3D printer counterfeit money

Illegal, Immoral, and Here to Stay: Counterfeiting and the 3D Printing Revolution

Skip Article Header. Skip to: Start of Article.

If you’re looking for a way to gauge how the 3D printing market will evolve, look no further than the dawn of two other revolutionizing technologies – the desktop printing market and the VHS standard. And be prepared for a decidedly off-color story.

While many of us have fond memories of watching a favorite movie when it first came out on VHS, or admiring the first three-color party invitation we printed on a laser printer, the fact remains that innocent pursuits were not the sole reason either of these technologies took off. And we shouldn’t expect 3D printing to be any different.

The reality is that in both cases, the illegal, illicit, and otherwise unwholesome played a major role in the growth of both the VHS and desktop printing markets. While it’s clear that most applications of these technologies were G-rated, there were plenty that weren’t. And when it comes to 3D printing, that unwholesome and downright illegal activity called counterfeiting is likely to become one of the major reasons why 3D printing will be a major growth industry in the coming years.

To be sure, as with all technologies, from the Paleolithic stone ax to 20th century nuclear fission, there are applications for good that hopefully outweigh the not-so-good. And 3D printing will have its fair share: from the manufacture of prosthetics and spare parts to on-demand organs, foods, and your child’s next toy, the 3D printing revolution will by and large have a positive impact on society as a whole.

But the threat of a major surge in counterfeiting based on the availability of relatively cheap 3D printers, increasingly sophisticated printing materials, and a never-ending supply of CAD designs available on the Internet will fuel an enormous black market in counterfeit parts. And the potential impact of 3D printers for counterfeiting just keeps on growing: A recent report by Gartner Group speculates that intellectual property loss due to 3D printer counterfeiting could total $100 billion by 2018.

What is it about 3D printing that will make it, in the words of Scientific American, “the counterfeiter’s best friend”? Just like the desktop printing industry of the 1980s, it’s that perfect storm of three important factors: the availability of a breakthrough device at a consumer price, the availability of the raw materials needed to copy something valuable, and the right software for turning the new technology into a counterfeiter’s “best friend.”

1985 was the year the perfect storm hit the desktop publishing market. The first widely available laser printer, the HP Laserjet, hit the market priced at the high end of the consumer market at about $3,000. This printer could handle pretty much any kind of paper, and print rapidly and accurately. At the same time, Aldus Pagemaker, the first widely available desktop publishing package, also hit the market, similarly priced at the high-end of the consumer market at under $700. Hello, forged credentials, certificates, permits, bills of lading, and eventually, money. Voila, another friend of the counterfeiter was born.

Voila, another friend of the counterfeiter was born.

The illicit side of the VHS market had a slightly different trajectory. In the mid-1970s, the Betamax video standard arrived, taking advantage of the ready availability of VCRs priced in the $1,200 range. In 1977, Sony’s Betamax was challenged by upstart JVC’s VHS standard, with a couple of twists. Twist number one was the VHS could record a full-length movie, while Betamax maxed out at an hour. Twist number two was that while Sony resisted licensing Betamax for use by the pornography industry, JVC had no such qualms. Within 10 years, VHS ruled the market, and the world of entertainment has never been the same.

