Ceramic 3d printers

Top Ceramic 3D Printers on the Market

Published on August 26, 2022 by Carlota V.

At the end of 2021, the research firm IDTechEx published a report that estimated that the ceramic additive manufacturing market would be worth $400 million by 2032, seven times more than the forecast for 2022. This is proof that this niche market continues to grow and interest many manufacturers. And if we look at the number of ceramic 3D printers available, we can see that it is also increasing. Remember that ceramics are a material that can be printed using several processes: stereolithography, powder bonding or extrusion. The types of ceramics are very varied. We can indeed find materials such as porcelain or clay, but there are more technical ceramics that will be more popular with manufacturers (alumina, zirconia, tungsten carbide, etc.). But which machines are adapted to technical ceramics? What are the solutions more oriented towards personal use? We have listed a few ceramic 3D printers, dividing them by type of application.

C3600 Ultimate from 3DCeram

French manufacturer 3DCeram is a major player in the ceramic additive manufacturing market. It has long been dedicated to the development of a wide range of professional solutions. One of its most prominent 3D printers is the C1000 Flexmatic, which has been designed to meet the industrial challenges of large-scale production. This machine uses a top-down stereolithography process where a laser hardens the liquid ceramic layer by layer. Thanks to this method, it is possible to consistently create parts with high precision and fine details without the need for supports. With a maximum manufacturing volume of 320 x 320 x 200 mm, the C1000 Flexmatic integrates all that is needed to support 3D printing of ceramic parts on a semi-automated line. If you want to learn more about this ceramic 3D printer, as well as see it in action, check out the video below or find more information HERE:

Admaflex 130 from Admatec

Intended for industrial applications, this ceramic 3D printer comes from Admatec, a company based in the Netherlands. Released in 2018, the Admaflex 130 is a 3D printer that prints with ceramics using DLP technology. With a build platform of 96 × 54 × 120 mm, the minimum layer width is 0.03 mm, and the Admaflex 130 also features an XY accuracy of 0.05 mm. The ceramic 3D printer, which weighs a total of 300 kilograms, is particularly suitable for the production of both functional and aesthetic parts that should feature complex geometries but also fine surfaces, according to the manufacturer. However, in addition to 3D printer manufacturing, the Dutch company also offers 3D printing services. If you want to know more about Admaflex 130, click HERE.

X1 160PRO from Desktop Metal

The X1 160PRO is an industrial machine originally from ExOne, now under the Desktop Metal brand since ExOne’s acquisition in 2021. The printer has a volume of 800 x 500 x 400 mm and uses binder jetting, making it the world’s largest binder jet 3D printer for the production of metal, ceramic or composite parts according to DM. The largest of the X-Series, it is possibly best known for its capabilities with metal 3D printing, but it is equally adept when it comes to ceramics allowing for parts with high density and repeatability. In addition to its generous volume, it can print a layer with a thickness between 30 and 200 microns, at a speed of up to 10,000 cm3 per hour. You can find more information HERE.

The printer has a volume of 800 x 500 x 400 mm and uses binder jetting, making it the world’s largest binder jet 3D printer for the production of metal, ceramic or composite parts according to DM. The largest of the X-Series, it is possibly best known for its capabilities with metal 3D printing, but it is equally adept when it comes to ceramics allowing for parts with high density and repeatability. In addition to its generous volume, it can print a layer with a thickness between 30 and 200 microns, at a speed of up to 10,000 cm3 per hour. You can find more information HERE.

CeraMax Vario V900 from Lithoz

The CeraMax Vario 900 3D printer from Lithoz is the first to produce large, thick-walled, fully dense parts from oxide and non-oxide ceramics. It is also capable of processing dark ceramics such as silicon carbide at full density. The printer is based on Lithoz’s new LIS technology, which enables additive manufacturing using industrial water-based suspensions with very low levels of organic binders. The CeraMax Vario 900 also stores and manages all process data with database support, thus guaranteeing seamless documentation of print jobs. The printing process can be monitored via real-time remote video transmission. Find out more in the video below or on Lithoz’s website HERE.

The CeraMax Vario 900 also stores and manages all process data with database support, thus guaranteeing seamless documentation of print jobs. The printing process can be monitored via real-time remote video transmission. Find out more in the video below or on Lithoz’s website HERE.

