3D printer hotend fan

5015 Brushless Cooling Fan 4PCS 3D Printer Blower DC 12V Fans 50x50x15mm Fan for Hotend Extruder Heat Sinks with 2 Pin Terminal and Other Small Appliances Series Repair Replacement(12V 0.18A) : Electronics

4.1 out of 5 stars 453 ratings

Currently unavailable.

We don't know when or if this item will be back in stock.

Color: 12V(5015)

| Brand | UMLIFE |

| Power Connector Type | 2-Pin |

| Voltage | 12 Volts |

| Cooling Method | Fan |

| Compatible Devices | Printer |

| Noise Level | 25 dB |

| Material | Plastic |

| Maximum Rotational Speed | 5700 RPM |

Product Specifications

| Bearing Type | Oil |

|---|---|

| Color | 12V(5015) |

| Compatible Devices | Printer |

| Connector Type | 2pin |

| Ean | 0701715546813 |

| Item Shape | Snails |

| Material | Plastic |

| Maximum Rotational Speed | 5700 rpm |

| Model Number | 5015-12V |

| Noise Level | 25. |

| Part Number | 5015-12V |

| Pin Type | 2 |

| Size | 4PCS |

| Specification Met | |

| UPC | 701715546813 |

| Voltage | 12.00 volts |

Specification for this product family

| Brand Name | UMLIFE |

|---|---|

| UNSPSC Code | 43201619 |

The importance of the layer fan

When talking about the functional parts of an FDM 3D printer, the layer fan is one of the most important components that can be found. A 3D printer usually has two fans in the HotEnd area, one in charge of cooling the HotEnd diffuser and another that cools the material that comes out of the nozzle. In this article we will talk about the latter, the layer fan.

When is it necessary

All users have tried to print some part with small area zones, where the nozzle is constantly moving in the same zone, a process that causes an excess of temperature that softens the part. The same happens when printing tall, slender parts, such as a small diameter cylinder, where heat accumulates in the same area and catastrophically deforms the part. Another typical deformation is that which occurs in very steep cantilevers, where the still hot material is deformed by the action of being suspended in the air, until it solidifies.

The same happens when printing tall, slender parts, such as a small diameter cylinder, where heat accumulates in the same area and catastrophically deforms the part. Another typical deformation is that which occurs in very steep cantilevers, where the still hot material is deformed by the action of being suspended in the air, until it solidifies.

All these problems are solved simply by using the layer fan correctly.

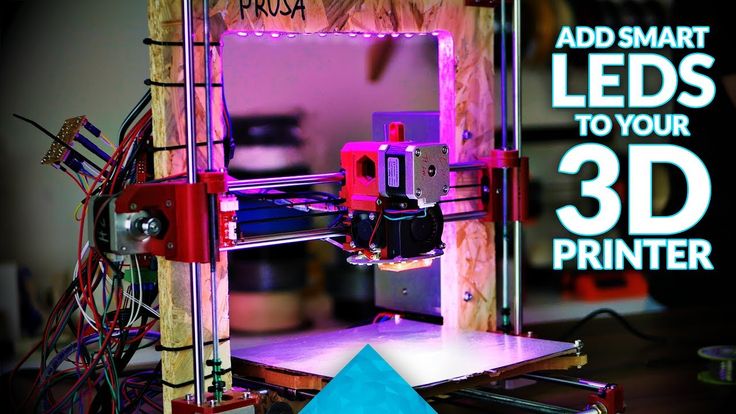

Image 1: Small parts without and with layer fan.

Compatible materials

Before commenting on how to configure the layer fan, the user must take into account with what materials it is recommended to use the layer fan and with which not.

PLA

The PLA is the material par excellence that the layer fan needs, due to its low softening point. This means that if the nozzle is placed in the same area for short periods of time, the piece will suffer irreversible deformation. For this reason, the layer fan is a crucial component in all FDM 3D printers that use PLA or some composite material containing this polymer as a base.

