3D printer ads

3D Viral Campaigns with 3D Advertising Solutions by Massivit 3D

Go viral with large format 3D Printed Campaigns. Guaranteed stopping power and shareability.

Whether out of home, in store, or zipping past on a promotional vehicle, large format 3D advertising gives you the power to surprise and charm your audience with every new campaign. Inject your omnichannel outreach with the sensory and physical impact of supersized characters and products; allow your consumers to touch, feel, and fall in love with your brand.

Why the Trend? Top Brands Adopt Massivit 3D

Recognized brands, including Coca Cola, Carolina Herrera, Louis Vuitton, Macy’s, Netflix, Nike and more have adopted large format 3D printing as part of their ongoing omnichannel strategy to create interactive and memorable consumer experiences. Massivit 3D makes guerilla marketing and other tactics easy to execute and can shave weeks off delivery time.

- Create a buzz. Make it shareable. Bring any supersized, captivating character or product to life.

- Produce an immersive, sensory consumer experience to complement your digital outreach.

- Tailor campaigns to optimize strategic locations or contexts with exclusive applications.

- 100% customizable. Release your wildest, creative fantasies. No limits to shape or size.

- 100% digital means controlled results. Adhere to brand guidelines and execute multipoint distribution.

- Accelerate turnarounds with super-fast, 3D printing.

- Associate your brand with the most advanced 3D printing technology.

DELOITTE: A UNIQUE SHOPPING EXPERIENCE CAN MAKE ALL THE DIFFERENCE

“In order to meet the consumer’s expectations for multi-channel shopping, the stores must reinvent themselves… 90% of retail sales worldwide are still made through physical stores.”

Deloitte Report – “Global Powers of Retailing 2018”

Want to start a 3D campaign?

CONTACT US TO LOCATE A 3D PRINT SERVICE

100+ Large Format, 3D Printed Campaign Applications

Massivit 3D is transforming the way high-level marketing and advertising creatives conceive campaigns because the possibilities are now infinite.

Stopping Power for Every Context – Retail, In Store, Out of Home, Exhibitions, Events…

- 3D giant, illuminated POP displays and dimensional security gates

- Stunning retail window displays and custom mannequins

- 2D/3D combined billboards

- Personalized exhibition booths and pop-up stores

- Supersized events props and irresistible selfie points

- Outdoor guerilla marketing stunts and bus shelters

- 3D bus wraps

- 3D logos, branded elements, and channel letters

- Customized, large-scale SEG frames (soft signage)

Get started with 3D advertising!

CONTACT US TO LOCATE A 3D PRINT SERVICE

Louis Vuitton – World’s First 3D Printed Pop-up Store, AustraliaLouis Vuitton’s vision: “To radiate the opulence of the company’s safari-inspired men’s line. ” Louis Vuitton shared with shoppers that 3D printing encapsulates Louis Vuitton’s innovation and fresh-thinking attitude. Robert Grosso, Innovation Director at OMUS/ SEEN Technology, said “Oversized 3D printing can interpret and deliver a designer’s visions in a way that no other fabrication method can. Louis Vuitton’s boldness and faith also went a long way to making it a reality.”

” Louis Vuitton shared with shoppers that 3D printing encapsulates Louis Vuitton’s innovation and fresh-thinking attitude. Robert Grosso, Innovation Director at OMUS/ SEEN Technology, said “Oversized 3D printing can interpret and deliver a designer’s visions in a way that no other fabrication method can. Louis Vuitton’s boldness and faith also went a long way to making it a reality.”

“We took over the major landmarks in Paris. For us, it was very important that we really engaged with the audience out there.”

Pier Paolo Righi – CEO, Karl Lagerfeld

Sony Pictures – Angry Birds Movie Launch, USASony Pictures demands dimensional 3D bus wraps for its movie launches. Traveling across several U. S states, the buses capture the attention of thousands of pedestrians and bring the animated characters to life.

S states, the buses capture the attention of thousands of pedestrians and bring the animated characters to life.

“Any company can advertise, but when your clients share and comment on your images and posts, it can go viral. We were looking for interesting engagement points to connect clients with our brand. We you introduced unique, physical 3D elements that they could touch and feel. When you’re standing on a huge boot or you have a huge, funny helmet on your head, it brings much more engagement and generate Likes, Shares, and Comments.”