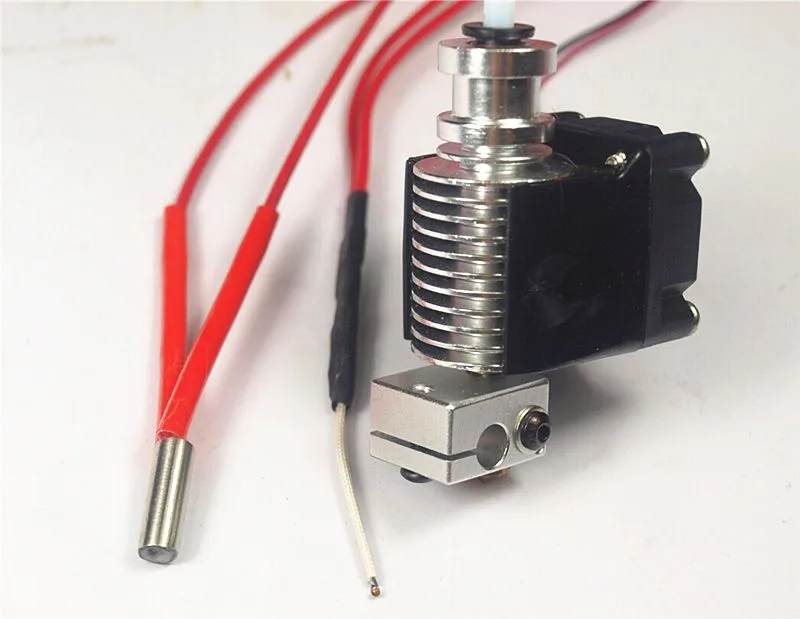

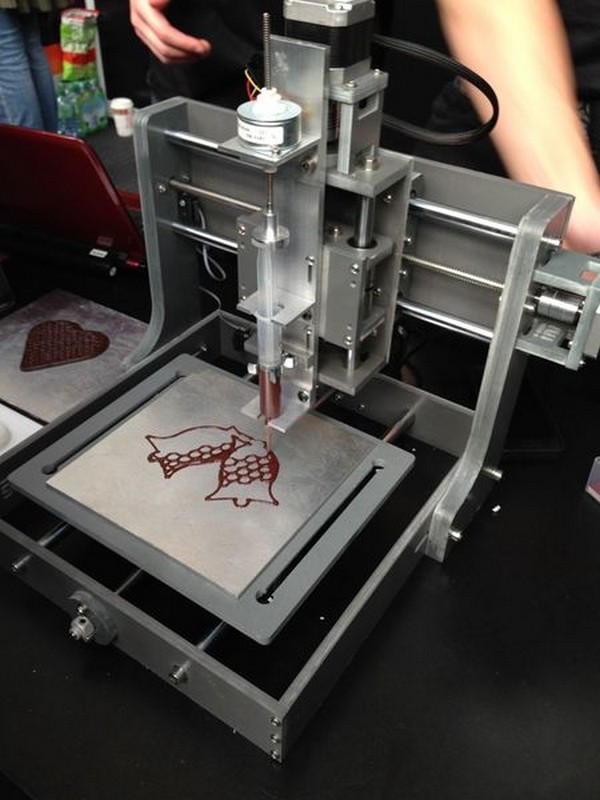

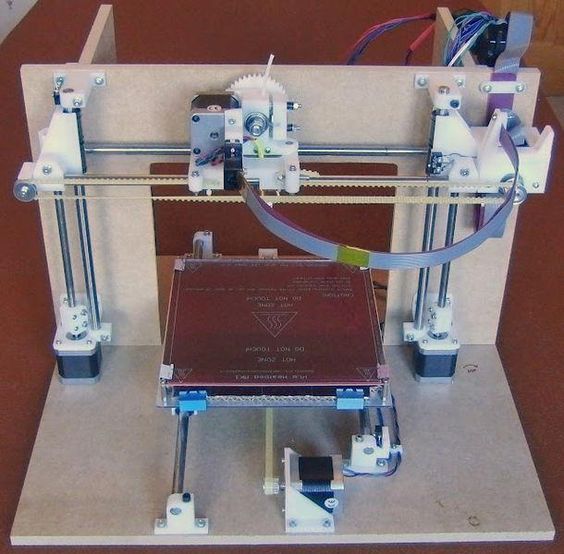

2014 was the years 1977 or 1985 in the world of 3D printing. Hobbyist 3D printers started showing up priced at less than $600, though a printer capable of handling the demands of the counterfeiter was still priced in the $2,500 range. And while the printers weren’t exactly free, a wide range of freeware, too numerous to mention here, showed up to allow would-be makers and counterfeiters an incredible pallet of designs, drivers, and controllers.

