3D printer in the philippines

PH Guide to 3D Printer Prices

PH Guide to 3D Printer PricesGUIDES

3D Printing

3D Printing

3D Printing

3D Printing Technology became popular in the development world. This additive manufacturing is making huge impacts on various industries including healthcare, education, architecture, engineering, consumer products, and a lot more.

The demand for this technology is increasing. Hence, it is a great way to start your business or incorporate it into your operations. If you are planning to buy a 3D printer, you might want to dig deep down on what you should buy. There are a lot of available 3D printers in the market and one factor that you should consider is the 3D printer price.

This question depends on your specific needs. 3D printers may vary in cost. The prices of 3D printers may differ depending on their features, quality, size, and performance.

If you want to know which is the right 3D printer price for you, you need to answer these questions: What do you want to print? And, what is your budget? This is a great start to narrow down your choices and to have a better decision.

To make the right choice in buying the perfect 3D printer for you, we’ve broken down the categories of each level.

Beginners 3D Printer (Php 5,000 to 10,000)

This category is for the entry-level or novices who want to learn 3D printing. If you are at this level, it is a great way to purchase 3D printers at this price range before upgrading to a more expensive one. Mostly, items that are used to print in this level are toys since they are a great way to experiment.

If you are planning to buy an entry-level 3D printer you need to consider the limitations in it. These 3D printers can only print 3-4 dimensions and have material restrictions. PLAs are often used here.

Moreover, 3D printers on this range can be noisy, slow, and not durable compared to expensive ones. The print quality is also not that good. You might also need to manually assemble the machine. Despite that, it does the job of printing smaller objects and serves as a guide in starting with 3D printing. Below are the best 3D printers for beginners:

Below are the best 3D printers for beginners:

- Elegoo Mars at Php 7,450

- Creality Ender 3 - at Php 9,450

- Monoprice Select Mini 3D Printer v2 at Php 9,500

Hobbyist 3D Printer (Php 10,000 to 30,000)

3D printers in this category are for people who are already familiar with 3D printing. It is now clear to them that they want to continue their passion and be ready for more explorations.

Hobbyist 3D printers are capable of the job but often have a few flaws. Like the beginners 3D printer, this also needs to be assembled which can take you time. The printer capacity is larger and can make anything over 5-6 dimensions. They are much faster than entry-level 3D printers and you can have more choices of materials to use. Moreover, it has better software that’s capable of cleaning and auto-leveling.

The downside is, this printer does not run for significant time lengths. Meaning you have to do monitoring, repairs, and maintenance to keep it running. 3D printers in this category are only good for hobbyists or those seeking 3D printing pleasures. Check out these Hobbyist 3D Printers:

Meaning you have to do monitoring, repairs, and maintenance to keep it running. 3D printers in this category are only good for hobbyists or those seeking 3D printing pleasures. Check out these Hobbyist 3D Printers:

- QIDI Technology X-one2 Single Extruder 3D Printer at Php 12,450

- Creality Ender 3 V2 at Php 13,100

- Creality Ender 4 at Php 15,000

- Monoprice Voxel at Php 19,950

Enthusiast 3D Printer (Php 30,000 to 100,000)

This category is for mid-range applications. 3D printers for this category meet the needs of those 3D Printing Enthusiasts. They are sturdy and solid with friendly features. It can print as good as 8-12 dimensions.

Compared to the beginners and hobbyist category 3D printers, this is faster and quieter. You can also have more material selection but sometimes require branded filaments. This can be used in production but in a very low volume as it cannot hold extra time.

In addition, these are also prone to repairs and maintenance if running for too long. Small businesses are suitable for this category but should be prepared if it requires maintenance. Here are the best Enthusiasts 3D printers:

Professional 3D Printer (Php 100,000 to 400,000)

If 3D printing is for you and you have proper knowledge of it, you might want to buy professional or performance 3D printers. These printers have the greatest value among the other printers mentioned and are well-built and have high-quality parts. It can build bigger projects around 12 dimensions.

The 3D printing materials that can be used are expanded like ABS, Resins, Nylons, and Carbon Fibers with different textures and colors. The 3D printing machines in this category can print fast and still have good quality. These printers are more expensive and you have to make the right decision in choosing your model.

