Best sandpaper for 3d prints

Ultimate Guide to Sanding 3D Prints

Sanding 3D printed models can be a great way to eliminate layer lines in preparation for painting, silicone molding, or vacuum forming.

In this “how to”, we will show you the best practices associated with sanding your 3D prints.

Working time will vary depending on your model. The process shown took us about 3 hours from start to finish.

SUPPLIES

Sandpaper (80, 120, 240, 220, 1000, 1500 grit)

Handheld electric sander

X-acto Knife

Needlenose pliers

Flush cutters

Chisels

Bin to hold water

Respiratory Mask

Eye protection

Gloves

Need some of these products? We've curated an Amazon wish list for you.

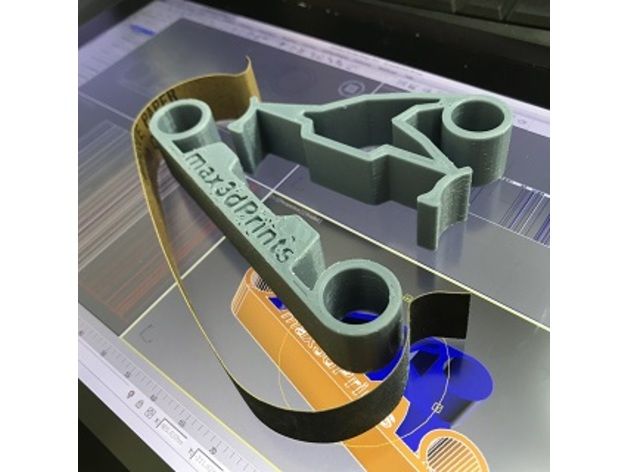

STEP 1: PREPARE & PRINT MODEL

Consider: Print settings, print orientation, number of build plates. Surfaces printed in the Z axis will have the smoothest surface finish.

Surfaces printed in the Z axis will have the smoothest surface finish.

Supplies used: Needle-nose pliers or flush cutters and chisels

A. Remove the print from the build plate

B. Remove rafts and support material from the model

When removing supports using pliers or clippers, be sure to wear eye protection.

C. Remove large pieces of support first, and then approach smaller pieces and fine details

D. Clean the edges and seams of your model to ensure better alignment of pieces

If you plan to glue your model, take care not to remove too much material around seams or joining surfaces, or you will need to use filler later on.

The 2021 Guide to 3D Printing Materials

Learn about polymers, composites, and metals all available for 3D Printing!

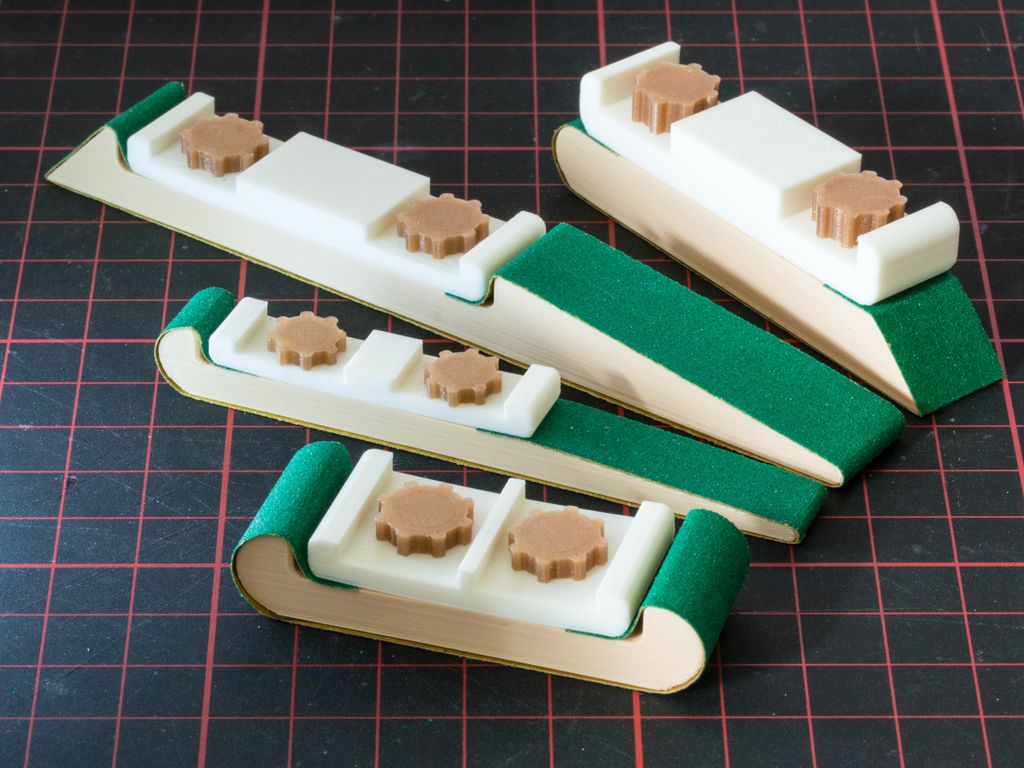

Supplies used: Electric sander and 80 grit sandpaper

A. Begin sanding with coarse (80 grit) sandpaper

Be sure to wear eye protection and a respiratory mask as sanding will release particulates.

