3D printer for steel

The Metal X 3D Printing System

Physical Dimensions

| Width | 575 mm |

| Depth | 467 mm |

| Height | 1120 mm |

| Weight | 75 kg / 165 lbs |

Build Volume

| Width | 300 mm |

| Depth | 220 mm |

| Height | 180 mm |

Printer primary Specs

- Printing Process

- Metal FFF

- Z Layer Resolution

- 50 μm - 125 μm (Post-Sinter)

- Printing Media

- Bound Powder Filament

- Internal Part Geometry

- Closed Cell Infill (Triangular) or Solid Parts

- Print Bed

- Heated, Auto Leveling, Replaceable Print Sheets

Wash & Sinter

Wash-1

- External Dimensions:

- 609 x 685 x 1,067 mm

- Weight:

- 136 kg (300 lbs)

- Washing Time:

- 12-72 hrs typical

- Solvent:

- Opteon SF-79

- Working Volume:

- 356 x 254 x 203 mm

Sinter-2

- External Dimensions:

- 1,200 x 700 x 1,500 mm

- Weight:

- 350 kg (772 lbs)

- Run Time:

- 17-31 hours

- Sintering Volume:

- 18,356 cu cm

- Peak Internal Temp.

:

- 1,300° C / 2,372° F

Materials

Compatible Materials

- Release Material

- Ceramic — Becomes Powder During Sintering Process

- Media (Spools)

- Bound Powder Metal Filament

System Details

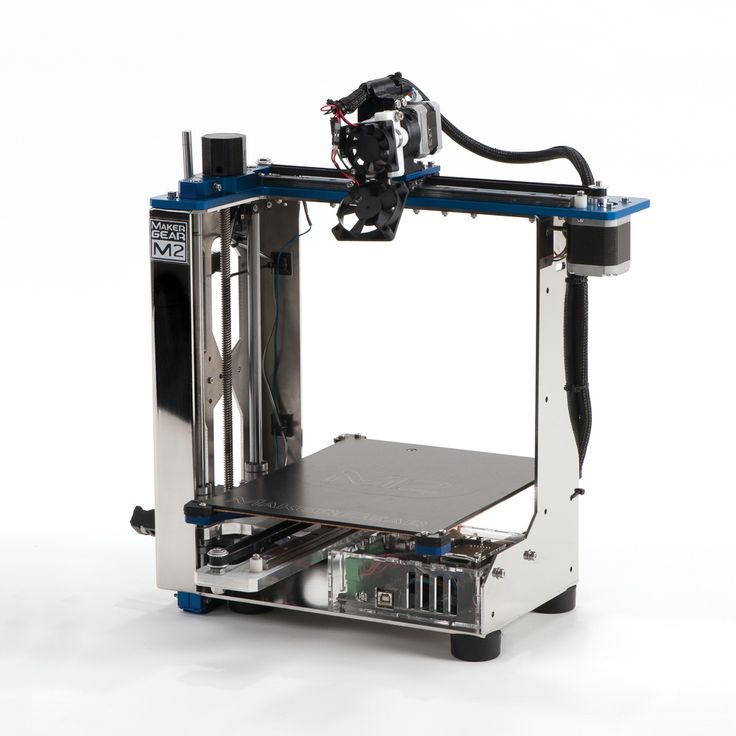

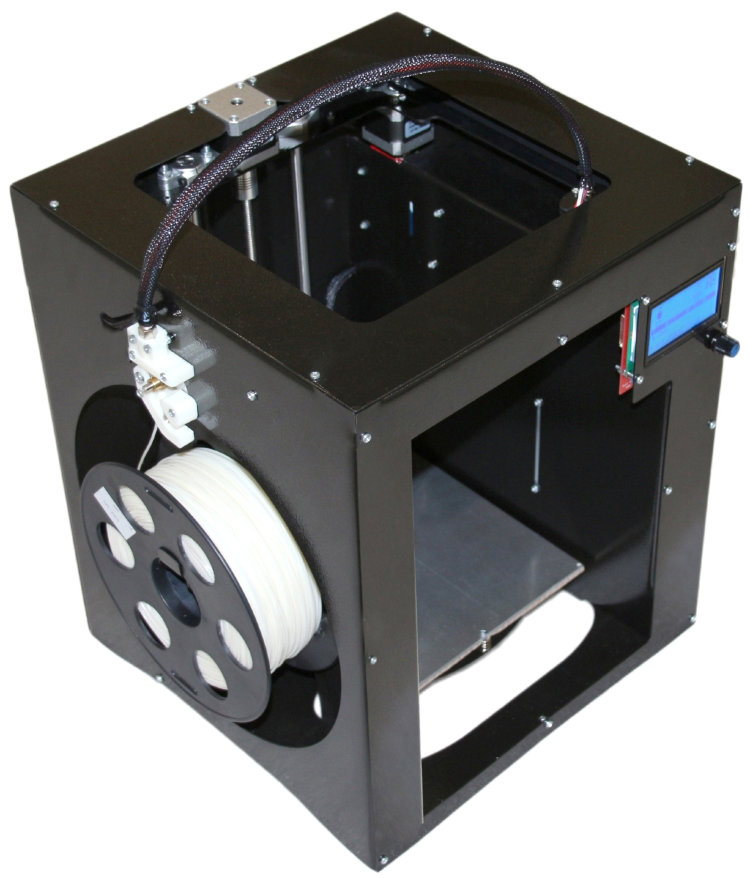

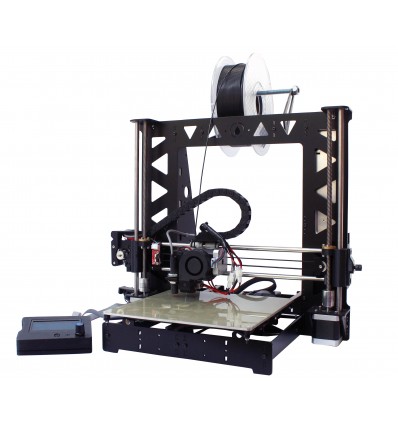

Metal X PrinterThe Markforged Metal X is a new kind of metal printer. By printing metal powder bound in a plastic matrix, Markforged has eliminated many of the safety risks associated with traditional metal 3D printers. That means no loose powder, no lasers, and none of the traditional safety precautions. It’s safe to use in a shop environment with minimal facility upgrades.