Ronen Katz – CEO, SkiDeal

Want to start a 3D campaign?

CONTACT US TO LOCATE A 3D PRINT SERVICE

3D Printing Advertising - meet the latest 3D printing advertising trend

A new 3D printing advertising trend is arising in the world of 3D printing. Companies outside of the 3D printing world have started to create accounts in file sharing sites to directly provide advertising materials to the public.

Companies outside of the 3D printing world have started to create accounts in file sharing sites to directly provide advertising materials to the public.

Heineken Beer stared the trend in 3D printing advertising by releasing 3 pieces on their Thingiverse page. The ice bucket, beer coaster, and bottle opener files were released as a promotional giveaway for a championship soccer game.

Cars

Ford is selling officially licensed 3D files for their 2016 model cars. These 3D printed models are a great way for small car dealers to get display models of new cars without ordering the full size car.

3D files and prints of 2016 models are for sale from FordFor RC car hobbyist, the 3D files are a great way to make a hot new shell for your RC car with 3D printing advertising.

Other 3D printing companies like TurboSquid have licensing deals with various companies to produce professional digital files (graphic and 3D print) and physical models of cars. These professional files can go to dealerships to help the customer visualize all the parts of a car order.

These professional files can go to dealerships to help the customer visualize all the parts of a car order.

TV Channel Syfy has recently release a set of free files for space ships and cosplay pieces in their new series “The Expanse”. These files make the show more engaging as fans can 3D print the ships at home.

3D printable props and cosplay pieces from “The Expanse”.For science fiction (Sci Fi) franchises that rely on deep fan loyalty, releasing the files for show items can serve two purposes.

First it gives fans tangible items from the show. Having props and models of the show can increase viewer engagement. These props also serve as physical advertising wherever they are displayed. By combing the “Wow” factor of 3D printing with 3D printable props from a show, a strong cult following can develop.

Second, the production company can control licensing of official merchandise through the sales of official files. This licensing will also lets the companies get a jump on fans who can 3D model show items from screen captures of the show. In this way a sci fi show can generate revenue through the sale of 3D printed merchandise as well as the digital media.

In this way a sci fi show can generate revenue through the sale of 3D printed merchandise as well as the digital media.

As 3D printing becomes more accessible, companies are looking more at 3D printing technology to advertise their business.

Advertising Advantages

3D printing advertising technologies have a property that other advertising premiums do not have. By releasing the files, the 3D printers bear the production cost of making the item, not the company.

Tree decorations released by Papa Johns for 3D printing.Right now 3D printing and advertising is a new idea. As 3D printers become more ubiquitous in the home, I can see how companies will want to expand to 3D printable advertising.

One way is to produce household items that match grocery goods. Chip companies can cross promote with dip companies to make a design for a custom chip / dip bowl.

Pizza companies can design custom plates to go with their pizza slices.

Papa John’s has release a set of Christmas files to help their business. These files are for simple Christmas tree decorations.

These files are for simple Christmas tree decorations.

Video game companies can release prop files that match their games. When Fallout 4 was released by Bethesda Softworks, they sold a collectors edition game that came with an actual Pip Boy controller. This controller let you use your smart phone to control the game. Naturally the gaming community gobbled this up, hook line and radiation proof sinker.

Fallout 4 Pip Boy controller, 3D printedIt did not take long for some intrepid 3D modeler to design their own, unlicensed 3D printable Pip Boy. This pip boy file exploded across file sharing sites, and 3D printing services experienced a rush to 3D print this massive file.

Bethesda missed a golden opportunity in the Pip Boy files. They could have sold the licensed files in conjunction with the commercially produced Pip Boys. They could have also outsourced domestic production of the Pip Boys to 3D printing services to help meet consumer demands.

Video game companies should take the case of Bethesda as an indicator of future trends in gaming.

3D modelers are producing thousands of unlicensed files for gaming accessories and cosplay pieces to every game. Future games can come out with the files to 3D print licensed props and gaming accessories built into the game. In this way, the gamer also becomes the manufacturing arm of the company. By 3D printing advertising with gaming items, the gamer also relieves issues caused by commercial manufacturing delays from overseas companies. By supporting local 3D printers, video game companies and gamer inject money back into the domestic economy, which supports further video gaming.