For this reason, the layer fan is a crucial component in all FDM 3D printers that use PLA or some composite material containing this polymer as a base.

ABS

This material and similar ones, such as ASA, are totally incompatible with the layer fan. This is because the ABS is very sensitive to the loss of temperature against drafts, such sharp increases that cause cracking (delamination of the layers) and the total failure of printing. For this reason, it is vital to use ABS and ASA with fully closed 3D printers.

Others

Apart from the materials discussed above, in 3D FDM printing there are many more types of filaments and each with a different print configuration, for that reason a table with the majority of available materials is shown below and it is indicated if they need or no layer fan:

Table 1: Layer fan depending on the material.

Expert Advice

Once the user already knows whether or not he needs to use the layer fan, he must know how to use it and when.

At the beginning of a print the user needs the first layer to adhere to the base with sufficient firmness so that it does not peel off during printing. This is achieved, not only using some product that improves adhesion, but also keeping the temperature stable, so the layer fan must be turned off during the first two layers. Once the print has a certain height, the speed of the layer fan must be adjusted to the geometry of the piece in each layer. In general, there are two cases where the speed must be varied: when the printing time of a layer is greater than 5 seconds and when it is less than 5 seconds. In the first case, the layer fan speed must be increased linearly from 70% with layer times of 20 seconds or more, up to 100% with layers of 5 seconds. When the layer time is less than 5 seconds, the user must use the layer fan at 100% speed, sometimes being an insufficient speed that causes deformation in the part. This problem, which usually occurs when narrow and tall pieces are made, is solved by printing several separate pieces simultaneously as much as possible so that each layer has time to cool.

This problem, which usually occurs when narrow and tall pieces are made, is solved by printing several separate pieces simultaneously as much as possible so that each layer has time to cool.

Any lamination software (Cura3D, Simplify3D, Slic3r...) allows you to modify the speed of the layer fan at the height of the piece that the user wants.

Image 2: Configure layer fan in Simplify3D. Source: Simplify3D.

Conclusion

It is important that all users of a 3D FDM printer know how to use the layer fan correctly, as it is a complement that elevates the quality and complexity of the parts.

Do you want to receive articles like this in your email?

Subscribe to our monthly newsletter and you will receive every month in your email the latest news and tips on 3D printing.

* By registering you accept our privacy policy.