In practice, the Metal X is essentially a very advanced FFF 3D printer. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the Metal X is equipped to reliably print you durable parts. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and brushes — accessible and trivial to swap.

Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the Metal X is equipped to reliably print you durable parts. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and brushes — accessible and trivial to swap.

The Wash-1 is a solvent-based debinding system. It primarily uses Opteon SF-79, a high-performance fluid designed to offer superior cleaning power, higher efficiency, and safety in an environmentally sustainable way — Opteon SF-80 or Tergo Metal Cleaning Fluid can be substituted if needed.

The Wash-1 operates with simple ventilation and features an extremely simple user experience. It’s been tested and verified as a shop-safe system.

Sinter-2 and Sinter-1The Markforged Sinter-2 and Sinter-1 are highly optimized tube furnaces used for sintering 3D printed metal parts. They provide leading edge sintering reliability and run times and are equipped with advanced safety features. The Sinter-2 is more advanced than the Sinter-1 — featuring a larger working volume, more precise temperature control, and a mechanical door interlock.

The Sinter-2 is more advanced than the Sinter-1 — featuring a larger working volume, more precise temperature control, and a mechanical door interlock.

The Sinter-1 and Sinter-2 typically have run times between 26 and 31 hours. However, the Sinter-2 can process small parts in express mode, where it can sinter up to 250g of parts in just 17 hours.

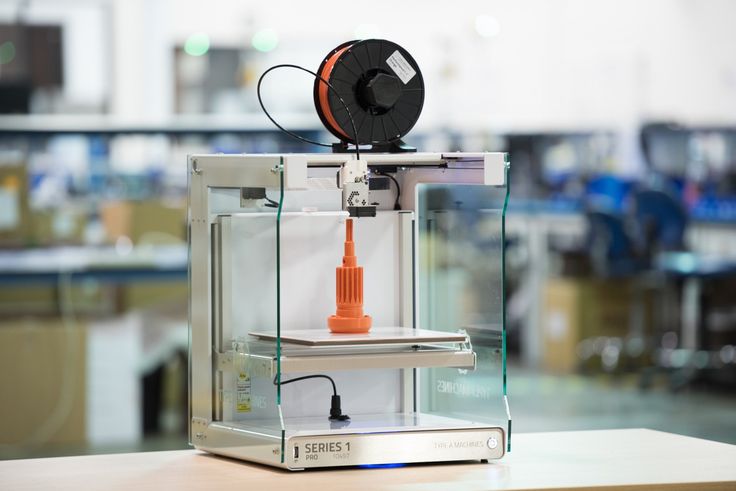

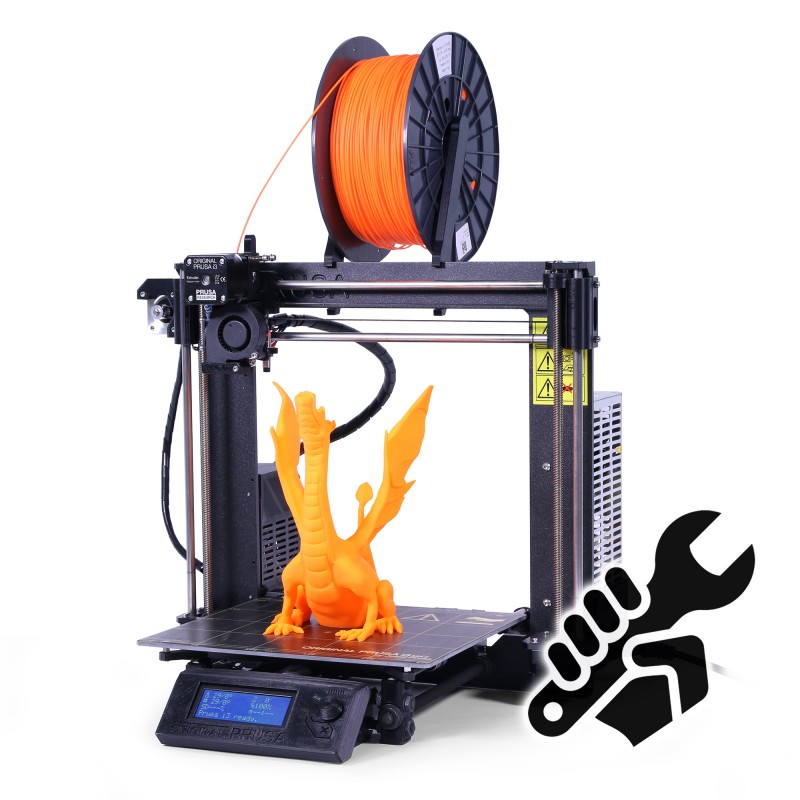

Desktop 3D Printers Designed for Professionals

Desktop 3D Printer Series

Professional desktop 3D printers built with the versatility to test design concepts and build strong end use parts. Our platform covers a wide range of applications - varying from flexible and elastic to strong and rigid.

Compare 3D Printers Talk to an Expert

Drive innovation. Right from your desktop.

Compare Our Desktop 3D Printer Models.

Onyx One™

Our core desktop printer for functional plastic parts with stunning surface finish.

Materials

Plastic

Onyx™

Specs

+320 x 132 x 154 mm build volume

+100 µm - 200 µm layer height

+Precision ground composite print bed

MSRP

$4,990

Talk to an Expert

Onyx Pro™

Our enhanced desktop printer for stunning prototypes, tools, and production parts.

Materials

Plastic

Onyx™

Precise PLA

Smooth TPU

Continuous Fiber

Fiberglass™

Specs

+320 x 132 x 154 mm build volume

+100 µm - 200 µm layer height

+Precision ground composite print bed

MSRP

$9,600

Talk to an Expert

Mark Two™

The best desktop printer for stunning prototypes, tools, high performance end-use parts, and replacement parts.

Materials

Plastic

Onyx™

Nylon White™

Precise PLA

Smooth TPU

Continuous Fiber

Continuous Carbon Fiber™

Aramid Fiber (Kevlar®)*

Fiberglass™

HSHT Fiberglass™

Specs

+320 x 132 x 154 mm build volume

+100 µm - 200 µm layer height

+Precision ground composite print bed

MSRP

$19,900

Talk to an Expert

Dupont™ and Kevlar® are trademarks and registered trademarks of E. I. du Pont de Nemours and Company

I. du Pont de Nemours and Company

What can I build on a desktop 3D printer?

