3D food printer buy

The 10 Best Food 3D Printers 2022 (All Price Ranges!)

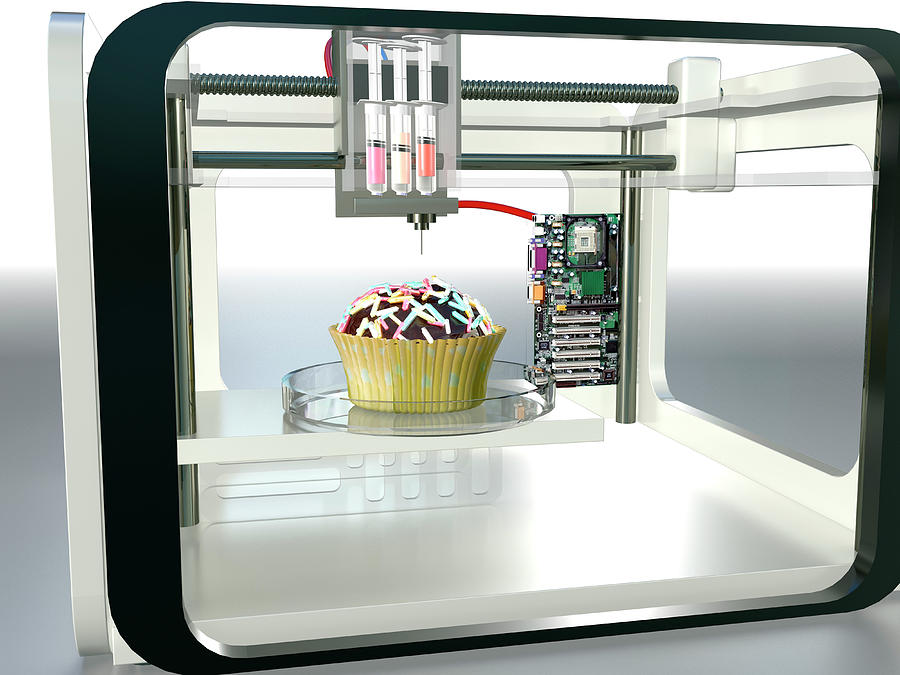

They’re here, and shaking up how we view and prepare food. Food 3D printers are usually hybrid FDM 3D printers that print food pastes rather than plastic filaments, printing delicious chocolate, jam or toffee layer-by-layer to create a custom dessert or savory dish based on your design.

Want to 3D print a model of your face in chocolate? Or print your company’s brand in biscuit to send to potential clients? You can do it all with food 3D printers.

Our ranking below features some of the best 3D printers for printing food, and compares them on accuracy, speed, variety of food types you can 3D printer, and more.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

The Best Delta 3D printers and where to buy them

| Name | Max Build Volume (mm) | Speed (mm/s) | Price | Where to buy for best price |

|---|---|---|---|---|

| Monoprice Mini Delta | 110 x 110 x 120 | 150 mm/s | $179 | Amazon here |

| FLSUN Q5 | 200 x 200 x 200 | 150-300 mm/s | $260 | Amazon here |

| He3D K280 Delta | 280 x 280 x 600 | 150 mm/s | $320 | Amazon here |

| FLSUN QQ-S | 255 x 255 x 360 | 300 mm/s | $379 | Amazon here |

| Frankensbox FX-800 | 150 x 150 x 175 | 150 mm/s | $299 | Amazon here |

| Monoprice Delta Pro | 270 x 270 x 300 | 150 mm/s | $699 | Amazon here |

| WASP Delta 2040 PRO Turbo | 200 x 200 x 400 | 500-600 mm/s | $3,400 | Amazon here |

- We’ve also written a feature story on 3D printed food.

- We also have a more specific ranking on the best chocolate 3D printers.

What is a Food 3D Printer?

Typical FDM 3D printing involves a 3D printer’s extruder depositing melted plastic filament along the dimensions specified in the STL file. It’s somewhat similar to icing a cake in that regard, but when you’ve completed one layer the next layer is then deposited on top of that existing layer.

3D printed food will have a layered appearance as FDM parts do — if you look hard you’ll see the tiny layers at slightly jagged angles like the steps on a pyramid, or a spring being pressed together.

With the icing a cake analogy, now assume that instead of icing, you can do the same action but with any edible food type. Chocolate, toffee, sugar, jam and savory flavors like tomato sauce / paste and cheese. Instead of being limited in the shapes you can make by the type of cake tin you use, you can now create incredibly intricate structures by perfectly depositing each part of food exactly where it is supposed to be. A 3D printed chocolate. You can see the layers on the side that have been printed on top of each other.

A 3D printed chocolate. You can see the layers on the side that have been printed on top of each other.

Food 3D printers are similar to FDM 3D printers — one printer on our list is a modified FDM printer — they deposit food instead of plastic filament in exactly the same way. This allows them to be more precise and accurate that any human could be, and also means that menial food jobs in restaurants and kitchens can be automated, saving time and energy.

What’s more, since you only extrude the exact amount of food you need, this makes for more efficient use of food, saving both money and the environment! This is a key and reoccurring theme in additive manufacturing.

Food 3D printers are gradually making their way into STEM education as a novel and fun new way of teaching both 3D printing skills and about what we eat. Food 3D printers for kids are also a great way of family bonding while creating something delicious to eat after, as well as by small businesses who want a new way of creating custom, up-market chocolates and other treats.

Benefits of a food 3D printer

- Better for the environment. 3D printed food materials can be created from alternative proteins like algae, leaves, and even insects, which are ground into a paste ready to be 3D printed. These ingredients otherwise would not be used, and are a form of protein and nutrients which may be key to future diets.

