objects that make life a little less annoying!

Nearly everyone these days has a smartphone, and we’ve likely all had moments where we wanted to prop up our phones for viewing video or photos and had to resort to piled books or whatever else is on hand. And it rarely works out as well as we hope! That makes this tiny project one of the coolest 3D printed objects on the list. Plus, they look like cats. Cats are good.

A perennial childhood favorite, kids love them just as much today. Of course, adults can enjoy these toys, too. They could be just the ticket to break through some creative block!

A truly inspiring 3D printing idea, these pop-out business cards allow you to speak to clients in a way they won’t have experienced many times (if ever) before! Rather than a drab piece of cardboard, hand them a toy they can assemble that speaks much louder than a traditional printed card.

Can’t sit still? Searching for a 3D printer project to help you focus? Look no further. Fidget spinners are an excellent way to occupy your mind, and this 3D printed object will definitely do the trick.

This is probably one of the most fun and cool things to 3D print, these gimmicky little toys are quite literally affixed to food items found in your house. A lemon helicopter? A banana-car? Why not! Easy to print and awesome for providing hours of enjoyment to restless rainy-day kiddos.

Definitely among the most interesting and cool things to 3D print in this list (and showcasing a bit more complexity than other entries), the dragonfly is a tiny little flying machine you can whip up in a short time. It’s perfect for providing a little entertainment for your kids on a rainy day.

Why settle for boring cutlery in your drawer? With minimal effort, you can produce some decorative handles for your eating utensils and wow visitors to your humble abode. When they inevitably ask “so, what can you print with a 3D printer?”, you can tell them they’re eating with it!

When they inevitably ask “so, what can you print with a 3D printer?”, you can tell them they’re eating with it!

Drop your phone into these useful little devices to amplify the sound from its speakers. They offer surprisingly high-quality sound—and now you don’t need to lug portable speakers around on picnics or at the beach.

If you’re looking for some more simple and cool 3D printing ideas, consider 3D printing a set of drink coasters. Thanks to simple 3D printer designs like this, we won’t need to spend our hard-earned cash on flimsy little discs anymore. Make your own coasters with whatever designs you want, and say goodbye to tacky freebies and over-priced novelty ones. This idea makes for one of the cool things to 3D print as gifts!

If you’re an audiophile, you’ll truly appreciate this entry as one of the best things to 3d print. By converting audio files, you can create your own records that will play on turntables. Why limit it to music? Record your own special messages to loved ones and send out the love!

By converting audio files, you can create your own records that will play on turntables. Why limit it to music? Record your own special messages to loved ones and send out the love!

Simple 3D printer designs like this are great to have on hand. Hinges are always useful, and come in handy all over the house. These particular designs are super-simple, even by 3D printing standards, requiring just a single step!

With a sliding clasp, these unique chip clip designs work quite well and are fantastically simple things to 3D print.

A larger-scale project than other 3D printing ideas, the Drawing Machine is quite unique: attach a pen and create works of art from files on your computer. This 3D printer project can help you produce invitations, cards or any other manner of drawings.

Some nostalgic old-timey engineering comes into play with these uber-neat 3D printing ideas. Relive the past and have your desk decorated with a sign that uses something other than LED or LCD displays!

Relive the past and have your desk decorated with a sign that uses something other than LED or LCD displays!

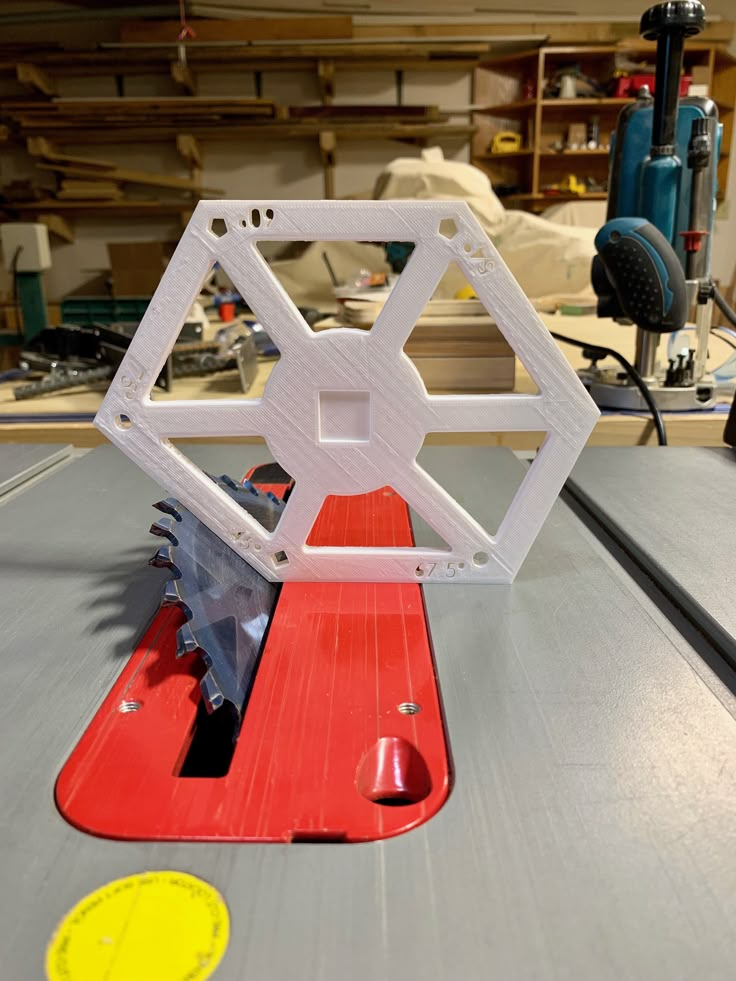

When it comes to 3D printing metal, there are people who may choose to use a laser cutter instead. The reason is that 3D printed projects using metal can be costly and time-consuming. However, the two are quite different. 3D printing is an additive process, while laser cutting is a subtractive process. Depending on your needs, those that are looking to create multiple pieces at a quicker pace may choose the laser cutter as it can conveniently cut multiple materials and larger size.

With digital trends of raw and rustic design, you might be considering 3D printing cool things at home with metal. However, printing metal is extremely costly due to its process and the machinery required. If you’re looking for cool things to 3D print at home with a metal-looking finish, we recommend using materials on the market that can create metal-like 3D printed objects instead. These materials give the illusion that your 3D printed pencil holder or camera mount is made out of metal but without the actual cost.