Micro carbon fiber filled nylon offers excellent heat resistance, surface finish, and chemical resistance

APPLICATIONS

- Functional Protos

- Production Covers

- Fit checks

- Job Aids

Learn more

Stiff, strong, and extremely light, carbon fiber reinforcement yields parts capable of replacing machined aluminum.

APPLICATIONS

- Custom production

- Bridge production

- High performance end-use parts

- High-strength tooling

Learn more

Colorful, cost-effective, and easy to print thermoplastic for design validation

APPLICATIONS

- Concept models

- Fit Checks

- Color-coded indicators

Learn more

HSHT Fiberglass delivers the highest impact resistance and heat deflection temperature of our continuous fibers, and can be used for low-temp molds.

APPLICATIONS

- Welding fixtures

- Ruggedized enclosures

- Low-temp molds

- Forming tools

Learn more

Inexpensive and 11 times stiffer than ABS, this is the perfect entry level continuous fiber for 3D printing functional parts.

APPLICATIONS

- Workholding tools

- Functional Prototypes

- Moderate strength end-use parts

Learn more

Extremely durable and extremely resistant to catastrophic damage, Kevlar is an excellent choice for harsh environments.

APPLICATIONS

- Workholding tools

- Ruggedized enclosures

- Flexures

Learn more

Rubber-like material for high quality, flexible, impact-absorbent parts on demand.

APPLICATIONS

- Seals and gaskets

- Shock absorbers

- Wheels and treads

- Belts

Learn more

Unmatched versatility

Our Desktop Series printers unlock production-grade performance and affordable prototypes, all on the same platform. Our most popular printing plastic, Onyx™, gives you a great start in material properties with excellent surface finish. Our selection of continuous fibers take our parts far beyond the mechanical and thermal properties of everyday FFF printing plastics, Smooth TPU 95A provides an efficient way to make high quality flexible parts in low-to-medium volumes, while Precise PLA delivers effective, reliable prototypes at an affordable price. No matter what properties you’re looking for, our desktop 3D printers have the right material for the job.

Our most popular printing plastic, Onyx™, gives you a great start in material properties with excellent surface finish. Our selection of continuous fibers take our parts far beyond the mechanical and thermal properties of everyday FFF printing plastics, Smooth TPU 95A provides an efficient way to make high quality flexible parts in low-to-medium volumes, while Precise PLA delivers effective, reliable prototypes at an affordable price. No matter what properties you’re looking for, our desktop 3D printers have the right material for the job.

How does CFR 3D printing work?

Talk with a

Desktop expert

Let us put together an additive manufacturing solution to suit your needs.

Steel 3D Printing - A Quick Guide / Sudo Null IT News

Any metal 3D printing technology can print with steel. This is the most popular material. But which steel grades and which technology is best for your application? Will printed steel parts really be as strong and durable as traditionally made parts?

Let's see how a 3D printed steel part is revolutionizing manufacturing and opening doors to new applications in aerospace, medical equipment, automotive, tool making, heavy industry, architecture and more. In addition, more affordable desktop printers are expanding the scope and scope of real steel 3D printed parts.

In addition, more affordable desktop printers are expanding the scope and scope of real steel 3D printed parts.

Strength of steel printed parts.

Cast steel part (left), 3D printed version (center). On the right, a fully 3D printed hinge requires no assembly. (Source: Desktop Metal)The most common question when it comes to a 3D printed metal model is "Will it be as strong as a forged or cast part?" ?". The short answer is yes... and no.

3D printed steel parts can be just as strong, and sometimes even stronger, than those made in the traditional way. It depends on many factors such as: end use, type of steel, choice of 3D printing method, post-processing and shape of the part. Also, the comparison depends on which of the strength characteristics you focus on: tensile strength, static load strength, fatigue strength, etc.

Parts printed from steel are used in the aerospace industry, for the military, and also, for example, for the manufacture of a footbridge, shown below. Therefore, the strength of printed products is beyond doubt, but let's take a closer look.

Therefore, the strength of printed products is beyond doubt, but let's take a closer look.

A 3D printed or laser powder sintered (LPBF) steel part has a finer grain structure than cast metal products. This provides better tensile strength characteristics, but in other respects the cast parts are currently still stronger. Most often, LPBF 3D printing is used to replace cast components, but in some cases, 3D printed components can replace forged parts.

One study showed that, under certain conditions, stainless steel parts made using LPBF 3D printers were three times stronger than parts made from the same steel using the traditional method.

In experiments comparing 3D printed steel parts to traditionally made steel parts, researchers create identical parts using two methods and compare their performance. However, head-to-head comparison of details is only part of the big picture.

