3D printing uk manufacturing

Popular 3D Printing Companies In The United Kingdom - I

3D printing is rapidly gaining popularity, and almost every country now has a number of 3D printing companies offering 3D printers, materials, components, and services. This article looks at some of the most popular 3D printing companies in the United Kingdom.

Contents

- 1 3D Printing Companies in the United Kingdom

- 1.1 Renishaw

- 1.2 Additive Manufacturing Technologies

- 1.3 Axial3D

- 1.4 Open Bionics

- 1.5 MyMiniFactory

- 1.6 Geomiq

- 1.7 4D Biomaterials

- 1.8 3DLifePrints

- 1.9 Tri-Tech 3D

- 1.10 3DGBIRE

- 1.11 3DPRINTUK

- 1.12 Graphite Additive Manufacturing

Renishaw

Above: Renishaw additive manufacturing systems at its solutions centre/Image Credit: RenishawRenishaw Plc is a British engineering firm headquartered in Wotton-under-Edge, England. The company is best known for its coordinate-measuring machines and machine tool products, and it specialises in measurement, motion control, healthcare, spectroscopy, and manufacturing.

It is also a global leader in metal additive manufacturing and offers industrial metal 3D printers that are completely designed and manufactured in-house. Its expertise lies in process development and in using the technology to provide turn-key and optimised additive manufacturing solutions for a broad range of applications in the industrial and healthcare sectors. The RenAM 500 series is its flagship line of multi-laser AM systems outfitted with 500W lasers.

Renishaw has a large global footprint with over 77 offices in 36 countries and more than 5,000 employees. It employs over 3,000 people in the UK alone, where most of its research & development and manufacturing is conducted.

Additive Manufacturing Technologies

Above: Digital Post-Production Hardware Systems for Additive 2.0 Manufacturing/Image Source: AMTAdditive Manufacturing Technologies (AMT), based in Sheffield, United Kingdom, is a technology company that creates digital post-production hardware systems for additive manufacturing. Post-processing is an important part of the AM workflow, and most 3D printed parts require it.

Post-processing is an important part of the AM workflow, and most 3D printed parts require it.

AMT’s PostPro is a digital post-production technology platform that automates the manual and costly steps associated with legacy additive 1.0 ‘low volume & prototyping’ post processing and enables 3D printers to produce functional ‘high-volume end-use parts.’

PostPro enables businesses to reap the benefits of additive manufacturing at scale by significantly increasing part throughput, performance, quality, cost, and safety.

Axial3D

Above: Axial3D specialises in patient-specific medical 3D imaging and modelling/Source: Axial3DAxial3D is a popular 3D printing company in the United Kingdom. It is a company that specialises in patient-specific medical 3D imaging and modelling in order to improve surgical planning, save time and money, and improve patient outcomes.

Axial3D’s vision of making patient-specific surgery routine is enabled by the development of a software platform that automatically converts all 2D imaging currently used in a patient’s surgical care pathway into incredibly precise, clinically relevant 3D images to vastly improve their standard of care.

Axial3D is able to create and validate models to the highest accuracy under ISO13485 medical standards by utilising SeAAS™ (Segmentation-as-a-Service) and its global 3D printing network. The models can then be printed using a variety of technologies to meet any surgical need.

Open Bionics

Above: Person using a DLSR camera with the Hero Arm/Source: Open BionicsOpen Bionics develops medical devices to help the human body. Its first product, the Hero Arm, is a fashionable bionic arm that is intended for people who have a limb difference below the elbow. Their bionic arms are fully functional, with lights, bio feedback vibrations, and a variety of functions that allow the user to grasp, pinch, high-five, fist bump, and thumbs-up. With this new bionic age inspired by science fiction, thanks to an incredible team and the support of the limb-different community.

MyMiniFactory

MyMiniFactory, which was founded in 2013, is a well-known 3D printing company based in the United Kingdom. It is a file distribution platform / marketplace and has an online platform which is home to digital creators, with a particular emphasis on 3D printing enthusiasts.