It’s true that the materials needed to do the most sophisticated counterfeits are not as widely available as the market will eventually require, but a wide range of thermoplastics, advanced polymers, and other materials are now available to assist the counterfeiter. And it’s a given that, as the printers become more sophisticated, and the consumers become more demanding, that list will only grow over time.

Where does it all end? There’s little doubt that a cat-and-mouse game of counterfeiting and counter-measures will soon ensue. The insertion of easily-detectable nanomaterials into a legitimate copy could be used to distinguish it from a counterfeit, much like watermarks are used to detect fraudulently printed documents. Certain high-value raw materials that can be used for reproducing highly specialized, dangerous, or restricted objects could have their sales and distribution tightly regulated. Preventing counterfeiting also promises to be a growth market.

Even more important, many experts agree, will be the need for a revolution in how intellectual property protections, such as patent, copyright, and trademark are applied to the new world of 3D printing. IP protection has always lagged technological advances, and 3D printing isn’t any different: while it is clearly illegal to print a patented object, merely possessing the plans for printing that object does not violate patent law. So the onus will be on the patent-holder to prove that the object has been printed. But if the print run is in single digits, finding and proving that the counterfeited objects were illegally printed, and by whom, will be an enforcement nightmare.

IP protection has always lagged technological advances, and 3D printing isn’t any different: while it is clearly illegal to print a patented object, merely possessing the plans for printing that object does not violate patent law. So the onus will be on the patent-holder to prove that the object has been printed. But if the print run is in single digits, finding and proving that the counterfeited objects were illegally printed, and by whom, will be an enforcement nightmare.

The best we can do as a society is try to ensure that the benefits outweigh the problems, and in that regard, 3D printing is also following the trajectory of previous innovations. It’s certainly clear that as this new technology evolves, and the rate of counterfeiting grows with it, there will be innovations in the use of 3D printing that will advance the art of counterfeiting in ways that were never anticipated.

But it’s also clear, as it was for the VHS format and desktop publishing, that the push provided by counterfeiting, albeit one that also advances the causes of criminality and illegality, will have a positive effect on expanding the use, and most likely lowering the cost, of 3D printing, while increasing the availability of new materials and software. The trick will be to be able to distinguish between “good” 3D printing, and “bad” 3D printing, and ensure that the barriers to the latter don’t inhibit the former. We’ve done this with VHS, desktop publishing, and for better and worse, we’ll be able to do it for 3D printing as well. The more things change, the more they remain the same…

The trick will be to be able to distinguish between “good” 3D printing, and “bad” 3D printing, and ensure that the barriers to the latter don’t inhibit the former. We’ve done this with VHS, desktop publishing, and for better and worse, we’ll be able to do it for 3D printing as well. The more things change, the more they remain the same…

For further exploration of these and other 3D printing issues, I’ll be speaking at the IEEE Computer Society’s Rock Stars of 3D Printing conference on March 17 in San Jose, Calif.

Josh Greenbaum is Principal at Enterprise Applications Consulting.

Originally posted by:

Josh Greenbaum

View original post

Go Back to Top. Skip To: Start of Article.Can 3D Printers Be Used To Print Money? – Printing It 3D

3D printers can be used to print multiple types of objects, including toys, machine parts, and even medical devices. It may seem like they can print virtually anything. But can 3D printers be used to print money?

But can 3D printers be used to print money?

3D printers can’t be used to print money. Printed money has a different surface texture that 3D printers cannot duplicate. Currency is also printed with unique designs to prevent counterfeiting, so replicating those security features can be challenging and illegal.

In this article, I’ll examine why 3D printers can’t be used to print money and how money is printed. Keep reading to learn more.

