3D printer flesh

3D printer for human flesh can replace damaged tissue

A 3D printer that can print human flesh in order to replace injured or diseased tissue has been demonstrated by scientists at Wake Forest Baptist Medical Centre in North Carolina.

Ear, bone and muscle structures that were printed by the machine and implanted into animals have subsequently matured into functional tissue and developed a system of blood vessels.

Although 3D printing has been used for medical purposes in the past, such as 3D-printed hip replacements, these used materials, such as metal, that are more traditionally used for bone replacements rather than tissue.

However, the new 3D printer is capable of producing fleshy structures. Dubbed the Integrated Tissue and Organ Printing System, it has been in development for 10 years.

The system deposits both bio-degradable, plastic-like materials to form the tissue ‘shape’ and water-based gels that contain cells.

In addition, a strong, temporary outer structure is formed. The printing process does not harm the cells.

The team said that one of the major challenges of tissue engineering was ensuring that implanted structures live long enough to integrate with the body.

In order to achieve this, they optimised the water-based ‘ink’ that holds the cells so that it promotes cell health and growth and they printed a lattice of micro-channels throughout the structures.

These channels allow nutrients and oxygen from the body to diffuse into the structures and keep them alive while they develop a system of blood vessels.

The technology was shown to work after test structures were implanted in rats and the structure was maintained two months later with cartilage tissue and blood vessels forming.

Printed muscle tissue was also implanted and tests confirmed that the muscle was robust enough to maintain its structural characteristics, become vascularised and induce nerve formation.

Jaw bone fragments were also printed using human stem cells, which after five months performed similarly well in the bodies of the rats.

"This novel tissue and organ printer is an important advance in our quest to make replacement tissue for patients," said Anthony Atala, director of the Wake Forest Institute for Regenerative Medicine and senior author on the study. "It can fabricate stable, human-scale tissue of any shape. With further development, this technology could potentially be used to print living tissue and organ structures for surgical implantation."

With funding from the Armed Forces Institute of Regenerative Medicine, a federally funded effort to apply regenerative medicine to battlefield injuries, Atala's team aims to implant bioprinted muscle, cartilage and bone in patients in the future.

Sign up to the E&T News e-mail to get great stories like this delivered to your inbox every day.

This Patch of 3D-Printed Flesh Is a Step Toward a Full 3D-Printed Heart

Around 20 people in the United States die every day waiting for a replacement organ. There simply aren’t enough people donating organs to save all of these people, but this isn’t even the biggest problem. Donated organs only last so long before the recipient’s body starts rejecting them, and medication can only delay that process. Eventually, all donated organs have an expiration date.

The solution to this problem is to replace a patient’s organs with new organs made from the patient’s own cells. This way, the patient’s immune system won’t attack the replacement organs. Obviously, the biggest downside of this method is that doctors have to create these replacement organs from scratch, using technology that doesn’t really exist yet.

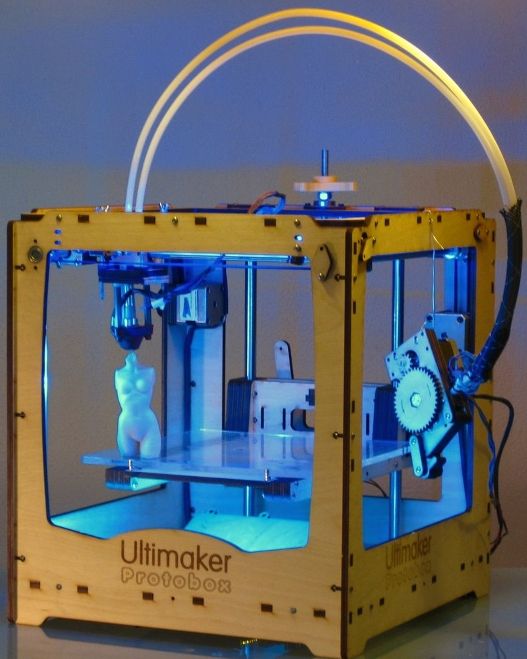

There are a few possibilities for what this future technology will look like, from genetic modification of existing organs to brand new organs grown in test tubes and petri dishes. But one of the more promising technologies is bioprinting: using 3D printing technology to build a new organ cell by cell.

But one of the more promising technologies is bioprinting: using 3D printing technology to build a new organ cell by cell.

This technology is still in its infancy, but a handful of companies are trying to bring organ printing into hospitals. One of those companies is BIOLIFE4D, which has taken the first step toward that goal by printing a patch of human cardiac tissue.

BIOLIFE4D is working toward their ultimate goal of printing a human heart using a patient’s own cells as the building blocks. The challenge here is not just that printing human tissue is hard, but that human hearts are very complex structures, with muscles, nerves, ventricles, valves, and blood vessels. The company not only has to build a bunch of cells in the shape of a heart but also has to make sure each cell is of the right type and functions properly.