Professional SportsFor big games, sponsoring companies can produce exclusive files with licensed logos. Imagine the next Super Bowl logo 3D printed on bar coaster, clothing apparel, and toys.

Professional sports leagues can sell licensed files en masse, and leave consumers with the actual production cost of these items. In this way they are not burdened by the inventory of logo items from unpopular teams or players involved in recent scandals.

With players like Carolina Panthers’ Thomas Davis wearing a 3D printed arm brace, other players will soon follow suit with their own 3D printed items. The players and leagues can release 3D printed items that are tied to each player. For fans of valued players, these 3D printed items can be a way to get close to the player. The leagues can also release the 3D scans of players for hardcore fans to put on their team shrines.

Sports leagues can use the data from 3D printing to monitor the public’s perception of teams and players. As part of a team’s goodwill outreach, they can sell files or physical items for charity.

As part of a team’s goodwill outreach, they can sell files or physical items for charity.

Professional sports teams can release officially licensed files for tailgating and events. They can also work with local 3D printers to bulk produce giveaways for a specific sporting event.

3D Printing Advertising: Data MiningThe sales, downloading, and 3D printing habits of the consumer can be a valuable data set for any marketing company. Just as consumer’s internet traffic yields information about their habits, the files they chose to download and 3D print can show consumer engagement and brand loyalty.

3D printing an item shows more brand loyalty then just the purchase of an object from a store. It shows that the consumer cares enough to download and slice the file, then wait the time it takes to 3D print the premium. By making files of different complexity and print time, marketing researchers can gauge customer loyalty through their 3D printing habits.

For more information about this kind of 3D printing advertising visit the following

http://www.crazyleafdesign.com/blog/3d-printing-in-advertising/

http://www.3dprinter.net/3d-printing-unique-advertising-campaign

http://www.thereviewcolorado.com/advertising-third-dimension-advertiser%E2%80%99s-guide-3d-printing

http://adage.com/article/news/3d-printing-adds-dimension-marketing/243870/

Overview of 3D printers for printing advertising signs and 3D letters

3D printing is becoming more and more popular even in industries such as advertising. The production of advertising signs and volumetric letters on modern high-tech equipment is a great way to save time and money. Find out what 3D printers are good for advertising and what equipment is better at handling tasks in this article.

3D printing and advertising

In addition to conventional printing, which is used to create advertising (leaflets, catalogs, banners), 3D printing is also used to produce advertising structures. This technology is often used to create outdoor advertising - three-dimensional letters, signs, signs and logos, as well as for souvenirs. nine0003

This technology is often used to create outdoor advertising - three-dimensional letters, signs, signs and logos, as well as for souvenirs. nine0003

3D printing capabilities allow you to create objects with complex geometry that can be placed outdoors or indoors. A wide choice of materials and colors provides freedom in the embodiment of any ideas.

Various printers are used for the production of advertising - from desktop to professional. Desktop are suitable for printing souvenirs and small branded products. Professional installations with a large print area are designed to create large products - letters and signs. nine0003

Unlike traditional production, 3D printing offers shorter production times as well as a wide range of material shades. On a 3D printer, you can quickly make a letter frame of the desired color without wasting time gluing, processing and coloring.

Features of 3D advertising printers

Professional equipment for advertising - these are large-format FDM devices that print with special materials that are resistant to ultraviolet and temperature changes. nine0003

nine0003

Professional advertising printing equipment has a large X and Y plotting area, which allows you to create large letters and even whole words. Since a large thickness of printed elements is most often not required, the height along the Z axis is limited to 100-150 mm.

Budget 3D advertising printers have an open body, a heated bed for improved adhesion and easy setup. All print options can be set in the software. Software capabilities allow you to produce complex parts - inclined and with bends, as well as provide holes for wires or fasteners. nine0003

Specially designed 3D printer for printing advertising signs, letters and words. The device allows you to create, among other things, advertising for the installation of LED lighting.