It is a file distribution platform / marketplace and has an online platform which is home to digital creators, with a particular emphasis on 3D printing enthusiasts.

In June 2018, MyMiniFactory launched an online STL file store where 3D designers can sell 3D printable files. MyMiniFactory also allows brands to crowdsource through 3D design competitions. The platform has worked with companies like Warner Bros Group – Turner’s Adventure Time, Rovio’s Angry Birds, Autodesk, Google, and the Exxon Group.

Geomiq

Above: Geomiq team/Source: GeomiqGeomiq is the leading Digital Manufacturing marketplace in the United Kingdom. Geomiq was founded in 2017 in London with the intention of transforming and streamlining the manufacturing industry. It has since grown to become the digital manufacturing platform of choice for over 1200+ professional engineers and procurement teams from over 500 fast-moving hardware companies, and it has partnered with over 260 exceptional suppliers from over 16 countries.

It has a large additive manufacturing fleet that includes technologies such as FDM, SLA, SLS, MJF, and DMLS and can deliver orders in as little as three days. Customers can also access 120+ latest 3D printers all over the world thanks to its 260+ partnerships with experienced manufacturers.

4D Biomaterials

4D Biomaterials® is the trading name of 4D Medicine Ltd, a company founded by the Universities of Birmingham and Warwick in April 2020. It is one of the most popular medical 3D printing companies in the United Kingdom.

Its mission is to commercialise a new class of materials called liquid resins, which can be printed into solid 3D scaffold implants to help patients recover from major medical procedures. 4Degra® resins based on polycarbonate-urethane are novel bioresorbable materials with good shape memory, tuneable mechanical and chemical properties, and promising tissue-healing performance. The resin composition is protected by the company’s patent family.

DSW Ventures, Mercia, and SFC Capital have each invested over £1. 85 million ($2.6 million) in the company, and Innovate UK has awarded grants totaling over £300,000 in total. These funds will be used to support the development of the 4Degra® resin-ink product line and 3D printed medical device prototypes in collaboration with 3D printing companies and medical device manufacturers.

85 million ($2.6 million) in the company, and Innovate UK has awarded grants totaling over £300,000 in total. These funds will be used to support the development of the 4Degra® resin-ink product line and 3D printed medical device prototypes in collaboration with 3D printing companies and medical device manufacturers.

3DLifePrints

Above: Surgical Portal – EmbedMed®/Source: 3DLifePrints3D LifePrints is a popular 3D printing company in the UK that was founded with the intention of personalising surgeries. Its comprehensive portfolio of ISO 13485-certified products and digital services has been clinically proven to improve patient outcomes while decreasing institutional operational costs. The 3D printed items can be delivered on-site or remotely. These include an AI-powered and VR-ready digital platform for virtual surgical planning and device ordering, patient-specific surgical guides, implants, and models, 3D design and segmentation, and surgical simulation solutions and phantoms.

3D LifePrints works with clinicians and surgeons to create patient-specific anatomical models, surgical guides, and custom titanium implants that can improve efficiencies and outcomes in difficult procedures.

Their one-of-a-kind service model focuses on delivering the advantages of 3D printing technological support to Orthopaedic Surgeons, Cardiologists and Cardiac Surgeons, Oncologists, Paediatric Surgeons, and Cranio-Maxillofacial Surgeons at the Point-of-Care. It has provided engineering talent, 3D software, and 3D printing hardware to the hospital over the years, allowing a diverse range of disciplines access to a team capable of adding layers of insight, certainty, and personalisation to their treatment strategies.