B. When sanding with 80 grit sandpaper, the goal is to remove any leftover blemishes from raft or support material, and create an even surface that you will later refine. This process will remove the most amount of material and take the most time.

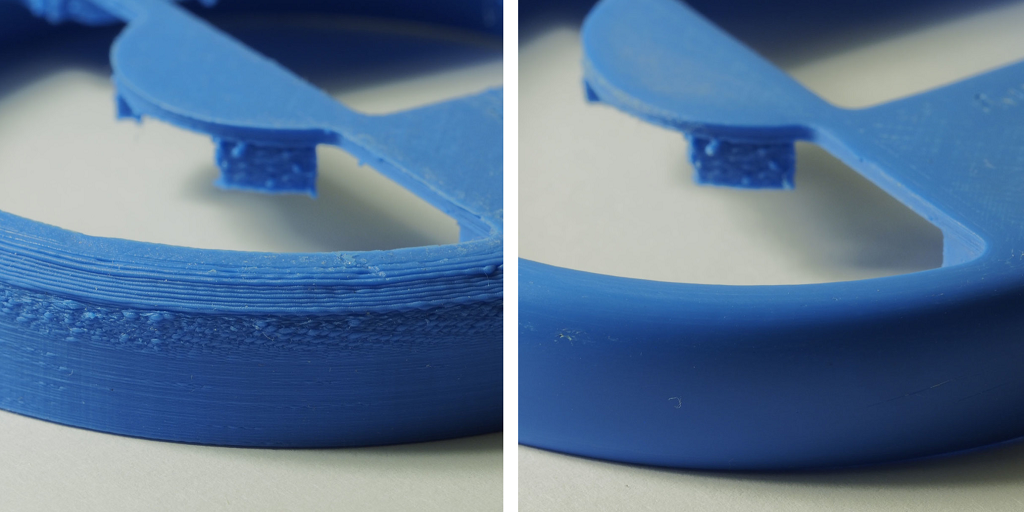

C. In early stages of sanding you will notice that your model surface that was once fairly shiny will become dull and rough and change in color. The shine will return as you move to higher sanding grits.

Be sure not to sand in one place for too long as heat generated from friction could melt the PLA.

D. To save some time you can use an electric sander or multitool. If using a multi tool, be sure to choose a low setting to avoid overheating/melting the PLA.

E. After each sanding stage, clean the model of any dust and inspect for a uniform surface finish

Move on to sanding with higher grits when all large to medium sized imperfections or blemishes have been removed.

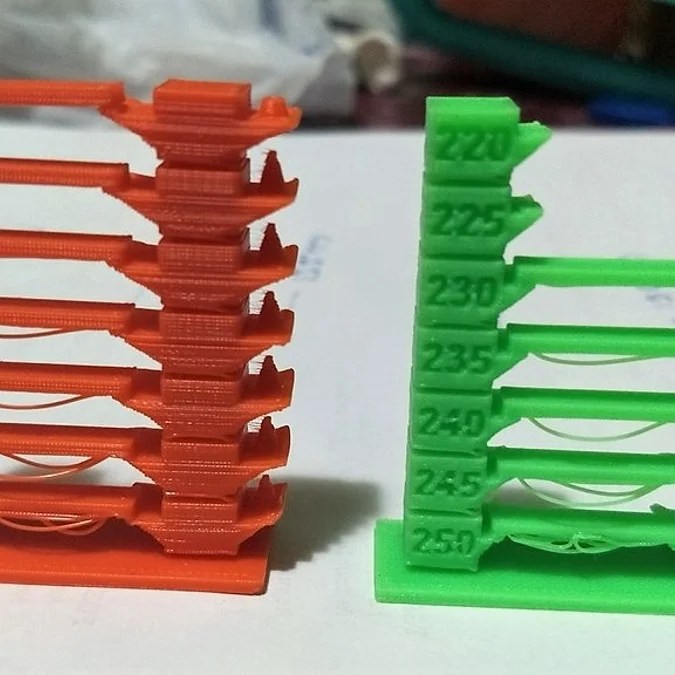

STEP 4: SAND WITH MEDIUM GRIT SANDPAPER (DRY)

Supplies used: Electric sander and 120 & 240 grit sandpaper

A: Sand with 120 grit sandpaper (dry)

B: Sand with 240 grit sandpaper (dry)

C: If you notice large imperfections that you have missed, return to a lower sanding grit to refine those areas

As you move up through various finer grits, sanding should require less time. You will also notice that the model’s texture becomes more refined and much smoother.