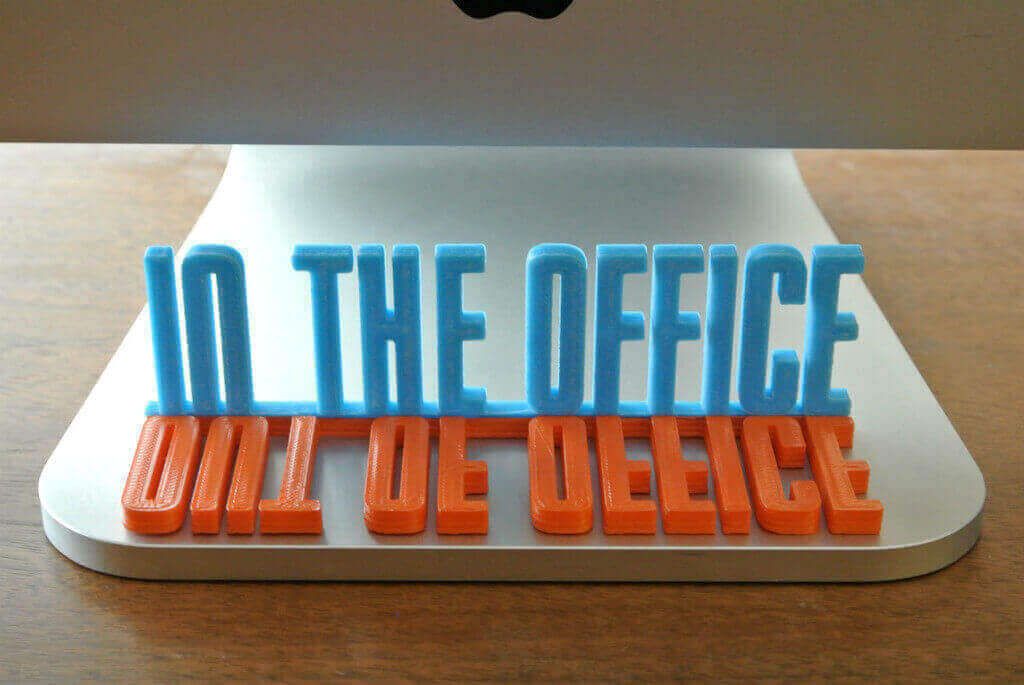

This budget 3D advertising printer has a printable area of 600x600x85 mm, a heated desktop and convenient operation. The ability to print with 2 types of plastic allows you to achieve interesting effects when installing internal lighting, as well as complete almost any design project.

Creatwit Industrial Led Letter 3D Printer K6 can work with translucent PETG plastic, which has a fairly high strength, moderate flexibility and resistance to most alkalis and acids. This material is ideal for creating signs due to its good light transmission. nine0003

K6 has a fairly high accuracy - 0.02 mm along the X, Y axes, as well as the ability to adjust the layer height from 0.1 to 0.6 mm. Convenient data transfer via USB or SD card allows you to quickly move on to printing.

Press examples

Technical characteristics:

- Print technology: FDM / FFF

- Press material: Plastic thread: Open

- Mm Diameter: 1.70049

- Number of print nozzles: 1 pc.

- Extruder temperature: 220 ° C

- Table temperature: 65 ° C

- Press area: 600x600x85 mm

- Calibration: Automatic

- layer thickness: 0.1 - 0.6 mm

- Axis XY: 0.02 mm

- Number of colors : 2 colors

- Heated table: Yes

- Forced chamber heating: No

- Nozzle: 0.6/0.8/1.0/1.2 mm

- Supported materials: PETG

- Supported file formats: STL, SVG, NC, BMP, JPG, STEP, DXF

A selection of articles from the "Knowledge Base" section from the LIDER-3D website: 1) Guide: print figures on a 3D printer • 2) Like 3D technologies are used in different industries • 3) How to choose a good portable 3D scanner

The top model in the Creatwit line. This 3D printer has an enlarged construction area of 800x800x85 mm, so it is suitable for creating large-format advertising.

Industrial printer has excellent performance and flexible settings for any task. The all-metal open body provides stable printing, and the heated work platform allows you to securely hold the object during the printing process. nine0003

The all-metal open body provides stable printing, and the heated work platform allows you to securely hold the object during the printing process. nine0003

K8 has automatic calibration, as well as convenient operation using a touch screen. The equipment comes with proprietary software that has a wide range of tools for work. The program features allow you to set personal settings to create bright and memorable designs.

Industrial Led Letter 3D Printer K8 prints with translucent PETG material and has the ability to work with 2 colors.