These materials give the illusion that your 3D printed pencil holder or camera mount is made out of metal but without the actual cost.

Thanks to 3D printing, it has also made highly-customizable prosthesis possible. One of the coolest things about 3D printed prosthesis is that they can create custom fits for the patient and also a much lower cost. Instead of creating static designs that are “one size fits all”, 3D print gives companies the opportunity to create products that are affordable and personalized. What would have cost lots of money to create is now more accessible thanks to 3D printed prostheses.

Beyond science, 3D printed homes and shelters have also become one of the cool things to 3D print across the world. To address the housing issue around the world, companies have been using this technology to print emergency shelters and 3D printed homes. With this technology, companies and cities can build a community in a much shorter amount of time and for a cost cheaper than traditional home building methods. Each home inside the community can then be purchased at a more affordable cost.

Each home inside the community can then be purchased at a more affordable cost.

If you love architecture and buildings, companies have created kits that allow people to replicate architectural structures and other cool things with a 3D pen. For boardgame lovers, you 3D print your own figurines by drawing it with your 3D pen. You can also turn your favorite cartoon show characters or movie heroes into 3D. While a 3D pen allows you to draw 2D things to 3D, their limitation tends to be the size of the project you can make. If you’re looking to 3D print a life-size chair, it may be easier to use a printer because 3D pens may not be able to create something as durable.

- Tangram: A super easy and fun game to play with your kids or friends. If you’re going on a road trip or simply trying to pass time, this 3D printed tangram makes for portable entertainment.

- Klöts (Quick shoe ties): Some cool things to 3D print for your kids are these quick shoe ties.

With this project, you’ll spend less time worrying about their shoelaces being undone and risking a fall.

With this project, you’ll spend less time worrying about their shoelaces being undone and risking a fall. - Puzzle Keychain: This heart puzzle is perfect as a gift or personal use. If you’re tight on schedule for an anniversary or valentine’s day gift, this heart puzzle is one of the quickest things to 3D print.

- Door Stop: Some things to 3D print for practical uses are these door stops. Whether you’re using it at home or for your office, printing them is super easy and fast.

- Light Switch Locks: This definitely tops for cool things to 3D print, especially for parents. This awesome tool can prevent your kids from turning the lights on and off at home. Keep certain lights off to save energy.

Ready to build a design portfolio website that captures clients’ attention? From gorgeous themes to a built-in proofing tool, we’ve got designers covered. Start your free trial with Format today!

Now get out there, get creative, and start turning heads with amazing 3D creations!

Need some more design project inspiration?

How to Start a Creative Project by ADAMJK

5 Ways to Fund Your Personal Project

10 Steps to Building Your Perfect Online Portfolio

15 Cool Things to 3D Print

Published on June 17, 2022 by Aysha M.

You know that we love to share STL files and ideas for you to print with your desktop 3D printer. Though many center on certain topics, like holidays or themes, this time we wanted to share with you some of the cool things to 3D print that we found for 2022. From useful tools to help you in your everyday life to incredible décor to fun projects for all geeks in your life, we have something for everyone. Check out our list below, divided into three categories (useful, decor, geek), and let us know what you think! Do note that in each description with you will the link to download the mostly STL files, both free and paid. Have fun and happy printing!

Useful Things

The 3D Printed Water Bottle Opener

I’m sure we all know the feeling. It’s a hot summer day and you just want a sip of water to relieve your parched throat, but the lid is screwed on too tight. However, with this next 3D printed gadget, you will no longer have to worry! This free STL file on Thingiverse from Terence Ang will allow you to unscrew even the hardest bottle caps thanks to its easy to hold shape and grippy edges. You can download it HERE.

You can download it HERE.

A Q-Tip Dispenser

Another useful object that you can’t miss on our list of cool things to 3D print is this Q-Tip dispenser. Now, with your 3D printer you can create this simple dispenser which can be installed on any sink. Its square shape is designed to be able to push the supply of cotton swabs through the upper opening and, as one is taken, the others come down, ready to be used. It also has a lid on the top to cover part of the dispenser and give a more aesthetic touch. If you want to make your own dispenser box, you can download the STL file from Thingiverse HERE.

A Cool Spaghetti Measurer Made With 3D Printing

Has it ever happened to you that you wanted to prepare spaghetti for one person and you go overboard with the quantity? Don’t worry, it happens to all of us. However, today we bring you the solution to the problem, with nothing more and nothing less than… a spaghetti measurer! Thanks to its design with various circumferences of different sizes, this object will allow you to measure the ideal portion of spaghetti according to the number of people who are going to eat it . If you have a 3D printer, you can now make this kitchen tool easily and simply. You can find the 3D file on the Thingiverse website HERE.

If you have a 3D printer, you can now make this kitchen tool easily and simply. You can find the 3D file on the Thingiverse website HERE.

A 3D Printed Laptop Stand

If you telecommute or spend time at home with a computer, you probably need a laptop stand. Laptop stands are accessories designed for two main functions: to place the computer in a more ergonomic position and to promote ventilation, a necessity when you start to feel your laptop’s fan overworking itself. There is a wide range of stands that fit any equipment: cooled bases, lecterns, fixed or height-adjustable, among other models. In recent years, the design and efficiency of laptop stands has improved enormously. HERE you can download an STL file which you can use to print your your very own computer stand.

Have A Better Snack with the Baby Yoda Cookie Holder

For the next useful tool on our list of cool things to 3D print, we bring you a tool that will turn snack time from ordinary to extraordinary. Who doesn’t know the famous Yoda from the Star Wars saga? Well this time this model is of Baby Yoda, or Grogu, the fan-favorite character of the Disney + The Mandalorian. The model is the perfect to put your favorite cookies before dipping them in milk. It is an easy to print piece, and can be printed in any size to fit the cookie you want. Of course, they recommend supports for the handle and base. Knowing you can can print your own very own Baby Yoda in resin, what are you waiting for? Download the STL file HERE.

Who doesn’t know the famous Yoda from the Star Wars saga? Well this time this model is of Baby Yoda, or Grogu, the fan-favorite character of the Disney + The Mandalorian. The model is the perfect to put your favorite cookies before dipping them in milk. It is an easy to print piece, and can be printed in any size to fit the cookie you want. Of course, they recommend supports for the handle and base. Knowing you can can print your own very own Baby Yoda in resin, what are you waiting for? Download the STL file HERE.