Why Printing Money With a 3D Printer Is Not Possible

3D printers, or additive manufacturing (AM) machines, can create three-dimensional objects by building them up layer by layer. This technology is revolutionizing how we design and manufacture many types of objects.

And while machines that are capable of printing currency do exist, there’s no device yet capable of replicating banknotes with security features printed on them, including watermarks and special inks only visible under ultraviolet light. For these reasons, a 3D printer cannot print a banknote that presents the same texture and appearance as a real bill.

Most 3D printers may not be able to handle ink either. Many currencies use multiple colors on their banknotes to add further complexity to the design, making it difficult to copy.

For example, U.S. banknotes have a mix of dark green and black ink on them. These inks help create the intricate designs and patterns that you see on each banknote. So, even if a 3D printer was able to imitate the texture of a banknote if it’s still unable to handle ink, it likely won’t be able to print detailed graphics on each banknote.

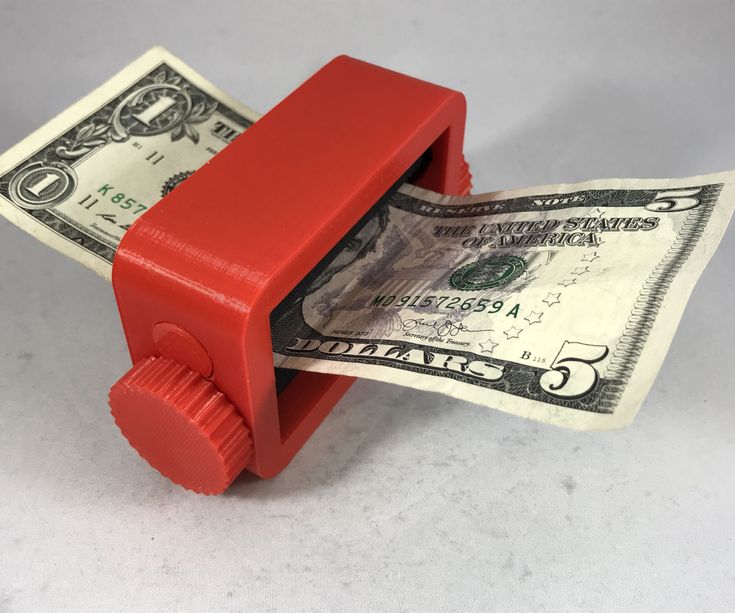

At the same time, 3D printers have been used to print coins and can even emboss the prints, so they look nearly identical to real coins. However, this doesn’t mean you should make 3D copies of your pocket change, as it could have severe consequences.

Consequences of Counterfeit Money

While it’s true that there is an increasing number of 3D printers entering homes and becoming more affordable, they aren’t being used to print money. Attempting to print currency with a 3D printer isn’t only dangerous for the user but also criminal.

Counterfeiting is a serious crime that is punishable under the law. Therefore, you should refrain from using your 3D printer to make counterfeit currency.

There are also no materials available that can replicate printed money’s exact look and feel. And if new security features are added to currency, such as micro-images or metal components, it’s doubtful that these could be completely replicated with a 3D printer either.

How Is Money Printed?

Money is printed in various ways, from hand-held bills to massive printing presses. The currency is printed at two facilities: the Bureau of Engraving and Printing in Washington, D.C., and the Federal Reserve Bank of Richmond, Virginia.

Money is printed using a printing press. Metal plates containing the design are pressed against pressure rollers that force ink onto the blank paper through fine screens.

Paper currency passes through multiple steps to acquire its unique and colorful designs. After being printed on sheets of paper, bills are then cut into individual notes that have their edges roughed up so they can’t be re-used. Finally, each bill is inspected for quality before being released into circulation.

After being printed on sheets of paper, bills are then cut into individual notes that have their edges roughed up so they can’t be re-used. Finally, each bill is inspected for quality before being released into circulation.