Printers in this category can be suitable for small to large businesses. See Professional 3D Printers here:

See Professional 3D Printers here:

- Raise3D E2 at Php 174,950

- Fusion3 F410 at 229,950

- Ultimaker S3 at Php 204,000

Industrial or Enterprise 3D Printer (Php 500,000 and up)

3D printers in the Industrial Category are for real and serious business. Above all the 3D printer categories, these 3D printers can print the fastest and have the highest quality. They are very durable and robust with great fabricated metal exteriors.

When it comes to interface, they are user-friendly and have the most features. To get all these leveled-up features, you will need to pay a significant amount of money. Not only for the 3D Printer but also the materials, filaments, and maintenance fee.

Before buying these big 3D printers, you should search for all the best options beforehand. While these printers are totally reliable, their prices are only suitable for large industries that can afford their large amount. Below are the best industrial printers:

Below are the best industrial printers:

- EnvisionTEC Perfactory P4K Series at Php 500,000

- Stratasys F120 at Php 600,000

- 3ntr A4 v4 at 750,000

Reliable 3D Printer Supplier in Manila, Philippines

If you are planning to buy good quality 3D printers, we can help you! MakerCarl has been in the 3D printing industry for years. Providing good quality 3D printers and 3D printing needs for all industries. Contact us to know more about our 3D printer prices.

Read more blogs on this topic

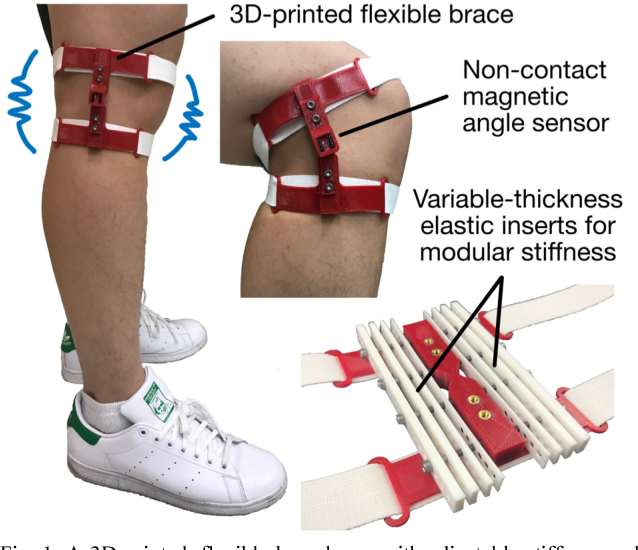

Practical Applications of 3D Printing in Medicine

Out of all the contributions of 3D printing, its applications in the medical industry are the most important. It helps doctors deliver better patient treatments.

Read More

PH Guide to 3D Printer Prices

3D Printing Technology became popular in the development world. This additive manufacturing is making huge impacts on various industries including healthcare, education, architecture, engineering, consumer products, and a lot more.

Read More

3D Printing in Automotive: A Metamorphosis Ahead

As it requires intensive labor, automobile manufacturing needed a change. Then comes, 3D printing paving the way for smarter additive manufacturing. Discover its benefits, applications, and real samples of 3D printed projects in this article.

Read More

10 Best 3D Printers in Philippines 2022

The market for 3D printers has been expanding rapidly over the past few years. It is not a question given their level of development and innovative specifications. In contrast to conventional printers, 3D printers produce physical objects from materials like plastic, metal, and wood from digital models.

You may design and print products for your workshop, office, and home, as well as construct entire objects and create replacement parts, all with the help of 3D printers. The best part is that it is generally accessible on the market so that anyone may get it.

Here are the top 3D printers to take into consideration, whether you're an expert or just starting started.

10 Best 3D Printers in the Philippines - Brands & Prices

Table of Contents

Best 3d Printer For Small Businesses

Anet ET4 PRO

What is a 3D Printer?