ProMaker L6000 from Prodways

The ProMaker L6000 is an industrial 3D printer designed by French manufacturer Prodways. This solution can handle highly viscous materials, making it perfect for manufacturing parts from ceramics. It uses Prodway’s MOVINGLight polymerization technology which provides high precision, resolution up to 42 μm and layer thickness between 25 and 150 μm. Designed to manufacture large parts at high speeds, the machine has a print volume of 800 x 330 x 400 mm. Thanks to its ability to design parts with a quality surface, Prodways’ solution has minimized the necessary post-processing steps once the parts are printed. According to the manufacturer, it is ideal for a wide variety of applications, particularly because of its ability to meet all levels of requirements. You can find out more HERE.

According to the manufacturer, it is ideal for a wide variety of applications, particularly because of its ability to meet all levels of requirements. You can find out more HERE.

Photo Credits: Prodways

VX1000 from Voxeljet

Next one our list of ceramic 3D printers is the VX1000 which was developed by German manufacturer Voxeljet, well-known for its industrial range of machines. This machine uses Binder Jetting technology to manufacture with ceramic materials, sand, and some polymers, such as polymethacrylate. The VX1000 is an industrial printer that specializes in the development of moulds and small production runs, it can also be used for research due to the range of materials it can manufacture with. It has a printing volume of 1000 × 600 × 500 mm and can reach a layer thickness of 80-300 μm. You can find more information HERE.