- Increased food customization. Though everybody’s food is already arguably customized, it isn’t to the level that food 3D printers offer. Not only can you create and pick the exact ingredients you want, but you can also create custom shapes and geographies that you want your food to occupy. Want a rabbit-shaped chocolate bar? Or an emoji-shaped burger? Easy. 3D printers conquer conquer the first three dimensions for you, saving you the fourth dimension — time.

- Saves time & stress. 3D food printers can automate the boring and repetitive kitchen tasks for you so you don’t need to do them.

Simple tasks such as presentation and laying out of ingredients can be done by the food printer, and if you are creating food from pastes then you don’t need to chop those ingredients up yourself.

Simple tasks such as presentation and laying out of ingredients can be done by the food printer, and if you are creating food from pastes then you don’t need to chop those ingredients up yourself.

The Best Food 3D Printer

We have created our list of the best 3D food printers based on a number of criteria. These include price-performance ratio, speed, amount of materials available, print volume, among others.

Note: this article is not intended to be objective fact, and is based on opinions. This content is independent and features no paid or sponsored content, but we have included links where you can buy a food 3D printer, which we receive commissions on.

1. WiiBoox Sweetin — Food 3D Printer For Kids

- Country based: China

- Food 3D printer cost: $1,599 — Available on Amazon here

- Maximum food printing area: 90 x 90 x 70 mm

- Food 3D printing speed: 15 – 70 mm/s

- Accuracy: 100 microns

The WiiBoox Sweetin is sold as the easy to operate, accessible food printer perfect for families at home together. The printer itself comes with a number of models to print out, and you’re free to unleash your creativity by designing or downloading your own STL files to print. It’s super simple to use: just load your design onto the supplied USB and print away!

The printer itself comes with a number of models to print out, and you’re free to unleash your creativity by designing or downloading your own STL files to print. It’s super simple to use: just load your design onto the supplied USB and print away!

The Chinese company bring their extensive 3D printing and scanning expertise to food 3D printing. They also sell an LCD 3D printer, an upmarket dual extruder 3D printer, as well as a range of 3D scanners.

The WiiBoox 3D food printer works by preheating the chocolate filament packs (or other food filament type), setting the temperature and speed you want to print at, and then it’s ready to start! You can change the print speed based on how accurate you want your 3D printed chocolate piece to be. Comments on Amazon recommend that you leave any 3D printed chocolate model for at least 10 minutes before removing it however to ensure it has cooled down and solidified.

The WiiBoox Sweetin is accurate with 100 micron precision so any cakes you decorate or chocolate food you 3D print will look crisp and smooth. Unlike some of the other food 3D printers on this list, the WiiBoox Sweetin appears to only use a 0.6mm diameter nozzle, and though it comes with their own 3D slicer you can also set it up to use Cura.

Unlike some of the other food 3D printers on this list, the WiiBoox Sweetin appears to only use a 0.6mm diameter nozzle, and though it comes with their own 3D slicer you can also set it up to use Cura.

Overall, it’s a low price food 3D printer with good reliability and is easy to use. We recommend it as a great food 3D printer for kids and families to enjoy spending time together cooking and having fun, and creating delicious chocolates and sweets at the same time.The WiiBoox Sweetin printing Albert Einstein in white chocolate.

2. FoodBot S2

- Food printer price: $2,100 — Available on 3DPrintersOnlineStore here

- Max print volume: 150 x 150 x 73 mm

- Food print speed: 15 – 70 mm/s

- Accuracy: 100 microns

A versatile food 3D printer, the FoodBot S2 can print chocolate, biscuit, jam, cheese, mashed potatoes, toffee and more! You can change the speed between 15 and 70 mm/s based on the accuracy and intricacy of your print, and alter the temperature based on your preferences.

What stands out however is how great the printer itself looks — if Apple ever made a 3D printer, this is how I imagine it would look. The design is futuristic, elegant and modern; it really adds a sci-fi feel to any kitchen. The 5.2 inch touchscreen and sleek UI add to this atmosphere.

As for accuracy, you’ll have no problem creating detailed food 3D prints with its 100 micron precision, with the ability to use nozzles ranging from 0.3 to 1.5 mm based on your needs. It comes with its own free 3D software to slice and prepare prints, and prints via either USB or SD card.

FoodBot stress how hygienic their S2 food printer is. The actual food filament never touches the printer, as it comes in disposable plastic dispenser tubes and is extruded straight through the nozzle. This makes keeping the printer clean and safe very easy, as there are no innards to clean, just the nozzle. Overall, it’s an impressive and easy to use food 3D printer with a wide variety of materials and uses.

3. Zmorph Fab (with Thick Paste Extruder Add-on)

- Price: $3,999 — Available at Matterhackers here / Available on 3DPrima Europe here

- Maximum print volume: 235 x 250 x 165 mm

- Thick paste extruder available here

Most people know of the Zmorph Fab as a workhorse 3D printer, drawing praise for its reliability, toughness and grit. It’s also known for being unbelievable versatile — it can be converted from a 3D printer into either a CNC mill or a laser engraver!

Now in addition to this, if you buy Zmorph’s thick paste extruder you can also print in chocolate, nutella, cookie dough and a few other food 3D printer filaments too. It prints pastes in a similar way to how it prints plastic filaments, so you benefit from the Zmorph Fab’s 50 micron layer resolution and excellent stability.Thick paste extruder add-on sold by Zmorph allows for chocolate 3D printing.