You will also notice that the model’s texture becomes more refined and much smoother.

Supplies used: 1000 grit sandpaper, plastic bin and water

When your model’s surface is even and refined it is time to wet sand the model using fine grit sandpaper. This process will not remove much material, but will do the most to polish its surface.

A: Submerge the model in a tub filled half way with water

Take care around fine features, round surfaces, and other small or difficult to reach places.

B. Using 1000 grit sandpaper, sand the model until it is completely smooth to the touch

C. Dry the model and inspect for a uniform surface finish

If you have properly sanded your model, its surface should now be even, blemish free, and glass-like to the touch.

Here you can see the difference between the unfinished surface and final sanded part.

Visit one of our other applications pages for tips on how to take your print even further.

We recommend that you visit our pages on:

Gluing

Painting

Silicone Molding

Last but not least, remember to share your work with us on Thingiverse and social media @MakerBot.

We can’t wait to see what you make!

Hair Dryer Shell

Ferro

10/2/2015

https://grabcad.com/library/hair-dryer-shell-1

Powered by MakerBot Learning.

Ultimate Guide to Finishing 3D Printed Parts

Time to read: 13 min

The purpose of this article is to detail the different finishing methods for FDM and PolyJet 3D printed parts and the techniques/tips that can elevate the look and feel of your prototypes.

A simple Apple Watch stand design will be utilized as a case study. This stand is a model with pockets and internal and external features that needs to be surface finished to a standard that complements the shiny exterior of an Apple Watch put on it.

Here’s a quick overview of the main points this article covers:

- PLA: If you’re working with a tight budget then PLA is going to be your best material choice; the results aren’t as polished but the price is cheapest.

- ABS: If your budget is moderate then go with ABS. It’s not as cheap as PLA but still at a low price point and the material is more reliable than PLA.

- VeroBlack or VeroWhite: For the highest quality parts go with VeroBlack/VeroWhite. This will give you the best dimensional accuracy and best overall polished look.

The 3d printing post-processing needed for the watch stand parts involves a combination of repairing and preparing the print for post-processing, sanding, and painting.

The finished sample 3D printed parts with all three materials should be smooth, matte black surfaces. Inherent to the 3D printing process, with every print are unique challenges and considerations to arrive at the best finish possible. Although there are ways to mitigate the challenges, experience in 3D printing goes a long way.

The print settings process for each material is detailed separately and a summation of the results may be found in the conclusion of this article.

ABS (Printed on a Dimension Elite)

The Dimension Elite prints are smooth, clean, and ready to sand out of the NaOH bath.

There are, however, clear stepping lines between the printed layers. If we don’t remove these stepping lines, they’ll show up in the final paint coat which will ruin our smooth finish. Thankfully, removing these will be easy thanks to ABS’s high melting point and easy sandability.

Materials Needed

The materials we’ll be using:

- Sandpaper (grits 100 to 600)

- Medium, fine, and extra-fine sanding sponges

- XTC-3D brush-on coating (As an alternative, Bondo putty is a common solution to fill holes in parts. We chose XTC-3D for its viscosity, sandability, and ability to penetrate small perforations, which makes it desirable over Bondo putty)

- Razor blade

- Foam brush, mixing cups and popsicle sticks

- Sandable Krylon Primer

- Montana Acrylic Primer in Shock Black

- Matte Acrylic Varnish

Sanding

Sanding the ABS print is simple and straightforward. First start with 100 – 200 grit sandpaper to remove stepping lines and then gradually increase up to 600 grit to achieve a smooth finish without sanding lines.

First start with 100 – 200 grit sandpaper to remove stepping lines and then gradually increase up to 600 grit to achieve a smooth finish without sanding lines.

Pro Tip: Sand in small circular movements evenly across the surface of the part. Avoid sanding in one direction only, especially in the direction of the stepping lines to prevent striations or “trenches” in the print.

Beware that ABS is very easy to sand, so be careful not to overdo it. Removing as little as .010” can be enough to completely remove any stepping layers and oversanding can compromise critical dimensions.

After sanding the parts, some holes are revealed on our part left by an incomplete layer around the letters DIM. These holes can perforate through the finished paint coat to create ugly sinkholes, so we need to find a solution.

As you can see in the Catalyst tray to the right, there are large holes between the DIM and the edge of the part. Moving the DIM up in our Solidworks model would solve this, but for now we’ll have to find a way to fill these holes with a sandable filler.

We’re going to use a thin, sandable epoxy called XTC-3D to fill the tiny holes and crevices in our print. XTC-3D is cheap (a 24 oz bottle costs about $25), quick, thin, and effective. Note that a small amount goes a long way (within the 10 minute pot life).

Pro Tip: Be sure to maintain a weight ratio of 100 Part A to 42 Part B. Mix thoroughly for one minute and coat your part within the 10 minute pot life. For more details, check Smooth-On’s technical bulletin here, and a great instructional example here.