Cool Thing to 3D Print: A Baby Yoda Cookie Holder

Cool Decor to Print

The Industrial MONSTERA POT

The Monstera pot is the perfect solution if you are looking for a unique and personalized flower pot. 3D printed, it has a striking design and is much lighter than traditional flower pots. The Monstera can be designed without a support structure and has a square shape, so it can also be used by people looking for a pot with unusual dimensions. As its name suggests, it can obviously be used to plant monsteras, a popular, distinctive looking house plant. Find the model HERE.

Find the model HERE.

A Cool Minecraft Lamp You Can 3D Print

Here is the perfect decor for fans of Minecraft! On Thingiverse, the maker Iron_Harrier offers a lamp that is inspired by the famous video game. Composed of 4 different shades of gray, the lamp has 5 sides which must be printed separately and then assembled. The designer specifies however that they should not be glued to the base of the lamp. A Philips smart bulb multicolor is used as a light source. you can find the 3D model HERE!

A Distinctive and Fun 3D Printed Birdhouse

As summer is upon us, why not 3D print a little birdhouse to welcome your local feathered friends? That’s what designer PA1 is offering on the Cults website. The house in question is “tooned,” or made to look like a cartoon for all of you out there who are young or at least young at heart.To ensure that no mistakes are made during the printing process, the maker has also added various instructions on the marketplace to follow. For example, he explains that large parts can be made with a layer height of 0.3 to speed up the printing time and that there is no need to move the parts, they are all already placed in the right orientation. Finally, if this one is not to your taste, PA1 also offers two other models of birdhouses to be 3D printed! You can find the model HERE.

For example, he explains that large parts can be made with a layer height of 0.3 to speed up the printing time and that there is no need to move the parts, they are all already placed in the right orientation. Finally, if this one is not to your taste, PA1 also offers two other models of birdhouses to be 3D printed! You can find the model HERE.

A 3D Printed Dragon Egg

If you are passionate about all things fantasy, then this application will definitely please you! For the next on our cool things to 3D print list, we turn to maker DoritoMojito who, on the Thingiverse website, has made an STL file available which would allow you to 3D print your very own dragon egg. Available in three colors, blue, purple and green, it is possible to print the dragon egg from a 3D resin printer and using FDM machines. The designer says he used the 3D printer Photon from Anycubic. Modeled on Blender software, the dragon egg is the perfect application to decorate your home or to offer a gift to a fan of the famous Game of Thrones series. Do note, that thankfully no baby dragons will be harmed in the 3D printing process. You can find the model HERE.

Do note, that thankfully no baby dragons will be harmed in the 3D printing process. You can find the model HERE.

Miss Pac-Man Lamp

With the next offering on our list of cool things to 3D print, let’s take a trip next to our childhood, when we spent hours playing the classic arcade game Pac-Man. Now, you can re-experience the same joy with this Miss Pac-Man lamp that you can place in your home! Easy to 3D print and wire with LED ribbon, this lamp not only looks cool, but is sure to be a real head turner…. For the 3D printing of this file, the user needs white, red, black and blue filament colored filament in addition to the world-famous Pac-Man yellow, so that Miss Pac-Man can shine in all her glory. You can download the file HERE for about $3 on Cults3D.

3D Printed Things for Geeks

SU-33 Flanker-D Kit Card

This kit card of a Su-33 Flanker-D not only provides a lot of fun during 3D printing, but also during the subsequent assembly of the plane. For those who are perhaps unfamiliar, the Sukhoi Su-27K, which is apparently now known as the Su-33, NATO reporting name: Flanker-D, is a Su-27 modified for carrier-based operations was modified for carrier-based missions. According to the creator of the kit, PhabulousPhantom, it differs from the SU-27 as it has a strengthened airframe, an arrestor hook, folding wings and stabilizers. Now, if you also want to 3D print this plane, then you don’t need any support structures for this. Gray PLA is specified as the material to be used, and you should print with a layer height of 0.2 mm and a 100% fill. Also, due to the relatively tight fit, the use of adhesive is recommended. The file is available for download HERE.

For those who are perhaps unfamiliar, the Sukhoi Su-27K, which is apparently now known as the Su-33, NATO reporting name: Flanker-D, is a Su-27 modified for carrier-based operations was modified for carrier-based missions. According to the creator of the kit, PhabulousPhantom, it differs from the SU-27 as it has a strengthened airframe, an arrestor hook, folding wings and stabilizers. Now, if you also want to 3D print this plane, then you don’t need any support structures for this. Gray PLA is specified as the material to be used, and you should print with a layer height of 0.2 mm and a 100% fill. Also, due to the relatively tight fit, the use of adhesive is recommended. The file is available for download HERE.

A Tablet holder for Easier Drone Flights

In addition to being interesting to print, this tablet holder can be used in a variety of ways. For example, this piece can make drone flights much easier! Specifically, the tablet holder offers the possibility to attach a drone controller. And thanks to this, the drone pilot can fully concentrate on the flight. It is however important to print a solid filling in order to ensure the necessary stability. You can download the file HERE on Thingiverse.

And thanks to this, the drone pilot can fully concentrate on the flight. It is however important to print a solid filling in order to ensure the necessary stability. You can download the file HERE on Thingiverse.

A Super Mario Keychain

Nintendo’s Super Mario games are probably the most popular and well-known video games in the world. For many of us, Super Mario is a sweet reminder of the countless hours of fun we’ve spent playing the adventures of the famous Italian plumber. This simple and easy-to-print keychain is a perfect accessory, which can be carried anywhere and bring back childhood memories every time you take out your key. The main part and individual letters are printed separately and can be easily put together afterward. The simplicity of the keychain makes it especially suitable for 3D printing beginners. You can download the keychain HERE.

A 3D Printed Dungeon for Tabletop Games

Another on the list of the really cool things to print is this 3D printed dungeon. The simple yet stylish parts can be put together in any way desired, providing a perfect board for any dungeon-themed game of your choice. Especially for fans of tabletop RPG games like Dungeons and Dragons, this 3D printed dungeon is a perfect way to give your next game an authentic-looking setting for exciting playing sessions. You can download the dungeon HERE.

