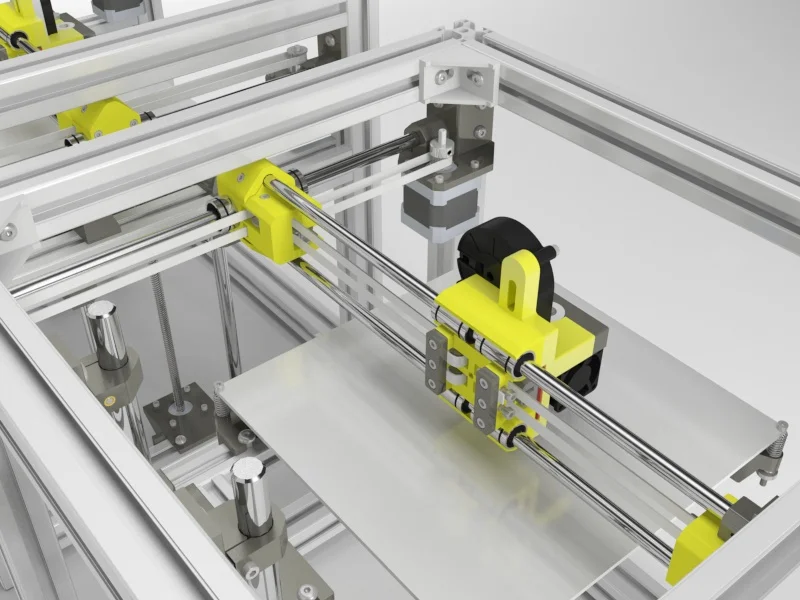

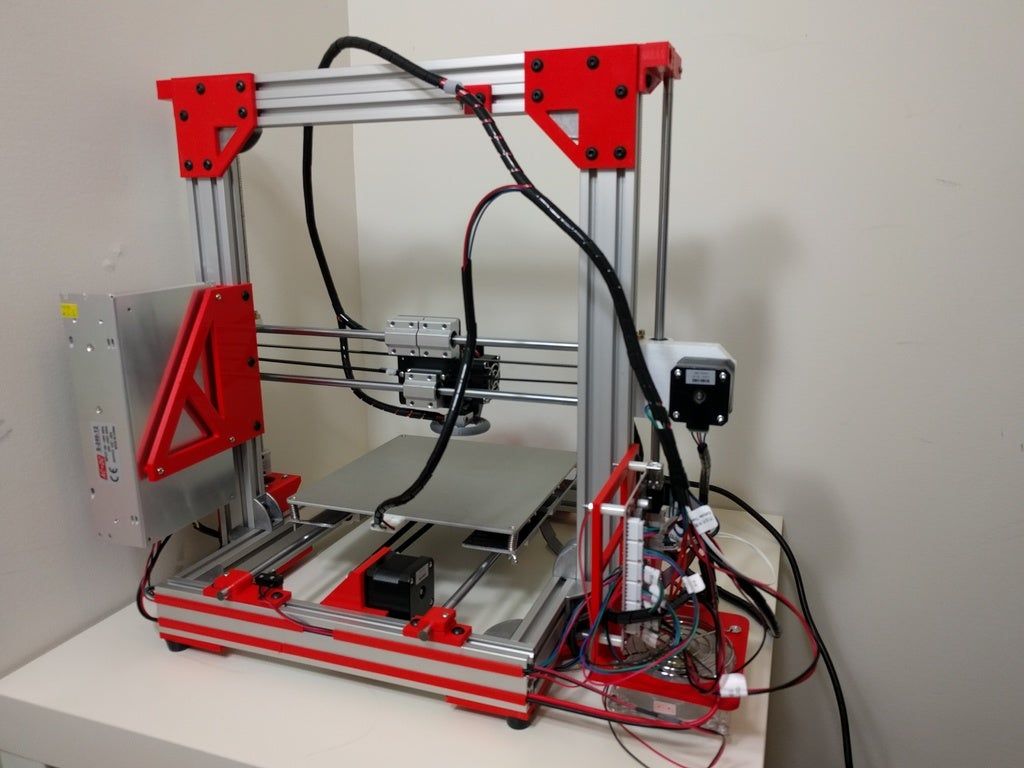

3D printer frame material

Guide to 3D Printing Materials: Types, Applications, and Properties

3D printing empowers you to prototype and manufacture parts for a wide range of applications quickly and cost-effectively. But choosing the right 3D printing process is just one side of the coin. Ultimately, it'll be largely up to the materials to enable you to create parts with the desired mechanical properties, functional characteristics, or looks.

This comprehensive guide to 3D printing materials showcases the most popular plastic and metal 3D printing materials available, compares their properties, applications, and describes a framework that you can use to choose the right one for your project.

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Recommend Me a Material

There are dozens of plastic materials available for 3D printing, each with its unique qualities that make it best suited to specific use cases. To simplify the process of finding the material best suited for a given part or product, let’s first look at the main types of plastics and the different 3D printing processes.

There are the two main types of plastics:

-

Thermoplastics are the most commonly used type of plastic. The main feature that sets them apart from thermosets is their ability to go through numerous melt and solidification cycles. Thermoplastics can be heated and formed into the desired shape. The process is reversible, as no chemical bonding takes place, which makes recycling or melting and reusing thermoplastics feasible. A common analogy for thermoplastics is butter, which can be melted, re-solidify, and melted again. With each melting cycle, the properties change slightly.

-

Thermosetting plastics (also referred to as thermosets) remain in a permanent solid state after curing. Polymers in thermosetting materials cross-link during a curing process that is induced by heat, light, or suitable radiation. Thermosetting plastics decompose when heated rather than melting, and will not reform upon cooling. Recycling thermosets or returning the material back into its base ingredients is not possible. A thermosetting material is like cake batter, once baked into a cake, it cannot be melted back into batter again.

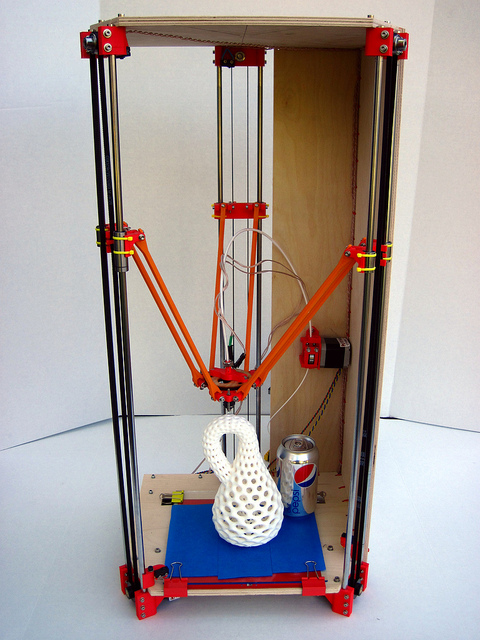

The three most established plastic 3D printing processes today are the following:

-

Fused deposition modeling (FDM) 3D printers melt and extrude thermoplastic filaments, which a printer nozzle deposits layer by layer in the build area.

-

Stereolithography (SLA) 3D printers use a laser to cure thermosetting liquid resins into hardened plastic in a process called photopolymerization.

-

Selective laser sintering (SLS) 3D printers use a high-powered laser to fuse small particles of thermoplastic powder.

Video Guide

Having trouble finding the best 3D printing technology for your needs? In this video guide, we compare FDM, SLA, and SLS technologies across popular buying considerations.