Before applying the XTC-3D, wash the part with soap and dry with compressed air to ensure your part is thoroughly clean and free of any oils or sanding dust. Also make sure to wear gloves so as not to get any hand oils or sweat on your part.

Fill in holes or gaps in your print with a very thin (1/64”) coat; a thin layer of XTC-3D will level itself out. We used a razor blade to scrape excess XTC-3D into the unwanted holes and gaps, making sure to avoid any areas we didn’t want filled (like the letters DIM).

Allow the XTC-3D sufficient time to become tack-free dry (approximately 2 hours). Now we’re ready to continue sanding away at the excess XTC-3D layer with 300 to 600 grit to reveal the repaired surface.

Then, after another thorough wash, we’re ready to begin preparing our repaired surfaces for painting.

Priming and Painting

Painting 3D printed parts is a vast world of acrylics, enamels, sprays, and airbrushes.

In this example, we’ll be using Montana spray can paints to follow a relatively straight forward process: prime, dry, paint, dry, varnish, dry.

Standard spray painting principles apply:

- First make sure your surface is oil-free, dust-free and hole-free

- Shake your cans for at least two minutes prior to painting

- Ensure your cap is clean to prevent drips

- Be aware of how the paint is accumulating on the part and look for any pooling or dripping

- Paint in many light coats rather than fewer heavy coats; this is especially important for 3D printed parts with internal and obscured geometries

- Paint in controlled, well-ventilated and well-lit areas

The Dimension prints started with very obvious stepping between layers. If you’ve sanded properly up until now to create as smooth a surface as possible, these layers shouldn’t show up in your final paint finish.

If you’ve sanded properly up until now to create as smooth a surface as possible, these layers shouldn’t show up in your final paint finish.

The finished ABS part is matte black and smooth to the touch with very little evidence of layering in most surfaces. A few important results to note here:

- Sharp internal pockets are tough to sand. After about 30 minutes of sanding, we still had a hard time removing all the layering and the stepping shows up even after priming, painting, and varnishing the print.

- Because we had to remove more surfaces from the sanding, there is some sacrifice in regards to the final geometry of the part.

- Filling the incomplete layer with a thin coat of XTC-3D worked very well; those holes are invisible in the final paint layer.

VeroBlack (Printed on an Objet30)

Thanks to .0011” resolution, the Objet30 prints have some stepping between layers, but nowhere near as obvious as in our FDM prints.

The Objet30 prints come out of the printer with a thick layer of support structure material so before we can begin finishing our VeroBlack part, we’ll need to remove this support structure and the residue it leaves behind.

VeroBlack 3D Printed Part Materials NeededThe materials needed for post-3D printing finishing:

- Sandpaper (grits 100 to 600)

- Medium, fine, and Extra fine Sanding Sponges

- Sandable Krylon Primer

- Montana Acrylic Primer in Shock Black

- Matte Acrylic Varnish

Start with 100 grit sandpaper to wet sand the residue and gradually move to wet sand with 300 grit sandpaper; the residue will fall off in small soft white chunks. This is the hardest part of the VeroBlack finishing process and it took us about 30 to 40 minutes to remove all the residual layer.

After removing the residual layer by wet sanding utilizing 300 grit sandpaper, the surface of the part will begin to feel smooth. If you rub the part with your fingernail, you’ll feel it’s harder and more plastic-like beneath the gummy residual coat. Continue wet sanding through to 600 fine grit sandpaper until the part is fully smooth.

If you rub the part with your fingernail, you’ll feel it’s harder and more plastic-like beneath the gummy residual coat. Continue wet sanding through to 600 fine grit sandpaper until the part is fully smooth.

Pro Tip: Water breaks up the residue, so wet sanding is a highly effective method to get a smooth, residue-free, paintable, and homogenous surface.

Thoroughly clean your part with soap and water before you move on to the next step to remove any additional residue. Again, we recommend using compressed air to dry the part and clear any accumulated dust.

Beware that VeroBlack is like ABS: very easy to sand, so be careful not to overdo it. Once you break through the residual layer, the actual VeroBlack will sand very easily. Removing as little as .005” can be enough to completely remove any stepping layers. Be careful as oversanding can compromise critical dimensions.

VeroBlack 3D Printed Part Priming and PaintingNext, we’re going to paint the VeroBlack part just as we did the ABS part: using Montana spray can paint with the following process: prime, dry, paint, dry, varnish, dry.

Standard spray-painting principles apply:

- First make sure you have a good surface quality which is oil-free, dust-free and hole-free

- Shake each paint can for at least two minutes prior to painting

- Ensure your cap is clean to prevent drips

- Be aware of how the paint is accumulating on the part and look for any pooling or dripping

- Paint in many light coats rather than fewer heavy coats; this is especially important for 3D printed parts with internal and obscured geometries

- Only paint in controlled, well-ventilated, and well-lit areas

The finished VeroBlack part is matte black and smooth to the touch. A couple points to note here:

- Some of the internal corners were not sanded enough to remove the residue, so you can see how the paint powdered up in these areas.