The simple yet stylish parts can be put together in any way desired, providing a perfect board for any dungeon-themed game of your choice. Especially for fans of tabletop RPG games like Dungeons and Dragons, this 3D printed dungeon is a perfect way to give your next game an authentic-looking setting for exciting playing sessions. You can download the dungeon HERE.

A 3D Printed Chessboard

Chess is one of the most known and played games in the world. No matter what your age, the strategy board game always manages to fascinate people and is without a doubt one of the best games ever invented. This 3D printed chess set has all you need to start playing the famous game. No matter if you want to play at home, use it to pass the time on a trip, or simply use it to put it on display somewhere, this chess set definitely is a cool thing to print for all chess fans out there. You can download the Chess set HERE.

What do you think about this list of cool things to 3D print? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

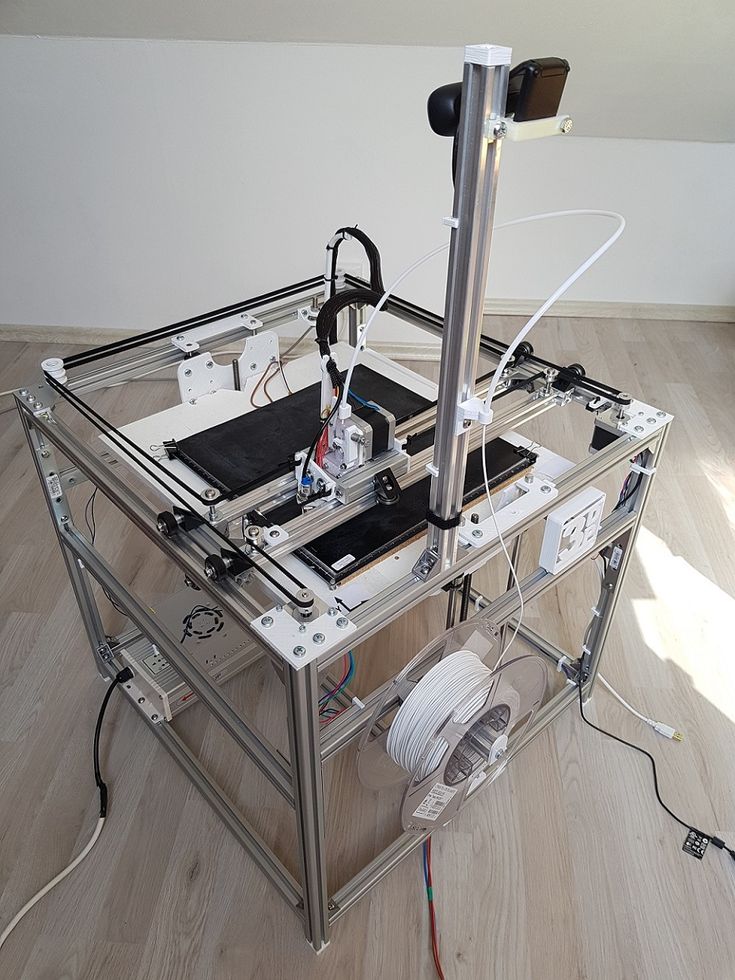

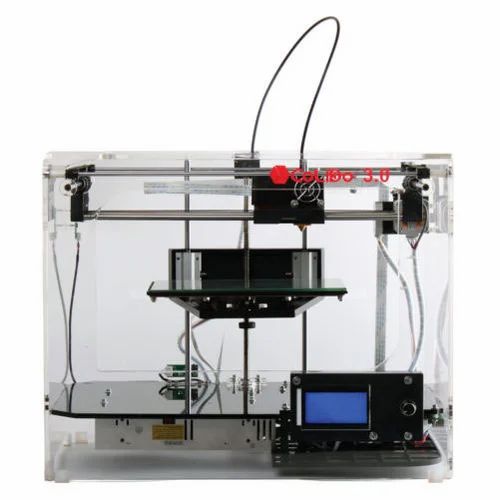

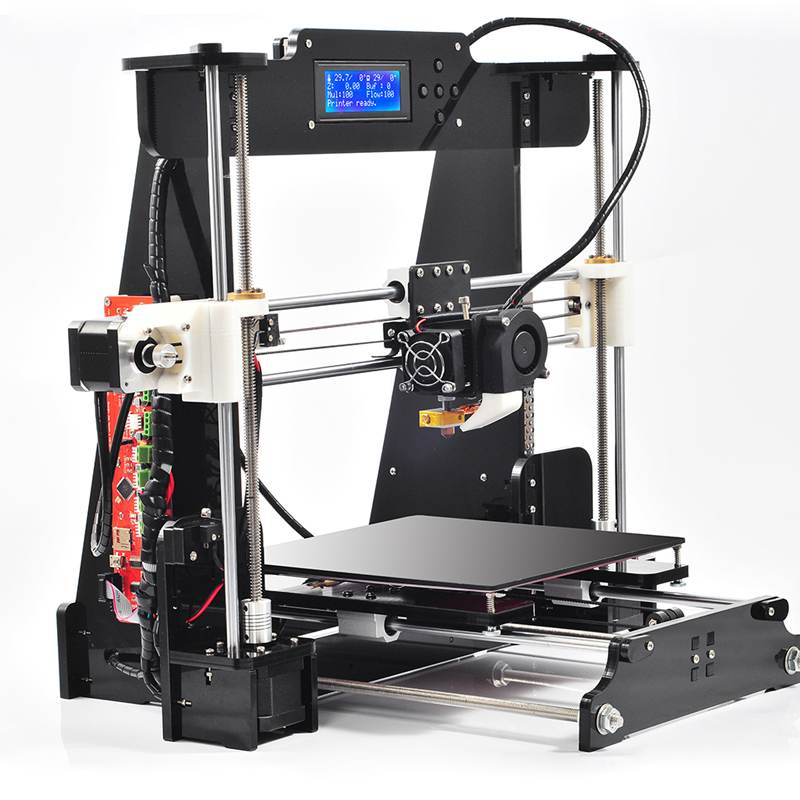

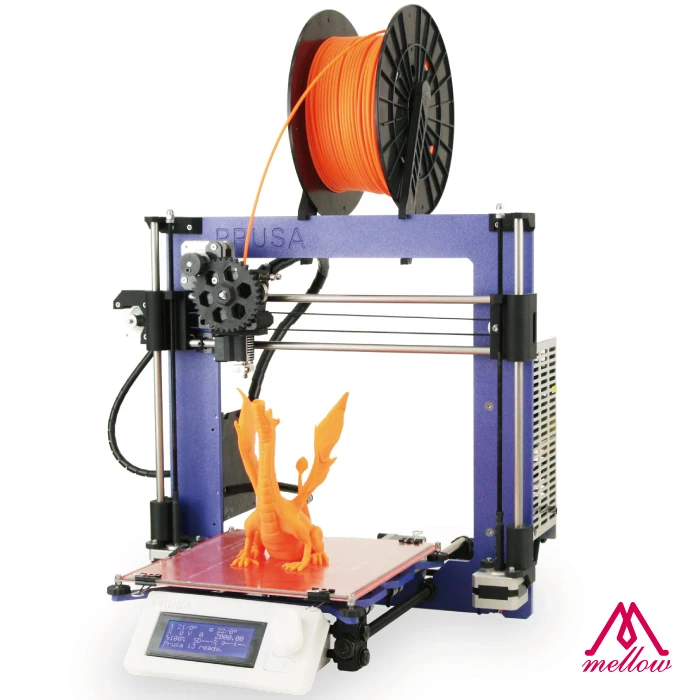

Design of FDM printers

Terminology, components, possible problems and ways to solve them

We have already considered FDM 3D printing technology in some detail ( Fused Deposition Modeling - layer-by-layer deposition or modeling by the deposition of a molten filament) and the consumables used materials, and also found out the reasons why FDM printers have become so common and popular today. Now it's time to get acquainted with the accepted terminology and consider the components and design features of such 3D printers.

Now it's time to get acquainted with the accepted terminology and consider the components and design features of such 3D printers.

Printhead: extruder and hot-end

The most important part of any printer, be it inkjet 2D or Fused Deposition Modeling 3D, is the printhead. In this case, it consists of a heater in which a plastic thread (sometimes not a thread, but a rod) is melted and then squeezed out through a nozzle with a small diameter hole - usually in the range of 0.15–0.5 mm, as well as a mechanism that provides dosed filament supply to the heater. The feed mechanism is usually called an extruder (from the English extrude - to push out, i.e. extruder - a pusher), and a heater with a nozzle is called a hot-end (hot-end; by analogy, the extruder is sometimes called cold-end). Sometimes the entire print head, including the hot-end and cold-end, is called the extruder for short, which is not entirely correct: the extruder is only the largest part of the head.

Recall that the thread or rods are supplied in two diameters: 1. 75 and 3.0 mm. The extruder can only work with one diameter, which must be specified in the printer specification and taken into account when purchasing consumables. To feed the thread, a stepper motor and a system of gears and shafts are used. The controller controlling the motor provides not only the desired filament feed speed, but also the reverse action - its extraction, for example, when changing the material.