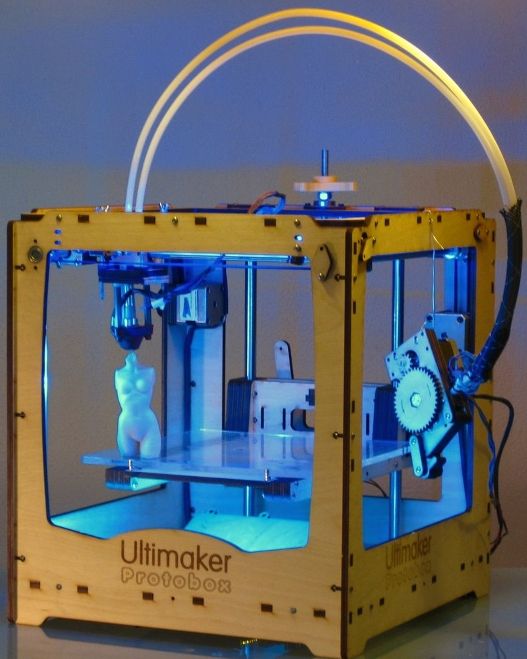

Additive manufacturing, also known as 3D printing, is the process of creating a three-dimensional object from a CAD model or digital 3D model. Materials can be combined, deposited, connected, or cemented using some computer-controlled procedures. For example, polymers, liquids, or powder grains can be fused, usually layer by layer.

The phrase "rapid prototyping" was more applicable at the time since 3D printing processes were seen as only being suited for the manufacture of functional or aesthetically pleasing prototypes. In 2019, 3D printing's accuracy, repeatability, and material variety have improved to the point that some 3D printing techniques are viewed as feasible as industrial production technologies. As a result, the terms 3D printing and additive manufacturing can be used interchangeably.

How Do 3D Printing Machines Work?

The additive manufacturing family includes 3D printers, which operate similarly to conventional inkjet printers but in three dimensions. To build a three-dimensional item from scratch, a mix of cutting-edge software, powder-like materials, and precise instruments is required.

Using 3D printing, a complete object is divided into thousands of minuscule slices, which are then assembled slice by slice. These minute layers adhere to one another to create a solid item. Due to the extremely complicated nature of each layer, 3D printers can include moving components like hinges and wheels into a single product.

How to Choose A 3D Printer?

Below is a rundown of the important tips to know in choosing a 3D printer.

Know what you want to print - The regularity of your printing, the location of the printed items, and the time commitment you're prepared to make should all be taken into account.

Identify your ideal 3D printer style - A printer known as a Fused Deposition Modeling (FDM) printer is utilized by many enthusiasts. To produce 3D-printed things, these printers expel heated materials and polymers, known as filament. Digital Light Processing (DLP), Stereolithography (SLA), and Selective Laser Sintering (SLS), which employs powder rather than resin, are some other printing techniques that use vats of liquid resin.

3D printer resolution - Microns are used to measure 3D printer resolution. The two most crucial elements for good printing are layer height and belt tension. Look for a printer with a higher micron count indicated in the specifications that is simple to modify.

Look for safety features - Generally speaking, 3D printers with safety features are well-designed. When you pause the job or the print is finished, some printers move the nozzle away from the object to prevent heat damage and excess filament from forming.

Look for high-quality features - Be on the lookout for items like heated glass beds, dual filament capability, and touchscreen user interfaces. A printer might be worth the expenditure based on something as simple as build volume or how much space you have to print.

Best Brands of 3D Printers here in the Philippines

With so wide variety of 3D printers on the market, you can surely take your time and choose the best one. When it comes to getting the best for your money, consider the quality features at a fair price The following 3D printer brands highlight the highest quality of the best 3D printer in the Philippines

Creality - Creality manufactures 3D printers that are reasonably priced and frequently have a huge print area. They created prints that were typically high quality and had incredible detail.

Anycubic - The AnyCubic has won over customers with the quality and use of their 3D printers. Their printer produced good prints for you, making it worth the cost.

Their printer produced good prints for you, making it worth the cost.

Elegoo - Elegoo has developed into a top supplier of many 3D printer solutions. The business works to make sure all of its products are of the highest caliber and have the best features that make 3D printing simple.

Kingroon - For the price, Kingroon produces an unquestionably good printer. They are sturdy and long-lasting, function admirably, and are ideal for everyone, whether a novice or an expert.

Anet - Anet is a contemporary maker of reasonably priced 3D printers that are ideal for small businesses, home and garage workshops, and training. It is a well-known Chinese manufacturer of affordable 3D printers that are utilized by both amateur and expert builders.