Watch the Videos

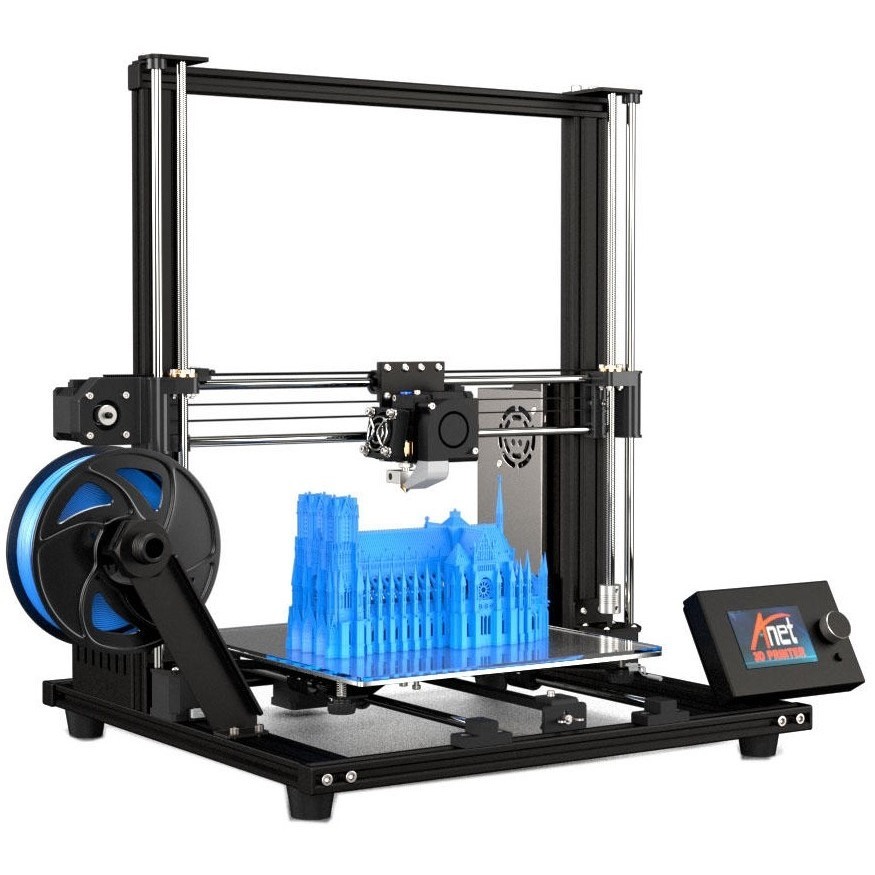

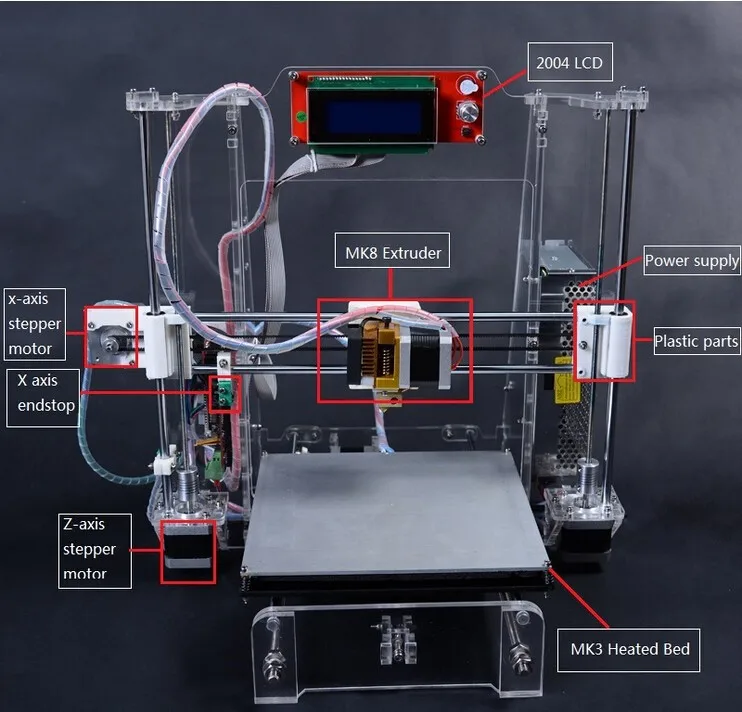

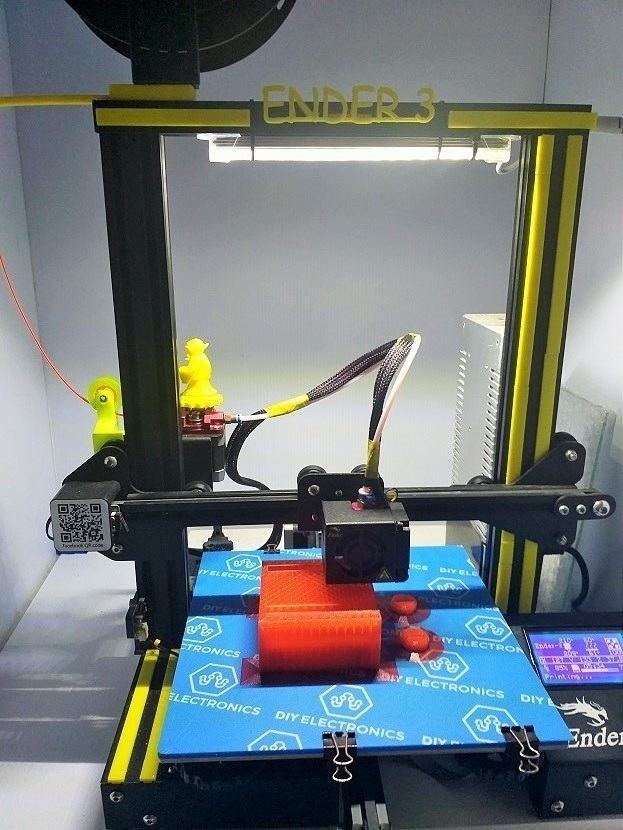

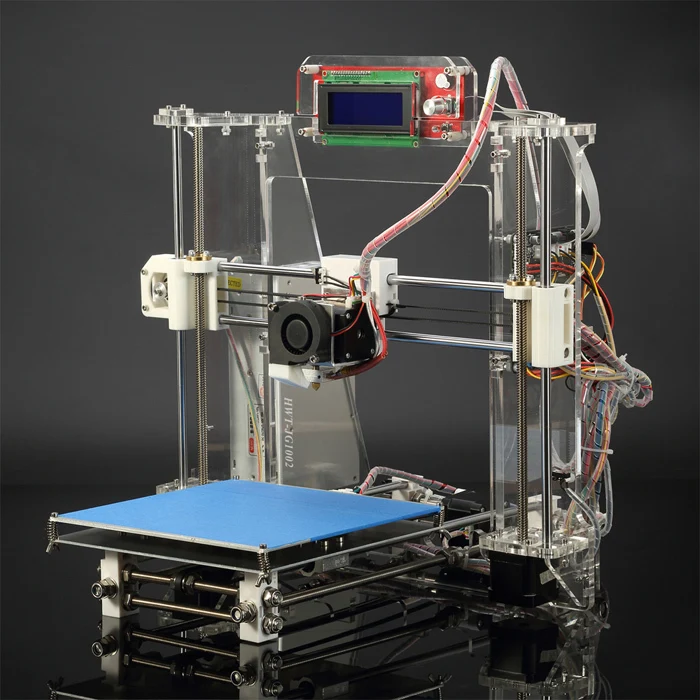

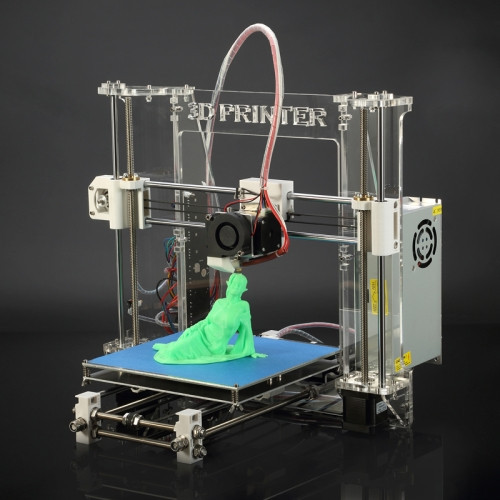

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers.

This technique is well-suited for basic proof-of-concept models, as well as quick and low-cost prototyping of simple parts, such as parts that might typically be machined.

Consumer level FDM has the lowest resolution and accuracy when compared to other plastic 3D printing processes and is not the best option for printing complex designs or parts with intricate features. Higher-quality finishes may be obtained through chemical and mechanical polishing processes. Industrial FDM 3D printers use soluble supports to mitigate some of these issues and offer a wider range of engineering thermoplastics or even composites, but they also come at a steep price.