Examples of print

Technical characteristics:

- Print technology: FDM / FFF

- Press material: Plastic thread

- PRICE BACK: Open

- DIECTION LIFE LIFE LIFE: 1.

75 mm 2 nozzles: 1 pc.

75 mm 2 nozzles: 1 pc. - Extruder temperature: 220°C

- Table temperature: 65°C

- Print area: 800x800x85 mm

- Calibration: Automatic

- Layer thickness: 0.1 - 0.6 mm

- XY Accuracy: 0.02mm

- Number of Colors: 2 Colors

- Heated Table: Yes

- Forced Chamber Heat: No

- Nozzle: 0.6/0.8/1.0/1.2mm

- Supported Materials file formats: STL, SVG, NC, BMP, JPG, STEP, DXF

Professional equipment from the industry leader from China. AD1 Channel Letter, unlike the other two models presented in our review, can print not only PETG, but also ABS, PLA and Flex plastics. This means that the printer can create both outdoor and indoor advertising, as well as implement the creative ideas of the designer. nine0003

The printer has a large construction area 600x600x70 mm, heated table up to 100°C. The equipment has the ability to print two materials alternately thanks to two filament supply channels.

The main advantage of the AD1 Channel Letter is the user-friendly and intuitive FlashAD software, which has intelligent features. You don't need to download additional software to get started - all the necessary tools are in FlashAD.

Users can enter text in the application, and then the program will automatically create a file for printing. But this does not negate the possibility of using third-party programs for preparing images, such as CorelDraw. nine0003

Like other FlashForge equipment, AD1 Channel Letter has access to the company's FlashCloud cloud service, which allows you to quickly share print files and manage devices.

Printing

Technical characteristics:

- Print technology: FDM / FFF

- Press material: Plastic thread

- Printer Corp0049

- Number of print nozzles: 1 pc.

- Extruder temperature: 260 °C

- Table temperature: 100 °C

- Print area: 600x600x70 mm

- Print speed / print speed: 40 - 200 mm/s

- Layer thickness: 0.009 0.49 0.49 growth axis XY: 0.5 mm

- Number of colors: 2 colors

- Heated bed: Yes

- Plastic control: Yes

- Print resume system: Yes

- Nozzle: 0.6 mm

- Supported materials: ABS, PLA, PETG, Flex

- Supported file formats: CDR, STL

Thank you all, the material was prepared by the LIDER-3D team of specialists, we will be glad to hear your questions in the comments.

If you are interested in 3D printers for advertising, you can get detailed expert advice by contacting us at LIDER-3D, as well as purchase this equipment on our website.

Follow us on social networks: Telegram, VKontakte, Ya. Zen, RuTube, YouTube, TikTok, Instagram, Facebook to be the first to receive the most interesting materials! nine00843D printers: a beautiful fairy tale of futurologists or a tool that will save Russia from sanctions [photo]

A Komsomolskaya Pravda correspondent sat down on the steps next to a printer that prints in metal and thought about the fate of Russian industry.

Photo: Andrey ABRAMOV

Pro 3D printers and additive technologies - this is how this area is generally called - I first wrote in 2014. Then the country was overlaid with post-Crimean sanctions. At the state level, they headed for import substitution.

From every iron they broadcast: the era of the fourth industrial revolution, 3D printers will print whatever you want. The first suppliers of such equipment appeared in Russia. Enthusiasts told me how cunning Chinese stamp houses, cars on printers…

Everything repeats itself in the spring of 2022: factory directors, judging by the business press, are tearing their hair out and don’t know how to work without imported parts. If you are a car owner and have opened spare parts catalogs over the past month, you should have been covered in cold sweat. Deliveries of parts for foreign cars are not expected yet. All that is left can be bought at exorbitant prices. nine0003

Eight years ago we were told about life-saving technology.

I myself promised readers heavenly places printed on 3D printers. It turns out that additive technologies cannot save our industry? Maybe it's a Potemkin village of futurologists...