While a two-dimensional patch of cardiac tissue is nowhere near a functional human heart, it does meet some of those conditions. The cardiac patch is fully functional human tissue with diverse cell types, and it can actually be implanted into the body to repair a patient’s malfunctioning heart.

The cardiac patch is fully functional human tissue with diverse cell types, and it can actually be implanted into the body to repair a patient’s malfunctioning heart.

BIOLIFE4D hopes that this type of cardiac patch could be used to treat victims of heart attacks and heart disease by replacing the affected heart tissue with brand new tissue. If they’re right, this tech could go a long way toward helping some of the millions of people who suffer from those conditions.

And while an effective treatment for cardiac patients sounds pretty good, BIOLIFE4D isn’t stopping until they make a full human heart. The next step for the company is to print a three-dimensional structure, and then achieve their next goal: a mini-heart, with the same structure and function of a full-sized one. From there, the company hopes to scale up their product and start implanting them in the people who need them.

Avery Thompson

twitter.com/physicallyavery

Mini Double Sided Sander For 3D Makers.

Miscellaneous

Subscribe to the author

Subscribe

Don't want

61

Hello everyone! Due to numerous requests from subscribers and friends, I made a Mini Sander for two discs 75mm and 50mm

A lot of effort, days and plastic were spent, but the result exceeded all expectations. It turned out to be a very powerful grinder for all occasions. Personally, I made it for processing printed models from ABS plastic. With what she copes with a bang. The heart of the whole movement is the 775 Motor. It works up to 36V and is capable of delivering about 15t rpm. Given the pulleys, the speed will be slightly less. For the first, rough plastic grout, this is an excess speed and the ABS will melt. Therefore, I installed Shim speed control and with it you can already set any speed. But for the final polishing with felt, which makes the model shine, high speed is just right! She can also easily sharpen knives, remove burrs from metal, and in general it all depends on the set circle, she has a lot of power. The price was not expensive, at first I ordered a motor with delivery from China for 480 rubles, waited 3 months, opened a dispute and ordered from the Russian warehouse, for 600 rubles, the next day the motor was brought home, despite the quarantine). I took an 8mm shaft from an old laser printer, bearings, a belt and pulleys are not expensive.

The price was not expensive, at first I ordered a motor with delivery from China for 480 rubles, waited 3 months, opened a dispute and ordered from the Russian warehouse, for 600 rubles, the next day the motor was brought home, despite the quarantine). I took an 8mm shaft from an old laser printer, bearings, a belt and pulleys are not expensive.

At first I thought that this was an overly complicated mechanism, there is a powerful motor, and two discs 50mm, 75mm. But upon completion of the project, I worked on it for several days and realized that this is an awesome tool, as versatile as possible and easy to manufacture. The table can be removed, or at any time printed at a different angle or wider. In general, it all depends on the tasks.

If you have any questions, write, I will be happy to answer. In the comments on YouTube, I answer faster. If not urgently, you can write people. Have a nice day, everyone!

As always a link to all models and components

Detailed assembly video.

More interesting articles

ski

Loading

10/14/2022

951

5

Subscribe to the author

Subscribe

Don't want to

Video post about how taking the right idea and implementation, you can bring to mind the whole concept...

Read more

one

Subscribe to the author

Subscribe

Don't want

Dear friends! Formlabs User Summit 2022 will take place on October 26 and 27

Last year...

Read more

115

Subscribe to the author

Subscribe

Don't want

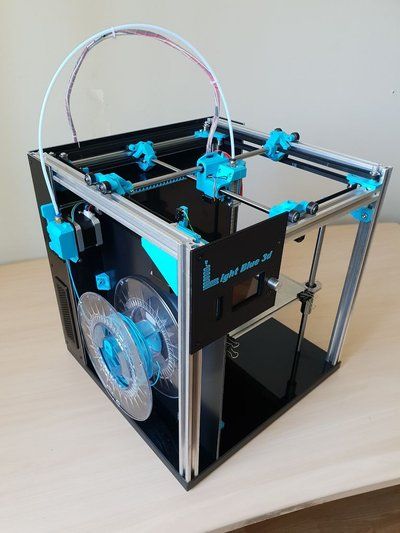

Printer with Core-XY kinematics on rails. Now the 'Z-Belt' version.

Now the 'Z-Belt' version.

which means 'os...

Read more

The biggest 3D printing inventions of 2015

Continuation of the story from

Media news2

Stories

Stories

Ekaterina Bochkareva

Editor of "History" RB.RU.