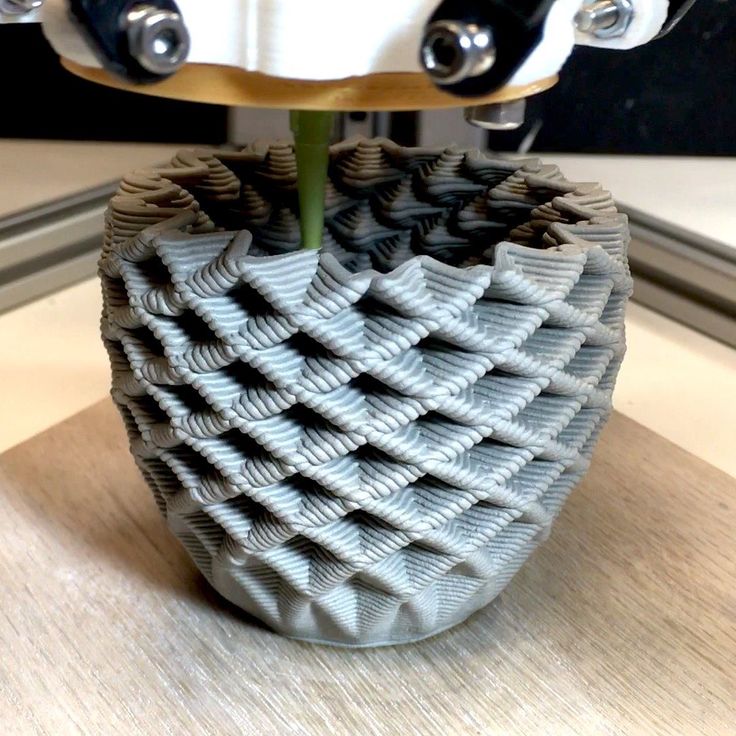

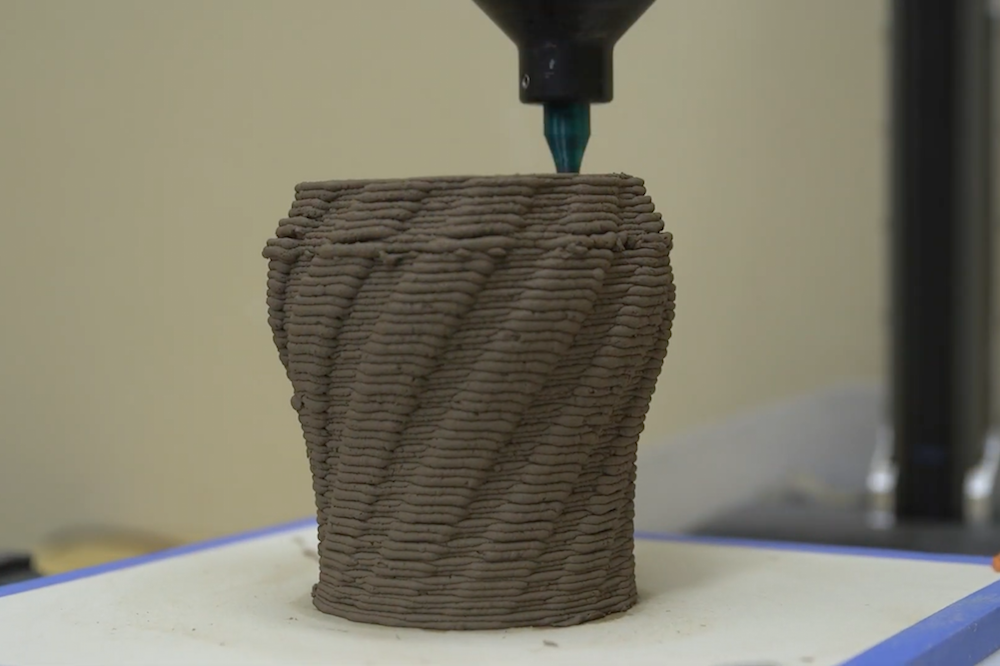

Desktop Ceramic 3D Printers3D PotterBot Micro 10 from 3D Potter

3D Potter is an American manufacturer that specializes in 3D printing ceramic materials with material deposition technologies. According to the manufacturer their range of ceramic 3D printers are the only ones on the market that allow fabrication with real clay. The Micro 10 is an entry-level ceramic 3D printer ideal for the classroom, or for an artist interested in ceramic 3D printing technology. The Micro 10 features a 1,000 ml extruder with a build envelope of up to 1 foot. Despite being the smallest clay printer the company has, it is capable of printing at high speeds and its compact design is ideal as it fits in any space. Find out more HERE.

According to the manufacturer their range of ceramic 3D printers are the only ones on the market that allow fabrication with real clay. The Micro 10 is an entry-level ceramic 3D printer ideal for the classroom, or for an artist interested in ceramic 3D printing technology. The Micro 10 features a 1,000 ml extruder with a build envelope of up to 1 foot. Despite being the smallest clay printer the company has, it is capable of printing at high speeds and its compact design is ideal as it fits in any space. Find out more HERE.

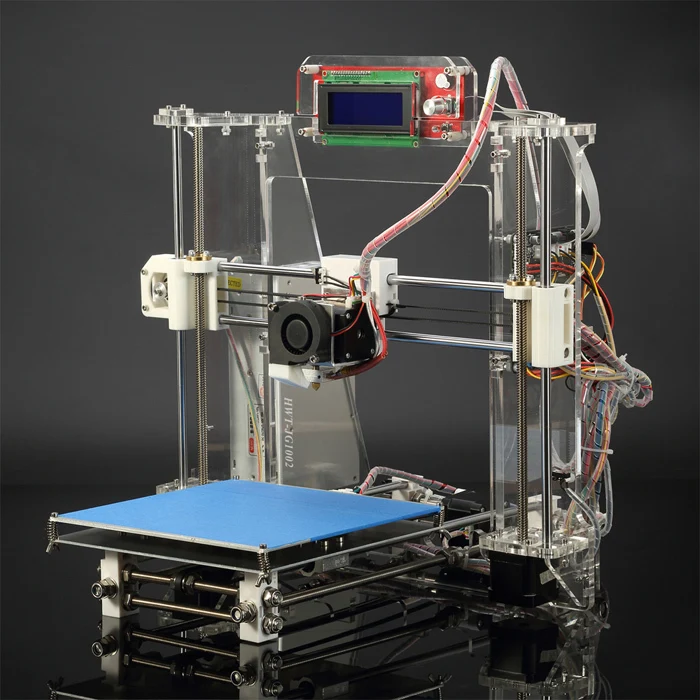

CERAMBOT

The CERAMBOT 3D printer is a desktop printer with two models – Pro and Air. The CERAMBOT Pro, which has a print speed of 5 – 50 mm/s while just weighing around 15 kilograms. The company, which is based in Shandong, China, claims that their model is 20% faster than other ceramic 3D printers. This can be attributed to the industrial linear guide rail, which still maintains printing accuracy of up to 0.1mm. Both the Pro and Air are easy to use with popular open-source slicing software for desktop FDM 3D printers. Learn more about CERAMBOT HERE.

Learn more about CERAMBOT HERE.