Tri-Tech 3D

Above: Tri-Tech 3D Platinum Resellers for entire Stratasys 3D Printer Lineup/Source: Tri-Tech 3DTri-Tech 3D, founded in 2007, is a leading 3D printing company in the United Kingdom. It supports the full range of Stratasys 3D printing technologies, including Polyjet, FDM, SLA, and SAF, as well as One Click Metal systems. Serving industries as diverse as automotive, aerospace, animation, general manufacturing, and many more! Tri-Tech 3D provides a wide range of services, including initial specification advice, 3D printing hardware supply, on-site installation, staff training, and ongoing product support.

Serving industries as diverse as automotive, aerospace, animation, general manufacturing, and many more! Tri-Tech 3D provides a wide range of services, including initial specification advice, 3D printing hardware supply, on-site installation, staff training, and ongoing product support.

Tri-Tech 3D was acquired in January 2017 by the Stanford Marsh Group. With the acquisition, the company now also offers CAD software solutions, CAD training, and wide-format printing.

3DGBIRE

3DGBIRE is a 3D printing company based in the United Kingdom that offers a variety of 3D printing services, including reselling and distributing a variety of 3D printers, consulting, dedicated support, and training. It also serves as a 3D printing service bureau, printing orders from customers.

It is able to deliver unprecedented results for its customers by closely integrating 3D printing systems, materials software, technical support, workforce training, and in-depth consultation.

3DGBIRE carries Ultimaker and Photocentric 3D printers, as well as Einscan 3D scanners and a wide range of 3D materials and filaments.

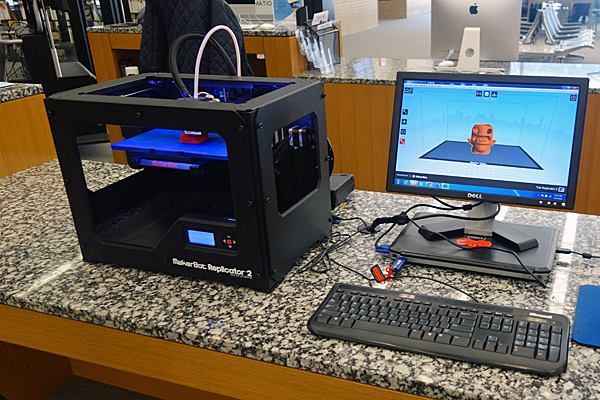

3DPRINTUK

3DPRINTUK, based in London, was founded in 2011 and specialises in high-quality 3D printing services at reasonable prices. It provides nylon SLS prototyping, small-batch production, and other 3D printing and CAD services.

3DPRINTUK is known for its friendly and helpful team that is always willing to assist customers with their designs and prints.

Graphite Additive Manufacturing

Above: Graphite Additive Manufacturing is a consulting firm/Source: Graphite Additive ManufacturingGraphite Additive Manufacturing is a 3D printing consulting firm that assists businesses in realising their full additive manufacturing potential. Engineers, model makers, industrial designers, and product designers collaborate closely with graphite to test concepts, improve designs, reduce production costs, and solve complex design challenges.

It also advises clients on how to improve the strength, weight, and cost-saving benefits of 3D printing.

Note: The list is based on the popularity of 3D printing companies in the country based on their online presence, ease of online search, metrics as obtained from SEO software, etc.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.

3DPRINTUK | 3D Printing Service London

PROFESSIONAL PLASTIC PART MANUFACTURE. HOW CAN WE HELP YOU?

I NEED TO PRODUCE A BATCH OF PARTS

Low Volume Batch Production

Order Parts when Required!

1 – 10,000 Parts

No Tooling Costs, No Set Up Fee

Price Breaks for Higher Volume

I HAVE AN STL FILE & NEED A QUOTE

If your model is ready to go, upload your stl file for an automatic adjustable quote. Our system will choose the cheapest pricing structure for you.

Our system will choose the cheapest pricing structure for you.