All the technology developed for the Zmorph Fab that makes it one of the best 3D printers around also works perfectly to make it a great food 3D printer. The accuracy, reliability and stability all apply in food 3D printing, and the Zmorph VX therefore is the perfect 3D printer for those who want a printer that can do it all. It’s ideal if you’ve been looking for both a food 3D printer and standard FDM 3D printer, but don’t want to buy two printers.

The accuracy, reliability and stability all apply in food 3D printing, and the Zmorph VX therefore is the perfect 3D printer for those who want a printer that can do it all. It’s ideal if you’ve been looking for both a food 3D printer and standard FDM 3D printer, but don’t want to buy two printers.

It is worth noting however that Zmorph do not certify that the printer’s food prints are edible or take any accountability for that. The add-on is therefore more of a fun extra to have fun at home with your family, but not for those looking to sell chocolate 3D prints or to use it in a restaurant. The printer was not built with food 3D printing strictly in mind, but it is a fun add-on for $250.

4. Createbot 3D Food Printer

- Price: $2,115 — Available on 3DPrintersOnlineStore here

- Max food 3D print size: 150 x 150 x 100 mm

- Speed: 20 – 30 mm/s

- Precision: 100 microns

There are definite similarities between the Createbot and Foodbot printers, in size, speed, price and appearance. One key difference however is that the Createbot food 3D printer comes in three different colors: Champagne Gold, Simple Silver and Rose Gold. All three options portray a stylish, expensive-looking machine.

One key difference however is that the Createbot food 3D printer comes in three different colors: Champagne Gold, Simple Silver and Rose Gold. All three options portray a stylish, expensive-looking machine.

It can print many of the same ingredients as the Foodbot S2 3D printer, including chocolate, biscuit, red and green bean paste, lotus seed paste, and other foods. The actual print speed depends on the material used: it is recommended to use 20 mm/s for chocolate printing, and 30 mm/s for other materials.

A cool feature with the Createbot is the ability to operate the printer from your laptop, tablet or smartphone. You can also carefully control the printer’s temperature to ensure prints retain their nutrition and print with the right consistency. Import your 3D printer model into Repetier-Host 3D slicer, slice it, and you’re ready to go!

5. Mmuse Delta Food 3D Printer

- Price: $1,140 — Available on 3DPrintersOnlineStore here

- Maximum print volume: 100 x 100 x 100 mm

- Speed: 150 – 300 mm/s

The only delta 3D printer on our list, the Mmuse delta brings the advantages of high printing speeds associated with these types of 3D printer to the food sector. Whereas some other food printers max out at around 70 mm/s, Mmuse claim the delta food 3D printer can print between 150 and 300 mm/s — depending on the quality of print and type.

Whereas some other food printers max out at around 70 mm/s, Mmuse claim the delta food 3D printer can print between 150 and 300 mm/s — depending on the quality of print and type.

It can print materials including chocolate, pancake, candy and tomato sauce, so you have the option of either sweet or savory. Unlike most delta printers it isn’t a DIY 3D printer, instead coming fully assembled and ready to print — saving time and effort. It’s also lighter than most of the other food 3D printers, at a very manageable 5kg.

Rather than offer a wide variety of nozzle sizes, the Mmuse delta sticks with the standard FDM 3D printer nozzle diameter of 0.4mm. It’s more of a fun food 3D printer for kids to enjoy and play with than an industrial food printer for restaurants. Don’t expect pinpoint accuracy and Michelin-level food presentation, but you can definitely still enjoy creating fun food prints of your favorite kids’ TV characters and other fun 3D printed food projects.

6. Foodbot D2 — Dual extruder food 3D printer

- Price: $5,999 — Available on 3DPrintersOnlineStore here

- Maximum print volume: 80 x 150 x 100 mm

- Print speed: 25 – 50 mm/s

- Precision: 100 microns

An upgrade on the Foodbot S2 that also features in our ranking, this extraordinary machine not only can print intricate food structures, but can print them with two materials concurrently!

The dual heads mean you can print either two different colors of the same food material, or two different materials. So you could create your own design in part toffee and part chocolate, or any other combination you want. Additionally, the 3.5 inch touchscreen and ergonomic UX makes food printing a breeze.

So you could create your own design in part toffee and part chocolate, or any other combination you want. Additionally, the 3.5 inch touchscreen and ergonomic UX makes food printing a breeze.

This second print head is very useful in commercial business opportunities such as creating custom edible brand logos that need to be in two different colors or materials. Custom cake decorations, intricate chocolate pieces, mini portrait pieces and busts, and general personalized gifts are made easy with the Foodbot D2.

Both the D2 and S2 food printers have solid, sheet metal frames which aid stability, accuracy and precision food 3D printing. The D2 prints at between 25 and 50 mm/s dependent on the material printed, and can be converted to use nozzles varying from 0.4mm to 1.5mm. It’s heavier however, at around 25kg — so keep this in mind if you need something very portable.

7. Mmuse Touchscreen

- Country based: China

- Food 3D printer price: $5,700 — Available on 3DPrintersOnlineStore here

- Print volume: 160 x 120 x 150 mm

Another chocolate 3D printer, the Mmuse is a food 3D printer that looks like something out of the matrix. It’s futuristic and beautiful, selling itself as a chocolate making experience, not just a 3D printer. It’s fast too, able to print between 30 and 60 mm/s of delicious 3D printed chocolate.

It’s futuristic and beautiful, selling itself as a chocolate making experience, not just a 3D printer. It’s fast too, able to print between 30 and 60 mm/s of delicious 3D printed chocolate.