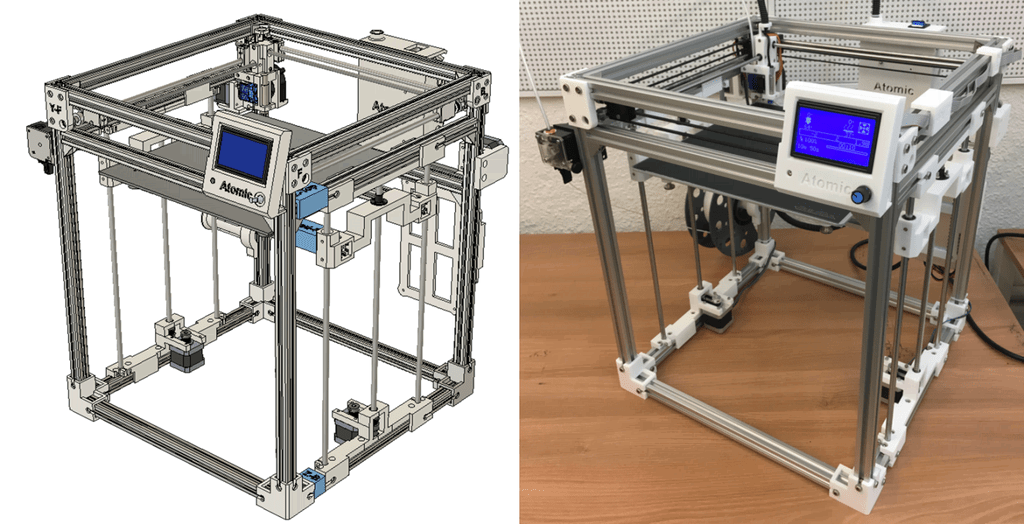

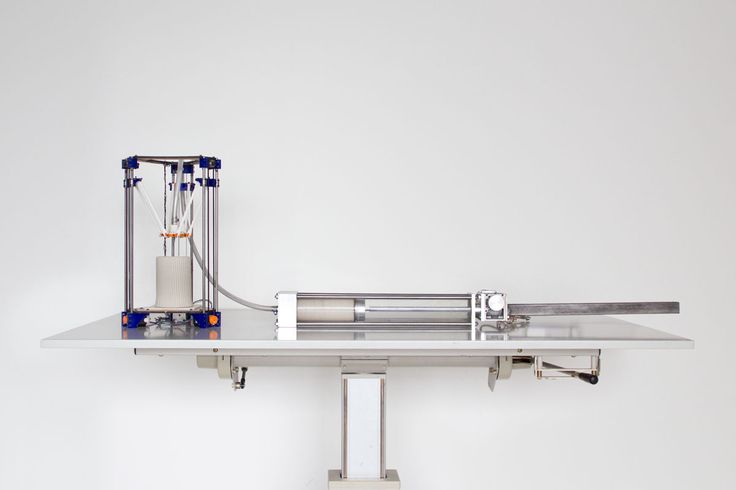

LUTUM from Vorm Vrij

The LUTUM Clay 3D Printer range comes from Dutch manufacturer VormVrij, a company that has been seeking to stretch the limits of clay 3D printing. The machines were designed to be sustainable and easy to maintain and is suitable for professionals and potters. The latest models in the series have been the LUTUM 4 and 5 mini clay printers, though there are a number of others. The older sibling of the LUTUM 5 mini is the LUTUM, a professional clay 3D printer with a 32bit operating system, 7” touchscreen, wifi connections and more. It has two extruders which can be used sequentially with different clay types and colors or used in parallel in order to increase clay output volume and print speeds. The LUTUM 5 is one of the larger machines has a slightly lower printing volume than the LUTUM 4. 6, 95L compared to 100L. Users can also find the largest model, the BRUTUM 1 which also uses extrusion and has a printing volume of 247L. You can find out more HERE.

6, 95L compared to 100L. Users can also find the largest model, the BRUTUM 1 which also uses extrusion and has a printing volume of 247L. You can find out more HERE.

The LUTUM 5 (left) and LUTUM 4 (right) are part of VormVrij’s LUTUM range (photo credits: VormVrij)