Banks use specialized machines to count stacks of money, which prevents them from being stolen or damaged during transport. This allows cashiers at businesses to take only small amounts of cash out at a time, keeping large quantities of money secure.

The Future of Printing Money

Today, most countries around the world use banknotes made with cotton fibers for paper bills. We may see governments begin to explore other options with regard to this material, though, which could lead to the implementation of alternate materials into banknote creation in the future.

Printing money with 3D printers would be difficult if it were to be attempted using today’s technology. As mentioned previously, these devices cannot replicate the subtle colors used on banknotes and tactile features that help prevent counterfeiting.

Other Uses for 3D Printers

While the technology isn’t yet capable of replicating money for counterfeiting purposes, 3D printers can be used to create a variety of items that allow designers and engineers to test prototypes faster.

Additionally, AM processes enable manufacturers to build products more efficiently with less waste, reducing finished goods inventories significantly. 3D printers can make prototypes and manufacture items such as medical implants or customized prosthetics.

3D Printers are also used to make tools and parts for personal use or gifting. But is there anything else 3D printers can print?

3D Printers Can Print Play Money

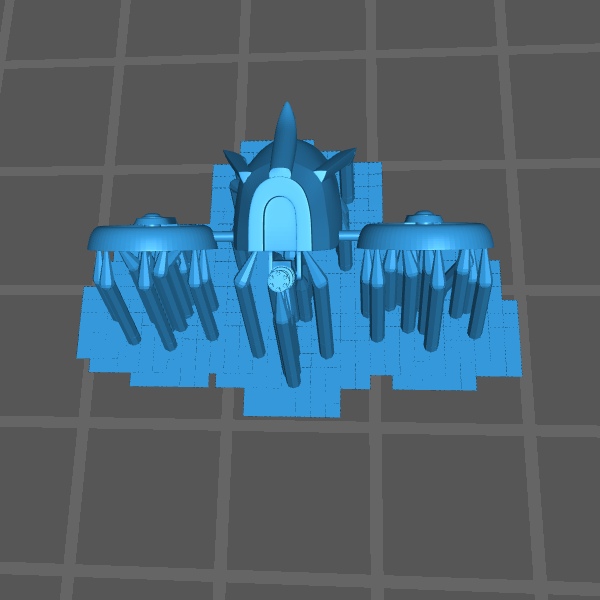

While they shouldn’t be used to try and print real currency, 3D printers can safely be used to print plastic tokens, coins, or chips. They can be helpful if you want to print play money for children, collection purposes, or to accommodate board games.

You can also use a 3D printer to print any other important board game pieces that have gone missing, such as figurines.

To learn more about printing play money, such as coins, check out this YouTube video:

Conclusion

3D printing technology has been used to create objects from computer models. However, 3D printers can’t be used to print money because they can’t replicate the surface texture of paper bills. They also can’t imitate the security features on most banknotes.

Although it is possible to print coins with a 3D printer, attempting to print fake currency is illegal and could land you in a lot of trouble.

Therefore, if you’re going to print any money using your 3D printer, make sure it’s play money, such as board game tokens.