There’s a reason for the high price. The Mmuse chocolate 3D printer is designed to be as convenient as possible to operate, so you can 3D print food via WiFi, USB or SD card. The beautiful touchscreen on the Mmuse makes printing a breeze, and features a strong aluminium shell. Mmuse also claim it utilizes an ‘intelligent temperature control technology’, allowing it to 3D print chocolate at the perfect temperature so the chocolate prints as smoothly and evenly as possible. Additionally, Mmuse have designed the printer nozzle to be as easy to clean and replace as possible to maintain hygiene over years of printing.

It comes fully assembled, so all you need to do is get hold of the chocolate bean filament, choose the print settings you prefer, and let it print away. The easy-to-use touchscreen makes delicious chocolate printing a pleasant experience. If you’ve got the money and you love chocolate enough, this may be the one for you. Also, if you’re a chocolatier and want to automate some aspects of production, this could be perfect.

If you’ve got the money and you love chocolate enough, this may be the one for you. Also, if you’re a chocolatier and want to automate some aspects of production, this could be perfect.

8. Natural Machines Foodini

- Country based: Spain

- Food 3D printer price: $4,000

- Print volume: 250 x 165 x 120 mm

One of the most well-known food 3D printers out there, the Foodini is a food 3D printer breaking barriers left, right and center in the foodtech sector. Foodini, made by Spanish firm Natural Machines, recognize that though cooking is an enjoyable process for many, there are many tasks that could be automated. The Foodini food 3D printer was therefore created to streamline the repetitive tasks which are time consuming and difficult to do by hand.

Foodini is a versatile food 3D printer, able to print pizza, spaghetti, and even burgers. Its glowing reviews led to fairly wide use in restaurants, like the byFlow Focus has similarly achieved. Restaurants which use the Foodini include London’s Food Ink restaurant, the entirely 3D printed restaurant, as well as La Endeca at Hotel Arts, in Barcelona.

Overall, the price is steep, but this is because of how advanced the Foodini is. It’s less of a cooking tool for use within homes and more of an industrial tool for professional kitchens, but this doesn’t make it any less of an incredible foodtech achievement.The Foodini food 3D printer has wide use across restaurants.

9. byFlow Focus

- Country based: Netherlands

- Food 3D printer price: €3,300

- Print volume: 208 x 228 x 150 mm

The byFlow Focus is a sleekly designed food 3D printer with a surprisingly wide reach in businesses around the world. Unlike most fanciful and futuristic machines that seem like they won’t see wide adoption for twenty plus years, the byFlow Focus is a 3D food printer which is already used in a number of restaurants and businesses.

Part of the reason is due to its reliability and ease of use. It can take a multitude of different 3D food printer materials, and switching them round is quick and easy. What’s more, you can even add your own recipes to the machine to 3D print with the ingredients you enjoy most. This allows you all the freedom you need to print any chocolate, pastry, or other 3D printed food dish you like, and byFlow even have over 50 downloadable 3D designs for free on their website.

This allows you all the freedom you need to print any chocolate, pastry, or other 3D printed food dish you like, and byFlow even have over 50 downloadable 3D designs for free on their website.

As a result, businesses such as B2B chocolatier Barry Callebaut giant use byFlow Focus food 3D printers, as well as well-reputed chef Jan Smink in his ‘Restaurant Smink’ restaurant.The byFlow Focus food 3D printer is another food printer used across restaurants, especially in Europe.

10. Choc Edge Choc Creator 2.0 Plus

- Country based: UK / China

- Food 3D printer price: €2,330

- Print volume: 180 x 180 x 40 mm

Originally based out of a uni campus, Choc Edge is now thriving as a leading food 3D printer manufacturer. The Anglo-Chinese chocolate 3D printer company’s third food 3D printer, the Choc Creator 2.0 Plus, is a picturesque and innovative machine. Though it prints edible objects, the Choc Creator still utilizes the same layer-by-layer method as with Fused Deposition Modeling. Retailing at just under $3,000, it’s a great option for niche bakers and chocolatiers out there.

Retailing at just under $3,000, it’s a great option for niche bakers and chocolatiers out there.

A few reasons why the Choc Edge Choc Creator 2.0 Plus is an industry leader are firstly how easy it is to use. The chocolate 3D printer features a large and responsive touchscreen for easy access and printing. The 0.8mm nozzle is easily removed and changed based on the 3D food material used, with the 30ml metal syringe just as easy to replace. Overall, it’s a one of the best chocolate 3D printer machines on the market, and prints in the same way as your average FDM 3D printer.The Choc Creator by Choc Edge is known as one of the best chocolate food 3D printers around.

Bonus: The Food 3D Printer That Never Happened — 3D Systems ChefJet & ChefJet Pro

- Country based: USA.

- Food 3D printer price: $5,000 & $10,000.

- Print volume: 203 x 203 x 203 mm.

The ChefJet food 3D printer created by industrial 3D printer giant 3D Systems is an unfortunate case.

3D Systems bought Sugar Labs in 2013, suggesting there may be movements from the American company in the foodtech sector in the future. Then, when they announced and demonstrated the ChefJet Food 3D Printer throughout 2014 and 2015, people couldn’t wait to get their hands on this incredible piece of tech. It could make 3D food structures out of sugar with flavours including chocolate, vanilla, mint, sour apple, cherry, watermelon, and even more!

3D Systems’ ChefJet Food 3D Printer now looks like it will get a worldwide release, thanks to a new distribution deal.But it wasn’t to be. Some internal friction within the company meant that the project was put on hold for several years. Then in late 2017, 3D Systems announced a partnership with CSM Bakery Solutions to create and distribute the food 3D printers along with custom-made food 3D printer material.