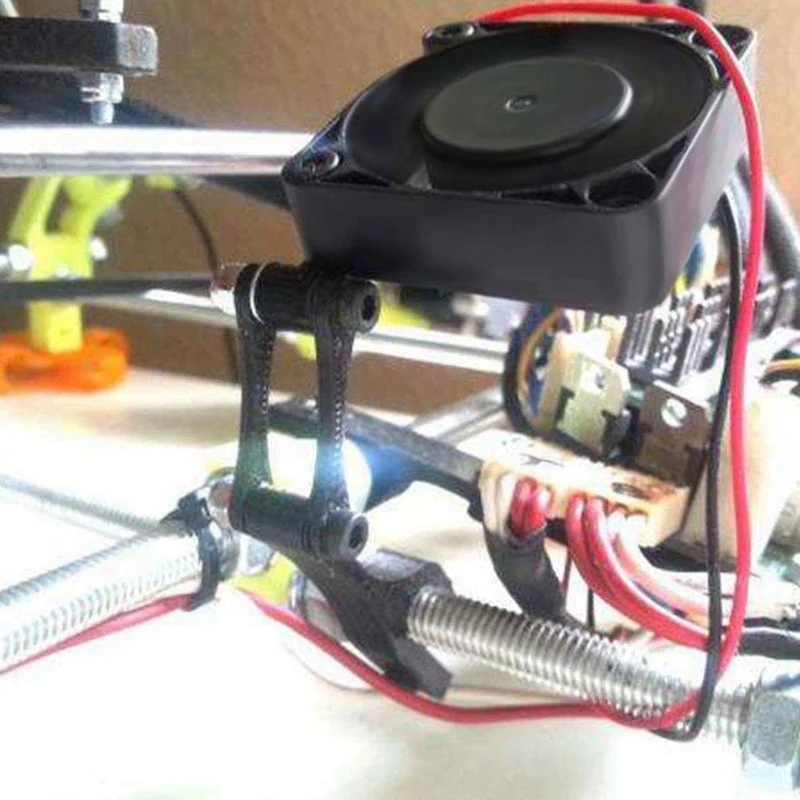

A series of troubles. Hotend fan, web

ZUBODAN

Loading

01/28/2020

1883

FAQ

Article applies to printers:

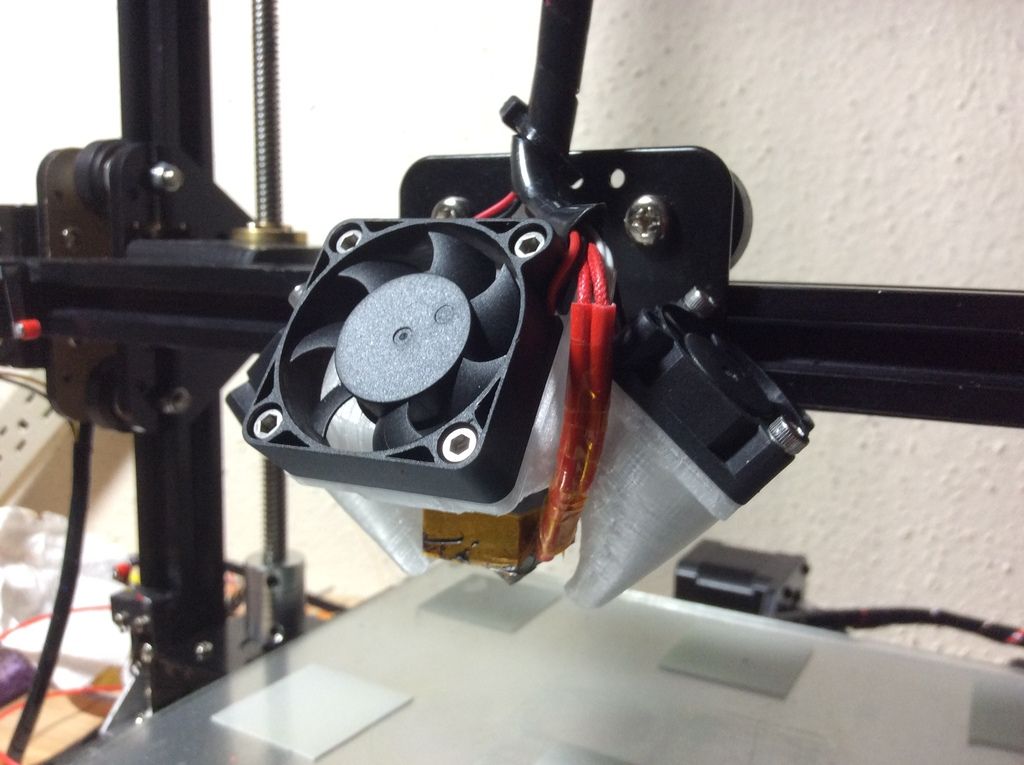

Anycubic i3 Mega Friends, help! I ran into some problems, please help.

Anycubic i3 mega printer.

Mother is a trigorilla.

PETG plastic.

Nozzle temperature 235.

The combination is set to move outside the shell.