75 and 3.0 mm. The extruder can only work with one diameter, which must be specified in the printer specification and taken into account when purchasing consumables. To feed the thread, a stepper motor and a system of gears and shafts are used. The controller controlling the motor provides not only the desired filament feed speed, but also the reverse action - its extraction, for example, when changing the material.

Naturally, the hot-end temperature is controlled by a thermistor, so four wires always go to this part of the head: two thicker wires to the heater and two thinner wires to the thermistor.

Since the operating temperature of most materials is quite high - 200-250°C, and sometimes even higher, measures must be taken to ensure that the filament is melted in the nozzle and to avoid heating the extruder, which may contain plastic parts.

For this, radiators are installed between the hot-end and cold-end, the extruder is additionally cooled with a small fan, and “thermal break” (thermal barrier) is also used: gaskets made of a substance with low thermal conductivity, which can be used as polytetrafluoroethylene ( PTFE, also known as Teflon and PTFE) or polyetheretherketone (PEEK, Latin PEEK). Since the hot-end temperature can approach 300 °C when working with some materials, gaskets must withstand this temperature not only without significant deformation, but also without releasing toxic substances. With regard to Teflon, there are suspicions in this regard, the validity of which we will not discuss and will only say that in any case it is better to work with an FDM printer in a well-ventilated area.

Since the hot-end temperature can approach 300 °C when working with some materials, gaskets must withstand this temperature not only without significant deformation, but also without releasing toxic substances. With regard to Teflon, there are suspicions in this regard, the validity of which we will not discuss and will only say that in any case it is better to work with an FDM printer in a well-ventilated area.

PTFE or PEEK tubes are also used to reduce friction between the filament and the walls of the heater hole, at the entrance to which the plastic of the filament is still solid, then, as it moves to a more heated zone, it passes the glass transition temperature, and only in the area with the most at high temperature it becomes molten. In the glass transition zone, where the filament material is no longer solid but not yet liquid, there is a high resistance to pushing through the filament, so it is highly desirable for the tube to reach a point where the filament is already melted.

The nozzle is considered a consumable item: its hole becomes clogged over time, covered with soot, and you either have to clean it (which is not easy, especially if the hole is 0.15 mm in diameter) or replace the nozzle. Therefore, it is highly desirable that the nozzle is not just replaceable, but also replaced without much hassle, for which a threaded connection is used. The nozzles of different printers are not always interchangeable: the pitch and diameter of the thread can be different, moreover, the thread on the nozzle itself can be not only external, as in the photo, but also internal.

There is not necessarily one print head: there are quite a few printers with two heads. They allow you to use two materials at once when printing - for example, one for the model itself, and the second, easily removed, for supporting structures, which we wrote about in the technology review.