This will likely result in peeling paint over time.

This will likely result in peeling paint over time. - Although very little stepping is visible on the part, you can see slight evidence of it here. This part could have probably used 30 more minutes of thorough sanding.

Now for the dreaded PLA, a notoriously difficult material to finish. But with some tricks and patience, it too can join ABS and VeroBlack in the ranks of matte black glory!

This Replicator print came off the plate with severe striations: see the parallel grooves in the layers of the part above. This could be a result of machine quality, but for now we’ll just have to find a way to maneuver these striations to a smooth part.

Sanding PLA is difficult, in part because of how soft and gummy it becomes if you try to sand too aggressively or quickly, so we’ll explore options on how to smooth 3d prints with minimal effort and abrasion.

PLA 3D Printed Part SandingIf you choose to sand the PLA directly, the process is straightforward. Note: PLA acetone smoothing is not advisable. PLA smoothing is not as forgiving as ABS when it comes to sanding and abrasion, so you will likely spend more time removing the stepping between layers, especially with the severe striations in a print like ours.

Note: PLA acetone smoothing is not advisable. PLA smoothing is not as forgiving as ABS when it comes to sanding and abrasion, so you will likely spend more time removing the stepping between layers, especially with the severe striations in a print like ours.

Begin with a low (100 – 200) grit sandpaper, sanding away at the bumpy striations and any raft or support material (aluminum foil) left behind. Particularly in the case of MakerBot support, it’s easiest to remove them with a flush cutter or pair of pliers and brush them with a rotary multi-tool first before sanding away at them.

Depending on the size and geometry of your part, you’ll likely be stuck in the 100 – 300 grit sandpaper range for a while to smooth out striations and pesky support structure remnants.

Once layering and striations are less prevalent, move through finer grits (400 – 600) sandpaper to achieve a shiny surface ready for priming and painting.

Pro Tip: Patience is key when sanding PLA. Turn on a movie or your favorite show, but don’t zone out! Sand in small circles evenly across the surface of the part. If you’re using a sanding multi tool on PLA, be careful not to overheat/melt your 3D printed part.

Turn on a movie or your favorite show, but don’t zone out! Sand in small circles evenly across the surface of the part. If you’re using a sanding multi tool on PLA, be careful not to overheat/melt your 3D printed part.

An alternative method to sanding PLA prints directly is smoothing the PLA print with the XTC-3D first and then sand on top of the coating.

PLA 3D Printed Part FinishingWe’re going to use XTC-3D to create a smooth, sandable, paintable layer of epoxy clear coat glossy finish around our PLA print.

Before applying XTC-3D, ensure that your part is thoroughly clean, free of any oils and sanding dust (sensing a pattern yet?). Wash the part with soap and dry with compressed air to clear any dust. Again make sure to wear gloves to protect both your part and your hands.

Brush on the XTC-3D in a thin (1/64”) coat; as long as the coat is thin enough, it will level itself out. Between coats, leave 1.5 hours for the XTC-3D to dry.

It may be difficult to coat an entire part at once, so don’t be afraid to do it in sections, making sure to keep overlapping to a minimum between sections. Wait 90 minutes between first and second coats and after you’ve finished wait 2 hours to allow the shiny surface to become tack-free.

Wait 90 minutes between first and second coats and after you’ve finished wait 2 hours to allow the shiny surface to become tack-free.

With striations as severe as ours, it will take multiple coats to get a smooth uniform surface, so patience is key. Remember that multiple thin glossy finish coats will level better than thick coats.

Pro Tip: Internal pockets are susceptible to pooling so be careful to suck up or remove any pooling that occurs before the XTC-3D begins to dry (that’s what we’re doing in the left picture above).

Beware that XTC-3D may compromise critical dimensions, but applying thin glossy finish coats will allow you to minimize the additional material.

After the XTC-3D layer has hardened (two hours after application of the last coat) it should be ready for sanding. Follow basic sanding guidelines, starting with 300 grit sandpaper (thanks to the smoothness of the XTC-3D) and sanding in small circular movements to even the surface. Any wavy patterns may require a coarser grit sandpaper to remove.

The sandpaper will scratch up the XTC-3D coat; focus on getting a level surface, moving through to 600 grit sandpaper.

After you’ve finished sanding 3D prints, make sure to thoroughly clean your part with soap and water and then dry using compressed air before moving on to the next step.

PLA 3D Printed Part Priming and PaintingPainting PLA parts follows the same process as the ABS and VeroBlack parts: prime, dry, paint, dry, varnish, dry.