Higher-quality finishes may be obtained through chemical and mechanical polishing processes. Industrial FDM 3D printers use soluble supports to mitigate some of these issues and offer a wider range of engineering thermoplastics or even composites, but they also come at a steep price.

As the melted filament forms each layer, sometimes voids can remain between layers when they don’t adhere fully. This results in anisotropic parts, which is important to consider when you are designing parts meant to bear load or resist pulling.

FDM 3D printing materials are available in a variety of color options. Various experimental plastic filament blends also exist to create parts with wood- or metal-like surfaces.

The most common FDM 3D printing materials are ABS, PLA, and their various blends. More advanced FDM printers can also print with other specialized materials that offer properties like higher heat resistance, impact resistance, chemical resistance, and rigidity.

| Material | Features | Applications |

|---|---|---|

| ABS (acrylonitrile butadiene styrene) | Tough and durable Heat and impact resistant Requires a heated bed to print Requires ventilation | Functional prototypes |

| PLA (polylactic acid) | The easiest FDM materials to print Rigid, strong, but brittle Less resistant to heat and chemicals Biodegradable Odorless | Concept models Looks-like prototypes |

| PETG (polyethylene terephthalate glycol) | Compatible with lower printing temperatures for faster production Humidity and chemical resistant High transparency Can be food safe | Waterproof applications Snap-fit components |

| Nylon | Strong, durable, and lightweight Tough and partially flexible Heat and impact resistant Very complex to print on FDM | Functional prototypes Wear resistant parts |

| TPU (thermoplastic polyurethane) | Flexible and stretchable Impact resistant Excellent vibration dampening | Flexible prototypes |

| PVA (polyvinyl alcohol) | Soluble support material Dissolves in water | Support material |

| HIPS (high impact polystyrene) | Soluble support material most commonly used with ABS Dissolves in chemical limonene | Support material |

| Composites (carbon fiber, kevlar, fiberglass) | Rigid, strong, or extremely tough Compatibility limited to some expensive industrial FDM 3D printers | Functional prototypes Jigs, fixtures, and tooling |

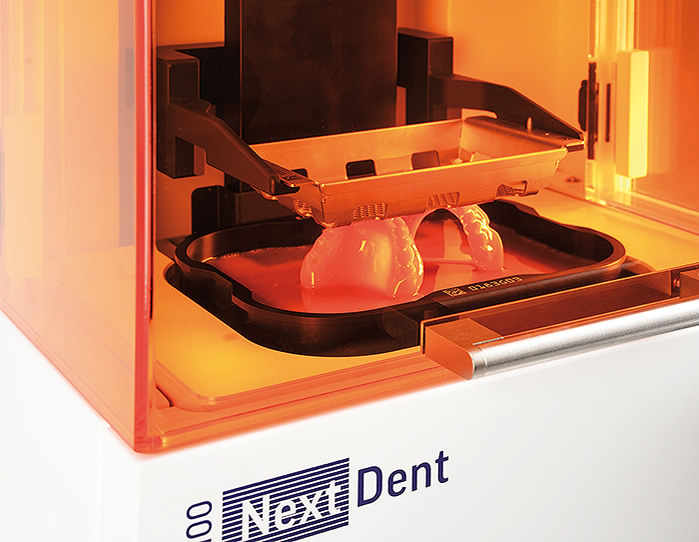

Stereolithography was the world’s first 3D printing technology, invented in the 1980s, and is still one of the most popular technologies for professionals.

SLA parts have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies. Resin 3D printing is a great option for highly detailed prototypes requiring tight tolerances and smooth surfaces, such as molds, patterns, and functional parts. SLA parts can also be highly polished and/or painted after printing, resulting in client-ready parts with high-detailed finishes.

Parts printed using SLA 3D printing are generally isotropic—their strength is more or less consistent regardless of orientation because chemical bonds happen between each layer. This results in parts with predictable mechanical performance critical for applications like jigs and fixtures, end-use parts, and functional prototyping.

SLA offers the widest range of material options for plastic 3D printing.

SLA 3D printing is highly versatile, offering resin formulations with a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

| Formlabs Materials | Features | Applications |

|---|---|---|

| Standard Resins | High resolution Smooth, matte surface finish | Concept models Looks-like prototypes |

| Clear Resin | The only truly clear material for plastic 3D printing Polishes to near optical transparency | Parts requiring optical transparency Millifluidics |

| Draft Resin | One of the fastest materials for 3D printing 4x faster than standard resins, up to 10x faster than FDM | Initial Prototypes Rapid Iterations |

| Tough and Durable Resins | Strong, robust, functional, and dynamic materials Can handle compression, stretching, bending, and impacts without breaking Various materials with properties similar to ABS or PE | Housings and enclosures Jigs and fixtures Connectors Wear-and-tear prototypes |

| Rigid Resins | Highly filled, strong and stiff materials that resist bending Thermally and chemically resistant Dimensionally stable under load | Jigs, fixtures, and tooling Turbines and fan blades Fluid and airflow components Electrical casings and automotive housings |

| Polyurethane Resins | Excellent long-term durability UV, temperature, and humidity stable Flame retardancy, sterilizability, and chemical and abrasion resistance | High performance automotive, aerospace, and machinery components Robust and rugged end-use parts Tough, longer-lasting functional prototypes |

| High Temp Resin | High temperature resistance High precision | Hot air, gas, and fluid flow Heat resistant mounts, housings, and fixtures Molds and inserts |

| Flexible and Elastic Resins | Flexibility of rubber, TPU, or silicone Can withstand bending, flexing, and compression Holds up to repeated cycles without tearing | Consumer goods prototyping Compliant features for robotics Medical devices and anatomical models Special effects props and models |

| Medical and dental resins | A wide range of biocompatible resins for producing medical and dental appliances | Dental and medical appliances, including surgical guides, dentures, and prosthetics |

| Jewelry resins | Materials for investment casting and vulcanized rubber molding Easy to cast, with intricate details and strong shape retention | Try-on pieces Masters for reusable molds Custom jewelry |

| ESD Resin | ESD-safe material to improve electronics manufacturing workflows | Tooling & fixturing for electronics manufacturing Anti-static prototypes and end-use components Custom trays for component handling and storage |

| Ceramic Resin | Stone-like finish Can be fired to create a fully ceramic piece | Engineering research Art and design pieces |

Explore Formlabs SLA Materials

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

We’ll ship a free sample part to your office.

Request a Free Sample Part

Selective laser sintering (SLS) 3D printing is trusted by engineers and manufacturers across different industries for its ability to produce strong, functional parts. Low cost per part, high productivity, and established materials make the technology ideal for a range of applications from rapid prototyping to small-batch, bridge, or custom manufacturing.

As the unfused powder supports the part during printing, there’s no need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features.

Just like SLA, SLS parts are also generally more isotropic than FDM parts. SLS parts have a slightly rough surface finish due to the powder particles, but almost no visible layer lines.

SLS 3D printing materials are ideal for a range of functional applications, from engineering consumer products to manufacturing and healthcare.

The material selection for SLS is limited compared to FDM and SLA, but the available materials have excellent mechanical characteristics, with strength resembling injection-molded parts. The most common material for selective laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is lightweight, strong, and flexible, as well as stable against impact, chemicals, heat, UV light, water, and dirt.

| Material | Description | Applications |

|---|---|---|

| Nylon 12 | Strong, stiff, sturdy, and durable Impact-resistant and can endure repeated wear and tear Resistant to UV, light, heat, moisture, solvents, temperature, and water | Functional prototyping End-use parts Medical devices |

| Nylon 11 | Similar properties to Nylon 12, but with a higher elasticity, elongation at break, and impact resistance, but lower stiffness | Functional prototyping End-use parts Medical devices |

| TPU | Flexible, elastic, and rubbery Resilient to deformation High UV stability Great shock absorption | Functional prototyping Flexible, rubber-like end-use parts Medical devices |

| Nylon composites | Nylon materials reinforced with glass, aluminum, or carbon fiber for added strength and rigidity | Functional prototyping Structural end-use parts |

Explore Formlabs SLS Materials

Sample part

See and feel Formlabs SLS quality firsthand. We’ll ship a free sample part to your office.

We’ll ship a free sample part to your office.