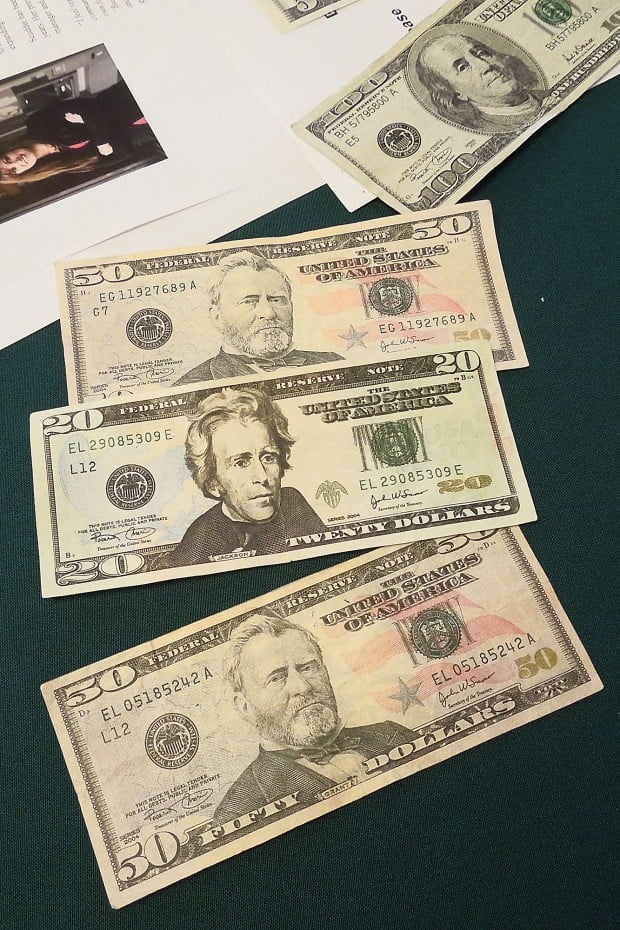

Counterfeit 100-dollar bills appeared in the USA, perfected with the help of 3D printers

In Philadelphia alone, scammers exchange real 50,000 dollars every day. How to recognize a fake?

How to recognize a fake?

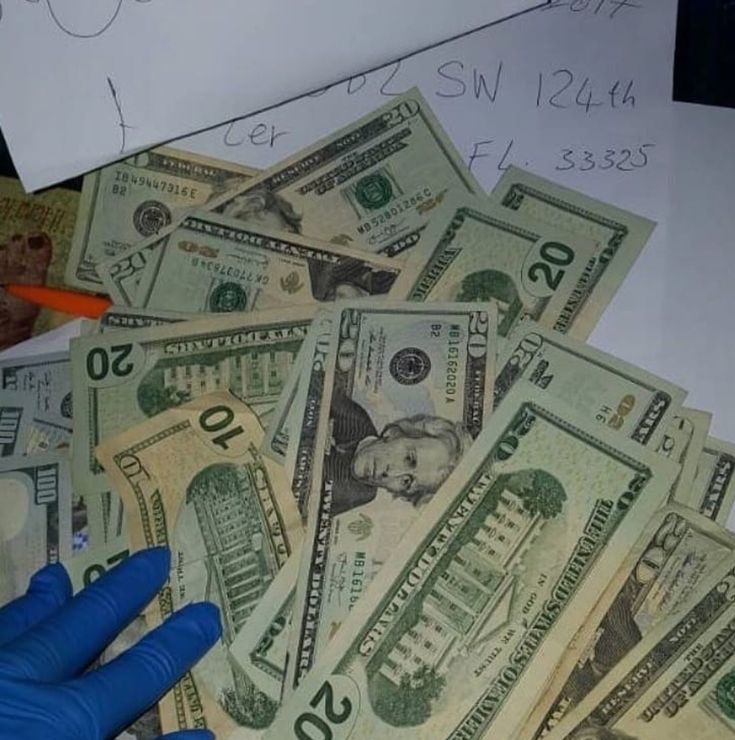

There are so many counterfeit bills that several Philadelphia companies have already suffered from them, according to 6ABC.

One of the victims was the owner of a 7-Eleven store in South Philadelphia, Vincent Emmanuel. Over the past few days, counterfeiters have paid with pseudo-money in his store several times.

Experts say that modern scammers seem to be using new printing technology and even using 3D printers.

In addition, they have learned to avoid checking banknotes with special markers that can easily detect a fake.

And yet check the money, and not only large denominations of 50 and 100 dollars, but also twenty.

In addition, pay attention to the following details:

Portrait

Portraits of American leaders on money look very naturalistic. And a little bulging. Whereas on fakes they are flatter and dull in color, with details often too dark or poorly drawn.