HERE TO HELP YOU SAVE ON PART PRODUCTION COSTS

Refer a Friend

Once your friend places an order

you both get a 10% discount token

Volume Price Breaks

We have designed our pricing structure with aggressive price breaks to benefit those who need higher quantities

ADDITIVE FOR MANUFACTURE

3DPRINTUK are specialists in low volume production using state of the art SLS and MJF 3D printing systems. Our aim is to bridge the void between prototype and injection moulding. If tooling costs are prohibitively expensive for your product or you don’t require the volume demanded by injection moulding it’s time to email us or give us a call.

Our aim is to make you the best plastic parts possible using state of the art 3d printing systems. With over 10 years experience, 3DPRINTUK have mastered the process of printing parts using both SLS and MJF technology, with no need for support material, virtually no layer lines and short turnaround times, you are guaranteed robust, accurate parts, time and time again.

We can produce one off rapid prototypes if that’s what you require or production runs of tens of thousands of parts, on demand.

Call or email us to discuss your project.

OUR SERVICES INCLUDE

MORE ABOUT 3DPRINTUK

Additive manufacture with 3DPRINTUK can save you £1000’s

Enter your tooling costs and quantity required into our low volume calculator and it will tell you at what point SLS is viable for manufacture and how much you can save in part production costs.

We want to save you money on part production costs, check out our tips and tricks video

Contact

Call: 0208 692 5208

Email:

General Enquiries - hello@3dprint-uk. co.uk

co.uk

OFFICE HOURS:

Mon-Friday 9.00am - 5.00pm

Daily cut off for new orders: 3.00pm

WE ARE SOCIAL

SEARCH

Search for:Unit D9

Leyton Industrial Village

Argall Avenue

London

E10 7QP

NEWSLETTER

Sign up to our Newsletter for the latest

service updates and special offers

OUR PRICING APP

GENERAL

SERVICES

3D PRINTING

PRICING

ABOUT US

UK government to invest $25 million to build 3D printing center

Siemens 3D printer for gas turbine parts

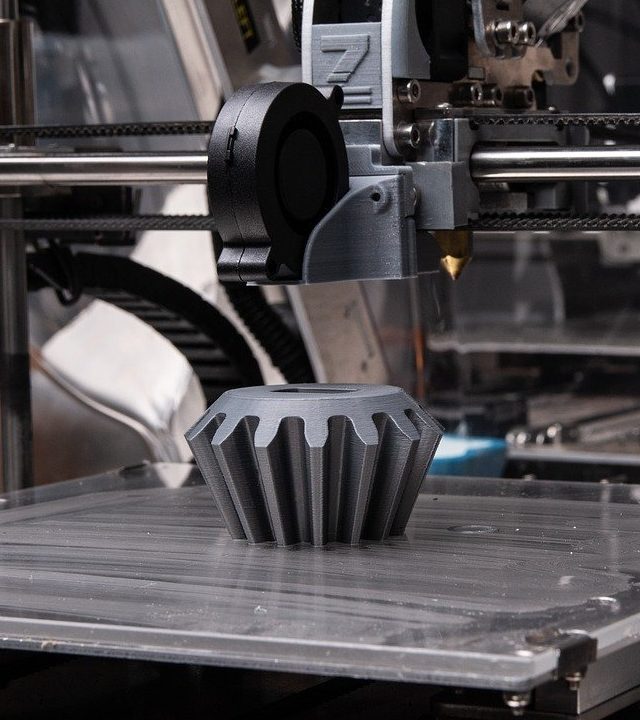

Treasury Secretary George Osborne yesterday unveiled a plan to build an Additive Technology, or 3D printing, center that will significantly reduce production costs difficult to manufacture products. According to the minister, the state will allocate 15.3 million pounds (about $25 million) for this, the BBC reported.

3D printing technology is the build-up of material on an object layer by layer. Historically, production has consisted not of layering, but of removing material, most often by cutting or drilling parts. The UK 3D Printing Center will be located in Coventry next to the Manufacturing Technology Center (MTC), which is funded by both public and private funds and supports new manufacturing technologies.