Standard spray painting principles apply:

- Make sure your surface is oil-free, dust-free and hole-free

- Shake your cans for at least two minutes prior to painting

- Ensure your cap is clean to prevent drips

- Be aware of how the paint is accumulating on the part and look for any pooling or dripping

- Paint in many light coats rather than fewer heavy coats; this is especially important for 3D printed parts with internal and obscured geometries

- Paint in controlled, well-ventilated and well-lit areas

The XTC-3D coated PLA part is matte, black, and has a smooth surface to the touch with a few problems:

- Although the XTC-3D has worked well to smooth the part and make sanding quicker and easier, it has left pooling in the internal pocket that has shown through the paint finish.

- Striations are still visible on the part. 30 more minutes of sanding 3D prints could have prevented these from showing through the final paint finish.

After finishing all three parts to a smooth, matte black finish, let’s take a look at the differences in process, time, materials and finish.

Differences in ProcessABS (Dimension Elite)- Sand from 100 to 600 grit

- Repair holes with XTC-3D (may not apply to your part)

- Sand away XTC-3D with 300 to 600 grit

- Prime, Paint, Varnish

- Sand from 100 to 600 grit

- Prime, Paint, Varnish

- Coat in 1 to 3 layers of XTC-3D (depending on how bad the striations on your print are)

- Sand away XTC-3D with 100 to 600 grit

- Prime, Paint, Varnish

The part that took the longest to finish was PLA due to the XTC-3D coating time. Even without XTC-3D, however, PLA typically takes longer to sand than ABS or VeroBlack.

Even without XTC-3D, however, PLA typically takes longer to sand than ABS or VeroBlack.

In our example, the VeroBlack was ultimately faster to finish since we repaired our ABS print with XTC-3D and stepping between layers was not as significant in the VeroBlack print.

All things considered, VeroBlack was the quickest to get to a smooth, matte black finish.

Pro Tip: If you’re in a rush to get from printer to photoshoot, pick the Dimension Elite or Objet30. Especially in models with overhangs and significant amounts of support material, the Dimension Elite and Objet30 both have support material that is quickly removable via dissolution, whereas the PLA support on a Replicator can significantly increase the time required to get to a smooth surface part.

Differences in Cost and MaterialsIt’s important to consider the amount of time it will take to finish your model as well as the overall look and dimension when considering the price.

PLA is the cheapest out of the three, at $20 per part, followed by ABS at $55, and VeroBlack at $110. In our opinion, VeroBlack is the best bang for your buck since it’s the shortest to surface finish and will give you the most accurate model.

In our opinion, VeroBlack is the best bang for your buck since it’s the shortest to surface finish and will give you the most accurate model.

At first glance, all three models may look very similar, but there are a few key differences in the final finish.

Both the ABS and the PLA finished prints have evidence of stepping between layers that is visible in the final paint coat. The VeroBlack print requires much less effort to remove these steps, which ultimately are not as obvious in the final paint coat.

Although the ABS and the VeroBlack finished prints have very similar surface finishes, more material (approximately .020”) was lost in the sanding process for the ABS to remove stepping between layers. In contrast, the VeroBlack print required less sanding, so the final object dimensions are closer to the original design intent.

Individual Summary of Each PartVeroBlack: High layer resolution (. 0011”) means little sanding is required to get a smooth, paintable part. Critical dimensions don’t need to be compromised to get a smooth surface quality part and no repairs are needed for fine detailed features.

0011”) means little sanding is required to get a smooth, paintable part. Critical dimensions don’t need to be compromised to get a smooth surface quality part and no repairs are needed for fine detailed features.

ABS: Parts are easy to sand, but small fine detailed features may require repairing and careful sanding to remove stepping between layers. Once this stepping is removed, painting is straightforward.

PLA: The cheapest option, but also has the potential to be the most difficult to finish, depending on support structures and quality of the print. May require significant sanding and repairing via XTC-3D or Bondo filler.

Browse our website to learn more about our capabilities, such as 3D Printing and CNC Machining.

Quick Facts:

- Finishing a 3D printed part often involves a combination of the following processes: smoother application, sanding, polishing, cleaning and painting. The process is unique to the material type.

- A smooth finish with 3D printing is achievable but, post-processing will greatly improve the smoothness of parts.

- Epoxy resins are an excellent choice for sealing PLA printed parts.

- Acetone smoothing is not recommended for PLA prints.

- In general, IPA or rubbing alcohol will not dissolve PLA but there are some varieties that may be IPA soluble. Consult your filament material datasheet or technical datasheet for more information.

- PLA may be smoothed without sanding by dipping it or spraying it with a coating.

- ABS is tougher and lighter than PLA which is stronger and stiffer. Both have their ideal applications, but PLA is typically considered a hobby material whereas ABS is ideal for prototyping.

Our hands are not for boredom, but Ceramo is for pens

In this simple master class, I will tell you how to print with our new material - Ceramo, how wonderful it is processed with sandpaper, and what happens as a result.