Request a Free Sample Part

Different 3D printing materials and processes have their own strengths and weaknesses that define their suitability for different applications. The following table provides a high level summary of some key characteristics and considerations.

| FDM | SLA | SLS | |

|---|---|---|---|

| Pros | Low-cost consumer machines and materials available | Great value High accuracy Smooth surface finish Range of functional materials | Strong functional parts Design freedom No need for support structures |

| Cons | Low accuracy Low details Limited design compatibility High cost industrial machines if accuracy and high performance materials are needed | Sensitive to long exposure to UV light | More expensive hardware Limited material options |

| Applications | Low-cost rapid prototyping Basic proof-of-concept models Select end-use parts with high-end industrial machines and materials | Functional prototyping Patterns, molds, and tooling Dental applications Jewelry prototyping and casting Models and props | Functional prototyping Short-run, bridge, or custom manufacturing |

| Materials | Standard thermoplastics, such as ABS, PLA, and their various blends on consumer level machines. High performance composites on high cost industrial machines High performance composites on high cost industrial machines | Varieties of resin (thermosetting plastics). Standard, engineering (ABS-like, PP-like, flexible, heat-resistant), castable, dental, and medical (biocompatible). | Engineering thermoplastics. Nylon 11, Nylon 12, and their composites, thermoplastic elastomers such as TPU. |

Beyond plastics, there are multiple 3D printing processes available for metal 3D printing.

-

Metal FDM

Metal FDM printers work similarly to traditional FDM printers, but use extrude metal rods held together by polymer binders. The finished “green” parts are then sintered in a furnace to remove the binder.

SLM and DMLS printers work similarly to SLS printers, but instead of fusing polymer powders, they fuse metal powder particles together layer by layer using a laser. SLM and DMLS 3D printers can create strong, accurate, and complex metal products, making this process ideal for aerospace, automotive, and medical applications.

-

Titanium is lightweight and has excellent mechanical characteristics. It is strong, hard and highly resistant to heat, oxidation, and acid.

-

Stainless steel has high strength, high ductility, and is resistant to corrosion.

-

Aluminum is a lightweight, durable, strong, and has good thermal properties.

-

Tool steel is a hard, scratch-resistant material that you can use to print end-use tools and other high-strength parts..

- Nickel alloys have high tensile, creep and rupture strength and are heat and corrosion resistant.

Compared to plastic 3D printing technologies, metal 3D printing is substantially more costly and complex, limiting its accessibility to most businesses.

Alternatively, SLA 3D printing is well-suited for casting workflows that produce metal parts at a lower cost, with greater design freedom, and in less time than traditional methods.

Another alternative is electroplating SLA parts, which involves coating a plastic material in a layer of metal via electrolysis. This combines some of the best qualities of metal—strength, electrical conductivity, and resistance to corrosion and abrasion—with the specific properties of the primary (usually plastic) material.

Plastic 3D printing is well-suited to create patterns that can be cast to produce metal parts.

With all these materials and 3D printing options available, how can you make the right selection?

Here’s our three-step framework to choose the right 3D printing material for your application.

Plastics used for 3D printing have different chemical, optical, mechanical, and thermal characteristics that determine how the 3D printed parts will perform. As the intended use approaches real-world usage, performance requirements increase accordingly.

| Requirement | Description | Recommendation |

|---|---|---|

| Low performance | For form and fit prototyping, conceptual modeling, and research and development, printed parts only need to meet low technical performance requirements. Example: A form prototype of a soup ladle for ergonomic testing. No functional performance requirements needed besides surface finish. | FDM: PLA SLA: Standard Resins, Clear Resin (transparent part), Draft Resin (fast printing) |

| Moderate performance | For validation or pre-production uses, printed parts must behave as closely to final production parts as possible for functional testing but do not have strict lifetime requirements. Example: A housing for electronic components to protect against sudden impact. Performance requirements include ability to absorb impact, housing needs to snap together and hold its shape. | FDM: ABS SLA: Engineering Resins SLS: Nylon 11, Nylon 12, TPU |

| High performance | For end-use parts, final 3D printed production parts must stand up to significant wear for a specific time period, whether that’s one day, one week, or several years. Example: Shoe outsoles. | FDM: Composites SLA: Engineering, Medical, Dental, or Jewelry Resins SLS: Nylon 11, Nylon 12, TPU, nylon composites |

Once you’ve identified the performance requirements for your product, the next step is translating them into material requirements—the properties of a material that will satisfy those performance needs. You’ll typically find these metrics on a material’s data sheet.

| Requirement | Description | Recommendation |

|---|---|---|

| Tensile strength | Resistance of a material to breaking under tension. High tensile strength is important for structural, load bearing, mechanical, or statical parts. | FDM: PLA SLA: Clear Resin, Rigid Resins SLS: Nylon 12, nylon composites |

| Flexural modulus | Resistance of a material to bending under load. Good indicator for either the stiffness (high modulus) or the flexibility (low modulus) of a material. Good indicator for either the stiffness (high modulus) or the flexibility (low modulus) of a material. | FDM: PLA (high), ABS (medium) SLA: Rigid Resins (high), Tough and Durable Resins (medium), Flexible and Elastic Resins (low) SLS: nylon composites (high), Nylon 12 (medium) |

| Elongation | Resistance of a material to breaking when stretched. Helps you compare flexible materials based on how much they can stretch. Also indicates if a material will deform first, or break suddenly. | FDM: ABS (medium), TPU (high) SLA: Tough and Durable Resins (medium), Polyurethane Resins (medium), Flexible and Elastic Resins (high) SLS: Nylon 12 (medium), Nylon 11 (medium), TPU (high) |

| Impact strength | Ability of a material to absorb shock and impact energy without breaking. Indicates toughness and durability, helps you figure out how easily a material will break when dropped on the ground or crashed into another object. | FDM: ABS, Nylon SLA: Tough 2000 Resin, Tough 1500 Resin, Grey Pro Resin, Durable Resin, Polyurethane Resins SLS: Nylon 12, Nylon 11, nylon composites |

| Heat deflection temperature | Temperature at which a sample deforms under a specified load. Indicates if a material is suitable for high temperature applications. | SLA: High Temp Resin, Rigid Resins SLS: Nylon 12, Nylon 11, nylon composites |

| Hardness (durometer) | Resistance of a material to surface deformation. Helps you identify the right “softness” for soft plastics, like rubber and elastomers for certain applications. | FDM: TPU SLA: Flexible Resin, Elastic Resin SLS: TPU |

| Tear strength | Resistance of a material to growth of cuts under tension. Important to assess the durability and the resistance to tearing of soft plastics and flexible materials, such as rubber. | FDM: TPU SLA: Flexible Resin, Elastic Resin, Durable Resin SLS: Nylon 11, TPU |

| Creep | Creep is the tendency of a material to deform permanently under the influence of constant stress: tensile, compressive, shear, or flexural. Low creep indicates longevity for hard plastics and is crucial for structural parts. Low creep indicates longevity for hard plastics and is crucial for structural parts. | FDM: ABS SLA: Polyurethane Resins, Rigid Resins SLS: Nylon 12, Nylon 11, nylon composites |

| Compression set | Permanent deformation after material has been compressed. Important for soft plastics and elastic applications, tells you if a material will return to its original shape after the load is removed. | FDM: TPU SLA: Flexible Resin, Elastic Resin SLS: TPU |

For even more details on material properties, read our guide to about the most common mechanical and thermal properties.

Once you translate performance requirements to material requirements, you’ll most likely end up with a single material or a smaller group of materials that could be suitable for your application.

If there are multiple materials that fulfil your basic requirements, you can then look at a wider range of desired characteristics and consider the pros, cons, and trade-offs of the given materials and processes to make the final choice.

Try our interactive material wizard to find materials based on your application and the properties you care the most about from our growing library of materials. Do you have specific questions about 3D printing materials? Contact our experts.