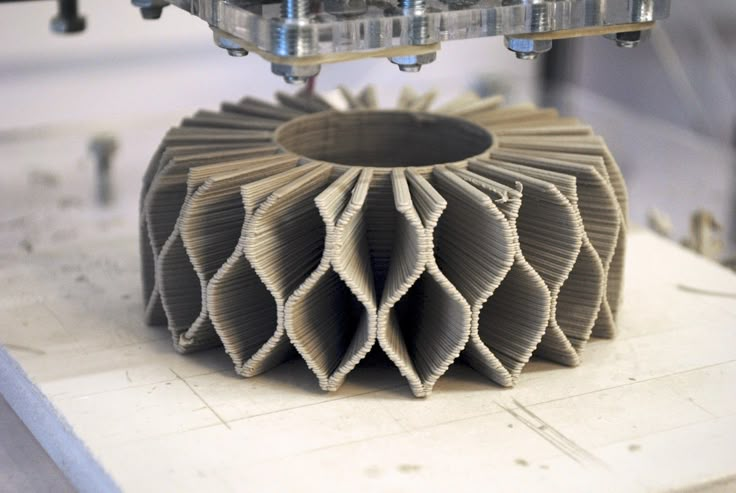

Delta WASP 40100 Clay from WASP

One of the solutions from the well-known, Italian manufacturer WASP is the Delta WASP 40100 Clay, a desktop-sized ceramic 3D printer that comes with a special feature. Printing is done directly onto the desired surface, such as the floor. So there is basically no printing plate. This gives the advantage of bypassing the necessary waiting time for drying. Also available is an XL extruder, which allows the printer to create larger prints in less time. It is compatible with various materials such as porcelain, stone, refractory materials and clay. The printer can also be complemented with a professional clay kit which includes the clay extruder and LDM WASP Extruder 3.0. This is suitable for all liquid-tight and ceramic materials. You can find more information HERE.

You can find more information HERE.

StoneFlower 3.0 from StoneFlower

Composed of researchers, scientists and engineers, StoneFlower is developing 3D printers that can handle ceramics. Among the company’s solutions is the StoneFlower 3.0. With a print volume of 50 x 50 x 50 cm, the extrusion-based printer incorporates an all-metal chassis for stability and speed. In addition, the 3D printer has a touch screen for ease of use and an option to pause and resume the printing process at any time. With a weight of 35 kg, its printing speed varies between 30 and 100 mm/s. Compatible with the vast majority of slicers available on the market, the StoneFlower 3.0 is, according to the company, ideal for easily designing ceramic parts. Find out more in the video below or on StoneFlower’s website HERE.

Pam Series MC

French company Pollen has introduced what might one of the most versatile ceramic 3D printers, capable of handling the widest variety of industrial materials to create functional parts. This 3D printer allows the direct use of materials in pellet form which can be extruded. The PAM Series printer is 834 x 834 x 925 mm in size, has a print speed of 160mm/s and a build volume of 300 x 300 mm (21×106 mm). Compared to its predecessor, the new Pam Series MC offers twice the printing speed in high temperature conditions. This breakthrough is the result of the development of new power electronics and a reinforced, lighter architecture to ensure high-speed print quality. Find out more HERE.

This 3D printer allows the direct use of materials in pellet form which can be extruded. The PAM Series printer is 834 x 834 x 925 mm in size, has a print speed of 160mm/s and a build volume of 300 x 300 mm (21×106 mm). Compared to its predecessor, the new Pam Series MC offers twice the printing speed in high temperature conditions. This breakthrough is the result of the development of new power electronics and a reinforced, lighter architecture to ensure high-speed print quality. Find out more HERE.

What do you think of our listing? Did you find what you were looking for? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