There was a problem when printing thin-walled dimensional parts (cases, etc.) - cobwebs and snot when idling along a long perimeter. I smoked the forum, set up a retract, enabled and disabled kickbacks, all to no avail. The bastard plastic flows from the nozzle and that's it. By the way, it flows constantly, it especially heats me up to remove it when warming up before printing starts. I did not stop squatting with this problem, I still think to try to lower the temperature to 210-220, but then yesterday I was looking at the operation of the printer and found that my hotenda fan was not working. I read somewhere that the web may be due to the lack of cooling of the radiator. Began to deal with the fan. Earlier, I sorted out the entire printer, made a thermal chamber for it and took the motherboard out from the PSU, maybe somewhere I either connected it wrong (although I hardly believe in this) or there is stupidly no contact somewhere. Dismantled the head, checked the fan - working. Printing starts - the fan does not work, popped the chip out of the board - the diode caught fire, I put it back in - it goes out. I decided to hastily throw a radiator blower fan in place of the part blower fan - there is no reaction, the fan does not work. And then another problem arose (rukalitso), I connected everything as it was and the fan for blowing the part now works all the time immediately when the printer is turned on and does not turn off. I suspect that there is a short circuit somewhere on the hotenda fan line, I’ll get to the multimeter today, because yesterday I freaked out and put the printer away from sin.

Dismantled the head, checked the fan - working. Printing starts - the fan does not work, popped the chip out of the board - the diode caught fire, I put it back in - it goes out. I decided to hastily throw a radiator blower fan in place of the part blower fan - there is no reaction, the fan does not work. And then another problem arose (rukalitso), I connected everything as it was and the fan for blowing the part now works all the time immediately when the printer is turned on and does not turn off. I suspect that there is a short circuit somewhere on the hotenda fan line, I’ll get to the multimeter today, because yesterday I freaked out and put the printer away from sin.

1. Could the cobwebs be caused by the lack of radiator cooling?

2. At what stage does the radiator fan turn on? When you start printing or immediately when you turn on the printer?

3. Where to look for the reason in the constant operation of the part blower fan? It seems that the key has broken, maybe there is a problem somewhere else?

4. What could happen to the operation of the radiator fan? Where to dig?

What could happen to the operation of the radiator fan? Where to dig?

Answers on questions

FAQ

ZIZ

Loading

29.10.2022

543

Hi all! For a long time I have been suffering from such a problem as "incomprehensible stripes" every 20 layers

Help whoever can. Thanks in advance!!

Read more

T34

Loading

11/08/2022

442

Greetings dear 3D printers! Has anyone encountered the manufacture of adhesive for 3D printing based on the drug (enterodes}? I'm interested in the composition ...

Read more

I decide to buy a printer, I think but have not yet decided which design to choose. On Ali I found this option ru.aliexpress.com/item/2016-Newest-TEVO-Tarant...

On Ali I found this option ru.aliexpress.com/item/2016-Newest-TEVO-Tarant...

Read more

Spare parts for the extruder (hotend) 3D printer - Page 3 of 3 Showing 51–71 of 71

Initial SortBy PopularityBy RatingSort By Latest Price: Ascending Price: DescendingPlastic feed gear in a 3D printer

25 UAH – 42 UAHIf you notice that the plastic filament does not feed well, slips, or, on the contrary, does not advance into the extruder, then we recommend checking the plastic feed gear in the clamping mechanism.

Add to cart

Thermal sensor of a 3D printer in an insulator with a wire. (Thermistor 100K)

30 UAHClassic 100 kΩ thermistor suitable for most modern 3D printers

Thermistor in a glass insulator (bulb) with a 1m wire and a black flat connector for connecting to the board.

Add to cart

3 in 1 Multi-color Extruder NF THC-01

1665 UAHON ORDER!!!

3 in 1 Multi-color Extruder

This extruder can be used to print 3 types of plastic alternately.

Extruder equipped with three 4mm tube fittings and only one nozzle. The plastic filament is fed into the heating chamber through one thermal barrier. This approach is very similar to the classic Diamond system, but this extruder is much more compact and equipped with a classic interchangeable nozzle.

The extruder is very compact and dissipates heat well. The use of a single nozzle system avoids problems with random plastic flow when printing in multiple colors.

Please note that this extruder does not mix colors. If you need an extruder for mixing colors, then you should go here.