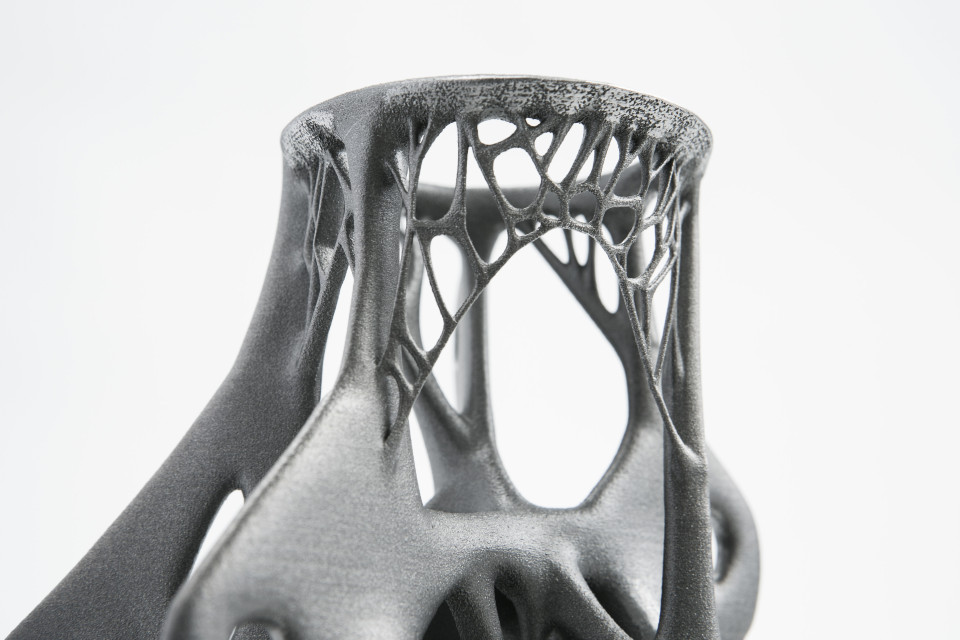

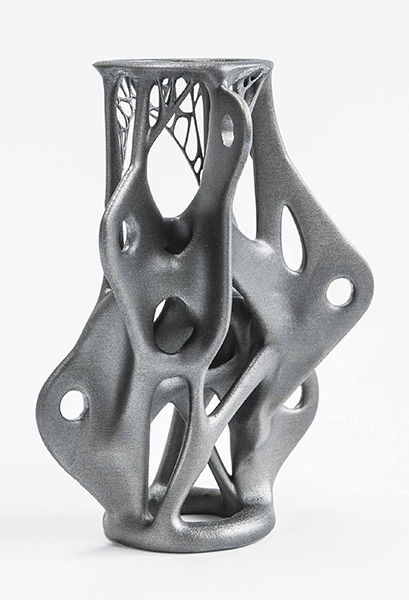

The main advantage of printing with steel is not only its strength, but also the unique ability to create internal channels and lattice fillings in parts, which is impossible using traditional manufacturing methods. Metal 3D printing makes it possible to produce parts faster than traditional production, since this method does not require the use of special equipment and tools, it allows you to create assemblies as a whole, eliminating the need for subsequent assembly and welding. Designing a printed part usually means that less metal is needed to make it, and therefore less weight, for the same strength.

MX3D Wire Arc Additive Manufacturing (WAAM) printed steel architectural support (Source: MX3D) Steel 3D printing is also more stable and cost effective as it reduces waste. When using subtractive manufacturing methods, such as CNC machining, you make a part by cutting it out of a large one, with a lot of waste. With additive manufacturing, you only use the material you need to make the finished product.

Steel 3D printing is not intended to replace traditional methods in all areas, but it may be a better choice for a wide range of applications. Particularly when the required parts are unique and designed for specific applications, such as rocket engines, racing cars or the oil and gas industry. 3D printing is the fastest and most flexible technology for mass production and prototype production. For military and industrial applications, steel 3D printing is a faster and more efficient way to create individual parts for vehicles and machines. Stainless steel 3D printing is rapidly finding applications in medicine to create unique surgical instruments and implants.

If you know what characteristics your final product should have (tensile strength, compressive strength, hardness, density, etc.), then all these parameters can be incorporated into the product at the production stage.

Types of steel for 3D printing

Metal powder is the most used metal material for 3D printing (Source: GKN Additive) There are thousands of different grades of steels and alloys with different mechanical properties, used in traditional manufacturing but in 3D printing there are only a few dozen of them, and some of them are unique, created specifically for this technology. Among the steel options, the following can be distinguished:

Among the steel options, the following can be distinguished:

-

Stainless steel (316L, 304L , 17-4PH, 15-5PH, 420, 254, Ph2, GP1, 630, 410).

-

Tool steel (D2, M2, h23, h21, MS1, 1.2709).

-

Low alloy steel (4140).

-

Structural alloyed (20MnCr5).

Recently, unique alloys have been developed specifically for 3D printing, designed to solve the problems that occur with classical production methods.

For example, 3D printer manufacturer Desktop Metal released a patented stainless steel in 2022 that the company says combines the tensile strength, ductility, and corrosion resistance of 13-8 PH stainless steel, combined with the hardness low alloy steel like 4140. The company says customers can go to market with this material and skip the galvanizing step to protect products from corrosion.

ExOne offers two special blends of steel and bronze that the company says allows 3D printed steel parts to achieve increased corrosion resistance while being easy to machine and polish.

While most of the metal powders used in 3D printing are similar to those used for other manufacturing methods, their numbers are on the rise as more companies adopt the technology. Some metal powder manufacturers, such as GKN, also make custom powders for specific 3D printing applications.

How to print with steel

The strength, properties and applications of 3D printed steel products largely depend on which 3D printing technology you use. Some methods produce stronger parts, other methods provide better hardness or abrasion resistance, and some technologies are simply very fast.

Below are the main metal 3D printing methods, their properties and some of the most common application examples.