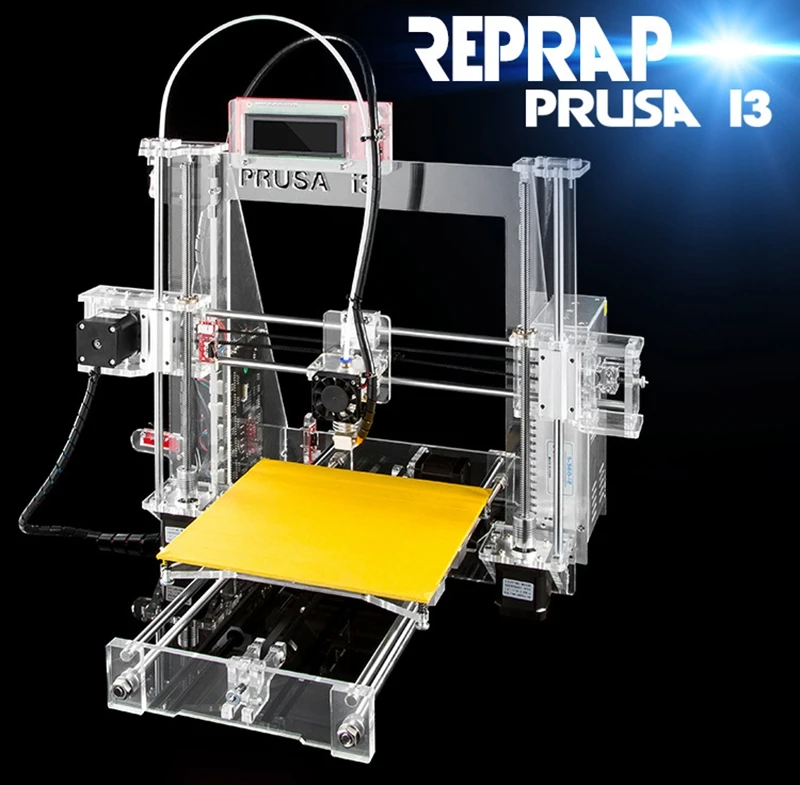

Desktop

The next important detail is the desktop or platform (print bed), on the surface of which the created model is formed. For the working table, it is necessary to ensure the possibility of sufficiently precise adjustment so that the distance between its upper plane and the nozzle outlet is the same over the entire working area. On the other hand, the table must move, so structural elements must be rigidly attached to it to ensure movement. Therefore, the platform is often a two-layer “sandwich”, the lower part of which is not subject to special requirements - it only serves to fasten such elements and is the basis on which the adjusted working surface is located, on which the 3D model will be created. It is about this part of the platform that we will talk further. We only add that in some prototypes created as part of the RepRap project, the lower part of the desktop can be made from the most affordable materials - MDF or plywood.

For the working table, it is necessary to ensure the possibility of sufficiently precise adjustment so that the distance between its upper plane and the nozzle outlet is the same over the entire working area. On the other hand, the table must move, so structural elements must be rigidly attached to it to ensure movement. Therefore, the platform is often a two-layer “sandwich”, the lower part of which is not subject to special requirements - it only serves to fasten such elements and is the basis on which the adjusted working surface is located, on which the 3D model will be created. It is about this part of the platform that we will talk further. We only add that in some prototypes created as part of the RepRap project, the lower part of the desktop can be made from the most affordable materials - MDF or plywood.

It is highly desirable that the fastening of the upper part of the table is not rigid, but spring-loaded: in this case, in particular, small adjustment errors are not so critical, when at some position the gap between the nozzle outlet and the platform surface becomes too small, and and even goes into the region of negative values.

Various materials are used as the material for the platform: glass, acrylic, aluminum. And one of the most frequent problems of FDM printing almost always has to be solved - reliable fixation of the first layer of the model on the platform, since the plastics used for printing do not adhere well to aluminum or glass. This is solved in various ways: platform perforation, coating, table heating, as well as a combination of these methods.

Coating requires materials that not only provide good adhesion, but also withstand the temperature of the molten thread during the application of the first layers. Kapton is often used, a thin yellow polyimide film that can withstand temperatures up to 400 °C. For printers, Kapton is used in the form of a self-adhesive tape with a width of 5 to 200 mm, the segments of which, glued end-to-end, cover the working surface of the platform. Of course, it is difficult to use a 5 mm tape for this - too many pieces will have to be glued, and a 200 mm tape is more difficult to stick evenly, so intermediate values \u200b\u200bare often used.

Another common option is 3M polypropylene-based Scotch Blue Tape. In fact, it is intended for painting and packaging work (for example, it is often used to protect the glossy parts of various products), but its high temperature resistance made it suitable for FDM printing.

For reference: the blue tape item number is 2090, and the following numbers determine the approximate width of the roll in inches: 2090-.75A - 18 mm, 2090-1A - 24 mm, 2090-1.5A - 36 mm, 2090-2A - 48 mm; there's more 2090-CM designed for corners. Roll length 55 m.

The advantage of the coating, consisting of individual strips, is that it can be replaced in part, but not entirely, as it wears out or if it is damaged.

There are other options, including "home-grown" - applying hairspray. Another material, self-adhesive film for laser printers, is used in the PrintBox3D One printer, which we will talk about in due time.

But even the presence of a coating does not provide proper adhesion for most consumables, so the platform has to be heated, for which, in a number of models, an electric heater is placed on the bottom of the desktop - made of nichrome wire, or made in the form of printed conductors, or even simply in the form several powerful low-resistance resistors.

This heater is also controlled by a thermistor. The heating of the platform should be uniform, which can be ensured by a sufficient thickness of the platform itself, but at the same time it is desirable that the desktop heats up quickly enough - not in seconds, of course, but at least within a minute or two. And such a popular plastic as ABS requires heating to a temperature of over a hundred degrees, so the heater must be powerful enough.

Bed heating is also needed to reduce the temperature gradient between the first printed layers and those that have just been created. The lower layers begin to cool, and especially quickly if they are in contact with a much more massive platform at room temperature. In this case, deformations occur, due to which the model may begin to bend, and sometimes it simply breaks away from the table. Therefore, heating is desirable even when working with materials whose adhesion to the surface of the table depends little on the temperature of this surface.

Note that both the heater and the thermistor are located on the bottom side of the platform, so the temperature of this side is controlled, and the part will be located on the top. Therefore, it is better to take your time and wait a bit for the whole platform to warm up, especially if it is made of a fairly thick material.

Movement mechanisms

During printing, both the head and platform must move. This requires both mechanisms that implement the actual movement (motors) and guides that ensure the accuracy of movement.

Normally the head moves along one of the horizontal axes, while the vertical movement and the second horizontal axis are provided by the movement of the desktop. Thus, three engines are needed. As in the extruder, stepper motors are used, typically having a step of 1.8 degrees, i.e. 200 steps per full turn. This is a full-step mode, there is also a half-step and micro-step mode, which is used to improve the accuracy of movement - the engine control electronics adds a certain number of intermediate steps, and often a significant one: the most popular controllers provide division of the engine step into 4, 8 and even 16 parts, and then the full the rotation of the motor rotor will already correspond to 3200 microsteps.