Therefore, though the ChefJet 3D printer isn’t out yet, we still felt it was worthy of its place on this list as it will get a release soon, and has demonstrated its ability to 3D print food. We look forward to seeing how far the ChefJet and ChefJet Pro can push 3D printed food in the future. The ChefJet is to retail at $5,000, whilst the ChefJet Pro will retail at $10,000.

We look forward to seeing how far the ChefJet and ChefJet Pro can push 3D printed food in the future. The ChefJet is to retail at $5,000, whilst the ChefJet Pro will retail at $10,000.

SHOP | Food Ink.

Interested in our 3D-Printed products? We have partnered with our suppliers to offer you world-leading innovation in technology and design at the best price.

QUOTE 'FOOD INK' FOR FASTER DELIVERY AND SPECIAL DEALS!

FOOD INK 3D-PRINTED FLATWARE 49 EURPRE-ORDER!

– Set contains 3D-Printed Fork, Knife and Spoon

– Food-safe PLA plastic

– High-temperature resistant (handwash-recommended)

– Designed by Polish artist Iwona Lisiecka

– 3D-Printed in Barcelona, Spain, by BCN3D Technologies

FOODINI BYNATURAL MACHINES

ORDER!

- Foodini is a 3D food printer + IoT (Internet of Things) new-generation kitchen appliance that promotes cooking with fresh, real ingredients.

- Made by Barcelona-based Natural Machines, the pioneer and leader in the 3D food printing category.

- The first 3D printer to print all types of foods from savory to sweet using fresh and real ingredients.

- Foodini ships with empty stainless steel food capsules. This open capsule design means that the consumer prepares and places fresh ingredients in Foodini, having total freedom and control over foods printed and in what form.

- User-friendly touchscreen, internal camera, and connectability to internet and other devices. Start printing immediately from many recipes freely available online– or easily make your own!

- Expands the creative possibilities for chefs by rapidly turning new ideas into unique, stunning and delicious dishes, which are then easy to replicate for multiple guests.

BCN3D TECHNOLOGIES

ORDER!

- The BCN3D Sigma is a professional FFF (Fused Filament Fabrication) 3D printer able to print just about any object you can imagine, and with very high detail.

- Made in Barcelona, Spain, by BCN3D Technologies.

- IDEX (Independent Dual Extruder) system allows it to print without geometric limitations, offering the possibility to combine multiple existing techniques such as multimaterial, multicolor and support printing.

- Materials: Filament diameter 2.85 +/- 0.05 mm. Compatible Materials: PLA, ABS, PVA, HIPS, TPE. Colorfabb co-polyesters 0.4mm nozzle // 0.6mm nozzle. Colorfabb Specials (0.6mm nozzle).

- Software and Electrical Properties: Processing files software: Cura-BCN3D, Slic3r, Simplify3D. Operating systems: Windows, Mac, Linux. Supported files: STL, OBJ, AMF. Input: AC 84-240V, AC 3,6-1,3A, 50-60Hz. Output: 24V DC, 13A. Power consumption: 240W.

- Overall Sigma 3D-Printer dimensions 465mm x 440mm x 680mm (cables included). Shipping package dimensions 550mm x 550mm x 630mm. Shipping package weight 21kg.

- What Is In The Box: 1 x BCN3D Sigma 3D-Printer; 1x Tool Kit; 1x 3DLAC; 1x Quick Start Guide; 2x Colorfila Spool.

(Note: 3DLAC not included in shippings to Greece, Ukraine or non-European countries due to air transporation safety regulations.)

(Note: 3DLAC not included in shippings to Greece, Ukraine or non-European countries due to air transporation safety regulations.) - Delivery Time: 24 hours to most countries.

BY WASP

ORDER!

- The ideal 3D-printer: precise and reliable with every material.

- Professional, compact 3D-printer to create objects up to 40 cm height, with a closed room and heated plate.

- DeltaWASP is the new line of clean design 3D-printers. Hot pad, controlled temperature ambience, and amortized bowden guarantee a controlled shrink of the material and better results in the final print.

- Accurate and reliable on all materials with pieces up to 40 cm in height.

- Made in Massa Lombarda, Italy, by WASP.

- Delivery time: 4 weeks.

07.04.2021

Content

-

- What is a food 3D printer

- Field of use

- used raw materials

- 9000 9000 9000 9000

- Top 10 Best Food Printers: A List of the Most Current Models

- 1.

PancakeBot 2.0

PancakeBot 2.0 - 2. Wiiboox Sweetin

- 3. Choc Creator V2.0 Plus

- 4. Choc Creator V2.0 Plus Food 3D Printer with Cooling Chamber

- 5. byFlow Focus

- 6. Chefjet Pro

- 7. Foodini

- 8. Mmuse – Chocolate 3D Printer Commercial ArtcakesOT7 .90BOT Printer F5

- 1.