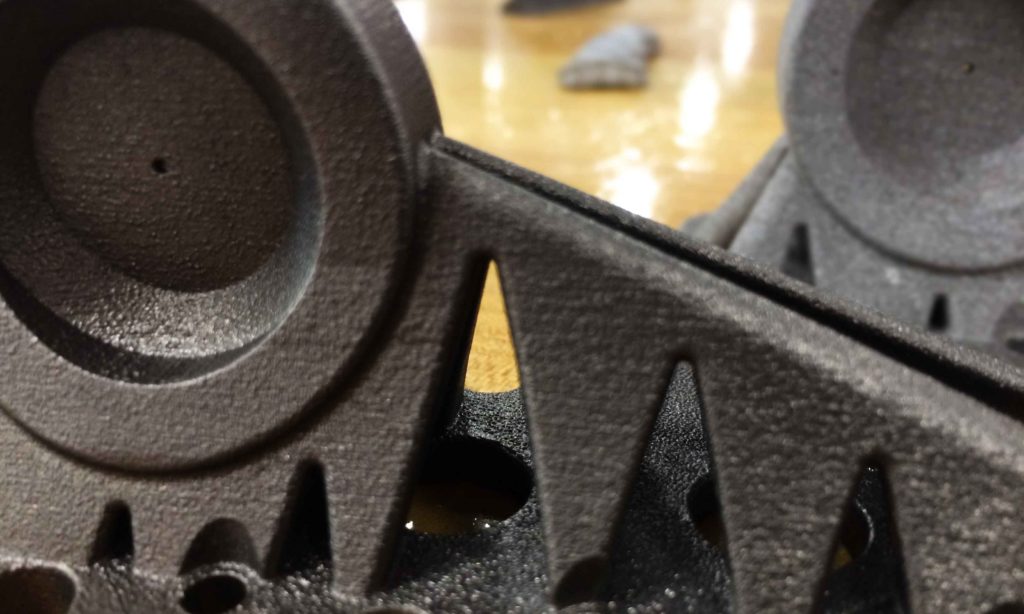

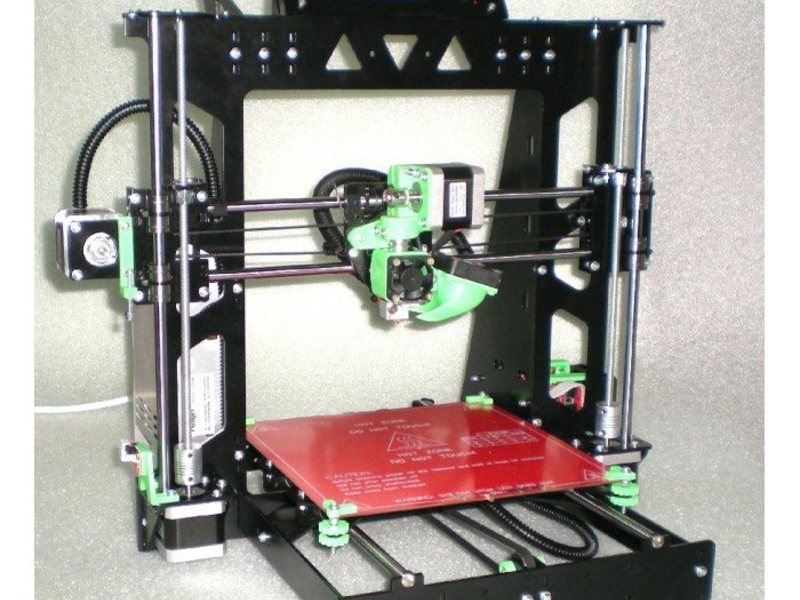

Fused Deposition Printing (FDM)

BCN3D's Epsilon printer extrudes metal filament from stainless steel (Source: BCN3D) as more printer manufacturers certify metallic filaments for use on their printers, such as Ultimaker, BCN3D, Makerbot, Raise3D. Raise3D has recently released a complete metal printing suite - Metalfuse (3D printer, debinding oven and sintering oven). This method is still much more popular for printing plastics, but with new plastic filaments filled with stainless steel powder, strong metal parts can be produced.

This method is still much more popular for printing plastics, but with new plastic filaments filled with stainless steel powder, strong metal parts can be produced. FDM media was once limited to thermoplastics. Companies like BASF Forward AM and The Virtual Foundry now offer metal filaments that can be used on almost any FDM printer as long as it has a hardened steel nozzle for abrasive media.

These materials are approximately 80% metal and 20% plastic. After printing, the post-processing process removes the plastic, resulting in 100% metal parts.

Due to the removal of the bonding plastic, FDM metal parts shrink during post-processing. The amount of shrinkage is constant and can be taken into account in CAD systems, which allows to obtain relatively accurate finished parts.

Forward AM's 316L Stainless Steel Ultrafuse filament produces finished parts with material properties that the company claims are comparable to injection molded metal parts.

(Source: BCN3D) While 3D printing with metallic materials may not be suitable for demanding applications such as aerospace, the economics of producing simple metal components without critical loads on an affordable FDM printer can outweigh the impossibility of applying them in some areas.

Metal prototype parts and finished parts that will not be subjected to extreme stress are ideal uses for this technology.