Price Range of 3D Printers here in the Philippines

The 3D printer price in the Philippines ranges from ₱10,000.00 to ₱30,000.00. The 3D printer for sale in the Philippines is in a very affordable range that you have to try and see for yourself!

Where to Buy 3D Printers here in the Philippines?

When shopping for the best 3D printer, you should check out Shopee and Lazada, two of the most popular online stores in the Philippines. They feature a wide range of rates for budget-conscious buyers and 3d printing service reviews from reliable customers, legitimate vendors, and 3d printing machine products.

They feature a wide range of rates for budget-conscious buyers and 3d printing service reviews from reliable customers, legitimate vendors, and 3d printing machine products.

Conclusion

Never has there been a better opportunity to enter the 3D printing industry or, for seasoned manufacturers, to improve. You may create models, toys, hooks, stands, replacement components, and more with the appropriate printer.

Be careful to think about the questions before deciding because there are many things to take into account before purchasing the finest 3D printer for you.

Related Articles- Best Printers

- Best Printers for Office

- Best Portable Printers

- Best Photo Printers

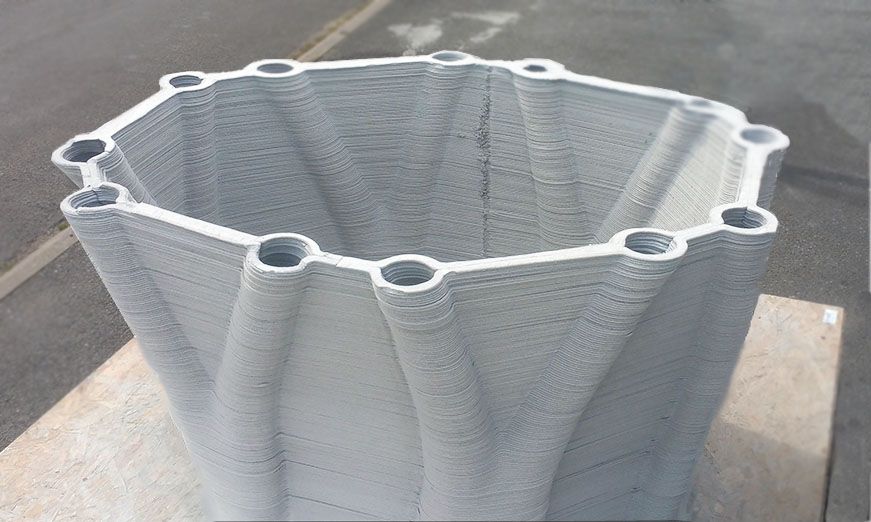

A top hotel in the Philippines will have a suite built with a concrete 3D printer.

News

Subscribe author

Subscribe

Don't want

3

Lewis Yakich, an experienced US developer, teamed up with renowned concrete 3D printing expert Andrey Rudenko to come up with the design of the hotel. The duo also worked tirelessly to figure out the right type of printer for the big project. Thanks in large part to Rudenko, the process of building the printed module took only two months. Rudenko even admits that their builds can be reproduced within a few weeks now. nine0003

The duo also worked tirelessly to figure out the right type of printer for the big project. Thanks in large part to Rudenko, the process of building the printed module took only two months. Rudenko even admits that their builds can be reproduced within a few weeks now. nine0003

After testing materials and blends for one month, the duo embarked on a revolutionary print.

The room designed for 3D printing will also have a printed Jacuzzi.

If you could stay in a hotel room built entirely with 3D printers, would you? Well, if you're planning a trip to the Philippines soon, you might just get the chance. In this country, the Lewis Grand Hotel has recently completed the construction of a new addition. A suite that was made almost entirely with a construction concrete printer. nine0003

In Angeles City (Pampanga), a 3D printed villa has appeared in the Lewis Grand Hotel. It has two bedrooms, a room with a jacuzzi (the jacuzzi was also 3D printed). The total area of the villa is approximately 120 square meters. The whole villa is approximately 10 by 12 meters in size, with high ceilings in the entire room - as much as 3 meters. This is a revolutionary number. The most impressive feature is the fact that he has a total number of hours to complete the printing of the entire issue - about 100. Add to this the time it took to install the plumbing, fittings and wiring. nine0003

The total area of the villa is approximately 120 square meters. The whole villa is approximately 10 by 12 meters in size, with high ceilings in the entire room - as much as 3 meters. This is a revolutionary number. The most impressive feature is the fact that he has a total number of hours to complete the printing of the entire issue - about 100. Add to this the time it took to install the plumbing, fittings and wiring. nine0003

“The Philippines is actually a great place to print with concrete because of the weather,” Yakich tells 3DPrint.com, “Nowadays everything is made of concrete. A 3D printer can do a lot of good in disaster areas, etc.'