- 10. ZMorph VX

- What is a food 3D printer

- Selection guide

- Output

A food printer is a high-tech device that is used to create culinary masterpieces. The decorative design of food products has reached a new level thanks to the use of modern technologies: high-quality and large-format printing is carried out on cakes, waffles, pancakes and even coffee. Here are the top best 3D food printers in different price categories for people who are fond of cooking. nine0003

What is a 3D food printer

The main feature of a food 3D printer is the raw materials used: instead of printing ink, the device is filled with edible ingredients. The database stores a large number of different recipes, and in order to print a dish, you just need to select one of them and activate the printing process. The final product is layered on a work surface or on a plate: it can be baked in the oven or sent to the freezer. nine0003

The database stores a large number of different recipes, and in order to print a dish, you just need to select one of them and activate the printing process. The final product is layered on a work surface or on a plate: it can be baked in the oven or sent to the freezer. nine0003

Application

Futuristic 3D Printed Sugar Candy

Cookies printed with icing

Chocolate logos of famous companies

Cream Photo Print

Buying a food 3D printer is worth the owners of coffee houses, author's bakeries and private workshops. The finished product has a unique shape and bright appearance. Food printers are often used to create custom wedding cakes, cartoon character cookies, Christmas gingerbread cookies, and so on. The possibilities of a baker who owns such a device are endless: the main thing is to buy quality products. nine0003

Raw materials used

The following ingredients are used as raw materials:

-

Chocolate without additives and impurities;

-

Mastic;

-

Sugar;

-

Whipped cottage cheese;

-

Vegetable and fruit pastes; nine0003

-

Fish and meat pates;

-

Flour;

-

Cheese, etc.

The confectionery pattern is applied to sugar, wafer or shock transfer paper. The first type has a sweetish aftertaste and aroma of vanilla. Due to the snow-white surface, no additional coating is required: the drawings look bright and clear. The wafer paper is made from rice flour and does not have a special taste, due to the light shade, the final drawings look less clear. Shock transfer paper is completely transparent and is suitable for transferring a design to a product (for example, a cake). For the packaging of finished products, food-grade plastic for a 3D printer is used. nine0003

Interesting! Food printers are involved in waste reduction. Unattractive fruit and confectionery leftovers are used in the preparation of printing mixes. This makes it possible to use the means of production more efficiently.

Types of 3D food printers

Cooking enthusiasts can take advantage of the following food printing devices:

-

Food 3D printers are devices that print dishes whose recipes are listed in a database.

The final product is layer-by-layer superimposed on the work surface, and the raw material comes from filled cartridges; nine0003

The final product is layer-by-layer superimposed on the work surface, and the raw material comes from filled cartridges; nine0003 -

Confectionery printers are used to transfer images onto specialty paper or to design small confectionery products such as candies. Such printers print an image on pre-prepared paper: rice, wafer or shock transfer;

-

Food plotters transfer the image not to paper, but directly to the finished product. For example, a plotter is used to transfer an image directly onto a cake. nine0003

There are several types of food 3D printers:

-

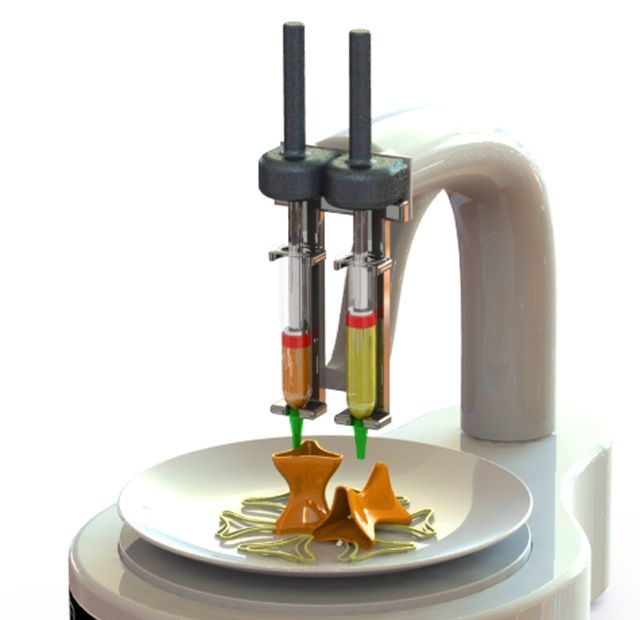

Extrusion - paint is applied to the surface before the dish is created. The process is controlled by the computer with the loaded image. The system has an extruder that heats the food mixture, and the distribution of raw materials depends on the print head. The raw material is loaded into a syringe placed in the head. This means that in order to combine different shades, you have to periodically stop printing and change the syringe; nine0003

-

A carousel-type food 3D printer also has an extruder, but its main feature is the method of feeding raw materials: the containers rotate around the working surface, the supply and dosage of the material used depends on the recipe specified in the program.

The storage can contain countless recipes, and operation does not cause difficulties even for an inexperienced user.

The storage can contain countless recipes, and operation does not cause difficulties even for an inexperienced user.

Popular brands

Eminent manufacturers offer the best value for money food 3D printer. Quality devices provide accurate printing, high speed, durability, simplicity and ease of use.

Wiibox

This company manufactures 3D printers with high build quality and high productivity. These are universal mechanisms that fill both chocolate paste and mashed potatoes. Numerous positive reviews confirm the high quality of Wiibox products. nine0003

byFlow

The Dutch company byFlow specializes in food printing technology. The pursuit of excellence helps the company open up new horizons: the technique prints products from spinach, meat emulsion and other materials. High build quality, ease of use and durability - all these characteristics are applicable to the products of this company.

Choc Edge

Choc Edge is committed to revolutionizing the world of chocolate making. Numerous experiments and focus on consumer feedback help to create more powerful devices that provide the optimal temperature for preparing and storing chocolate figures.

Numerous experiments and focus on consumer feedback help to create more powerful devices that provide the optimal temperature for preparing and storing chocolate figures.