Historically, production has consisted not of layering, but of removing material, most often by cutting or drilling parts. The UK 3D Printing Center will be located in Coventry next to the Manufacturing Technology Center (MTC), which is funded by both public and private funds and supports new manufacturing technologies.

The 3D Printing Center will, among other things, develop new components for jet engines, an industry in which the UK is a major player thanks to Rolls-Royce's leadership position. Its creation will also support the automotive and medical industries. However, the aerospace industry will still receive the main benefit - state investment is made as part of the authorities' strategy aimed at supporting this sector, writes the Financial Times. The strategy calls for £2bn ($3.3bn) from the government and industry to go into research to build the next generation of passenger aircraft.

The government will also provide £15 million to a new aerospace center at MTC that will develop technologies for new materials such as carbon fiber reinforced plastics for aircraft fuselage and wing parts.

The companies will invest an amount equal to the government allocation. As a result, a total of 60 million pounds ($98 million) will go to finance both projects. The money will also be used for vocational training and advanced training for 1,000 engineers.

The UK aerospace industry is the second largest in the world in terms of revenue after the US.

The 3D printing center is due to open in 2015. The government will "feel free" to support the success of British manufacturers, Osborne said.

3D printing technology is beginning to be used more and more in production. At the end of last year, the German Siemens announced that from January it would use it to produce spare parts for gas turbines. This will allow it to speed up the repair work (in some cases, for example, when repairing propulsion systems - from 44 weeks to four) and reduce costs.

Siemens will be one of the first industrial companies in the world to apply 3D printing to everyday metal production..jpg) Meanwhile, a number of the largest industrial companies, from EADS to General Electric, are also preparing to introduce this technology into production; the latter said last year that it plans to produce jet fuel injectors in this way.

Meanwhile, a number of the largest industrial companies, from EADS to General Electric, are also preparing to introduce this technology into production; the latter said last year that it plans to produce jet fuel injectors in this way.

In July 2013, the US space agency NASA announced that it had successfully tested a 3D printed engine part for a rocket engine. NASA said in a statement that it normally takes a year to make, but the new technology has reduced that time to less than four months and cut costs by more than 70%.

In 2012, the total 3D printing services market was worth $2.2 billion. Only 28.3% of that was used in the manufacture of parts for finished products, according to Wohlers Associates. According to the agency's forecasts, this market should grow to $6 billion by 2017 and to $10.8 billion by 2021.

Media news2

Is advertising distracting? Subscribe to hide itDMC brings silicone 3D printing back to the UK

You are here

Home

The 3D printing service bureau Digital Manufacturing Center (DMC) or "Digital Manufacturing Centre" has introduced a process in the UK called silicon additive manufacturing (SAM). The technology, developed by the Swiss company Spectroplast, is intended for the automotive, industrial and medical sectors.

The technology, developed by the Swiss company Spectroplast, is intended for the automotive, industrial and medical sectors.

High quality elastomeric parts are still quite rare in 3D printing compared to hard materials. This is due to the limited range of elastomers that can be processed with various 3D printing technologies. In extrusion engineering, thermoplastic polyurethane (TPU) is a key resource. The same applies to powder bed sintering, where there are even more restrictions on the types of raw materials that can be worked with.

As a thermosetting resource, silicone is rare in the industry, but exhibits physical properties not available with TPU and other thermoplastic elastomers. In particular, its resistance to chemicals, a wide range of temperatures and UV radiation is useful for certain applications such as sterilizable medical equipment.