Although construction has already finished at the Grand Lewis Hotel and the villa is ready, it is not known exactly when the hall will open to the public, and how much it will cost a night at the villa.

But it is known that this building made a splash and captured the attention of other enterprises in the Philippines. A construction pro like Yakich is in a position to secure a contract to build affordable housing in the country, something he plans to start in November. Considering how much money and time was spent on an addition to his chic Philippine hotel, such construction can be considered very effective. It seems likely that his next 3D printer construction contract won't be his last. nine0003

Subscribe to the author

Subscribe

Don't want

3

3D printers in construction: prospects for application

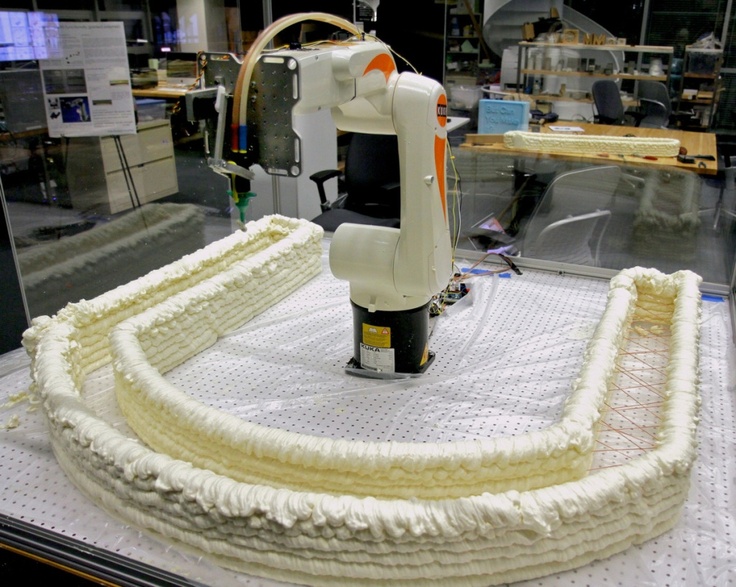

At first glance, 3D printing structures seem to be some kind of shell of a half-finished building. But upon closer examination, you will not find even a brick. Layers of material seem to build up one on top of the other - this is how a complex structure is created. It's a futuristic world of 3D printing where robotic arms automatically layer and compress layers of concrete or plastic or any other material into a foundation and build a structure. nine0003

nine0003

This method of construction is quite niche today - only a few prototypes of 3D houses and offices have been printed in the world. However, this technology represents an exciting and potentially powerful solution to building change.

What is 3D printing in construction, what is the potential, and will we be working on 3D printed projects in the near future?

- What is 3d printing in construction?

- 3D printers in construction: how is it done?

- 5 examples of innovation

- How can 3d printed projects help construction companies?

- 3D printing distribution

- 3D printing in civil engineering

- Wiki House technology - an open source project for 3D printing: what is behind the concept

- Reverse side of the coin

- How 3D printing can be integrated into construction

- About PlanRadar

3D printing in construction - what kind of technology?