3D Potter - Real Clay 3D Ceramic Printers

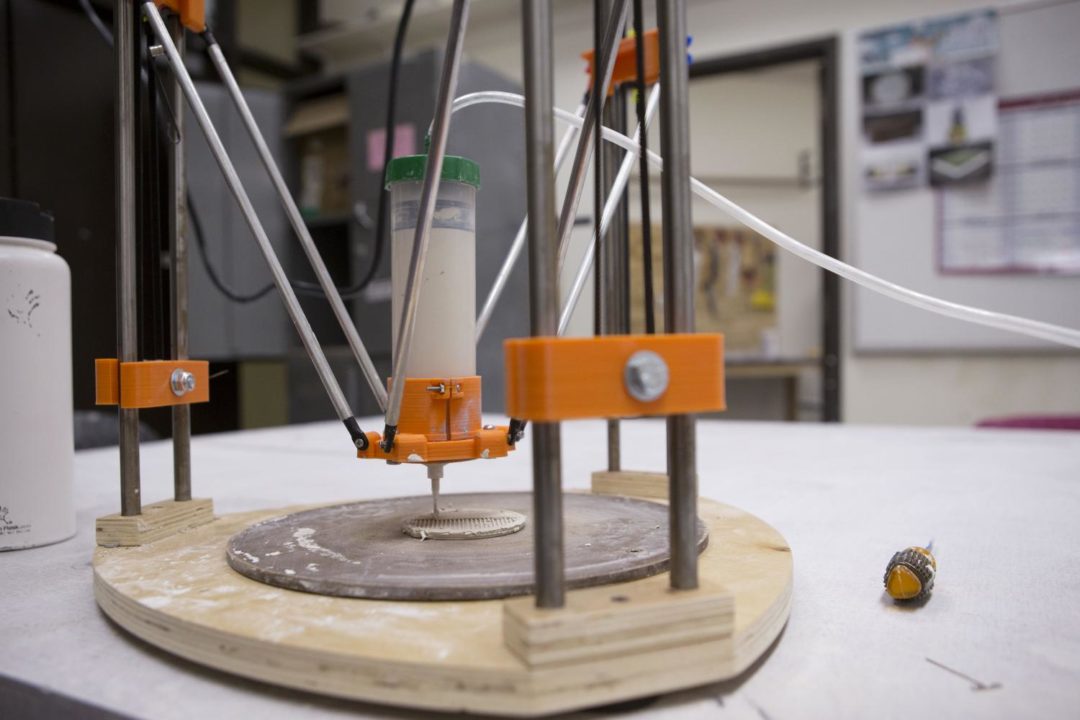

Our line of 3D Clay printers have some unique features when compared to other 3D printers. We use a cardinal axis system, rather than a delta printer configuration. This allows for precise control with minimal effort. Most clay printers use a pressurized system using compressed air, with a 3D Potterbot a high-pressure system is not needed.

We use a cardinal axis system, rather than a delta printer configuration. This allows for precise control with minimal effort. Most clay printers use a pressurized system using compressed air, with a 3D Potterbot a high-pressure system is not needed.

3D Printing Cement is here! We have combined our Scara Elite and Small 50 pump with Sikacrete® 3D printer cement developed by Sika USA. This is a versatile and convenient way of printing large-scale architecture and structures.

The Scara Elite is the first viable large-scale ceramic 3D printer using 3D printing material. It is capable of printing multiple objects non-stop. The Elite with the Small 50 can pump up to 3. 5 gallons of material per minute through 85 feet of 1″ hose.

5 gallons of material per minute through 85 feet of 1″ hose.

They work together so well, we decided to make them a package.

The possibilities are endless!

PR Articles/Videos

Great entry-level printer

More info

10 Proreliable and accurate

More info

Full size, Full control

More info

View this post on Instagram

A post shared by Hybrid Objects (@hybrid.obj) featuring non-planar printing.

View this post on Instagram

A post shared by Arina Erdélyi (@arinaerdeyli) featuring a print taken to new heights.

View this post on Instagram

A post shared by Atlas of Lost Finds (@atlas_of_lost_finds) featuring large-scale printing.

See More

3D Potter is proud to offer assembly tutorials and troubleshooting videos for our printers. Our printers can be used with Potterware, a beginner-friendly program to design pots and vases of all shapes, sizes, and patterns.Check out our Youtube channels to see our videos!Assembly Videos

Main Channel

3D Potter accepts payment of Bitcoin (BTC) for our products. If you wish to pay by BTC, please contact us.bitcoincash:qr5wmqhnylzr0hcewfrla852xxy9zhp94uugrxy9ay

Here at 3D Potter, we like forward-thinking and preserving the environment. Tesla vehicles are a great example of both. So, if you plan on purchasing a Tesla, use our referral code at checkout and you will receive a discount and charging miles.

Tesla vehicles are a great example of both. So, if you plan on purchasing a Tesla, use our referral code at checkout and you will receive a discount and charging miles. https://www.tesla.com/referral/dan47410

Home - 3D Ceram

Our news expense

3D printers

Ceramic oxide compounds

Ceramic irrigation compositions

Read more from our cars.

We offer 3D printing training that allows you to control the process on Ceramaker machines to successfully complete your projects. nine0003

3DCeram offers tools for integrating 3D printing solutions into ceramic parts projects.

-

The aerospace and defense industries are constantly striving to optimize the performance of their equipment (satellites, measuring instruments, optical instruments, etc.) by exploiting the properties of ceramics and setting new challenges, accompanied by a strong trade-off between performance and cost. In this context, products should be more technologically advanced and reduce development time.

DETAILS

DETAILS Read more

3DCeram offers production lines tailored to the operating conditions of industrial markets (electronics, chemistry, telecommunications, etc.) that seek to integrate this new technology.

More details

3DCeram has been using SLA 3D printing technology for more than 10 years to produce custom or small batch bone implants (intervertebral cages and osteotomy-tibia wedges), as well as cranial and maxillary implants… READ MORE

More

-

3DCeram is the preferred partner of large research groups and universities. Indeed, the resistance and various properties present in ceramic make it the material of choice.