Attention! Printing dishes helps save time on cooking: instead of culinary worries, the user can simply activate the printing process and get on with other things.

nine0134Free shipping

Add to compare

Item added to compare Go

Manufacturer Choc Edge Available on credit. To checkout, add the product to the cart and follow the instructions Go nine0003

Manufacturer Wiiboox Free Shipping

Add to compare

Item added to compare Go

Manufacturer Choc Edge Top 10 Best Food Printers: List of the Most Current Models

Before you buy a food 3D printer, you need to familiarize yourself with the most popular devices on the world market.

The top is based on ratings and customer reviews. nine0003

1. PancakeBot 2.0

PancakeBot 2.0 is easy to use, which means it's suitable for inexperienced users too. Users can choose from suggested designs in the software, or create their own. Used to print pancakes.

Pros:

Ease of operation;

A wide range of proposed projects; nine0003

High speed.

Cons:

2. Wiiboox Sweetin

Buying a food printer from Wiiboox is worth not only for confectionery lovers, but also for ordinary chefs: the device prints cakes, cookies and even mashed potatoes. The main raw materials can be meat, cheese, chocolate, jam, mashed potatoes, dough and much more. A convenient touch panel helps to set the desired mode of operation, and a stylish appearance complements the interior of any establishment. nine0003

Pros:

Versatility: the ability to print not only sweet dishes, but also side dishes;

Attractive appearance;

High build quality;

Convenient control by touch panel.

nine0173 Cons:

High price.

3. Choc Creator V2.0 Plus

When talking about which chocolate 3D printer to buy, it is worth mentioning the numerous advantages of Choc Creator V2.0 Plus. The new model has become more perfect: the developers have worked hard to eliminate the shortcomings of the previous version. The modern model has small dimensions, thanks to which it can be used in any kitchen, and the uniform heating of the syringe ensures high-quality and uninterrupted operation. In practice, the chocolate printer has shown tremendous potential: it prints complex figures from chocolate. nine0003

Pros of :

Attractive appearance;

Uninterrupted work;

Durability;

The ability to create durable and beautiful chocolate figures.

Cons :

4.

Choc Creator V2.0 Plus 3D food printer with cold chamber

The new version of the Choc Creator V2.0 Plus printer is equipped with cooling chambers by popular demand. Users say that maintaining the optimal temperature in the room to preserve the integrity of chocolate figures is too problematic: therefore, the new device cools the raw materials. The price of a food 3D printer with a cooling system is slightly higher than a classic one, but the high performance of the final product justifies any costs. nine0003

Pros of :

Availability of a cooling system for finished products;

High printing precision;

Long service life;

Ease of use: You can turn the fans on and off with the side buttons.

Cons :

High price.

Attention! Confectionery food 3D printers are often used by artists to create edible masterpieces.

This is a unique technology that helps to unleash the creative potential of the chef.

5. byFlow Focus

Food printer from the Dutch company byFlow, which specializes in 3D printing of food. The compact high-tech device is used for the bakery industry, and the cartridges are suitable for the application of any pasty ingredients. nine0003

Pros:

Cons:

6. Chefjet Pro

Buying a ChefJet Pro food printer is a must for people who dream of making bright and stylish sweets. The device is created on the principle of inkjet printing: sugar-containing powder materials are used instead of paints. The final product is made by powder layering. The printer is suitable for combining different shades and creating gradients. nine0003

Pros:

The ability to create unique flavors;

Neat and bright printing;

Aesthetic appearance of the device.

Cons:

- nine0015

High price.

7. Foodini

The 3D food printer from Foodini works on the principle of a stationary printer, but instead of printing inks, layer-by-layer imposition of edible raw materials is used: dough, cream, chocolate, cream, etc. The device is versatile: the user himself can choose the material, or use ready-made cartridges with products.

Pros:

Practicality; nine0003

High build quality;

Attractive appearance;

Availability of an online platform with unique recipes.

Cons:

8. Mmuse – Chocolate 3D Printer

The closed MMuse 3D printer is suitable for chocolate printing. Chocolate beans are used as raw materials: they are heated in an extruder and fed to the work surface through the print head.

nine0003

Pros:

Cons:

9. ZBOT Commercial Art Pancakes Printer F5

ZBOT Commercial Art Pancakes Printer F5 3D Printer

A food printer from Chinese manufacturers is used in the process of making pancakes of various shapes. Ease of operation allows the device to be used by children under adult supervision. nine0003

Pros:

Ease of operation;

High build quality;

Affordable cost.

Cons:

10. ZMorph VX

A multifunctional 3D printer capable of printing not only food, but also rubber, ABS plastic, polylactide, PVA, nylon, elastic and metal materials. The product is able to print with chocolate, butter, cookies, icing and other ingredients. In addition, there is a function of engraving and CNC milling. nine0003

Pros:

Cons:

High price.

Selection guide

The modern market offers a wide range of food printers. Before making a purchase, you need to carefully study the characteristics of each model and build on your own preferences. Experts have created several recommendations for choosing: nine0003

In case you want to create realistic images for confectionery 3D printing, pay attention to the diameter of the nozzle: the narrower it is, the more accurate the image will be;

- nine0007

It is better for people living in regions with a warm climate to purchase chocolate 3D printers with a cooling system: such devices ensure that the figurines are kept at the optimum temperature;

The possibility of self-refilling the cartridge is the most practical and economical way to operate the printer;

Print speed is an important consideration for restaurant owners. Large batches of dishes must be produced quickly, and for home use this is not a very strict selection criterion.

Output

In the catalog of our online store, you can choose the best food printers from famous brands to create culinary masterpieces. Explore our range, learn about the characteristics of each printer and make great purchases. nine0003

#Useful

Expert in the field of additive and subtractive technologies, 3D equipment and CNC machines with over 10 years of experience.