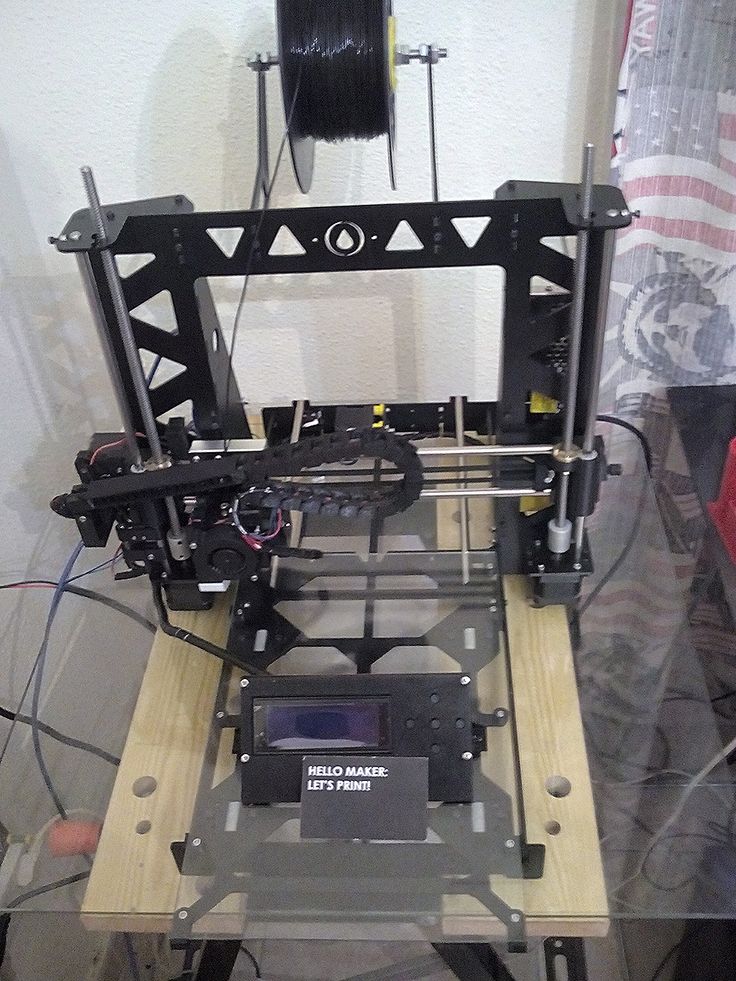

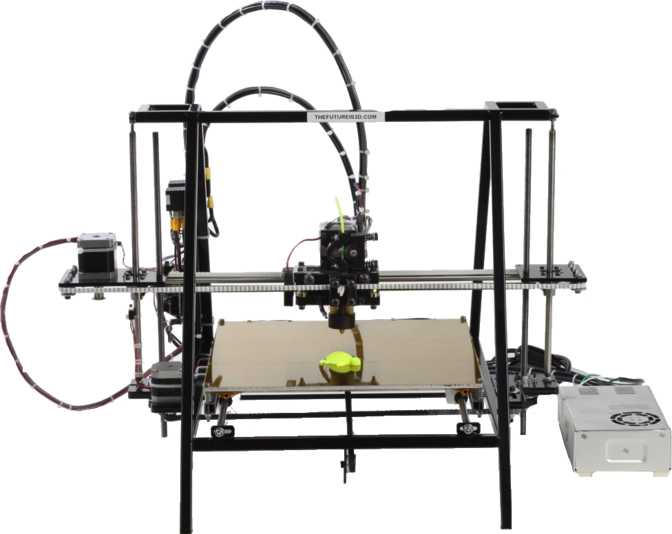

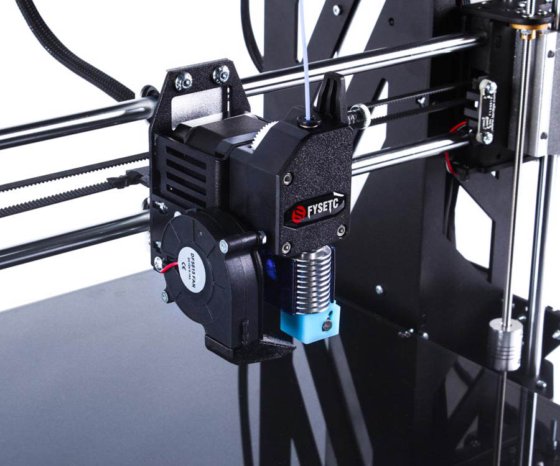

Bound Metal Deposition (BMD)

Desktop Metal's Studio System 3D printer used bonded metal bars that were extruded layer by layer to form a metal part (Source: Desktop Metal)Similar to FDM, Metal mesh deposition method (BMD) or bonded powder extrusion (BPE) is a 3D printing process based on extrusion. This method uses bonded metal rods or bonded powdered metal filaments, which consist of a much higher percentage of metal powder than the filaments used in FDM. As with FDM, post-treatment to remove the binder and heat treatment in a final sintering oven are required.

There are only a few 3D printers using this method such as Desktop Metal, Markforged and more recently 3DGence, but more companies are entering this market, so stay tuned. These printers are valued as a convenient solution for office 3D metal printing, they are more expensive than most FDM printers, but cheaper than the powder-based metal 3D printing technologies described below.

These printers use their own proprietary filament. Desktop Metal and Markforged offer four types of steel.

Ideal niches for this technology are metal prototype parts, where it is necessary to test the functionality of a part before mass production using traditional methods. Popular applications are molds, punching dies, nozzles, impellers, fasteners and heat exchangers.

For example, Shukla Medical uses Markforged's Metal X printer to print steel prototypes of its orthopedic implant removal instruments.

Laser powder sintering.

Laser powder sintering technology uses one or more lasers to melt powdered metal into a desired shape layer by layer (Source: GE Additive) metal printing. This technology is used by 80% of all metal 3D printers on the market.This method uses powerful lasers to selectively sinter metal powder layer by layer.

LPBF 3D printers are available in a wide range of sizes, prices and laser powers. These and other characteristics affect the properties of the finished part, print speed and other parameters of the finished products.

Steel and steel alloys are the most popular material for LPBF equipment and, unlike FDM and BMD, metal powders are commercially available as they are most commonly used in traditional production methods.

LPBF is a technology that maximizes the quality of a 3D printed part. Applications include aerospace components such as monolithic thrust chambers, rocket engine components and heat exchangers, molds, tools and other applications, as well as high wear parts and surgical instruments.

Binder Jetting

Binder 3D printing technology uses metal powder and a binder to form metal parts (Sorrce: ExOne) binder, and not with a laser. During post-processing, the binder is removed.Binder application stands out for its high printing speed compared to other 3D printing methods or traditional manufacturing, and metal parts made with this technology have material properties equivalent to those made by metal injection molding.

The number of manufacturers producing metal-bonded inkjet 3D printers is much smaller than that of LPBF machines. Leading manufacturers include ExOne, Desktop Metal, Digital Metal, GE Additive and HP.

Leading manufacturers include ExOne, Desktop Metal, Digital Metal, GE Additive and HP.

Binder blasting is ideal for medium to high volume production of metal tools and spare parts.

In fact, HP claims that its Metal Jet 3D printer was designed specifically for mass production of 316L stainless steel products. HP has partnered with Parmatech to produce metal parts for the medical industry. Pennsylvania-based ExOne uses this technology to manufacture hard metal cutting tools and tool steels.

Electron Beam Melting (EBM)

(Source: GE Additive)Electron Beam Melting (EBM) is another powder cladding technology. It works in a similar way to selective laser melting (SLM), but instead of using a laser as the energy source, it uses a much more powerful beam of charged particles.

The recoater moves the powder onto the printing plate and an electron beam selectively melts each layer of powder. After each layer is printed, the plate is lowered and another one is applied on top of the previous layer.

EBM can be much faster than SLM, but SLM produces smoother and more accurate pieces. The electron beam is wider than the laser beam, so EBM cannot produce the same precise parts as SLM. Another difference is that the manufacturing process takes place in a vacuum chamber, which reduces the amount of impurities in the material that can lead to defects. That is why EBM is often chosen for printing components for the aerospace, automotive, defense, petrochemical and medical implant industries.

Titanium is the most popular metal for most EBM applications, however steel can be used.

Cold Spray

(Source: Impact Innovations)Cold spray 3D printing is done by injecting metal powders through a jet nozzle into a supersonic stream of pressurized gases such as air, nitrogen or helium. The process is called "cold" because the metal particles do not melt, but hit the metal substrate and adhere to its surface during the so-called plastic deformation.

Cold spray printed products are not prone to porosity, thermal cracking and other defects associated with melt-based technologies. This method has several advantages over other production methods. The technology is used in the military and aerospace industries around the world. For example, the US Army uses cold spray to repair the mounts of a worn Bradley 25mm steel turret gun.