Federal Reserve and Treasury Seals

Federal Reserve logos and Treasury seals appear very clearly on real banknotes. On fake ones, as a rule, they are uneven, dull and with poorly traced edges.

On fake ones, as a rule, they are uneven, dull and with poorly traced edges.

Borders and lines

Thin lines on, let's say, the border of a real banknote, are very clearly drawn, they are not interrupted anywhere. On fakes, such lines are often blurry and fuzzy.

Serial numbers

Authentic serial numbers are unique in style and evenly spaced. In addition, they are printed with the same color ink as the treasury seal. On counterfeit money, serial numbers may have different colors or shades. In addition, numbers may not be written at the right distance.

Paper

Real money paper has tiny red and blue fibers embedded throughout. Counterfeiters, as one, try to copy such fibers and also print them along all lines on paper. BUT. As a rule, on fake banknotes, blue and red fibers are only in the outer layer, and not deep inside the paper.

By the way, it is for this reason that a special marker reveals a fake.

Watermark

The watermark is one of the most obvious signs of the authenticity of a paper banknote. It is clearly visible if you hold the bill in the light.

Law enforcement estimates that about $50,000 worth of counterfeit money is cashed weekly in Philadelphia alone.

If you have any questions about the authenticity of the currency, please contact your bank or local secret service.

You can read about all the differences between real banknotes and counterfeit ones on the official website of the Federal Reserve System.

Photo by Jp Valery on Unsplash

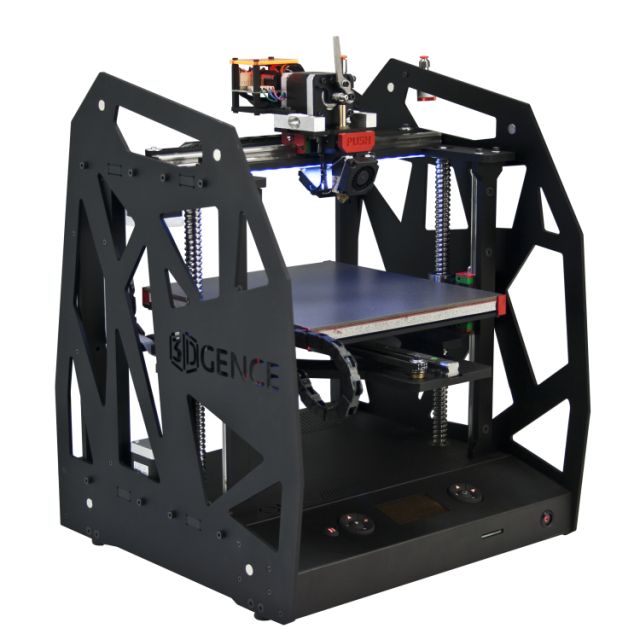

10 Benefits of a 3D Printer: Saving Time and Money

More recently, 3D printing has been viewed as something completely new. The technology was underdeveloped, the hardware was too expensive for widespread use. But only a few years have passed, and the situation has changed radically. Not only did more and more 3D printers begin to appear in stores, but also some enthusiasts began to assemble this equipment themselves.

1. Cost-Effective

While large-scale projects with thousands of 3D printed parts are not cheap, they are still much more cost effective than other technologies. Many manufacturers use 3D printing for small runs or for prototyping. Plastic can also be used for injection molding, but casting small batches can require expensive equipment. But even in this case, manufacturers can produce cast 3D parts several times cheaper than using aluminum.

Prototype parts printed on Prusa i3 Bizon 3D printer, layer height 0.1mm, PLA material

Compared to traditional production methods, the entire process can take weeks or days, and most products are printed in hours. Some manufacturers have even begun to make parts to order, which has also allowed them to optimize their warehouse capacity and resource management scheme, making them more flexible. With this new approach, the manufacturer does not need to store every single part or component, they can simply be printed as needed and immediately put into action.