The rotation of the rotors of the motors must be converted into translational movements of the head and work table. For this, either pulley and timing belt systems or threaded shafts are used. Shaft transmission is cheaper, but it cannot provide positioning accuracy at high speeds, so it is most often used for vertical movement of the platform, which is quite slow, and only in cheap models is it also used for movements in the horizontal plane.

Guides use cylindrical in cheap models and linear in more expensive ones. The material, of course, is steel, and high demands are placed on the accuracy of manufacturing and the cleanliness of processing, because the accuracy of printing will directly depend on this.

A complex and durable platform will have a considerable mass, which will create a serious load on the engine, ensuring its movement in the horizontal plane (in the vertical direction, movement is both slower and not constant). The engine will heat up, which at some point may cause skipping steps and other troubles. Therefore, they try to lighten the desktop as much as possible - of course, not at the expense of strength, the printing speed sometimes has to be limited and measures must be taken to normalize the thermal regime of the engine (for example, by providing thermal contact with a massive metal frame).

Therefore, they try to lighten the desktop as much as possible - of course, not at the expense of strength, the printing speed sometimes has to be limited and measures must be taken to normalize the thermal regime of the engine (for example, by providing thermal contact with a massive metal frame).

The extreme travel positions of both the head and the platform are monitored by sensors installed at appropriate locations. In the simplest case, the sensor can be a mechanical contactor or disconnector, but both the accuracy and reliability of such a sensor are not always sufficient, so sometimes they use optical (LED and photodiode, at the right time the gap between them is covered by a shutter) or magnetic, on Hall sensors.

Temperature conditions of the model

There is another point that is taken into account in many printers. It is due to the fact that the plastic that comes out of the nozzle does not solidify immediately, and therefore is subject to deformation. This is especially critical in the presence of so-called "bridges" - long horizontal bridges supported only at the edges: the threads of plastic that has not yet solidified will inevitably sag, which will require the creation of additional supporting structures, which will then have to be removed. But even if there are no “bridges” in the model, there may be curling corners with a small radius of curvature (curling corners), and on elements of a small size, the previous layer will sag, which did not have time to harden before the next one was applied.

This is especially critical in the presence of so-called "bridges" - long horizontal bridges supported only at the edges: the threads of plastic that has not yet solidified will inevitably sag, which will require the creation of additional supporting structures, which will then have to be removed. But even if there are no “bridges” in the model, there may be curling corners with a small radius of curvature (curling corners), and on elements of a small size, the previous layer will sag, which did not have time to harden before the next one was applied.

To a certain extent, these problems can be avoided if measures are taken to cure the plastic as soon as possible, and this can be done in one way: cooling with an additional fan, one or more. Choosing a fan is not difficult, there are many models of different sizes designed for computers; controlling the speed of their rotation is also not difficult, but choosing the location of the fan itself and the correct direction of air flow from it is a whole art. In this regard, FDM printing has an unpleasant duality: on the one hand, it is necessary to quickly cool the plastic extruded from the nozzle, and on the other hand, this must be done evenly so that one side of the model does not cool faster than the other, otherwise thermal deformations are inevitable. In addition, the cooling air flow should not noticeably affect those elements of the printer that must have a constant high temperature: the hot end and the heated table.

In this regard, FDM printing has an unpleasant duality: on the one hand, it is necessary to quickly cool the plastic extruded from the nozzle, and on the other hand, this must be done evenly so that one side of the model does not cool faster than the other, otherwise thermal deformations are inevitable. In addition, the cooling air flow should not noticeably affect those elements of the printer that must have a constant high temperature: the hot end and the heated table.

Therefore, the FDM printer is “afraid” of drafts, and some models even provide a protective cover, which, when used at home, at the same time helps to limit children's access to dangerous parts of the device. But under the casing, a closed space is formed, heated by the hot end, and the heated platform, and the running engines, and the cooling plastic of the already created part of the model, which slows down the curing of the extruded thread and leads to even greater deformations.