This method has several advantages over other production methods. The technology is used in the military and aerospace industries around the world. For example, the US Army uses cold spray to repair the mounts of a worn Bradley 25mm steel turret gun.

In the automotive industry, cold spray steel is used for crash repairs because the high strength steel substrates in cars can be susceptible to thermal repair methods such as welding.

Direct Energy Deposition (DED) and Wire Arc Additive Manufacturing (WAAM)

WAAM Steel Parts from MX3D (Source: MX3D) Direct Energy Deposition (DED) uses welding powder or wire that enters through a nozzle and is fed into the power source to melt the metal. A melt region is created and applied to the substrate. DED is a new process, reminiscent of an old building technology known as "cladding", in which a coating is applied to a substrate, often for thermal insulation or weather resistance. DED is useful for fabricating large objects as a whole, as well as complex geometries that require extensive machining. DED can get such parts much closer to finished than traditional CNC machining.

DED can get such parts much closer to finished than traditional CNC machining.

Because DED uses a coating process, it can be used to add complex geometries to existing steel parts, thus combining complexity with cost reduction. For example, the French company AddUp advertises a rocket nozzle that uses a preformed large 304 stainless steel hopper cone printed with an isogrid structure, usually made from a larger piece by traditional methods.

A technology related to DED is wire-arc additive manufacturing (WAAM). Instead of powder, WAAM uses a metal wire that is melted by an electric arc. The process is controlled by robotic arms. WAAM is also capable of producing large-sized metal parts, as demonstrated by the Dutch company MX3D and its nine thousand-pound 41-foot stainless steel bridge in Amsterdam, as well as an oil and gas equipment repair part, proving that parts can be made in the field.

Micro 3D printing

Micro parts printed from steel (Source: 3D MicroPrint) Micro scale additive manufacturing, or micro 3D printing, can produce products with a resolution of a few microns (or less). There are three micro 3D printing methods to produce metal parts.

There are three micro 3D printing methods to produce metal parts.

LMM (lithography-based metal fabrication) is a light-based technology that creates tiny parts from raw materials, including stainless steel, for applications such as surgical instruments and micro-mechanical parts.

Electrochemical deposition is the latest micrometal 3D printing process developed by the Swiss company Exaddon. In this process, the printing nozzle applies liquid with metal ions, creating details at the atomic level.

A third micrometal 3D printing method is microselective laser sintering, in which a layer of metal nanoparticle ink is applied to a substrate, then dried to produce a uniform layer of nanoparticles.

German researchers have successfully tested micro SLS printing of hollow microneedles using 316L stainless steel.

Metal parts from 3D Systems, Desktop Metal, MX3D and Materalise.How metal 3D printers work. Overview of SLM and DMLS technologies. additive manufacturing.

3D metal printing.

3D metal printing. Metal 3D printing. Additive technologies.

SLM or DMLS: what's the difference?

Hello everyone, Friends! 3DTool is with you!

BLT metal 3D printer catalog

Selective laser melting ( SLM ) and direct metal laser sintering ( DMLS ) are two additive manufacturing processes that belong to the family of 3D printing , using the powder layer method. The two technologies have much in common: they both use a laser to selectively melt (or melt) metal powder particles, bonding them together and creating a pattern layer by layer. In addition, the materials used in both processes are metals in granular form.

The differences between SLM and DMLS come down to the basics of the particle bonding process: SLM uses metal powders with a single melting point and completely melts the particles, while in DMLS the powder consists of materials with variable melting points.

In particular:

SLM produces single metal parts while DMLS produces metal alloy parts.

Both SLM and DMLS technologies are used in industry to create final engineering products. In this article, we will use the term "metal 3D printing" to summarize the 2 technologies. We will also describe the main mechanisms of the manufacturing process that are necessary for engineers to understand the advantages and disadvantages of these technologies.

There are other manufacturing processes for producing dense metal parts, such as electron beam melting (EBM) and ultrasonic additive manufacturing (UAM). Their availability and distribution is rather limited, so they will not be presented in this article.

How metal 3D printing SLM or DMLS works.

How does metal 3D printing work? The basic manufacturing process for SLM and DMLS is very similar.

1. The printing chamber is first filled with an inert gas (such as argon) to minimize the oxidation of the metal powder. It then heats up to the optimum operating temperature.

2. A layer of powder is spread over the platform, a powerful laser makes passes along a predetermined path in the program, fusing the metal particles together and creating the next layer.

3. When the sintering process is completed, the platform moves down 1 layer. Next, another thin layer of metal powder is applied. The process is repeated until the entire model is printed.

When the printing process is completed, the metal powder already has strong bonds in the structure. Unlike the SLS process, parts are attached to the platform via support structures. The support in metal 3D printing is created from the same material as the base part. This condition is necessary to reduce deformations that may occur due to high processing temperatures.

Unlike the SLS process, parts are attached to the platform via support structures. The support in metal 3D printing is created from the same material as the base part. This condition is necessary to reduce deformations that may occur due to high processing temperatures.

When the 3D printer's chamber cools down to room temperature, excess powder is removed manually, such as with a brush. The parts are then typically heat treated while they are still attached to the platform. This is done to relieve any residual stresses. They can then be further processed. The removal of the part from the platform occurs by means of sawing.

Scheme of operation of a 3D printer for metal.

In SLM and DMLS, almost all process parameters are set by the manufacturer. The layer height used in metal 3D printing varies from 20 to 50 microns and depends on the properties of the metal powder (fluidity, particle size distribution, shape, etc. ).

).