Miniature parts printed by Wanhao Duplicator 7 photopolymer 3D printer, layer height 0.5mm, photopolymer resin material

It not only affects the reputation of the company in its industry, insufficient technical control can lead to injury to employees and customers. Since 3D printing uses a completely different production method than most machine tool operations, the process has significantly fewer weaknesses and flaws overall.

Model printed on Picaso Designer X PRO 3D printer, 0.2 mm layer, ABS materials, HIPS

4. Less waste

The press is gaining more and more support in the form of supporters of the "green" movement. Because 3D printing produces significantly less waste than traditional processing, the technology is more environmentally friendly while reducing costs. 3D printing has even made its way into the textile industry, allowing clothing and prototypes to be printed.

Hercules Strong 3D printed yacht steering parts. Details printed in 15 hours with a 0.5 mm nozzle and a layer height of 0.3 mm at a speed of 60 mm/s.

Details printed in 15 hours with a 0.5 mm nozzle and a layer height of 0.3 mm at a speed of 60 mm/s.

5. Greater customization

3D printed products are also highly customizable. Parts can be printed not only with light plastic, some next-generation models may also have a metal coating. As a result, objects are not only aesthetic, but also functional. In addition, they can acquire thermal and chemical resistance. The existing metallization method can also be used for plastic.

Functional parts printed on Hercules. Material ABS, nozzle diameter 0.5 mm, layer height 150 µm, filling 100%. The model consists of 3 parts: the body and 2 halves of the latch, after printing and processing, the parts were glued together with acetone.

6. Customer Availability

If some craftsmen set up small mechanical workshops, for example, in garages, then most of us cannot afford such a luxury. 3D printing allows you to bring a significant part of the manufacturing process directly into the home, made possible by the availability of user-grade 3D technology. While it turns out to be quite expensive for one-off projects, the price of 3D printers and consumables is dropping rapidly.

3D printing allows you to bring a significant part of the manufacturing process directly into the home, made possible by the availability of user-grade 3D technology. While it turns out to be quite expensive for one-off projects, the price of 3D printers and consumables is dropping rapidly.

Technical wing caps in REC RUBBER or REC FLEX. The models are printed on a Prusa i3 Steel 3D printer.

7. High complexity

In most cases, when it comes to complex parts and elements, the manufacturing process imposes certain limitations. Techniques used in casting and finishing objects may not be subtle enough for sophisticated design details. 3D manufacturing processes make it possible to realize almost any design solution, regardless of its complexity, and in a reasonable time. This not only eliminates the extra assembly steps required by traditional methods, but also provides more freedom to create future-proof designs.

Zenit 3D printed large engine parts

While there are inherent risks associated with these new technologies, in terms of day-to-day business, 3D printing risks are significantly lower than with traditional manufacturing methods.

Not only is 3D printing much cheaper when it comes to testing a new design or product, the printed prototypes themselves can stir up investor and customer interest and get them to decide whether to proceed with mass production of a product, whether it is worth the time and effort required.

Not only is 3D printing much cheaper when it comes to testing a new design or product, the printed prototypes themselves can stir up investor and customer interest and get them to decide whether to proceed with mass production of a product, whether it is worth the time and effort required. Printing miniature model on Wanhao Duplicator i3 3D printer

9. Variety of materials

The materials used in today's 3D printers are much more diverse than most raw materials in traditional production methods. 3D printing also provides the ability to mix different substances, a luxury that is not always available with conventional methods. Although many 3D printer manufacturers offer their own, very limited set of sources, 3D printers can work not only with original materials, allowing you to simulate ceramics, metal, glass and more.

Wanhao D6 3D Printer PEGT, ABS-PC, PLA, SBS

The manufacturer not only needs to clearly understand what the customer wants, the manufacturer must also be able to explain what he himself can.