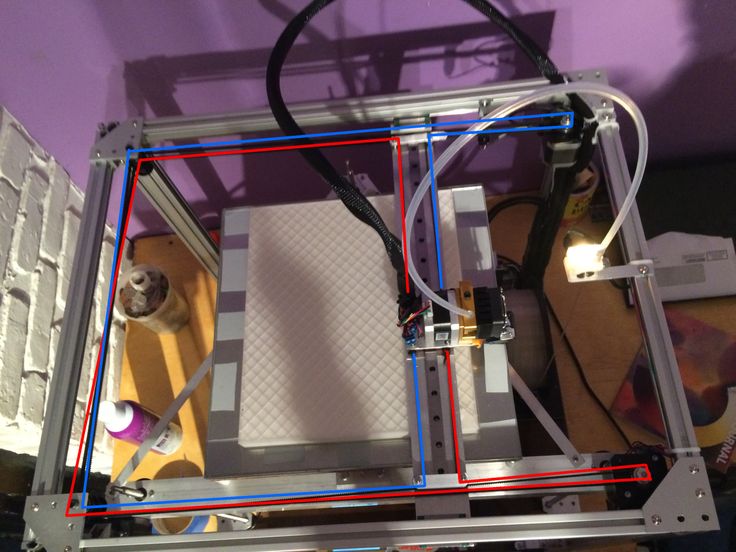

3D printing for construction uses both a 3D printer, which has a robotic "crane-arm" that builds structures right on the construction site, and the creation of certain elements by printers at the factory, which are already assembled into a structure on site. nine0003

nine0003

The concept of 3D printing is not new: it first appeared in the 80s. But it's only in the last decade that this technology has been improved enough (and the cost significantly reduced) to become a real mainstream.

3D printers are not much different from conventional inkjet office printers. The software tells the printer about the dimensions of the final product. And then the printer starts to output the material to the platform according to the plan. 3D printers often use liquid metals, plastics, cement, and variations of various materials that, when cooled and dried, form a structure. nine0003

In a 3D construction printer, the CAD or BIM programs tell the device what to print, and the machine begins layering the material according to the design plan.

3D printers in construction: how do they work?

3D printing concept - the printer extrudes a certain liquid mixture in layers, level by level, creating a design based on a three-dimensional model. The prepared mix of concrete, filler, plasticizer and other components is loaded into the hopper of the device and fed to the print head. The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

The prepared mix of concrete, filler, plasticizer and other components is loaded into the hopper of the device and fed to the print head. The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

Robotic printer

Read also: New technologies in construction 2021

5 innovative examples of 3D printing

To date, only a few 3D printing projects have been implemented in the construction industry. Here are five of the most impressive and promising projects:

Dubai City Hall Office Building, UAE

1. Dubai City Hall Office Building, UAE

3D printed building. The office block built in the UAE is 9,5 meter high building with an area of 640 m2.

An Apis Cor 3D printer moved around an open-air construction site with a crane and erected different parts of the structure.

2. Office of the Future, UAE

Office of the Future, UAE

Office of the Future, UAE

Another impressive 3D printed building in the UAE, the Office of the Future is a unique, fairly large structure that currently houses a temporary headquarters organization Dubai Future Foundation. nine0003

For this building, the elements were not created on site and were printed in 17 days, while the building itself was assembled in 48 hours.

3. WinSun 3D Printer Homes, China

WinSun 3D Printer Homes, China

WinSun 3D Printing Company of China has also used factory-built 3D printers to build residential buildings. The company has created several house projects, including a small multi-storey building. All construction details can be printed quickly and cheaply and then quickly assembled on the construction site. nine0003

The company calculated that it would cost as little as $161,000 to build and print their five-story building.

4. 3D printed license plate at Lewis Grand Hotel, Philippines

3D printed license plate at Lewis Grand Hotel, Philippines

When planning a trip to the Philippines, consider staying at the Lewis Grand Hotel in Angeles City , Pampanga, where visitors will be greeted with the world's first 3D printed hotel suite. The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours. nine0003

The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours. nine0003

5. Two-story mansion in Beckum, Germany

Two-story mansion in Beckum, Germany

The first 3D-printed residential building with an area of about 80 square meters - the brainchild of the German construction company PERI GmbH and the architectural design bureau MENSE-KORTE ingenieure + architecture. A BOD2 3D printer was used to print one square meter of double wall cladding in 5 minutes. The building is a structure with three-layer hollow walls filled with insulating mass. Installation of hollow pipes and connections during printing was carried out manually. nine0003

3D printing in construction seems really impressive, but what are the real benefits of such technology?

How can 3D printed designs be useful for construction companies?

Proponents of 3D printing houses and commercial offices point to several advantages of this construction method:

- Zero waste construction

In the UK, almost a third of the waste comes from the construction industry. According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste. nine0003

According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste. nine0003

Conversely, 3D printing can reduce waste to almost zero. A 3D printer uses a well-defined amount of material that is required to print a design - no more, no less. This can be a big savings.

