3D printer filament supplier

Keene Village Plastics

FREE SHIPPING on All Orders $75.00 or More

ABS

View All ABS

PLA

View All PLA

PC

View All PC

PETG

View All PETG

Overview Although there are many different printers available, only nine basic types of 3D printing technology currently exist: Fused Deposition Modeling (FDM) Stereolithography (SLA) Digital Light Processing (DLP) Selective…

Read More

TYPES OF 3D PRINTING

MATERIALS OFFERED

EVENTS

Sorry, we couldn't find any posts. Please try a different search.

View All

FEATURED PRODUCTS

We use top quality raw materials for our products, working with the innovative 3-Axis laser system and producing the most exceptional products for the 3D printing industry. Each filament has different properties, strengths, and weaknesses, which allow the material to match a particular kind of purpose.

Do not hesitate to ask our staff for information about your spool options. Contact us today for more information about our products.

MANUFACTURER AND SUPPLIER OF 3D PRINTING FILAMENTS

Keene Village Plastics (KVP) is the largest manufacturer of high-quality 3D printer filaments in the United States. If you are looking to integrate 3D printing in your process, we offer a range of services in support of your initiative.

We are a one-stop shop for 3D printer filament materials, 3D printing services, and thermoplastic welding rods, serving retail buyers and wholesalers.

A PIONEER IN PRODUCTION AND QUALITY

All KVP products are manufactured in Euclid, Ohio under our proprietary quality control system.

We source top-quality raw materials and apply laser-controlled precision practices to ensure that we have the highest-quality filaments in the market. In creating PAPC, 3D Solve, KVP, ABS, HIPS, and several other 3D printing materials of superior craftsmanship, we are the 3D printing filament supplier of choice.

Look no further than Keene Village Plastics if you’re looking for where to buy 3D printing filaments.

OUR STORY

When the industry was young, enthusiastic creators were asking "what is a 3D printer filament” and “how does a 3D printing extruder work." There was a void of information because there were no defined standards for 3D printing yet.

Village Plastics is one of the original 3D printing filament suppliers, and our company helped establish the standards for filaments in the mid-2000s. During the same period, we also started to provide 3D printing materials to hobbyists and companies who were just getting started in using 3D printing. In 2008, we became a back-end filament supplier for the biggest brands in the industry.

From 2013 until 2017, 3D Systems acquired the company to serve as an internal division in their organization. Keene Building Products acquired the company in 2017, re-establishing the business as Keene Village Plastics, an independent operator and a quality leader in 3D printing and thermoplastic welding rod markets.

THE HIGHEST QUALITY PRODUCTS FOR THE 3D PRINTING INDUSTRY

Experienced Teams, Advanced Equipment

With us, you can expect the most experienced team in the industry working on the most advanced equipment, ensuring we make the most demanding of polymers and meet the most exacting specifications.

Quality Vs. Price

We believe in producing quality filaments over cheap filaments. These low-cost 3D printing materials that flood the market have inconsistent tolerances, colors, and spool winding. All of which will ultimately cost you a failed print. In offering our superior filaments at a competitive price, we can deliver bigger benefits.

Custom Quality Control System

As a pioneering 3D printing filament supplier, technology is a big part of our process. We employ a state-of-the-art 3-axis micrometer and a proprietary quality assurance system. We do not only use top-quality raw materials to produce our filaments; we reduce the chances of blind spots and manufacturing flaws by about 268 percent compared to a dual-axis micrometer.

Extensive Options

In our facility in Barberton, Ohio, we have dedicated production lines for 3D printing filaments and thermoplastic welding rods. Quantity, and especially quality, is never a problem. We manufacture spooling options from 500g up to 30lbs, and copper coils from 100g to 15lbs.

JOIN THE COMMUNITY & STAY UP-TO-DATE!