Read more

Aerospace, collaboration between Anywaves and 3DCeram

Anywaves has developed an innovative ceramic antenna concept for the aerospace industry. 3DCeram assists Anywaves with a 3D-AIM service to refine the entire manufacturing process https://www. tctmagazine.com/additive-manufacturing-3d-printing-news/anywaves-designs-new-satellite-antenna-with-3dceram-ceramic -/ https://www.3d-grenzenlos.de/magazin/3d-objekte/prototyp-bandantenne-gnss-l1-e-mit-3d-drucker-hergestellt-27649103/ https://siusystem.ru/news/servis-3d-aim-ot-3dceram-pomog-anywaves-zapustit-vypusk-antenn-dlya-kosmosa

tctmagazine.com/additive-manufacturing-3d-printing-news/anywaves-designs-new-satellite-antenna-with-3dceram-ceramic -/ https://www.3d-grenzenlos.de/magazin/3d-objekte/prototyp-bandantenne-gnss-l1-e-mit-3d-drucker-hergestellt-27649103/ https://siusystem.ru/news/servis-3d-aim-ot-3dceram-pomog-anywaves-zapustit-vypusk-antenn-dlya-kosmosa

DETAILS

Additive manufacturing, innovative in nature

3DCeram Sinto, a French company based in Limoges, has 15 years of experience in 3D printing complex ceramic parts, offers a wide range of services and a line of 3D printers. Interceram met with Nicolas Rousselet, Aerospace Segment Manager, and Karen Malsalle, Marketing Manager, to discuss a new service that meets the expectations of aerospace customers. Read Article

DETAILS

3D printed blade cores

3D printing opens the door to mass production of optimized blade cores. The rods are an important component in the manufacture of aircraft cooled turbine blades and land based gas turbines. The internal channels of the turbine blade reduce its temperature. This reduces fuel consumption and therefore reduces emissions. But, above all, it increases the efficiency of the turbine. Note that the demand for complex rod designs is growing to meet the demand for smaller, more efficient, and therefore more profitable engines. The engines of the new […] 9Ol000

The rods are an important component in the manufacture of aircraft cooled turbine blades and land based gas turbines. The internal channels of the turbine blade reduce its temperature. This reduces fuel consumption and therefore reduces emissions. But, above all, it increases the efficiency of the turbine. Note that the demand for complex rod designs is growing to meet the demand for smaller, more efficient, and therefore more profitable engines. The engines of the new […] 9Ol000

Overview of 3DCeram ceramic 3D printers

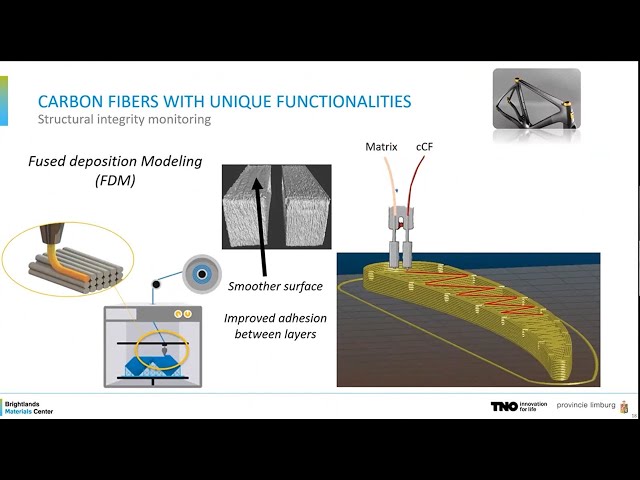

Ceramic is a unique material. Due to its low weight, strength, chemical resistance, toughness and biocompatibility, the resource is in demand in various industries, providing the ability to quickly produce useful things on a 3D printer. Additive manufacturing of ceramic products allows you to create objects of individual configuration. The technique involves the prompt introduction of design changes and helps to achieve the desired characteristics of a part or a finished item. nine0003

nine0003

Printing technologies used

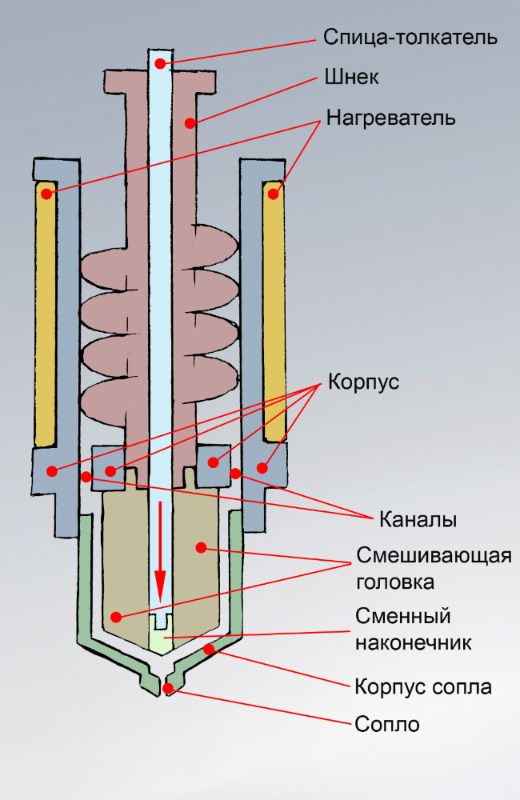

Ceramic 3D printing is done in different ways: paste extrusion, powder sintering or photopolymerization.