- Reduced energy consumption

3D printing in construction encourages the use of locally available materials and natural ingredients. This practice can reduce energy costs in transportation, construction and manufacturing, as most local materials require less energy to process or install. If traditional materials with toxic chemical impurities are replaced with natural ones, then the toxicity of the entire construction can be reduced. In addition, local materials are often better suited to local climates and can reduce a building's heating or cooling load, which also reduces construction costs. nine0003

nine0003

- Save time and money

As with AI in construction, a 3D printer can run 24 hours a day, 7 days a week. This means construction projects have the potential to be completed much faster and a number of low-skilled labor costs can be avoided. What's more, 3D printing eliminates the need for temporary structures, such as formwork and scaffolding, that are commonly used in traditional construction. Studies of 3D printed concrete structures have shown a significant reduction in formwork requirements, reducing costs by 35-60%. nine0003

- Can realize unusual design shapes

One of the most attractive characteristics of 3D printers is their ability to create complex and unusual design designs, including a single, unique one. Since the job of a 3D printer is to layer the material, they can be programmed into absolutely any unusual shape that would be much more difficult to create with traditional techniques.

- Minimize human error and improve safety

The published injury statistics at the workplace by the American agency BLS in 2020 indicates that construction is one of the most traumatic areas and a high incidence of diseases. Every day, about 5333 workers die on the construction site. And with the advent of 3D printing, the number of work injuries and fatalities will obviously decrease, as it makes construction more programmable and automated. Robotic construction requires standardized, accurate and complete digital building information, making this technology more accurate and efficient, with minimal rework due to human error or any information inconsistencies. The usual problems with materials and components that need to be stored somewhere, protected from damage are leveled out, problems with installation and work in progress due to damage also disappear - 3D elements are created as they are built, they do not need to be moved and stored. nine0003

nine0003

- Exploring new markets

The use of a 3D printer also allows construction companies to enter new market sectors that were previously inaccessible to them. And for start-up companies, having a 3D printer will be a competitive advantage. What's more, 3D printing is a brilliant way to elevate or improve the reputation of a construction company's brand among those who believe that concrete production has an impact on the planet's environment.

Distribution of structural 3D printing

3D printing for structural reinforcement, small scale components and structural steel could revolutionize design, construction and space exploration. In addition, the European Space Agency (ESA) believes that using 3D printed metals to create high-quality complex shapes can significantly reduce their cost, and they will become very common.

ESA has developed a project with the European Commission to improve the printing of metal components that can be used in space. In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products). nine0003

In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products). nine0003

Almost everything can be designed on a computer, so AMAZE plans to install a 3D printer on board the spacecraft, and as soon as an astronaut needs any part, a tool, he can simply print it.

Structural 3D printing

Civil engineering 3D printing

Civil engineering 3D printing has been gaining popularity over the past decade, as has the aerospace and biomedical industries. This revolutionary manufacturing technique is based on its unique ability to create any geometric shape without any formal restrictions, minimizing waste but increasing productivity and results. The construction industry's push towards automation has recently reached important milestones, including the creation of the first structures using robotic "arms" and 3D printing technology. nine0003

nine0003

The use of 3D printing in the creation of structural elements from polymer materials, concrete and metals is becoming more common.

These civil engineering technicians can create freeform and innovative architectural designs using CAD-integrated software.

However, despite considerable research in the aerospace and bioengineering industries to evaluate and analyze this mechanism, there is still a lack of understanding of its use, the impact of 3D printed materials in civil structures, both in terms of material properties and structural response. nine0003

Imperial College London

Read also: Best Building Apps in 2021

WIKI HOUSE - 3D printing in construction: what is the concept behind

Wiki House is an innovative project created by a small group of architects in London in 2011 . It offers an open source digital house design system that allows users to create, upload and share designs and print their own houses.

The kit does not require any special knowledge and training and can be created in 1 day. Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

A standard two bedroom house can be built for less than £50,000 and additional components such as cladding, insulation, windows and more can be added to the main frame of the structure. The first house that was built on the basis of the open source Wiki House technology was a two-story building. The 3D printed house was presented at the London Design Festival in 2014. nine0003

The Wiki House movement was spearheaded by Alastair Parvin, whose TED presentation "Architecture for People, Built by People" talked about the promise of 3D printing in construction. The creator of this project believes that Wiki House can help solve the housing problem, especially in emergency situations such as earthquakes (there is already evidence that 3D-printed houses can withstand shocks up to magnitude 8).