Sokolniki recently hosted the 3D-Expo 2016 exhibition, in which we had the honor to participate. Our booth, among other printouts, was decorated with a pen, the case for which was printed on a conventional FDM printer. Some visitors refused to believe that this pen was printed - the surface looked so perfectly even after sanding. Today I will tell you how it was done.

We will need:

- 3d printer (failsafe MZ3D-360 helped me)

- pen model (STL can be purchased cheaply here)

- Repetier-Host and Slic3r programs

9004 - 9004 -0 Ceramo plastic waterproof sandpaper with a grain size of 160-200 microns for initial processing and 300-500 microns for finishing- water

First you need to sand the model, taking into account some of the nuances of the material. It is better to place all the elements of the pen on the printing table at once. The material will be less likely to "float", because. handle diameter is small.

Flow should be reduced to 92-95%. Speed is also not worth picking up much, for the above reasons. Otherwise, in the future you will have to devote more time to the sanding process :)

Speed is also not worth picking up much, for the above reasons. Otherwise, in the future you will have to devote more time to the sanding process :)

Airflow is necessary on this model. However, the print settings of other models from #Ceramo need to be approached individually - the higher the speed and the smaller the perimeter, the stronger the airflow, and vice versa. On parts with a large area, you can (and even need to!) Do without airflow to reduce the likelihood of shrinkage or cracking.

Printing temperature for Ceramo approx. Here are some more screenshots to understand the settings:

Of course, the number of perimeters can be any, but at least two to get a more or less even surface. Pay attention to the unchecked checkbox in the "Detect Thin walls" option - it's better to turn it off.

Completed 100%. The model is small, the plastic will take a little - you can afford it. But in the hand when using the pen, a pleasant heaviness will be felt :)

The speeds are low, but even that turned out to be too much for such a perimeter, and in the end I reduced the print speed from 100% to 85%. In general, the pen is printed 2.5-3 hours.

In general, the pen is printed 2.5-3 hours.

This is an important screenshot. Many people set the values in the Advanced tab as a percentage, but you can get a much more predictable print result by specifying the nozzle diameter (extrusion width) programmatically (in this case, with a 0.4mm nozzle, the extrusion width was indicated as for a 0.5mm nozzle). Sometimes you can cheat a slicer for your own mercenary purposes :)

In addition, due to the fluidity of the material, I used the “XY Size Compensation” option, which ensures that the plastic does not fill the internal holes much during thermal expansion.

But the hole for the tip of the rod still had to be drilled)) The first rod that came to hand was taken and it turned out to be a bit too big.

I already wrote about this moment - the feed should be reduced due to the thermal expansion of the plastic. For each printer, this value may be different, depending on the model of the extruder.

So, the settings are set, the model is calculated, you can start printing! We start the printer and go about our business. To ensure that the brittle rod does not break, it is recommended to use a flexible tube from the spool to the extruder.

When the pen is finished printing, wait for the platform to cool down, and the printout will snap off the table with a slight crackle. Comfortable! And the brim (if there is one) easily breaks off with your fingers.

First glue the cone screw into the back. I used cyanoacrylate, deciding to avoid solvent bonding. Otherwise, it will corrode the plastic from the inside, and the model may be damaged.

After waiting for the glued parts to seize, we assemble the handle. The thread must be “lapped in” by applying a small amount of force when screwing in for the first time. Or just go over the outer spiral with sandpaper to clean off excess plastic. The handle is assembled, you can proceed to machining.

We have to sand the printing flaws and bring the pen to the ideal. Fortunately, the case is modeled in such a way that the sandpaper will get to any place in the printout. We take sandpaper for initial processing (with a grain of 160-180 microns) and blow into the bathroom. It is better to skin next to a stream of water, periodically rinsing the sandpaper. Water does not allow the plastic to warm up during friction and clog the sandpaper with dust. And there will be less fine dust in the air, which Ceramo plastic gives during mechanical processing.

After obtaining a smooth surface without layers and seams, we move on to finer sandpaper (with a grain of 300-500 microns) and bring the body to the ideal. To understand whether the work is finished or not, it is sometimes necessary to wipe the body of the pen with a dry towel and see if printing flaws appear. Under water, they are not as noticeable as on a dry surface.

Tip: In pursuit of perfection, do not rub sandpaper through the outer perimeter of the printout! Correcting this oversight will then be very difficult.

For the final assembly of the handle, I printed a small spacer from a rubbery transparent blue material. She allowed to twist both halves of the case more tightly, and brought a pleasant zest.

And now the pen is almost ready! Beauty)) It remains only to insert the rod and you can use it. It turned out to be a beautiful and useful gift for friends, acquaintances and business partners. Well, for myself, my beloved :))

I express my gratitude to the creator of the whd3 handle body model You can buy a model from the author for a symbolic amount at the link: http://3dtoday.ru/market/for-office/accessories/ruchka_ceramo/

We wish you all creative success with Filamentarno plastics!