Share

all materials

Printed body: scientists have developed a 3D printer for the production of meat | Articles

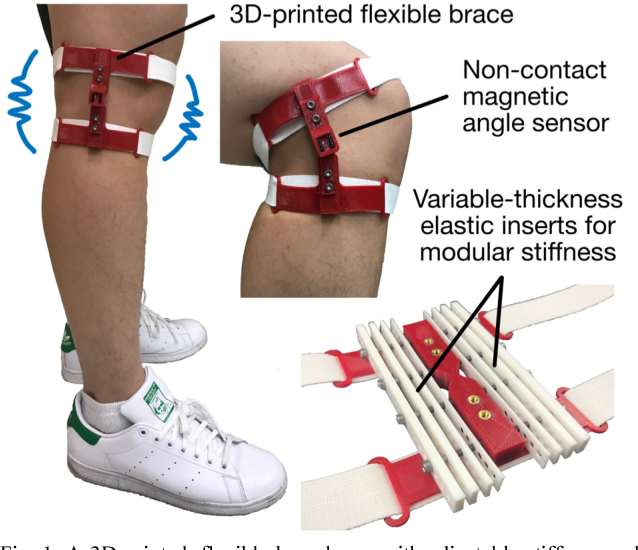

Russian specialists develop 3D farms and 3D printers for food printing . With the help of new technology, you can create a cake, pancakes and even meat. To produce, say, a piece of beef, scientists grow cow cells in bioreactors and achieve their reproduction, and then they can “print” a steak or steak from the resulting material. Food prepared in this way can be not only ethical, but also functional if vitamins and minerals that are missing for a particular person are added to the dish.

True, so far, cultured meat is a thousand times more expensive than regular meat and is unlikely to become popular if scientists do not find a way to reduce its cost. nine0003

Edible ink

Scientists of the Moscow State University of Food Production (MGUPP) create 3D food farms and 3D printers that will allow food products to be “printed” at the cellular level as an alternative to traditional food . Now the farm is already working, students and graduate students assemble printers on their own and debug the production technology. Such machines already print chocolate and dough , but this is only the beginning, the developers say. nine0575 Next in line is artificially grown (cultivated) meat . For its production, animal cells are taken as a basis, and then their reproduction is achieved in laboratory conditions.

- Such meat can certainly be called ethical, and it will obviously be in demand in the market. Most often, a biopsy is taken - a piece of tissue is plucked from the animal, without injuring it.

Cells are isolated from sample , they multiply in special bioreactors . This stage lasts for several months. The second stage is the preparation of raw materials. A special plant-based substrate is printed on which living cells are applied. Layers of animal and plant materials alternate,” said Alexei Kuchumov, Vice-Rector for Research and Development of MGUPP. nine0003

Printed body_2

Photo: MGUPP press service

All materials are applied with a special device - a bioprinter, which has already been developed by 3D Bioprinting Solutions engineers (a laboratory for the production of meat products on the basis of the university was opened jointly with this organization). Bioprinter produces products according to the given digital model .

Development is carried out within the framework of the strategic project "Biogorod" under the Priority 2030 program.

Hidden hunger

As Aleksey Kuchumov explained, the project is dedicated to solving the problem of “hidden hunger” .

Replacing conventional products with industrial analogues leads to the fact that people often get enough kilocalories, proteins, fats and carbohydrates from food, but experience a deficiency of micronutrients - vitamins, microelements, antioxidants . Suppose someone may lack potassium, someone magnesium, someone has an iron deficiency. These components can be incorporated into 3D printed food, creating personalized functional foods . You can make up for deficiencies with the help of tablets, but the consumption of missing nutrients in the form of fortified foods increases digestibility by an order of magnitude and brings more benefits to a person, scientists are sure.

- We are currently working on a database of smart recipes , which will be like instructions for the printer, like a calculation card for the chef , - said Alexey Kuchumov. nine0003

The developed printers are somewhat similar in their principle of operation to devices that print figures from plastic, but differ in the most important units, modified for printing tasks with food raw materials .

So far, the printer prints with relatively simple components: chocolate, dough, puree-like masses. With it, you can make a cake, pancakes and something similar to a piece of squid. In the future, the technology can be used to design vending machines that print products on customer order , according to the developers.

Printed body_1

Photo: MGUPP press service

— In the near future we will additionally modify the device for printing materials with a more complex texture. To do this, you need to master printing with two-component mixtures: plant fibers and animal cells. And this is practically a sausage, a cutlet or even a steak,” said Alexei Kuchumov.According to him, researchers are already able to obtain the structure and organoleptic properties of meat, similar to natural. nine0576

- The technology of printing with vegetable fibers with subsequent application of cell culture to the printed fibers has been developed, special food bioprinters have been developed that allow automating the printing process.

For example, nuggets were prepared using this technology,” Yusef Khesuani, managing partner of 3D Bioprinting Solutions, told Izvestia.

A dish not for the poor

World practice shows that meat grown in reactors is still too expensive . At this stage, cultured beef costs about a thousand times more than natural . Although scientists are coming up with various ways to cut its price . Thus, specialists from SCiFi Foods (California, USA) reduced the cost of cultivated beef to the level of meat of natural origin through the use of gene editing of a cell line using CRISPR technology.

If all goes according to plan, pilot production on the coast of San Francisco Bay will start in the second half of 2024. nine0575 SCiFi estimates that a hybrid burger made from plant components and animal cells will cost no more than $10 , and as production develops, the price can be reduced to $1. At the same time, the first burger with cultured meat, released in 2013, was estimated at $325,000.

Learn more