In the future, this could become a real alternative to low-cost houses, while allowing the customer to control the design of the project. nine0003

3D building built using Wiki House

Will 3D printing be the sustainable future of building?

3D printing has the potential to revolutionize the supply chain and structure through a new method of design and manufacturing. According to the study, 3D printing can help the construction industry become more economical, more efficient and greener.

Saxon University of Applied Sciences scientists Ivo Kotman and Neils Faber claim that 3D printing technology will be a "game changer". They explored the possibilities of 3D printing concrete, and their conclusions are:

- 3D printing shortens the supply chain and the overall design process. 3D printing right on the job site eliminates time-consuming steps in the design process. The architects, engineers, contractors, clients, and executives who normally have to be actively involved in a project are no longer needed in 3D printing.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs. - Pipe fitting and electrical wiring become easier and more efficient. Heating systems, insulation, plumbing and electricity all require the laborious on-site installation of conventional construction. However, in 3D printing, some of these features can be incorporated into the 3D printing process. Cavity wall printing is less resource intensive, improves insulation, and allows the use of 3D-printed hot or cold water channels. Moreover, the need for on-site installation is eliminated, which directly affects the reduction of waste. nine0052

- The best logistics. 3D printing eliminates 3 logistics and shipping issues. Firstly, a lot of materials and elements often deteriorate upon delivery, and if everything is printed on site, then damage is minimized

Secondly, in order to withstand transportation, the parts must be with increased technical characteristics, which by default increases the cost of them, and therefore the entire project. 3D printing right on the construction site will help to avoid such additional costs. nine0003

3D printing right on the construction site will help to avoid such additional costs. nine0003

- Creation of individual house designs available to the general market. Usually, building a house with the involvement of an architect is an expensive pleasure for most consumers. But with concrete 3D printing, you don't have to worry about the chosen shape, it won't cost more. In fact, this means that in the future more people will be able to buy houses of their own design according to their individual needs

Reverse side of the coin

While 3D printing is definitely attractive, it's still important to look at it impartially, removing some of the promotional stimulus. Skeptics note several disadvantages of this technology.

- Research and development costs

Most construction companies operate with relatively low profitability. To start using 3D printing everywhere, significant investments will be required.

- Will consumers see this as a marketing ploy? nine0146

3D printed houses, offices, shops and other infrastructure are often impressive. But do most people really want to live or work in one? For most people, brick houses are much more familiar and attractive. Other technologies such as prefabricated houses also seemed like an attractive technology of the future for some time, but have not been widely adopted, despite the fact that in many cases they were cheaper than traditional ones. nine0003

- Difficulty integrating with other components

3D printers can create unique and interesting designs. However, if you need a building that will use different materials or different elements that will not be suitable for 3D printing, then it will be a challenge to include a 3D printer for the building process.

- Lack of skilled labor

With the current problem of a shortage of skilled labor in the construction sector in general, 3D printing will require an even larger set of specialized knowledge and skills, which will have to be selected from an already small niche of candidates. So finding specialists to work in 3D printing for construction may be another difficult task in the future. nine0003

- Construction quality control

Weather conditions can slow down the traditional building process, but things are even worse for 3D printing. The environmental factor for commercial construction may reduce the demand for 3D printing. What's more, quality control can be a much more serious task, requiring constant monitoring of the process by real people at the construction site.

- No standards and regulations nine0191

Despite the regular mention of 3D printing in the media, it still has not had a significant impact on the construction sector. There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry. nine0003

There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry. nine0003

Read also: New technologies in construction 2021

How can 3D printing be integrated with construction?

At the moment there is strong evidence that 3D printing is worthy of attention and can be applied in the construction segment, and it is likely that this technology will be used more in the coming years. True, it is not known how widely these devices will be used on the construction site, or whether they will remain only a tool for the manufacture of block elements for prefabricated structures. But for certain projects, it is reasonable to assume that 3D printers and this technology in construction will be a must-have tool in the arsenal of builders.