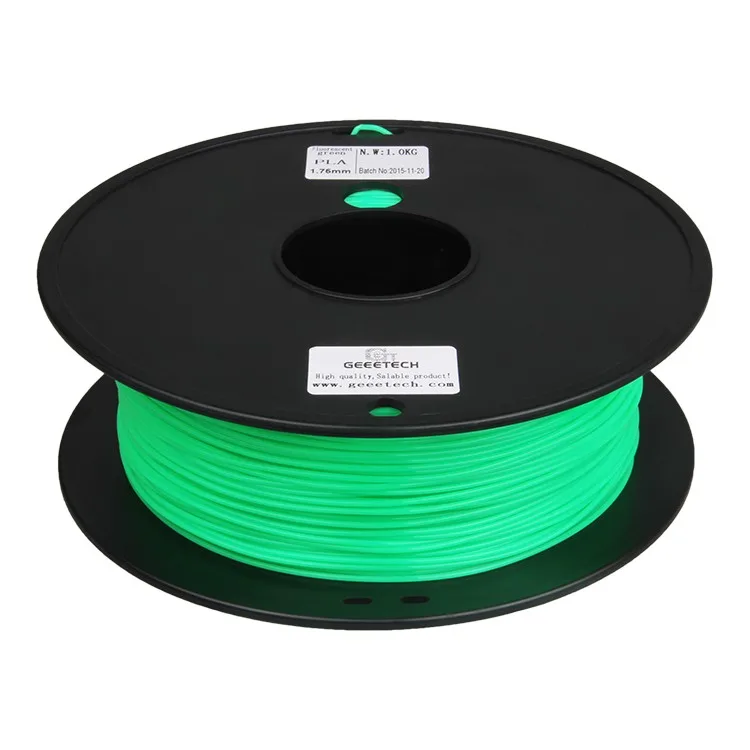

PLA – Keene Village Plastics

Description

Users

Beginners

Available Sizes

1.75 mm

3 mm (Filament diameter measures 2.88 mm)

Available Packaging Stock

1 kg reels

5 lb reels

Available On Request

0.5 kg reels

10 lb reels, 15 lb reels, 30 lb reels (lead time maybe longer)

Coils in various weights

Full Box Packaging

0.5 kg reels packaged 14 to a box

1 kg reels packaged 12 to a box

5 lb reels packaged 6 to a box

Each box contains the same material, size and color.

All filaments are vacuumed sealed with desiccant.

Tolerances

+ 0.003” / -0.003”

Recommended Printer Specifications

Optimal Print Temp: 195ºC – 215ºC

Optimal Bed Temp: 60ºC

Quality

All Keene Village Plastics 3D printer filaments are manufactured in Barberton, Ohio, USA with top quality raw materials and 3-Axis laser-controlled precision providing the highest class of products for the 3D printing industry. More Information

What is the PLA Filament Made From?

The most commonly used 3D printing material today, PLA 3D filament materials are biodegradable thermoplastics made from cornstarch, tapioca roots, sugar cane, or potato starch. This makes it the most environmentally friendly 3D printing material, and one of the easiest 3D printing materials to use. Being considerably less toxic than other petrochemical-based plastics, PLA 3D prints are suitable in biomedical applications.

Where can you use PLA Filament

Most commonly, PLA filaments are used in making food packaging (candy wrappers, containers, and cups), disposable tableware and garments, bags, and biodegradable medical implants. It is not recommended in thin or high-strength applications.

Using it as a Printing Material

With a lower temperature threshold than other popular 3D printing materials, PLA often extrudes at about 195°C to 215°C. A heated printbed is not necessary to render designs on PLA filaments, but heating the bed plate to 60°C can improve the quality of the finished product. The material also flows better, so you can render more detailed designs and achieve defined corners in faster speeds.

As a finished product, PLA prints are brittle out of the press but are tough once they are cooled down. It only emits a slight odor, described as sweet, like corn or maple syrup, so a fume hood is not necessary when printing PLA. You can sand it down to achieve a glossy finish, and you can paint the surface with acrylic paint (some suggest using a primer first).

For biomedical applications, it is generally recommended to avoid pigmented PLA 3D printer filaments. The coloring agent may not be non-toxic like the material itself.

Go to KVP for high-quality PLA 3D printing filaments for sale. Call or email us for your orders or inquiries.

PEEK CF10 for 3D Printer Filament Manufacturers and Suppliers - China Factory

PEEK CF10 for 3D Printer Filament Manufacturers and Suppliers - China Factory - Julier TechnologyHome > Products > Plastic Raw Materials > Quick Look

High Mechanical Strength, Corrosion Resistance, Low Creep Properties

Certificates: ISO, SGS, ROHS, CO, CTI, FTA

Sample: Provide an estimated service price per kg

appearance: translucent granules of ivory of ivory

Factory delivery

Send, promise

Detailed information on products