Recommend Me a Material

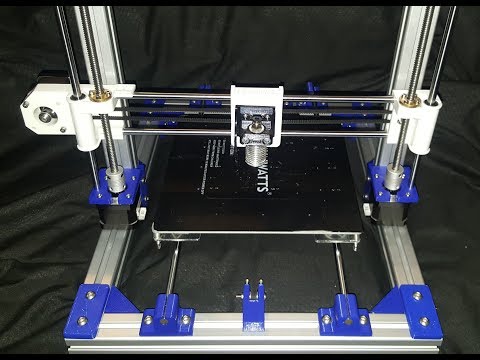

3D Printer 8020 How-To Video

IMPORTANT SAFETY INSTRUCTIONS Your safety and the safety of others are very important. Read instructions thoroughly prior to assembly. Please follow assembly instructions. Check for all parts before beginning assembly using the provided parts list to verify that all parts required to assemble the product are included. This kit contains parts that can be damaged if assembled incorrectly or in the wrong sequence. 80/20 shall not be responsible for replacing parts lost or damaged due to incorrect assembly. [Assistance is required during parts of the assembly].

80/20 QUALITY POLICY 80/20 is dedicated to providing its products free of actual defects in material and workmanship.

80/20 will replace or repair, at 80/20’s option, any product which, upon 80/20’s inspection is found to have a defect in material and/or workmanship provided such defect is reported to 80/20 in writing within one (1) year of the date of shipment from 80/20’s factory (“Quality Policy”). This Quality Policy does not cover failures due to abuse, accidental damages, or when repairs have been made or attempted by anyone other than 80/20. Should replacement of the defective items be unavailable, 80/20 reserves the right to substitute items of 80/20’s choice with items of similar style, color and quality. The terms of this Quality Policy are subject to change without notice. This Quality Policy is subject to the limitations set forth above. In addition, this Quality Policy is made to the original purchaser only and is effective only if items are purchased from 80/20 or one of 80/20’s authorized distributors. 80/20’s obligations under the Quality Policy is non-transferrable.

80/20 will replace or repair, at 80/20’s option, any product which, upon 80/20’s inspection is found to have a defect in material and/or workmanship provided such defect is reported to 80/20 in writing within one (1) year of the date of shipment from 80/20’s factory (“Quality Policy”). This Quality Policy does not cover failures due to abuse, accidental damages, or when repairs have been made or attempted by anyone other than 80/20. Should replacement of the defective items be unavailable, 80/20 reserves the right to substitute items of 80/20’s choice with items of similar style, color and quality. The terms of this Quality Policy are subject to change without notice. This Quality Policy is subject to the limitations set forth above. In addition, this Quality Policy is made to the original purchaser only and is effective only if items are purchased from 80/20 or one of 80/20’s authorized distributors. 80/20’s obligations under the Quality Policy is non-transferrable. 80/20 LIMITED WARRANTY All 80/20 products are guaranteed to be free of actual defects in material and workmanship, provided any such defect be reported to 80/20 in writing within one (1) year of date of purchase.

This warranty is limited to replacing or repairing, at 80/20's option any part which, upon 80/20 inspection is found to have a defect in material and/or workmanship.

This warranty is limited to replacing or repairing, at 80/20's option any part which, upon 80/20 inspection is found to have a defect in material and/or workmanship. DISCLAIMER OF IMPLIED WARRANTIES No warranty is made by 80/20, express or implied, that 80/20 products as used in a customer’s design and specifications are fit for that customer’s specific purpose. APART FROM THE ABOVE QUALITY POLICY, THERE ARE NO WARRANTIES, EXPRESS, IMPLIED, OR STATUTORY, INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF.

LIMITATION OF REMEDIES YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS QUALITY POLICY SHALL BE PRODUCT REPAIR OR REPLACEMENT AS PROVIDED HEREIN. 80/20 SHALL NOT BE LIABLE FOR SPECIFIC, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF 80/20 PRODUCTS. This quality policy provides customer with specific legal rights, and customer may have other rights which may vary according to relevant state laws.

MAINTENANCE Regularly check fastener hardware for tightness.

CONTACT INFORMATION For assistance in the U.S.A, call 1-260-248-8030. If you need further assistance, you can write 80/20 Inc. with any questions or comments at 1701 South 400 East, Columbia City, IN 46725 Visit us on the web at www.8020.net

We have temporarily removed catalog hard copy requests. Please refer to the Virtual Catalog if you would like to view it.

Address Information

Company

Phone Number

Street 1

Street 2

State/Province

Zip/Postal Code

Country

CanadaUnited StatesAfghanistanÅland IslandsAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua & BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia & HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBritish Virgin IslandsBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCape VerdeCaribbean NetherlandsCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongo - BrazzavilleCongo - KinshasaCook IslandsCosta RicaCôte d’IvoireCroatiaCubaCuraçaoCyprusCzechiaDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard & McDonald IslandsHondurasHong Kong SAR ChinaHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKosovoKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacao SAR ChinaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmar (Burma)NamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorth KoreaNorth MacedoniaNorwayOmanPakistanPalauPalestinian TerritoriesPanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandsPolandPortugalPuerto RicoQatarRéunionRomaniaRussiaRwandaSamoaSan MarinoSão Tomé & PríncipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia & South Sandwich IslandsSouth KoreaSpainSri LankaSt. BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSudanSurinameSvalbard & Jan MayenSwedenSwitzerlandSyriaTaiwan, Province of ChinaTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUruguayU.S. Outlying IslandsU.S. Virgin IslandsUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabwe

BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSudanSurinameSvalbard & Jan MayenSwedenSwitzerlandSyriaTaiwan, Province of ChinaTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUruguayU.S. Outlying IslandsU.S. Virgin IslandsUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabwe

Miscellaneous

How did you hear about us?

Select OneWebFriendProfessional DesignerCatalogTV commercial or other advertisementNewspaper, magazine article, or TV showOther

Comments

how to optimize design and speed up production

Rapid prototyping

Experts recommend

Author: Viktor Naumov

Author: Viktor Naumov

Benefits of 3D Printed Cases | Developing custom electronics cases: what material to choose for 3D printing? | How to design enclosures for 3D printing | Access to components | The strength of the 3D printed case | Quality and precision | Order a 3D printing service nine0003

Adopting additive manufacturing can bring more value to your business than you might think. Manufacturing electronics is a lot of work, but with 3D printers, the process can be simplified. We will look at one particular detail: the body of an electronic device. How can it be improved and thereby optimize the entire production process? This will be discussed in the article.

Manufacturing electronics is a lot of work, but with 3D printers, the process can be simplified. We will look at one particular detail: the body of an electronic device. How can it be improved and thereby optimize the entire production process? This will be discussed in the article.

Scalable Electronics Manufacturing

The manufacture of electronic devices is associated with certain difficulties. How can the creation of electronics cases affect the success of related projects and business as a whole? nine0003

See the benefits of scalable and adaptable enclosures. When designing electronic devices, you must keep pace with changing market demands, including record-breaking project turnaround times. This is made possible by an optimized and scalable manufacturing process. Implementing Just-In-Time principles in part manufacturing can also be a huge business benefit.

In the electronics industry, additive manufacturing opens up many opportunities. Consider the example of a plastic case. This is where 3D printing technology can bring significant benefits. The introduction of 3D printing is a solution that can speed up production processes and increase competitiveness. But that's not all. Additive technologies will also enable innovation and improved hull design. nine0003

Consider the example of a plastic case. This is where 3D printing technology can bring significant benefits. The introduction of 3D printing is a solution that can speed up production processes and increase competitiveness. But that's not all. Additive technologies will also enable innovation and improved hull design. nine0003

iQB Technologies Experts Recommend Article: 14 Frequently Asked Questions About FDM Production Printing

Benefits of 3D Printed Cases

Adaptability

Additive manufacturing provides almost limitless freedom of action. In the manufacture of cases on a 3D printer, it is possible to provide for latches, locking connections, threaded connections and flexible hinges. Thanks to thoughtful functionality, the case will become more versatile. nine0003

3D printing provides design flexibility not available with injection molding. Indeed, it is almost impossible to make changes to the design of the finished mold. If you want to change the project, you will have to start all over again.

With 3D printing, everything is different: you just need to make changes to the 3D file, which will not stop the manufacturing process for a minute. The ability to quickly adjust workflows increases production agility at no extra cost. Thanks to 3D files, there is no need to worry about the service life of the body structure or other part. Changes can be made at any time as needed. nine0003

Another significant advantage of additive manufacturing is mass customization. You can customize the work files according to the client's needs. Making several iterations of the case on a 3D printer will not increase the cost of production!