With such mixed feelings, I went to look for answers to the largest enterprise in Russia that deals with 3D printing - SIU System Innovation Center . It operates on the territory of the former Moskvich automobile plant, which has now been turned into the Moskva technopolis (see "By the way"). nine0003

THIS IS NOT "CUTTING THE EXCESS", BUT GROWING THE NEW

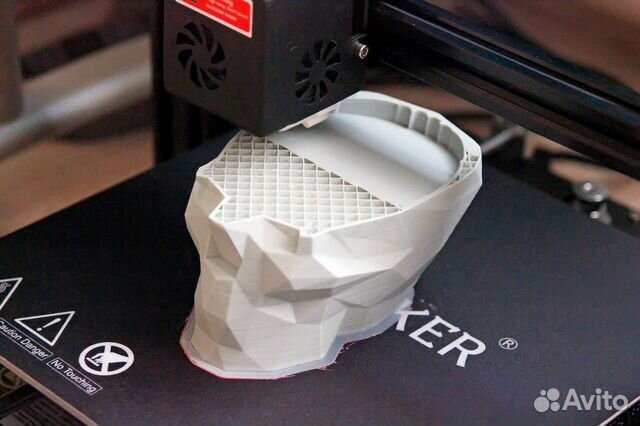

The 3D workshop does not look like a typical plant. There is no blast furnace pouring hot metal, no conveyor running around which workers are fussing. Even boring ... Production is divided into two zones. An ordinary office, where employees clung to monitors. The second is production. There are fifty "boxes" along the walls. This is what 3D printers are. They only hum a little.

Let me remind you how this miracle works in general.

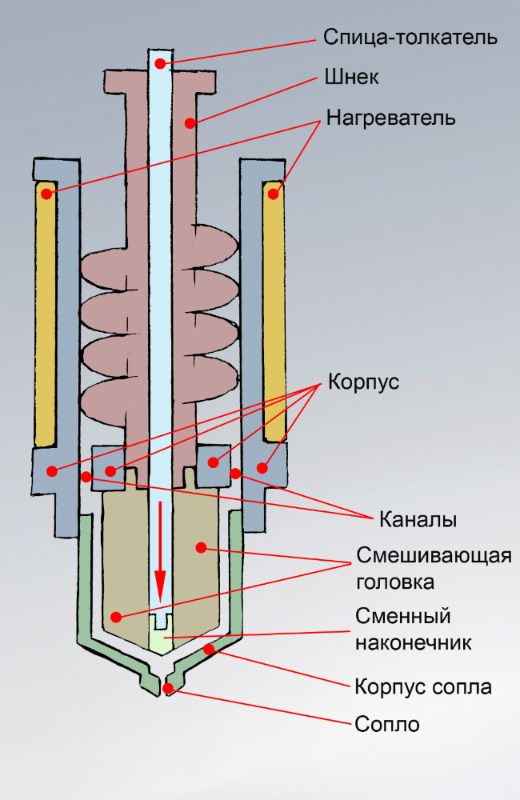

Let's do without hundreds of nuances - believe me, there are enough of them in additive technologies. 3D printers are different. The simplest ones are printed with plastic. They are put in the shopping mall for the amusement of the public, they are bought for school classes in computer science. Such machines are filled with bobbins with plastic thread. Souvenirs and industrial components are printed on them. nine0003

The machine heats up the material and in the molten form lays out layer by layer what the operator has programmed. First you need to draw a three-dimensional model on the computer, which the printer will embody. You can not draw, but take an object, scan it with a special device and get contours for printing.

— Traditional technologies: I took the material, cut off the excess — I got the part. Additive is growing layer by layer of the new, explains the executive director of SIU System Maria Borisova.

Executive director of SIU System Maria Borisova next to a printer that prints ceramics.