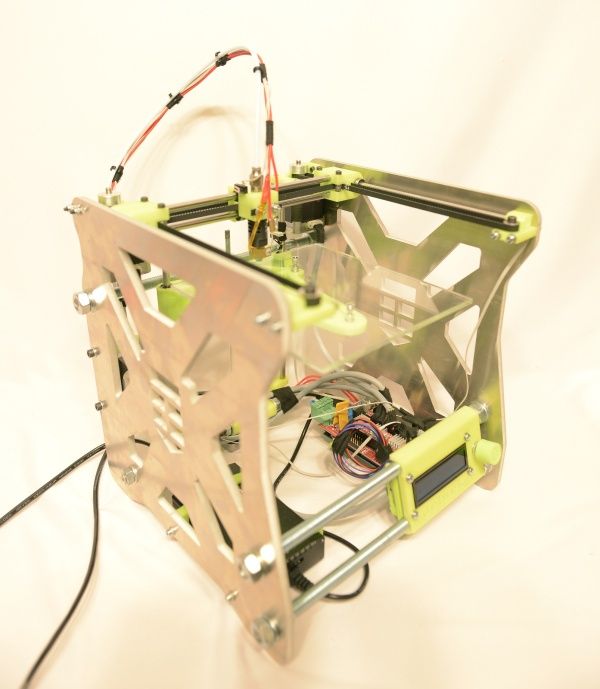

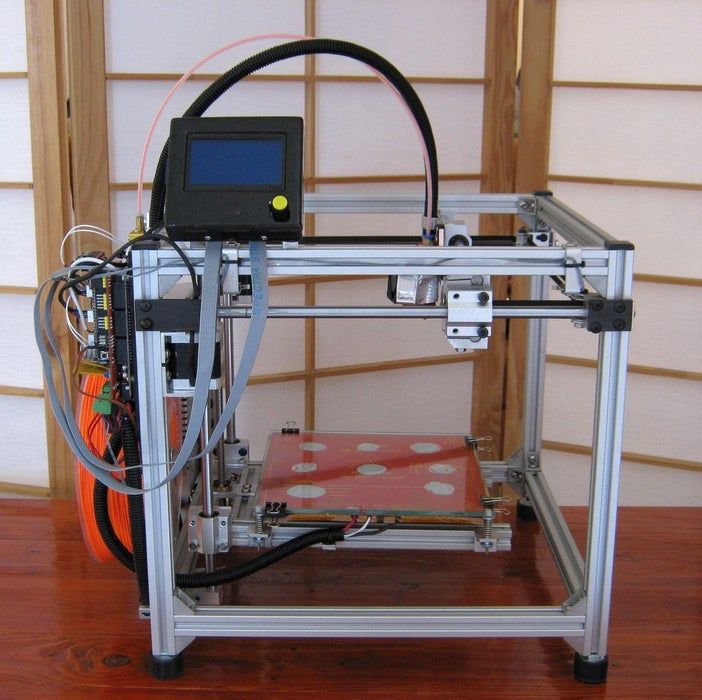

Frame

Of course, all of the listed components must be located on a sufficiently strong and rigid frame that ensures long-term preservation of geometry and the absence of backlash, regardless of various adverse conditions - ambient temperature and humidity, as well as vibrations that occur during printing.

The frame is often made from inexpensive aluminum profiles, such as those used as furniture fittings, and sometimes even ordinary threaded rods, which can be bought at hardware stores. They are connected into a single whole with the help of plastic couplings, clamps and other elements fastened with nuts and bolts. This is permissible only in home-made printers, where the minimum cost of structural elements and their maximum availability for sale are at the forefront.

In some models, including "factory" models, the frame is made of plexiglass or plywood, and it is emphasized that the plywood elements are made by laser cutting; Of course, no laser can turn plywood into metal, so the durability of such structures and the absence of problems when working with such printers are highly doubtful.

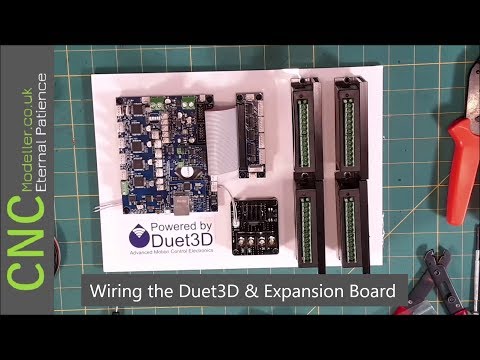

Electronics

Now on to the control electronics.

The controller controls the operation of all printer components, which receives the program in the G-code language. It is generated on the basis of an STL file prepared in some 3D editor that describes the future model. G-code is quite simple to understand: the lines of the program contain commands to move the head and platform, turn heaters and fans on and off, so it is not a problem for a more or less experienced specialist to edit the finished code.

It is generated on the basis of an STL file prepared in some 3D editor that describes the future model. G-code is quite simple to understand: the lines of the program contain commands to move the head and platform, turn heaters and fans on and off, so it is not a problem for a more or less experienced specialist to edit the finished code.

The vast majority of 3D printer controllers run on the Arduino platform, which has an open architecture and software code. The programming language is based on C/C++ and is easy to learn, while the Arduino programming environment means working through a USB port without any additional programmers.

Common and relatively inexpensive Atmel microcontrollers: ATmega32u4, ATmega328, ATmega2560, ATmega1280, etc. have been used and are still used as Arduino hardware from the earliest versions, and the latest developments use a 32bit Cortex-M3 microprocessor ARM SAM3U4E . In FDM printers, the ATmega2560 is more common.

To control various devices (in 3D printers, these are motors, heaters, fans) and receive data (from thermistors and limit sensors), additional modules are used, primarily stepper motor drivers, capable of providing the appropriate output currents and operation in microstepping mode.

For the convenience of interfacing such modules with the microcontroller board, RAMPS intermediate boards (RepRap Arduino Mega Pololu Shield, where Pololu is the name of a company specializing in the production of components for robotics) are used. These boards come in different versions, currently the most common is RAMPS 1.4 with smd components. On the one hand, such a board has groups of pin connectors for connecting to the microcontroller board, and on the other, connectors for connecting modules and external equipment (motors, heaters, thermistors). The result is a single compact unit, which, after loading the control firmware into the microcontroller, is ready to work as part of an FDM printer.

Some printers can only be controlled via a computer (usually via a USB port, but there are models connected via Wi-Fi), while others have their own control panel, with which, in the simplest case, you can control temperatures using the LCD indicator, start and stop printing, and in more advanced versions, also calibrate, load and unload plastic filament. There are printers with a built-in SD card reader or a USB flash drive port, through which you can upload a file and then print the model without using a computer. All this is ensured by "hanging" the appropriate modules on the microcontroller and, of course, implementation at the firmware level in the firmware.

There are printers with a built-in SD card reader or a USB flash drive port, through which you can upload a file and then print the model without using a computer. All this is ensured by "hanging" the appropriate modules on the microcontroller and, of course, implementation at the firmware level in the firmware.

From the controller to the printhead, even if there is only one, there is a thick bundle of wires: to the stepper motor, to the heater and hot-end thermistor, possibly to the extruder fan (if any). Another similar bundle connects the controller to the desktop. Of course, you can simply tighten the wires with ties, which is done in the most budgetary home-made designs, but the main thing: both of these elements are constantly moving, and even with a sufficient length of the bundles, there is a real danger that some wire will either get into moving parts, or through some -that time will simply fray or break off. Therefore, these wires are placed in special flexible sheaths that ensure free movement of the head and desktop, but at the same time insure against breaks and short circuits.

It is clear that the printer will not work without power. Moreover, if the capabilities of the USB port, to which the printer is usually connected, are often enough to power electronic circuits, then for engines and especially heaters (at least hot-end, if table heating is not provided), you cannot do without a power supply of appropriate power.

Since the printing process can be very long - the production time for complex models can take 10-15 hours or more, it is advisable to take care of the uninterrupted power supply of both the printer itself and the computer to which it is connected (unless, of course, working codes are not loaded from the printer's built-in card reader). It is clear that the total energy consumption will be considerable, and it is not easy and expensive to select a UPS capable of providing operation for many hours, but at least you need to take measures against strong impulse noise on the power line to which the printer is connected and turn it off in the control computer enters power saving mode - except, of course, blanking the screen.

Illustrations obtained from various sources on the Internet

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

Known for its daVinci line of desktop 3D printers, XYZprinting is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines.