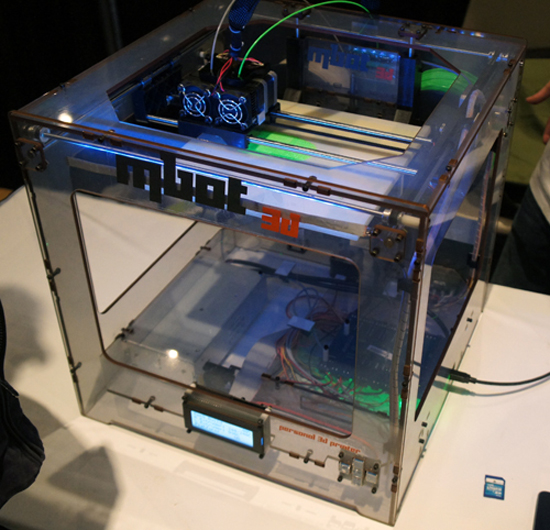

3D printer for prototyping

What is Rapid Prototyping with 3D Printing?

What is Rapid Prototyping with 3D Printing? - Stratasys Stratasys Invests in Axial3D to Make Patient-Specific 3D Solutions Available to All - Learn MoreUSA & Canada

Select your country and region

- Americas

- English

- Español (México)

- Português (Brasil)

- EMEA

- English (United Kingdom)

- Deutsch

- Español

- Français

- italiano

- APAC

- 中文(简体)

- 日本語 (日本)

- 한국어(대한민국)

- English (India)

USA & Canada

What is Rapid Prototyping?

Rapid prototyping with 3D printing is the quick, easy, cost effective way to turn great ideas into successful products. Do you need concept modeling to put your newest ideas to the test? What about functional prototyping to gauge performance before committing to costly production tooling? Rapid prototyping solutions from Stratasys will give you the flexibility to create, test and refine in ways you never thought possible so you can go to market faster than ever before.

See how 3D printed rapid prototypes are changing the way the world does business

"Every time we avoid cutting a tool, we save 8 to 12 weeks."

Randy Larson, Polaris Industries

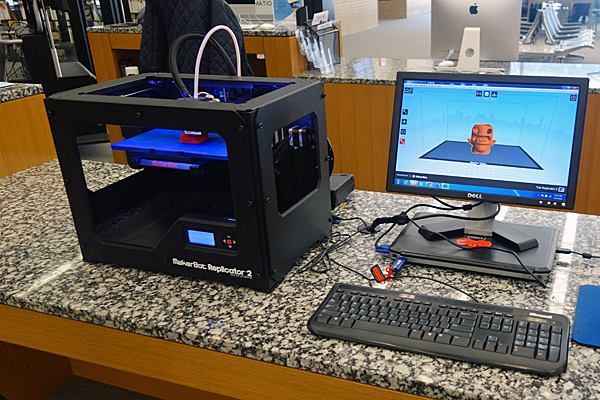

3D Printers for Rapid Prototyping

Go from idea to manufacturing ready prototype in a matter of hours

with Stratasys 3D printers

Get A Quote

Prototype Faster and more Effectively with Reliable 3D Printing Technology

Stratasys 3D Printers dramatically tighten design and development cycles, improve communication and collaboration, and resolve issues between design and engineering. They speed products to market and reduce costly mistakes — all while keeping your intellectual property onsite. Very soon, you’ll wonder,

They speed products to market and reduce costly mistakes — all while keeping your intellectual property onsite. Very soon, you’ll wonder,

- Metal Prototyping 3D Printers

Metal Prototyping 3D Printers

Prototype Faster and more Effectively with Reliable 3D Printing Technology

Desktop Metal® Shop System™

A metal binder-jetting 3D printer designed for machine shopsAs the first binder jetting system designed for machine shops, Shop SystemTM lets your shop take advantage of affordable, high-quality binder jetting technology. It prints end-use metal parts with unrivaled speed, print quality and productivity. A complete, end-to-end solution, the Shop SystemTM includes a printer, powder station and furnace, and easily integrates with your existing shop operations.

View Item

X Series – InnoventX

Compact binder jet 3D printer for the production of metal, ceramic, or composite parts

The Desktop Metal InnoventX is engineered to 3D print high-density near-net-shape parts in a wide range of standard MIM powders, metal alloys, ceramics, or technical composites. Powered by Triple ACT Powder Compaction and a piezoelectric print head system, the InnoventX produces parts with tight tolerances, excellent surface quality, and the part density needed for functional applications. Discover how binder jetting can enhance education, research, prototyping, rapid product development, and the short-run production of small components.

Powered by Triple ACT Powder Compaction and a piezoelectric print head system, the InnoventX produces parts with tight tolerances, excellent surface quality, and the part density needed for functional applications. Discover how binder jetting can enhance education, research, prototyping, rapid product development, and the short-run production of small components.

View Item

FIGUR G15 | Desktop Metal

Low-mid volume metal sheet forming on-demandFigur G15 is the first commercial platform to directly shape standard sheet metal on demand from a digital design file using all-new, patent-pending Digital Sheet Forming (DSF) technology. This translates into no stamping tools, molds, dies, or presses that traditional sheet metal fabrication requires.

View Item

Desktop Metal® Fiber™

High-Resolution Parts with Industrial-Grade Composites from a Fast, Affordable Desktop 3D PrinterFiberTM is the world’s first desktop 3D printer that lets users build high-resolution parts with the industrial-grade continuous fiber composite materials used in automated fiber placement (AFP) processes. Users can print parts of exceptional strength and stiffness (twice the strength of steel at 20% of the weight), in a broad range of materials that previously required million-dollar AFP systems. All from their desktop.

Users can print parts of exceptional strength and stiffness (twice the strength of steel at 20% of the weight), in a broad range of materials that previously required million-dollar AFP systems. All from their desktop.

View Item

Give us a call and speak to an expert.

Contact Us

Sign Up to Receive Our Latest News & Hottest Promotions

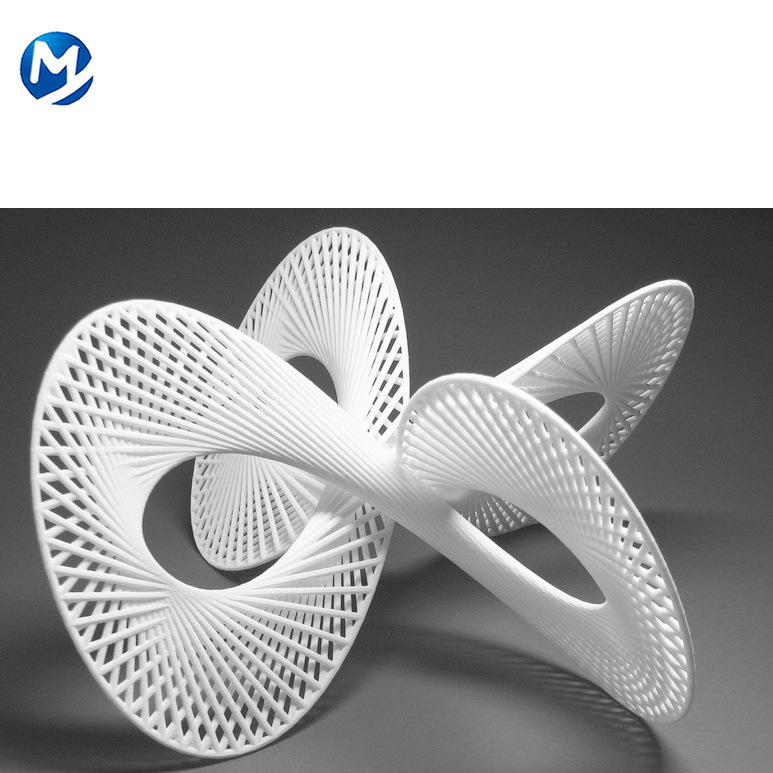

What is 3D prototyping - creating models on 3D printers

When buying a 3D printer DISCOUNT for plastic and polymers up to 10%

What is 3D prototyping?

21.02.2018 powernic

What is 3D prototyping?

More recently, 3D printing and 3D technology in general were beyond fantasy. It never occurred to anyone that 3D printing would be used on an industrial scale, and even ordinary people could afford such small devices for household needs and hobbies. But today additive technologies are actively used even by children, drawing with a 3D pen or working with a 3D printer in a circle or at school. But a completely natural and not understandable question arises, what is 3D prototyping? And the answer to it is not so difficult.

But a completely natural and not understandable question arises, what is 3D prototyping? And the answer to it is not so difficult.

3D prototyping is the process of creating a three-dimensional prototype of an object. Initially, it was carried out by removing excess material from the workpiece. These are methods of milling, forging, turning, etc. But in the 80s, scientists developed a different approach, which became a real breakthrough. It consisted in the layered formation of the object. It is this technology that formed the basis of modern 3D printers.

How does it work?

How does 3D prototyping work? Initially, 3d prototyping involves modeling an object on a computer. In a special program, a model is created with parameters specified in three-dimensional space. This model is sent for printing to a special device - a 3D printer, where a prototype is formed in layers.

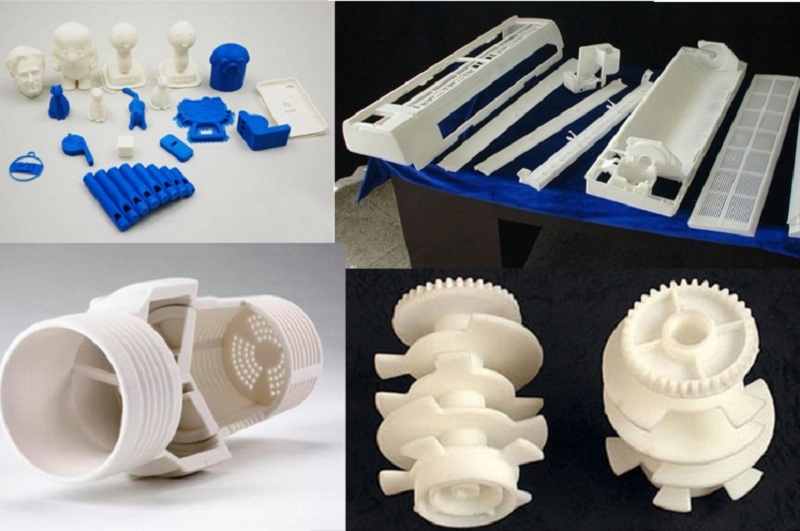

There are many 3D printing technologies:

- FDM is the easiest printing method;

- stereolithography;

- photopolymer printing and many others.

Depending on the technology, different prototyping materials are used: plastics, photopolymer resins, gypsum and even powdered metals. But the essence remains the same - the object is formed layer by layer in the camera of the device. In this case, the thickness of the layer will characterize the accuracy of 3d printing and, in many respects, its quality.

The use of 3D prototyping

3D prototyping has found a very wide application:

- creation of models in architecture and construction;

- printing of product samples and master models;

- manufacture of souvenirs, toys and costume jewelry;

- piece production;

- production of spare parts and much more.

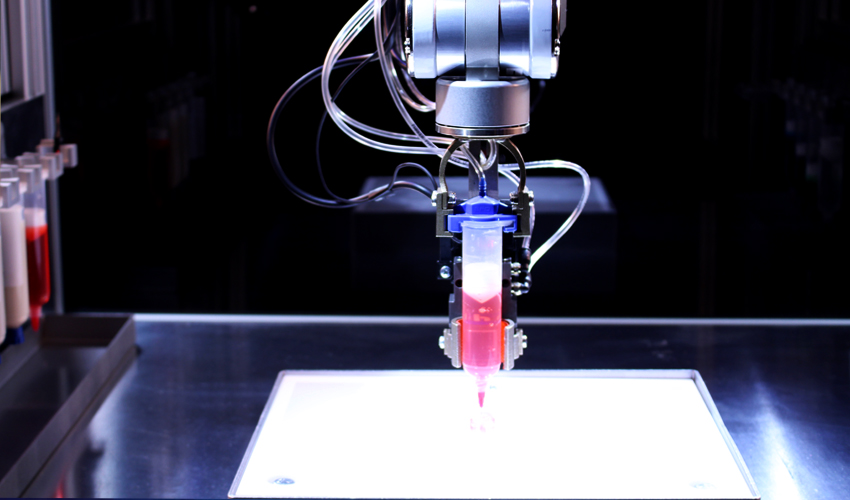

In medicine and dentistry, 3D printers are used to print surgical instruments, templates, prostheses, organ models, etc.

It is simply impossible to list all the areas and possibilities of using 3D printing. Even houses are now being built using 3D printers, unique cars are being produced, and additive manufacturing is conquering new heights. Very soon, human lives will be saved thanks to printed living organs, and even this is not the limit. Technologies are developing, equipment is being improved, and in the future they will surprise us more than once.

Very soon, human lives will be saved thanks to printed living organs, and even this is not the limit. Technologies are developing, equipment is being improved, and in the future they will surprise us more than once.

Recommended 3D Equipment

in the chosen

Compare

Fast View

In the basket

In the Favorite

Compare

Quick View

In the Favorites

Compare

Fast Viewing

In the corner of 9000 9000 in the corner of articles:

3D prototyping of models, parts - additive technologies from DDM.Lab

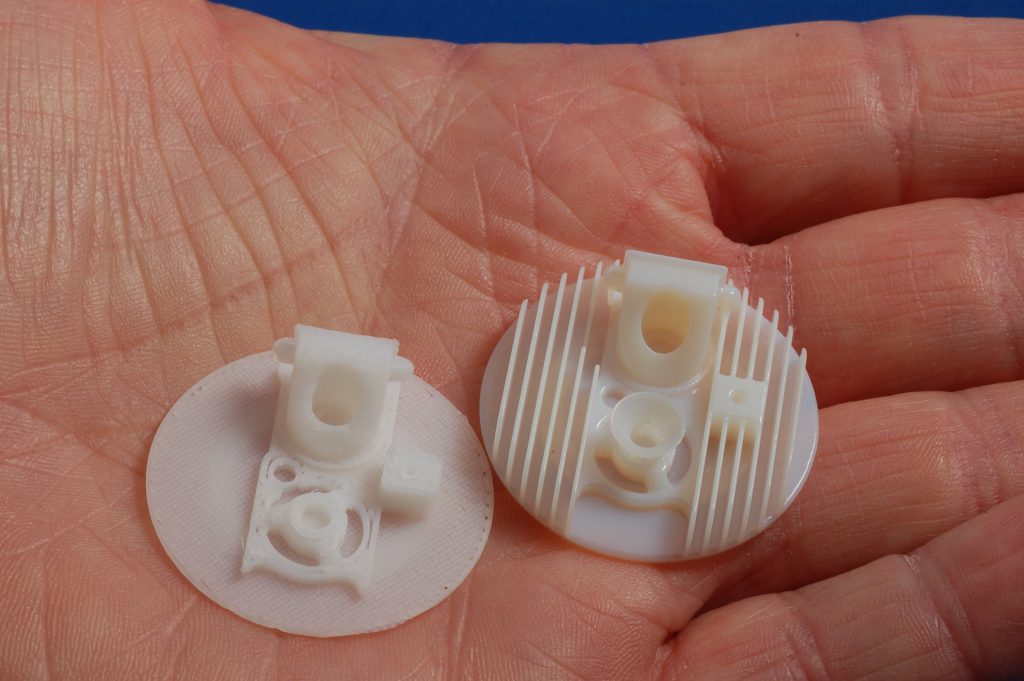

Modern technologies allow you to create a really worthwhile product without spending a lot of development resources. 3D prototyping is the ability to produce an object according to a drawing or mathematical model in full size or scale, without losing the main functions of the final product. When using metals, thermoplastics, polymer blends and composites, high quality and functionality can be achieved without resorting to classical production.

Prototyping 3D models eliminates the risk of inaccurate design and engineering calculations and, consequently, unnecessary costs.

3D printing a model from a simplified (non-final) material or mass production material is the optimal solution for product development. You will be able to test a sample, check its functional properties and assembly compliance, make a presentation, and correct shortcomings even before the start of mass production.

Work stepsPrototyping typesTechnologiesPrices for 3D prototyping

Work steps

3D prototyping allows you to quickly start production in several basic steps: Testing the finished product, adjusting the digital model if necessary

With a prototype, you can evaluate its appearance, ergonomics, and even experience its functionality. If the object meets the requirements of the company, it can be used as a master model or tooling for the first batch of goods - in DDM. Lab you can order the production of products by molding into silicone (from 10 to 1000 pieces) or single- or reusable production tooling.

Lab you can order the production of products by molding into silicone (from 10 to 1000 pieces) or single- or reusable production tooling.

Prototypes are most often ordered by large machine-building and instrument-making companies, developers of innovative products and designers interested in the speedy release of plastic and metal products. Leave a request, and our experts will select for you the best way to introduce additive technologies into production!

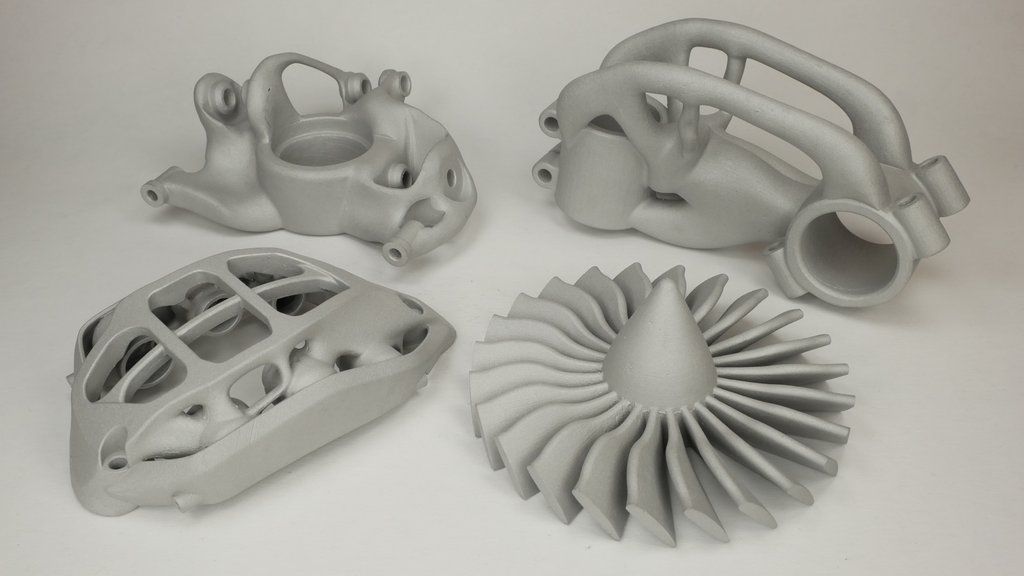

Types of prototypes

Conventionally, prototypes can be divided into several types:

- Industrial - created for large manufacturing enterprises (assemblies, housings, parts and spare parts)

- Transport - such prototypes are used in mechanical engineering, aviation, shipbuilding (from development to individual parts or components of land, water and air transport)

- Product prototypes allow you to work out the format of the future product and its packaging

- Presentation models, for example, a model of an apartment, a building or an entire city, make it possible to convey the project with its architectural features and interior design as clearly as possible for solving the problems of orthopedics, endoprosthesis, orthodontics.

Technologies

- FDM thermoplastic deposition modeling allows you to quickly and inexpensively produce fully functional samples of products and production tooling from a wide range of materials

- Inkjet printing with PolyJet photopolymers allows printing highly realistic color and multi-material products and tooling

- Selective laser fusion of LBM/SLM metals is often used for high-precision manufacturing of end products with complex geometry from metal-powder compositions of small fractions

- Gas-powder jet deposition using directed energy exposure DED/LMD is used for quick repair of worn surfaces of products, as well as for the manufacture of products from "scratch" from metal powder compositions

- 3DMP Arc Welding/Arc Welding - the most affordable and productive solution for the rapid production of high-stress end metal parts

- BJ inkjet printing by applying material powder and bonding it with a binder to create molds from sand-polymer compositions

- Selective SLS laser sintering for the rapid production of full-featured parts, production tooling from a wide range of polyamide and composite (polyamide-based) powders, and polystyrene powders for creating burnable master patterns for foundries

- SEAM screw extrusion hybrid additive manufacturing for rapid production of large-sized products using granular thermoplastics, including those filled with carbon fibers binder.

Learn more