Fan 50 mm for 3d printer

56 UAHThis fan is more efficient and quieter than its counterparts 40mm.

Due to its good performance, this fan has become popular among 3D printer manufacturers. Miniature dimensions allow you to place it even on the extruder of a 3D printer.

12V and 24V available

Add to cart

Recessed plastic feed gear

35 UAH If you notice that the plastic filament does not feed well, slips, or vice versa does not advance into the extruder, then we recommend checking the plastic feed wheel in the clamping mechanism.

Add to cart

Extruder Multi-color 3 in 1 out Hotend kit

1385 UAHThe extruder is a more compact and improved version of the Diamond extruder.

In contrast to the classic extruder, this version contains a special mixing chamber for plastics, so that any shade can be achieved.

You only need 3 colors of 3D printing plastic.

Classic E3D interchangeable nozzles are used in the extruder.

Teflon plastic feed tube 1.75mm and 2.85mm

60 UAH – 98 UAH1.75 mm filament

Teflon tube 2 x 4 mm.

ID 2, OD 4.

For 2.85 mm plastic thread

Teflon tube 4 x 6 mm.

ID 4, OD 6.

Tube is sold by the metre. The price on the site is per meter.

Heating block E3D Cyclop

125 UAHHotend for E3D Cyclop extruders are designed for 3D printing with two plastic filaments at the same time.

The heating block allows you to mix two plastics inside while achieving a color gradient.

Add to cart

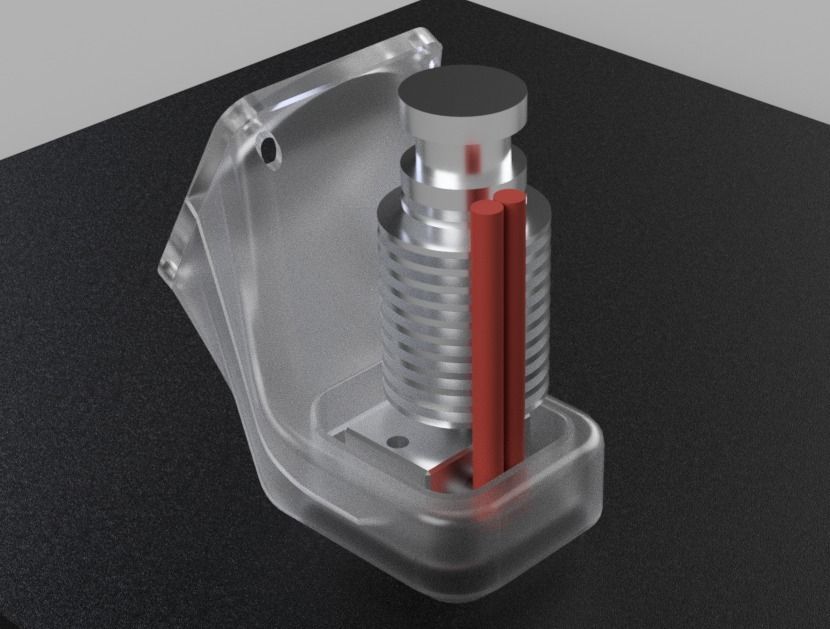

Hotend Radiator – E3D Chimera / Cyclop

155 UAHE3D's new extruders are designed for 3D printing with two plastic filaments at the same time.

These radiators have become structurally more complex, but at the same time they have become much more compact.

Hot end heatsink for 3D printer – E3D v6

55 UAH – 60 UAH Please note!

E3D v6 Direct - M6 thread - for thermal barrier with M6 thread (recommended to use a barrier with a groove)

E3D v6 Bowden - thread in the radiator M7 - for a thermal barrier with a transition thread M7-M6 (it is recommended to use a barrier with a groove)

Diamond E3D Color 3D Printing Extruder

430 UAHExtruder for mixing 3 colors of plastic for color 3D printing.

Diamond extruders allow you to print with 3 filaments using only one nozzle and one heating element. This solution avoids problems with randomly flowing plastic from an unused nozzle.