Prototype laser housing 3D printed by TWIZE

3D printer: ProtoFab SLA600 DLC

Material: photopolymer Formula W

Layer thickness: 100 microns

Print time: 12 hours

The result of the work: a laser body suitable both for checking the assembly and as a master model for casting in silicone

Want to try 3D printing prototypes or functional products? Test service is free!

Order a 3D printing service

Innovations

Additive manufacturing provides an opportunity to innovate and improve designs. With 3D printing, you can focus on what you want to create, rather than what you can, given the limitations of traditional manufacturing. Experiment and improve your designs with cutting-edge technology. nine0003

With 3D printing, you can focus on what you want to create, rather than what you can, given the limitations of traditional manufacturing. Experiment and improve your designs with cutting-edge technology. nine0003

You can take into account all the functional features of the part and integrate them directly into the device.

Acceleration of production processes

Speeding up processes drives business growth. When creating an electronic device, the design and ergonomics of the case are just as important as its performance. This requirement is easily implemented due to the ability to create complex forms very quickly. 3D printing is the fastest prototyping technology: unique prototypes can be produced without a mold, resulting in low part cost. nine0003

With 3D printing, the price does not depend on the number of parts, but on the amount of material used. By making multiple iterations of the same case, 3D printing will be a much more sustainable and sustainable manufacturing method than traditional ones. Using a 3D printed prototype, you can check the ergonomics, material features, as well as the fit of internal components or additional elements. With a wide range of 3D printing materials, you can evaluate their benefits and build quality based on project requirements. nine0003

Using a 3D printed prototype, you can check the ergonomics, material features, as well as the fit of internal components or additional elements. With a wide range of 3D printing materials, you can evaluate their benefits and build quality based on project requirements. nine0003

3D printing is ideal for making plastic cases. Whether you need to customize a product or follow Just-In-Time principles, the benefits of this technology for your business are undeniable.

iQB Technologies Experts Recommend Article: From Aircraft Prototype to Biomedicine: Sharebot Unleashes New Opportunities

Development of customized electronics enclosures

Which 3D printing material to choose? nine0027

What is the best material for case making? To develop a project and start 3D modeling, you must select the material and take into account the design parameters.

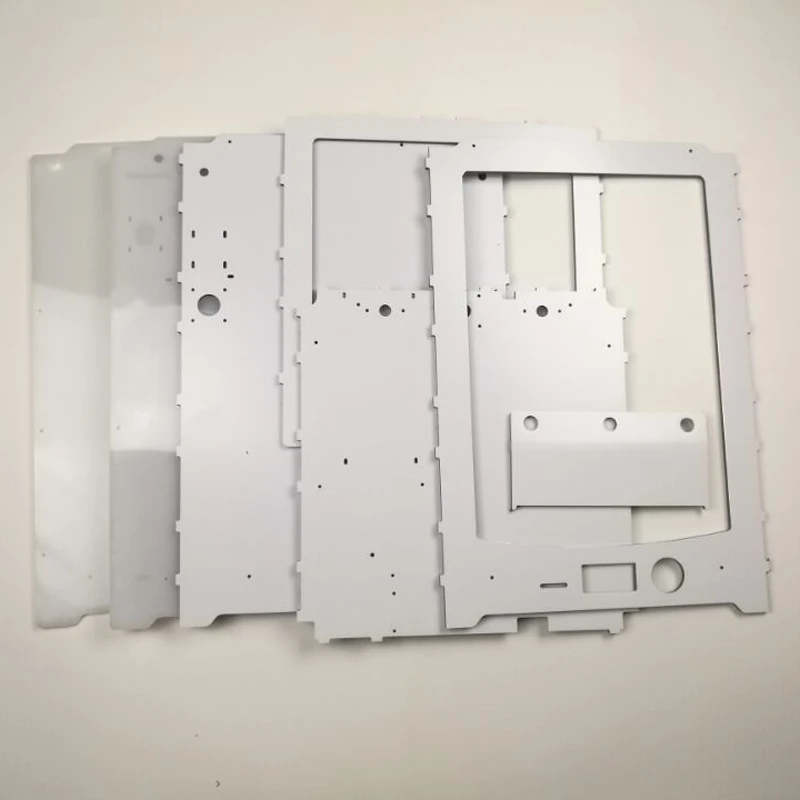

Plastic enclosures for electronics can be developed through additive manufacturing using adapted materials. Nylon-based materials such as Nylon PA12 or Nylon PA11 are especially suitable for 3D printing plastic cases. These are low-cost materials that can be used to make prototypes, as well as small or large series. Photopolymers with a variety of mechanical properties are also suitable for printing prototypes and finished products. nine0003

Nylon-based materials such as Nylon PA12 or Nylon PA11 are especially suitable for 3D printing plastic cases. These are low-cost materials that can be used to make prototypes, as well as small or large series. Photopolymers with a variety of mechanical properties are also suitable for printing prototypes and finished products. nine0003

How to design enclosures for 3D printing

Before you start modeling a case, it is recommended that you start designing with the components that it will contain. This way you can place components and make sure everything fits, as well as provide clearance for connectors or cables. To ensure that all components will fit, we recommend leaving a gap of 0.5mm between the components and the 3D printed elements.

Access to components

The first thing to think about when designing a case is what to put in there and how to access it later. If you don't need access to the components, you can design custom fasteners or use adhesive to completely seal the case during assembly.

If access to the chassis components is required, the following mechanisms can be used:

-

semi-rigid eyelets; nine0003

-

sliding panels;

-

screws;

-

conventional and flexible hinges;

-

prefabricated structures.

Eyelets, slots and flanges help with assembly and alignment of parts. In addition, if the minimum dimensions of these elements are observed, they can increase the strength of the hull. nine0003

Durability of 3D printed case

The main thing to consider is the thickness of the walls of the case. This parameter determines the weight, stiffness, strength and possible applications of the hull. Even if the 3D printer is capable of printing small parts and thin walls, we recommend keeping the minimum wall thickness of 2mm. This value provides structural strength while keeping the weight of the part light. The optimum thickness can also be determined using the design guide for the material used. nine0003

nine0003

However, be careful, because depending on the length of the casing, the 2 mm thick walls can bend, which can lead to some shrinkage.

Corner rounding is a key feature of 3D printing because hard corners can be printed poorly. Roundings are necessary both inside the case and outside.

Roundings avoid sharp corners and reduce stress

For external corners, a slight rounding (1 or 2 mm) can be used on the housing surface. nine0003

Inside the case, the corners can be reinforced with thickenings and roundings. A very small radius simplifies 3D printing and reduces stress concentration at corners.

Thickening and rounding inside the body reduce stress around the hole

3D printed housing: quality and precision

If the design contains gaps or holes for fasteners, select a material that provides the desired accuracy. 3D printing plastic provides high precision, but we recommend drilling or punching holes after printing with special tools. nine0003

nine0003

If you slightly increase the diameter of the holes for the fasteners, the result will be better.

At the same time, for a tighter connection of the fasteners with the body, the diameter of the holes should be reduced.

Small walls and thin-walled elements are often added to the housing to hold components. These elements must meet the minimum thickness of the material used, and in addition, we recommend adding structures such as corners or stiffeners, which will make the element more durable and ensure correct 3D printing. nine0003

Corners and stiffeners reduce stress and make thin-walled elements and the case itself stronger

Finally, remember that in addition to rapid iteration and prototyping, 3D printing can be used to mass-produce cases.

The article uses materials from Sculpteo

Article published on 03/25/2021, updated on 06/15/2022

Rigidity of the 3D printer case

Printing on my Wanhao Duplicator i3 Mini, I realize more and more that I lack its capabilities. And its print area is small (120 x 135 x 100), and there are restrictions on the materials used. In this regard, and with my ever-growing interest in the designs of various printers, there was a desire to make my own 3D printer, and not buy a ready-made more advanced one.

And its print area is small (120 x 135 x 100), and there are restrictions on the materials used. In this regard, and with my ever-growing interest in the designs of various printers, there was a desire to make my own 3D printer, and not buy a ready-made more advanced one.