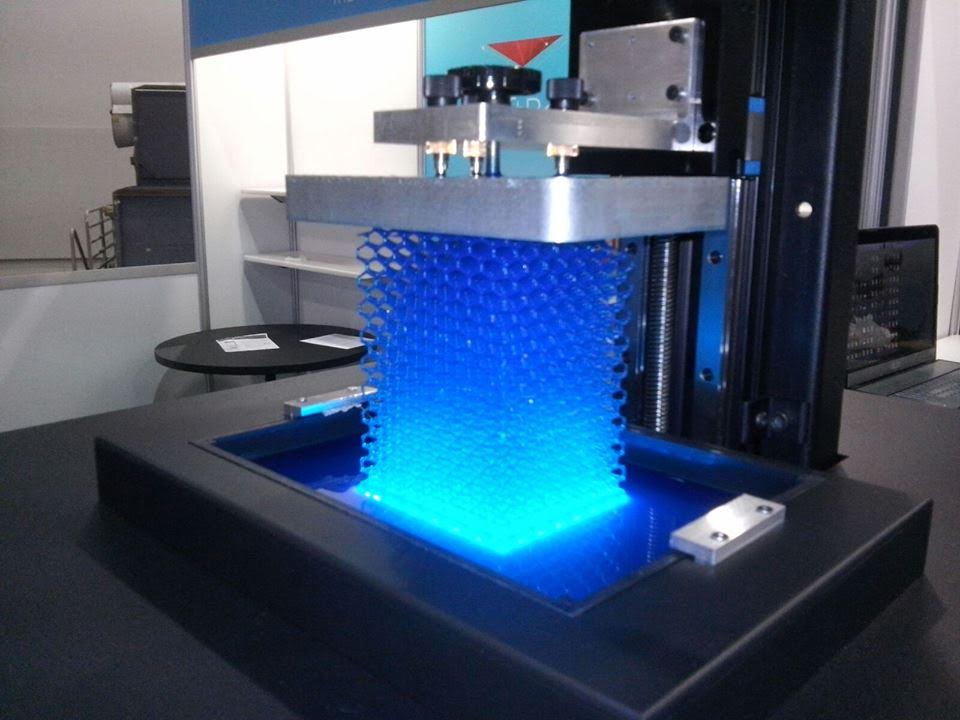

Spectroplast is a subsidiary of the renowned Swiss public research university ETH Zurich. The specifics of the SAM technology have yet to be revealed, but the firm describes it as a process that is similar to SLA using a concentrated light source. DMC explains that printing silicone molds on a 3D printer involves selectively exposing liquid silicone to a light source to form very thin, solid layers that coalesce to create the finished object.

DMC explains that printing silicone molds on a 3D printer involves selectively exposing liquid silicone to a light source to form very thin, solid layers that coalesce to create the finished object.

Photo: https://spectroplast.com/

In addition, parts made using SAM are described as isotropic. This means they exhibit uniform physical properties in all directions, unlike most 3D printed items. This suggests that silicone additive manufacturing includes the option of continuous DLP technology, which is confidential information.

The company currently offers four types of silicone with hardness A20, A35, A50 and A60 respectively. All four options are considered biocompatible and comply with ISO DIN EN109 standards93-05/10. This means that the compound is not only safe for skin contact, but can also be implanted, allowing the material to be used in medical devices, prostheses and more. With temperature resistance ranging from -50 to +200°C, SAM products can be used as gaskets, seals, bushings, dampers and pipes for industrial applications. The achievable layer thickness is currently 0.1mm and the working volume of the current platform is 120x130x75mm, but Spectroplast is working on increasing the printable area to 200x440x300mm.

The achievable layer thickness is currently 0.1mm and the working volume of the current platform is 120x130x75mm, but Spectroplast is working on increasing the printable area to 200x440x300mm.

DMC is now developing this technology in the UK. DMC opens a subsidiary of the engineering company KW Special Projects with a production area of 2000 sq.m., which has been offering 3D printing services since the first quarter of this year. The company is setting up work on printing three-dimensional objects, including mass production of parts.

Although DMC claims to be the first to offer silicone 3D printing in the UK, Picsima developed the silicone 3D printing method around 2014. Unfortunately, the organization announced the sale of its patents in 2020 as the founder began his teaching career.

Meanwhile, Wacker Chemie, an international silicone company, has developed its own method for 3D printing silicone. Its 3D printing department continues to operate using inkjet technology, so UK customers can order parts from that organization as well.