Best regards, Filamentarno team! www.filamentarno.ru

Beginner's Guide to Smoothing 3D Models

3DPrintStory 3D printing process Anti-Aliasing PLA: A Beginner's Guide to Anti-Aliasing 3D Models

Sooner or later, all 3D printer owners think about smoothing the surface of 3D printed models. In this article, we will look at how to achieve a smooth surface of the printed model if you are using PLA plastic for 3D printing.

In this article, we will look at how to achieve a smooth surface of the printed model if you are using PLA plastic for 3D printing.

Sanding the printed model

Almost any model will require sanding to smooth it out. It is best to use sandpaper with different levels of grit. You can start with a grit of 200, and continue to increase the grit up to 4000. It is best to sand in a circular motion against the fibers of the layer lines.

Resist the urge to use a power tool because the strong vibrations generated by power tools will easily melt plastic, deforming the surface. Even when sanding by hand, remember that friction generates heat that can damage the 3D model by melting the plastic.

The best sandpaper is waterproof or wet/dry because you can wet it to cool the plastic. You should also constantly rinse the 3D model to remove any particles that form during the sanding process. An added benefit is that the water prevents small plastic particles from getting into the air and being inhaled. Wet/dry sandpaper can be distinguished by color. Its grains are black, not brown or beige.

Wet/dry sandpaper can be distinguished by color. Its grains are black, not brown or beige.

Polishing options with pastes and special coatings

With PLA smoothing, sanding will never completely eliminate layer lines. One effective method is to apply polishing paste to the remaining lines of the layer. Polishing pastes have varying degrees of quality, following the example of sandpaper. These compounds are usually designed for use with metals, but work quite well with plastics. Simply apply the compound to a sanding wheel or similar rotary tool attachment, then apply it to the plastic for a smooth and shiny finish. As with sanding, remember that polishing creates friction and therefore heat. When smoothing PLA with a grinding wheel, it is better to use a lower speed.

Another method for smoothing PLA is to use a sandable primer with a high filler content. Thin, even coats dry quickly, after which the primer can be sanded down to plastic so that it remains only in the recesses of the layer lines. Repeat the process until all 3D printing flaws are gone.

Repeat the process until all 3D printing flaws are gone.

For both procedures, always use primer and paint from the same manufacturer and never mix acrylic and enamel. This can crack the paint and put an end to all the hard work you've done before.

Another product worth mentioning is Smooth-On's XTC3D Finish Coat. It uses two liquids, one of which catalyzes the other, to create a resin-like material that can be brushed onto a 3D model. The coating is evenly leveled, leaving no brush strokes. Although Smooth-On claims that XTC3D does not melt plastic, the resin definitely gets hot as the mixture begins to set. The end result is a smooth and hard appearance that can be painted over or used as a final coat.

Heat gun

A less popular option for smoothing PLA plastic is to use a heat gun. This method requires some practice because the tool obviously generates a lot of heat which can destroy your 3D model. Pre-sanding the model helps to expose the plastic, making the final effect much more effective. The key is to keep the gun moving across the surface of the model, never letting the gun linger on one area that could easily melt the plastic.

The key is to keep the gun moving across the surface of the model, never letting the gun linger on one area that could easily melt the plastic.

Although PLA does not generally emit odors when extruded, heat will certainly produce fumes as the plastic softens. Regardless of which PLA flattening method you choose, always try to work in a well-ventilated area because heated plastic, resins, and spray paint release potentially harmful fumes.

Using Polymaker's Polisher

A well-known method to get smooth 3D models out of ABS is to place the model in a sealed container filled with acetone mist. The acetone interacts with the ABS and slowly melts the plastic, creating a super smooth model. Note : be sure to read the necessary precautions if you decide to try this method.

Unfortunately, you cannot perform the same procedure with PLA because it does not react in the same way with acetone. Some other chemicals will do the same but are difficult to obtain and very dangerous and toxic to use.

Polymaker, best known for its 3D printing materials, has introduced its own anti-aliasing agent called Polysher. Using a proprietary PLA-like filament formula, the 3D model is lowered into a sealed chamber where isopropyl alcohol is sprayed, creating a mist around the object to be smoothed out. The 3D model rotates in an alcohol mist that reacts with the plastic and melts it. The longer the process, the smoother the model will be. When you take the 3D model out of Polysher, its surface will be sticky, so it's best to leave it for about half an hour. It also improves the final look, which may not be as smooth as you would expect.

As with the other procedures described here, a little sanding helps the process but is not necessary. Tip : Expose the 3D model to shorter Polysher sessions and flip the model between sessions. Surprisingly, this method also produces near-transparent models when used with Polymaker's transparent PolySmooth material.

Findings

Creating smooth surfaces on 3D models will require some work.