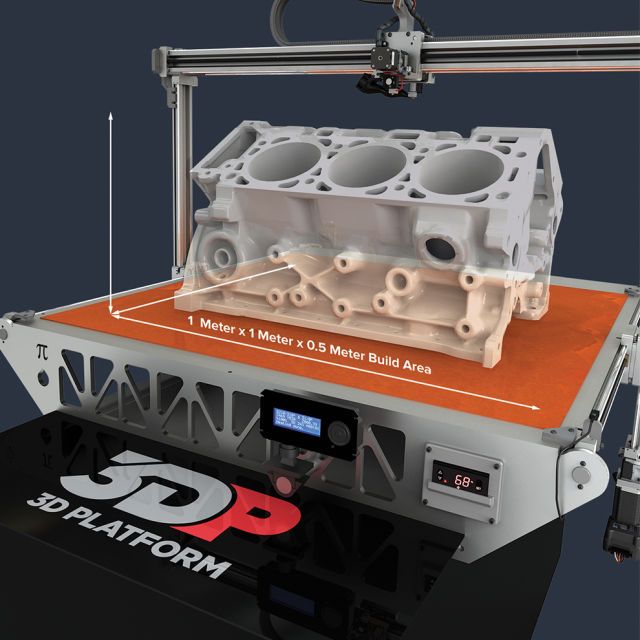

The basic size of the print area on metal 3D printers is 200 x 150 x 150 mm, but there are also larger sizes of the working area. Printing accuracy is from 50 - 100 microns. As of 2020, metal 3D printers start at $150,000. For example, our company offers 3D metal printers from BLT.

Metal 3D printers can be used for small batch production, but the 3D printing capabilities of such systems are more like those of mass production on FDM or SLA machines.

The metal powder in SLM and DMLS is recyclable: typically less than 5% is consumed. After each impression, the unused powder is collected and sieved, and then topped up with fresh material to the level required for the next production.

Waste in metal printing, are supports (support structures, without which it will not be possible to achieve a successful result). With too much support on the manufactured parts, the cost of the entire production will increase accordingly.

Adhesion between coats.

3D metal printing on BLT 3D printers

SLM and DMLS metal parts have almost isotropic mechanical and thermal properties. They are hard and have very little internal porosity (less than 0.2% in 3D printed condition and virtually non-existent after processing).

They are hard and have very little internal porosity (less than 0.2% in 3D printed condition and virtually non-existent after processing).

Metal printed parts have higher strength and hardness and are often more flexible than traditionally made parts. However, such metal becomes “tired” faster.

3D model support structure and part orientation on the work platform.

Support structures are always required when printing with metal, due to the very high processing temperatures. They are usually built using a lattice pattern.

Supports in metal 3D printing perform 3 functions:

• They form the basis for creating the first layer of the part.

• They secure the part to the platform and prevent it from deforming.

• They act as a heat sink, removing heat from the model.

Parts are often oriented at an angle. However, this will increase the amount of support required, the printing time, and ultimately the overall cost.

Deformation can also be minimized with laser sintering templates. This strategy prevents the accumulation of residual stresses in any particular direction and adds a characteristic surface texture to the part.

Since the cost of metal printing is very high, software simulations are often used to predict how a part will behave during processing. These topology optimization algorithms are otherwise used not only to increase mechanical performance and create lightweight parts, but also to minimize the need for supports and the likelihood of part distortion.

Hollow sections and lightweight structures.

An example of printing on a BLT 3D printer

Unlike polymer powder melt processes such as SLS, large hollow sections are not typically used in metal printing as the support would be very difficult to remove, if at all possible.

For internal channels larger than Ø 8 mm, it is recommended to use diamond or teardrop cross-sections instead of round ones, as they do not require the construction of supports. More detailed recommendations on the design of SLM and DMLS can be found in other articles on this topic.

As an alternative to hollow sections, parts can be made with sheath and cores, which in turn are machined using different laser power and pass speeds, resulting in different material properties. The use of sheath and cores is very useful when making parts with a large solid section, as it greatly reduces printing time and reduces the chance of warping.

The use of a lattice structure is a common strategy in metal 3D printing to reduce part weight. Topology optimization algorithms can also help design organic lightweight shapes.

Consumables for 3D metal printing.

SLM and DMLS technologies can produce parts from a wide range of metals and metal alloys, including aluminum, stainless steel, titanium, cobalt, chromium and inconel. These materials meet the needs of most industrial applications, from aerospace to medical applications. Precious metals such as gold, platinum, palladium and silver can also be processed, but their use is of a minor nature and is mainly limited to jewelry making.

These materials meet the needs of most industrial applications, from aerospace to medical applications. Precious metals such as gold, platinum, palladium and silver can also be processed, but their use is of a minor nature and is mainly limited to jewelry making.

The cost of metal powder is very high. For example, a kilogram of 316 stainless steel powder costs approximately $350-$450. For this reason, minimizing part volume and the need for supports is key to maintaining optimal manufacturing cost.

The main advantage of metal 3D printing is its compatibility with high-strength materials such as nickel or cobalt-chromium superalloys, which are very difficult to process with traditional methods. Significant cost and time savings can be achieved by using metal 3D printing to create a near-clean shape part. Subsequently, such a part can be processed to a very high surface quality.

Metal post-processing.

Various post methods. treatments are used to improve the mechanical properties, accuracy and appearance of metal printed products.

treatments are used to improve the mechanical properties, accuracy and appearance of metal printed products.

Mandatory post-processing steps include the removal of loose powder and support structures, while heat treatment (heat annealing) is typically used to relieve residual stresses and improve the mechanical properties of the part.

CNC machining can be used for critical features (such as holes or threads). Sandblasting, plating, polishing, and micro-machining can improve the surface quality and fatigue strength of a metal printed part.

Advantages and disadvantages of metal 3D printing.

Pros:

1. Metal 3D printing can be used to make complex custom parts, with geometries that traditional manufacturing methods cannot provide.

2. Metal 3D printed parts can be optimized to increase their performance with minimal weight.

3. Metal 3D printed parts have excellent physical properties, metal 3D printers can print a wide range of metals and alloys. Includes difficult-to-machine materials and metal superalloys.

Includes difficult-to-machine materials and metal superalloys.

Cons:

1. Manufacturing costs associated with metal 3D printing are high. The cost of consumables is from $ 500 per 1 kg.

2. The size of the working area in metal 3D printers is limited.

Conclusions.

• Metal 3D printing is most suitable for complex, one-piece parts that are difficult or very expensive to manufacture using traditional methods, such as CNC.

• Reducing the need for building supports, will significantly reduce the cost of printing with metal.

• 3D printed metal parts have excellent mechanical properties and can be made from a wide range of engineering materials, including superalloys.

And that's all we have! We hope the article was useful to you.

Catalog of 3D printers for metal BLT

You can purchase metal 3d printers, as well as any other 3d printers and CNC machines, by contacting us:

• By email: Sales@3dtool.