And the first thing I started with was thinking about the design of the hull.

For those who prefer to watch in video format, here is a link to the video.

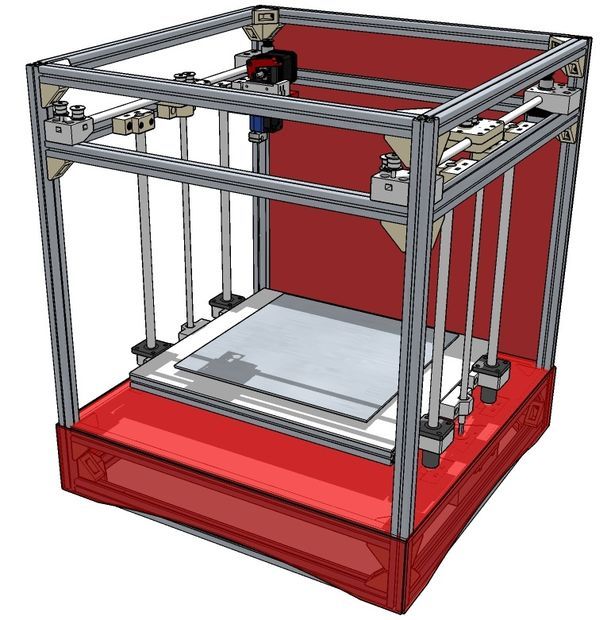

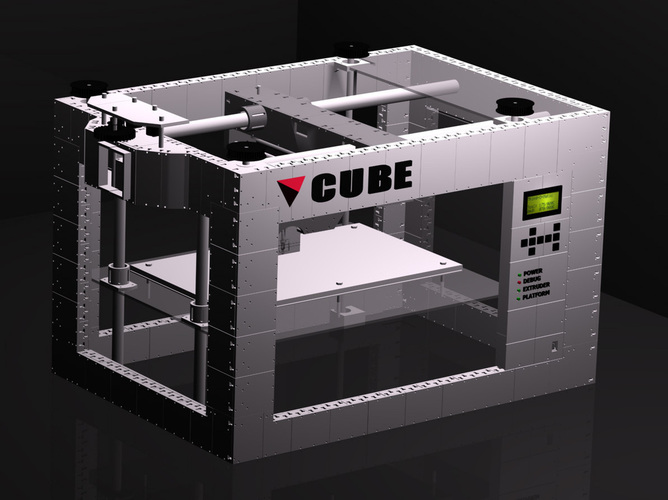

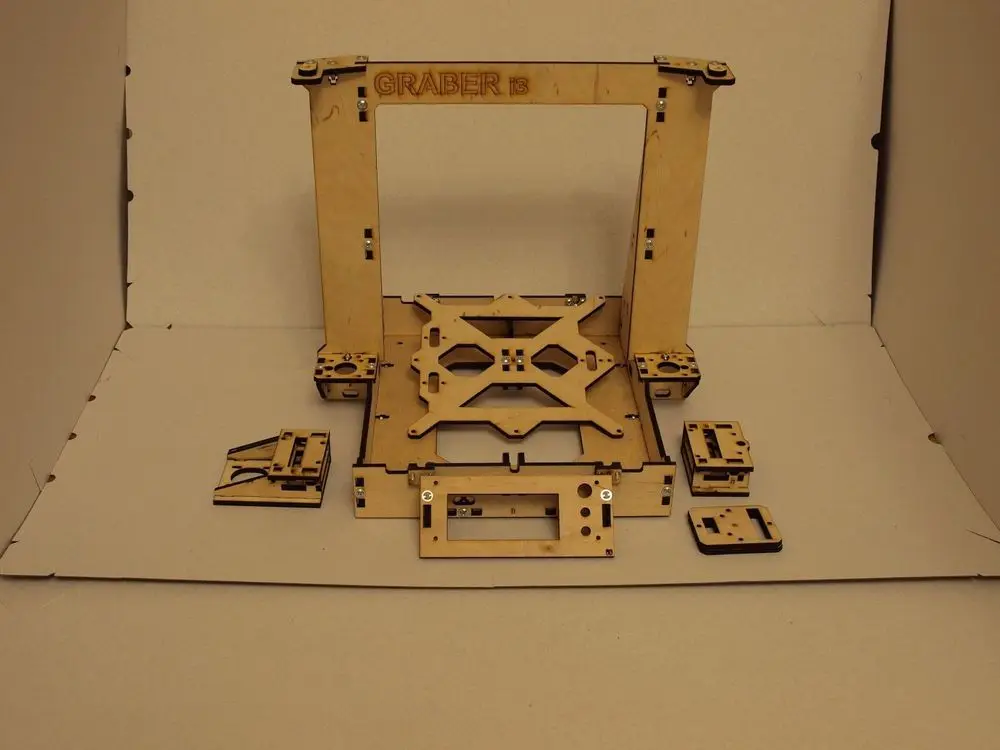

There are a wide variety of 3D printer case designs, and in my opinion, the essential characteristic of any case will be its rigidity. Experienced makers recommend using two options as a case:

- frame made of metal sheets;

- structural profile frame.

At the same time, it is considered that it is better to leave printed parts in the housing design. If there are printed parts in the case design, then such a 3D printer will have some limitations in terms of maximum acceleration and printing speed. nine0003

nine0003

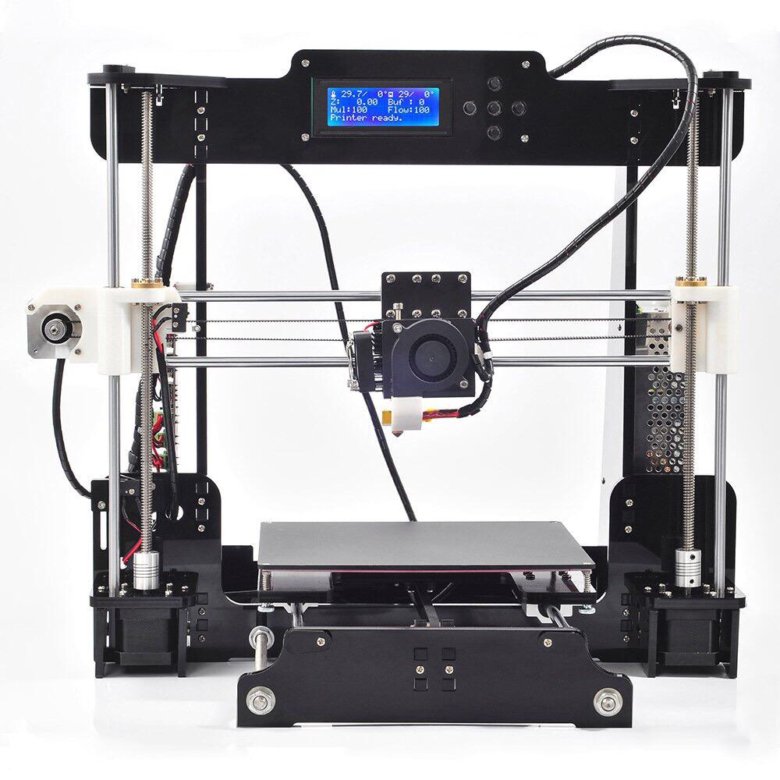

I have not seen any quantitative comparisons of the rigidity of printer cases. As a rule, all the results are obtained empirically from people who have independently assembled far from one 3D printer. In this regard, it became interesting for me to check the static stiffness of various variants of 3D printer cases. I have taken a few of the more common ones. The first case is the Prusa i3 printer case made of steel, the thickness of the material is 3 mm.