Photo: Andrey ABRAMOV

HOW FAST YOU CAN PRINT

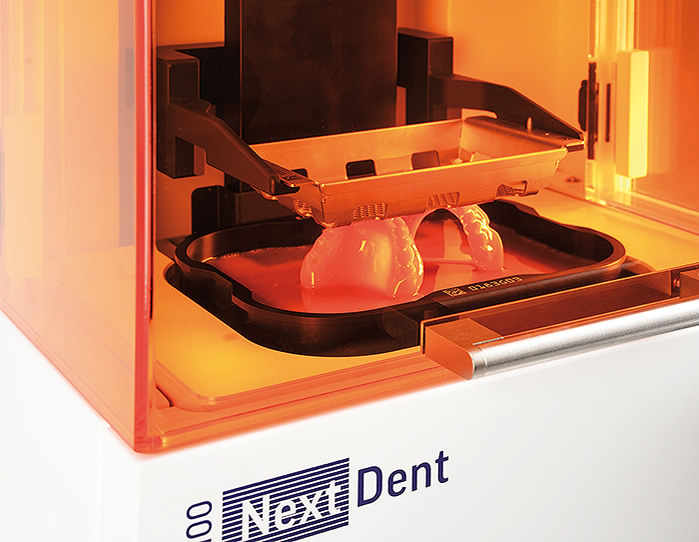

Industrial 3D printers have their own technologies. Imagine a metal cabinet three by three meters. Behind the glass, a bath of liquid polymer is a cloudy goo. A laser beam runs through it. Where he walked, the polymer hardens. Millimeter by millimeter, the outline of the future creation appears from the bath.

This is what an industrial 3D printer that prints with liquid polymer looks like. Photo: Andrey ABRAMOV

- These are blanks for aligners that dentists use to correct an overbite. Each is unique, as it is printed for a specific patient, says Maria.

There are printers that work with metals. They are filled with powder - a titanium part is needed, titanium is poured, etc. Our enterprises make powders. They show me the nozzle of a jet engine. His machine printed in 30 hours. By the way, the speed of all printers is different. On the fastest products grow out of the polymer at 1 cm per minute.

nine0003

There is a sand seal to make casting molds. I filled them with metal, broke the sandy shell, and the detail turned out. Or ceramics - the paste lays down in layers, a laser beam and firing in furnaces make the product hard. Not tea pairs with vases are printed here, but microelectronic components, parts for aviation and astronautics, cages - intervertebral implants.

- A 3D printer can be selected for any production. It is necessary to produce something new - quickly reconfigured the equipment and began production. When the covid epidemic began, we began to print Venturi valves - this is a part for ventilators. Although they didn’t do this before, ”recalls Maria Borisova. nine0003

The printers are capable of producing a complete mechanism. They show me the interweaving of a dozen gears that rotate like a jewelry piece. That is, you do not need to print each component separately, you can immediately mechanism. But it is naive to believe that finished products always come out of the printer.

Some also need post-processing. For example, grinding.

MAN AGAINST THE PRINTER

For an hour I was taken around the shop, told about the miracle of printing. I was already thinking about going to the exit in order to sing to the readers again what a wonderful 3D aleco awaits us soon. I woke up the skeptic in myself and attacked the executive director with questions. nine0003

— If 3D printers really can do anything, where is it in our industry?

— Technology is used, but can be used much more actively. Few people understand the possibilities of 3D printing. There is no wide range of centers in Russia, like ours, to see industrial printers in operation. We are used to thinking in stereotypes about technology. To produce something, you need to take a piece, cut off the excess and you get a part.

Customers come with orders and say: take this material and print the part. And in additive manufacturing, we need a clear technical task, we start from the properties of the final product, because changes occur in the process of printing under the influence of a laser beam.

nine0003

- Here are your dentures. But when I come to dentistry, they sell Korean or Swiss implants. You show me printed auto parts, while Lada Vesta, meanwhile, is half assembled from imported parts. Why, with the limitless possibilities of 3D printing, can't we move our industry on this track?

- We need high-quality equipment, software, suitable materials and trained personnel. If one of the components is missing or saved on it, the result will be far from ideal. nine0003

Europe is moving away from manual labor and towards automation. It's an investment, but it pays off. In Russia, the approach is different: we will put a better person, and in other areas we will save. Industrialists come to us and ask the question: where do you have ten employees around each machine? We explain: one is enough. But this is not accepted…

The black and green box on the right is the Russian Hercules printer. Photo: Andrey ABRAMOV

— Conveyor principle: at each section, the workman picks up the product, adds it, and passes it on to the next one.

nine0230

— It's different here. We produce more than 20 thousand different parts per month, and not so many people work for us (we look at the office area, there are hardly ten people there - ed.). There is a designer and a topological optimization specialist who will develop 3D models of products, taking into account material savings and speeding up printing speed. There is a print operator and his assistant who will prepare the printer, start it up, control the print and, if necessary, post-process the product. There are engineers who control the process and maintain the operation of the equipment. nine0003

- What about the personnel?

- Universities and colleges have training programs for 3D printing engineers and 3D printer operators. We are involved in the development of training standards.