Ekaterina Bochkareva

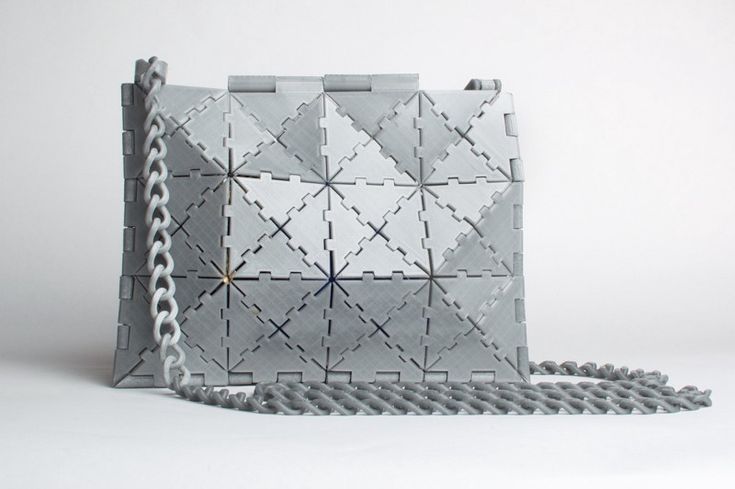

2015 is a year of amazing discoveries in the field of 3D printing, which proved that this unique technology can change the world around us very soon. From construction projects to life-changing surgeries, all of the year's innovations have given us a chance to look at groundbreaking possibilities in 3D printing.

Ekaterina Bochkareva

Among the most high-profile events of 2015 are powerful medical breakthroughs. For example, a 3D-printed chest and a prototype of a human heart, a printer using human flesh for bio-ink, an artificial beak for a toucan, low-cost and fast alternatives to expensive prostheses. Perhaps the most touching case of 3D printing is the story of two students who designed and printed a special wheelchair for a kitten with no hind legs.

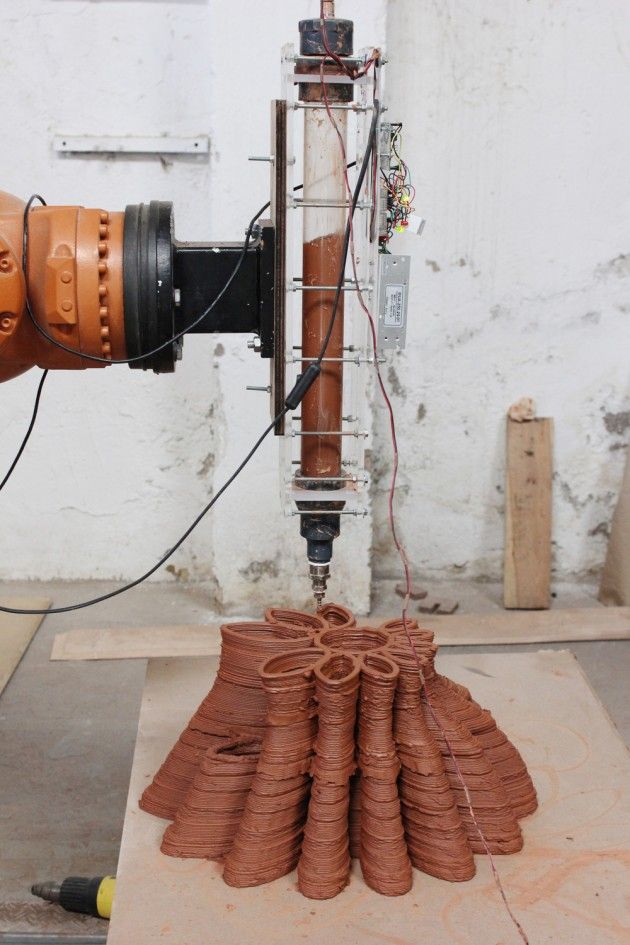

3D printing has opened up amazing possibilities for architecture. This year, robots started building bridges without the help of humans. Entire office buildings are being unpacked in Dubai. An Italian company has even developed a 12-meter 3D printer for this. With it, they are already building cheap buildings for shelter in case of a disaster. Engineers are actively thinking about how to print 3D structures on Mars.

The Year In 3D Printing3D printing promises to revolutionize just about every facet of our lives, and in 2015, that promise came even closer to reality. http://voc.tv/1JstA5L

Published by Vocativ on December 21, 2015

No one knew that in 2015 3D printing would offer limitless possibilities and innovation in almost every aspect of life. Can't wait to find out what inventions await us in the future.

Source.

Related materials:

How to build a business on a 3D core

A 3D-printed prosthesis received a license

The world's largest printed drone was tested in Dubai

Scientists were able to reduce the reducing of the 3D human organs by 100 times

Russian 3D printing service created a prototype of the human heart

Plant for 3D printing of cars will cost $ 10 million

videos on the topic:

- Biotechnology

- Results

- one Do you want to build a 3D printing business? Here's what to know

- 2 At 95% cheaper: what is the effectiveness of 3D printing for modern business

- 3 MPEI will print airplanes: young scientists presented an innovative 3D printer

- four 3D common sense: why do companies introduce additive technologies?

- 5 Create what no one has created.

- 90ISE 3D printing

Found a typo? Select the text and press Ctrl + Enter