The second case considered is the case of the Ultimaker 2 printer. The material is steel, 3 mm thick. nine0003

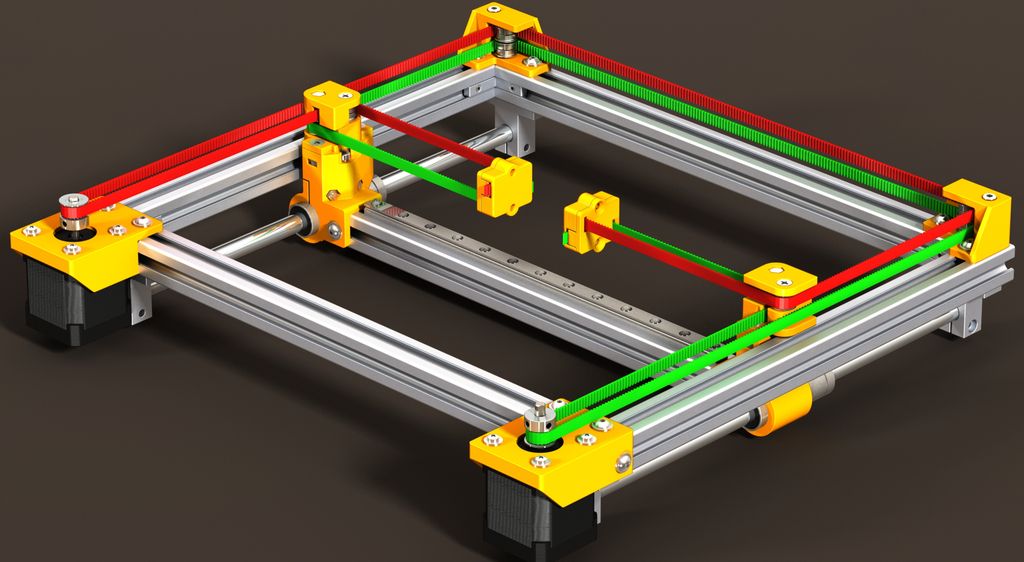

Then I looked at several cases made from a 20x20 mm structural profile. Material - aluminum. Here is the first option:

The second version is reinforced with L-connectors 60x60 mm in size and 2 mm thick

And the last variant considered is the hull variant reinforced with diagonal structural elements. At the same time, one of the side walls is open, since work with the 3D printer table is carried out through it. nine0003

nine0003

All models considered have comparable print area sizes, which will clearly demonstrate the difference in rigidity.

Concerning the last version of the homemade housing with diagonal elements, I will do a little demonstration with a children's construction set to show how much diagonals can increase rigidity.

A square truss is made from a children's construction toy. Each of the four nodes of the truss has a hinge and can be easily deformed. nine0003

Now let's add a diagonal element.

The truss is then completely immobile, despite the fact that each of its four nodes still has a hinge, i.e. an element with zero torsional rigidity.

Let's move on to the calculation results. All calculations were performed by the finite element method in the free program Z88 Aurora V5. The following scheme was chosen as the design scheme for all printer bodies: nine0003

As can be seen from the figure, the bottom of the printer was fixed, and a load of 10 kg was applied to the upper part along the X and Y axes separately. First along the X axis, then along the Y axis. The result of the calculations is the amount of body movement in millimeters. You can watch the animation of the deformation of all the hulls in the video from the beginning of the article.

First along the X axis, then along the Y axis. The result of the calculations is the amount of body movement in millimeters. You can watch the animation of the deformation of all the hulls in the video from the beginning of the article.

Results for the Prusa i3 printer body. The scale of deformations is increased for clarity. X-axis deformation:

Y-axis deformation: nine0003

Here are the results for the Ultimaker 2 printer body. X-axis deformation:

It can be seen that due to the rigidity of the rear solid wall, the main deformation occurs in the area of the front wall of the housing.

Y-axis deformation:

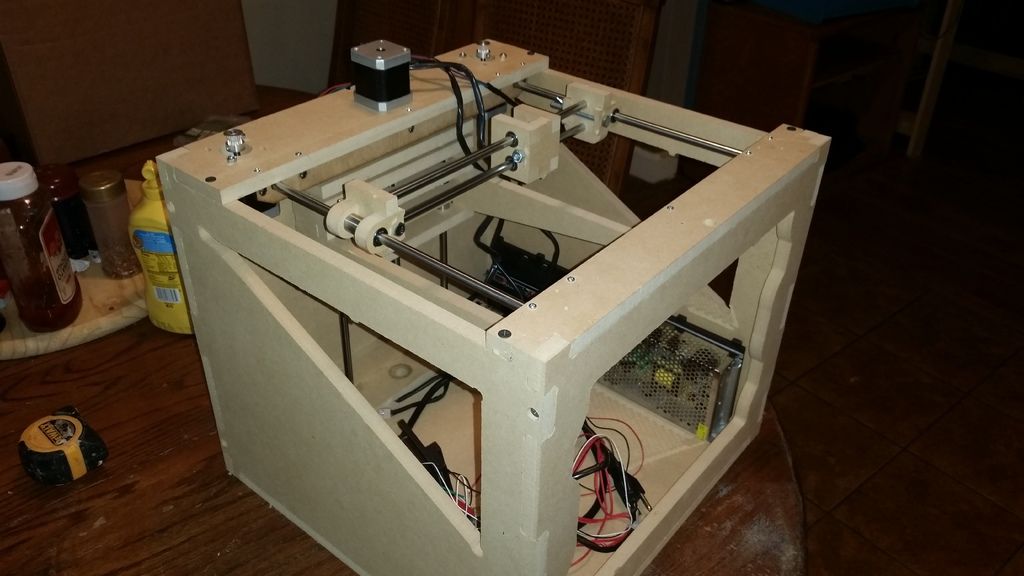

And now let's move on to the results of calculating the case options, often used in homemade 3D printers. The first version does not have any reinforcing elements. Such a design can be roughly considered as a case design, in which printed connecting elements are used, the rigidity of which leaves much to be desired. nine0003

nine0003

Due to the fact that the body is symmetrical, the load was applied only once along one axis:

The next version of the self-made case is reinforced with corners, the so-called L-connectors, 60x60 mm in size. Due to symmetry, the load was also applied only once.

As we can see, in comparison with the first version, the amount of deformation has significantly decreased.

And the last version of the self-made body, reinforced with diagonal elements. Since this version of the body is not symmetrical, the load was applied along the X and Y axes. Deformation along the X axis: nine0003

It can be seen that there is no significant increase in rigidity along the X axis, in comparison with the version reinforced with L-connectors. At the same time, it can be seen from the figure that the main deformations are concentrated in the front frame of the case, where there is no diagonal element.

Y-axis deformation:

Y-axis distortion is significantly lower and comparable to that of the Ultimaker 2 printer body.

The histogram shows the calculation results for all blocks: nine0003

As we can see, the case of the Ultimaker 2 printer turned out to be the winner - the deformation of this case turned out to be minimal. The second place was taken by the Prusa i3 printer body. And then there are various options for a makeshift hull, which are designated as RepRap.

Note the fairly significant difference in stiffness between all the homemade cases and the Prusa i3 and Ultimaker 2 cases. Only the diagonal case homemade case came close to them in terms of stiffness and only along one axis. At the same time, the low rigidity of this option along the X axis is explained by the absence of a diagonal on the front wall. nine0003

Next, I will consider several options for strengthening this case in order to increase its rigidity.

Considering that the Ultimaker 2 printer case turned out to be the leader in rigidity, I decided to consider adding a 3 mm thick wall to the front frame of the printer as the first reinforcement option:

This reinforcement made it possible to increase the rigidity of the body along the X axis by approximately two times.

L-connectors 60x60 mm in size have been added to the front panel as the next case reinforcement: nine0003

This variant does not increase the body rigidity so much.

As a final revision, a diagonal was added to the top wall of the case:

For this modification, the stiffness was comparable to adding a 3 mm wall to the front panel.

Below is a histogram comparing all the considered options for a homemade case with the Ultimaker 2 printer case. nine0003

It can be seen that when creating the hull from structural profiles, we failed to achieve a rigidity comparable to the hull from sheet material. The case with diagonal elements and a front panel made of 3 mm sheet turned out to be as close as possible.

Conclusions from the calculations:

First, the opinion of experienced printer builders is once again confirmed that the case made of sheet metal is the most rigid and durable.

Secondly, it is possible to make a case from structural profiles, but for this we will need to sacrifice the convenience or aesthetic appearance of the case.

Performance requirements include strict lifetime testing with cyclic loading and unloading, color fastness over periods of years, amongst others like tear resistance.

Performance requirements include strict lifetime testing with cyclic loading and unloading, color fastness over periods of years, amongst others like tear resistance.