But most often ceramic printers work on SLA technology. The method is based on the illumination of ceramic paste with a laser to form three-dimensional objects or prototypes. The construction is done in layers, and each layer is scanned and drawn with a beam according to the digital model. After building the next level, the working platform is lowered to a given layer thickness, a new portion of the paste is leveled, and the process of scanning the next section of the part is performed. nine0003

The technique helps to achieve uniform shrinkage during sintering, which guarantees maximum accuracy in the construction of the element.

The Ceramaker 3D printer series is a development of the company that implements the additive technology of layer-by-layer curing of a specialized paste - a composite of a photopolymer substance with ceramic powder. After completion of the model building cycle, the surface is freed from particles of non-polymerized composition and washed in a special solution. Then the object goes through the stage of burning out the photopolymer, which acts as a temporary binder. Next, the final sintering of the workpiece at a high temperature is performed. nine0003

After completion of the model building cycle, the surface is freed from particles of non-polymerized composition and washed in a special solution. Then the object goes through the stage of burning out the photopolymer, which acts as a temporary binder. Next, the final sintering of the workpiece at a high temperature is performed. nine0003

Ceramic Printing Materials

3DCeram has developed original formulations that use its ceramic 3D printers. Raw materials are fed evenly, with a given accuracy, which ensures the high quality of the manufactured object and its compliance with strict industrial criteria.

Ceramic resources are neither metallic nor organic. Usually they are molded at room temperature, and acquire special properties during the sintering process. The choice of material for printing a product depends on the conditions in which the parts are to be used. nine0003

3DCeram offers the following options:

Zirconia is a material with excellent mechanical properties that are stable at all temperatures. The composition is characterized by low thermal conductivity and chemical inertness. Products from this resource are hard and wear-resistant.

The composition is characterized by low thermal conductivity and chemical inertness. Products from this resource are hard and wear-resistant.

Alumina is the base material in demand in industry. AL203 stands out for its mechanical strength and is a good dielectric. nine0089

Silicon nitride - compound resistant to heat and corrosion. The resource is actively used in the manufacture of pumps and valves.

Silicore is a compound used to make blade cores. Porous ceramics with good leaching properties are compatible with various alloys.

Tricalcium phosphate is a biocompatible raw material used for the production of implants;

Hydroxyapatite is a resource in demand in biomedicine for “growing” bone substitutes, since it is characterized by good osseointegration; nine0003

Aluminum nitride - electrical insulator with high thermal conductivity, in demand in the electronics industry;

Cordierite is a low thermal expansion ceramic suitable for vacuum applications.

Raw materials are supplied by means of a hopper filled before starting the printer. However, it is permissible to fill the device during the operation of the equipment.

Ceramic 3D printer software

The company supplies equipment with open source software that allows the buyer to develop and use their own formulations. The printers support Windows, Linux and OSX operating systems.

Review of 3DCeram ceramic 3D printers

The French engineering company offers interesting solutions for the manufacture of complex ceramic parts for various industries. What can be done with a 3D printer for sale? The possibility of printing finished items and individual elements of ceramics interested jewelers and watchmakers. End products and spare parts are durable, resistant to scratches and chips, hypoallergenic. 3D printing with clay is in demand for creating designer masterpieces, art objects and interior elements. Also, proprietary technology is actively involved in the aerospace and aviation industries, mechanical engineering, and biomedicine. nine0089 The Ceramaker printer series is designed to produce detailed and functional elements with consistently high quality.

nine0089 The Ceramaker printer series is designed to produce detailed and functional elements with consistently high quality.

Popular ceramic printers

Ceramaker 100 is a design and prototyping device. The printer is easy to operate and uses materials economically. The equipment is equipped with modules of various sizes, which makes it possible to optimize the consumption of paste during printing. Open settings allow you to adapt to personal requirements. nine0003

Ceramaker 900 – industrial technology. The device creates models with high surface quality, is used to manufacture functional elements that have the same characteristics as parts created by traditional methods (pressing, casting). It is the only machine on the market capable of producing objects according to the established specifications and criteria of the end user. This multi-component printer is capable of producing both simple structural elements and full-fledged functional devices.