IN RUSSIA THEY DON'T LIKE TO SHARE

— Let's dream: tomorrow our factories will be banned from buying equipment, except for 3D printers.

They give subsidies for the purchase of equipment, train specialists. At this rate, in how many years will we print our Boeing?

- We can print a car, it's more difficult with an airplane. Aviation has a very long certification process to keep everything safe. There are companies in the world that are very actively using 3D technologies. For example, Elon Musk's rockets (American billionaire engineer, founder of the private space company SpaceX - ed.). In world practice, dozens of metal or polymer industrial 3D printers are purchased at once in order to expand production. nine0003

This is a jet engine nozzle surrounded by other "pieces of iron" that were also printed. Photo: Andrey ABRAMOV

In Russia, a factory often takes one printer and tries to integrate it into the production chain. Employees contact us. We all show, explain, tell. After a while, we can get an answer: the team is not ready to try. The manufacturing process is built in such a way that the 3D printer does not fit very well.

You need to change something, educate people, change their habits ...

Or a factory comes to us with a desire to buy equipment. Sets a condition: print the part, we'll see if it works for a month, then we buy it. Then they say: let it work for another six months, more and more ... As a result, all the other parts failed, ours is still standing, and the company changed its mind about buying. Or decides to take another printer, which does not guarantee the result.

At the same time, there are industries in Russia that are actively introducing 3D technologies. But we are not used to sharing our developments. And additive technologies are about promotion. We have signed a non-disclosure agreement with all customers. So we would publish great news every day. Others would see and be inspired. nine0003

So far, it turns out that those who competently use 3D printers are one step ahead of the rest, but they do not always tell how.

— Do we produce our own printers?

- 3D printers were invented in the USA.

There are European manufacturers. Some of them have now temporarily suspended deliveries. But we think things will get better. Domestic producers are reaching a very good level. We test their developments and, if we are sure of the quality, we start using them. nine0003

The blue light that illuminates the bust of Ilyich is the projection of the scanner. He creates a virtual 3D model of the part so that it can then be printed. Photo: Andrey ABRAMOV

— If you disassemble our printer, what is the probability of finding parts that are not made in Russia?

- There is a possibility. There was no task that all equipment should be made only from domestic parts. But in the future, I think it is realistic to create such a printer.

— And yet, do we urgently need to switch to additive technologies in order to save the industry? nine0230

- A 3D printer, when used correctly, allows you to create a product that you could only dream of before.

If you're stamping or casting simple shapes, you might want to leave things as they are. But to improve the part, move on to the production of more technically complex components, start producing new things in a short time - only 3D printing can handle this.

Maria Borisova is holding a 3D-printed robot arm nearby. Photo: Andrey ABRAMOV

BY THE WAY

"Innovation Center SIU System" is based in the SEZ "Technopolis Moscow". There are ample opportunities for industrial cooperation with local residents. In the SEZ "Technopolis Moscow" there is a whole cluster of enterprises engaged in the production of composites and nanomaterials. In addition to it, about 200 companies from the metropolitan SEZ have united into clusters of microelectronics and optics, medical devices and biopharmaceuticals, information and communication technologies, energy-efficient and high-tech industries. nine0003

Read also

Age category of the site 18+

Online publication (website) registered by Roskomnadzor, certificate El No.

FS77-80505 dated March 15, 2021

CHIEF EDITOR

I.O. EDITOR-IN-CHIEF OF THE SITE - KANSKY VICTOR FYODOROVICH.

THE AUTHOR OF THE MODERN VERSION OF THE EDITION IS SUNGORKIN VLADIMIR NIKOLAEVICH.

Messages and comments from site readers are posted without preliminary editing. The editors reserve the right to remove them from the site or edit them if the specified messages and comments are an abuse of freedom mass media or violation of other requirements of the law. nine0003

JSC "Publishing House "Komsomolskaya Pravda". TIN: 7714037217 PSRN: 1027739295781 127015, Moscow, Novodmitrovskaya d. 2B, Tel. +7 (495) 777-02-82.

Exclusive rights to materials posted on the website www.kp.ru, in accordance with the legislation of the Russian Federation for the Protection of the Results of Intellectual Activity belong to JSC Publishing House Komsomolskaya Pravda, and do not be used by others in any way form without the written permission of the copyright holder.

Learn more